Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Zinc cyanide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc cyanide is the inorganic compound with the formula Zn(CN)₂. It is a white solid that is used mainly for electroplating zinc but also has more specialized applications for the synthesis of organic compounds.

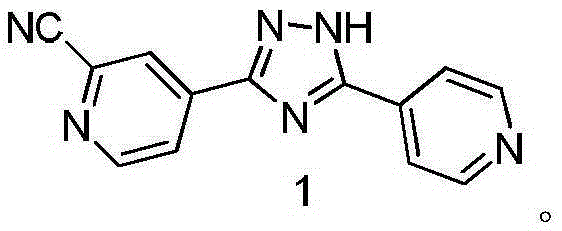

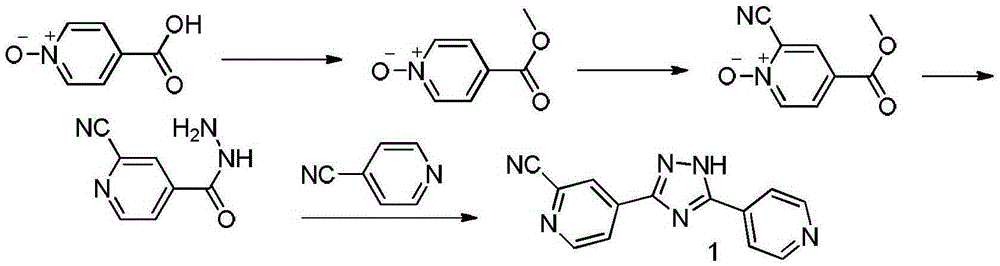

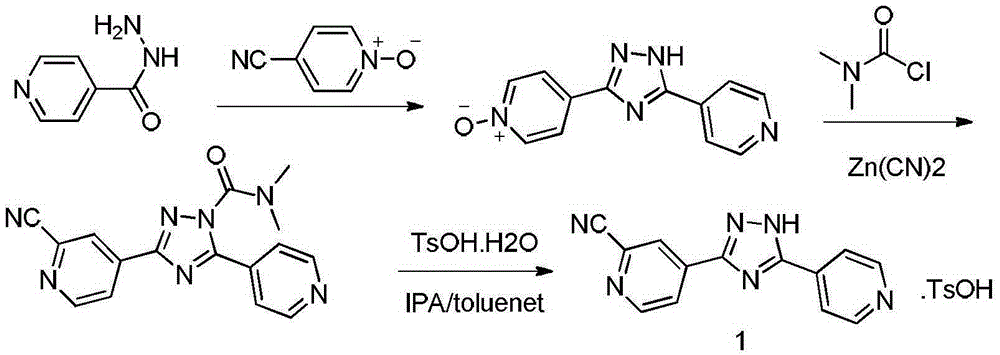

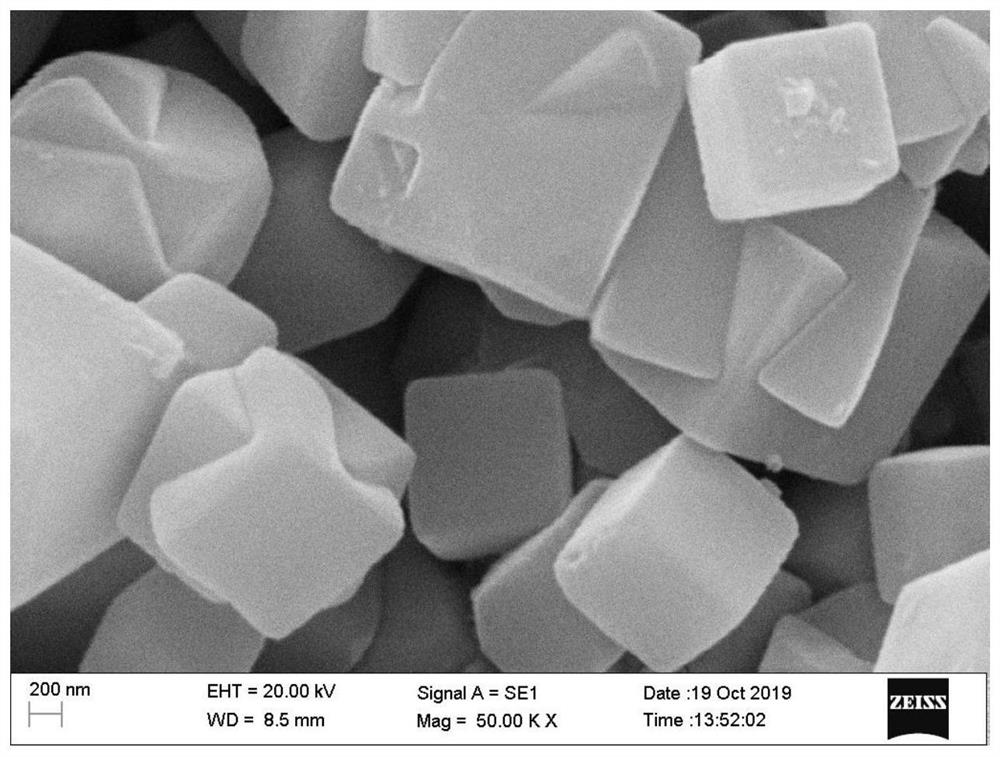

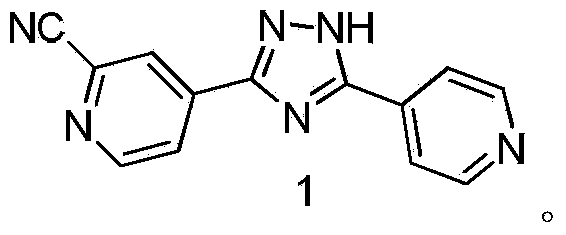

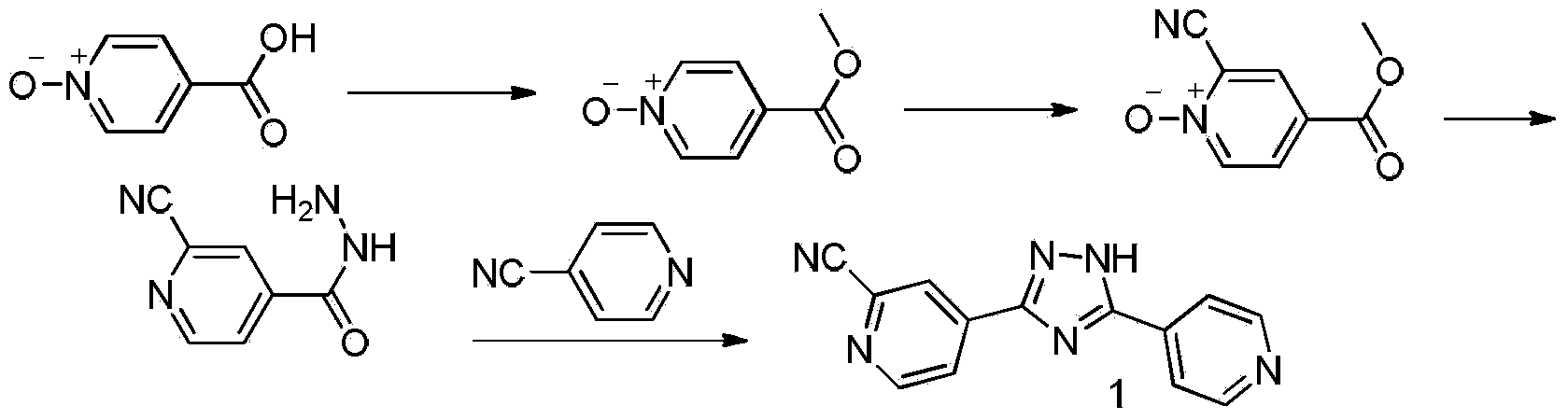

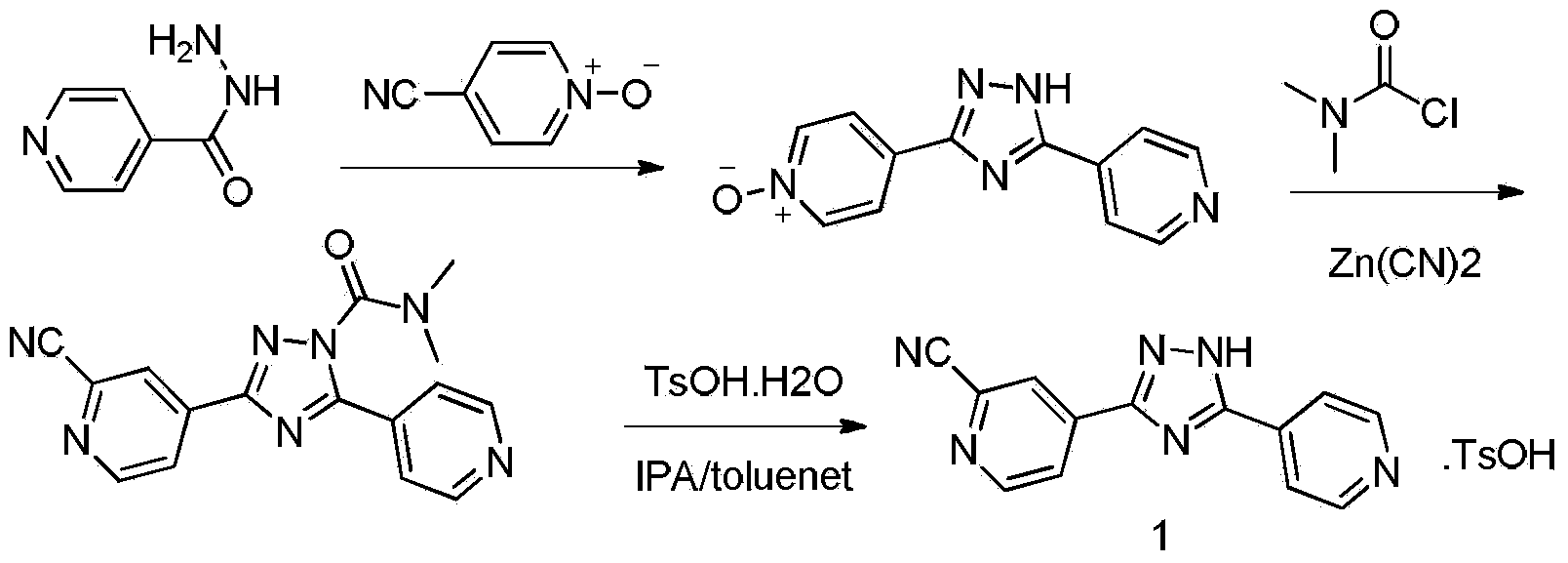

Preparation method of topiroxostat

The invention relates to a preparation method of topiroxostat, which comprises the following steps: reacting an initial raw material compound isoniazide disclosed as Formula (6) with a compound 4-cyano-pyridyl-N-oxide disclosed as Formula (5) to generate a triazole compound disclosed as Formula (4), reacting the triazole compound disclosed as Formula (4) in the presence of a copper catalyst (CuX), zinc cyanide (Zn(CN)2) and dimethylamino formyl chloride to generate a cyanotriazole compound disclosed as Formula (3), reacting the compound disclosed as Formula (3) in the presence of p-toluenesulfonic acid to generate a compound disclosed as Formula (2), and finally, alkalifying with inorganic alkali to obtain the target compound disclosed as Formula (1) (topiroxostat). The method is simple in operation and after-treatment, and greatly lowers the consumption of the zinc cyanide due to the use of the copper catalyst, so that the reaction conditions are milder, and the purity of the prepared product is high; and the method is suitable for industrial production.

