Environment-friendly resin non-combustible thermal insulation material and preparation method thereof

A technology of thermal insulation materials and environmentally friendly resins, applied in the field of thermal insulation materials, can solve the problems of easy pulverization, foam without strength, high density, etc., and achieve the effect of light weight and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

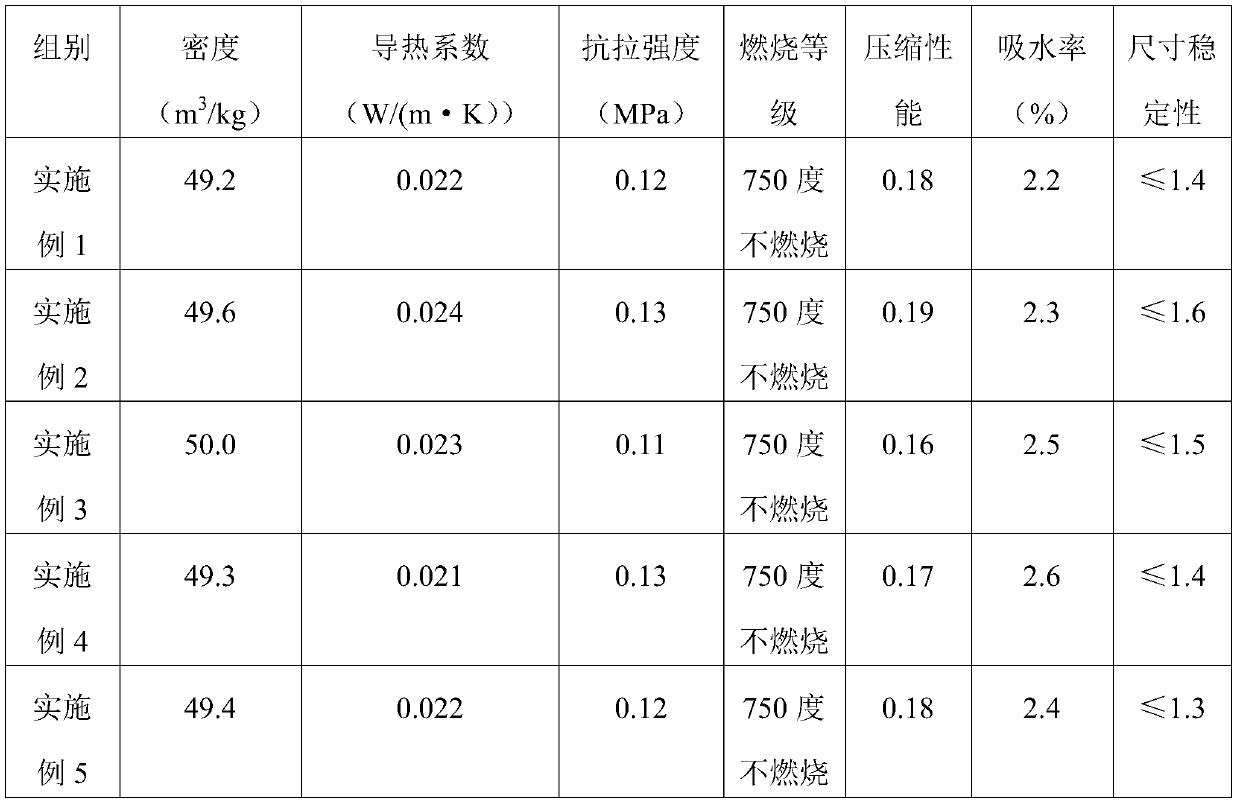

Examples

Embodiment 1

[0028] This embodiment discloses an environmentally friendly resin non-combustible thermal insulation material, which is made of the following raw materials: polyester polyol kR-3550 40kg, polyester polyol RP-3940 20kg, polyether polyol yD-401P 7kg, clay 8kg, silicone oil BL-88893kg, trimerization catalyst TMR-2 6kg, aluminum hypophosphite 25kg, melamine cyanurate 15kg, urea 3kg, tris(2-carboxyethyl)phosphine 30kg, purified water 5kg and polymethylene polyphenylisocyanate 150kg.

[0029] The preparation method of the environmentally friendly resin non-combustible thermal insulation material of the present embodiment comprises the following steps:

[0030] (1) according to the weight of each raw material, take by weighing respectively for subsequent use;

[0031] (2) Mix and stir the spare polyester polyol kR-3550, polyester polyol RP-3940, polyether polyol yD-401P, silicone oil BL-8889, trimerization catalyst TMR-2, and the temperature of mixing and stirring is 20 ℃, the sti...

Embodiment 2

[0034] This embodiment discloses an environmentally friendly resin non-combustible thermal insulation material, which is made of the following raw materials: polyester polyol kR-3550 45kg, polyester polyol RP-3940 25kg, polyether polyol yD-401P 9kg, clay 9kg, silicone oil BL-88894kg, trimerization catalyst TMR-2 7kg, aluminum hypophosphite 28kg, melamine cyanurate 18kg, urea 4kg, tris(2-carboxyethyl)phosphine 33kg, purified water 7kg and polymethylene polyphenylisocyanate 160kg.

[0035] The preparation method of the environmentally friendly resin non-combustible thermal insulation material of the present embodiment comprises the following steps:

[0036] (1) according to the weight of each raw material, take by weighing respectively for subsequent use;

[0037] (2) Mix and stir spare polyester polyol kR-3550, polyester polyol RP-3940, polyether polyol yD-401P, silicone oil BL-8889, trimerization catalyst TMR-2, and the temperature of mixing and stirring is 21 ℃, the stirrin...

Embodiment 3

[0040] This embodiment discloses an environmentally friendly resin non-combustible thermal insulation material, which is made of the following raw materials: polyester polyol kR-3550 50kg, polyester polyol RP-3940 30kg, polyether polyol yD-401P 10kg, clay 10kg, silicone oil BL-88894.5kg, trimerization catalyst TMR-2 8.5kg, aluminum hypophosphite 30kg, melamine cyanurate 20kg, urea 5kg, tris(2-carboxyethyl)phosphine 35kg, purified water 8kg and polymethylene polyphenyl base isocyanate 170kg.

[0041] The preparation method of the environmentally friendly resin non-combustible thermal insulation material of the present embodiment comprises the following steps:

[0042] (1) according to the weight of each raw material, take by weighing respectively for subsequent use;

[0043](2) Mix and stir the spare polyester polyol kR-3550, polyester polyol RP-3940, polyether polyol yD-401P, silicone oil BL-8889, trimerization catalyst TMR-2, and the temperature of mixing and stirring is 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com