Photoelectric module assembly with constant temperature control function and manufacturing method thereof

A photoelectric module and constant temperature control technology, applied in the direction of electrical components, electric solid-state devices, laser components, etc., can solve problems such as large volume, poor process quality consistency, insensitive temperature control, etc., to achieve precise control and high sensitivity temperature The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

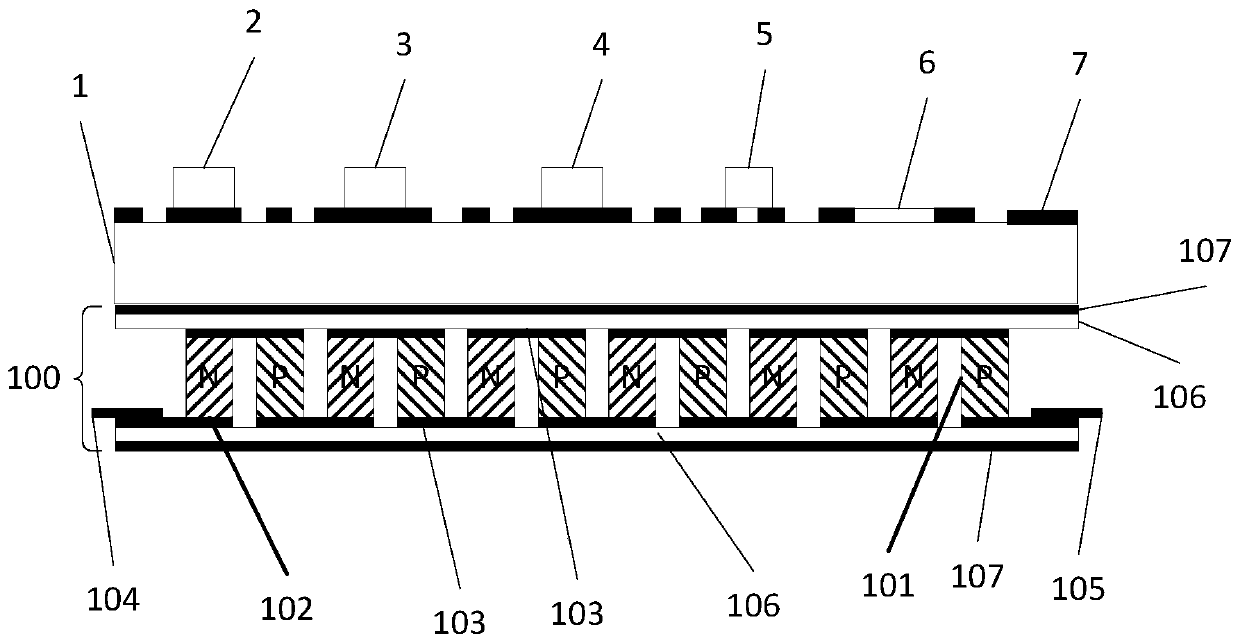

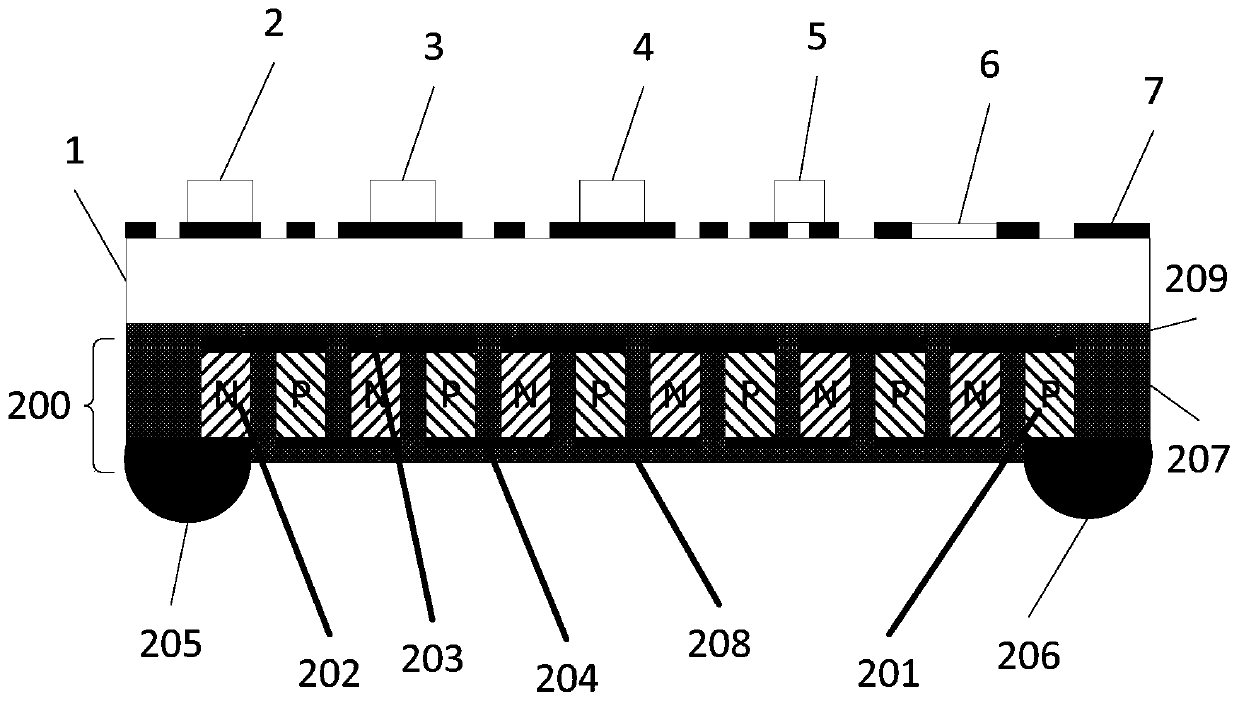

[0057] 1. An optoelectronic module assembly with a constant temperature control function, the integrated TEC p-type semiconductor (201) uses p-type bismuth telluride semiconductor material, and the p-type bismuth telluride semiconductor material is Bi 2 Te 3 -Sb 2 Te 3 The thickness of the integrated TEC p-type semiconductor (201) is 0.2mm-0.6mm.

[0058] The integrated TEC n-type semiconductor (202) uses an n-type bismuth telluride semiconductor material, and the n-type bismuth telluride semiconductor material is Bi 2 Te 3 -Bi 2 Se 3 The thickness of the integrated TEC n-type semiconductor (202) is 0.2mm-0.6mm.

[0059] 2. A photoelectric module assembly with a constant temperature control function, wherein the material of the integrated TEC top metal electrode (203) and the integrated TEC bottom metal electrode (204) is a nickel-chromium-copper-nickel-chromium-gold composite conductor.

[0060] 3. A photoelectric module assembly with a constant temperature control function, wherein ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com