Owner:于宗光

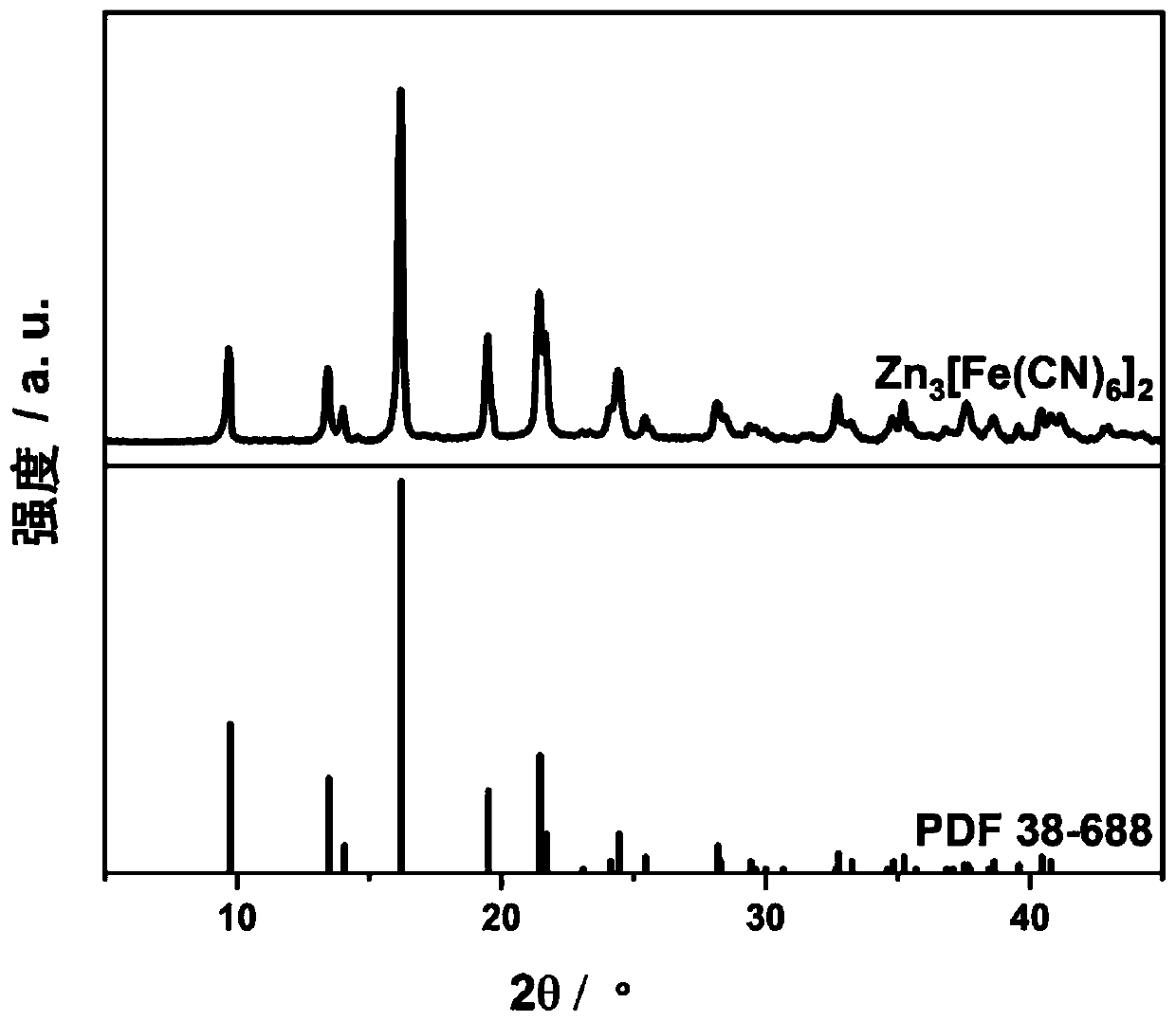

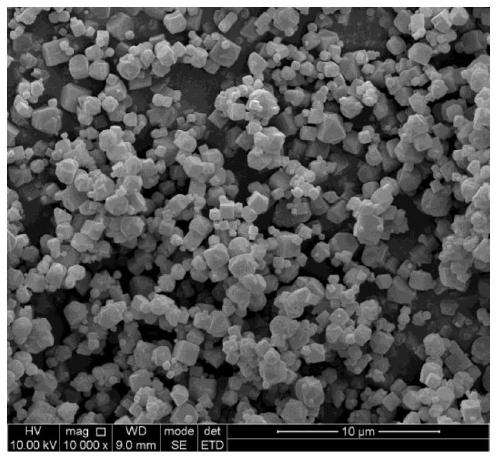

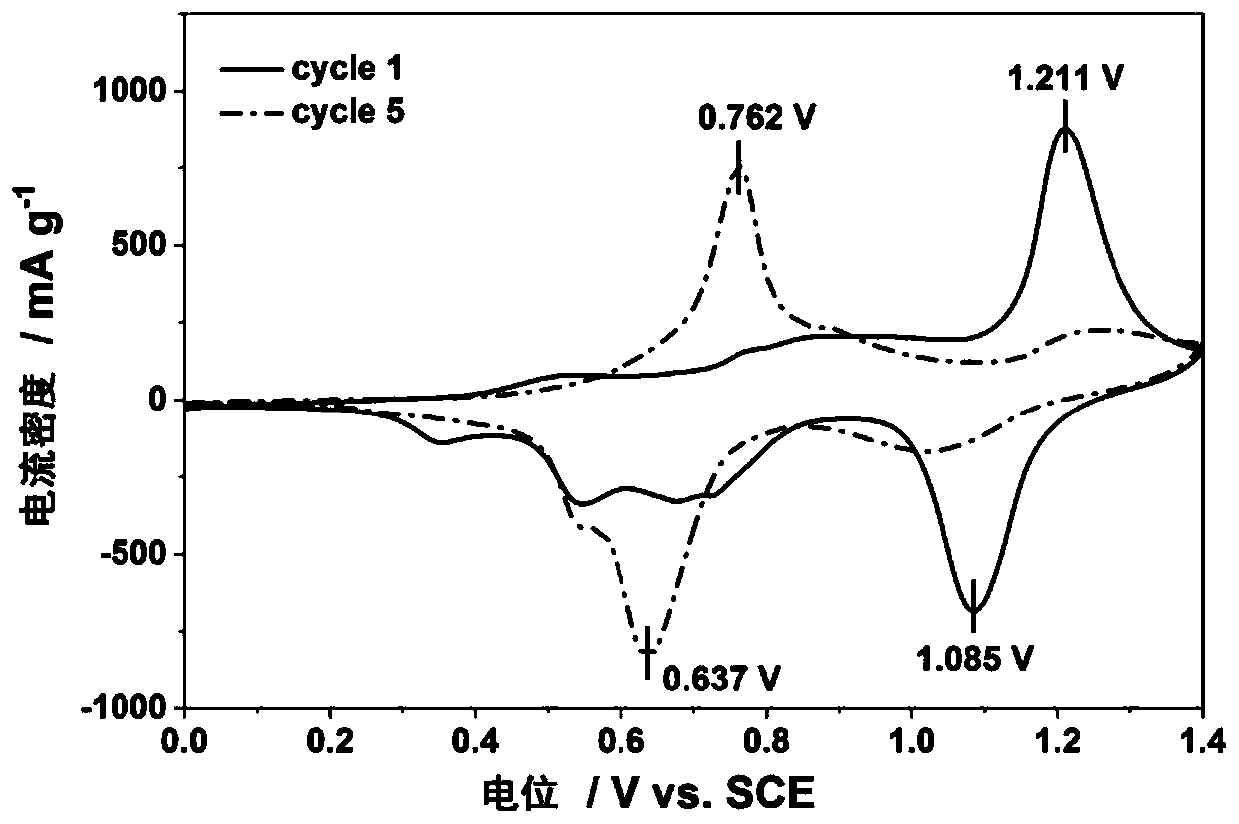

Manganese-doped modified zinc ion battery positive electrode active material and preparation method and application thereof

ActiveCN111732112AImprove cycle performanceImprove cycle stabilityIron cyanidesSecondary cellsZinc ionAqueous solution

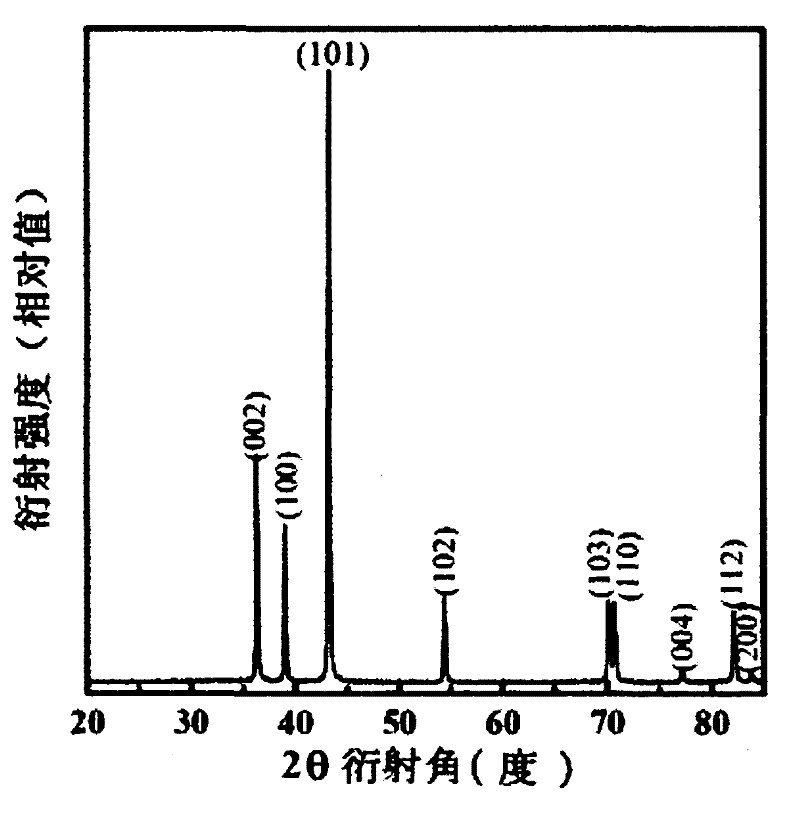

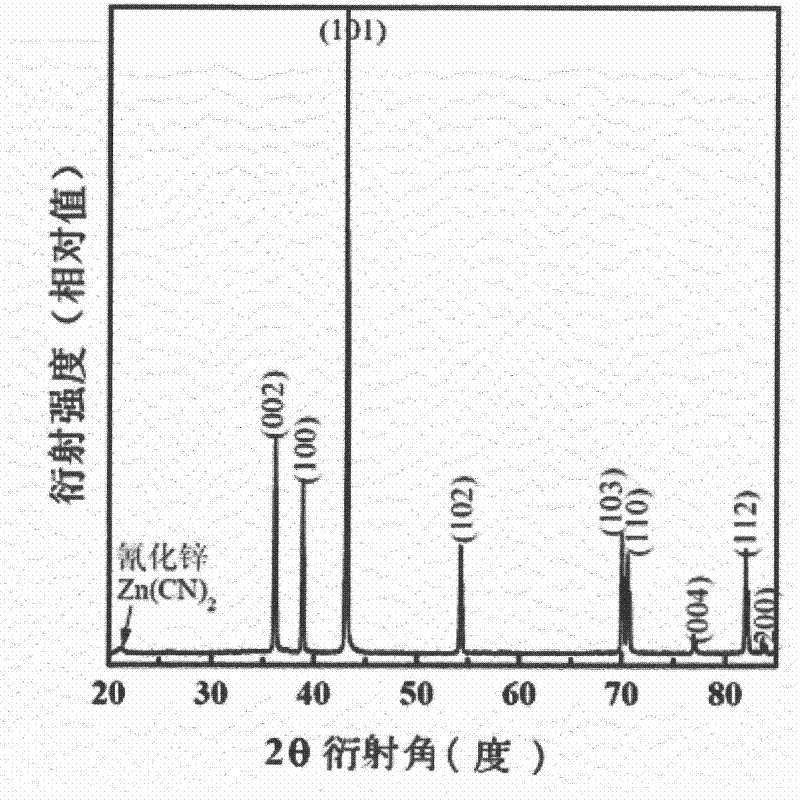

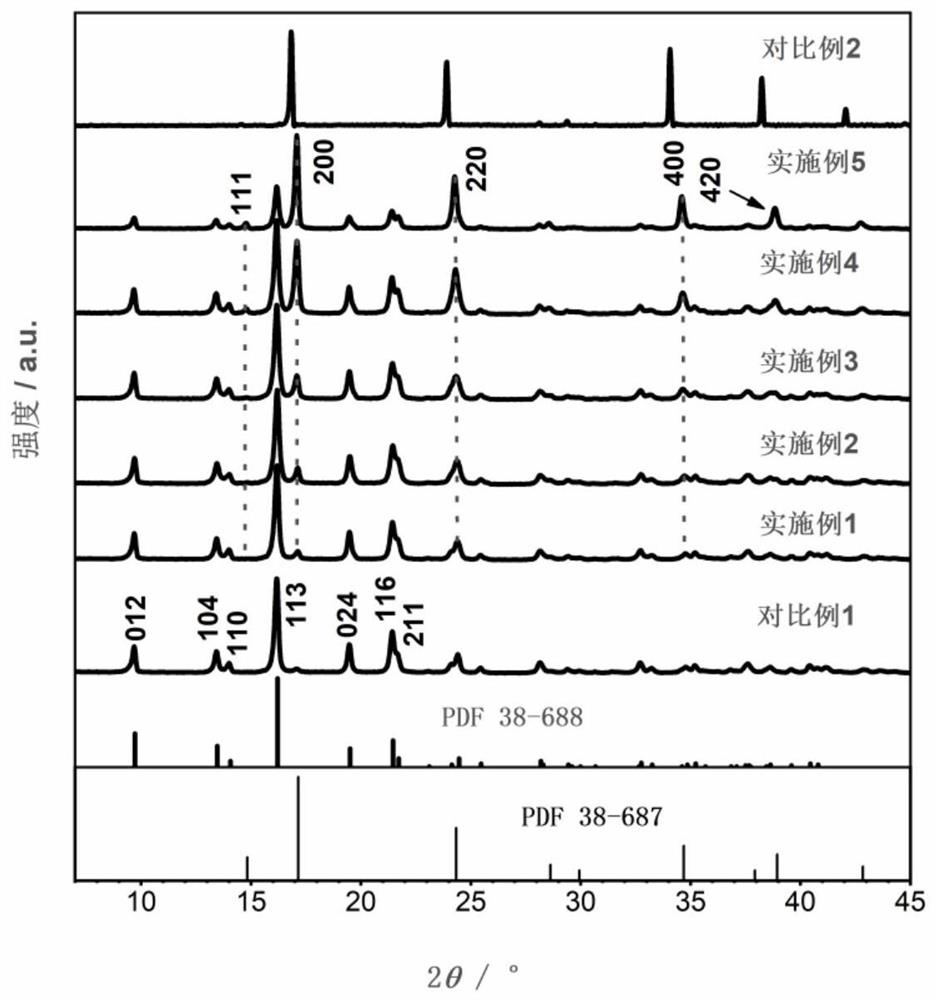

The invention relates to a manganese-doped modified zinc ion battery positive electrode active material and a preparation method and application thereof. The positive electrode active material contains manganese zinc ferricyanide. The X-ray diffraction pattern of manganese zinc ferricyanide has absorption peaks at diffraction angles 2 theta of 9. 68 degrees, 13.42 degrees, 14.00 degrees, 14.78 degrees, 16.16 degrees, 17.08 degrees, 19.46 degrees, 21.42 degrees, 21.64 degrees, 24.26 degrees, 34.60 degrees and 38.82 degrees, and the error of 2 theta is + / - 0.2; preferably, the manganese zinc ferricyanide is prepared by a method comprising the following steps: blending a zinc salt aqueous solution, a manganese salt aqueous solution and a ferricyanide ion solution, and then reacting to obtainthe manganese zinc ferricyanide. The positive electrode active material provided by the invention can improve the performance of the zinc ferricyanide positive electrode active material and obviouslyimprove the cycling stability of the positive electrode material.

