Method for enhancing vanadium shale ore grinding and leaching efficiency through microwaves

A technology for vanadium shale and shale, which is applied in the field of vanadium extraction from shale, can solve the problems of long processing time, microwave processing time, and large carbon emissions, and achieve the goal of improving the processing effect, shortening the processing cycle, and shortening the processing cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for enhancing vanadium shale grinding and leaching efficiency using microwaves. The steps of the method described in this embodiment are:

[0045] Step 1. Crushing and screening the vanadium shale raw ore to obtain vanadium shale raw ore with a particle size of less than 1.5 mm and vanadium shale raw ore with a particle size of 1.5-10.0 mm.

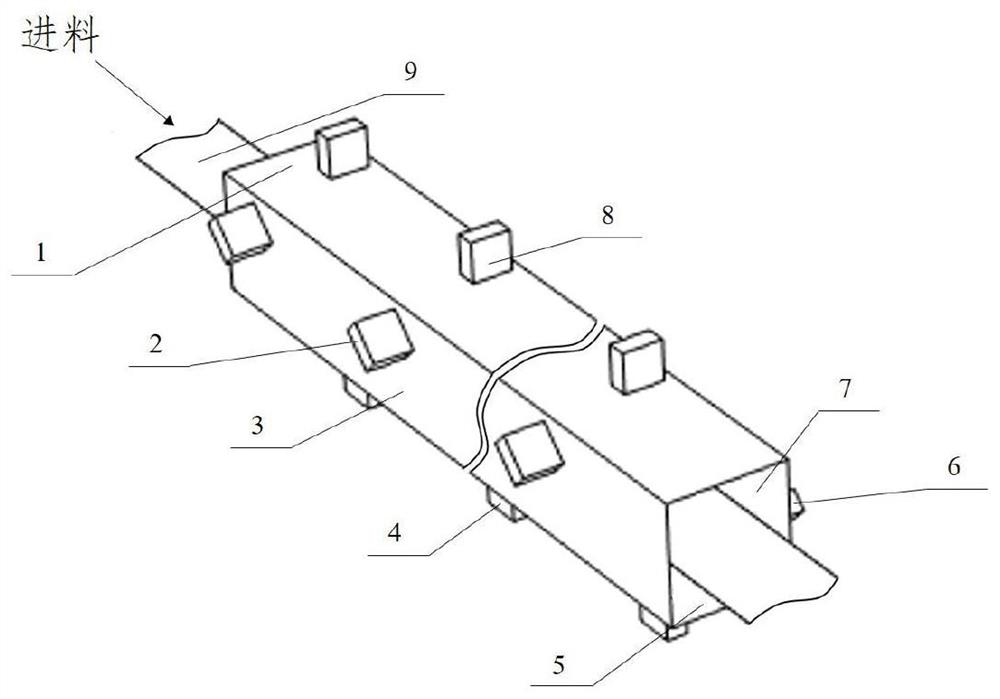

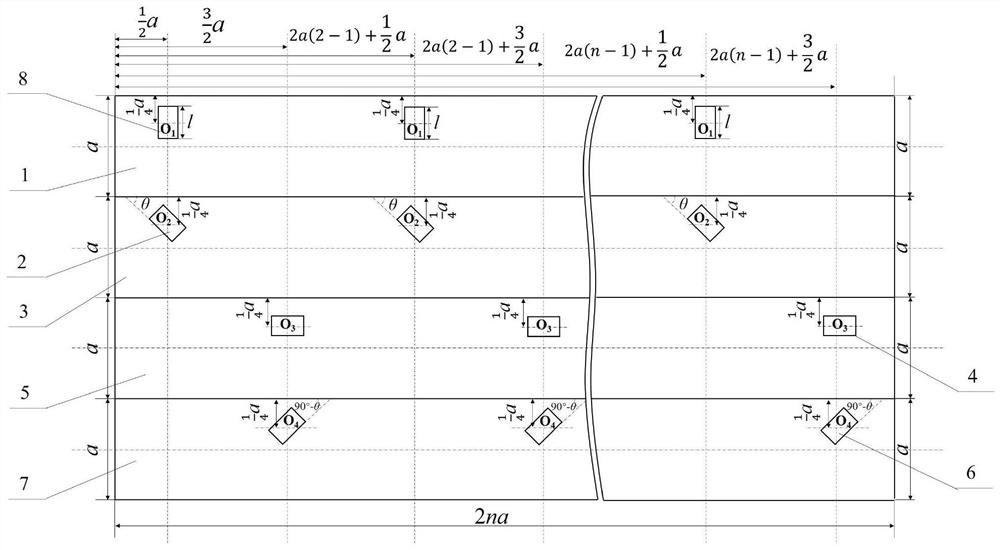

[0046] Step 2. Use the "Continuous Microwave Treatment Device for Strengthening Vanadium Shale Grinding and Leaching Efficiency" for microwave treatment, set the transport speed of the conveyor belt 9, turn on the switches of all wave sources in the continuous microwave treatment device, and start conveyor belt 9.

[0047] The vanadium shale raw ore with a particle size of 1.5-10.0 mm is fed from the feed port of the obtained continuous microwave treatment device, and the feeding amount is 60kg / h; Microwave-treated vanadium shale.

[0048] Step 3. According to the mass ratio of the microwave-treated vanadium shale to wa...

Embodiment 2

[0062] A method for enhancing vanadium shale grinding and leaching efficiency using microwaves. The steps of the method described in this embodiment are:

[0063] Step 1. Crushing and screening the vanadium shale raw ore to obtain vanadium shale raw ore with a particle size of less than 1.5 mm and vanadium shale raw ore with a particle size of 1.5-10.0 mm.

[0064] Step 2. Use the "Continuous Microwave Treatment Device for Strengthening Vanadium Shale Grinding and Leaching Efficiency" for microwave treatment, set the transport speed of the conveyor belt 9, turn on the switches of all wave sources in the continuous microwave treatment device, and start conveyor belt 9.

[0065] The vanadium shale raw ore with a particle size of 1.5-10.0 mm is fed from the feed port of the continuous microwave treatment device, and the feeding amount is 100 kg / h; from the discharge port of the continuous microwave treatment device, namely microwaved vanadium shale.

[0066] Step 3. According ...

Embodiment 3

[0080] A method for enhancing vanadium shale grinding and leaching efficiency using microwaves. The steps of the method described in this embodiment are:

[0081] Step 1. Crushing and screening the vanadium shale raw ore to obtain vanadium shale raw ore with a particle size of less than 1.5 mm and vanadium shale raw ore with a particle size of 1.5-10.0 mm.

[0082] Step 2. Use the "Continuous Microwave Treatment Device for Strengthening Vanadium Shale Grinding and Leaching Efficiency" for microwave treatment, set the transport speed of the conveyor belt 9, turn on the switches of all wave sources in the continuous microwave treatment device, and start conveyor belt 9.

[0083] The vanadium shale raw ore with a particle size of 1.5-10.0mm is fed from the feed port of the continuous microwave treatment device, and the feeding amount is 150kg / h; from the discharge port of the continuous microwave treatment device That is to obtain microwave-treated vanadium shale.

[0084] Ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com