Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

89results about How to "Achieve direct contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

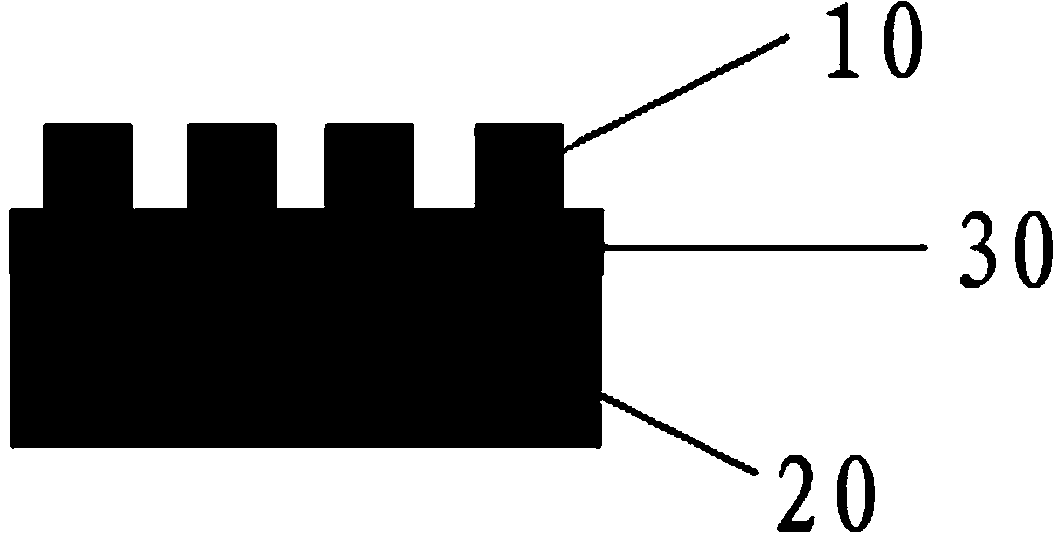

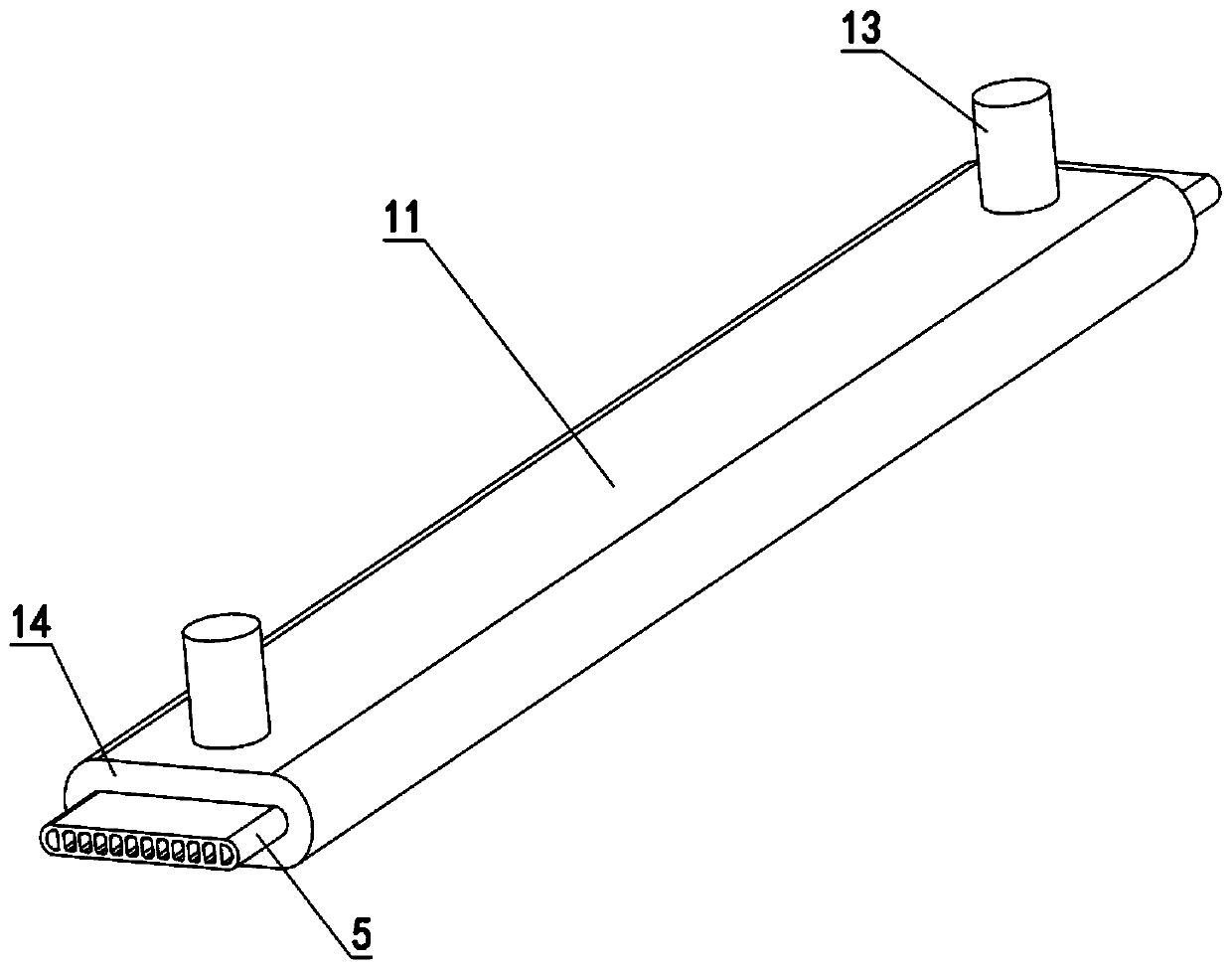

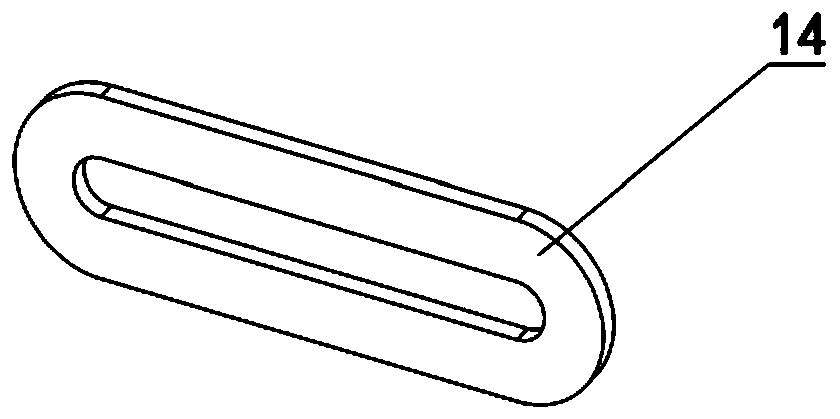

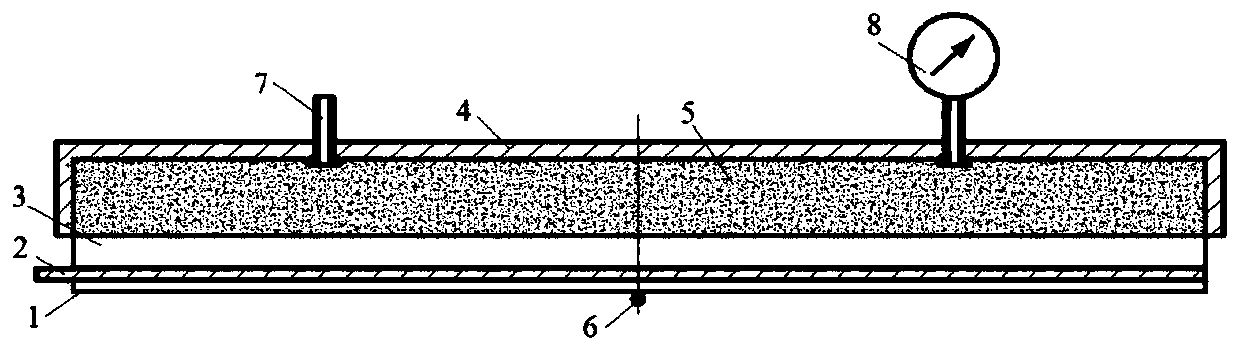

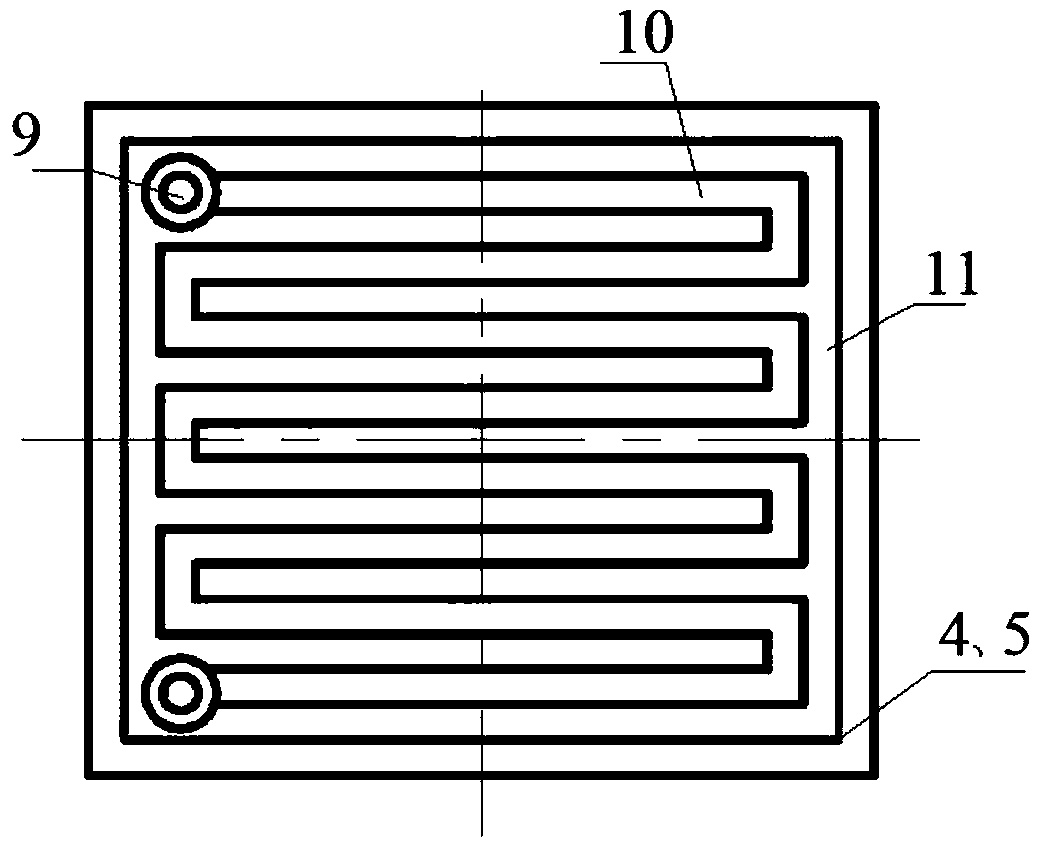

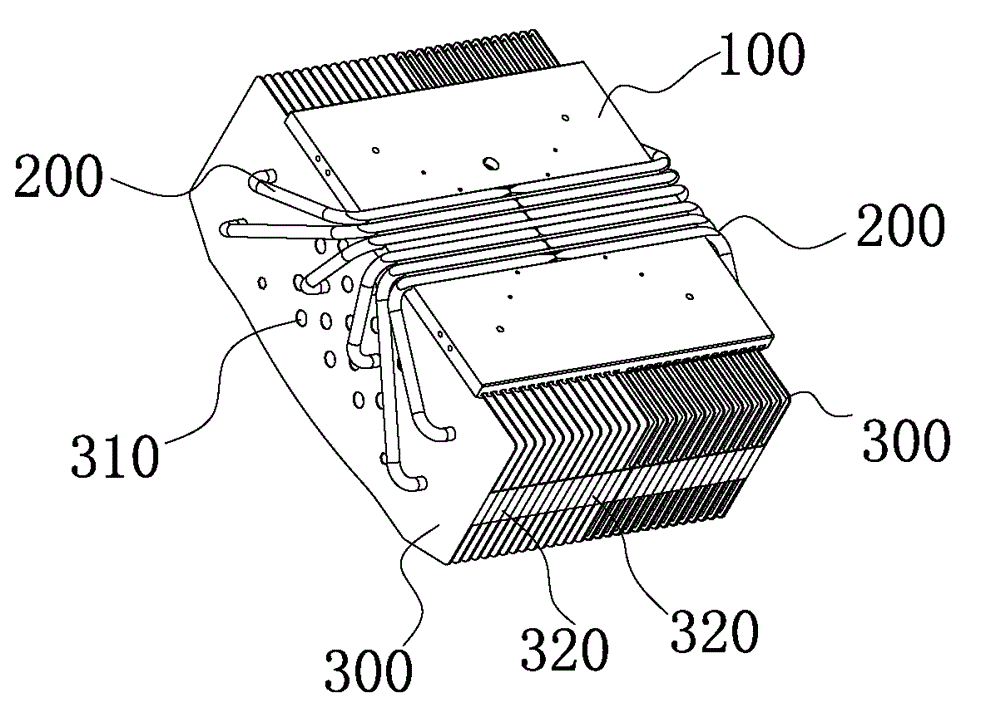

Submerged jet micro-injection direct liquid cooling heat dissipating device

ActiveCN109637987AReduce mutual interferenceThe cooling effect is weakDigital data processing detailsSemiconductor/solid-state device detailsJet flowDirect liquid cooling

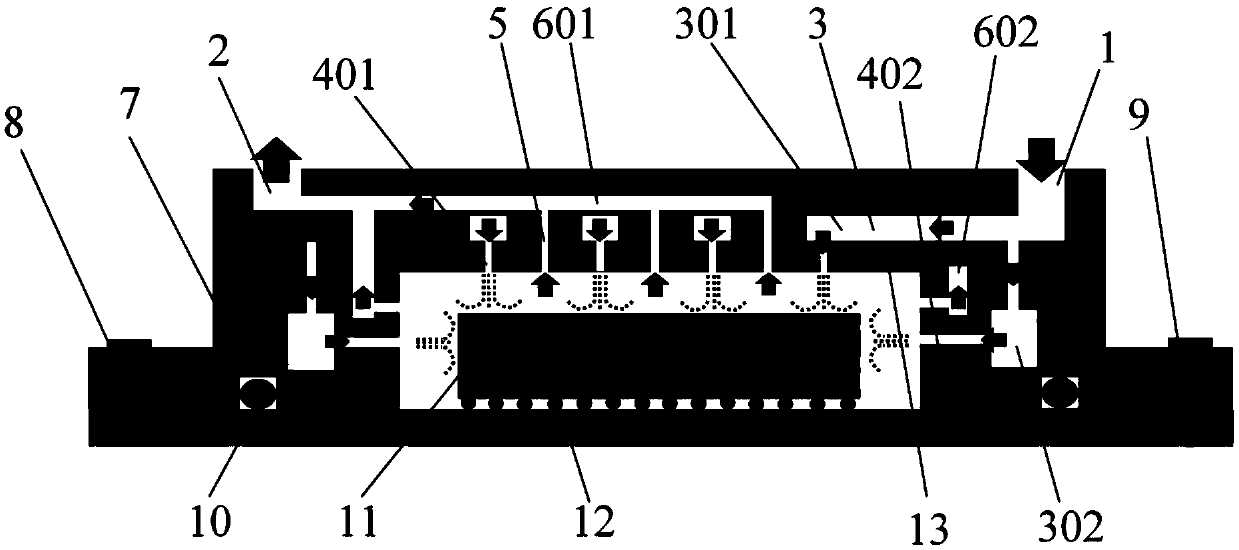

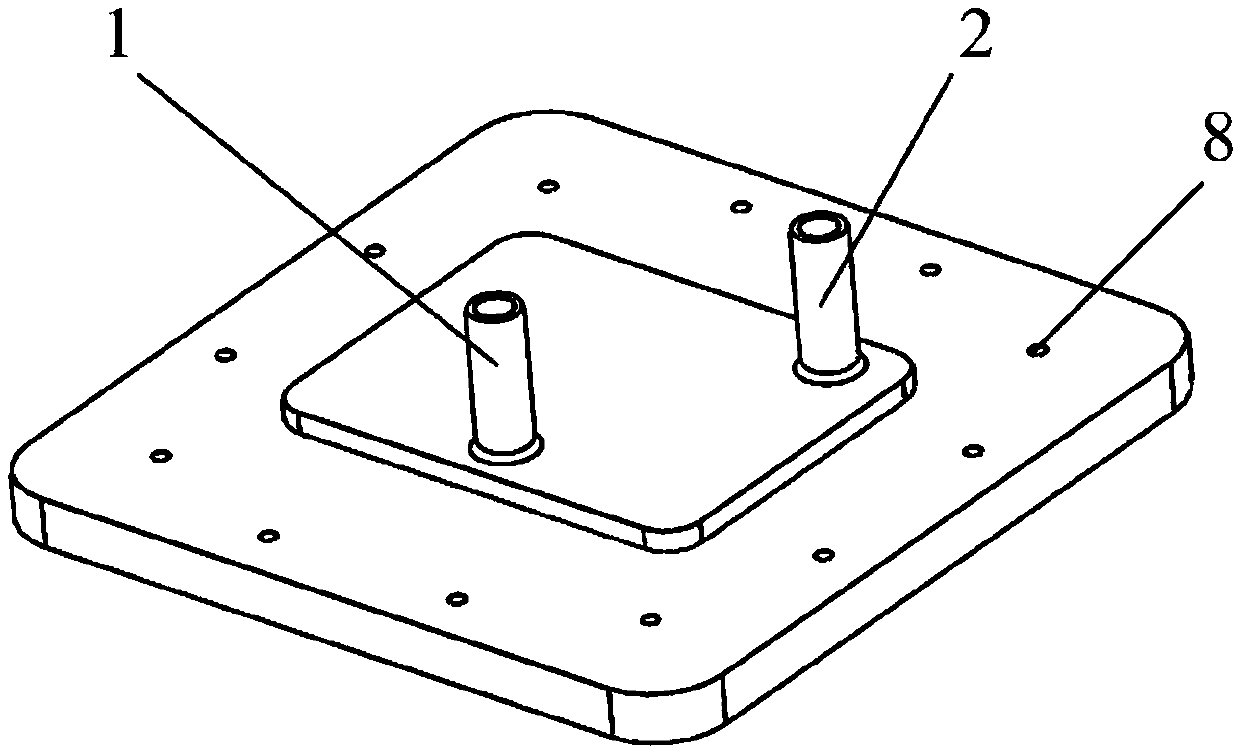

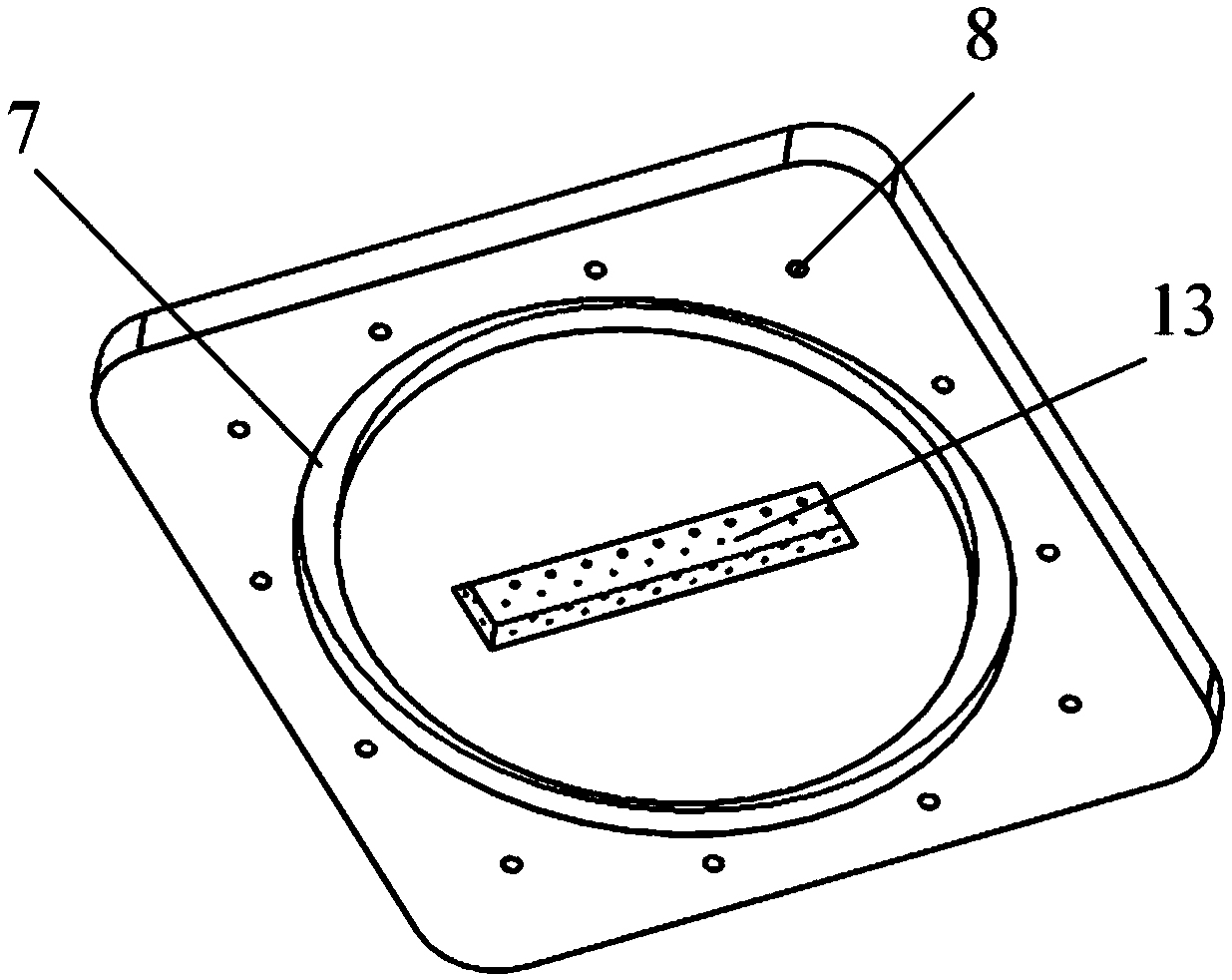

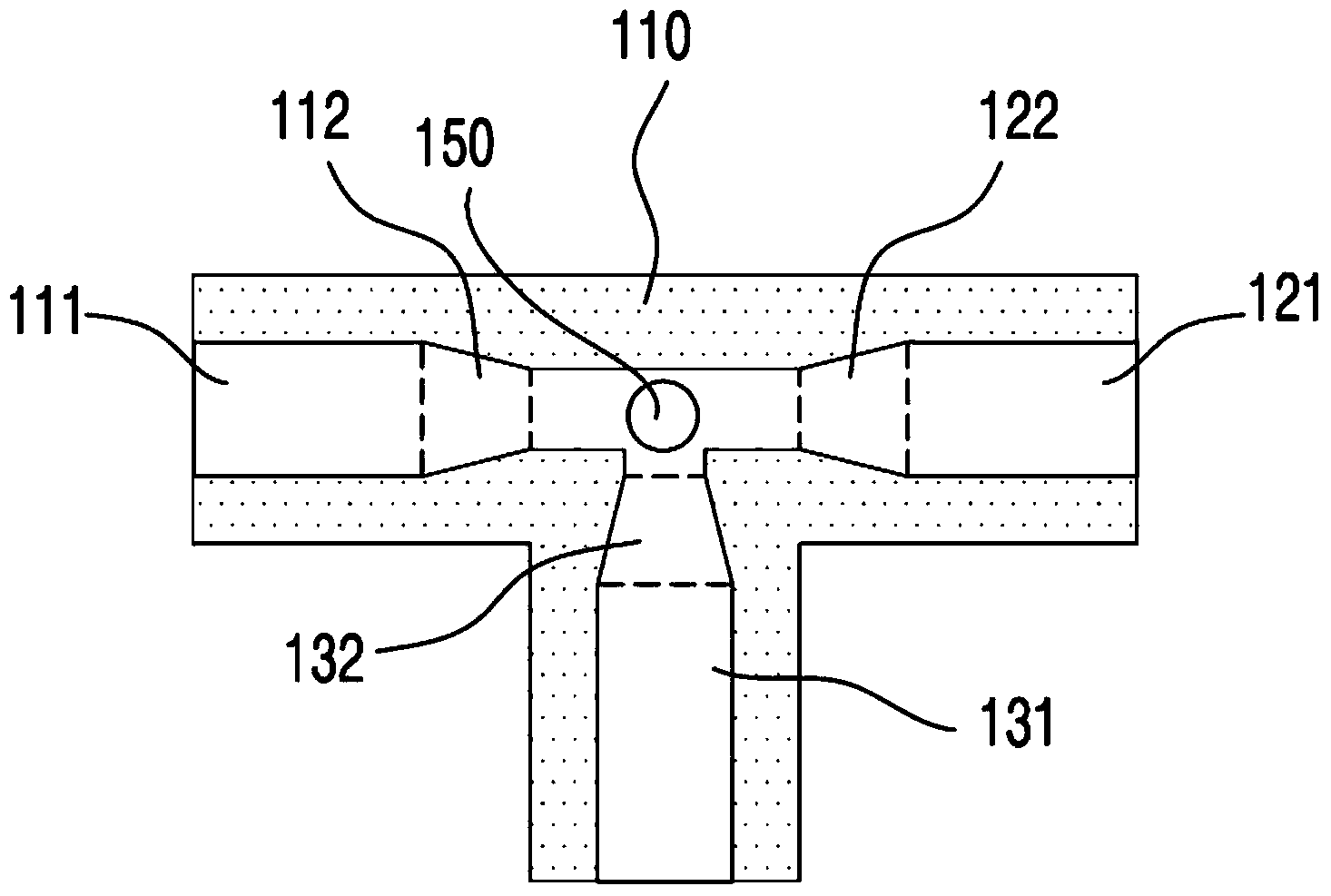

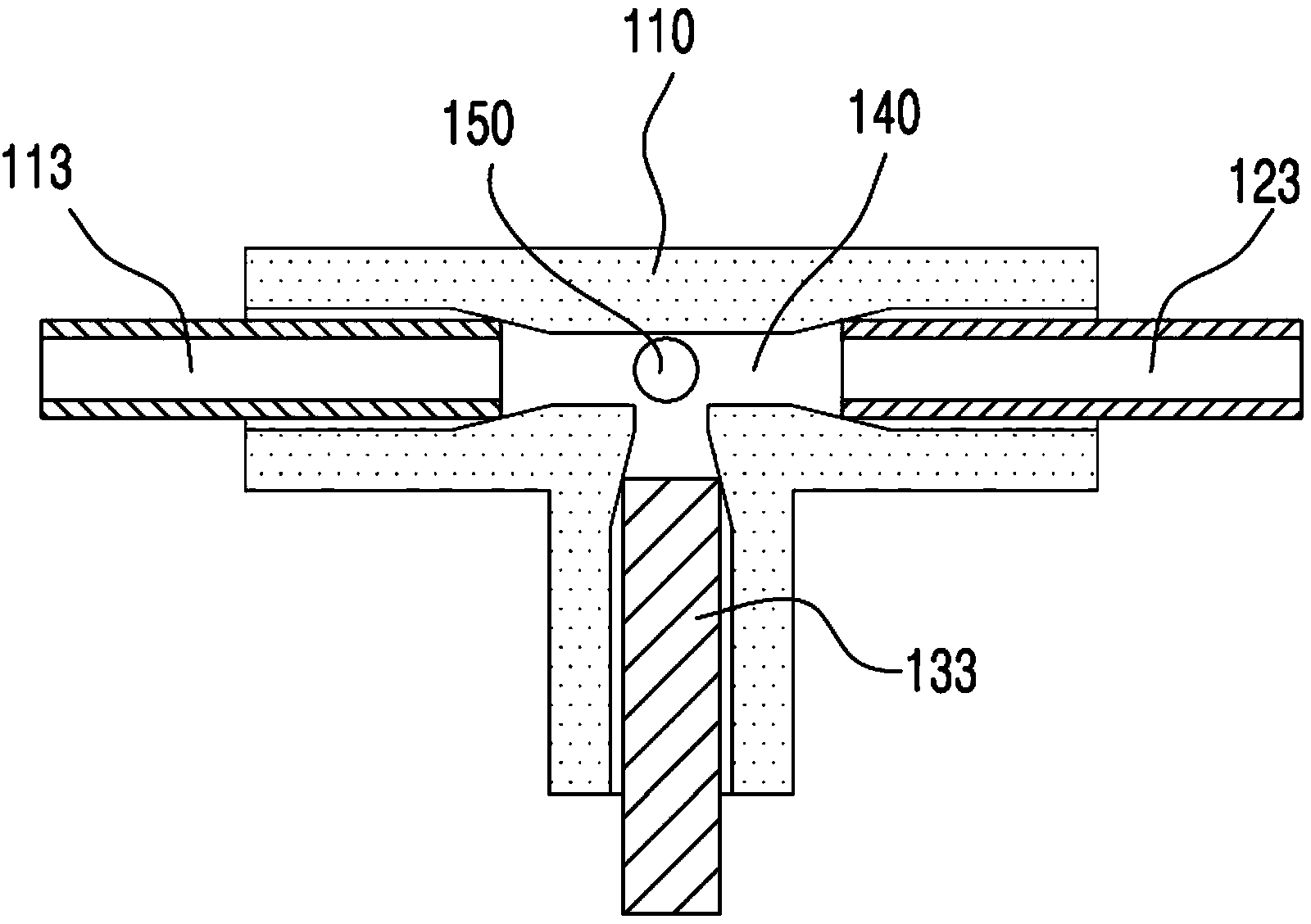

The invention belongs to the field of heat dissipation of electronic devices, and discloses a submerged jet micro-injection direct liquid cooling heat dissipating device, wherein the bottom of the heat dissipating device is provided with a first groove to form a sealed space with the circuit board of an object to be cooled, a second groove is arranged in the first groove for placing the object tobe cooled, the coolant enters from the inlet pipe to the nozzle through the liquid separation cavity, and the coolant sprays from the nozzle on the surface of the object to be cooled; the coolant enters from the liquid pumping hole into the outlet pipe through the collecting cavity, and then flows out from the outlet pipe, thereby realizing the collection of the cooling liquid; a plurality of nozzles and a liquid pumping hole are disposed on each surface of the second groove, the liquid pumping hole is arranged on a center line extension line of the connection of the two nozzles, and the liquid pumping hole is higher than the nozzles to avoid interference on the coolant sprayed from adjacent nozzles. Through the invention, the heat dissipation area of the chip is effectively improved, thetemperature of the chip is lowered, and the uniformity of the temperature of the chip is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