Owner:HEFEI UNIV OF TECH

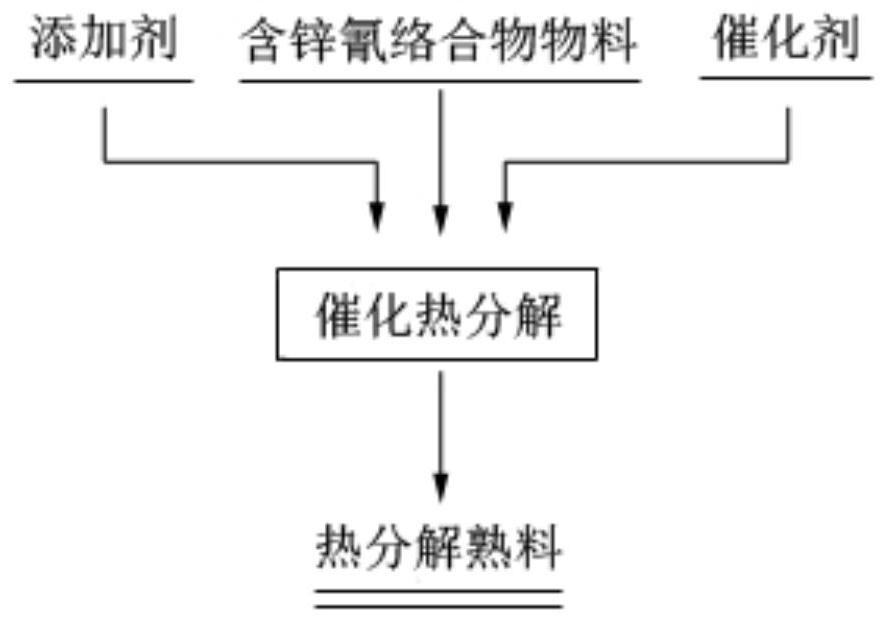

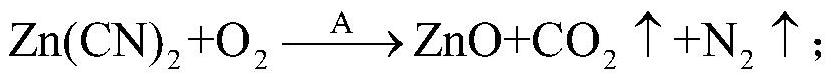

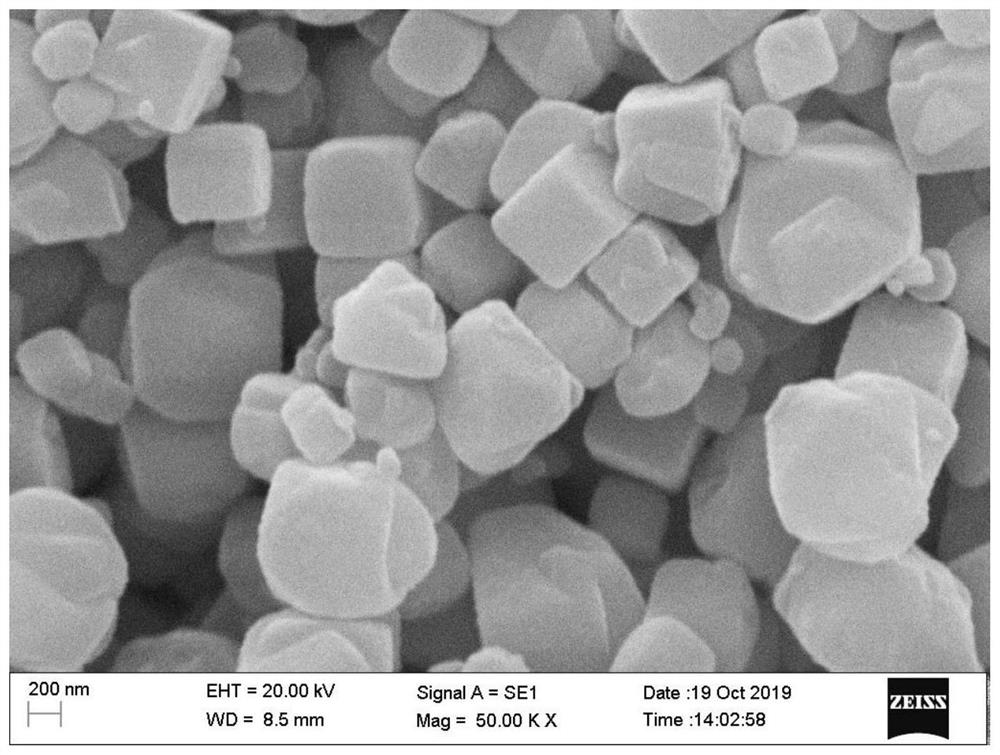

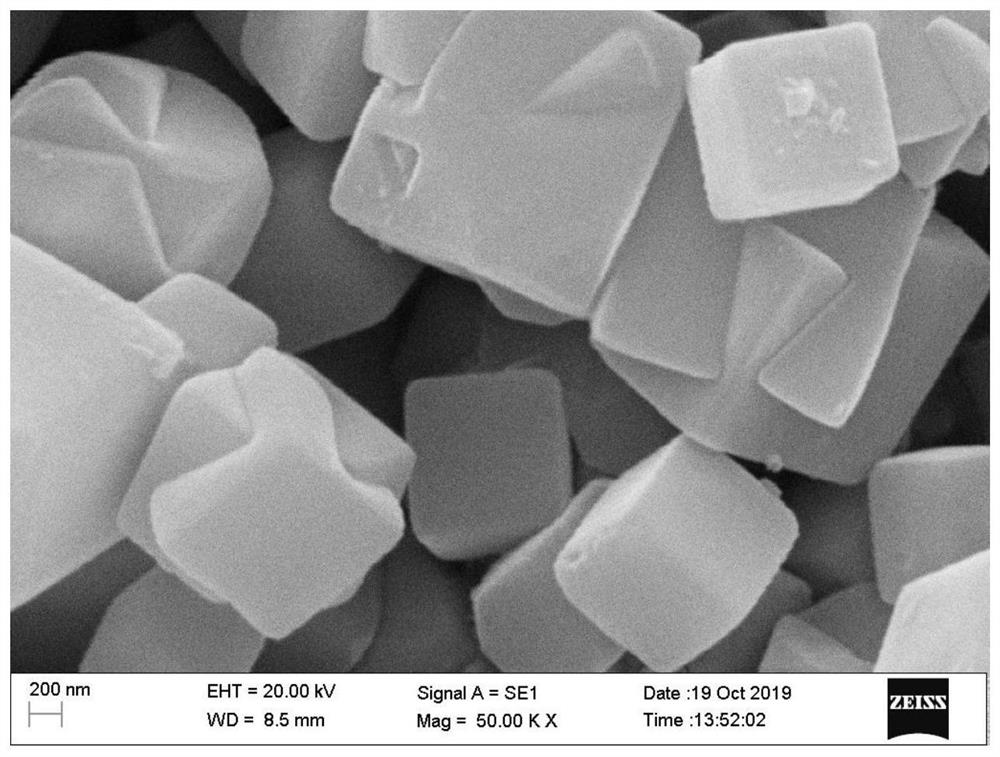

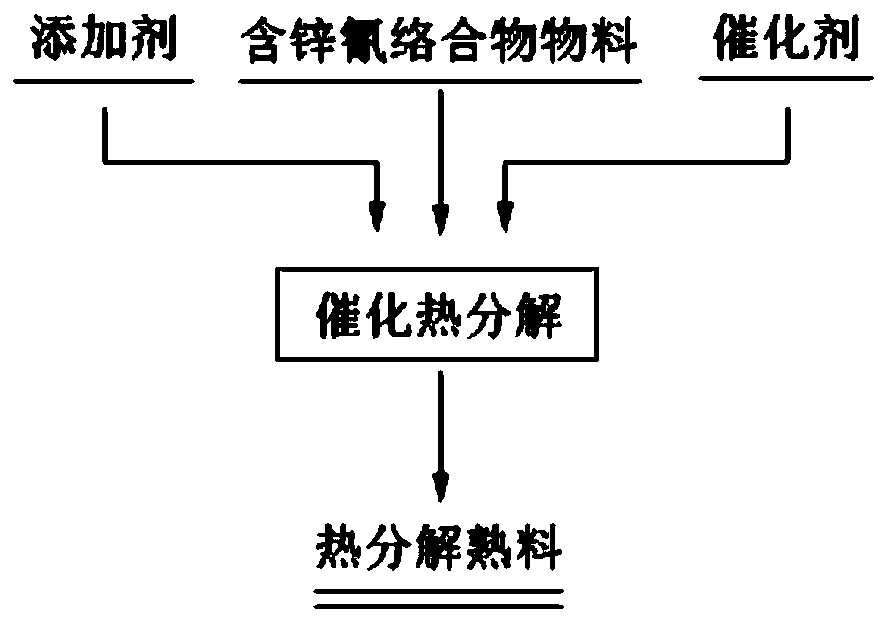

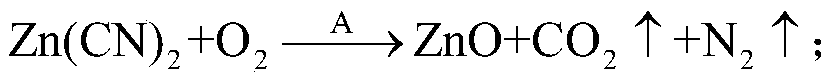

Method for catalytic thermal decomposition to remove zinc-cyanide complex

InactiveCN110090385AAvoid pollutionNo secondary pollutionDispersed particle separationPollutionAtmosphere

A method for catalytic thermal decomposition to remove a zinc-cyanide complex is provided. The method includes adding a catalyst into a solid zinc-cyanide complex raw material or a raw material containing the zinc-cyanide complex to prepare a raw material mixture, with the mass of the catalyst being not less than 1% of the mass of the zinc-cyanide complex in the raw material; adding the raw material mixture into a thermal decomposition device, heating the mixture to 250-470 DEG C for thermal decomposition, and maintaining the temperature for 0-150 min when the temperature is 250-470 DEG C to remove the zinc-cyanide complex and obtain a thermal decomposition clinker; directly stacking the obtained clinker or utilizing the clinker for backfill treatment or secondary utilization. Beneficial effects of the method are that clean conversion of the solid zinc-cyanide complex raw material or the raw material containing the zinc-cyanide complex is achieved under the functions of the catalyst, thermal decomposition and oxidation atmosphere, the cost is low, the zinc-cyanide complex removing effect is good, and the thermal decomposition clinker after low-temperature thermal decomposition reaches requirements on ordinary solid waste. The method has characteristics including a simple process, low equipment investment, no secondary pollution and easy promotion.

Owner:NORTHEASTERN UNIV

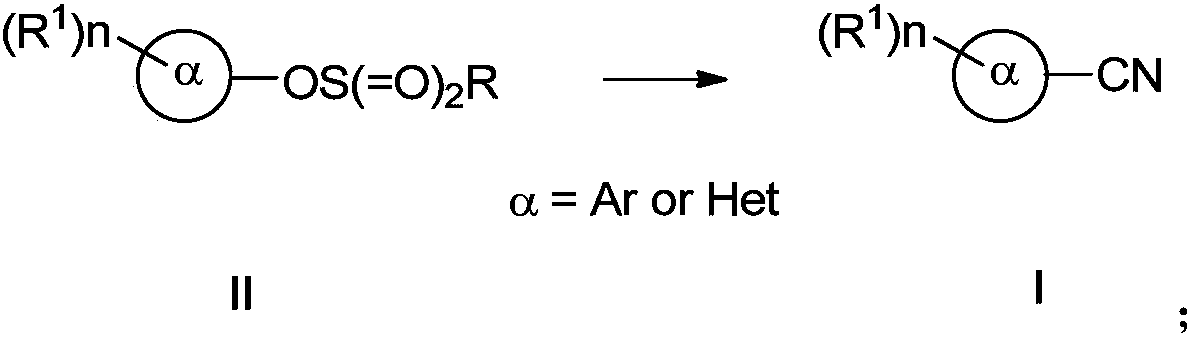

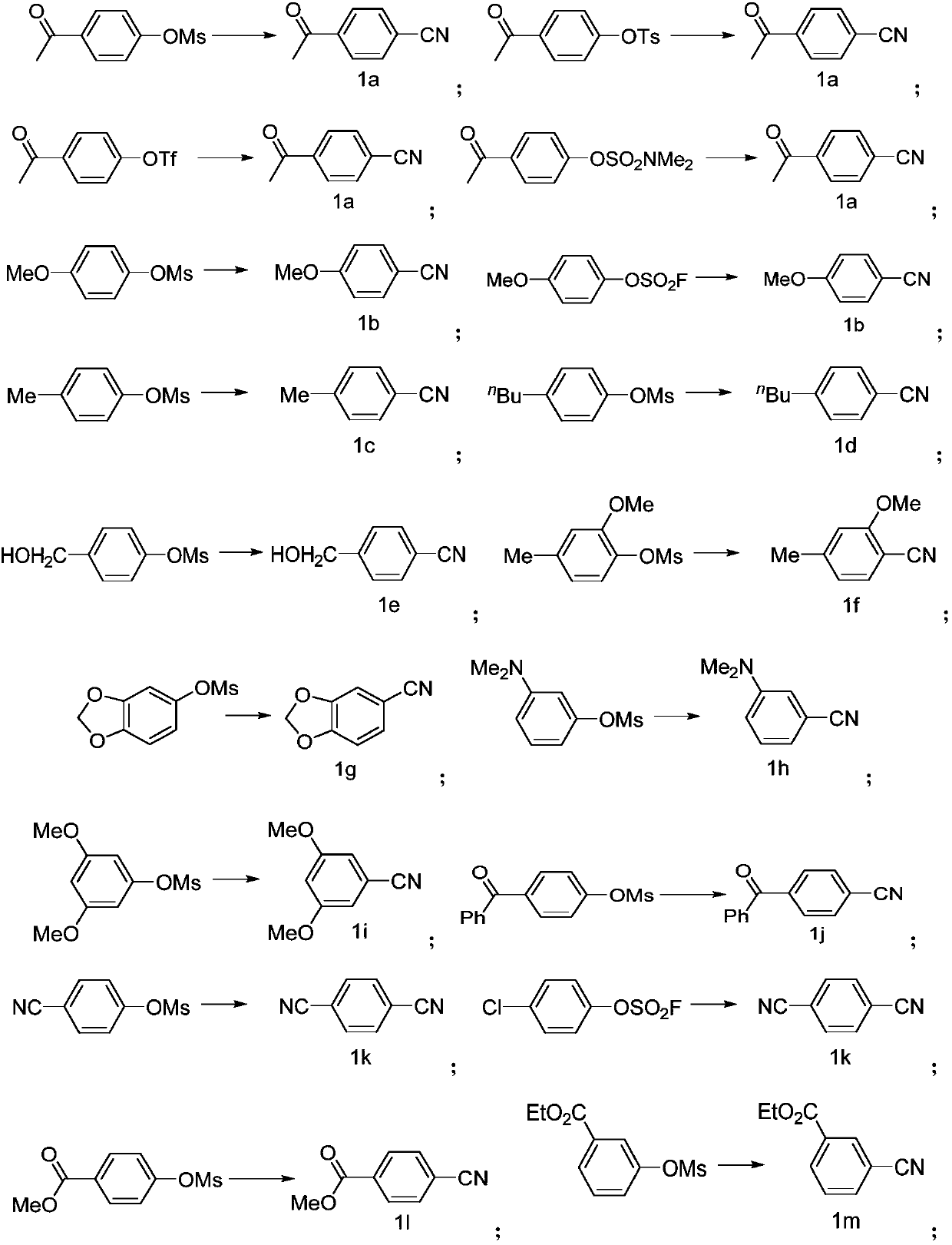

Preparing method of aromatic nitrile or alkenyl nitrile compound

PendingCN110117237AImprove compatibilityImprove universalityPreparation by cyanide reactionSteroidsArylSolvent

The invention discloses a preparing method of an aromatic nitrile or alkenyl nitrile compound. The preparing method comprises the following step that under protection of inert gas, an aryl or heteroaryl sulphonate compound shown in a formula II or an alkenyl sulphonate compound shown in a formula IV and a cyanation reagent are subjected to a cross-coupling reaction as is shown below in a solvent under the condition of the presence of a nickel complex, metal zinc and an additive to obtain the aromatic nitrile or alkenyl nitrile compound, wherein 4-dimethylamiopryidine (DMAP) is adopted as the additive, and zinc cyanide is adopted as the cyanation reagent. By means of the preparing method, cyanation of aryl sulphonate, heteroaryl sulphonate or alkenyl sulphonate can be simply and efficientlyachieved with a cheap catalysis system; moreover, the functional group compatibility and substrate universality are good, and a better application prospect and higher using value are provided for achieving industrial synthesis of the aromatic nitrile or alkenyl nitrile compound.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Electroplated zinc and copper alloy

The invention relates to an electroplated alloy, particularly to an electroplated zinc and copper alloy, which belongs to the metallurgy industry. The electroplated alloy comprises zinc cyanide, coprous cyanide, sodium cyanide, sodium citrate, potassium sodium tartrate and sodium hydroxide. The electroplated alloy is characterized in that D-potassium gluconate, ammonium nitrate, magnesium carbonate (anhydrous) and piperonal(dehyde) are added in the formula; the formula comprises the following components in parts by weight: 39 to 49 parts of zinc cyanide, 4 to 8 parts of coprous cyanide, 20 to 30 parts of sodium cyanide, 20 to 25 parts of sodium citrate, 25 to 35 parts of potassium sodium tartrate, 25 to 35 parts of sodium hydroxide, 40 to 50 parts of D-potassium gluconate, 0.5 to 1.5 parts of ammonium nitrate, 25 to 35 parts of magnesium carbonate (anhydrous) and 1 to 1.5 parts of piperonal(dehyde). The electroplated alloy is mainly used for daily products, such as glass frames, and the like. The electroplated zinc and copper alloy has the advantages of stable plated layer, strong corrosion resistance, long service life and low cost and is convenient in use.

