Integrated heat-pipe heat dissipating device

A technology of heat dissipation device and heat pipe, applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of limited heat dissipation effect and the inability of heat dissipation device to meet the requirements, and achieve the effect of excellent heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

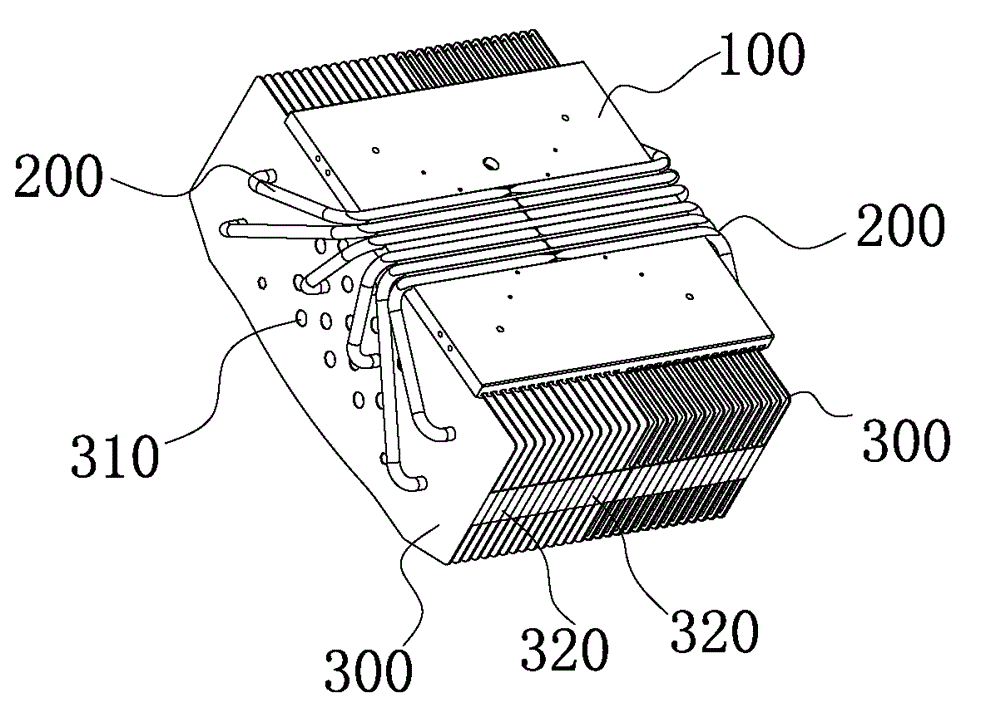

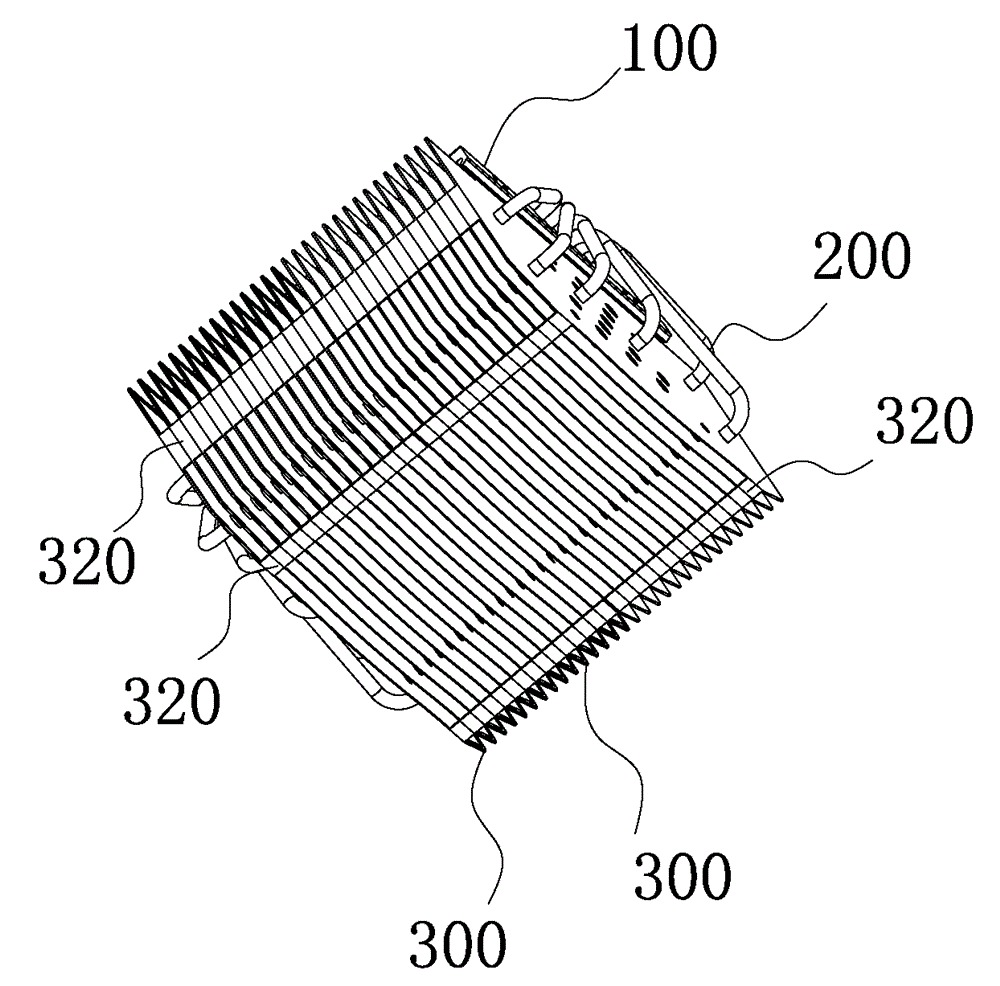

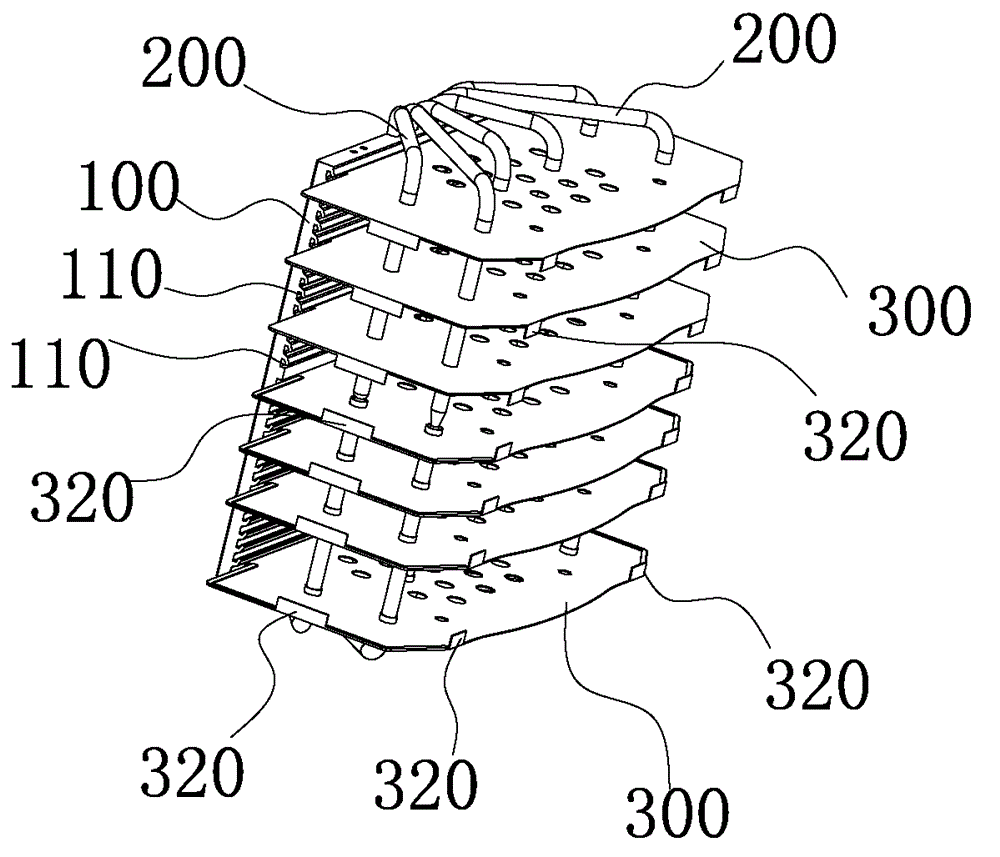

[0047] An integrated heat pipe cooling device, such as Figure 1 to Figure 5 As shown, a plurality of heat dissipation pipes 200, a heat conduction base 100 and a plurality of heat dissipation fins 300 are provided, and the plurality of heat dissipation fins 300 are respectively fixedly mounted on one side of the heat conduction base 100 and the heat dissipation fins 300 are in contact with the heat conduction base 100 to dissipate heat. The fins 300 are perpendicular to the heat conduction base 100 , the heat receiving sections of the plurality of heat dissipation pipes 200 are attached to the other side of the heat conduction base 100 without gaps, and the heat dissipation sections of the heat dissipation conduits 200 are assembled on the plurality of heat dissipation fins 300 .

[0048] During use, the heat source such as a chip is directly assembled on the heat dissipation section of the heat dissipation pipe 200 installed on the heat conduction base 100 . The heat generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com