Gas sensor based on polyaniline/stannic oxide composite nanofibers and preparation method thereof

InactiveCN105651828ALarge specific surface areaIncrease active pointMaterial resistanceFiberResponse sensitivity

The invention discloses a gas sensor based on polyaniline / stannic oxide composite nanofibers and a preparation method thereof. The gas sensor comprises a substrate, an interdigitated microelectrode and a gas sensitive material. The gas sensitive material is polyaniline / stannic oxide composite nanofibers prepared through the combination of electrostatic spinning and a low-temperature hydrothermal method. The structure of the nanofibers obtained through electrostatic spinning has the large specific surface area, the active sites of adsorption of the gas sensitive material and gas are added, metal salts contained in the nanofibers processed through the low-temperature hydrothermal method are converted into nano-structure stannic oxide in situ, and the gas response sensitivity, resilience and stability of the sensor under the room temperature are improved due to the p-n junction formed by p-type polyaniline and n-type stannic oxide. The preparation method of the gas sensor is simple, no complex equipment is needed, the reaction temperature is low, and the gas sensor is suitable for large-scale production.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

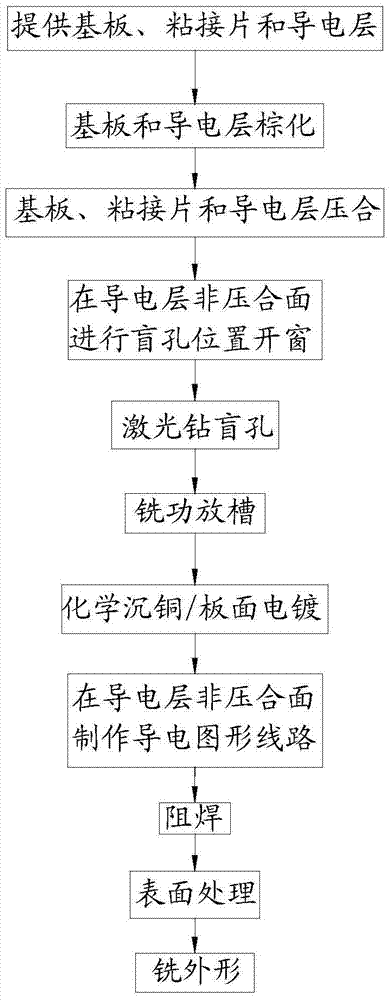

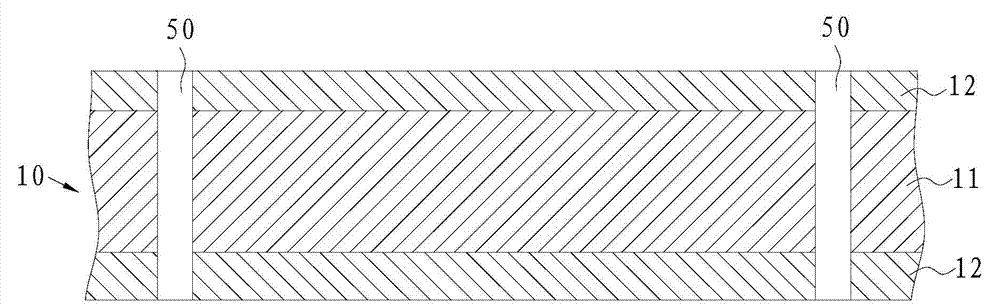

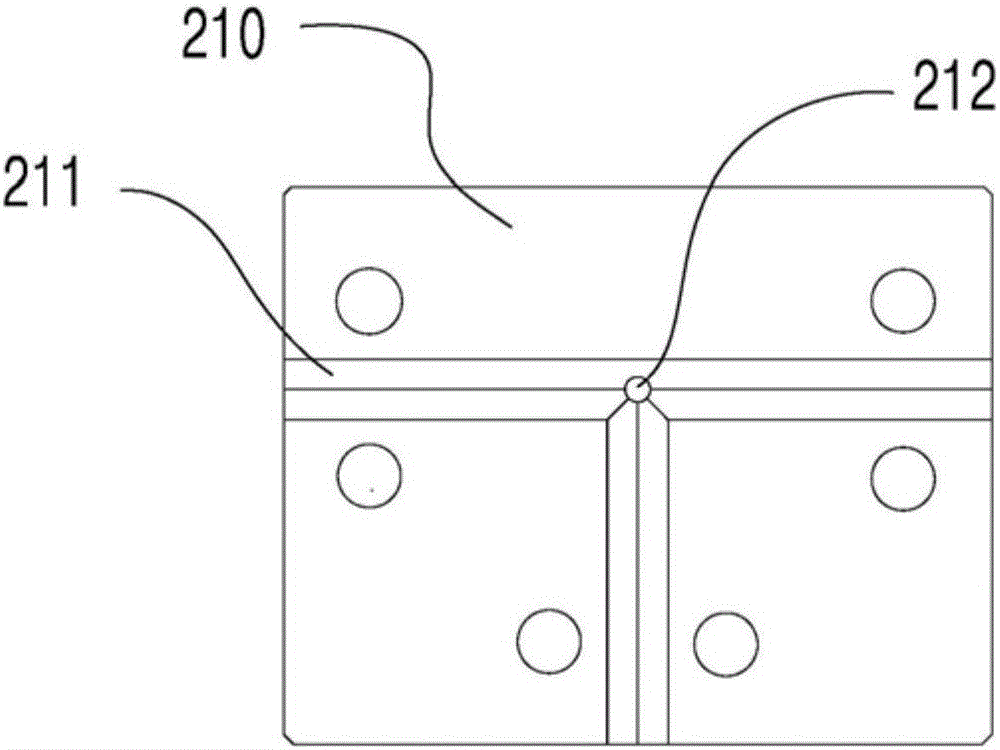

Method for manufacturing high-thermal-conductivity printed circuit board and printed circuit board

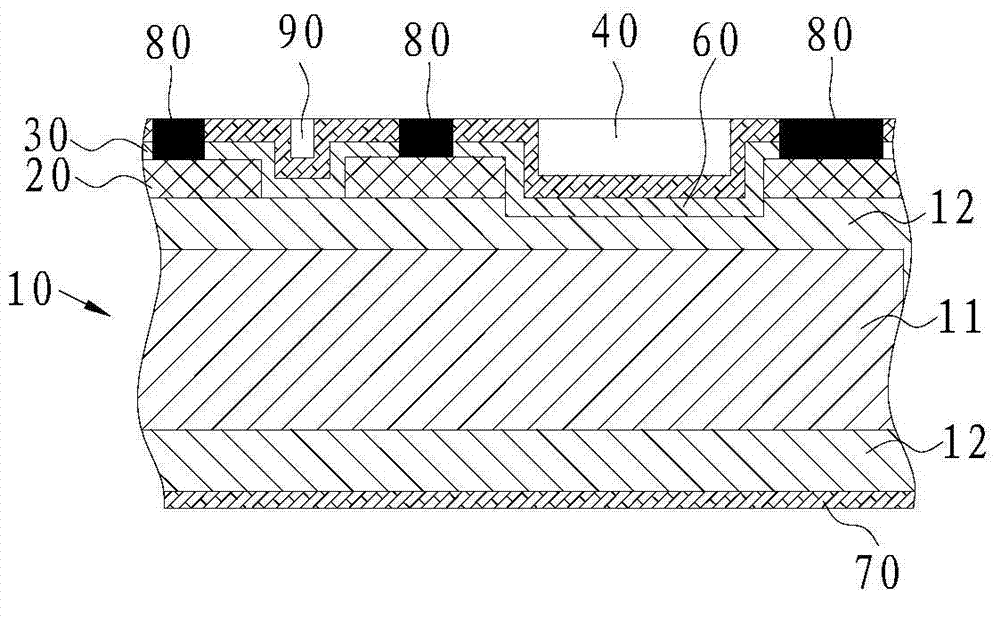

ActiveCN103491706AReduce weightInhibit sheddingPrinted circuit detailsPrinted circuit manufactureMetal coatingCopper

The invention discloses a method for manufacturing a high-thermal-conductivity printed circuit board. The method includes the steps of providing a substrate, a bonding sheet and a conducting layer, and sequentially stacking and pressing the substrate, the bonding sheet and the conducting layer into a whole, wherein the substrate comprises at least one first metal layer and a second metal layer, the first metal layer is a copper layer, the second metal layer is an aluminum layer, and the first metal layer is pressed onto the surface of the second metal layer to form a metal composite board. The metal composite board serves as the substrate, the first metal layer of the metal composite board is the copper layer, the second metal layer of the metal composite board is the aluminum layer, the metal composite board, the bonding sheet and the conducting layer are pressed into the whole through the press fit process, therefore, the weight of the substrate can be effectively reduced, the cost can be reduced, and metal coatings in holes or grooves which are formed to enable the conducting layer to be communicated with the substrate are prevented from falling off.

Owner:DONGGUAN SHENGYI ELECTRONICS

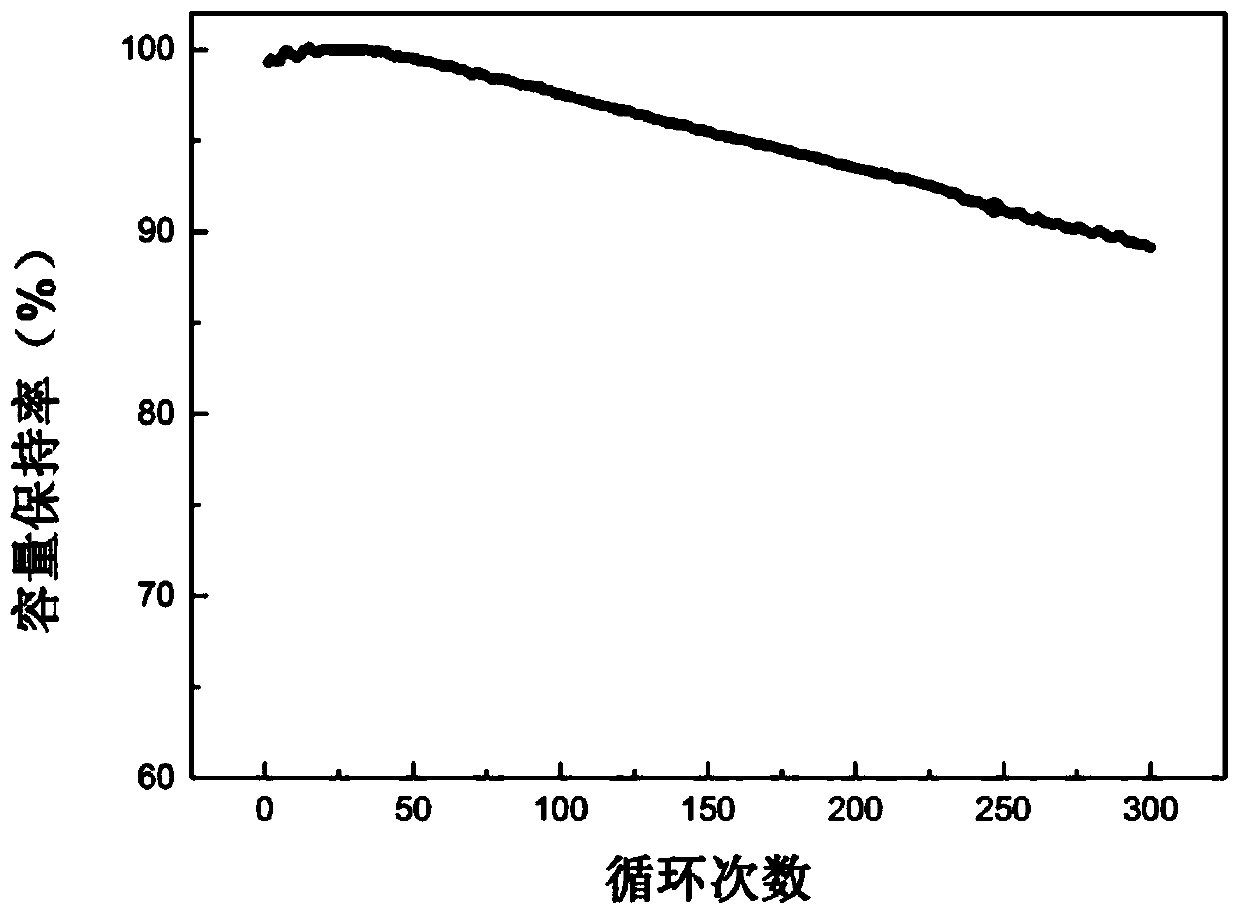

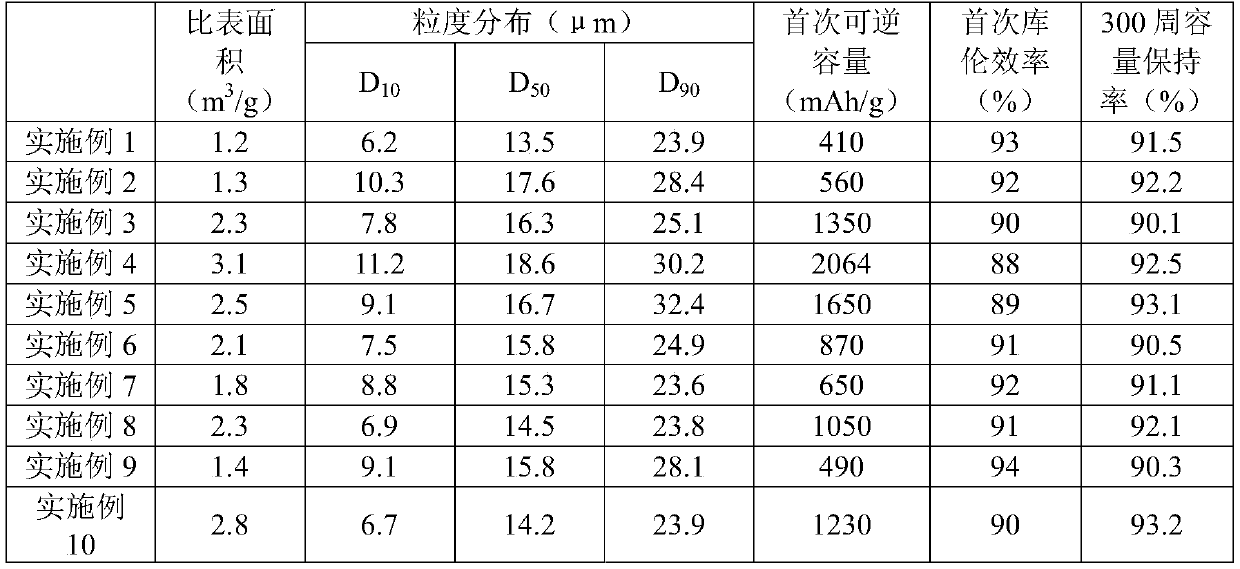

Silicon-carbon composite negative electrode material for lithium-ion battery and preparation method thereof

InactiveCN109755517AAvoid reunionPrevent floatingMaterial nanotechnologyCell electrodesCarbon compositesCarbonization

The invention provides a silicon-carbon composite negative electrode material for a lithium-ion battery and a preparation method thereof. The method includes steps: step 1, dispersing micron silicon in a solvent, and performing grinding to form nanometer silicon slurry; step 2, adding a carbon matrix, a binder and a conductive agent to the solvent for uniform mixing to obtain slurry 1, and addingthe nanometer silicon slurry in step 1 into the slurry 1 for uniform mixing to obtain slurry 2; step 3, drying the slurry 2 to obtain a precursor material 1, performing fusion on the precursor material 1 and a covering agent to obtain a precursor material 2, and placing the precursor material 2 in a protection atmosphere for thermal treatment to obtain a precursor material 3; step 4, crushing theprecursor material 3, mixing the crushed precursor material 3 with the covering agent, and performing high-temperature thermal covering to obtain a precursor material 4; and step 5, placing the precursor material 4 in the protection atmosphere for high-temperature carbonization treatment to obtain the silicon-carbon composite negative electrode material. According to the material and the preparation method thereof, the silicon-loaded carbon matrix is wrapped by conductive carbon so that direct contact of the silicon negative electrode and electrolyte is isolated, and the cycle performance of the battery is enhanced.

