High-temperature flexible loading device

A loading device, high-temperature flexible technology, applied in the field of experimental mechanics, can solve the problems of structure surface temperature application, structure uniform distribution or surface load, low cost and other problems, and achieve the effect of rapid heating, scientific method, simple and reliable device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the object, technical solution and effect of the present invention clearer and clearer, the following examples are given to further describe the present invention in detail. It should be pointed out that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

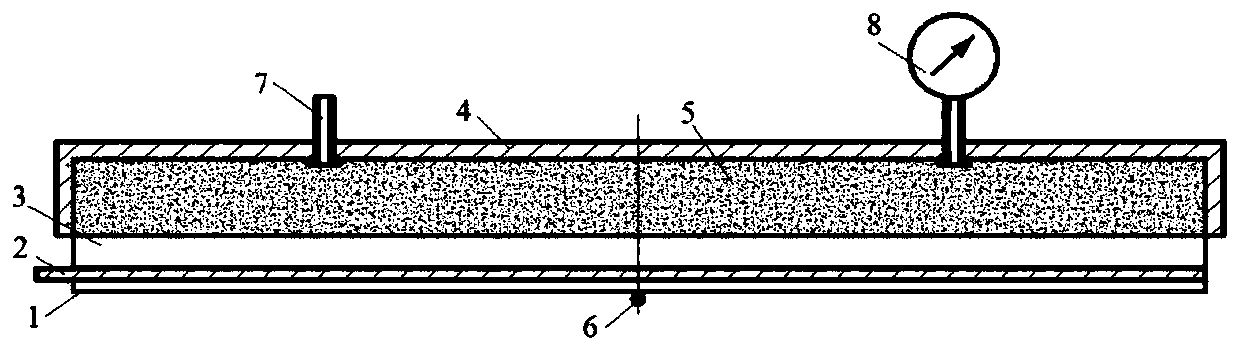

