System for an utility vehicle comprising a screw compressor and an electric motor

An electric motor, screw technology, applied in the components of the pumping device for elastic fluid, machine/engine, rotary piston machine, etc., can solve the problem of increasing the inertia of the system, and achieve the effect of low cost and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

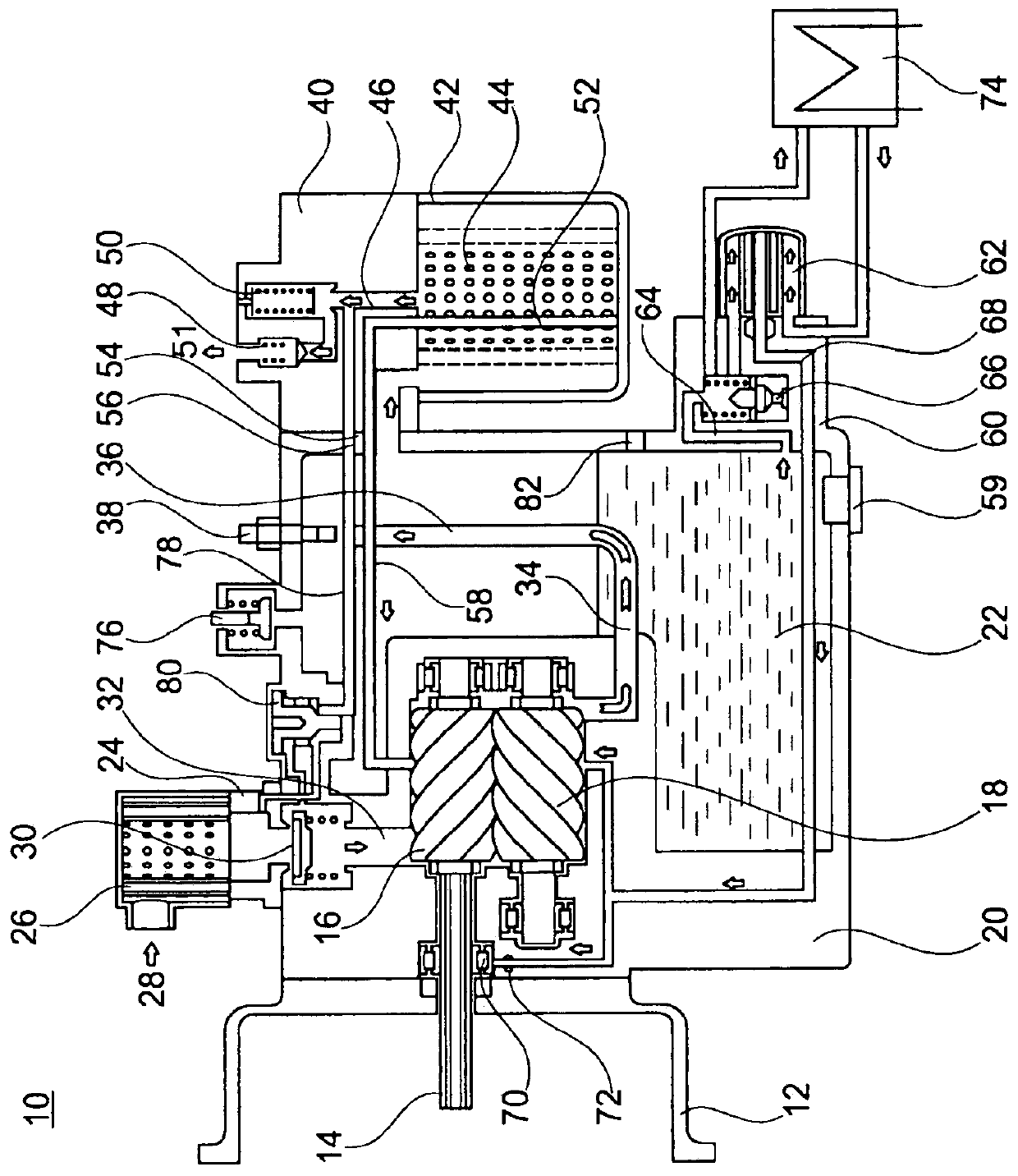

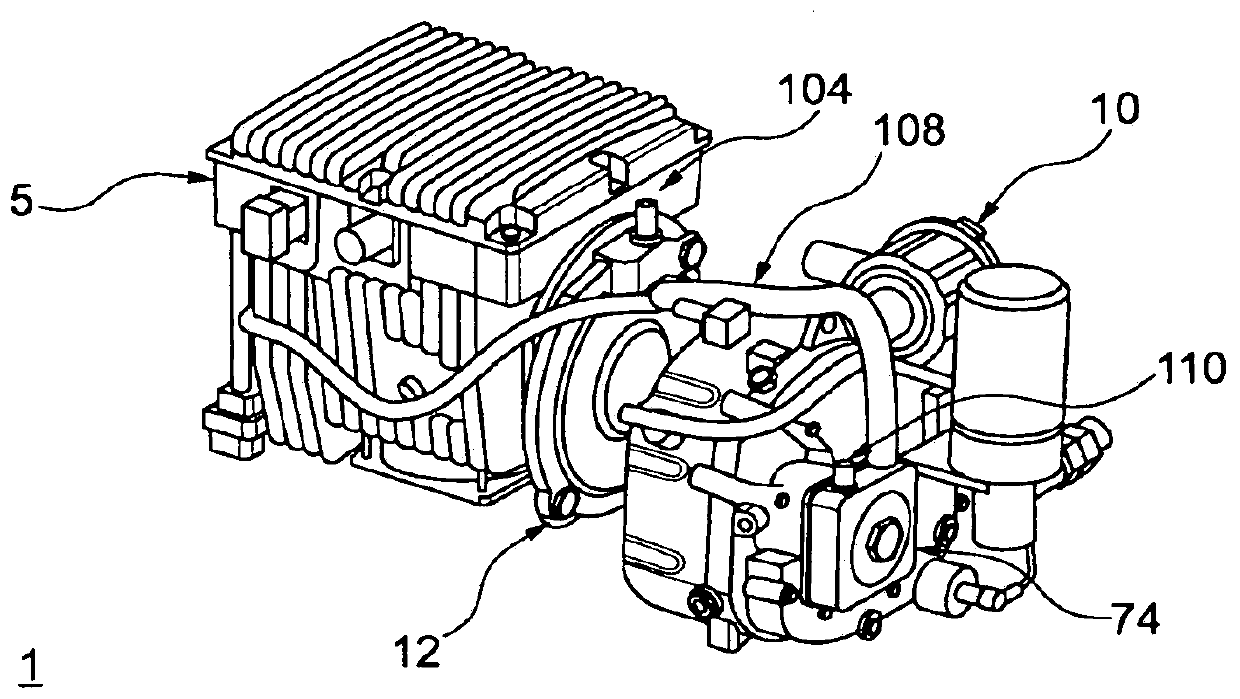

[0026] figure 1 A screw compressor 10 in the sense of an embodiment of the invention is shown in a schematic sectional view.

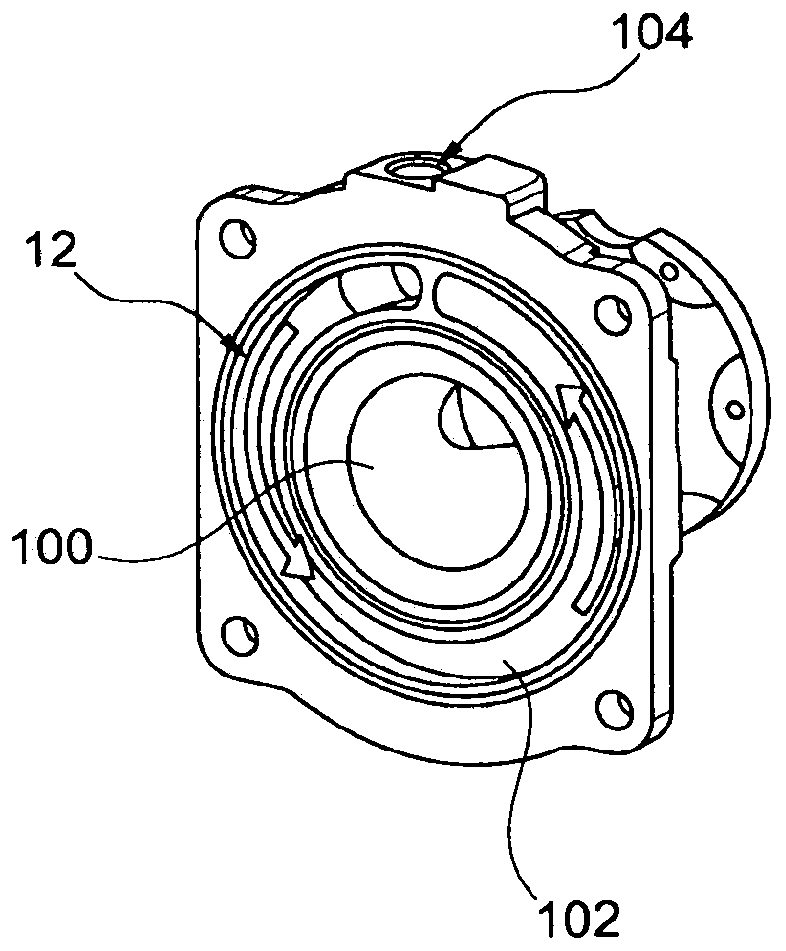

[0027] The screw compressor 10 has a fastening flange 12 for the mechanical fastening of the screw compressor 10 to an electric motor (not further shown here).

[0028] However, the input shaft 14 is also shown, via which the torque of the electric motor is transmitted to one of the two spindles 16 and 18 , namely the spindle 16 .

[0029] The screw 18 meshes with the screw 16 and is driven via the screw 16 .

[0030] The screw compressor 10 has a housing 20 in which the main components of the screw compressor 10 are installed.

[0031] Housing 20 is filled with oil 22 .

[0032] An inlet connection 24 is provided on the housing 20 of the screw compressor 10 on the air inlet side. The inlet connection 24 is designed in such a way that an air filter 26 is arranged thereon. Furthermore, air inlet openings 28 are arranged radially on the air inlet co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com