Owner:SHAANXI COAL & CHEM TECH INST

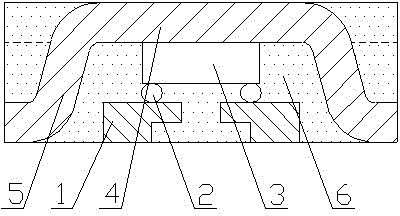

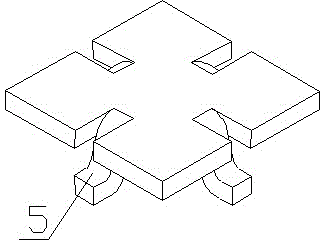

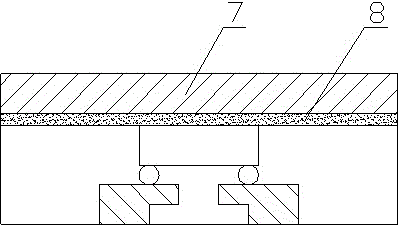

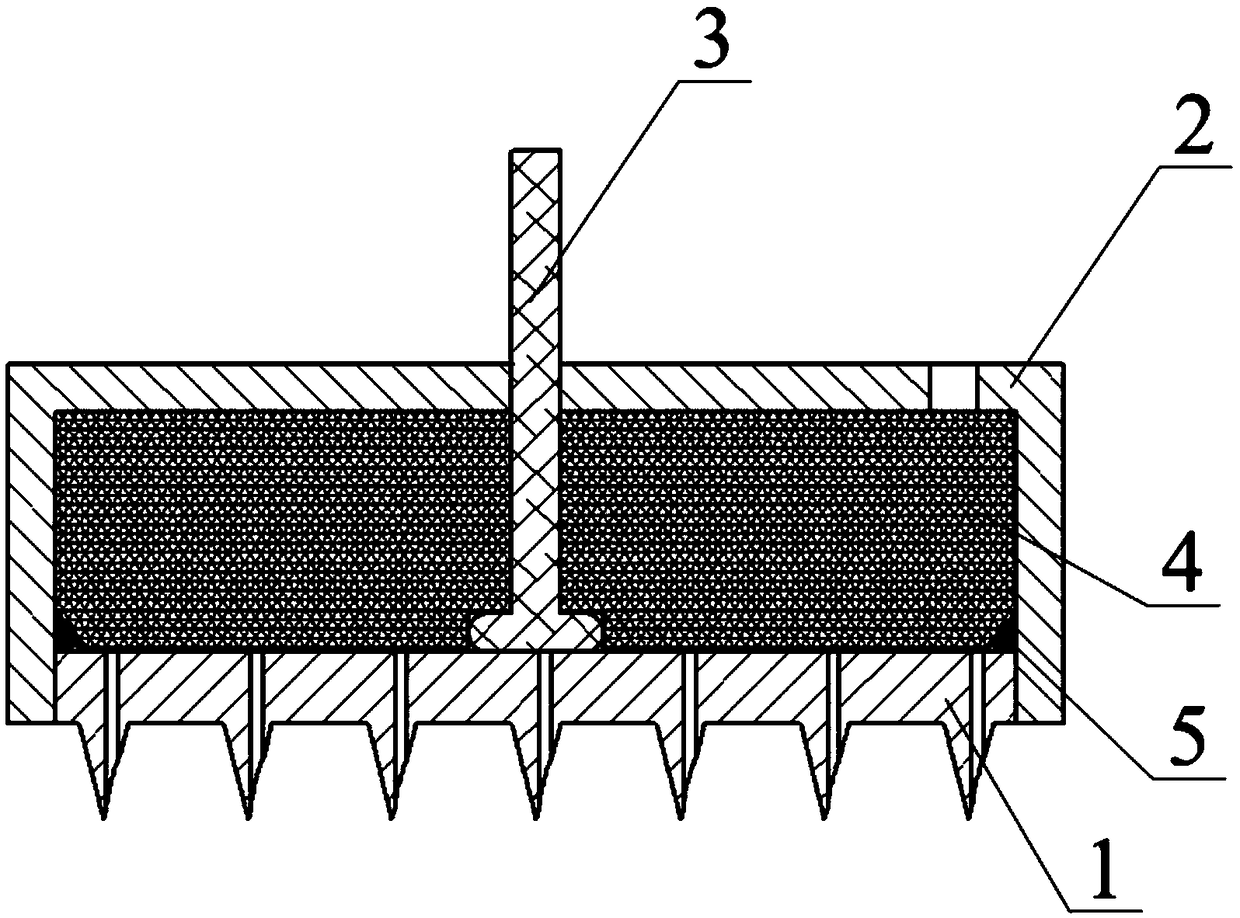

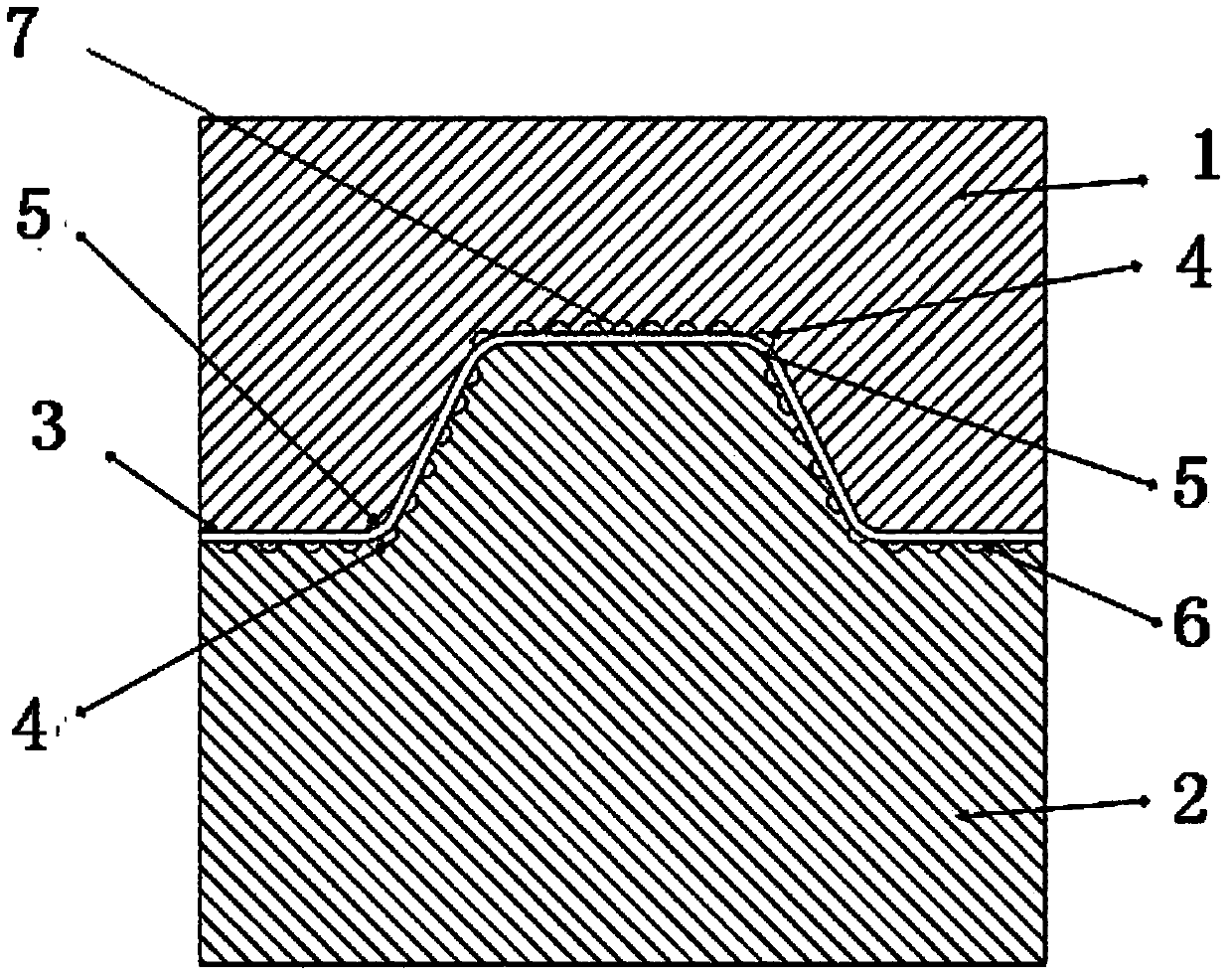

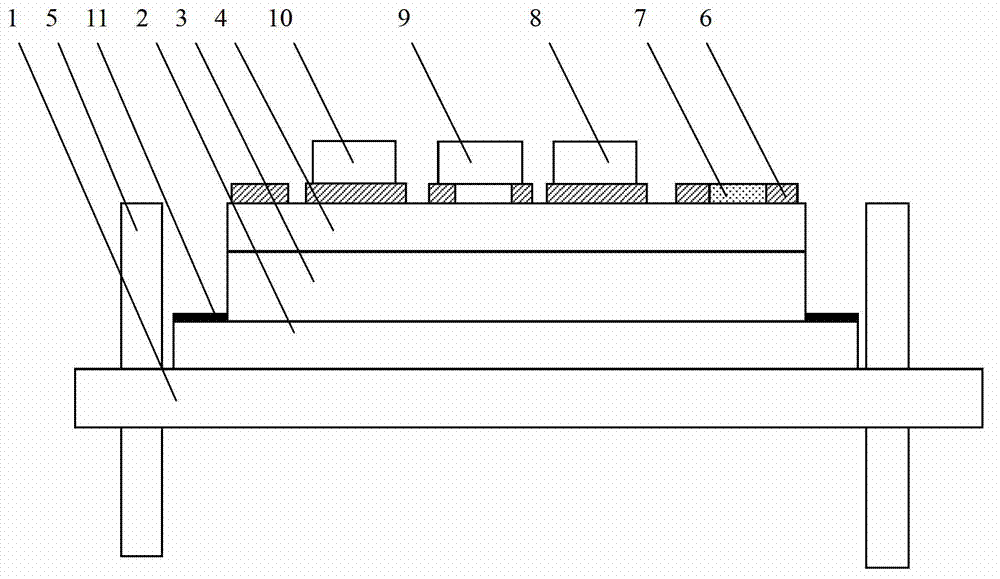

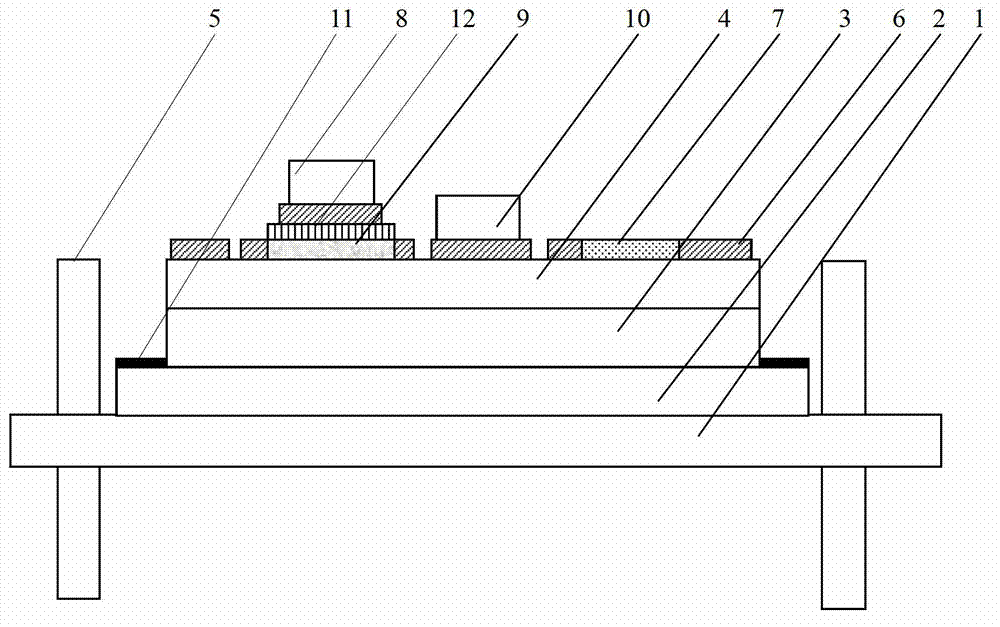

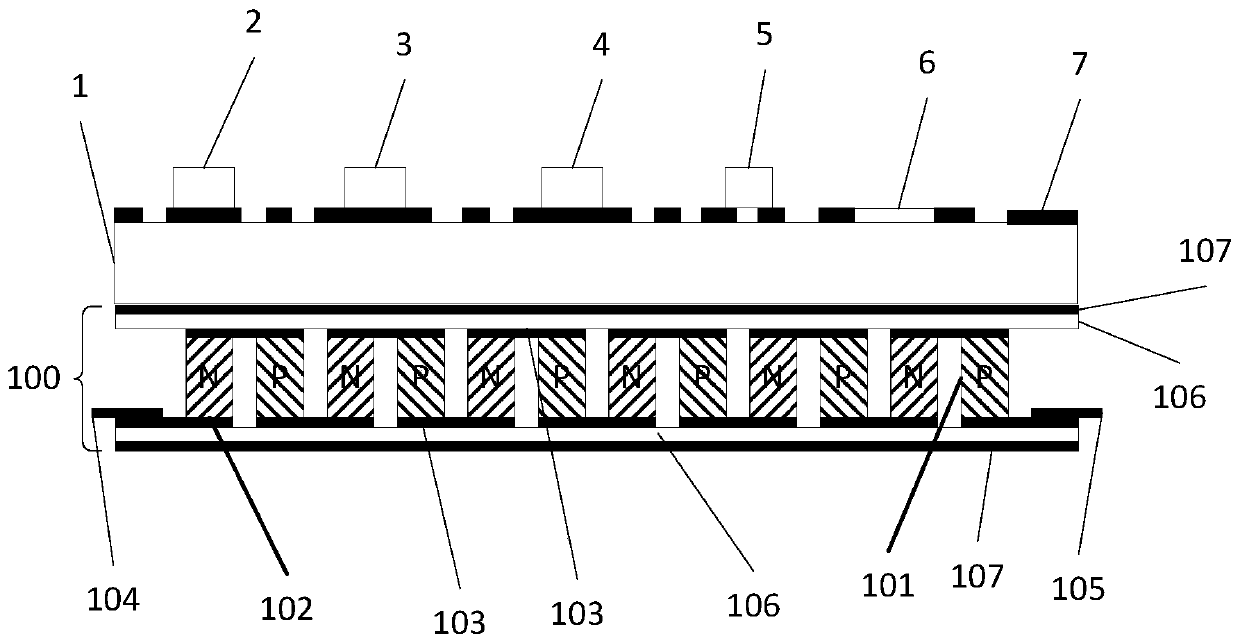

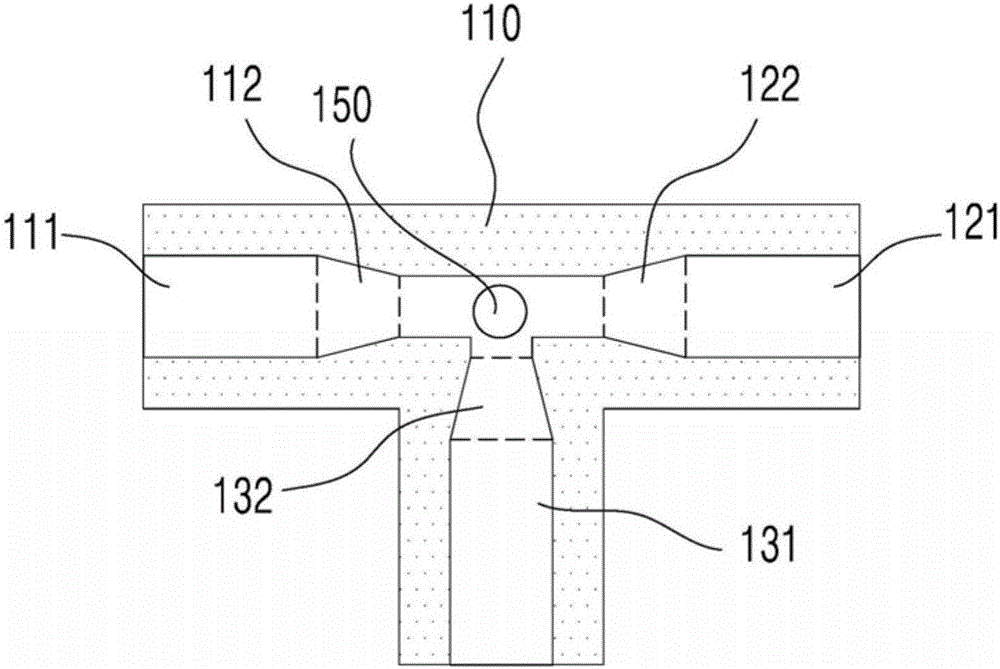

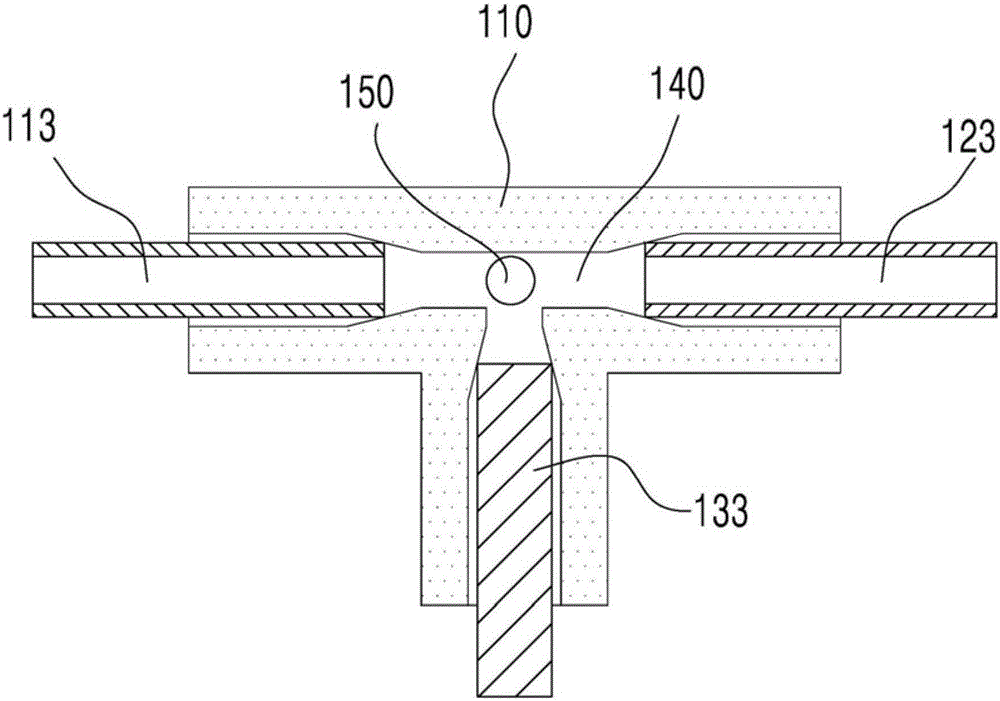

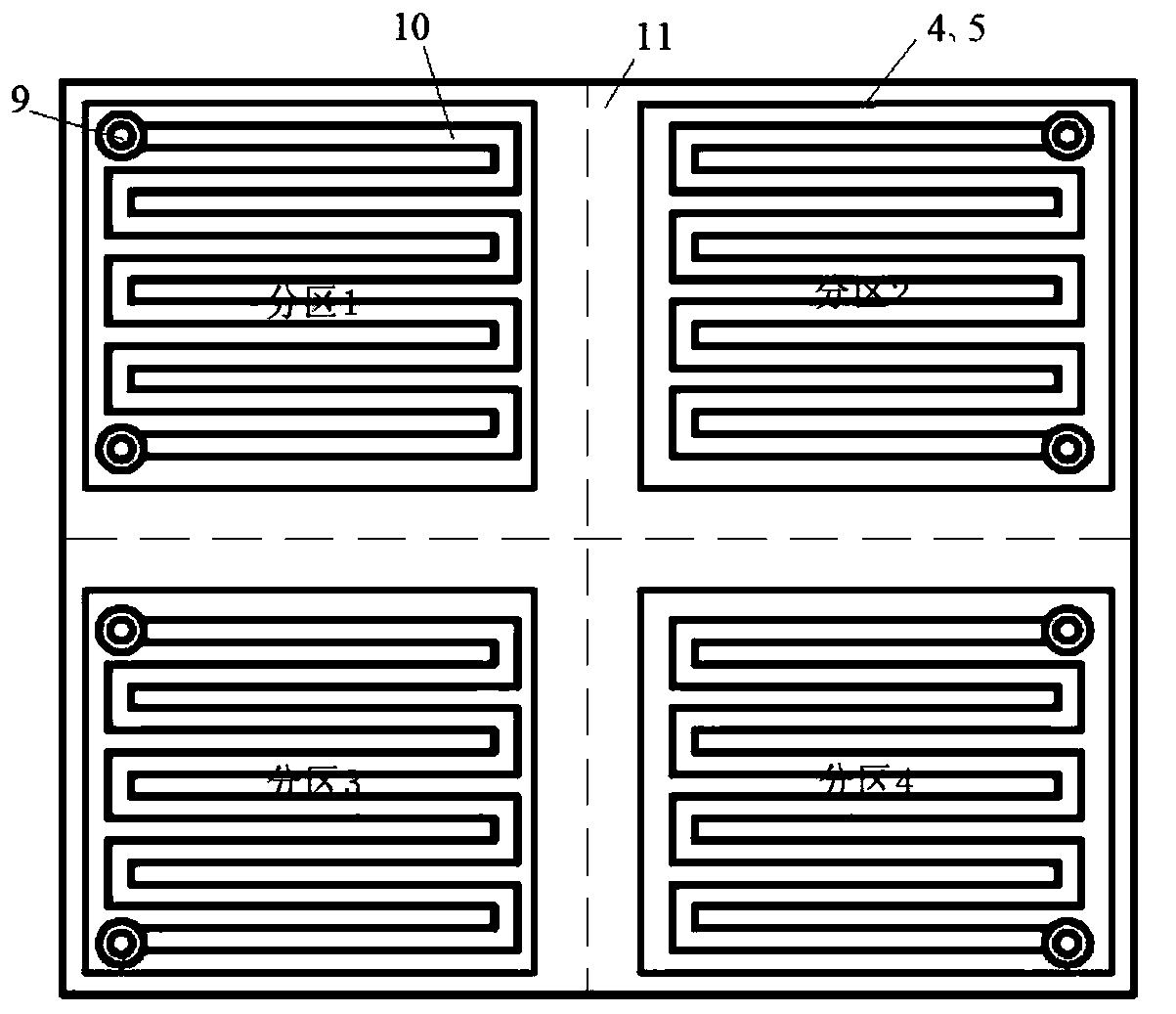

Packaging structure capable of achieving electricity property and heat dissipation through mechanical press mode and process method

ActiveCN104465551AAchieve direct contactImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesElectricitySolder ball

The invention relates to a packaging structure capable of achieving electricity property and heat dissipation through a mechanical press fit mode and a process method. The structure comprises pins (1). A chip (3) is arranged on the pins (1) through solder balls (2) in an inverted mode and is provided with a heat dissipation frame (4). The four sides of the heat dissipation frame (4) are downwards provided with clamping claws (5). Molding compounds (6) are arranged among the pins (1), the chip (3) and the heat dissipation frame (4) and outside the heat dissipation frame (4) in a packaging mode. By means of the packaging structure capable of achieving the electricity property and heat dissipation through the mechanical press fit mode and the process method, the problems that traditional packaging with heat dissipation pieces is high in cost and prone to failure are solved.

Owner:JCET GROUP CO LTD

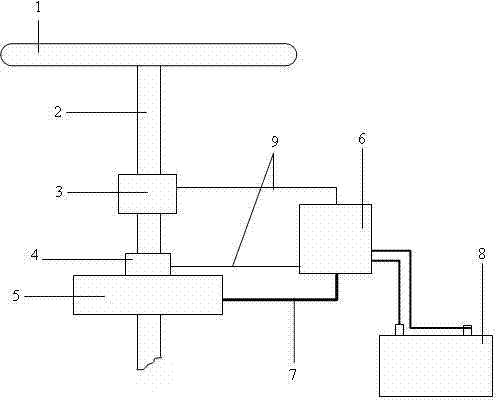

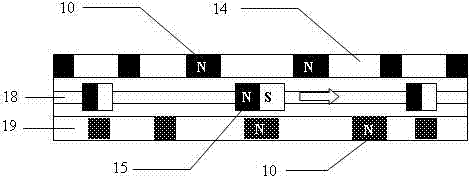

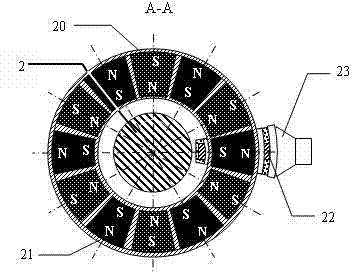

Automobile steering non-overshoot electromagnetic power assisting device

ActiveCN103029746ARich feedbackAchieve direct contactPower driven steeringSteering wheelDriver/operator

The invention relates to an automobile steering non-overshoot electromagnetic power assisting device, which consists of a torque sensor 3, an aspect sensor 4, an electromagnetic power assisting disk 5 and an electric control board 6, wherein a revolving shaft of the torque sensor 3, a revolving shaft of the aspect sensor 4 and a shaft of a rotor of the electromagnetic power assisting disk 5 are coaxial with a steering shaft 2 of a steering wheel; the torque sensor 3 and the aspect sensor 4 are used for transmitting a torque signal and an aspect signal of the steering wheel operated by a driver to the electric control board 6 through a single wire 9; and the electric control board is used for controlling the electromagnetic power assisting disk 5 through an electric control power supply line 7. In the automobile steering non-overshoot electromagnetic power assisting device, power-assisted steering is realized by adopting the electromagnetic power assisting disk instead of a motor, so that a steering command is not required to be transmitted to the motor, and overshoot is eliminated fully; and the steering disk and a steering wheel are connected through pure mechanical components, so that the road effect is direct, the structure is extremely simple, the reliability is improved, the manufacturing cost is lowered, the aims of convenience, energy saving and rapid response are fulfilled, and the automobile steering non-overshoot electromagnetic power assisting device has a plurality of advantages and a great market prospect.

Owner:NANLING WANGKE INTPROP MANAGEMENT CO LTD

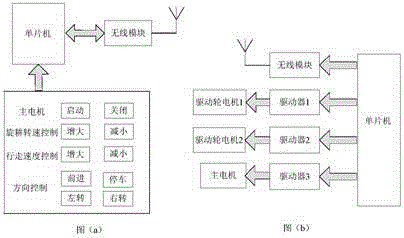

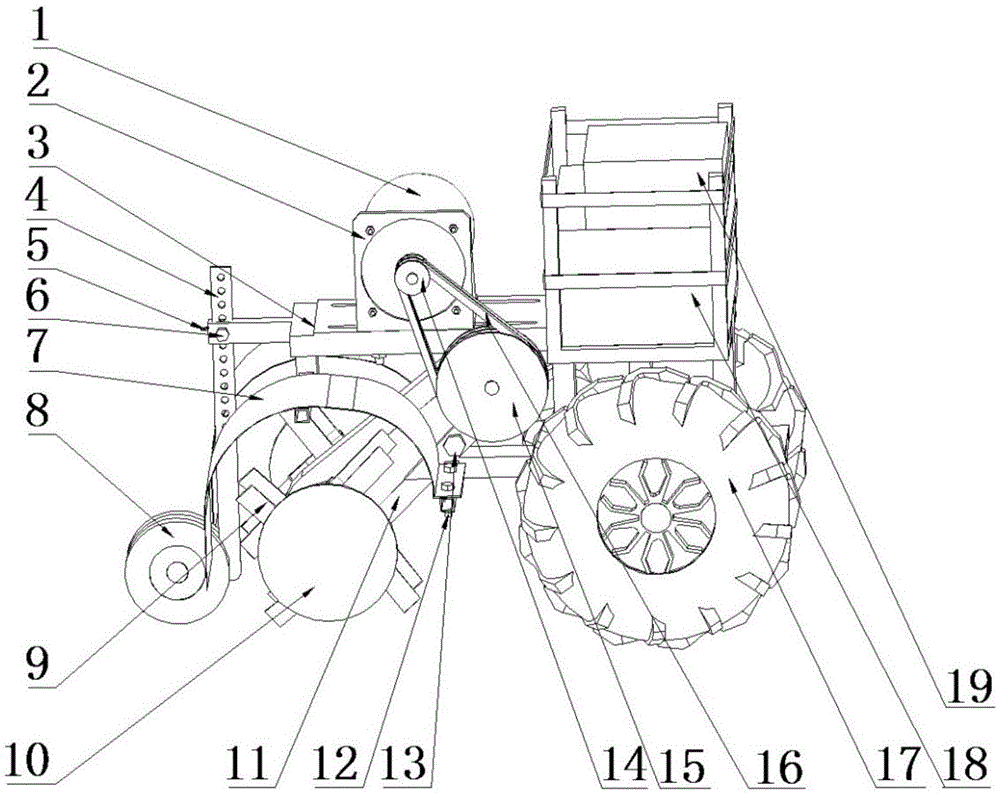

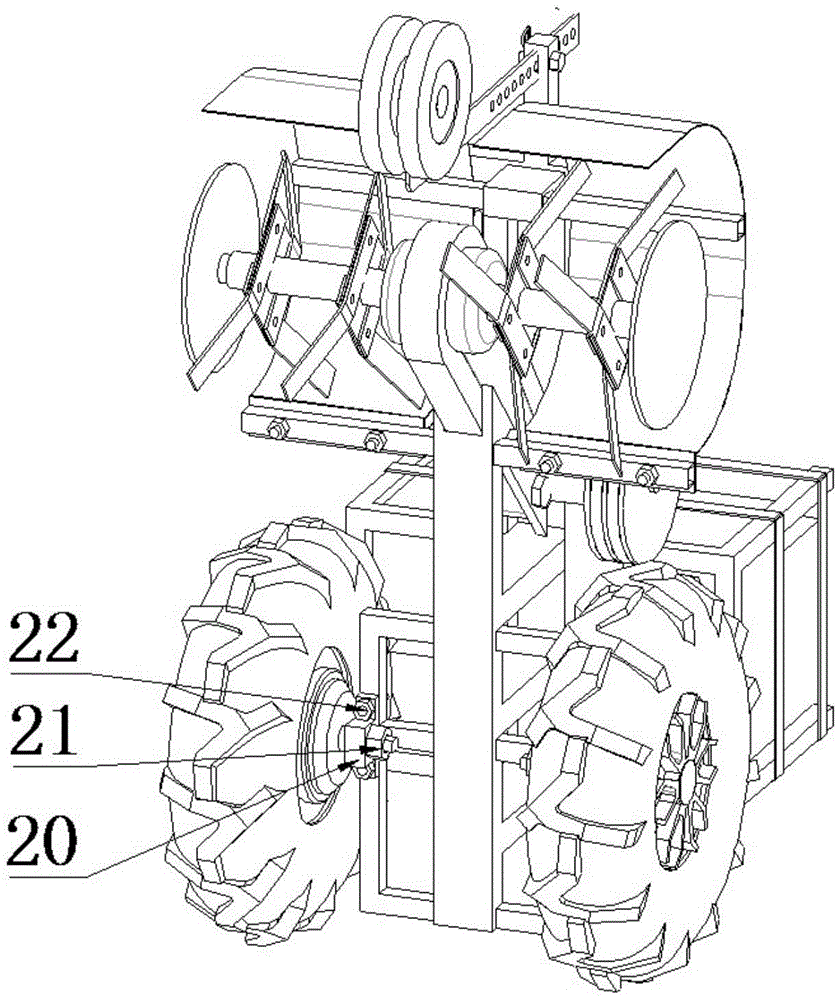

Remote control electric micro tilling machine with hub motors

InactiveCN105667590AAchieve direct contactAvoid direct contactAuxillary drivesTilling equipmentsVehicle frameElectric machine

The invention discloses a remote control electric micro tilling machine with hub motors. The remote control electric micro tilling machine comprises a power supply, a power unit, a rotary blade assembly, a tilling depth adjusting assembly, a walking driving assembly, a control device and a vehicle frame. The electric micro tilling machine is remotely controlled, the situation that an operator directly makes contact with the micro tilling machine is avoided, and security of the operator is guaranteed. The electric micro tilling machine is purely power-driven, free of pollution and friendly to environment. A battery is used for supplying power to a main motor, a control cabinet and driving motors, so that the operating time of the main motor, the control cabinet and the driving motors and the stability of the continuous operating time of the micro tilling machine are guaranteed, and operation convenience of the micro tilling machine is improved. Meanwhile, the micro tilling machine can be steered by controlling the speeds of a left walking wheel and a right walking wheel, so that a mechanical steering mechanism is omitted, and a mechanical structure is simplified. A supporting wheel bracket is provided with a graduated scale which is used for adjustment of the tilling depth and can show the tilling depth visually. Two slots are formed in the vehicle frame of the micro tilling machine so that the gravity center of the whole micro tilling machine can be adjusted conveniently to keep the micro tilling machine in a good working state.

Owner:HUBEI UNIV OF TECH

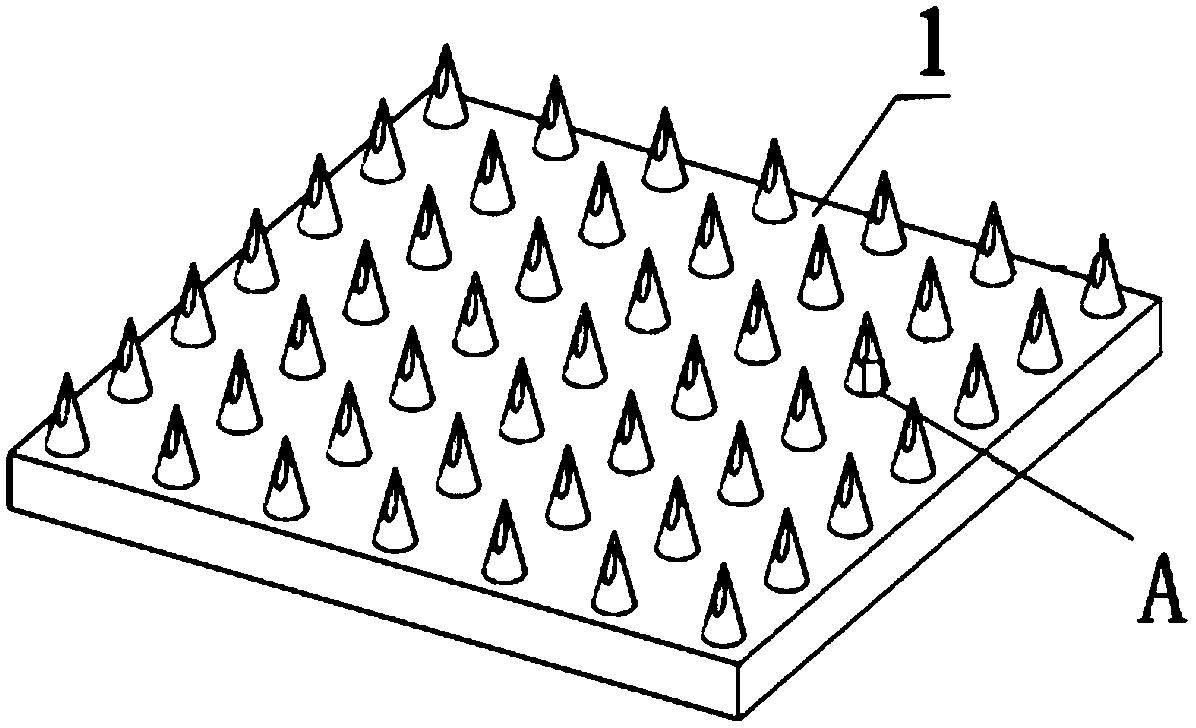

Porous metal capillary seepage microneedle electrode and preparing method

PendingCN109330711AAvoid damageSimplify preparationDiagnosticsSurgeryContact impedanceSignal-to-noise ratio (imaging)

The invention discloses a porous metal capillary seepage microneedle electrode and a preparing method. The porous metal capillary seepage microneedle electrode comprises a porous microneedle array electrode slice, an insulated shell, an electric signal line and a capillary liquid absorbing core ring, and multiple porous microneedles with groove channels are arranged on the porous microneedle arrayelectrode slice; a cavity is formed inside the insulated shell, an opening is formed in one side of the insulated shell, the porous microneedle array electrode slice and the opening of the insulatedshell are sealably spliced to form a cavity, and the cavity is filled with the capillary liquid absorbing core ring; the groove channels are communicated with the cavity. According to the porous metalcapillary seepage microneedle electrode, based on the advantages of the microneedle structures, the adsorptivity and diversion performance of the porous groove channel structures on a solution and the conductivity of the solution are utilized for achieving direct contact between a sensor and the corium layer of the skin, the contact impedance is greatly reduced, and bio-electricity signals with ahigh signal-to-noise ratio can be collected.