Owner:耿香珍

Method for processing cyanogens-containing waste water from gold mine

InactiveCN106315944AEfficient removalDecrease coolnessWaste water treatment from quariesMultistage water/sewage treatmentFlocculationSulfate

The invention discloses a method for processing cyanogens-containing waste water from gold mine. The method comprises the following steps: waste water adjusting, coagulation processing, secondary coagulation processing, ultraviolet ray processing, and concentration reducing processing. According to the invention, a coagulant and a flocculant employed in the invention can effectively reduce the amount of suspended impurity in the waste water, a crude flocculation body can be aggregated rapidly, so that rapid separating from water can be carried out, most pollutant in the waste water can be removed effectively through precipitation, by adding zinc sulfate, the cyanide is precipitated with a zinc cyanide mode, then is acidified by sulfuric acid, the concentration of the cyanide is reduced to lower than 0.1 mg / 1, an iron-cyanogen complex is removed, The method provided by the invention has the characteristics of rapidity and high efficiency, and is the excellent method for processing cyanogens-containing waste water from gold mine.

Owner:铜仁市万山区盛和矿业有限责任公司

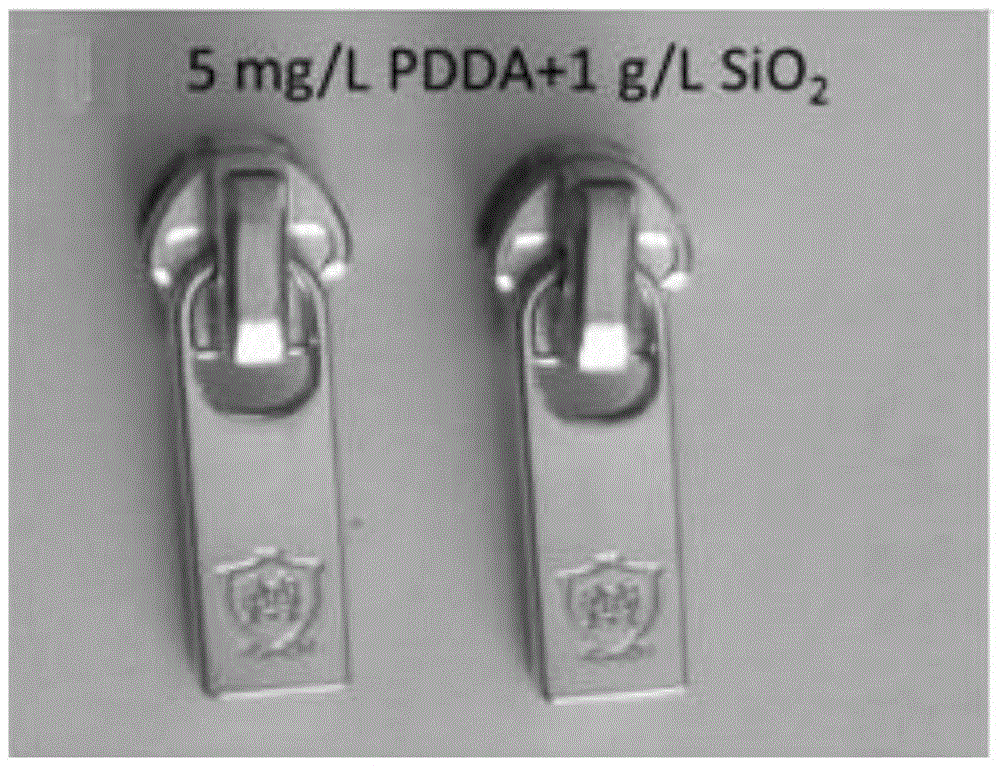

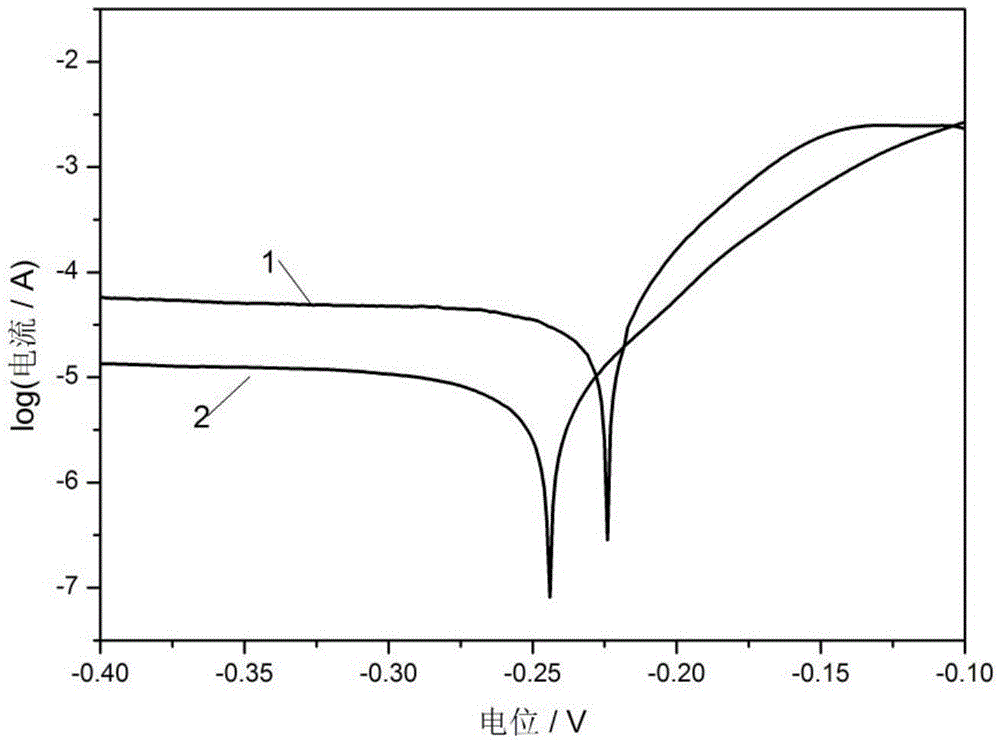

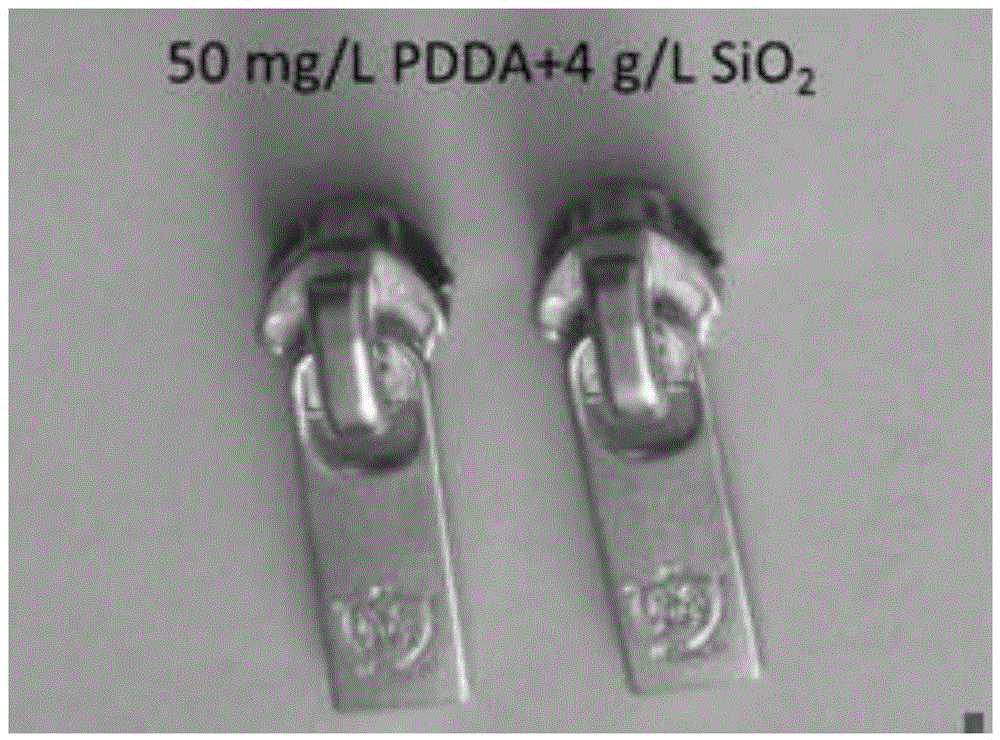

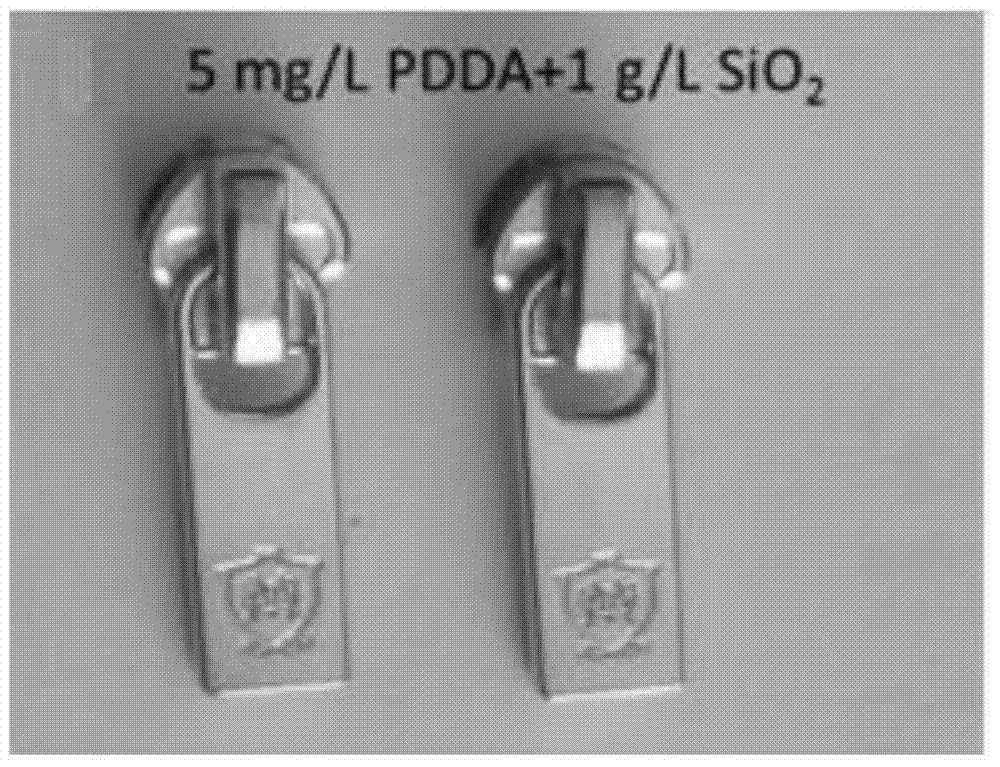

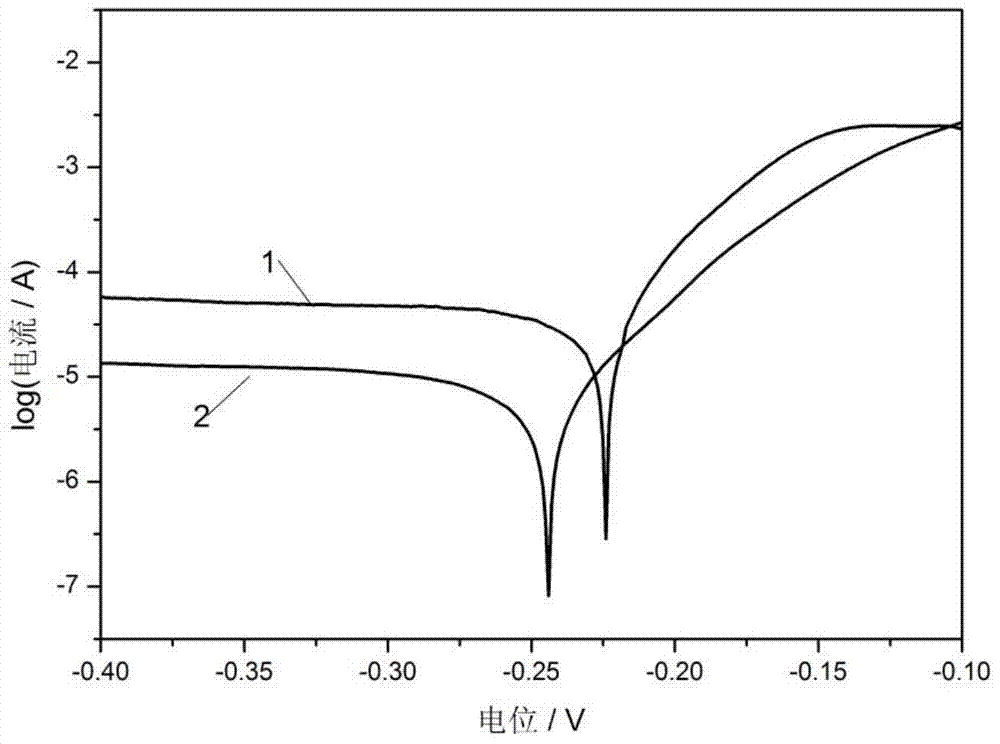

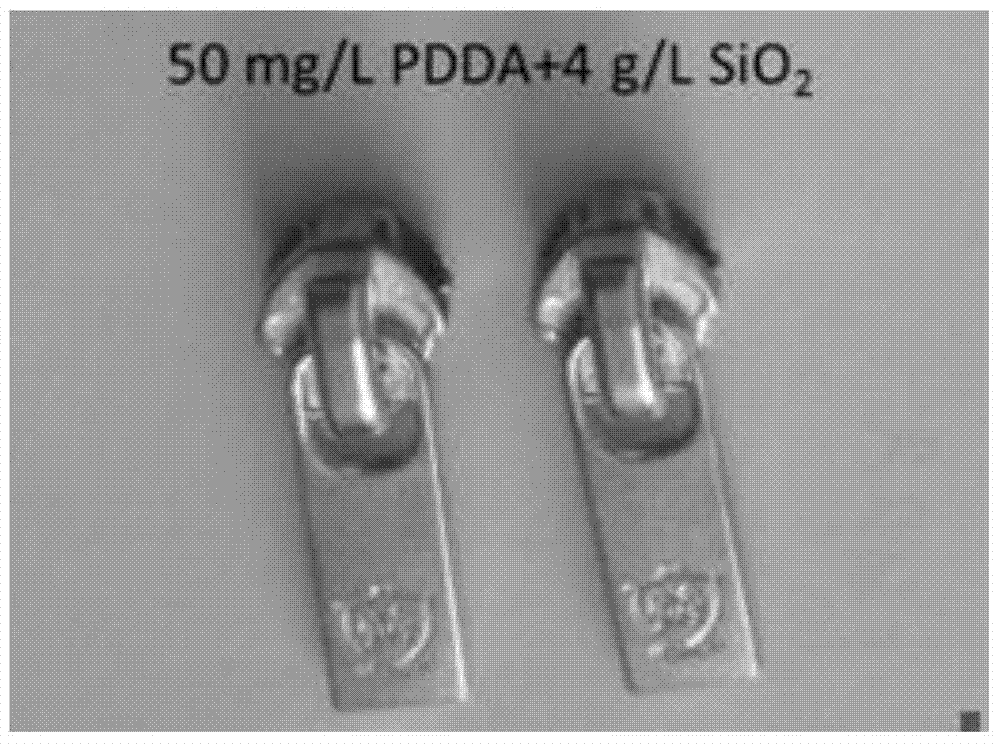

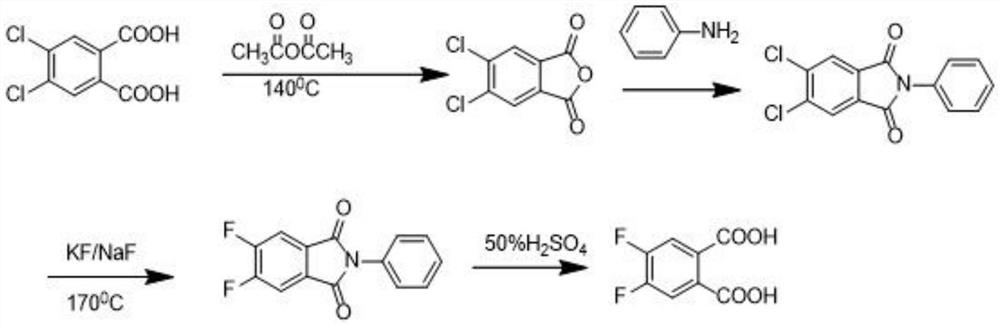

Nano-composite electroplating solution, preparing method of nano-composite electroplating solution and zinc alloy electroplated part