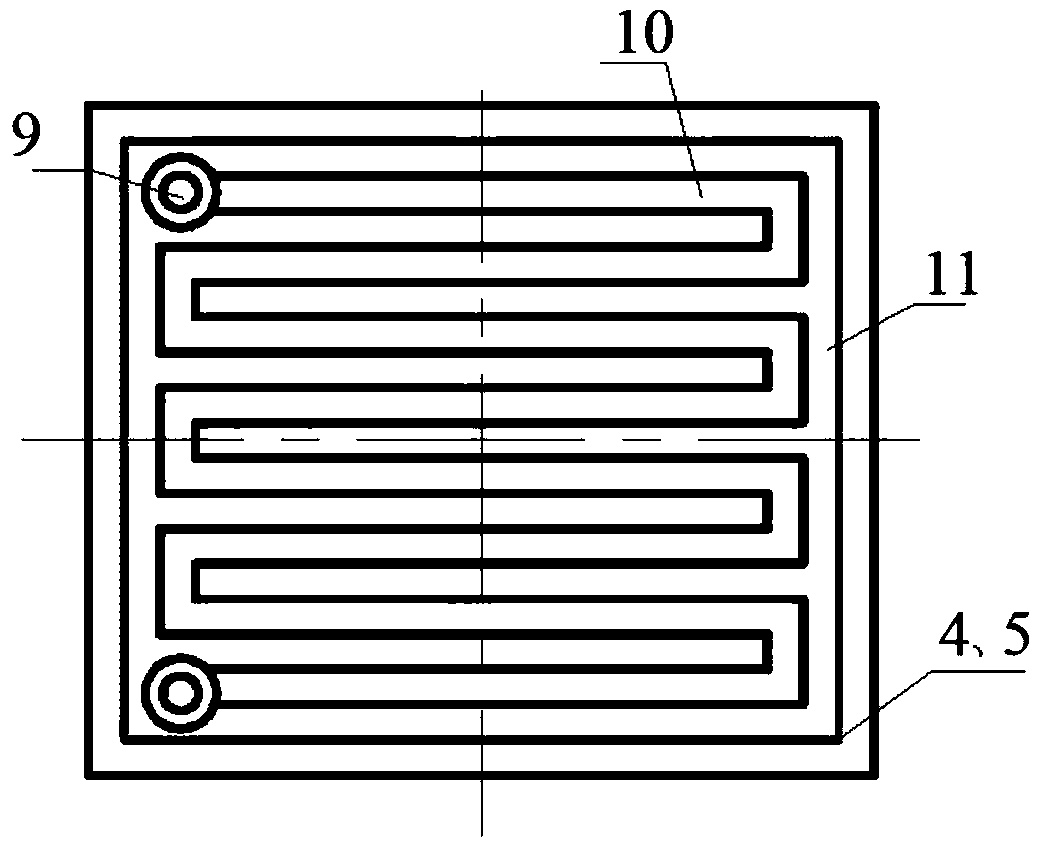

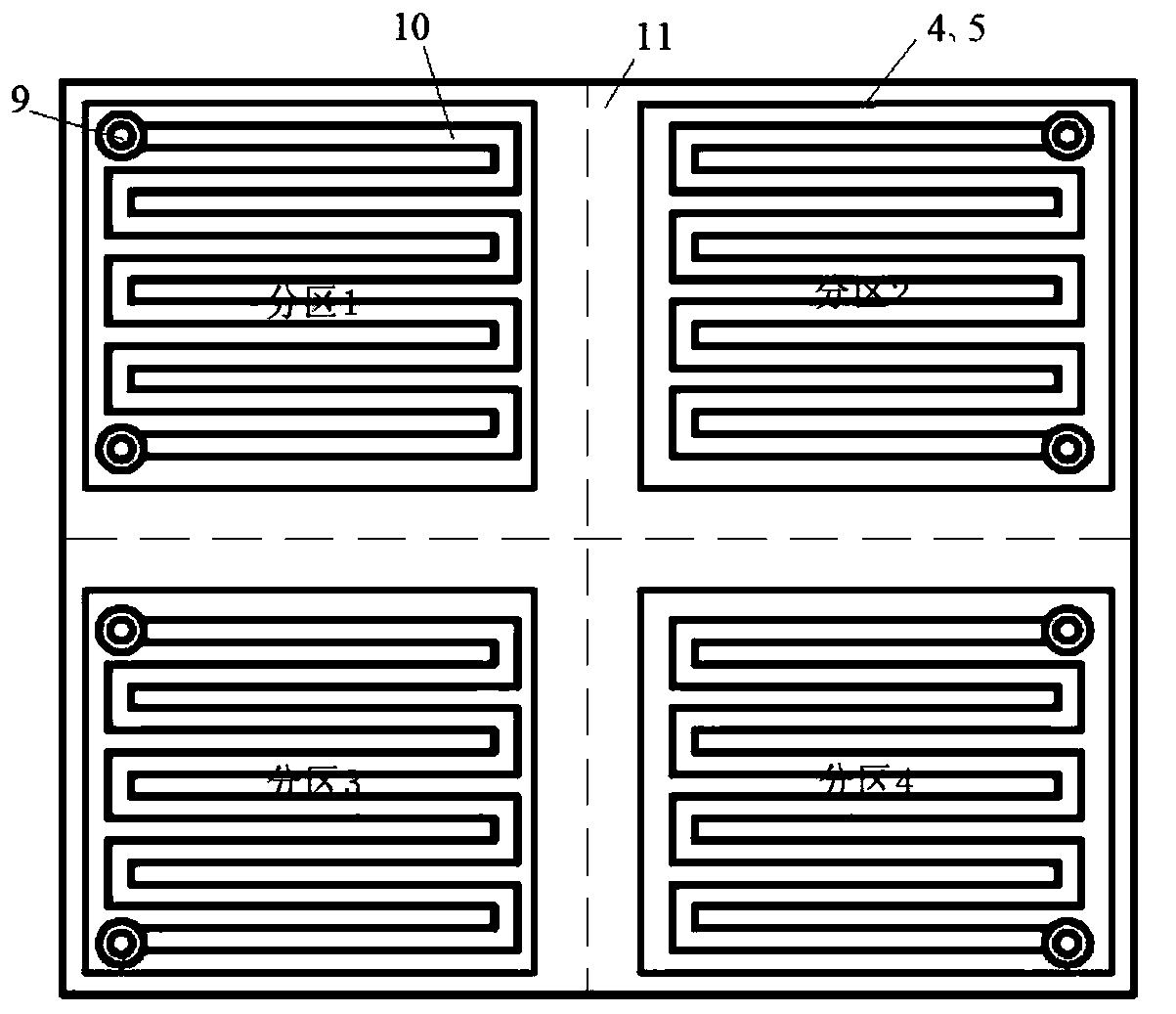

[0023] Such as Figure 1~Figure 2 As shown, the high-temperature flexible loading device of the first structural test of the present invention comprises a heating body 2, an insulating layer 1, a thermal insulation layer 3, a water bag 5 and a water bag cover 4, and a thermocouple 6, by the above The steps are installed in sequence to form a heating loading device with heating load capacity; when the thermal loading device is installed on a metal structure, first install a thermocouple at the point where the metal structure surface needs to measure temperature (control the temperature in this area) required), lead the thermo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com