Owner:广东中昇华控智能科技股份有限公司

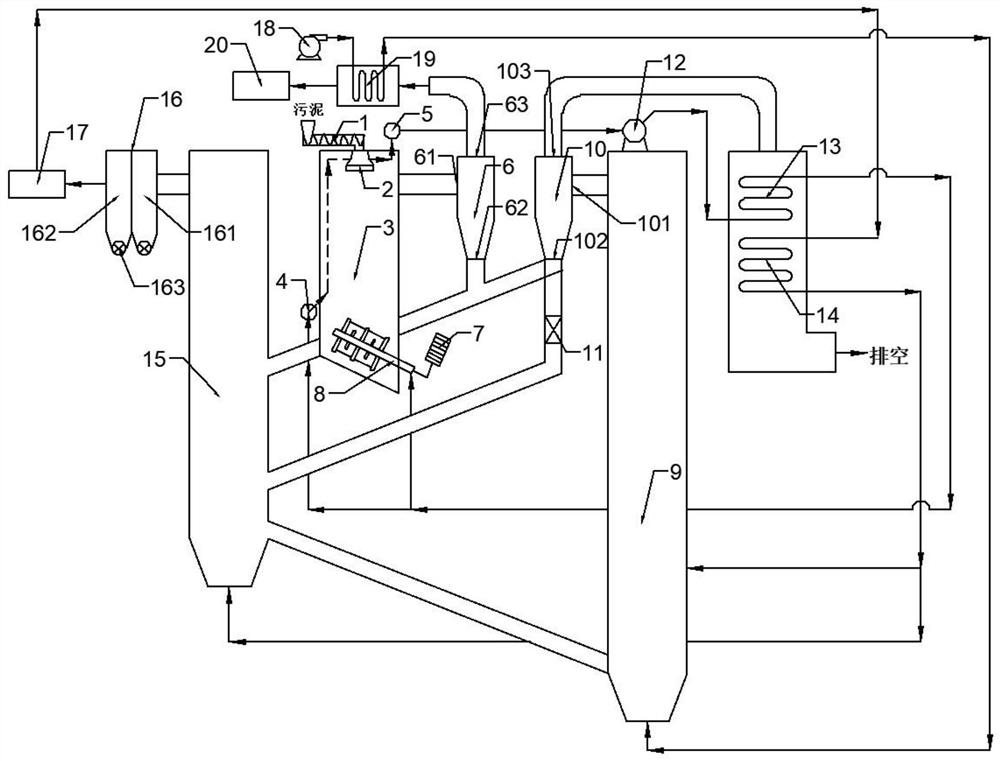

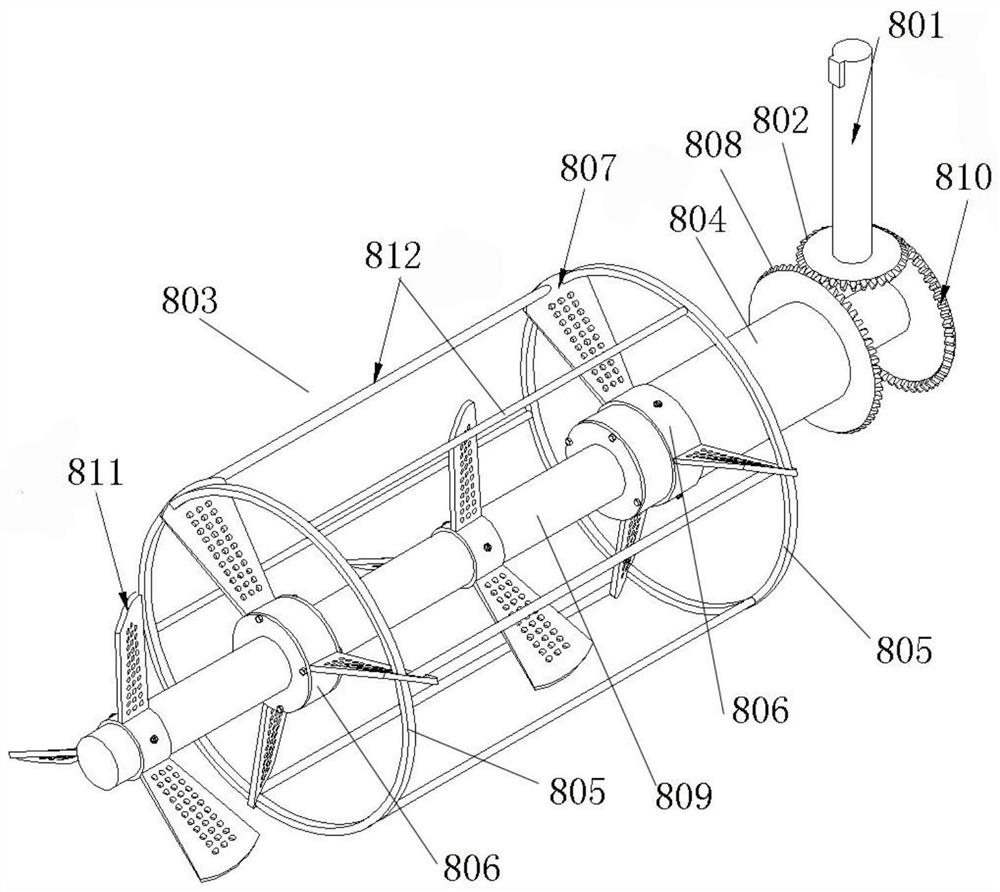

Sludge pyrolysis and gasification system

ActiveCN112174473AImprove drying effectAchieve direct contactSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisAir preheaterCombustion chamber

The invention discloses a sludge pyrolysis and gasification system which comprises a screw feeder, a nozzle, a sludge heat drying chamber, a stirrer, a sludge pyrolysis and gasification chamber, a catalytic modification tower, a synthesis gas storage tank, a coke combustion chamber, a steam drum, a first cyclone separator, a second cyclone separator, a synthesis gas preheater, a superheater, an air preheater, an air blower and a water treatment workshop; sludge is fed into the nozzle rotating at a high speed through the screw feeder to be granulated and then sprayed into the sludge heat dryingchamber, and the sludge makes direct contact with superheated steam and heat circulating ash under the action of the stirrer for heat exchange; the dried sludge enters the sludge pyrolysis and gasification chamber to generate synthesis gas and coke; and the coke and a part of synthesis gas enter the coke combustion chamber to be combusted, and water is heated into saturated steam. The superheatedsteam and the heat circulating ash are used as drying media, sludge is subjected to heat drying in a multi-stage coupling heat exchange mode, so that the drying effect is improved, and meanwhile, sludge resource utilization is achieved through the sludge gasification-coke roasting gradient utilization technology.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

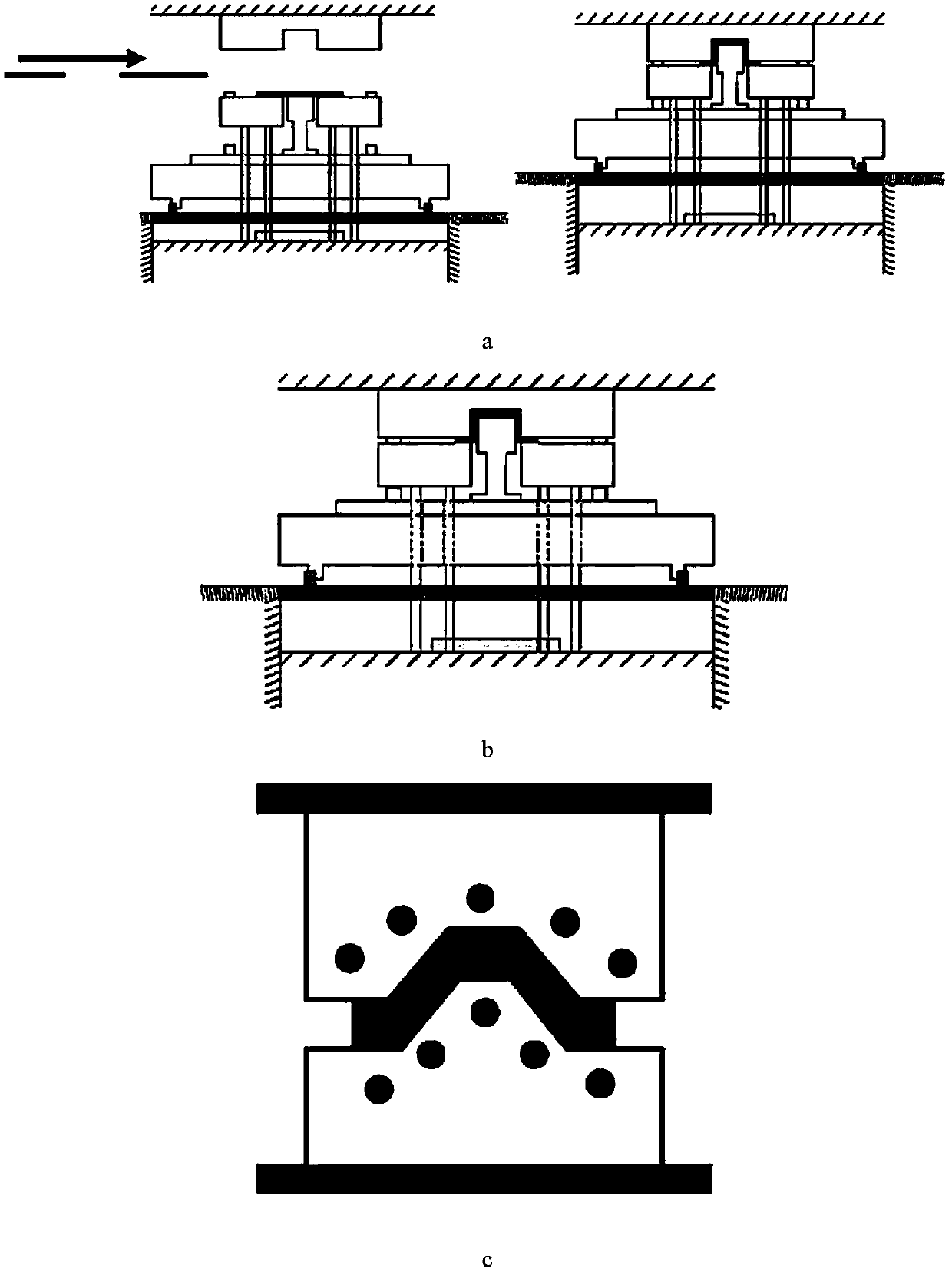

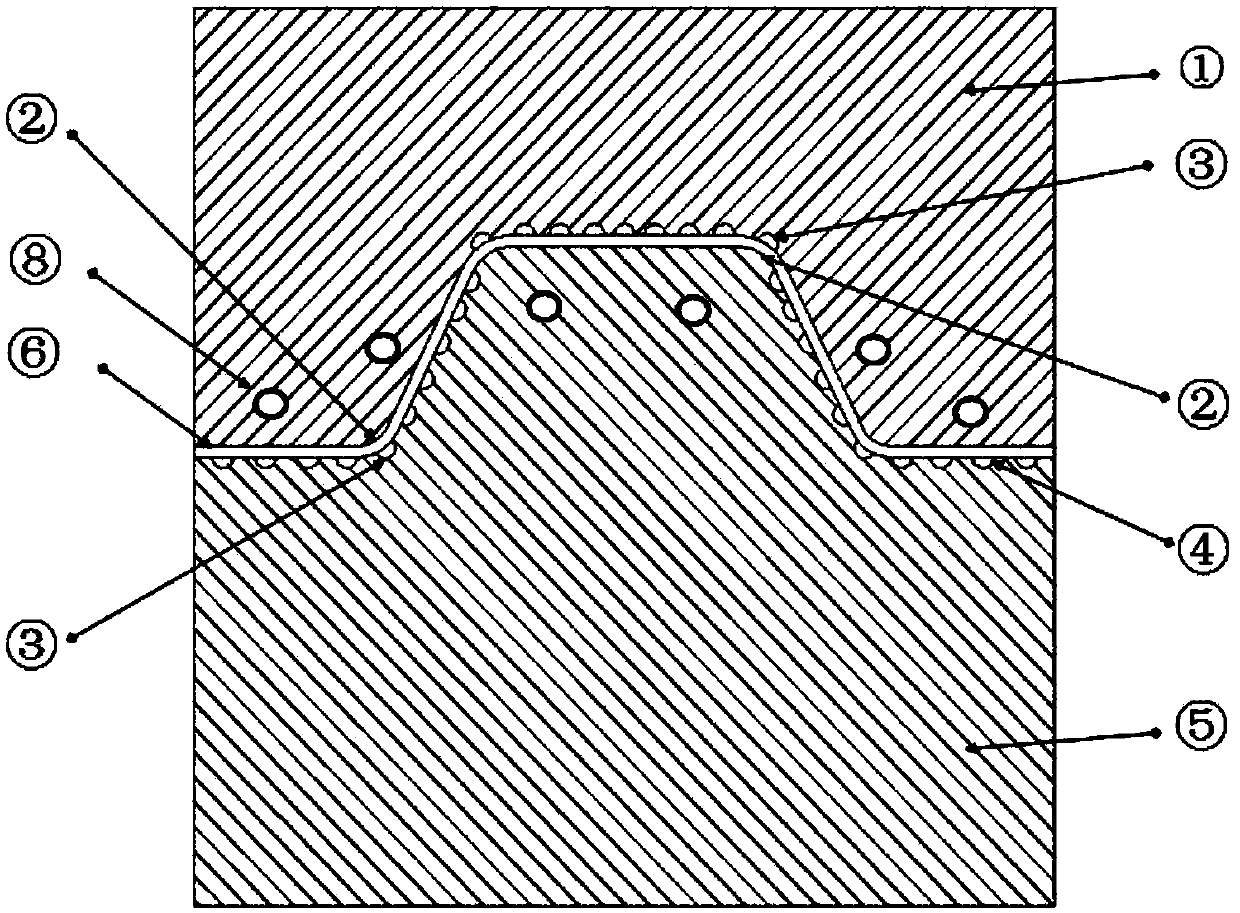

Cooling-gas direct cooling process and device based on hot forming mould of boron steel plate

The invention relates to a cooling-gas direct cooling process and device based on a hot forming mould of a boron steel plate, belonging to the technical field of heat-treatment plastic forming. The device comprises an upper die, a lower die, semi-open cooling gas passages and a cooling gas supply system, wherein the semi-open cooling gas passages are arranged in the contact surface of the upper die and the lower die, and the cooling gas supply system is provided by a press machine for the mould; the upper die and the lower die are respectively composed of a plurality of plane areas, a convex angle area and a concave angle area; and the semi-open cooling gas passages are respectively arranged in the plane areas and the concave angle area of the lower die and the plane areas and the concave angle area of the upper die. The device can cause a workpiece to be formed smoothly through mould stamping in a forming stage and can also realize that cooling gas directly cools the workpiece in a pressure-maintaining cooling stage.

Owner:陈扬

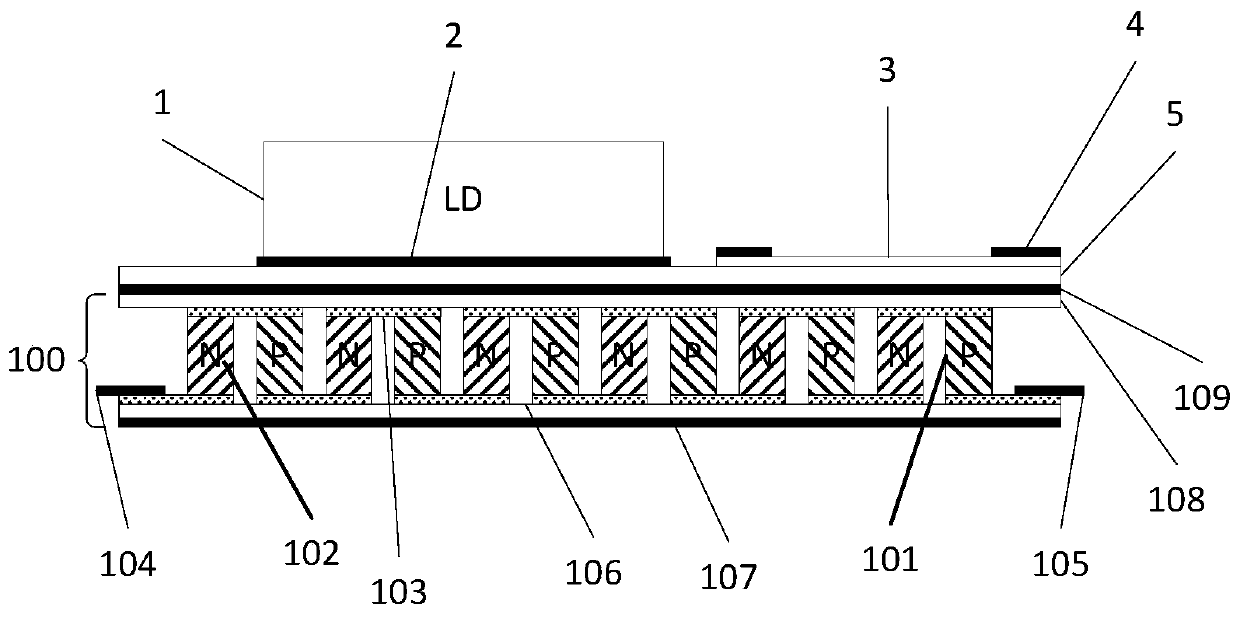

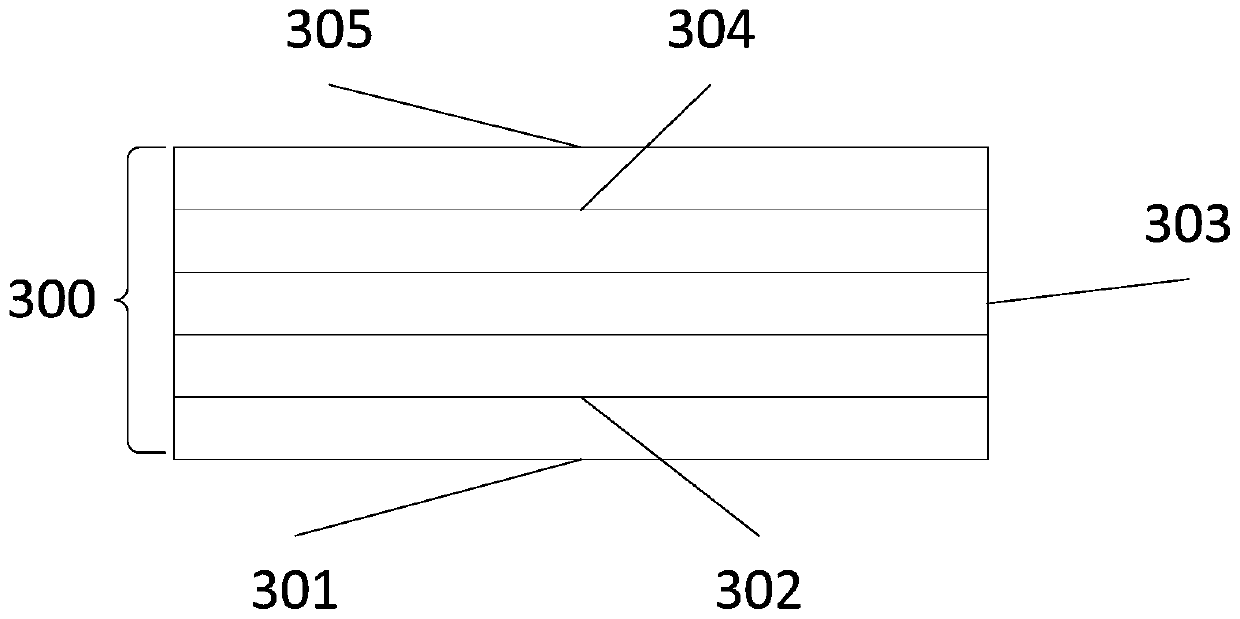

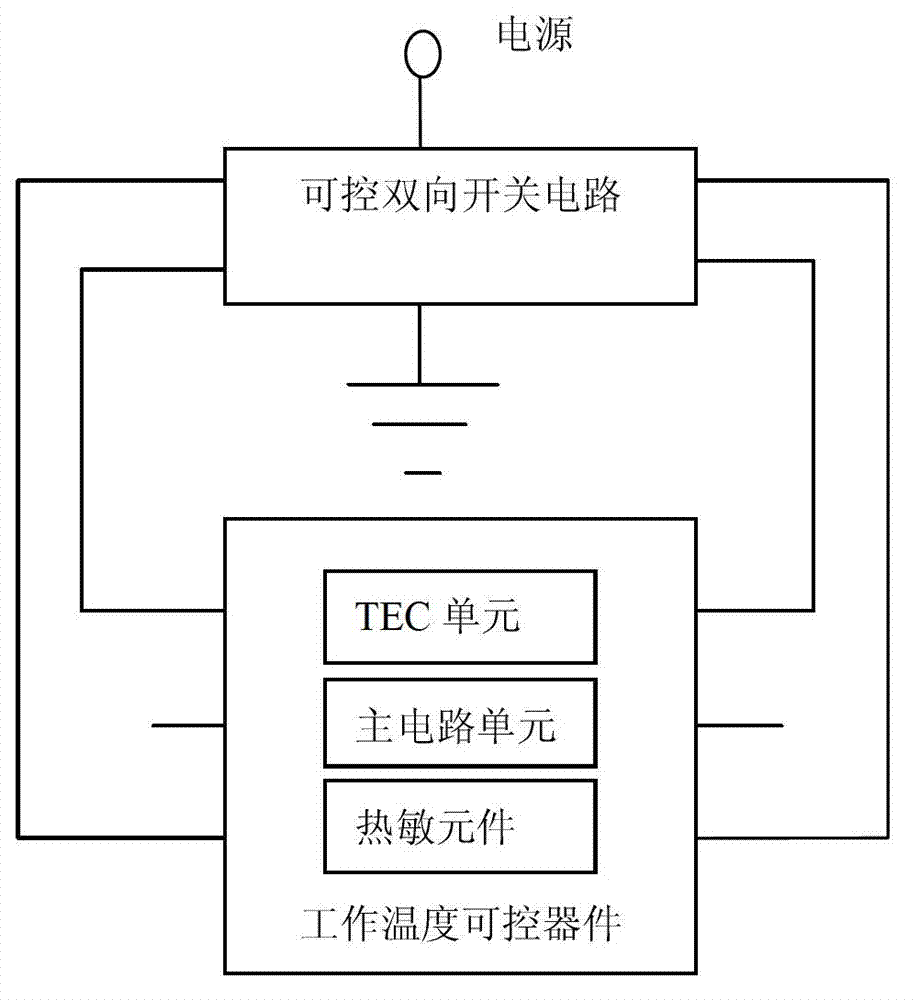

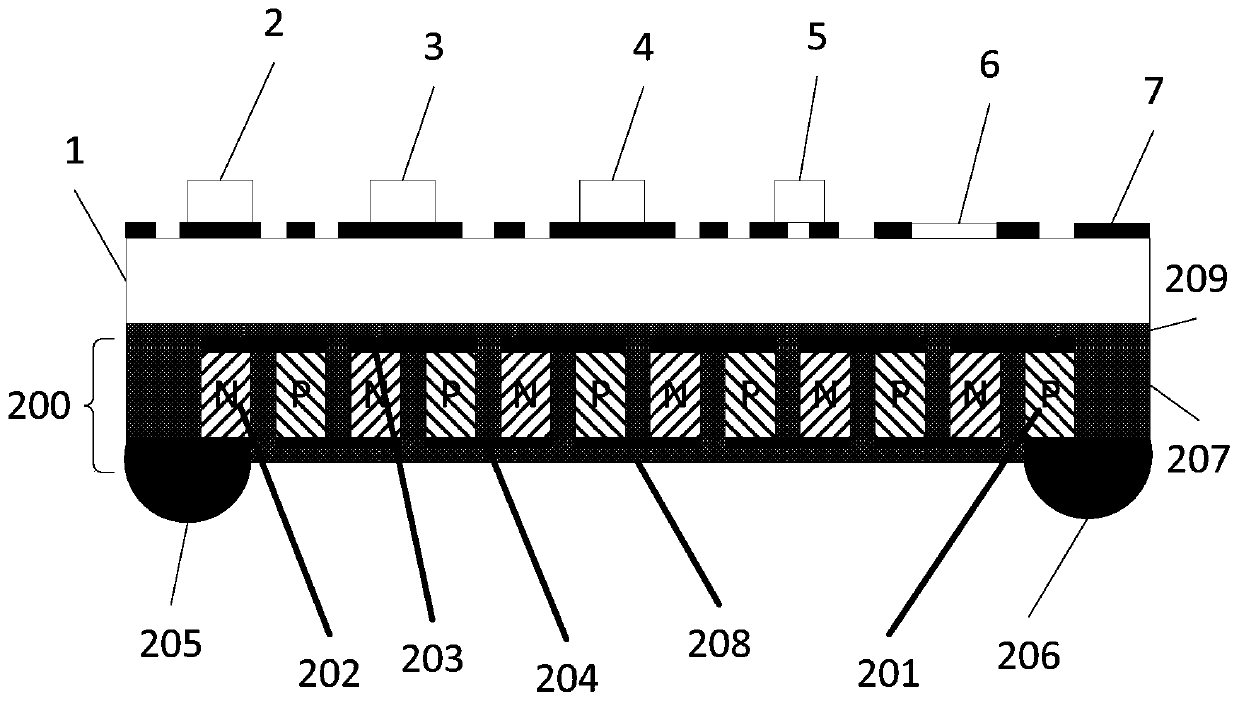

Semiconductor laser device with constant temperature control function and manufacturing method thereof

PendingCN111370993APrecise control of photoelectric performance parametersControl current directionLaser detailsSemiconductor lasersManufacturing technologyPhysical chemistry

The invention relates to a manufacturing method of a semiconductor laser device with a constant temperature control function, which organically integrates a semiconductor laser chip, a semiconductor thermoelectric refrigerator and a thermistor with a negative temperature coefficient on the basis of the existing semiconductor laser chip manufacturing technology. The semiconductor laser device includes: a semiconductor substrate, a first silicon dioxide layer, an n-type buffer layer, an n+ Omega contact layer, an n electrode, an n-type cap layer, a p-type cap layer, a P electrode, a p+ Omega contact layer, an integrated TEC thermoelectric cooler, a semiconductor laser active region, a second silicon dioxide layer, an NTC thin-film resistor, an NTC thin-film resistor metal electrode and a thermoelectric cooler spherical electrode. The purposes of accurate temperature control and high reliability are achieved, and accurate control over photoelectric performance parameters of the semiconductor laser is achieved. The semiconductor laser device is widely applied to the fields of environmental atmosphere detection, communication, aerospace, aviation, ships, precise instruments, geologicalexploration, oil exploration, field operation, industrial control and the like, and has a wide market prospect.