ActiveCN105463534AInhibit growthImprove corrosion resistanceSlide fastenersElectrolytic coatingsPorositySodium potassium tartrate tetrahydrate

The invention provides a nano-composite electroplating solution. The nano-composite electroplating solution is prepared from, by concentration, 23-26 g / L of cuprous cyanide, 10-12 g / L of zinc cyanide, 43-51 g / L of sodium cyanide, 25-35 g / L of sodium carbonate, 10-20 g / L of sodium potassium tartrate tetrahydrate, 4-8 g / L of ammonium chloride, 1-4 g / L of nano SiO2 and the balance water. By adding the nano SiO2, the degree of polarization of the cathode is increased, and growth of Cu-Zn alloy grains is prevented, so that a coating is more refined and compact, the porosity of a deposited layer is decreased, the particle-reinforced metal-based composite coating is formed, and accordingly the corrosion resistance of the coating is improved. It is indicated through test results that the corrosion current of the coating is greatly decreased, and it is proved that the corrosion resistance of the nano-composite coating is obviously improved compared with a Cu-Zn alloy coating. The invention further provides a preparing method of the nano-composite electroplating solution and a zinc alloy electroplated part.

Owner:ZHEJIANG WEIXING IND DEV

The method of cyanide balance in gold concentrate zinc cyanide powder displacement gold extraction process

ActiveCN104962752BReduce consumptionImprove production conditionsProcess efficiency improvementSludgeCyanate compound

The invention discloses a method for achieving cyanide balance in a gold concentrate cyanidation and zinc powder replacement gold extraction process. According to the method, the cyanide balance, based on water and material balance, in the gold concentrate cyanidation and zinc powder replacement gold extraction process is dynamic balance and includes the balance among the input quantity, the quantity of lost cyanide which is decomposed or oxidized or deposited in the production process, the quantity of thiocyanide, cyanate, ammonia nitrogen and others which are converted into a liquid phase or solid phase, the total quantity of cyanide in discharged contaminants such as cyanide residues and cyanidation water treatment sludge or other gases or liquids and the quantity of cyanide which is destroyed by treatment in the production process but not recovered; and meanwhile the cyanide balance shows the stock of cyanide in various facilities in the production process and the quantity of cyanide which is recycled in the production process. Products of the gold concentrate cyanidation and zinc powder replacement gold extraction process are generally crude gold ingots free of cyanidation loss.

Owner:CHANGCHUN GOLD RES INST

Calcium ion battery positive electrode material and preparation method and application thereof

PendingCN111313017AIncrease working voltageRaise the electromotive forceCell electrodesSecondary cellsElectrical batteryBattery cell

The present invention relates to a calcium ion battery positive electrode material, a preparation method and applications thereof, the calcium ion battery positive electrode material comprises a positive electrode active material, a conductive agent and a binder, the positive electrode active material comprises zinc ferricyanide, and the zinc ferricyanide accounts for 60-92% by mass of the positive electrode material; preferably, the molecular formula of zinc ferricyanide is Zn<3>[Fe(CN)<6>]<2>.XH<2>O, and x is 0-10. The positive electrode active material disclosed by the invention can show arelatively high working potential, and the battery voltage can be improved, so that the energy density of the battery is improved; and meanwhile, the material is applied to the calcium ion battery andshows relatively good cycle performance.

Owner:HEFEI UNIV OF TECH

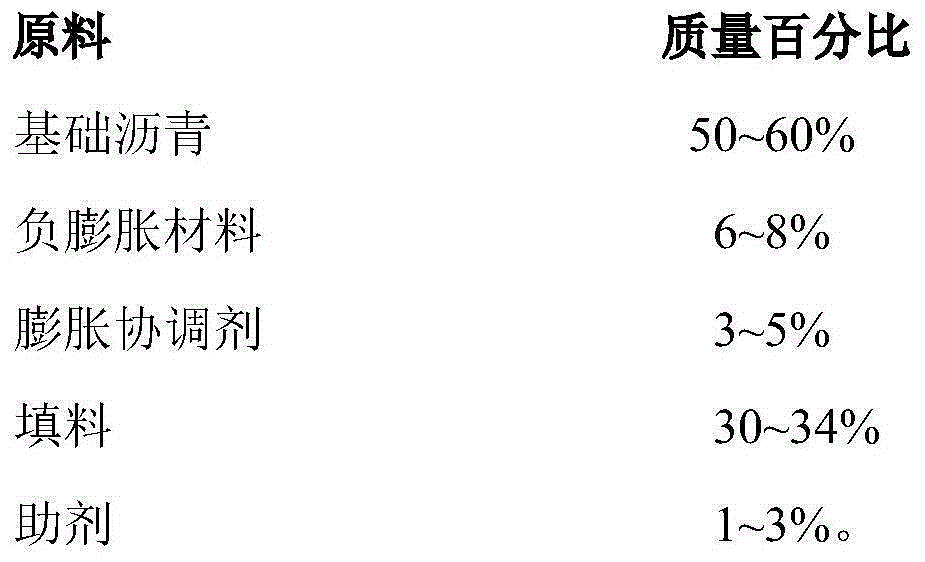

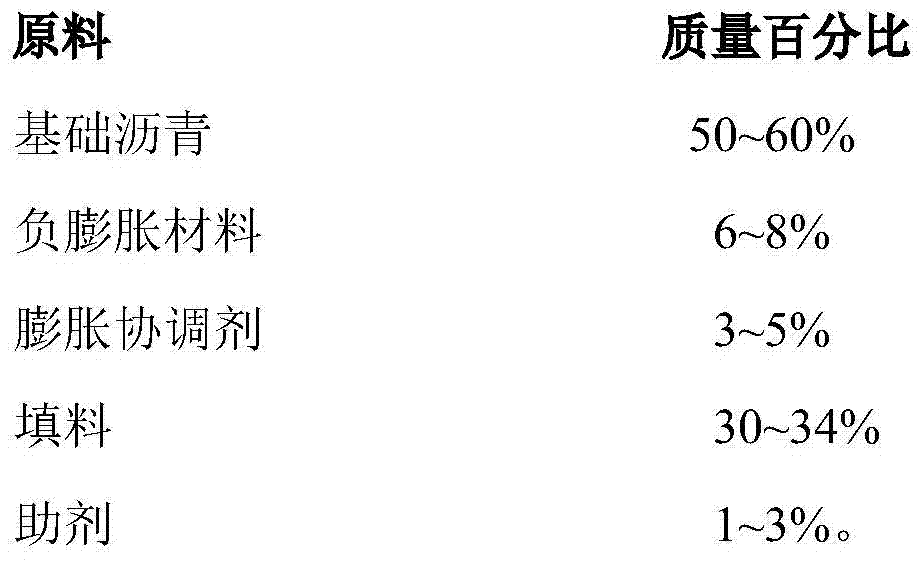

Negative thermal expansion modified asphalt caulking material

ActiveCN105111754AEfficiently regulates temperature sensitivityAdjust temperature sensitivityPaving detailsBuilding insulationsRoad surfaceCopolymer

The invention belongs to the technical field of pavement materials, and specifically discloses a negative thermal expansion modified asphalt caulking material and an application method thereof. The modified asphalt caulking material comprises the components in percentages by weight: 40-62% of base asphalt, 4-10% of negative thermal expansion materials, 3-5% of expansion coordination agents, 30-42% of filler and 1-3% of additives. The base asphalt is SBS modified asphalt, the negative thermal expansion materials are zinc cyanide, cadmium cyanide; the expansion coordination agent is zirconium phosphate sodium; the filler is calcium power, and the additives are sodium polyacrylate or polyoxyethylene polyoxypropylene copolymers. The caulking material disclosed by the invention can effectively control crack propagation caused by material thermal expansion and contraction, so that cracks in old cement concrete pavement can be effectively filled, so that the material plays a role of water resistsance, and the driving comfort can be improved. The caulking material disclosed by the invention can be popularized and applied in functional repair of old cement concrete pavement and building cracks filling engineering.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

