Packaging structure capable of achieving electricity property and heat dissipation through mechanical press mode and process method

A technology of mechanical lamination and packaging structure, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of easy failure, high cost, etc., and achieve the effects of good electrical performance, cost reduction, and good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

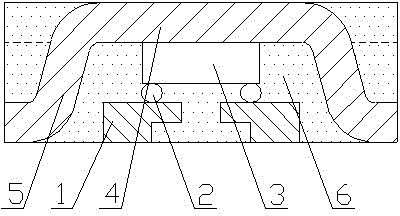

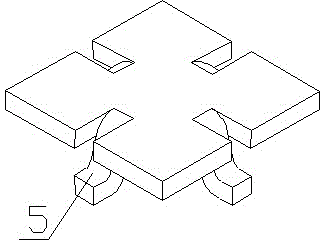

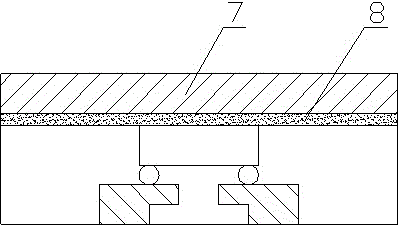

[0047] see figure 1 , figure 2 , the present invention is a packaging structure that realizes electrical properties and heat dissipation by means of mechanical pressing, which includes a pin 1, on which a chip 3 is flip-mounted through solder balls 2, and a heat dissipation frame 4 is arranged on the chip 3 , the four sides of the heat dissipation frame 4 are provided with claws 5 downward, and the spaces between the pins 1 , the chip 3 and the heat dissipation frame 4 and the periphery of the heat dissipation frame 4 are encapsulated with a plastic encapsulant 6 .

[0048] The bottom of the claw 5 is flush with the bottom of the pin 1 .

[0049] Its process method is as follows:

[0050] Step 1. Take the metal substrate

[0051] Step 2. Paste photoresist film

[0052] Paste a photoresist film that can be exposed and developed on the front and back of the metal substrate;

[0053] Step 3. Remove part of the photoresist film on the front and back of the metal substrate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com