Owner:广东鸿芯科技有限公司

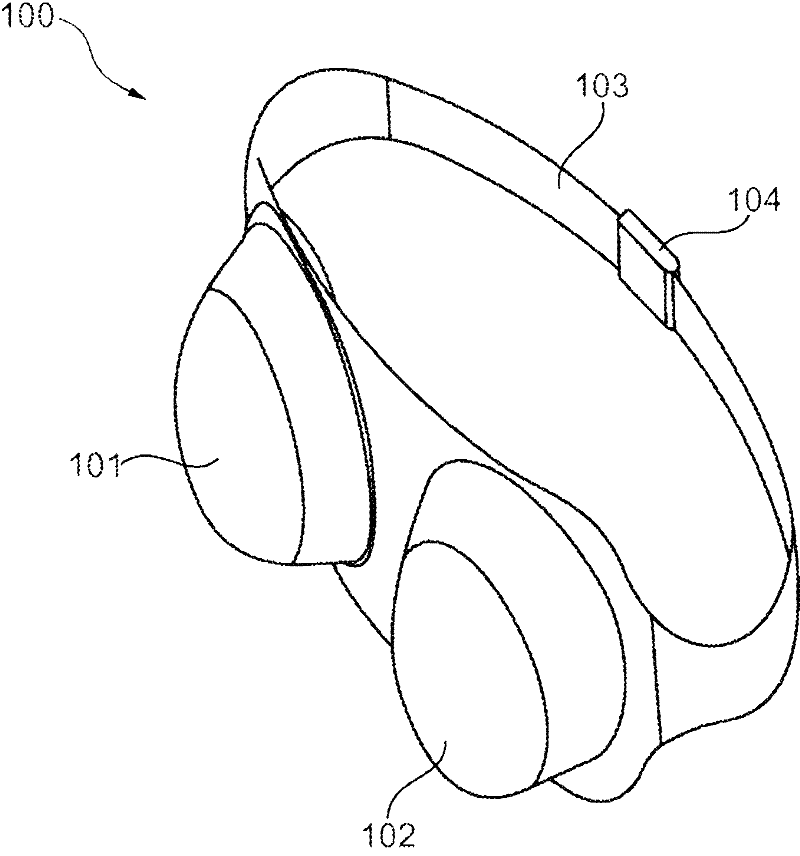

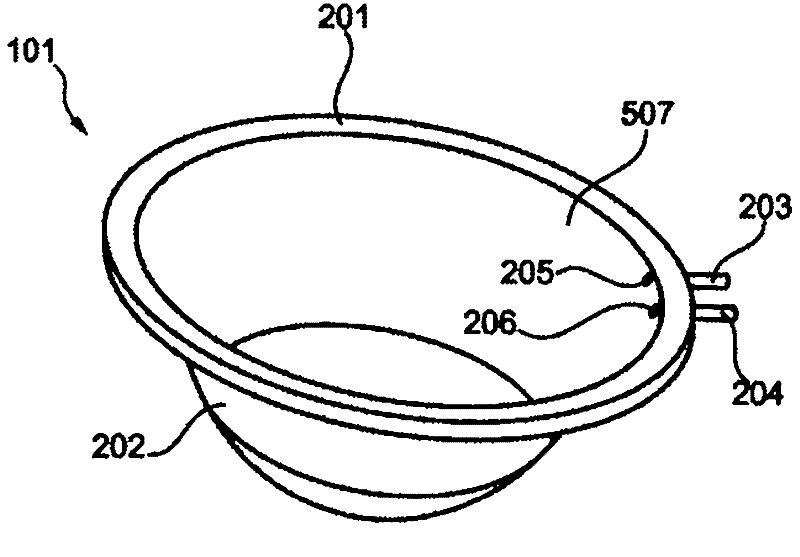

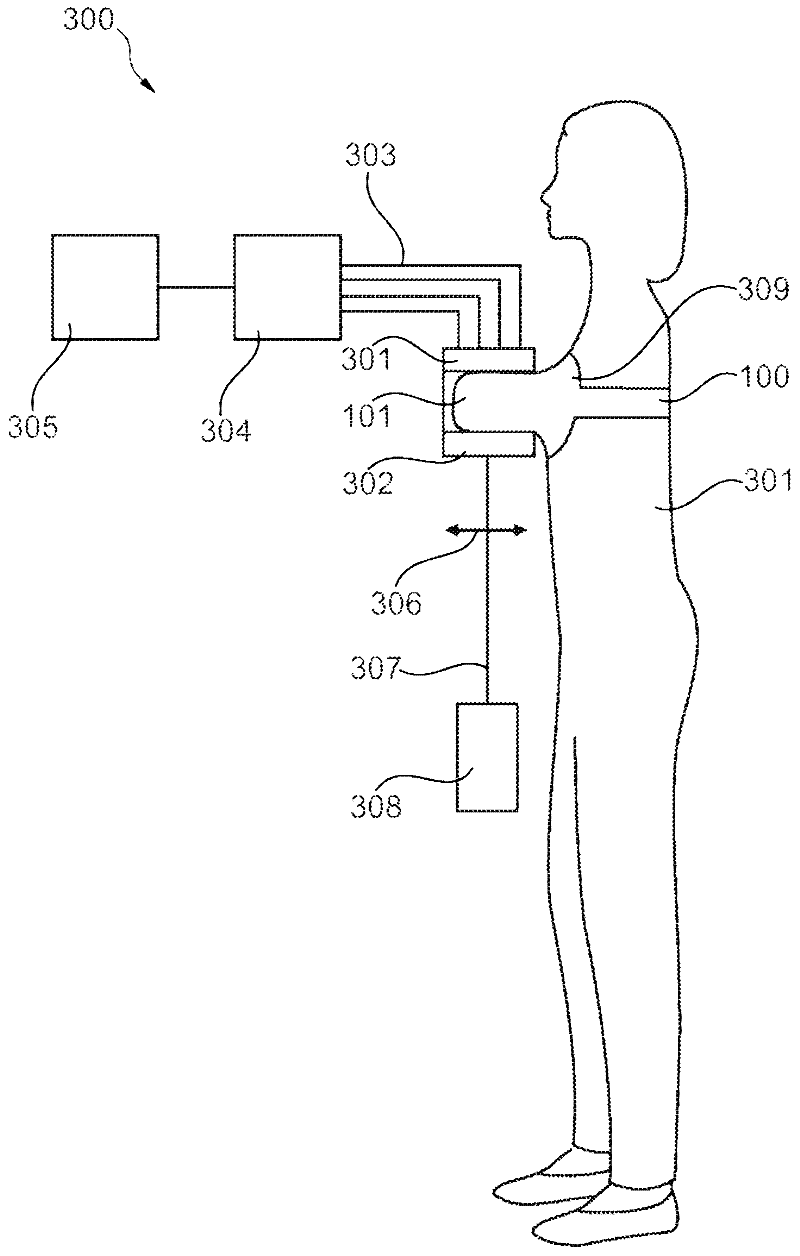

Interface device, imaging system and method for rim-imaging

InactiveCN102316791AAchieve direct contactIncreased horizontal scan rangeOrgan movement/changes detectionPatient positioning for diagnosticsX-rayField of view

The invention relates to imaging systems in which during imaging of an object a matching medium is used to match the object to its surroundings. An interface device is used for phase contrast rim-imaging of the object, which comprises a compartment in which a deformable matching material is contained which can be pushed to the side when the object to be imaged is compressed. Thus, a lateral field of view for X-ray phase contrast mammography may be increased.

Owner:KONINKLIJKE PHILIPS NV

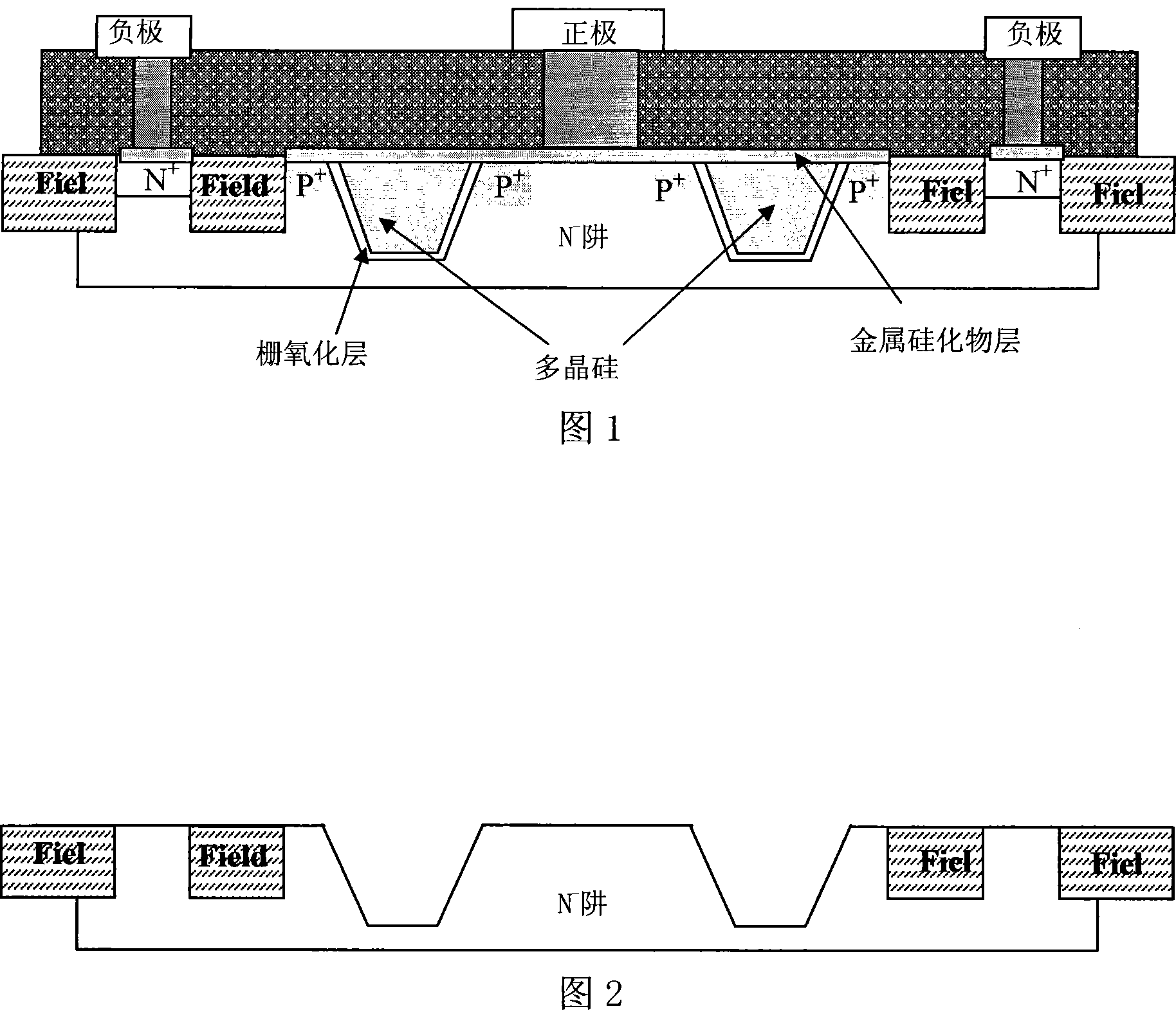

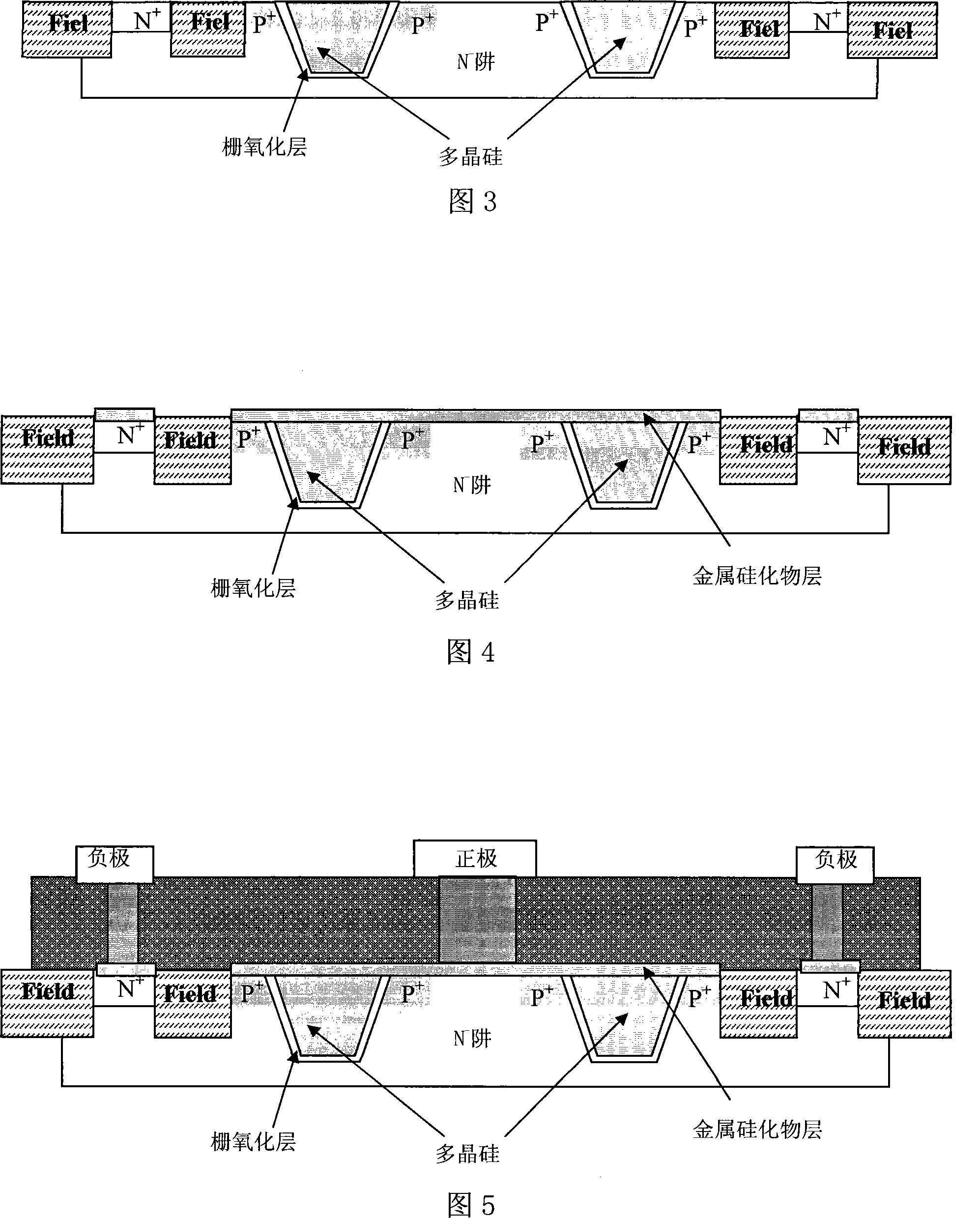

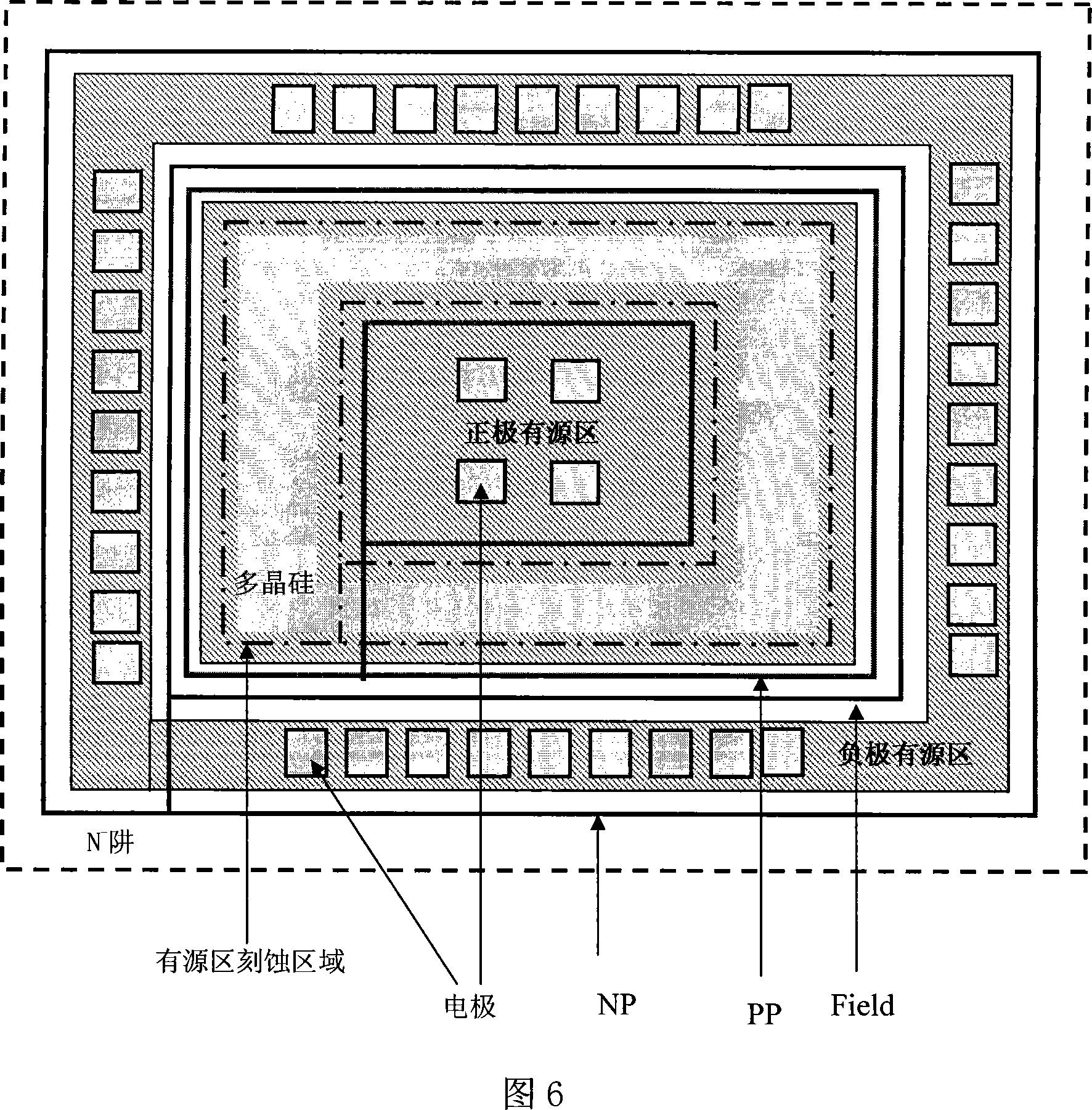

Schottky barrier diode device and manufacturing method thereof

ActiveCN101452967BAchieve direct contactLow reverse breakdown voltageSemiconductor/solid-state device manufacturingSemiconductor devicesSalicideSchottky barrier

The invention discloses a schottky barrier diode device. An anode active region on an N<-> well comprises an annular silicon groove; the silicon groove is filled with polysilicon; the polysilicon and the N<-> well are isolated with a gate oxide layer; the upper parts of two outer sides of the groove are both provided with a P-type impurity heavily doped region; and the anode active region and a cathode active region are both covered with a metal silicide layer. The invention also discloses a method for manufacturing the schottky barrier diode device. The method comprises the steps of manufacturing an isolation region on the N<-> well, etching the annular silicon groove, growing the gate oxide layer and depositing the polysilicon in turn and performing etching, doping the P-type impurity heavily doped region and the cathode active region, and depositing the metal silicide layers above the anode active region and the cathode active region. The method has simple process steps, accuratelycontrols the contact area with metal silicide by doping P-type impurities beyond a schottky contact region, raises the reverse breakdown voltage of schottky diode, and reduces electric leakage.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Integration method of high-sensitive temperature-controlled thin film hybrid integrated circuit

InactiveCN102931144AImprove long-term reliabilitySave integration spaceSemiconductor/solid-state device manufacturingEvaporationHeat sensitive

The invention relates to an integration method of a high-sensitive temperature-controlled thin film hybrid integrated circuit; the integration method comprises the following steps of: firstly growing a thin film resistor, a thin film conduction band and a bonding region on the surface of an aluminium nitride (Al3N4) ceramic substrate in a thin film sputtering manner or an evaporation manner; then forming a thermistor thin film in the same manner and forming an insulating medium layer and a metallization layer required for pasting a chip on the thermistor thin film in the same manner; mounting a thermo-sensitive sensing signal processing chip, a temperature controller main chip and other active or inactive components on the substrate; and finally, bonding by adopting a bonding wire, and sealing a tube base and a tube cap in a specific atmosphere to obtain the high sensitive temperature-controlled thin film hybrid integrated circuit. The integration method can be used for realizing the gapless contact, which belongs to interatomic contact, of a thin film thermistor and the temperature controller main chip on the maximum contact surface, so that the heat of the main chip can be rapidly conducted to the thermistor to the maximum extent, and thus high-sensitive temperature control can be realized.