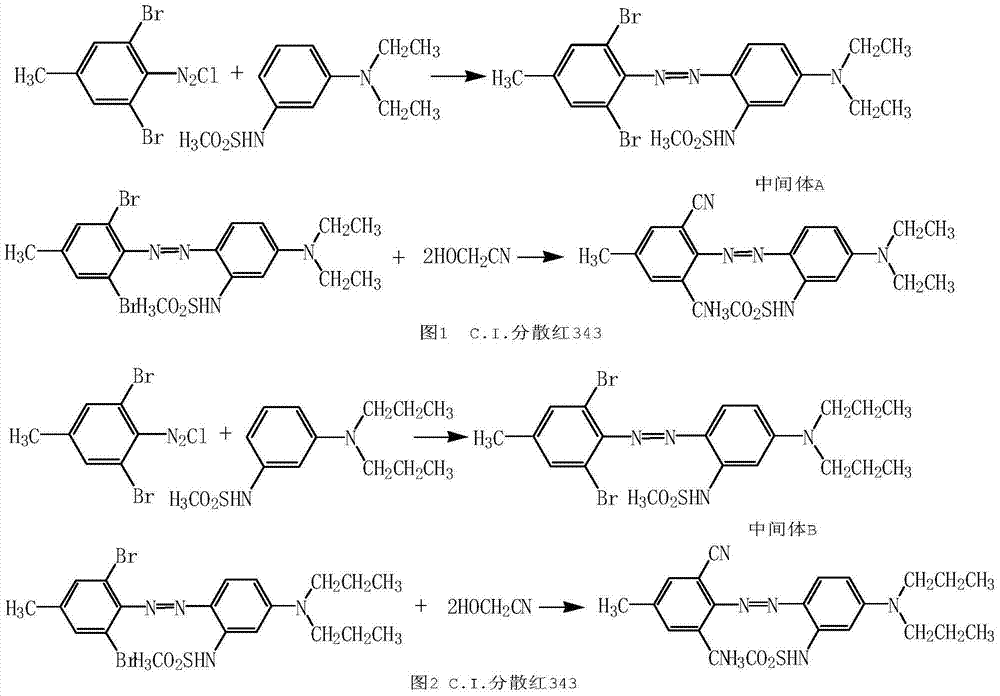

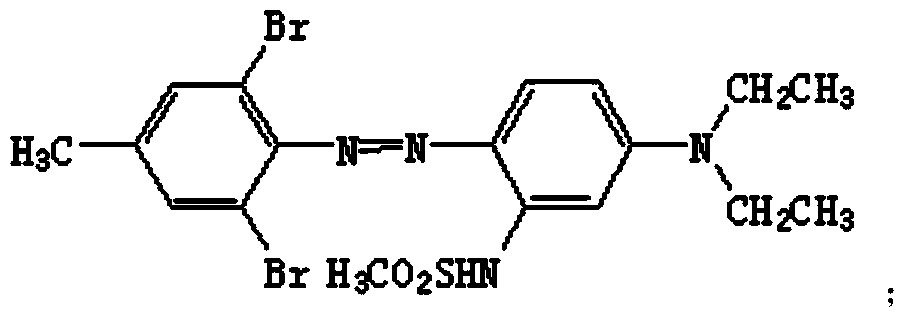

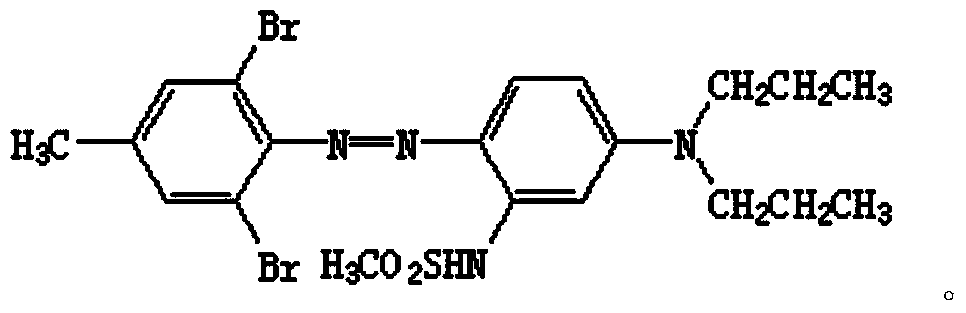

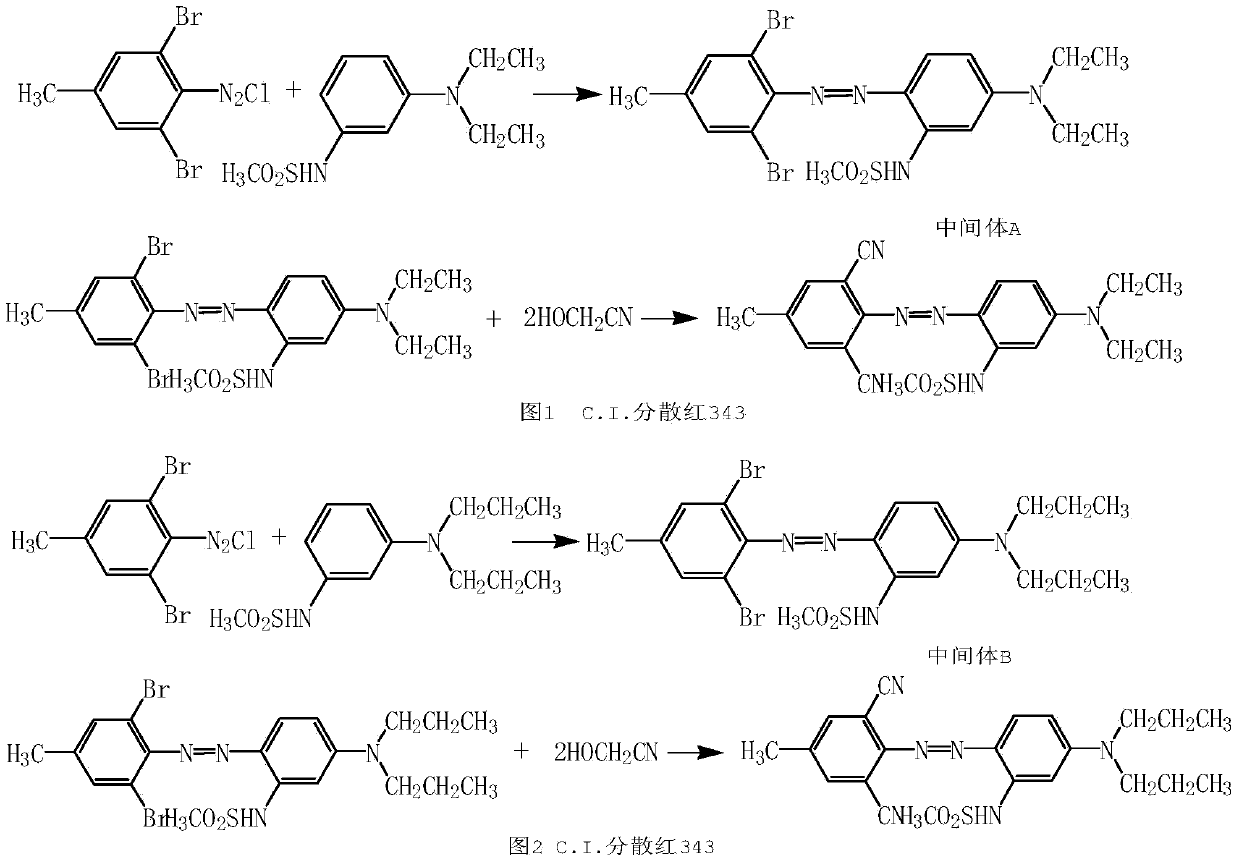

Method for producing disperse red 343

The invention provides a method for producing disperse red 343. The method specifically comprises the following step of cyaniding intermediates A and B by using cyano alcohol in a two-phase system under catalysis of a phase transfer catalyst. According to the method, the step of cyaniding the dried intermediates A and B by cuprous cyanide and zinc cyanide reagents in a DMF (Dimethyl Formamide) solvent in the conventional process is replaced, so that pollution caused by heavy metal ions in a dye is avoided. The cyaniding process is carried out by two phases, and operation of drying the intermediates A and B is omitted, so that the energy consumption and dust pollution are reduced. The method is a brand new pollution-free and environment-friendly synthetic process.

Owner:JIANGSU D I A N CHEM CO LTD

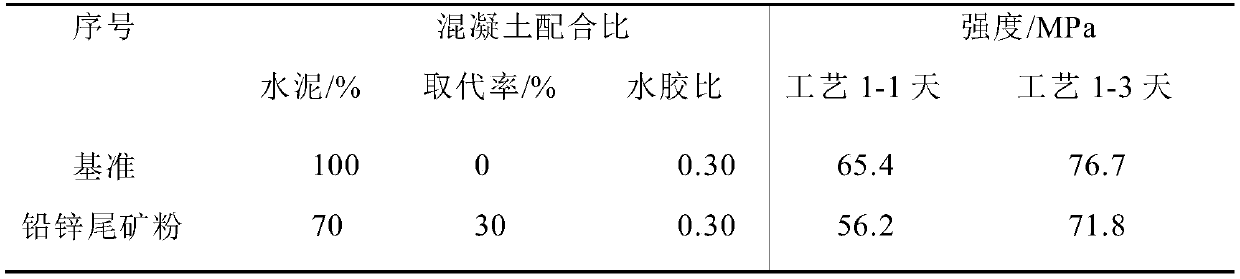

Utilizing method for utilizing tailings containing silver, lead and zinc to extract silver and waste slag of tailings containing silver, lead and zinc

InactiveCN110616324AReduce processing costsSolid waste managementProcess efficiency improvementLeadhilliteSlag

The invention belongs to the technical field of new materials, and environmental protection, and relates to a process method for preparing a precast concrete component. The process method is characterized in that silver is extracted from lead and zinc cyanide tailing powder containing a small amount of the silver through utilizing a technology, the silver is reduced in the tailing powder, and theremaining lead and zinc tailing powder is used for replacing part of cement; the method comprises the following steps that (1), lead zinc ore is subjected to cyanide extraction to generate a "package"effect on the silver in mineral powder, the content is quite high in lead and zinc cyanide tailing slag, and the risk that the lead and zinc tailing powder is applied to the precast concrete component is high, therefore, the cyanide tailing slag needs to be pretreated, and the cyanide tailing slag is ground to 200 meshes; (2), wet leaching is carried out on the cyanide tailing powder, the silveris released from the "package" through using a catalytic acidolysis iron leaching process, and cyanide leaching is achieved; (3) the lead and zinc cyanide tailing powder after reduction of the silveris dried for 5 hours to 3 days; and (4) the dry powder is admixed to cement, and the precast concrete component is made in combination with sand and gravel aggregates.

Owner:苏州重于山新材料科技有限公司

Imitation gold electroplating liquid and using method thereof

The invention discloses an imitation gold electroplating liquid. The imitation gold electroplating liquid consists of cuprous cyanide, zinc cyanide, sodium cyanide, sodium phosphate and sodium fluoride, wherein the concentration of cuprous cyanide is 70-80g / L, the concentration of zinc cyanide is 8-10g / L, the concentration of sodium cyanide is 90-110g / L, the concentration of sodium phosphate is 10-25g / L, and the concentration of sodium fluoride is 2-5g / L. The raw materials of the imitation gold electroplating liquid are readily available, and the imitation gold electroplating liquid is simple to prepare, low in cost, stable in performance and good in electroplating performance. The invention also discloses a using method of the imitation gold electroplating liquid. The using method is simple and convenient to operate, and has a good electroplating effect.

Owner:HENGYANG FENGSHUN AXLE CO LTD

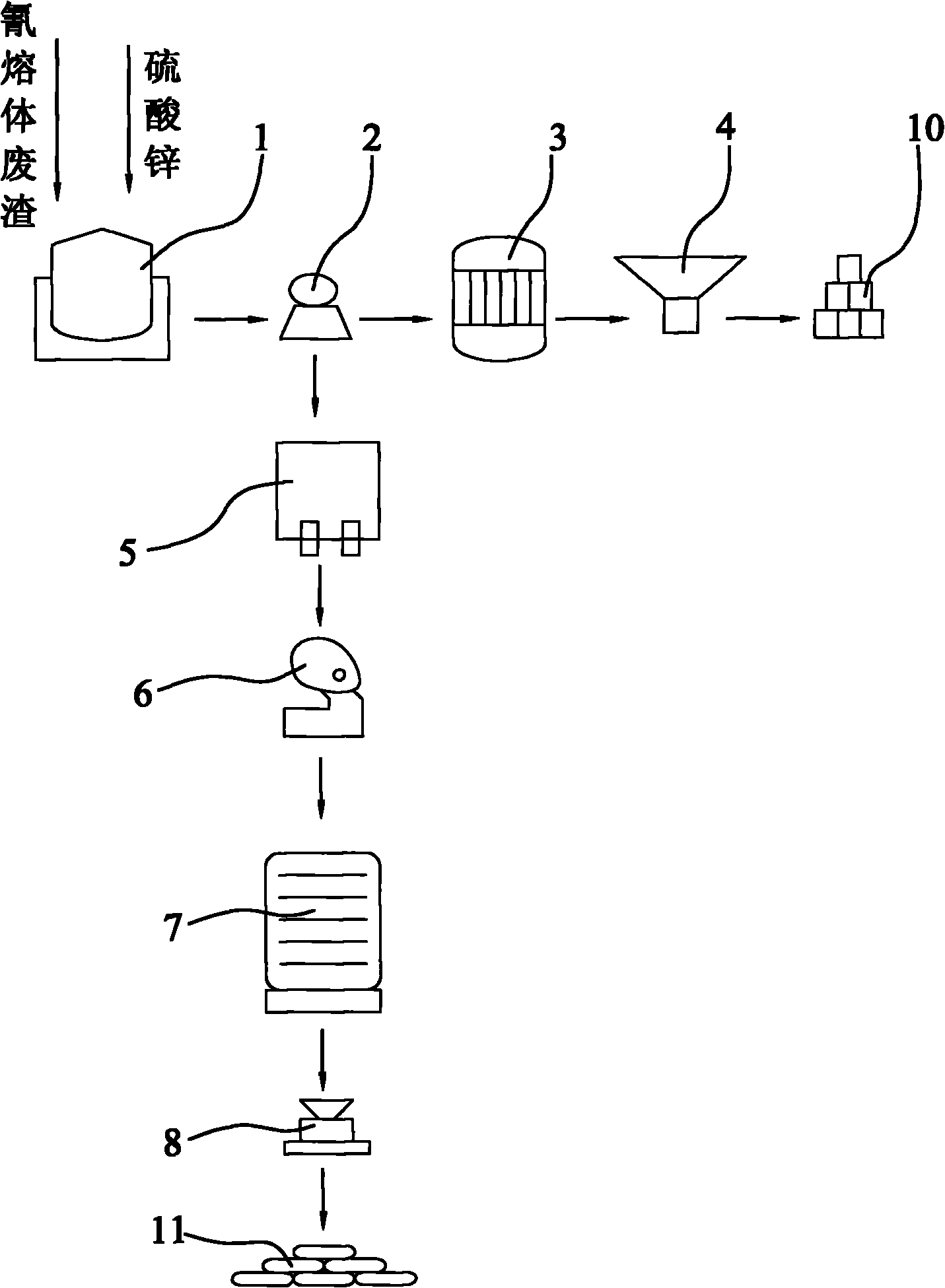

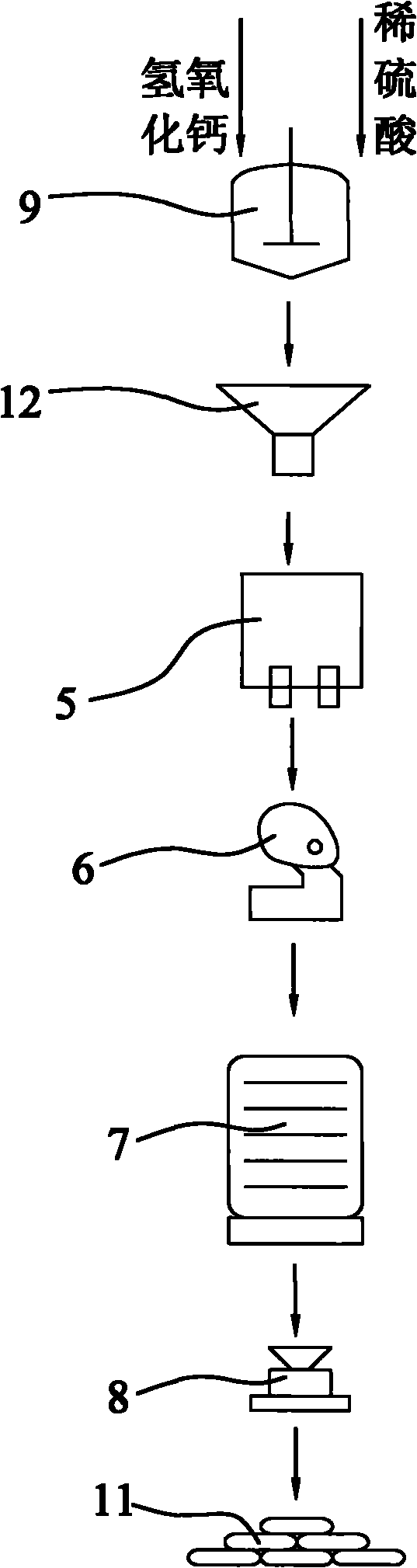

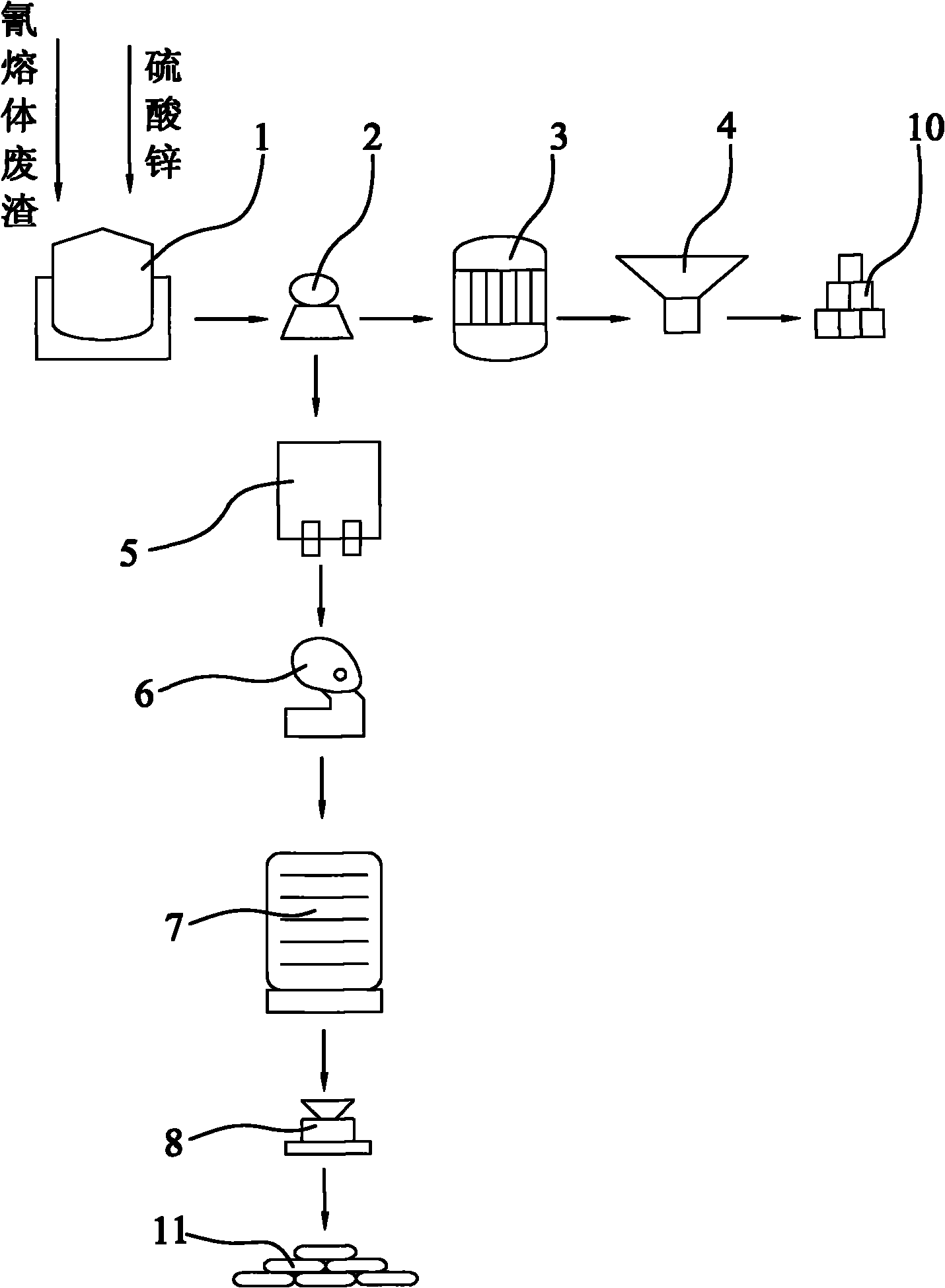

Method for preparing zinc cyanide coproduced with calcium sulfate by utilizing cyanide melt slag

InactiveCN101955194AEasy to operateLess investmentCalcium/strontium/barium sulfatesMetal cyanidesPolymer scienceChemical reaction

The invention provides a method for preparing zinc cyanide coproduced with calcium sulfate by utilizing cyanide melt slag, comprising the following specific steps: throwing the cyanide melt slag with excessive zinc sulfate with mass concentration of 5-10% into a pipe reactor to carry out chemical reaction for 2-5h under the temperature lower than 40-50 DEG C and carrying out suction filtration on the reaction products in a suction filtration pump to obtain clear cyanide filtrate and calcium sulfate filter cakes; feeding the clear cyanide filtrate into a vacuum distiller to undergo vacuum distillation at 40-50 DEG C and then cooling the distilled product to obtain mixed solution containing zinc cyanide crystals; filtering the mixed solution containing zinc cyanide crystals by a filter to obtain the zinc cyanide crystal products and dilute sulfuric acid solution; and washing the obtained calcium sulfate filter cakes in a washer, carrying out filter pressing on the calcium sulfate filter cakes by a filter press, drying the calcium sulfate filter cakes in a dryer, grinding the calcium sulfate filter cakes by a grinder and packaging the powder of the calcium sulfate filter cakes, thus obtaining the white calcium sulfate products. The method thoroughly utilizes the cyanide melt slag, ensures the content of cyanides in the cyanide melt slag to be lower than the discharge standard and creates economic value for the enterprises.

