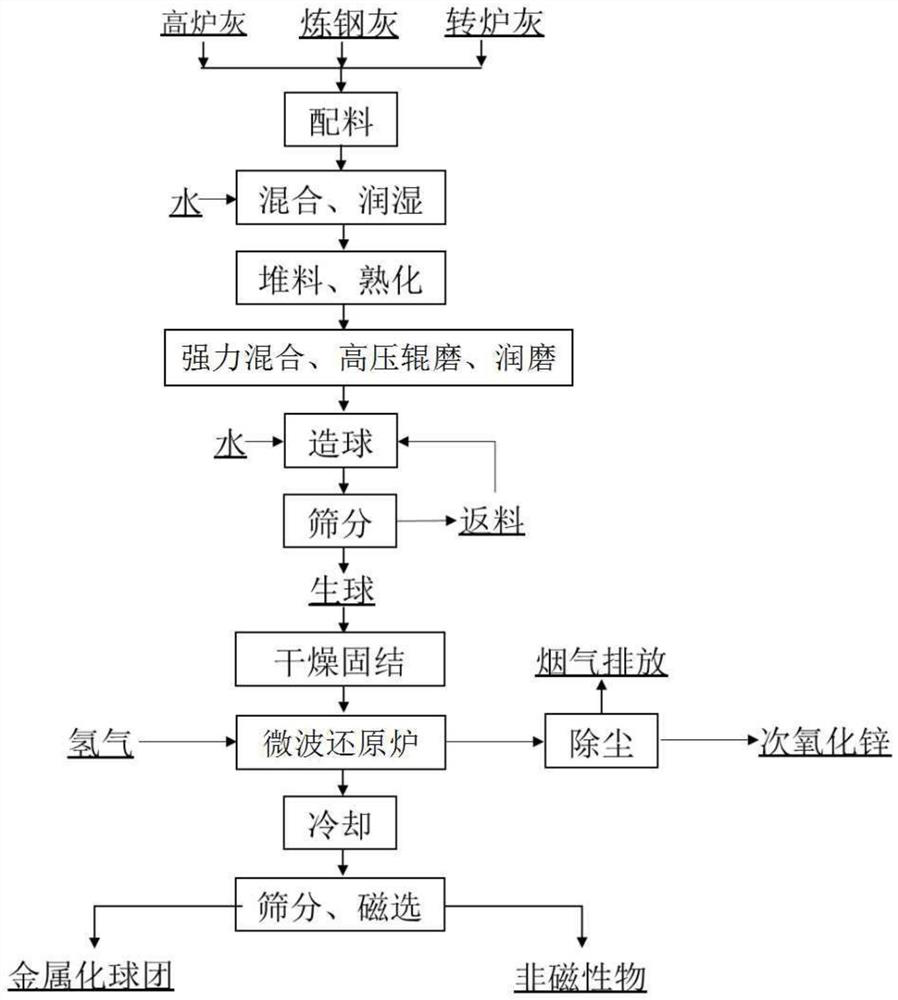

Method for dezincification of zinc-containing dust through microwave hydrogen reduction

A dust and microwave technology, which is applied in the field of iron and steel metallurgy, can solve the problems of large carbon emissions, low product quality, and high energy consumption, and achieve the effects of small heat loss, increased reaction rate, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The present invention is a microwave hydrogen reduction dezincification method containing zinc dust, comprising the following steps:

[0043] (1) The blast furnace dust removal ash, electric furnace dust removal ash and steelmaking converter soot are ore-blended, and the C content in the control mixture is 10%;

[0044] (2) Add 1.5% of the composite binder to the mixture (bentonite accounts for 35%, sodium humic acid accounts for 45% and polyacrylamide accounts for 30%) to mix evenly, and the resulting mixed material is strongly stirred, the stirring speed is 1500rpm, the mixing time is 3min; then, the high-pressure roller grinding is carried out sequentially, the high-pressure roller grinding water is divided into 7.5%, and the roller grinding pressure is 1.0N / mm 2 , the grinding time is 3min;

[0045] (3) The pretreated material is added to the disc ball machine for ball making, the ball making time is 12min, the moisture of the raw ball is controlled at about 13%, and th...

Embodiment 2

[0049] The present invention is a microwave hydrogen reduction dezincification method containing zinc dust, comprising the following steps:

[0050] (1) The blast furnace dust removal ash, electric furnace dust removal ash and steelmaking converter soot are mixed with ore, and the C content in the control mixture is 15%;

[0051] (2) Add 1.5% of the composite binder to the mixture (bentonite accounts for 35%, sodium humic acid accounts for 45% and polyacrylamide accounts for 30%) to mix evenly, and the resulting mixed material is strongly stirred, the stirring speed is 1500rpm, the mixing time is 3min; then, the high-pressure roller grinding is carried out sequentially, the high-pressure roller grinding water is divided into 7.5%, and the roller grinding pressure is 1.0N / mm 2 , the grinding time is 3min;

[0052] (3) The pretreated material is added to the disc ball machine for ball making, the ball making time is 12min, the raw ball moisture is controlled at about 13%, and the ra...

Embodiment 3

[0056] The present invention is a microwave hydrogen reduction dezincification method containing zinc dust, comprising the following steps:

[0057] (1) The blast furnace dust removal ash, electric furnace dust removal ash and steelmaking converter soot are ore-blended, and the C content in the control mixture is 20%;

[0058] (2) Add 1.5% of the composite binder to the mixture (bentonite accounts for 35%, sodium humic acid accounts for 45% and polyacrylamide accounts for 30%) to mix evenly, and the resulting mixed material is strongly stirred, the stirring speed is 1500rpm, the mixing time is 3min; then, the high-pressure roller grinding is carried out sequentially, the high-pressure roller grinding water is divided into 7.5%, and the roller grinding pressure is 1.0N / mm 2 , the grinding time is 3min;

[0059] (3) The pretreated material is added to the disc ball machine for ball making, the ball making time is 12min, the raw ball moisture is controlled at about 13%, and the raw b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| burst temperature | aaaaa | aaaaa |

| burst temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com