Owner:GUIZHOU ZHENHUA FENGGUANG SEMICON

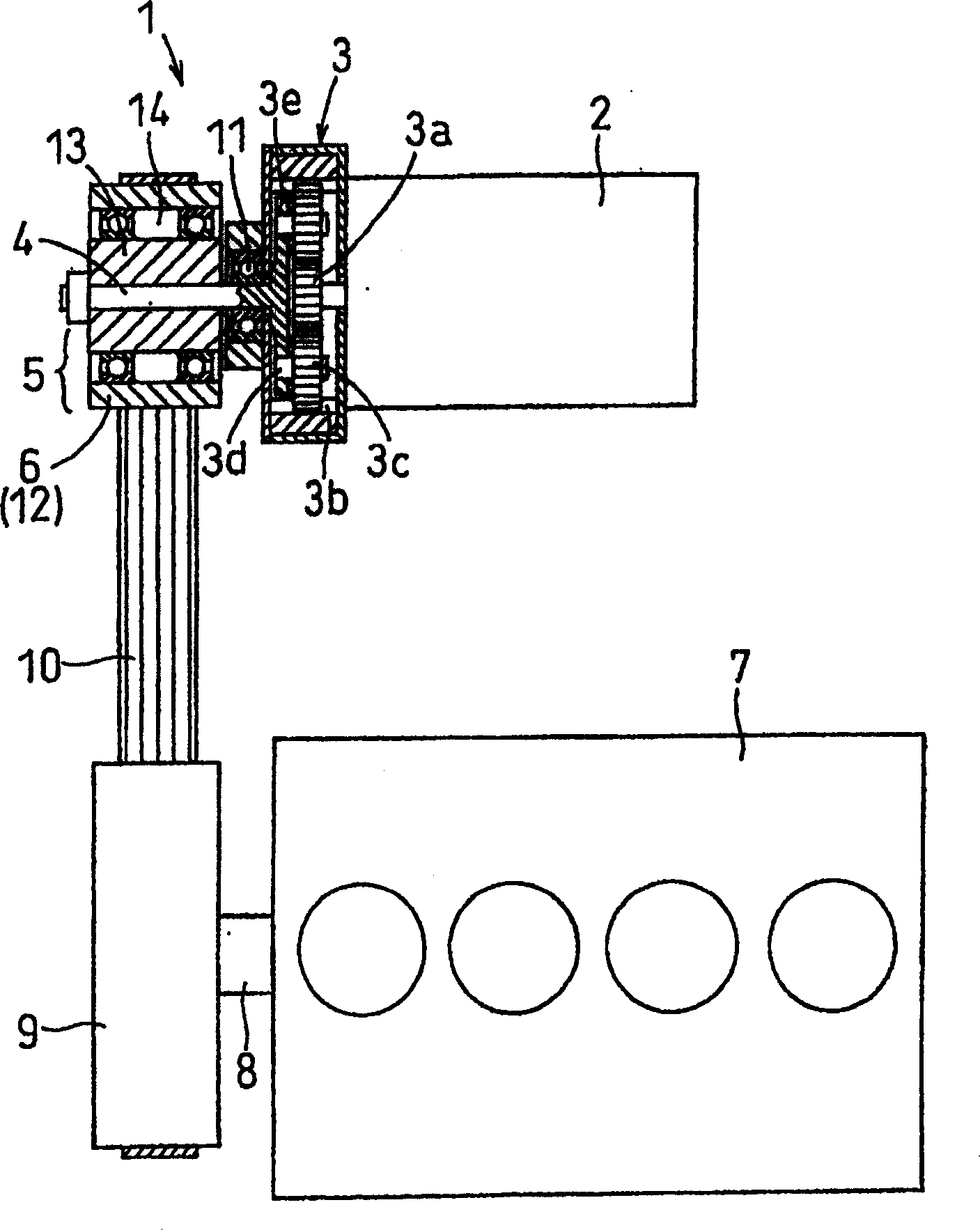

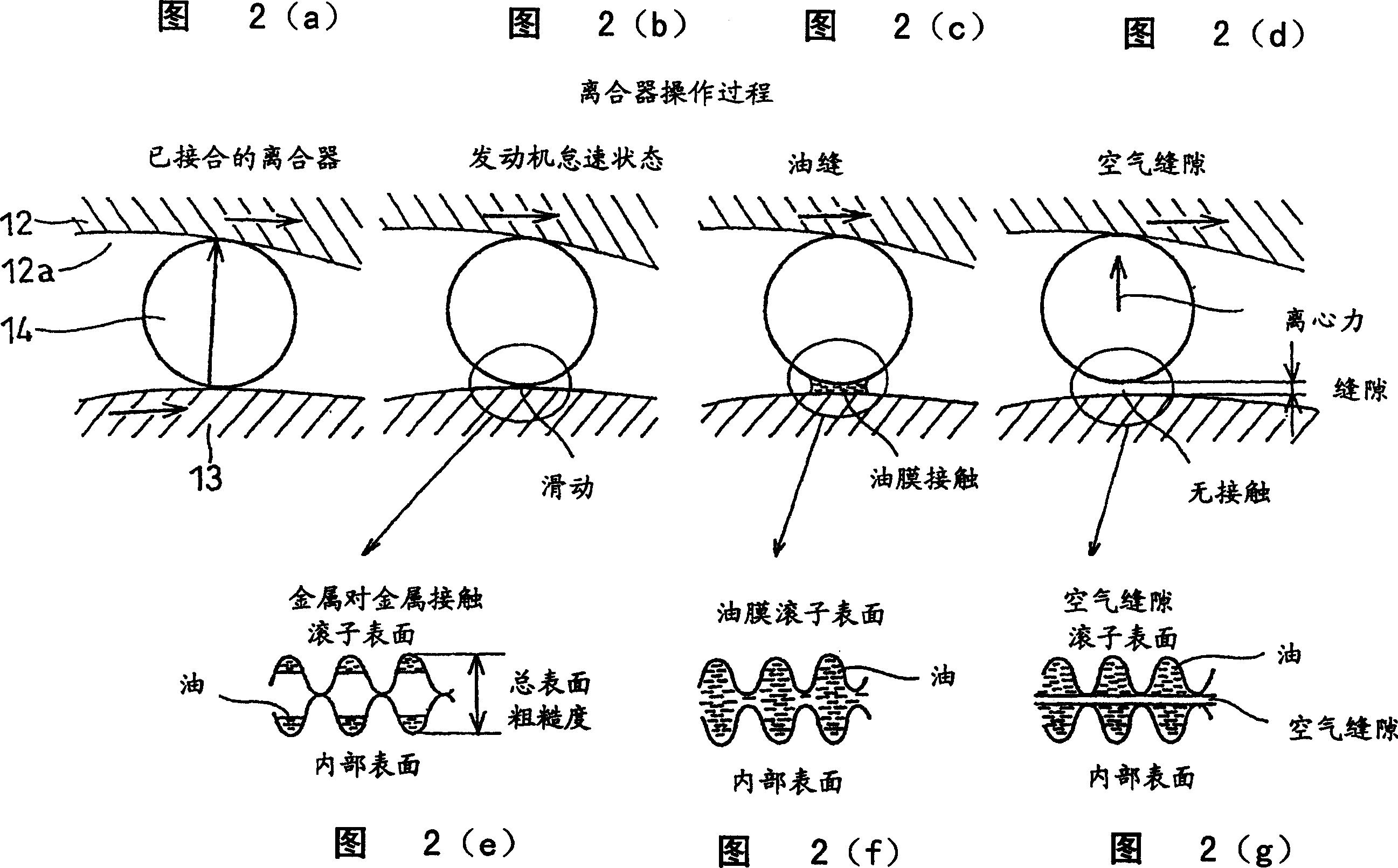

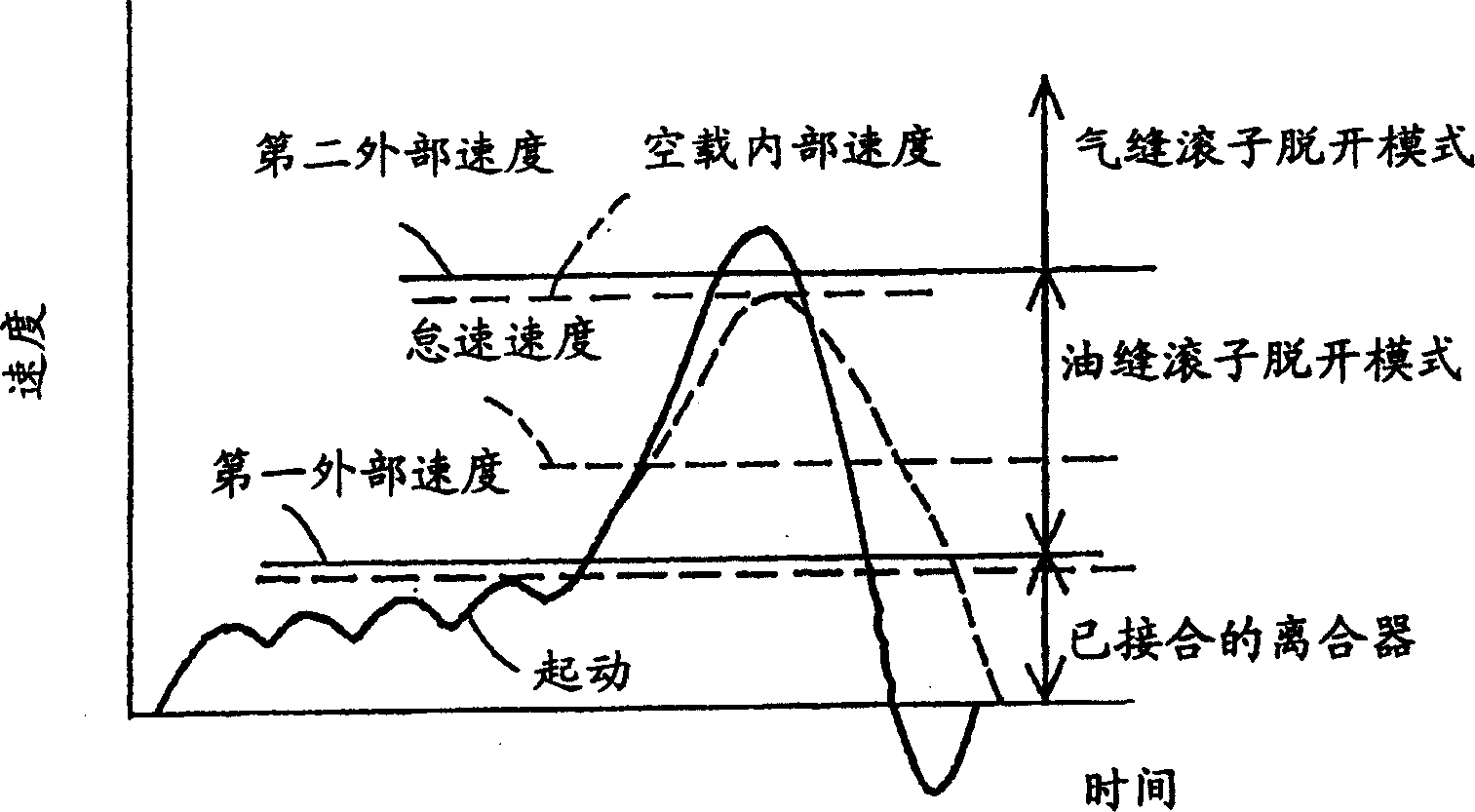

Non-collision structure of engine starter

InactiveCN1573086AGuaranteed contactReduce wearPower operated startersElectric motor startersEngineeringCentrifugal clutch

The invention provides an engine starter with a centrifugal clutch, wherein, the clutch comprises an internal part rotated under the drive of the engine motor torque, an external part always connected with a crank shaft of the engine, and a roller arranged next to the clutch. The engine starter is characterized in that the speed of the external part of the clutch that the roller is pushed far away from the internal part of the clutch with the centrifugal force and an oil-film is produced between the roller and the internal part of the clutch is higher than the speed of the internal and the external part of the clutch when the engine motor is rotated in no-load condition, therefore, when the engine is shut down and the starter motor is restarted, the direct contact between the roller and the clutch or the indirect contact with the help of the oil film can be realized; thus the service life of the centrifugal clutch and the reliability of the engine starter improved.

Owner:DENSO CORP

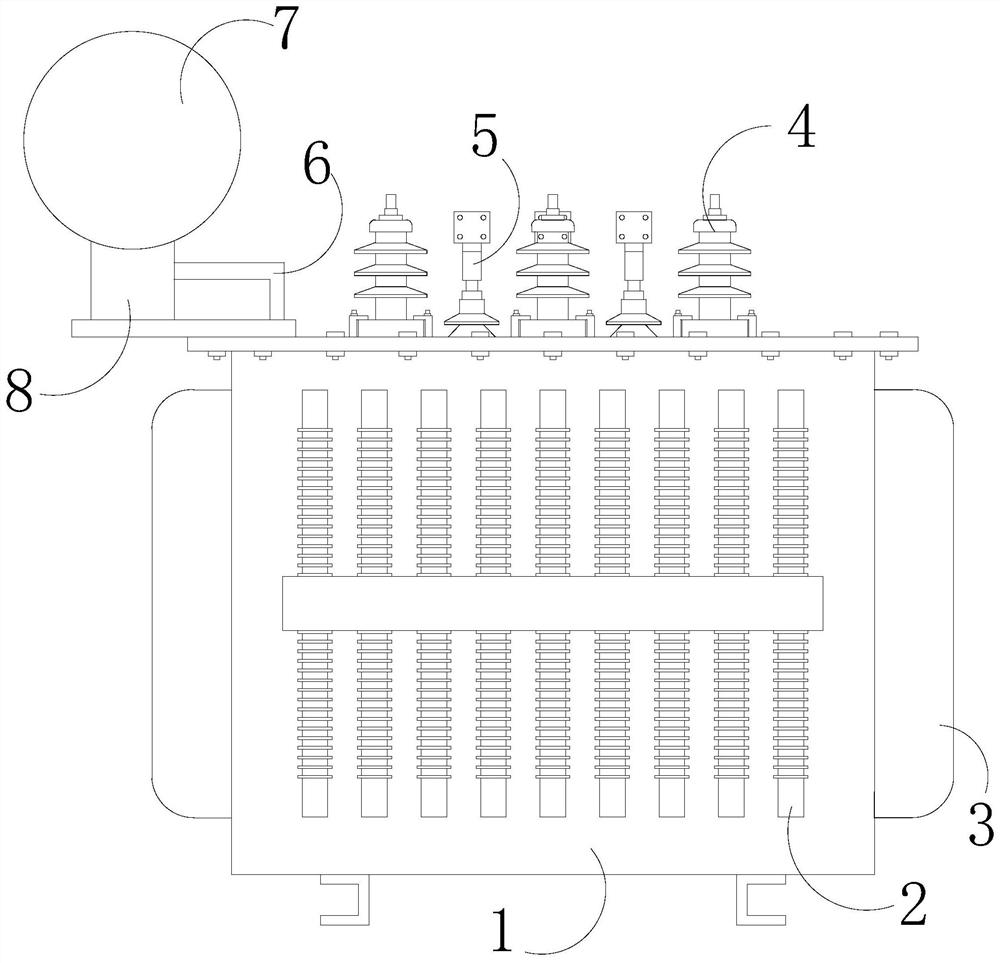

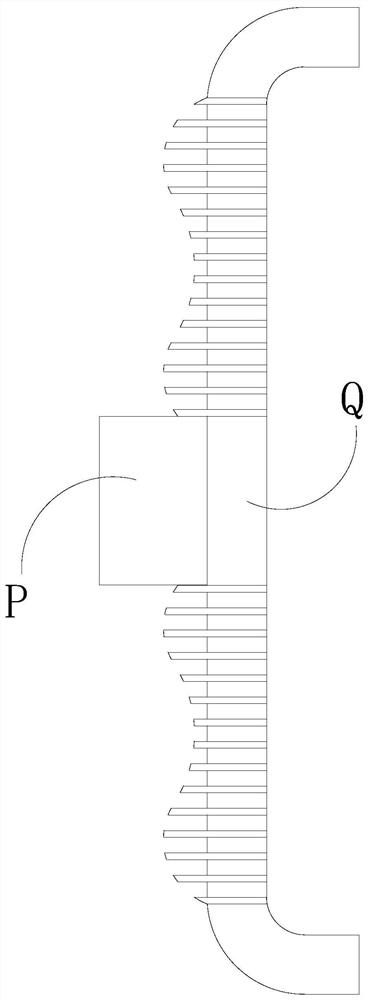

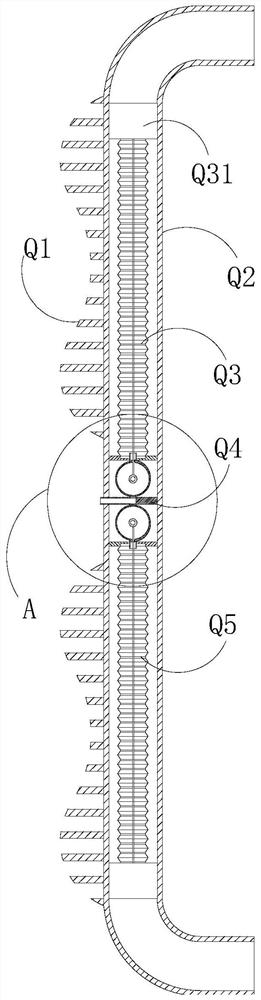

Oil-immersed power transformer

PendingCN112382467ASmall fluxAvoid heat dissipationTransformers/inductances coolingOil canEngineering

The invention discloses an oil-immersed power transformer which structurally comprises an oil tank, a heat dissipation device, corrugated cooling fins, a high-voltage terminal, a low-voltage terminal,an oil pipe, an oil conservator and a supporting frame, the top of the oil tank is mechanically connected with the supporting frame, the oil conservator is installed on the supporting frame, and theoil conservator is communicated with the oil tank through the oil pipe. Compared with the prior art, the power transformer has the beneficial effects that the heat dissipation pipe communicated with the oil tank is additionally arranged outside the oil tank, direct contact between oil and the heat dissipation pipe is achieved, heat dissipation of the oil is facilitated, the U-shaped cooling fins of different specifications are arranged outside the heat dissipation pipe body to be wavy, air circulation is facilitated, the heat dissipation efficiency can be further improved, a piston block, a measuring tape, a corrugated pipe and other components are additionally arranged in the heat dissipation pipe, oil can be pushed into the oil tank to reduce oil heat, rapid heat dissipation of transformer oil can be achieved, the piston block can prevent transformer oil residues from adhering to the interior of the heat dissipation pipe while pushing the oil, and therefore it can be avoided that a channel in the inner wall of the heat dissipation pipe becomes small, oil flux is reduced, and oil heat dissipation is affected.

Owner:张于标

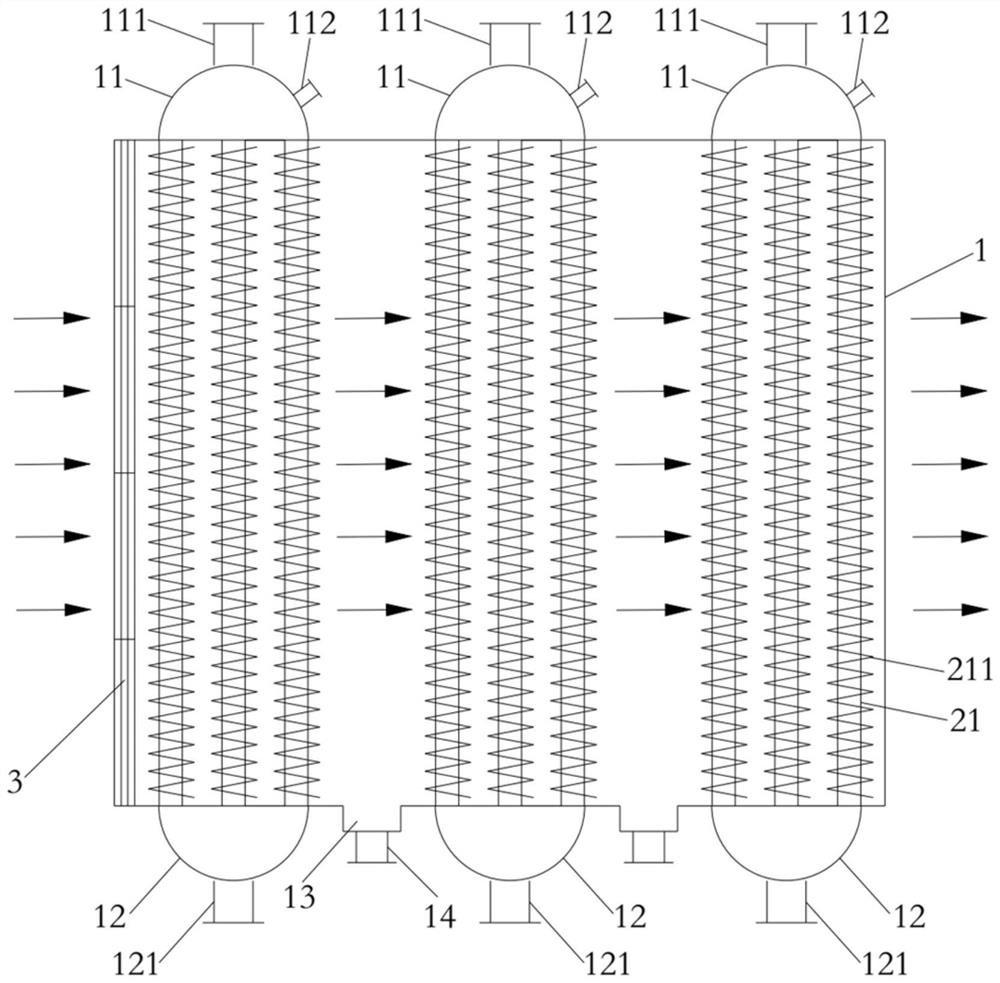

Heat exchange device

PendingCN111609738AImprove applicabilityAchieve recyclingCorrosion preventionStationary tubular conduit assembliesCirculator pumpEngineering

The invention discloses a heat exchange device, and belongs to the technical field of heat energy recovery. The heat exchange device comprises a shell and a heat exchange structure arranged in the shell, the shell is provided with an air inlet and an air outlet, the top of the shell is provided with a plurality of upper headers, and the bottom of the shell is provided with a plurality of lower headers in one-to-one correspondence with the upper headers; and the heat exchange structure comprises a plurality of heat exchange tubes, a preset included angle is formed between the extending direction of each heat exchange tube and the flowing direction of air, and at least one heat exchange tube is communicated between each upper header and the corresponding lower header. Compared with the priorart, the heat exchange device has the advantages that heat contained in mine return air can be recovered, and meanwhile, a heat transfer medium in the heat exchange pipes is prevented from being in direct contact with air, so that blockage of a circulating pipeline and a circulating pump due to dust contained in the heat transfer medium is avoided, and the maintenance difficulty is reduced.

Owner:北京中矿赛力贝特节能科技有限公司 +1

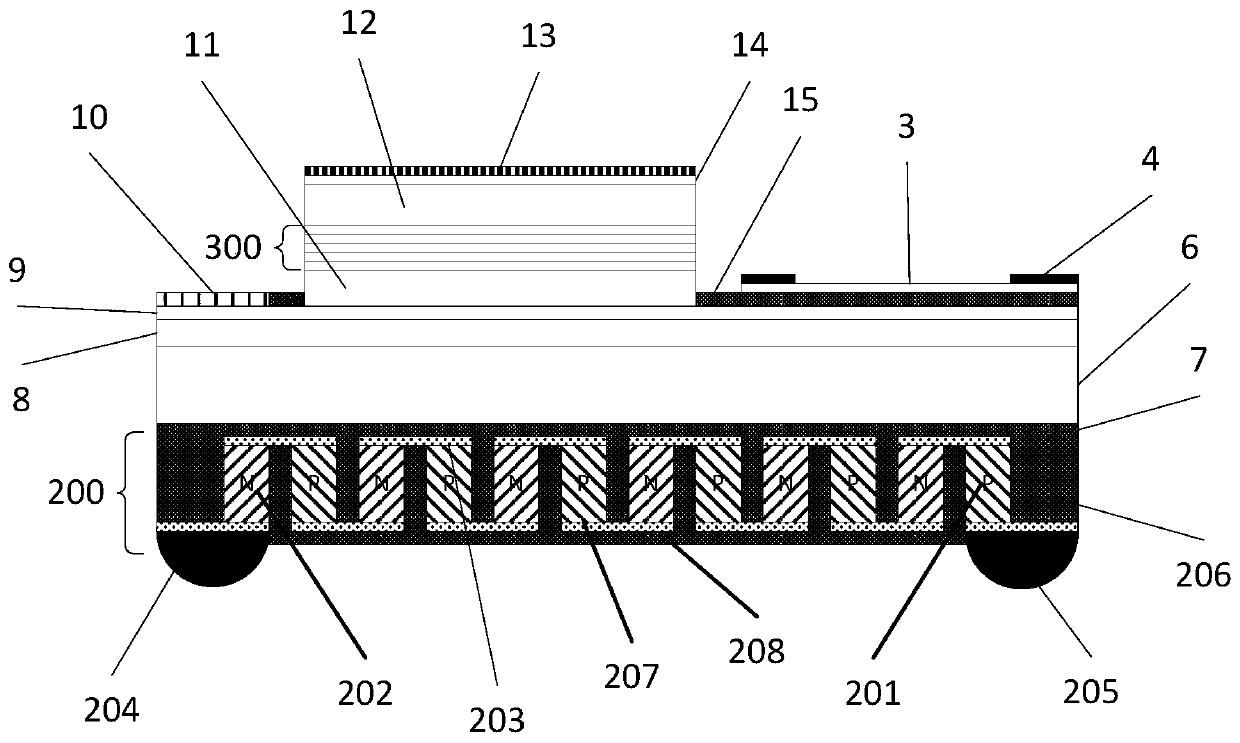

Photoelectric module assembly with constant temperature control function and manufacturing method thereof

ActiveCN111370396AControl current directionPrecise control of photoelectric performance parametersLaser detailsSolid-state devicesFilm resistanceTemperature control

The invention discloses a photoelectric module assembly with a constant temperature control function and a manufacturing method thereof. The photoelectric module assembly comprises a ceramic or glasssubstrate, a light emitting assembly, a light receiving assembly, an integrated circuit chip, a chip component, an NTC thin film resistor, a top metal electrode of the photoelectric module assembly and an integrated TEC thermoelectric cooler. The ceramic or glass substrate is used as a carrier, and the light emitting assembly, the light receiving assembly, the integrated circuit chip, the chip component, the NTC thin-film resistor and the like are integrated into a whole on the front surface of the ceramic or glass substrate. The integrated TEC thermoelectric cooler is organically integrated on the back surface of the ceramic or glass substrate, so that the temperature is accurately controlled, and the photoelectric performance parameters of the photoelectric module assembly are accuratelycontrolled. The photoelectric module assembly is widely applied to the fields of environmental atmosphere detection, communication, aerospace, aviation, ships, precise instruments, geological exploration, oil exploration, other field operations, industrial control and the like, and has a wide market prospect.

Owner:广东鸿芯科技有限公司

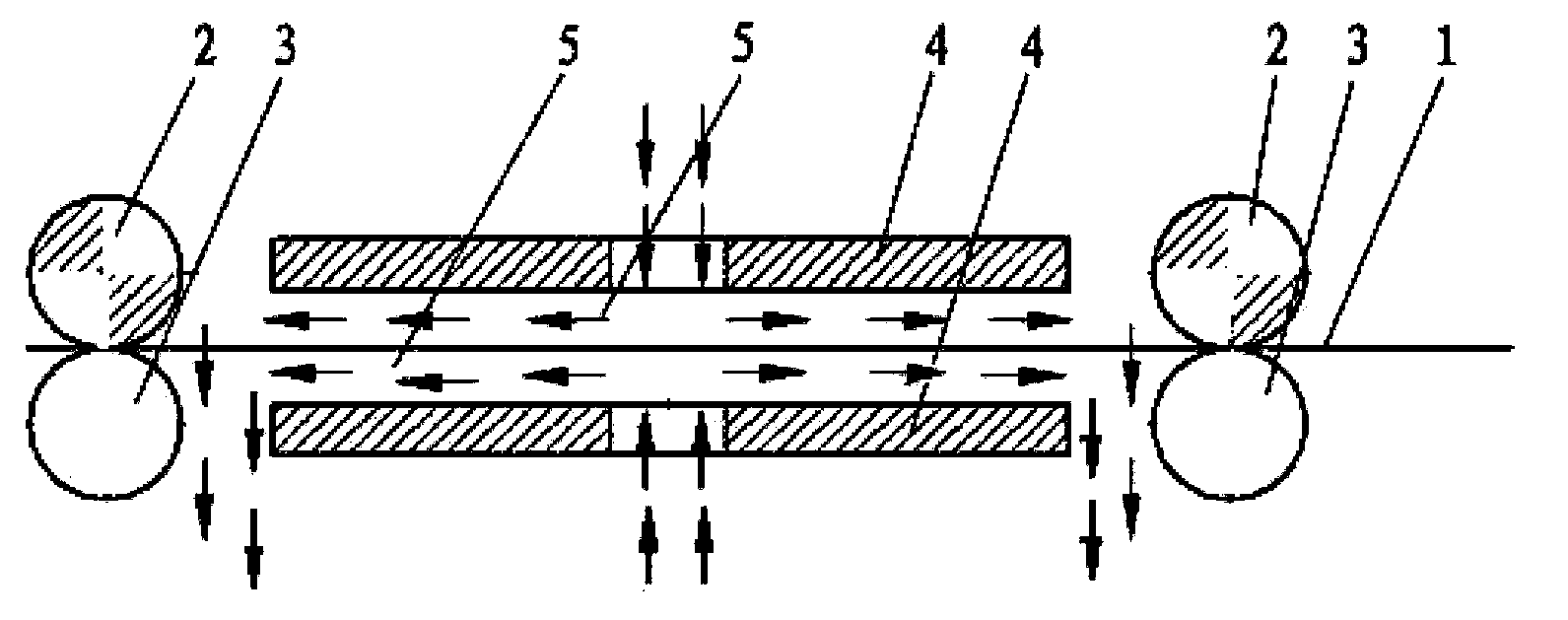

Horizontal electroplating bath and electroplating zone negative and positive pole gap automatic compensation method

ActiveCN103834982AElectroplating to achieveThe electroplating process went smoothlyCellsTanksPower flowStrip steel

The invention provides a horizontal electroplating bath including a conductive roller (2), a conductive supporting roller (3) and a positive pole plate (4), the conductive roller (2) is used for transmission of a strip steel (1) and conduction of cathodic current in the electroplating process, the conductive supporting roller (3) is used for compacting the strip steel (1) and the conductive roller (2), the horizontal electroplating bath is characterized by also including a tilting device, the tilting device comprises a pivot (6) located at the positive pole plate end, under the action of a lifting device (7), the positive pole plate (4) can pivot around the pivot (6) to change the relative position of the positive pole plate (4) and the strip steel (1). The invention provides an electroplating zone negative and positive pole gap automatic compensation method of the horizontal electroplating bath, delta automatic compensation can be realized by regulating the tilting device according to gap compensation amount DELTA (delta) = D-delta. The electroplating zone negative and positive pole gap automatic compensation method realizes the real-time compensation of a negative and positive pole gap so as to avoid the direct contact of negative and positive poles, mechanical damages and electrical short circuit and realize smooth running of the electroplating process.

Owner:BAOSHAN IRON & STEEL CO LTD

Total contact fluorescence detection pool for capillary electrophoresis

InactiveCN104048918AEffective physical contactEliminate stray light interferenceMaterial analysis by optical meansFiberCapillary electrophoresis

The invention discloses a total contact fluorescence detection pool for capillary electrophoresis. The detection pool comprises a detection pool body assembly, a positioning assembly and a fixing assembly. The fluorescence detection pool adopts a quadrature optical path structure, and makes an excited fiber, a fiber II and a liquid optical path vertically conjugate crossed in a pairwise conjugate manner; a simple structure is adopted to realize the physical contact of a liquid flow path, the excited fiber and a reception fiber, and a detection zone adopts a quartz material, guarantees the continuous running of an electroosmotic flow, and is suitable for capillary electrophoresis-fluorescence detection; and additionally, the positioning element and the fixing assembly matched with the detection zone are designed to make the installation and use of the detection pool convenient.

