Porous metal capillary seepage microneedle electrode and preparing method

A porous metal, capillary wick technology, applied in the field of medical devices, can solve the problems of increasing the impedance link in the test process, small signal-to-noise ratio of electrical signals, poor quality of electrical signals, etc. Reduce the effect of relative slip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

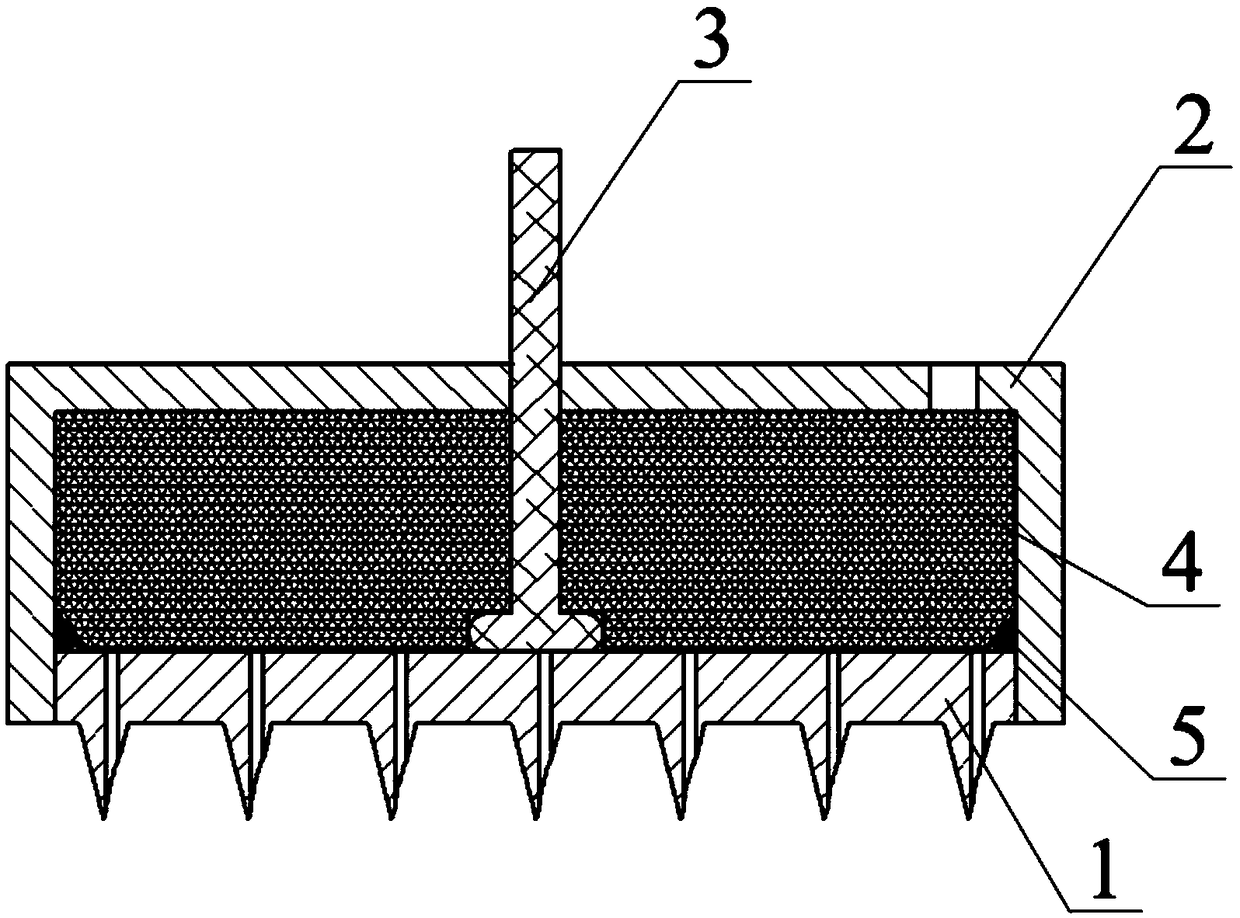

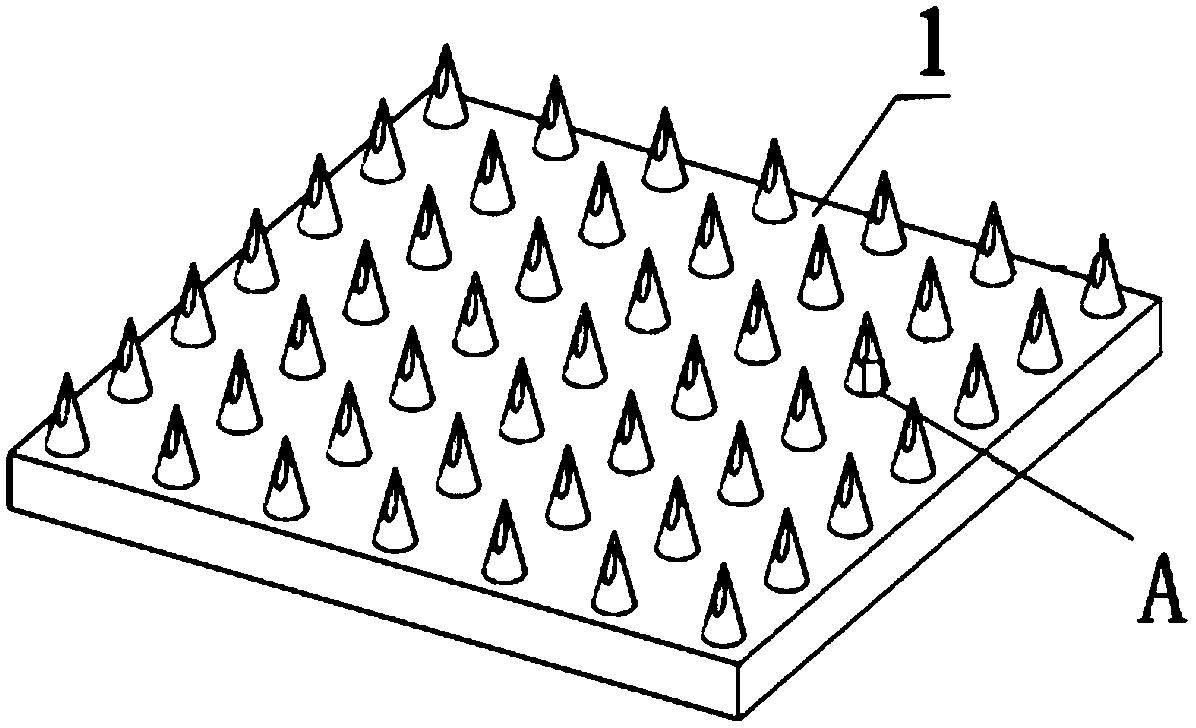

[0040] Such as Figure 1-9 as shown, figure 1 It is a cross-sectional view of a porous metal capillary seepage microneedle electrode of the present invention; figure 2 It is a structural schematic diagram of a porous microneedle array electrode sheet; Figure 4 It is a schematic diagram of the structure of the insulating shell.

[0041] Such as figure 1 and Figure 4As shown, a porous metal capillary seepage microneedle electrode includes an insulating shell 2, the interior of the insulating shell 2 forms a cavity, and has an opening on one side, and an electrical signal line is opened on the insulating shell Holes 9 and solution injection holes 10; a porous microneedle array electrode sheet 1, the porous microneedle array electrode sheet 1 is combined with the opening and sealing of the insulating casing 2, and the porous microneedle array electrode sheet 1 is provided with multiple A porous microneedle with a channel 12, the channel 12 is parallel to the central axis o...

Embodiment 2

[0057] The porous metal capillary liquid-permeable microneedle electrode of this embodiment is the same as that of Embodiment 1, except that the thickness of the porous metal microneedle array electrode sheet is 1.5 mm. The bottom diameter of the microneedle is 300 μm, the height is 500 μm, the pitch is 1 mm, and the diameter of the channel 12 is 100 μm. The insulating shell 2 is made of silica gel, and the adhesive 5 is a silica gel elastic sealant.

[0058] The preparation method of the porous metal capillary seepage microneedle electrode is similar to that of Example 1, except that the diameter of the titanium metal particles is 5 μm, and the titanium metal particles, ethanol, PVB, BBP, and dispersant are 46:46: The mass fraction ratio of 1:6.5:1.5 is mixed. And in the step (4), the sintering is carried out under the atmosphere of nitrogen gas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com