Owner:汪晋强

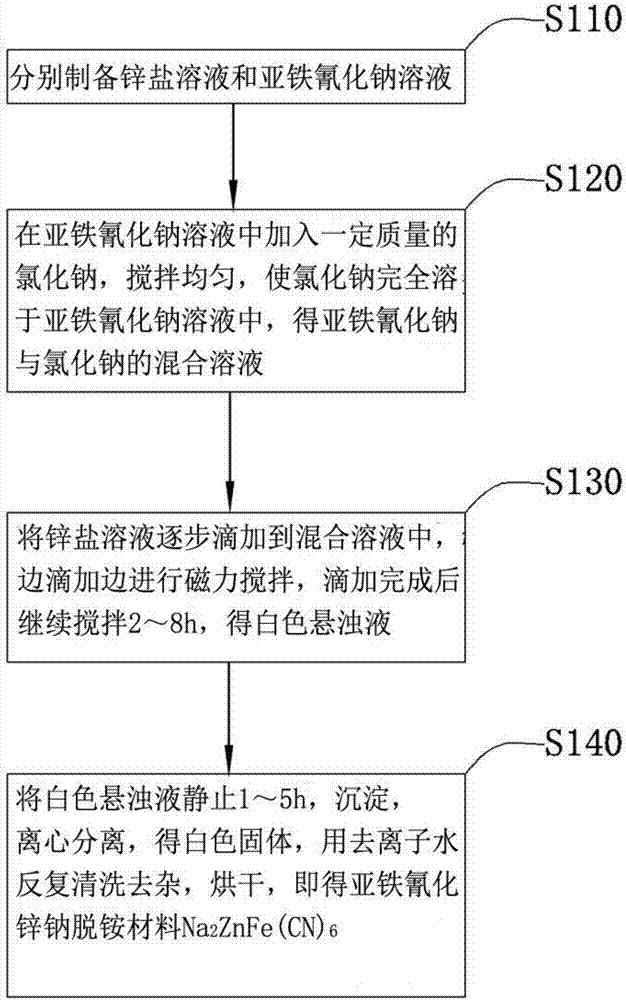

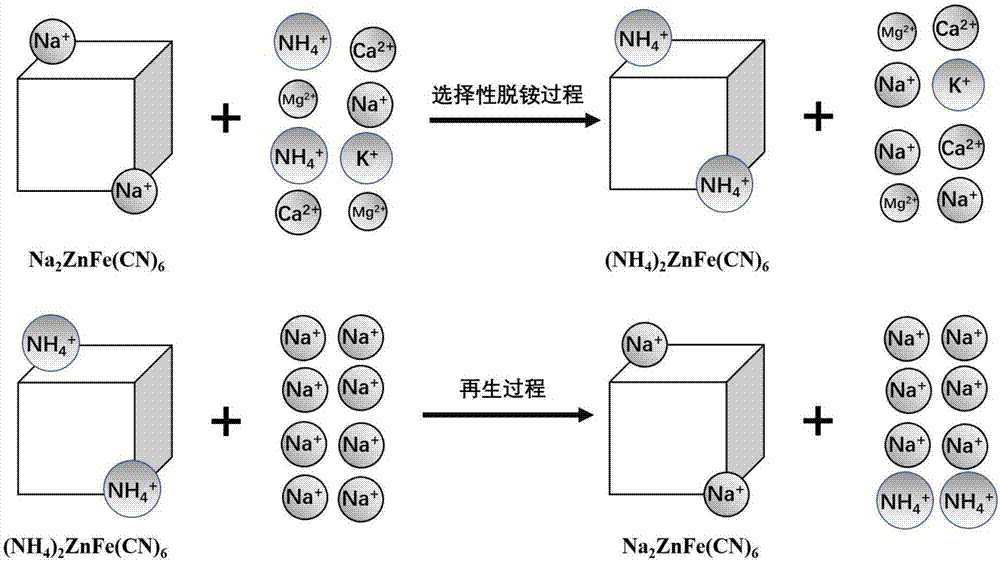

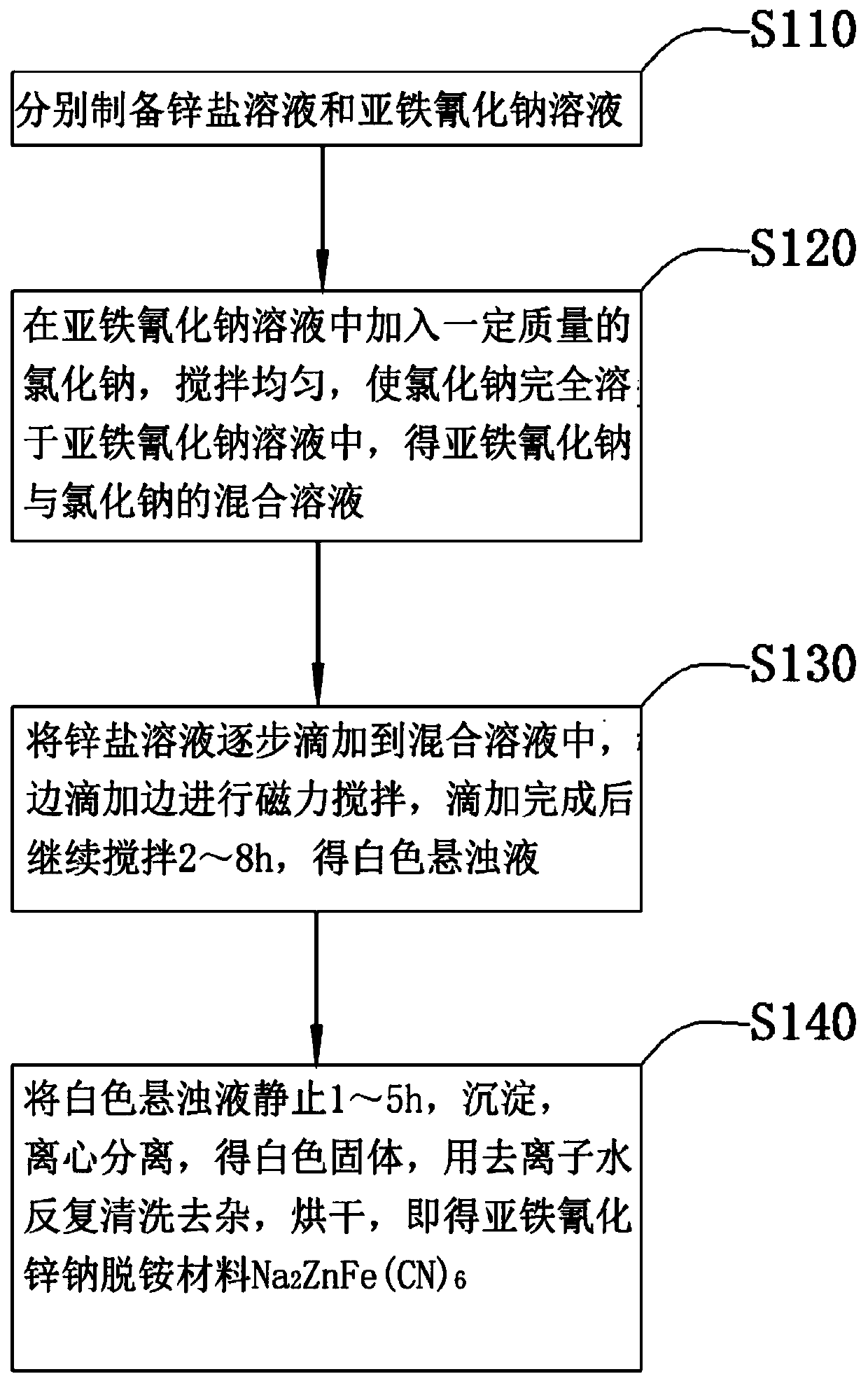

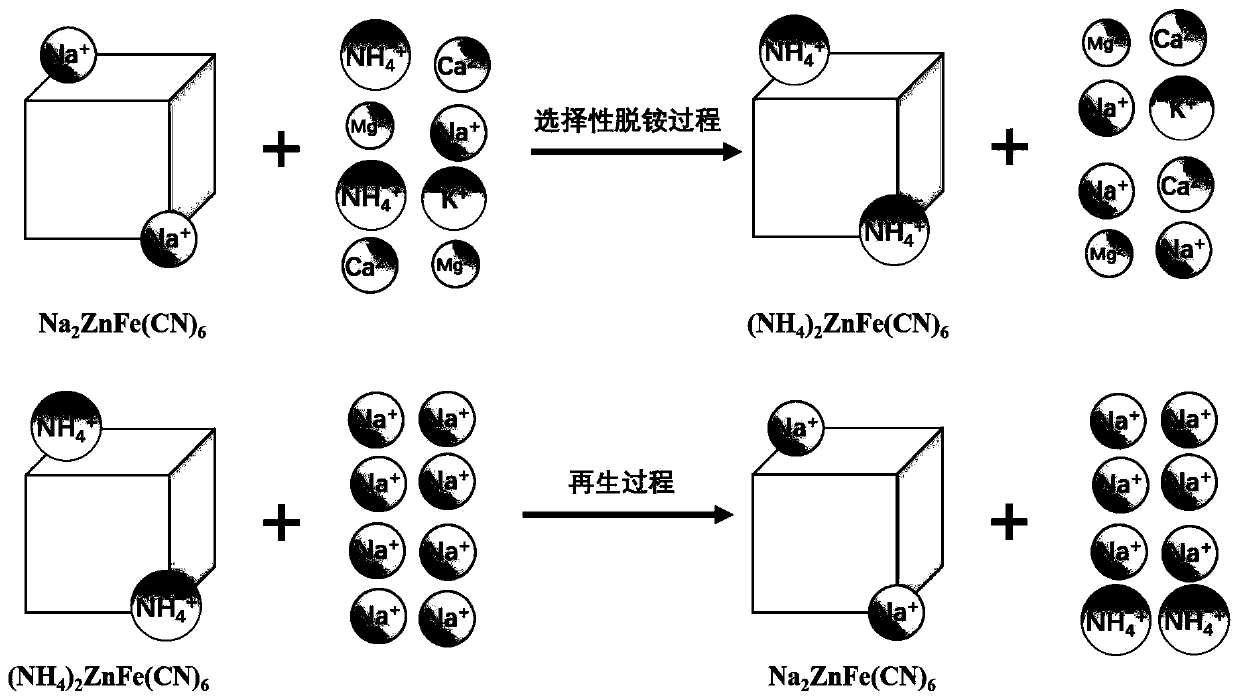

Preparation method of ammonium removing material for ferrous zinc sodium cyanide deammonium material and application of deammonium material to sewage ammonium removal

ActiveCN107486131AAdsorption capacity does not affectThe adsorption capacity has no obvious attenuationOther chemical processesWater contaminantsSodium cyanideAdsorption selectivity

The invention provides a preparation method of an ammonium removing material of ferrous zinc sodium cyanide deammonium material and application of the deammonium material to sewage ammonium removal and belongs to the technical field of the sewage ammonium removal. A chemical formula of the ferrous zinc sodium cyanide is Na2ZnFe(CN)6; the preparation method of the material comprises the following steps: preparing a zinc salt solution and a ferrous sodium cyanide solution respectively; adding a certain mass of sodium chloride into the ferrous sodium cyanide solution to completely dissolve the sodium chloride into the ferrous sodium cyanide solution, so as to obtain a ferrous sodium cyanide and sodium chloride mixed solution; gradually dropwise adding the zinc salt solution into the mixed solution; carrying out magnetic stirring while dropwise adding the zinc salt solution; after dropwise adding the zinc salt solution, continually stirring to obtain white suspension liquid; standing and precipitating; centrifuging and separating to obtain white solids; repeatedly washing the white solids with de-ionized water to remove impurities; drying to obtain the ammonium removing material Na2ZnFe(CN). The ammonium removing material provided by the invention has the advantages of large ammonium ion adsorption capability, high adsorption selectivity, low production cost and stable performance.

Owner:TIANJIN BISHUIYUAN MEMBRANE MATERIAL CO LTD

A kind of nanocomposite electroplating solution, its preparation method and zinc alloy electroplating parts

ActiveCN105463534BInhibit growthImprove corrosion resistanceSlide fastenersElectrolytic coatingsPorositySodium potassium tartrate tetrahydrate

The invention provides a nano-composite electroplating solution. The nano-composite electroplating solution is prepared from, by concentration, 23-26 g / L of cuprous cyanide, 10-12 g / L of zinc cyanide, 43-51 g / L of sodium cyanide, 25-35 g / L of sodium carbonate, 10-20 g / L of sodium potassium tartrate tetrahydrate, 4-8 g / L of ammonium chloride, 1-4 g / L of nano SiO2 and the balance water. By adding the nano SiO2, the degree of polarization of the cathode is increased, and growth of Cu-Zn alloy grains is prevented, so that a coating is more refined and compact, the porosity of a deposited layer is decreased, the particle-reinforced metal-based composite coating is formed, and accordingly the corrosion resistance of the coating is improved. It is indicated through test results that the corrosion current of the coating is greatly decreased, and it is proved that the corrosion resistance of the nano-composite coating is obviously improved compared with a Cu-Zn alloy coating. The invention further provides a preparing method of the nano-composite electroplating solution and a zinc alloy electroplated part.