Owner:徐静 +4

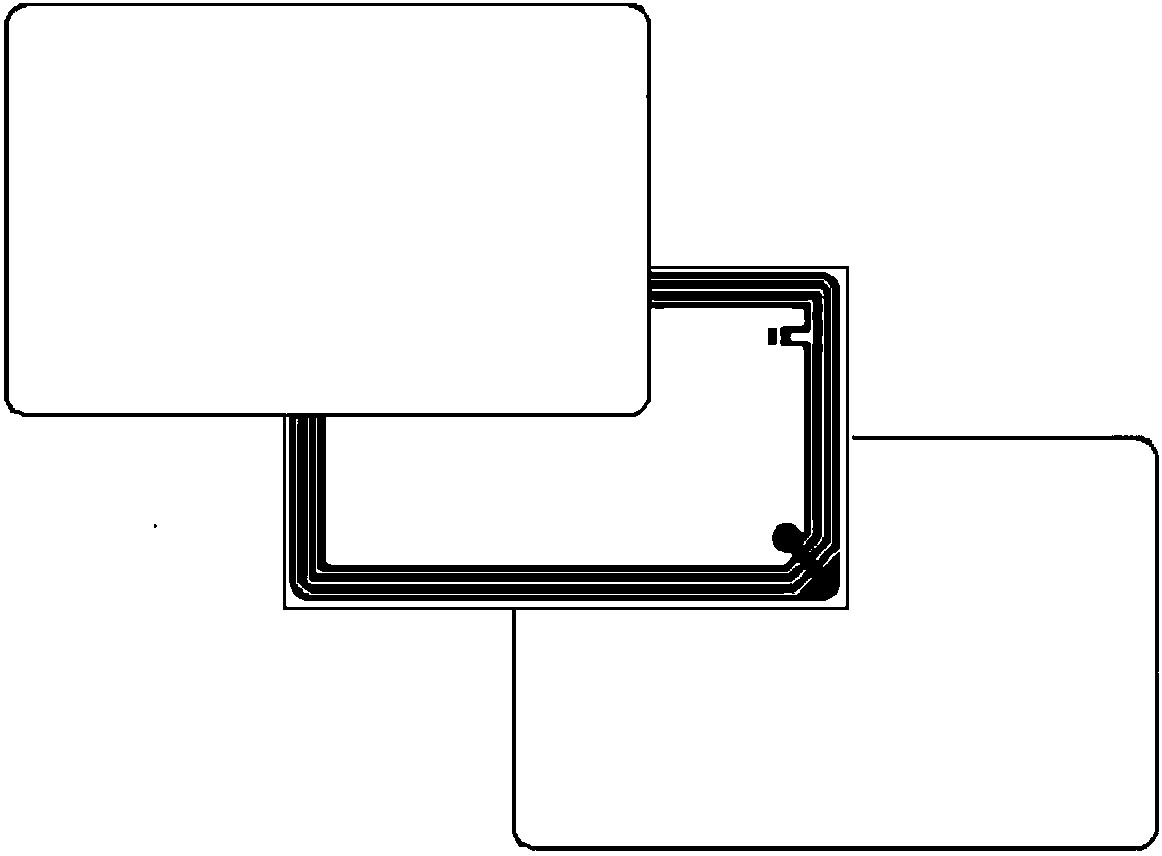

Aluminum etched antenna card and manufacturing method thereof

InactiveCN104241812ASolve layeringImprove applicable environmentAntenna supports/mountingsLoop antennasPolyesterEngineering

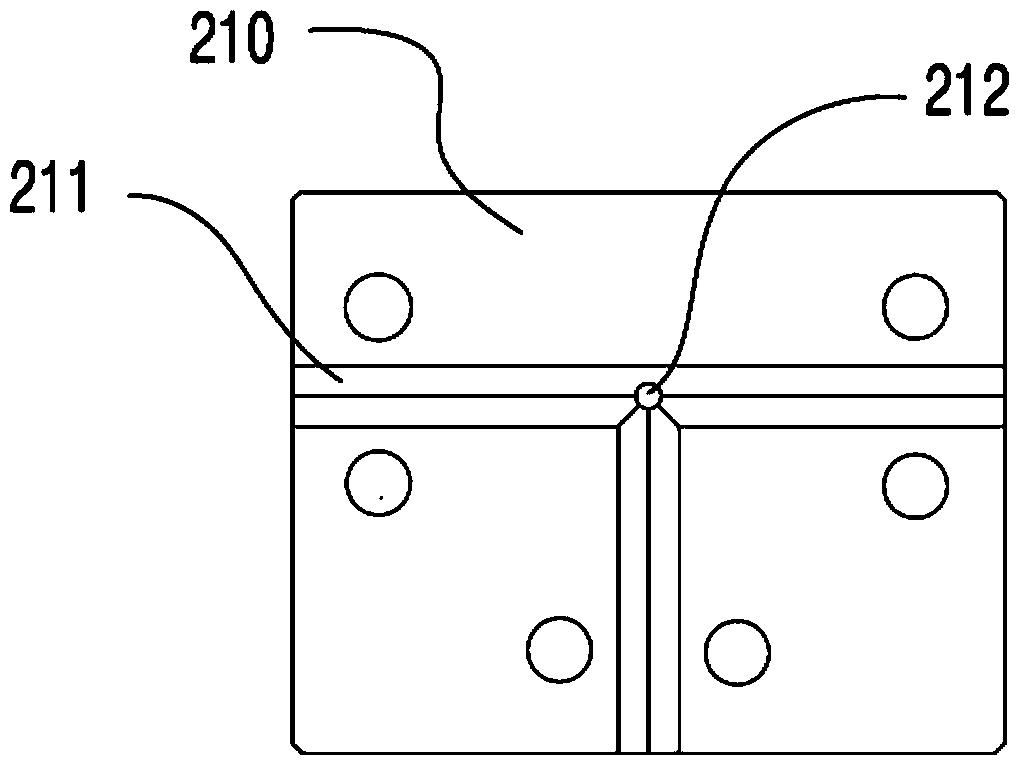

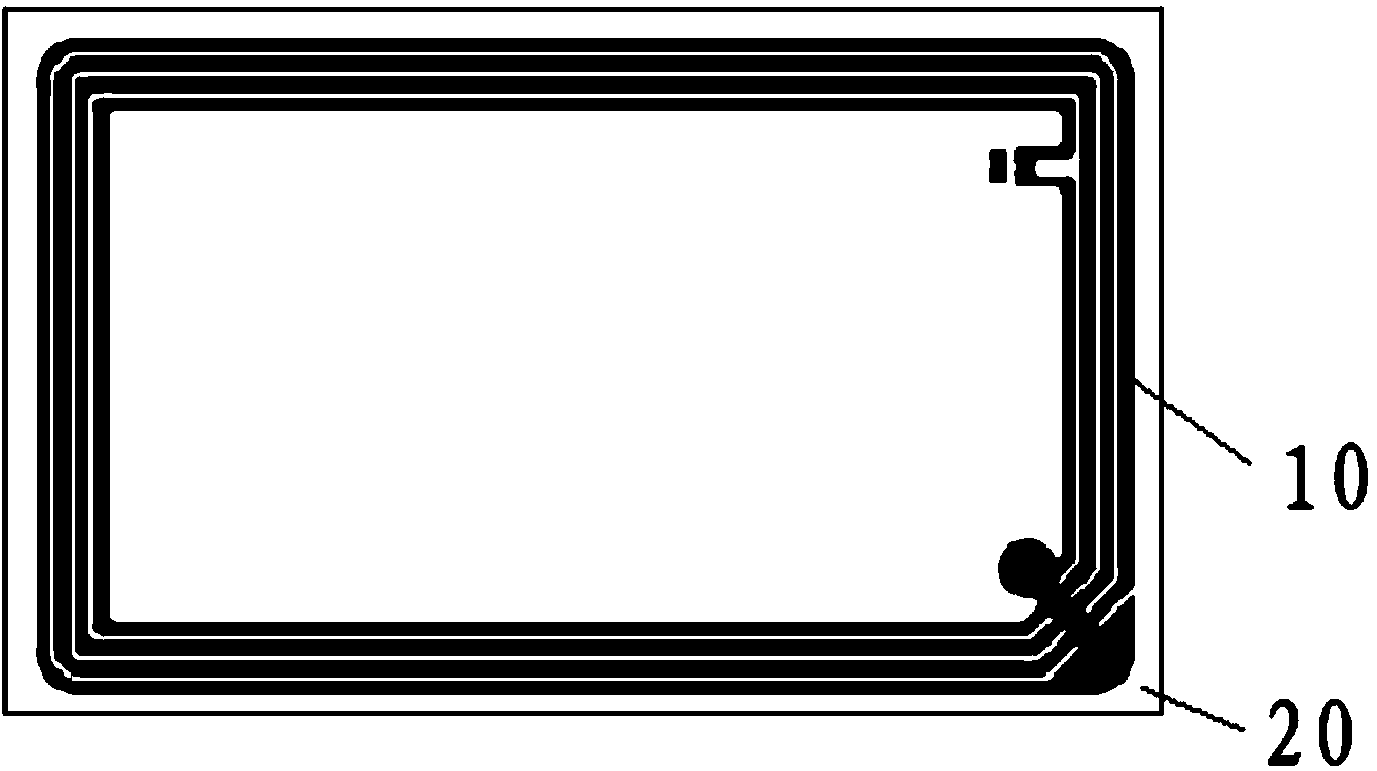

The invention discloses an aluminum etched antenna card and a manufacturing method of the aluminum etched antenna card. The aluminum etched antenna card comprises a polyester film antenna layer (1) and covering layers, wherein the polyester film antenna layer (1) comprises a polyester film and an aluminum etched antenna coil which is fixed to the polyester film, the covering layers include the upper covering layer (2) and the lower covering layer (3), the size of each covering layer is larger than that of the polyester film antenna layer (1), multiple holes (4) are formed in the polyester film antenna layer (1), and the upper covering layer (2), the polyester film antenna layer (1) and the lower covering layer (3) are combined in sequence through hot pressing. According to the aluminum etched antenna card, the upper covering layer can be in direct contact with the lower covering layer, in this way, connection of the same kind of materials is achieved, the problem of layering of existing aluminum etched antenna cards is solved, and the range of application environments of the card is effectively widened.

Owner:WATCHDATA SYST

Glass coating suspension deep undercooling fast directional solidification device and solidification method thereof

ActiveCN106903266AReduce manufacturing costEasy to operateFoundry mouldsFoundry coresCopper moldDirectional solidification

The invention discloses a glass coating suspension deep undercooling fast directional solidification device and a solidification method thereof. The solidification device comprises a closed furnace body. A glass pipe, a glass pipe clamp, a ball screw, an induction heater, a thermal insulation mold shell and a water cooling copper mold are arranged in the closed furnace body. The glass pipe in the closed furnace body is placed on the clamp. The clamp is driven by the ball screw. The glass pipe is filled with alloy raw materials. The closed end of the glass pipe is located in the inner axial position of the heater. After installation, the closed furnace body is vacuumized and is filled with argon. A power source of the heater is started for heating, thus the alloy raw materials are subjected to suspension melting, an alloy melt is purified, heating is continued, and thus the alloy melt is overheated. The electric current of the heater is lowered, and a deep undercooling alloy melt is obtained. Under the action of the gravity, the deep undercooling alloy melt enters a mold cavity formed by the water cooling copper mold and the thermal insulation mold shell. Fast one-way growth of a block sample is achieved. In the operation process of the solidification method, expensive Ga-In-Sn liquid alloy is not used, thus production cost is low, and operation is simple and convenient.

Owner:ZHENGZHOU UNIV

A full-contact fluorescent detection cell for capillary electrophoresis

InactiveCN104048918BEffective physical contactEliminate stray light interferenceMaterial analysis by optical meansFiberCapillary electrophoresis

The invention discloses a full-contact fluorescent detection cell for capillary electrophoresis, which includes a detection cell body component, a positioning component and a fixing component. The fluorescence detection cell of the present invention adopts an orthogonal optical path structure, so that the excitation, optical fiber II and liquid optical path are vertically conjugated in pairs; the simple structure is that the liquid flow path and the excitation and receiving optical fibers are in physical contact, and the detection area is still The use of quartz material ensures the continuous operation of electroosmotic flow, and is suitable for capillary electrophoresis-fluorescence detection; in addition, the matching positioning components and fixing components are designed to make the installation and use of the detection pool more convenient.

Owner:徐静 +4

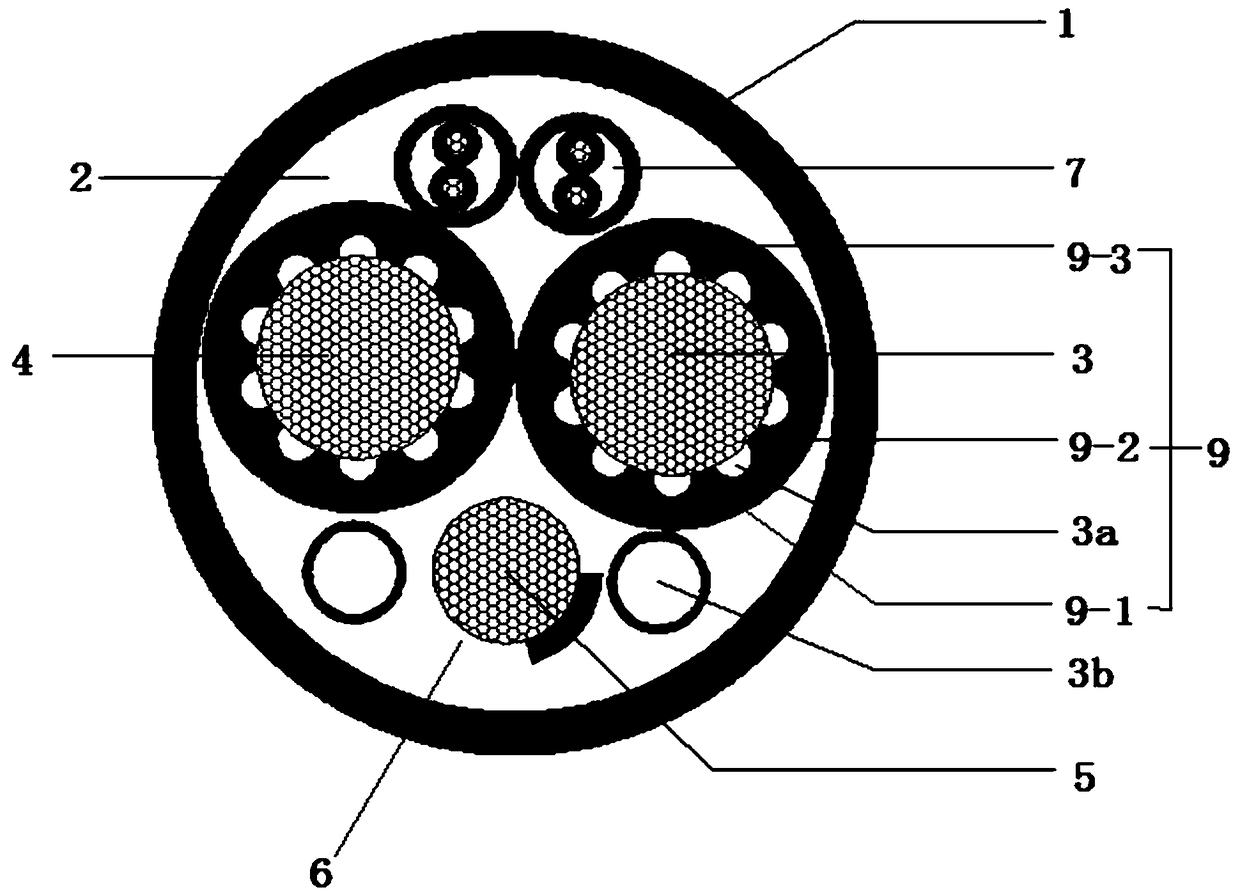

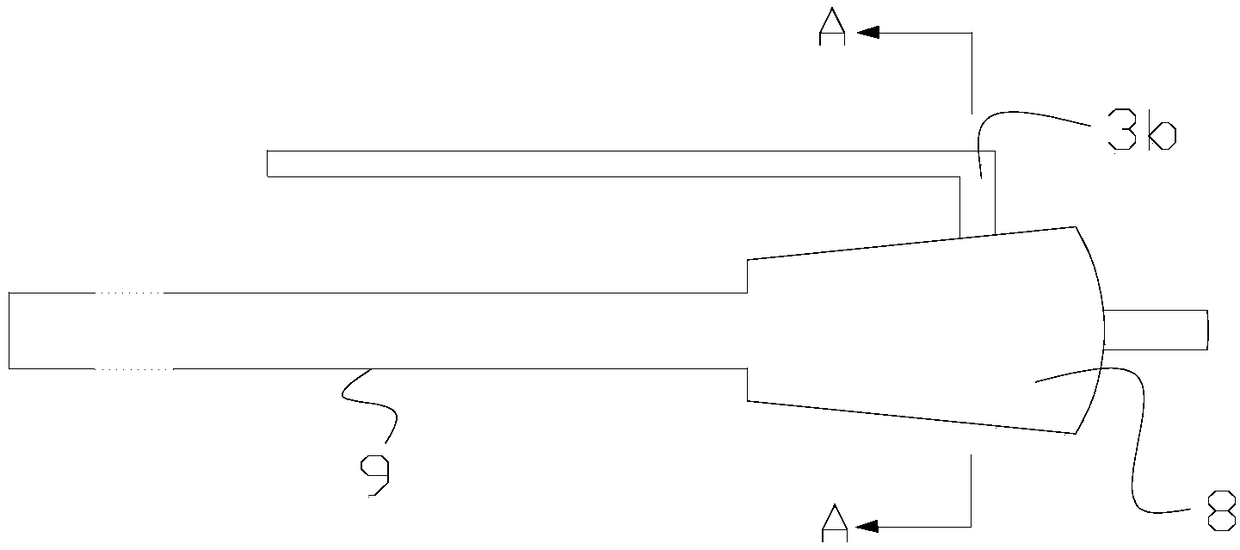

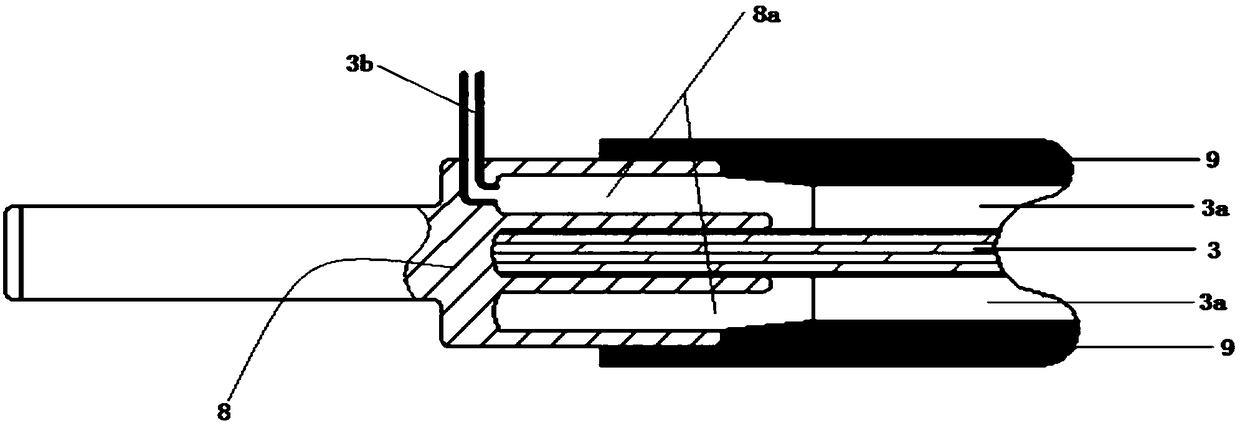

Refrigeration cable applicable for power transmission line

InactiveCN108806874AAvoid high voltage and squeeze until the insulation is brokenAchieve direct contactFlexible cablesFlexible conductorsElectrical conductorNegative power

The invention discloses a refrigeration cable applicable for a power transmission line. The refrigeration cable comprises an outer protective jacket, a packing layer positioned inside the outer protective jacket, and a positive power transmission line core conductor, a negative power transmission line core conductor, a ground line conductor, a first insulating protective layer coated on the positive power transmission line core conductor, a second insulating protective layer coated on the negative power transmission line core conductor and a ground line insulating protective layer coated on the ground line conductor which are arranged inside the outer protective jacket respectively. The refrigeration cable also comprises first passages formed between the first insulating protective layer and the positive power transmission line core conductor respectively and second passages formed between the second insulating protective layer and the negative power transmission line core conductor respectively which are used for circulating a coolant, and first coolant guide pipes and second coolant guide pipes which communicate with the first passages and the second passages respectively. The cable disclosed by the invention can avoid the occurrence of hazardous conditions such as short circuits while realizing efficient cooling.

Owner:CHENGDU DATANG CABLE

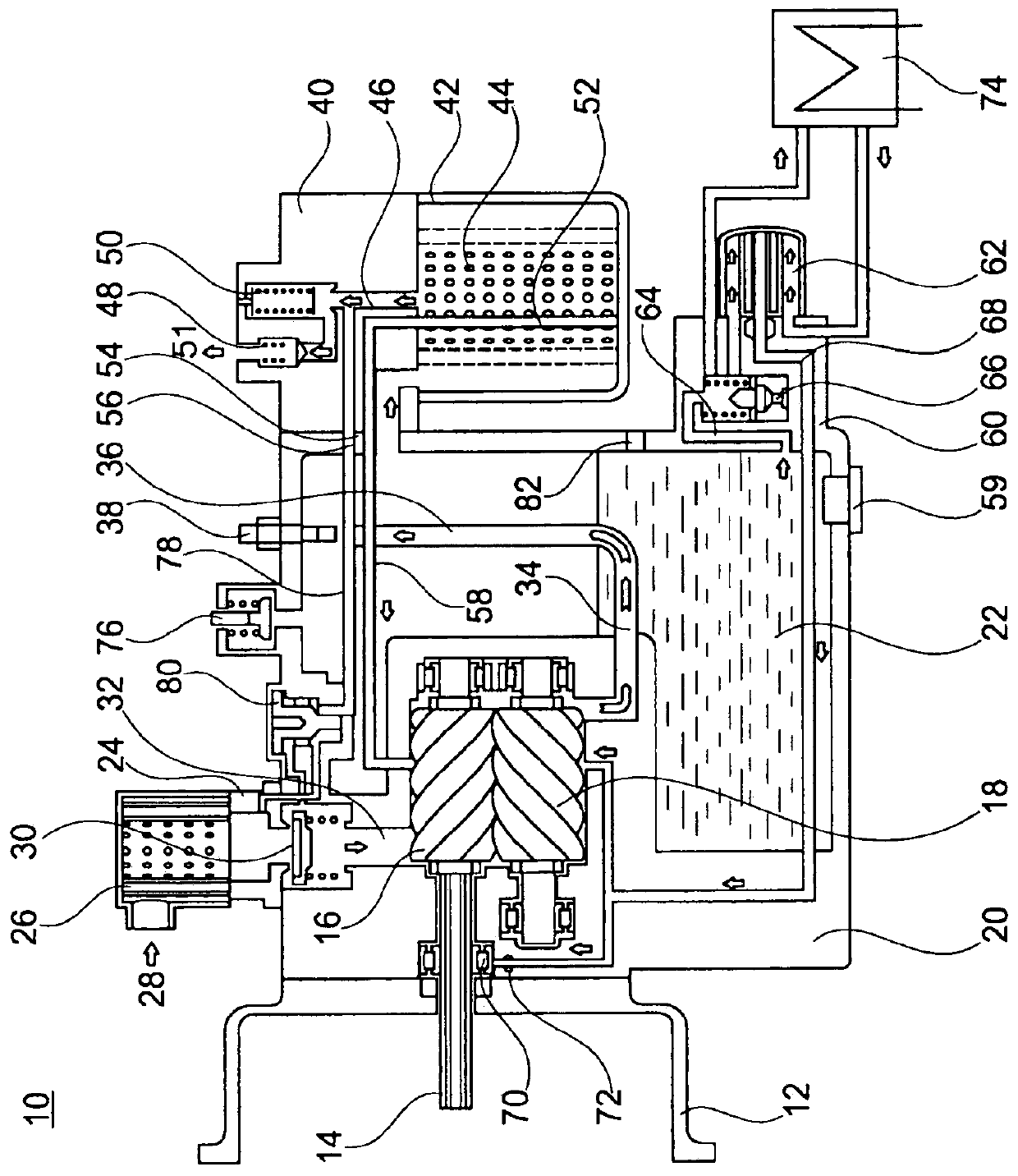

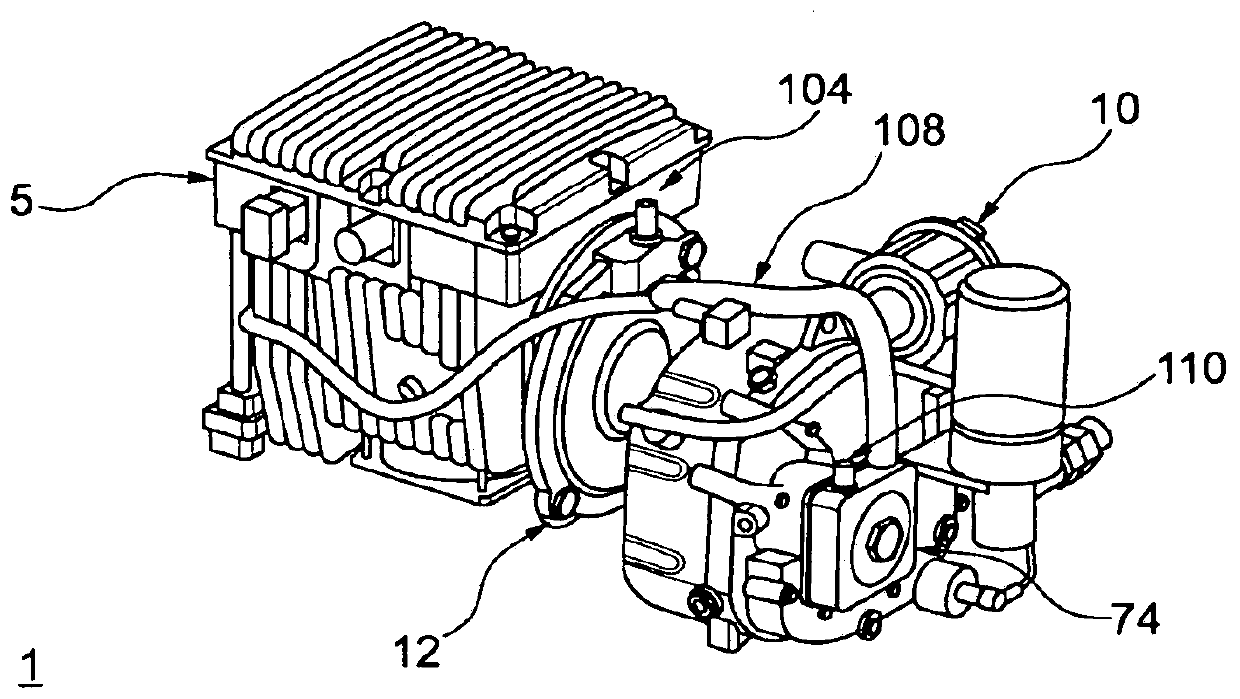

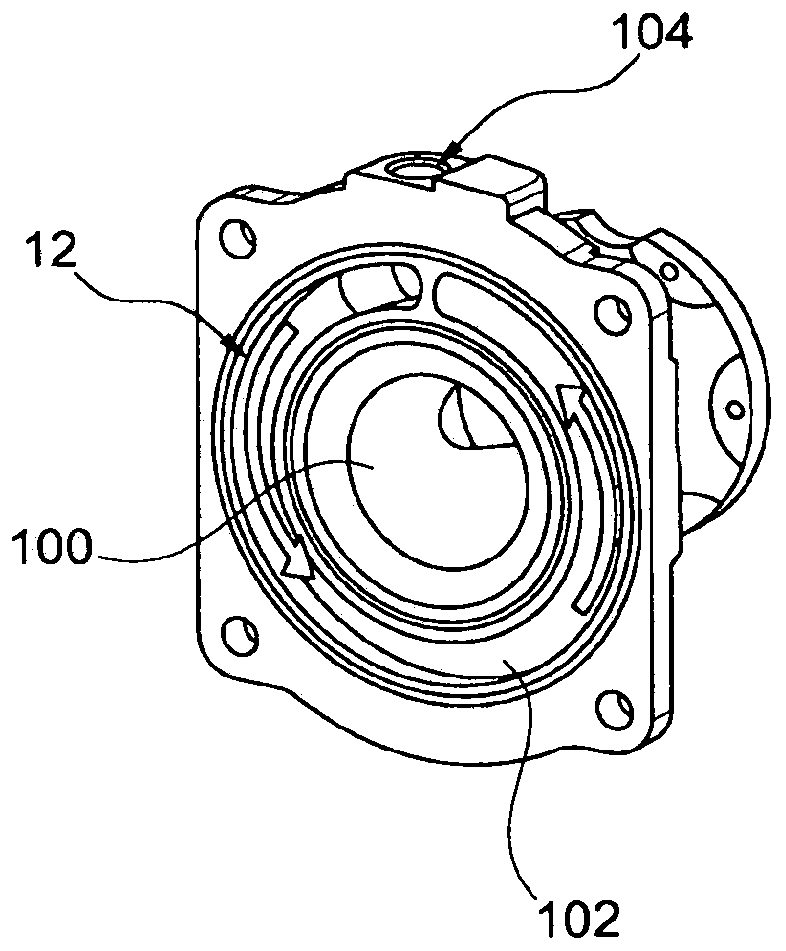

System for an utility vehicle comprising a screw compressor and an electric motor

InactiveCN109790838ASave spaceAchieve coolingRotary/oscillating piston combinations for elastic fluidsEngine fuctionsGas compressorCooling channel

The invention relates to a system (1) for a utility vehicle comprising a screw compressor (10) and an electric motor (5), said electric motor (5) driving the screw compressor (10). The electric motor(5) is connected to the screw compressor (10) by means of a flange (12) which comprise at least one cooling connection (104, 106) and a cooling channel is provided in the flange (12).

