Aluminum etched antenna card and manufacturing method thereof

A production method and aluminum etching technology, which is applied to antennas, loop antennas, antenna supports/mounting devices, etc., can solve the problems of weakened peeling strength, smaller applicable environment of cards, and weak adhesion of polyester films, etc., to achieve expansion Applicable environment, the effect of solving layered problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

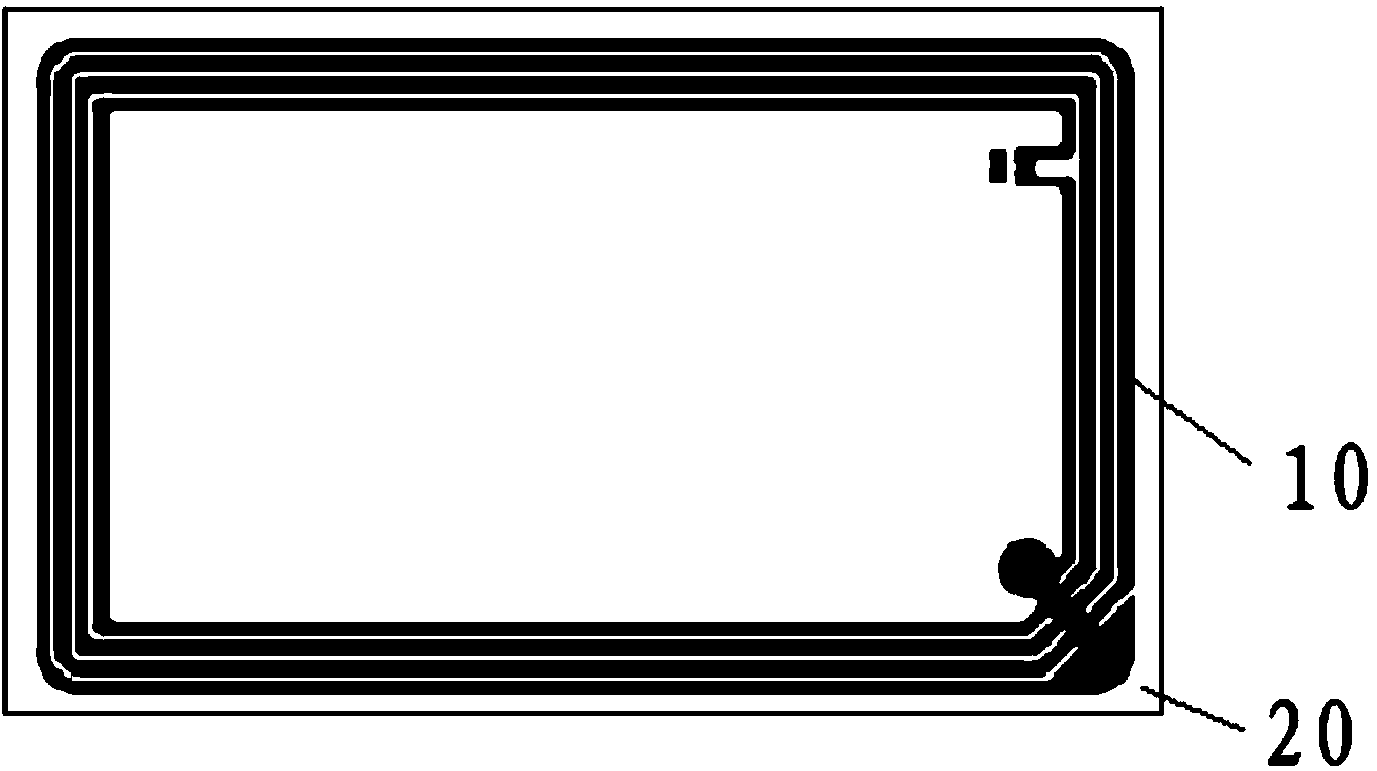

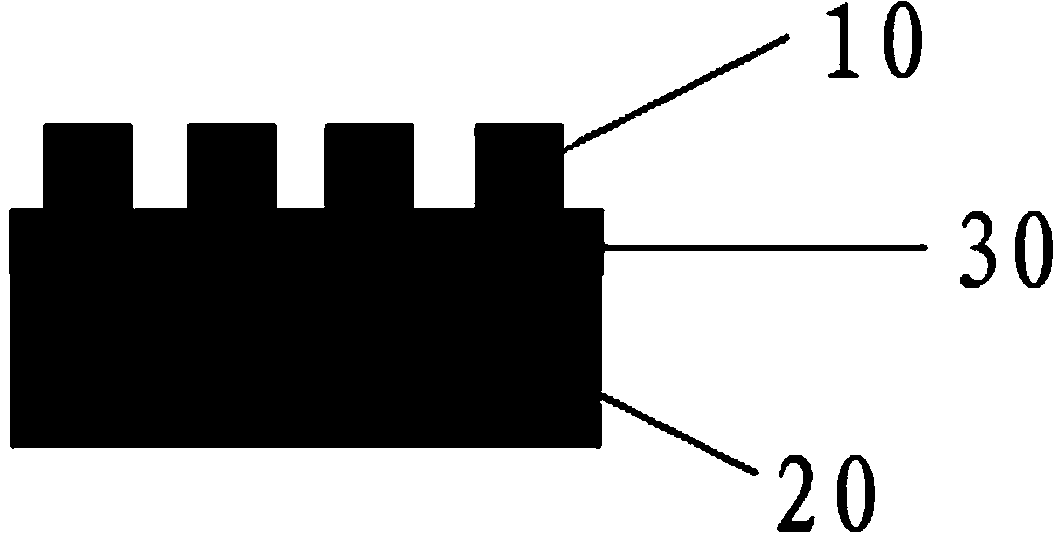

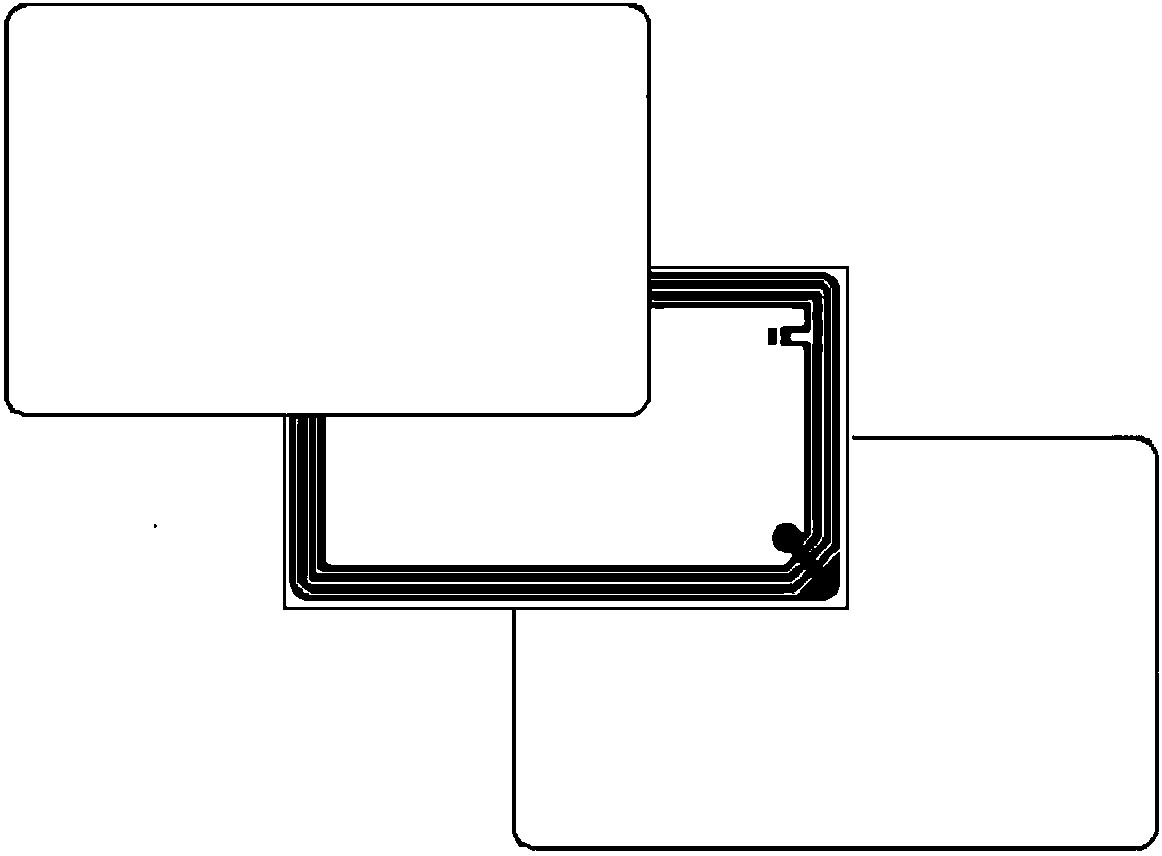

[0027] Figure 4 A schematic diagram of an aluminum etching antenna card in a specific embodiment of the invention is shown, the card mainly includes a polyester film antenna layer 1 and a cover layer, and the polyester film antenna layer 1 includes a polyester film and an antenna fixed on the polyester film. An aluminum etching antenna coil, the cover layer includes an upper cover layer 2 and a lower cover layer 3, wherein the size of the cover layer is greater than the size of the polyester film antenna layer 1, and the polyester film antenna layer 1 is provided with a plurality of holes 4, The upper covering layer 2, the polyester film antenna layer 1 and the lower covering layer 3 are bonded sequentially by thermocompression. In this embodiment, the upper cover layer 2 and the lower cover layer 3 are recorded as the two-layer sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com