Comprehensive Utilization Method of Molybdenum in Waste Molybdenum

A waste acid liquid and molybdenum dioxide technology, which is applied in the fields of molybdenum compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems that are not conducive to emission reduction and environmental protection, slow oxidation process, high production cost, etc., and achieve short chemical reaction time , high molybdenum yield and short processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

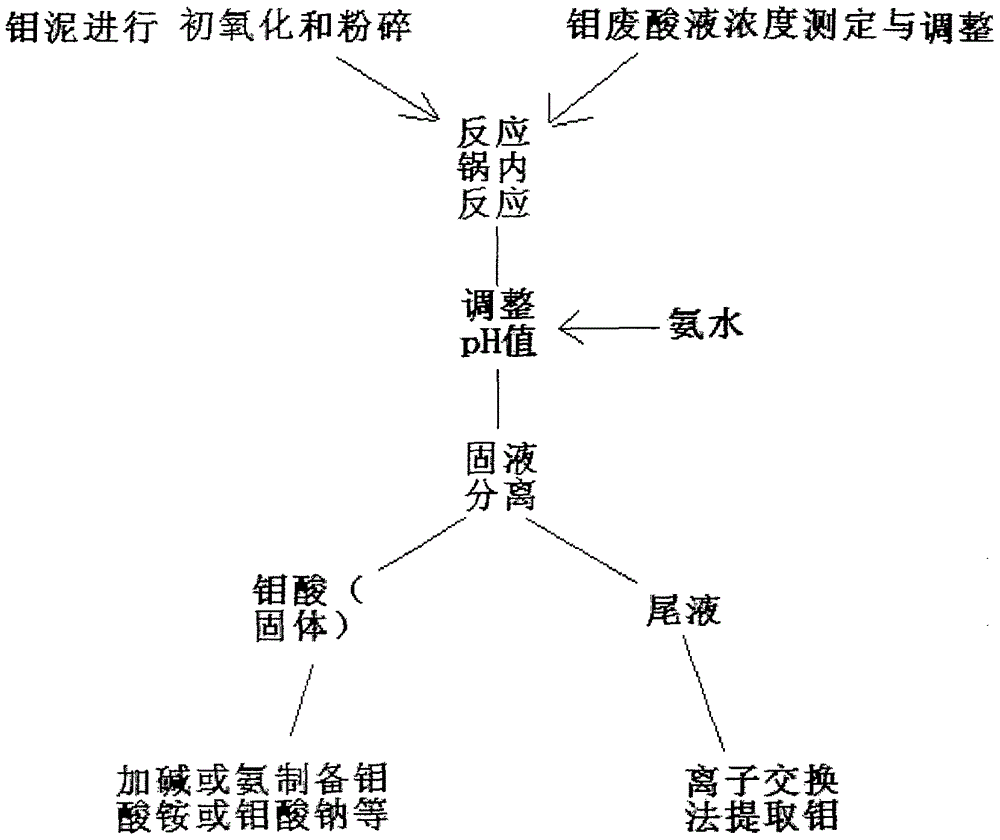

[0025] see figure 1 , the comprehensive utilization method of molybdenum in waste molybdenum, comprises the steps:

[0026] S1. Pretreatment of waste molybdenum: initial oxidation and crushing of molybdenum mud, polishing in the molybdenum circle is carried out in the state of water mill, after decanting the water in the mud collection bucket, the molybdenum mud will gradually oxidize when it encounters air into molybdenum dioxide, then dry it in the air, and crush it into a particle size of 20 mesh, which should not be too fine, otherwise the reaction will be too strong and difficult to control.

[0027] S2. Adjusting the concentration of the molybdenum waste acid solution refers to the determination and adjustment of the concentration of nitric acid in the molybdenum waste acid solution. Calculated by the weight of the added molybdenum mud, the weight of nitric acid is 10%-20% more than the weight of molybdenum mud. Refers to nitric acid with a concentration of 3mol / L;

[...

Embodiment 2

[0033] A method for comprehensive utilization of molybdenum in waste molybdenum, comprising the steps of:

[0034] S1. Pretreatment of waste molybdenum: initial oxidation and crushing of molybdenum mud, polishing in the molybdenum circle is carried out in the state of water mill, after decanting the water in the mud collection bucket, the molybdenum mud will gradually oxidize when it encounters air into molybdenum dioxide, then dry it in the air, and crush it into a particle size of 15 mesh, which should not be too fine, otherwise the reaction will be too strong and difficult to control.

[0035] S2. Adjusting the concentration of the molybdenum waste acid solution refers to the determination and adjustment of the concentration of nitric acid in the molybdenum waste acid solution. Calculated based on the weight of the added molybdenum mud, the weight of nitric acid is 10% more than the weight of molybdenum mud. Nitric acid refers to the concentration 3mol / L nitric acid;

[00...

Embodiment 3

[0041] A method for comprehensive utilization of molybdenum in waste molybdenum, comprising the steps of:

[0042] S1. Pretreatment of waste molybdenum: initial oxidation and crushing of molybdenum mud, polishing in the molybdenum circle is carried out in the state of water mill, after decanting the water in the mud collection bucket, the molybdenum mud will gradually oxidize when it encounters air into molybdenum dioxide, then dry it in the air, and crush it into a particle size of 17 mesh, which should not be too fine, otherwise the reaction will be too strong and difficult to control.

[0043] S2. Adjusting the concentration of the molybdenum waste acid solution refers to the determination and adjustment of the concentration of nitric acid in the molybdenum waste acid solution. Calculated by the weight of the added molybdenum mud, the weight of nitric acid is 15% more than the weight of the molybdenum mud. Nitric acid refers to the concentration 3mol / L nitric acid;

[0044...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com