Owner:KNORR BREMSE SYST FUER NUTZFAHRZEUGE GMBH

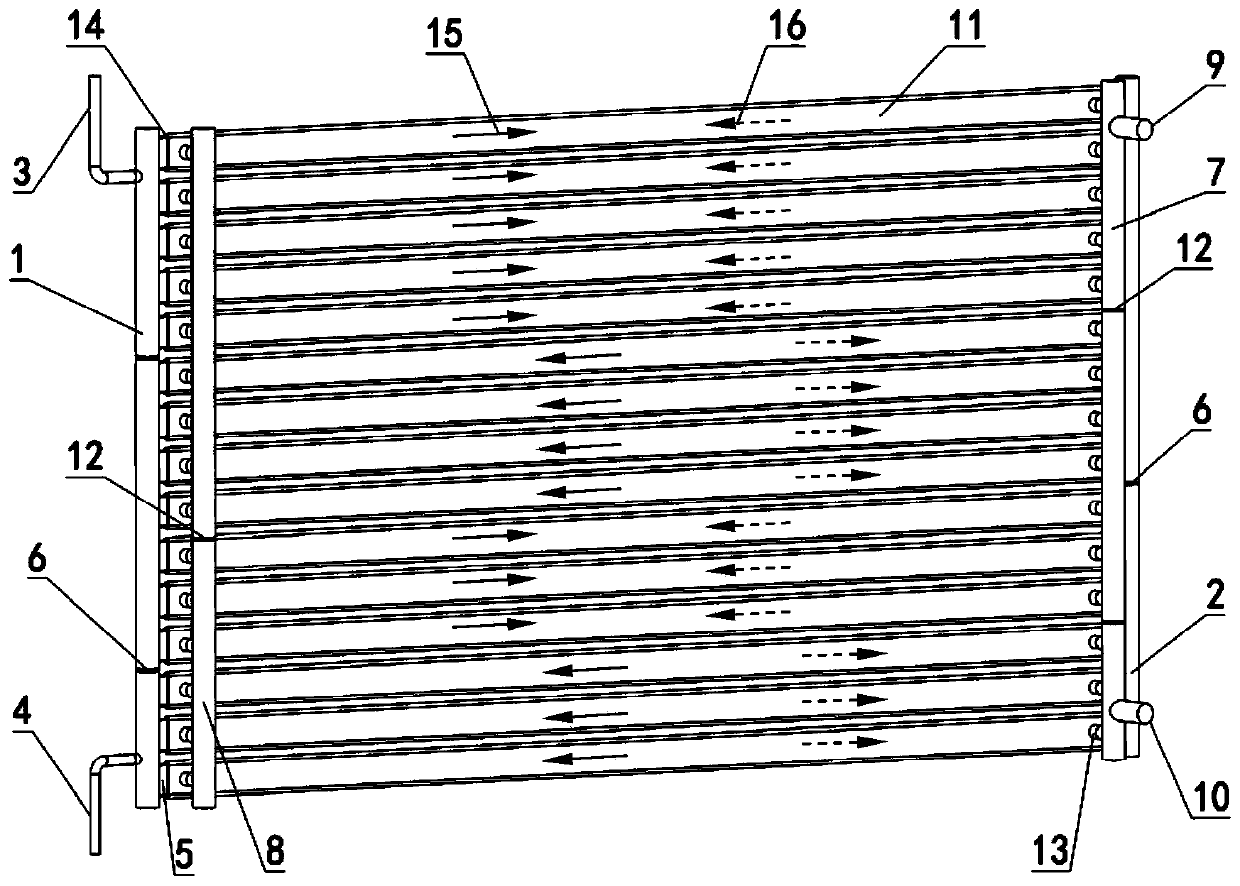

Micro channel condenser for circulating type air source heat pump water heater

PendingCN110595114AReduce chargeImprove pressure bearing capacityEvaporators/condensersWater flowEngineering

The invention discloses a micro channel condenser for a circulating type air source heat pump water heater. According to the micro channel condenser for the circulating type air source heat pump waterheater, refrigerant micro channel flat tubes are adopted to be parallelly arranged between a first refrigerant flow collecting tube and a second refrigerant flow collecting tube, a first water flow collecting tube and a second water flow collecting tube both communicate with a plurality of water flow dividing tubes, each water flat tube is sleeved on the outer side of each refrigerant micro channel flat tube to form a sleeve type structure, end covers penetrate through the refrigerant micro channel flat tubes to be welded to the two ends of each water flat tube to make the two ends of a ring-shaped water flow channel be closed, and a refrigerant air inlet tube and a refrigerant liquid outlet tube are connected with corresponding pipelines inside an air source heat pump system correspondingly to make a refrigerant perform circulation flowing inside the system. The micro channel condenser for the circulating type air source heat pump water heater is simple in structure, easy to machineand convenient to install; by means of an all-aluminum material lightweight design, recycling is performed easier, and circulation use is performed; by means of micro channel flat tube structures, therefrigerant side heat exchange coefficient is enhanced, the refrigerant filling quantity is reduced, and the micro channel condenser for the circulating type air source heat pump water heater can beused for higher pressure systems; and by means of the sleeve type structure, water and the refrigerant can be made to form pure countercurrent heat exchange, so that the heat transfer temperature difference is increased, and the heat transfer quantity is increased.

Owner:春意环境科技有限公司 +1

High-temperature flexible loading device

InactiveCN111103199AFast heatingSimple and reliable deviceMaterial strength using tensile/compressive forcesThermal insulationHeating film

The invention discloses a high-temperature flexible loading device, and belongs to the field of experimental mechanics. The loading device comprises one or more heating and loading units. The heatingand loading units realize partitioned thermal loading force loading, and each heating and loading unit sequentially comprises a thermocouple, a heating body, a heat preservation and insulation layer and a water bag cover from bottom to top. A water bag is arranged in a space formed by the water bag cover and the heat preservation and insulation layer. The device is simple, reliable, rapid in heating, high in loading precision and low in test cost. The surface of a test piece is covered with a flexible heating film and a thermal insulation material. The test piece is rapidly heated. The heatingfilm directly covers the test piece, so that the heating is rapid, the surface temperature of the test piece can reach 300-1000 DEG C within tens of seconds, the heat preservation and insulation layer is paved outside the heating layer, the heating speed and the energy consumption loss are well ensured, the water bag is used for loading, and the test requirements of flexible and rapid heating andloading are met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

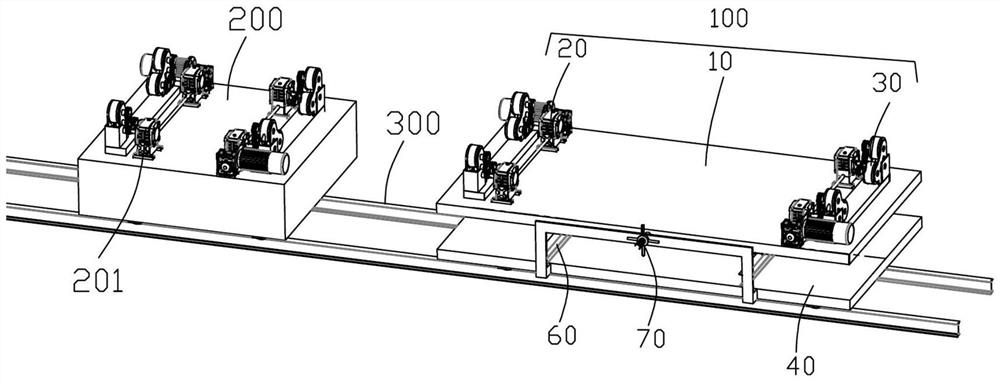

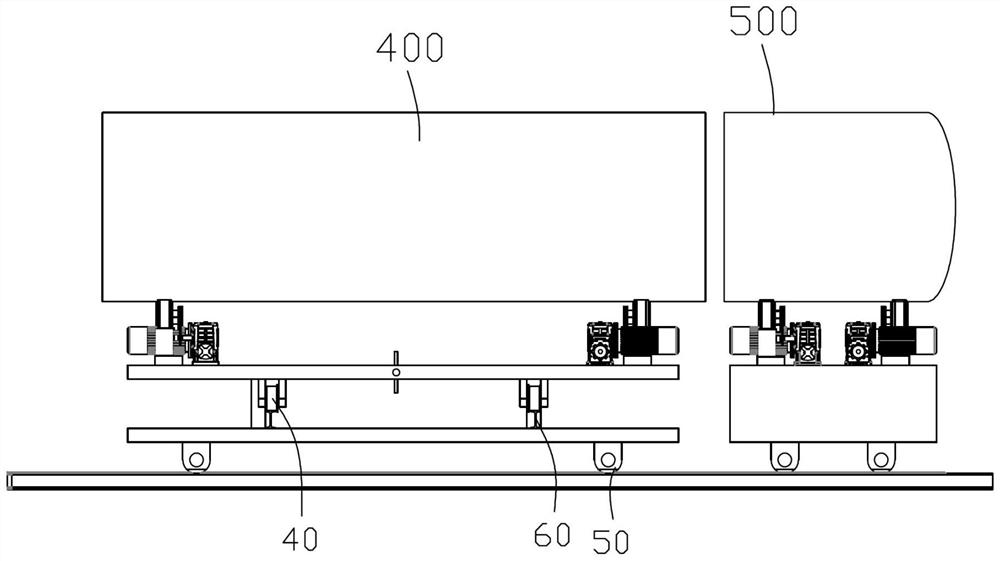

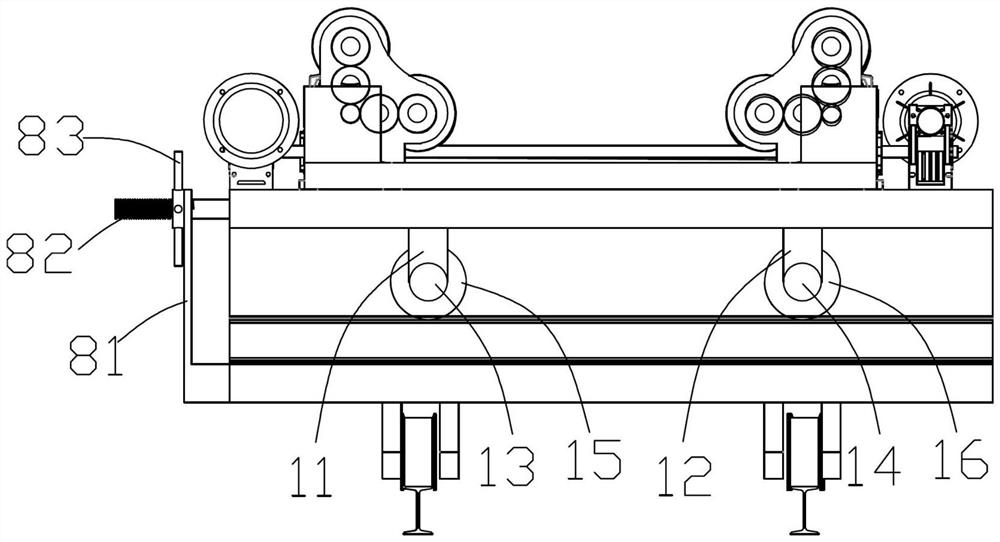

Automatic position finding and welding integrated machine for end cover and cylinder body

InactiveCN112475677AAchieve direct contactRealize automatic weldingWelding/cutting auxillary devicesAuxillary welding devicesPhysicsElectric machinery

The invention provides an automatic position finding and welding integrated machine for an end cover and a cylinder body. The machine comprises a cylinder body alignment device, an end cover alignmentdevice and a one-way ground rail; the cylinder body alignment device comprises a lower adjusting mechanism and an upper adjusting mechanism; and a cylinder body roller carrier is further arranged above the upper adjusting mechanism and used for supporting and driving a tank body to rotate. According to the machine, spot welding in advance is not needed, the cylinder body alignment device drives the tank body to rotate and stably limit and fix the tank body at the same time, the end cover alignment device drives the tank body to synchronously rotate and stably limit and fix the end cover at the same time, and the axial distance between the cylinder body alignment device and the end cover alignment device is adjusted through the one-way ground rail, so that the butt joint seam of the cylinder body alignment device and the end cover alignment device make direct-facing contact; a motor is started, the cylinder body and the end cover rotate synchronously, an automatic welding gun directlyfaces the butt joint seam, and automatic welding is achieved.

Owner:宁夏新开河储罐有限公司

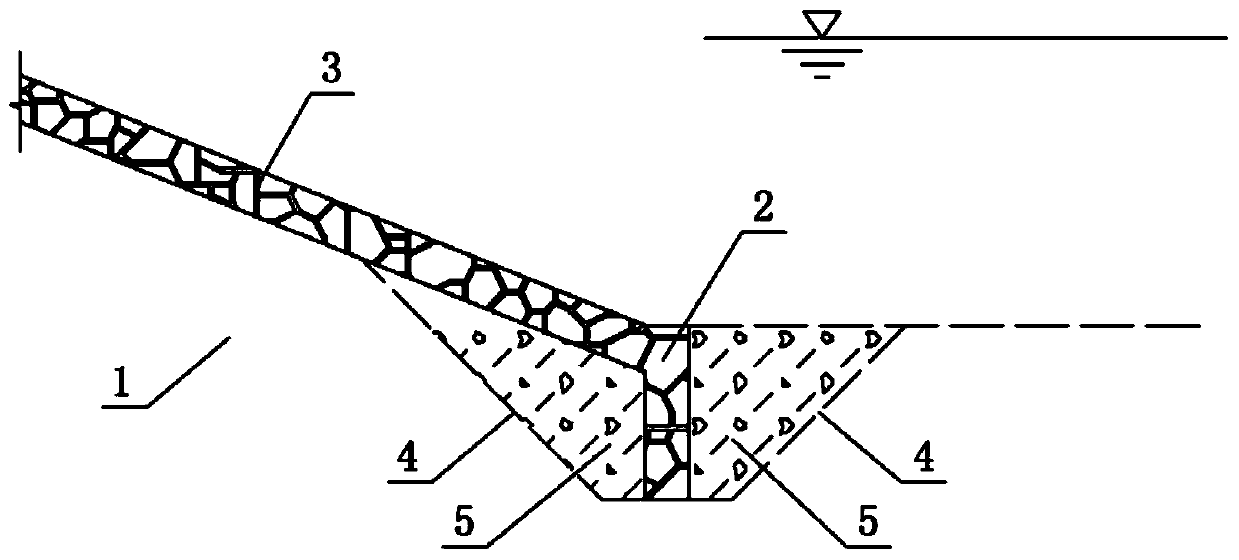

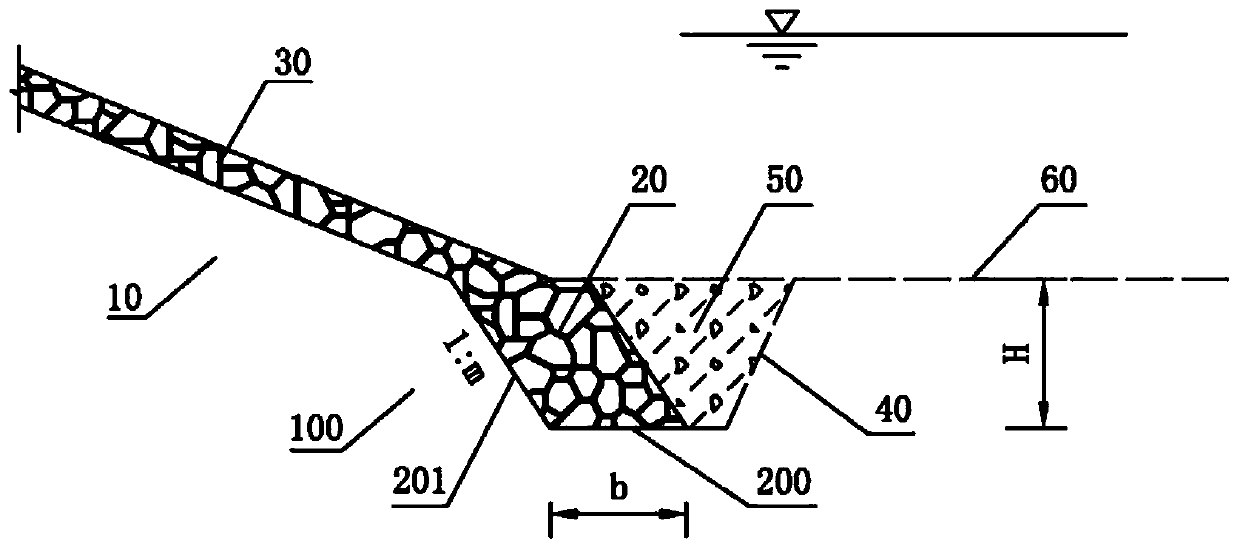

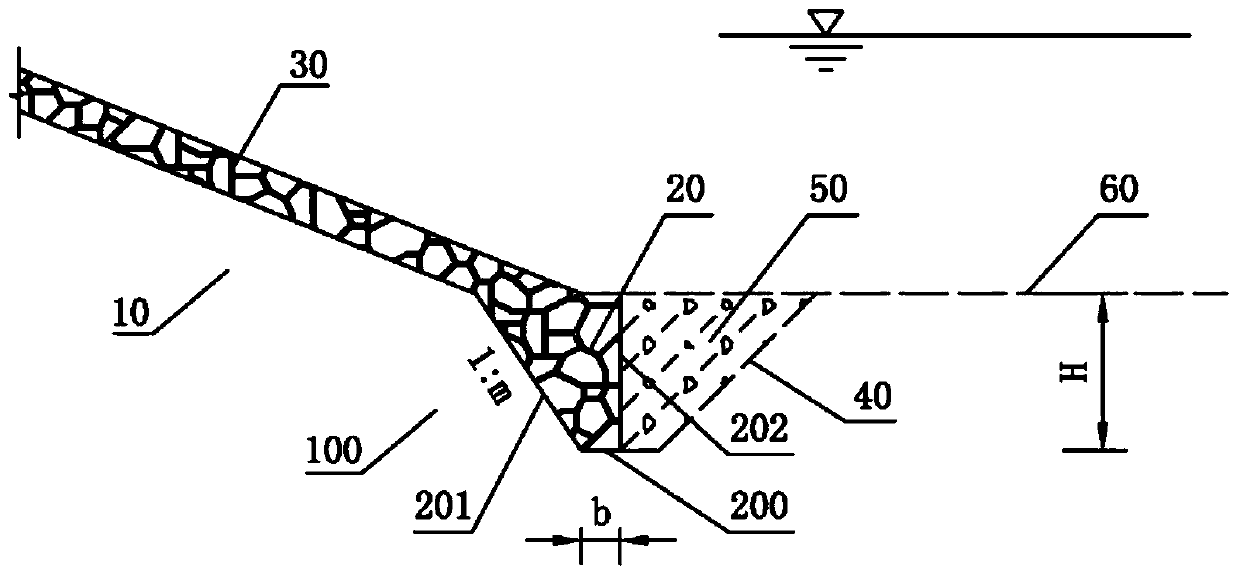

Anti-scour structure of banket for embankment and construction method

PendingCN111519579AImprove security and stabilityAvoid floating phenomenonBreakwatersQuaysArchitectural engineeringEngineering

The invention provides an anti-scour structure of a banket for an embankment and a construction method and relates to the technical field of embankment engineering. The construction method comprises the following steps of determining structural parameters of a key wall; excavating a foundation pit; constructing the key wall; and carrying out back-fill consolidation on construction spaces on two sides of the key wall and the construction foundation pit. In the anti-scour structure of the banket for the embankment constructed by the construction method, the side, facing a slope toe, of the key wall is a bevel, and the included angle formed between the bevel and the surface of a bank slope is an obtuse angle, so that the key wall is in direct contact with the slope toe. Meanwhile, the bevel of the key wall disperses gravity to the slope toe, so that a suspending phenomenon of the key wall as a result of uncompacted backfilled soil texture at the slope toe is avoided and the anti-scour structure of the banket for the embankment is prevented from being damaged, and therefore, the safety and stability of the embankment are further improved effectively.

Owner:SHEN KAN QINHUANGDAO GENERAL ENG DESIGN & RES INST CORP MCC

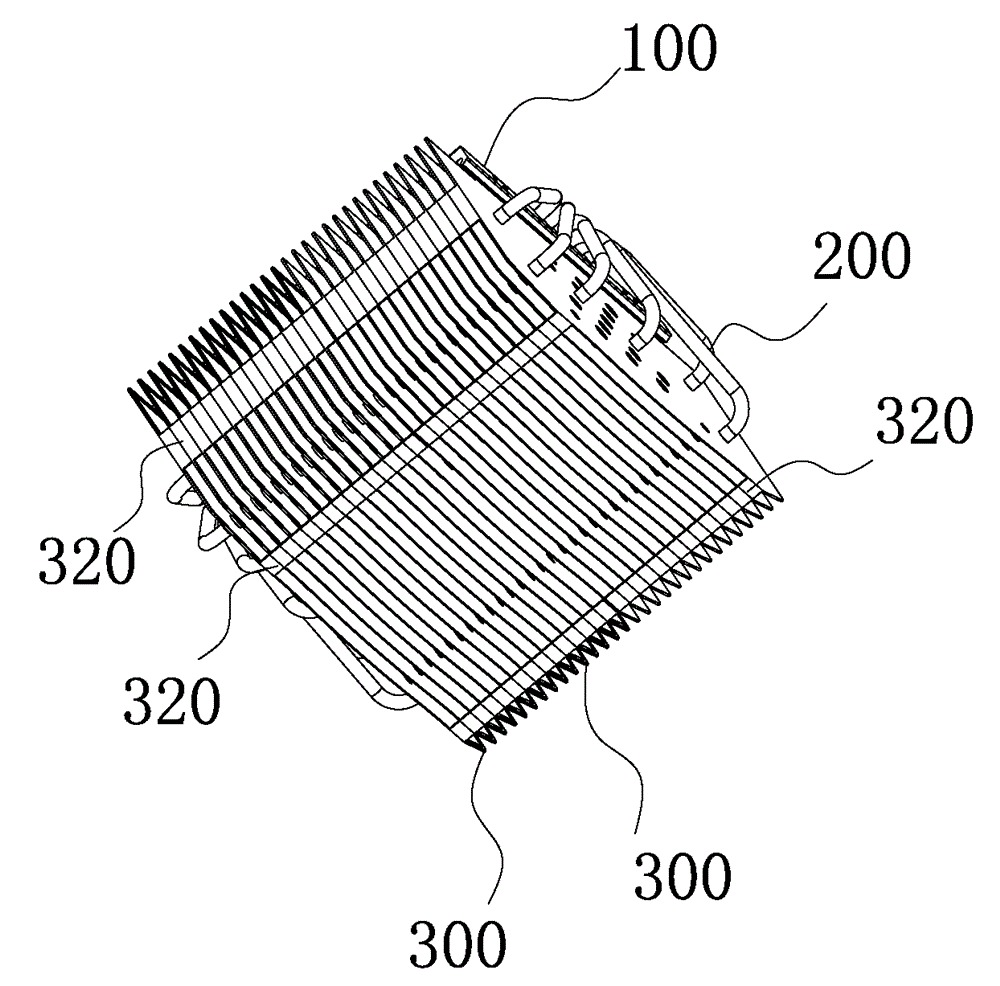

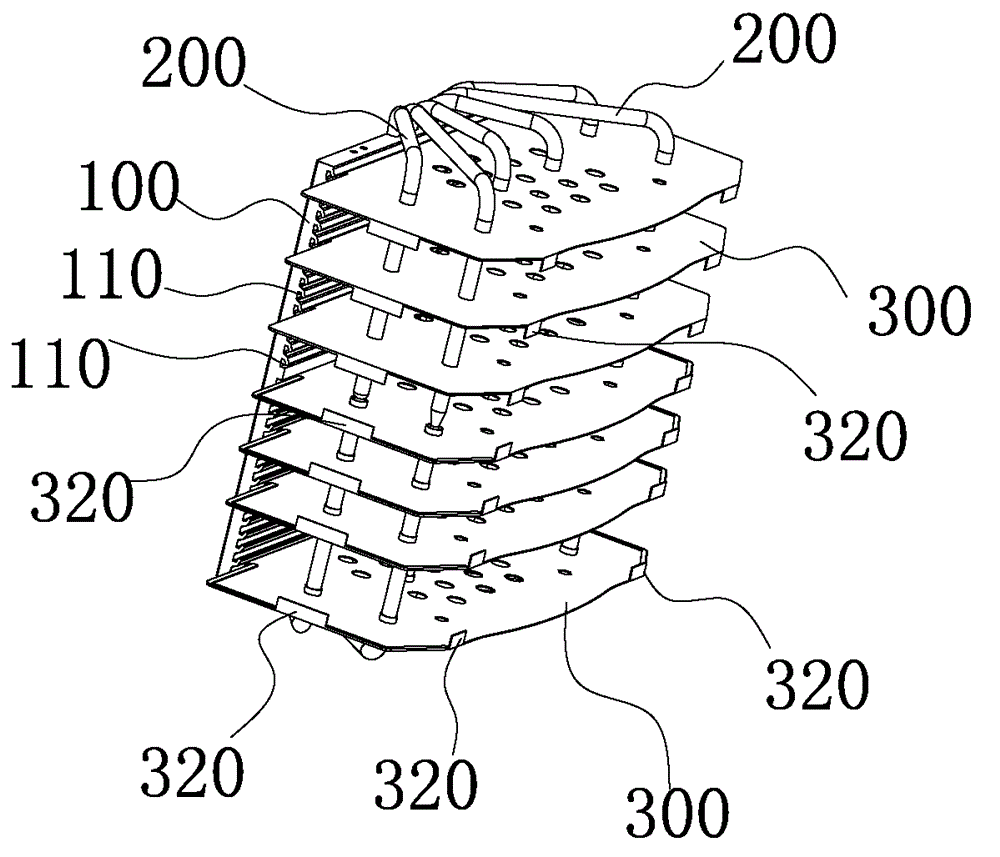

Integrated heat-pipe heat dissipating device

InactiveCN104869794AAchieve direct contactSpeed up distributionCooling/ventilation/heating modificationsThermodynamicsHeat conducting

An integrated heat-pipe heat dissipating device comprises a plurality of the heat dissipating pipes, a heat conducting seat and a plurality of heat dissipating fins, wherein the heat dissipating fins are fixedly assembled on one surface of the heat conducting seat separately, and propped against and perpendicularly connected to the heat conducting seat; the heated sections of the heat dissipating pipes are matched with the other surface of the heat conducting seat in a gapless manner; the heat dissipating sections of the heat dissipating pipes are assembled in the heat dissipating fins; two sub pipes adopting the same structure are separately arranged on each heat dissipating pipe; a plurality of circular through holes are formed in the heat dissipating fins, and a plurality of scrape-proof baffles are arranged on the heat dissipating fins. The integrated heat-pipe heat dissipating device has the characteristics of being good in heat dissipating effect.

Owner:DONGGUAN SHUHUA METAL PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com