Owner:ZHEJIANG WEIXING IND DEV

A kind of method adopting normal pressure method to synthesize zinc cyanurate

ActiveCN102391196BLow reaction temperatureEasy to controlOrganic chemistryPolymer scienceCyanuric acid

The invention relates to a method for synthesizing zinc cyanurate by adopting a normal pressure method. Cyanuric acid and zinc oxide are mainly used as raw materials. The method comprises the following steps of: stirring the raw materials for 1 to 2 hours at the temperature of between 50 and 120 DEG C, drying to remove moisture, crushing the materials, and thus obtaining superfine zinc cyanurate powder with good dispersibility. The zinc cyanurate can be used for modification of an azodicarbonamide (ADC) foaming agent, is suitable for foaming of multiple rubbers of PVC, XPE, EVA and the like, and is uniform in sheet foamed holes and high in whiteness.

Owner:HANGZHOU HI TECH FINE CHEM

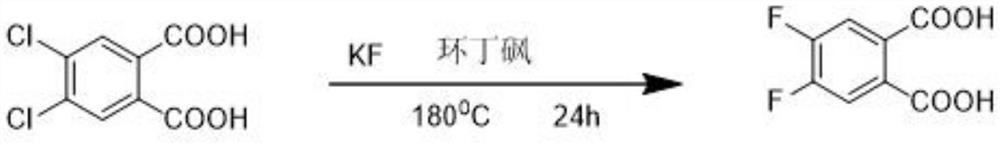

The preparation method of 4,5-difluorophthalic acid

ActiveCN112707807BLow costSafe and efficient processFinal product manufacturePreparation by cyanide reactionSodium bicarbonateBenzylideneacetone

Owner:苏州当量生物医药有限公司

Preparation method of sodium ferrocyanide zinc deammonization material and its application in deammonization of sewage

ActiveCN107486131BAdsorption capacity does not affectThe adsorption capacity has no obvious attenuationOther chemical processesWater contaminantsSodium cyanideAdsorption selectivity

Owner:TIANJIN BISHUIYUAN MEMBRANE MATERIAL CO LTD

A negative expansion modified asphalt joint filling material

ActiveCN105111754BEfficiently regulates temperature sensitivityAdjust temperature sensitivityPaving detailsBuilding insulationsAdjuvantPavement engineering

The invention belongs to the technical field of pavement material engineering, and specifically discloses a negative expansion modified asphalt joint filling material and an application method thereof. The modified asphalt joint filling material of the present invention comprises: 40-62% of base asphalt, 4-10% of negative expansion material, 3-5% of expansion coordinating agent, 30-42% of filler and 1-3% of auxiliary agent, in terms of mass percentage, Total 100%. Among them, the base asphalt is SBS modified asphalt, the negative expansion material is zinc cyanide and cadmium cyanide, the expansion coordinator is sodium zirconium phosphate, the filler is calcium powder, and the additive is sodium polyacrylate or polyoxypropylene polyoxyethylene copolymer . The joint filling material of the invention can effectively control the problem of crack expansion caused by material thermal expansion and cold contraction, effectively fill the cracks in the old cement concrete pavement, play a waterproof role, and can also improve driving comfort. The joint filling material of the invention will be popularized and applied in functional maintenance of old cement concrete pavement and crack filling projects of buildings.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

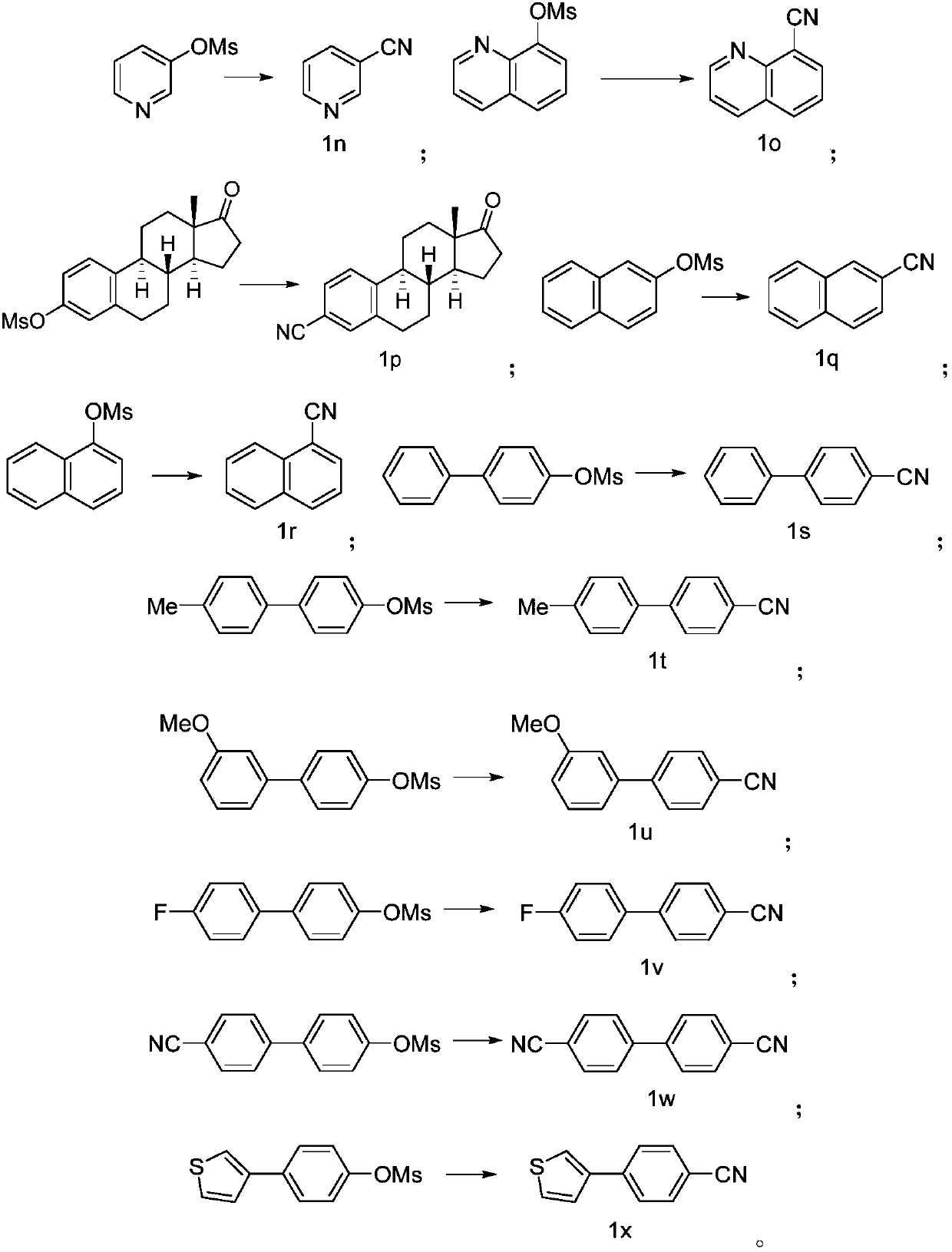

Method for synthesizing 1-(2-fluorobenzyl)-1h-pyrazolo[3,4-b]pyridine-3-formamidine hydrochloride

ActiveUS20140309425A1High yieldMild reaction conditionsOrganic chemistryChemical synthesisSynthesis methods

The present invention relates to the field of chemical synthesis, and in particular to a method for synthesizing 1-(2-fluorobenzyl)-1H-pyrazolo[3,4-b]pyridin-3-formamidine hydrochloride, which is an important intermediate of Riociguat that is an anti-thromboembolic-disease medicine. The method is characterized in that: 3-iodo-1H-pyrazolo[3,4-b]pyridine is used as a raw material; the raw material is reacted with fluorobenzyl bromide to form a compound (10); the compound (10) is reacted with zinc cyanide to form a compound (6); the compound (6) is reacted with sodium methoxide, ammonium chloride, acetic acid and methanol to form a compound (8); and the compound (8) is reacted with chlorine hydride gas to form 1-(2-fluorobenzyl)-1H-pyrazolo[3,4-b]pyridin-3-formamidine hydrochloride. The method has the characteristics of cheap and readily available raw materials, high yield, mild reaction conditions and the like, and is a synthesis method having a large-scale preparation value.

Owner:PHARMABLOCK SCIENCES (NANJING) INC

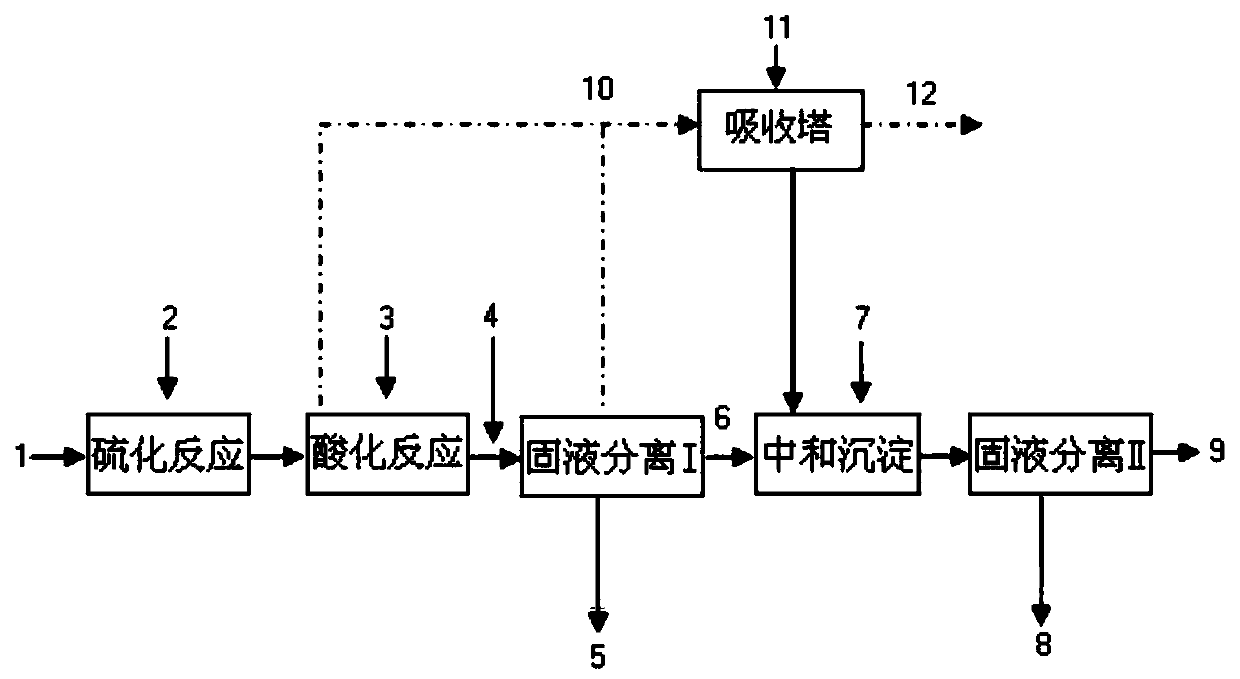

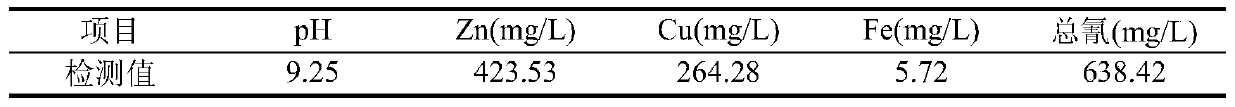

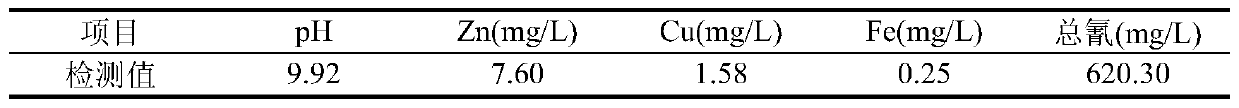

Zinc cyanide barren solution treatment method

ActiveCN105330064BEfficient removalEfficient recyclingWater contaminantsWaste water treatment from metallurgical processZinc smeltingTower

The invention relates to a method for treating zinc-containing cyanide barren solution, comprising the following process steps and conditions: sulfuration acidification reaction, first adding soluble sulfide to the zinc-containing cyanide barren solution, then adding concentrated sulfuric acid to carry out acidification reaction, and adjusting the pH value of the solution , add PAM, set aside for settling, solid-liquid separation Ⅰ, separate sediment Ⅰ, tail gas and supernatant, and transport sediment Ⅰ to the zinc smelting enterprise for comprehensive recycling; to neutralize the sediment, first add Alkali, adjust the pH value to 9.0-11.5 for neutralization and precipitation, then solid-liquid separation II, separate sediment II and tail water, sediment II and cyanide tailings are treated together, tail water is returned to the cyanide system for reuse, and tail gas recovery , send the tail gas produced in the first step to the absorption tower through negative pressure, add lye, separate the absorption liquid and empty the purified gas, and return the absorption liquid to neutralize the precipitation. It has the ability to efficiently remove Zn, Cu, Fe and other metals, efficient recovery of cyanide, toxic and harmful gas absorption treatment, comprehensive recovery of Zn and Cu in sediment, short process flow, simple and safe operation, easy to implement, etc., suitable for zinc-containing cyanide barren solution in gold smelting industry Handle the application.

Owner:ZIJIN MINING GROUP

A kind of method of producing disperse red 343

The invention provides a method for producing disperse red 343. The method specifically comprises the following step of cyaniding intermediates A and B by using cyano alcohol in a two-phase system under catalysis of a phase transfer catalyst. According to the method, the step of cyaniding the dried intermediates A and B by cuprous cyanide and zinc cyanide reagents in a DMF (Dimethyl Formamide) solvent in the conventional process is replaced, so that pollution caused by heavy metal ions in a dye is avoided. The cyaniding process is carried out by two phases, and operation of drying the intermediates A and B is omitted, so that the energy consumption and dust pollution are reduced. The method is a brand new pollution-free and environment-friendly synthetic process.

Owner:LEPING SAFELY PHARMA

Method for preparing immobilized enzyme based on reaction adsorption method

ActiveCN106148319BIncrease the number of reusesOvercome the disadvantage of easy falling offOn/in organic carrierOn/in inorganic carrierCalcium bicarbonatePhytic acid

The invention discloses a method for preparing immobilized enzyme based on a reactive adsorption method, and relates to the technical field of bionts. The method comprises the following steps: enabling reaction between two or more compounds in an enzyme-containing aqueous solution, and adsorbing and wrapping enzyme molecules by precipitates in a process of forming one or more precipitates such as calcium phosphate, calcium hydrogen phosphate, calcium carbonate, calcium hydrogen carbonate, aluminum hydroxide, calcium phytic acid, zinc ferrocyanide and chitosan organic matters to prepare the immobilized enzyme. The method is an improved adsorption method, aims to increase the bonding force between a carrier and the enzyme and to overcome the shortcoming that the immobilized enzyme has high probability of falling off, has the characteristics of simple operation, low cost and stable enzyme activity, and is worthy of being popularized and applied.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

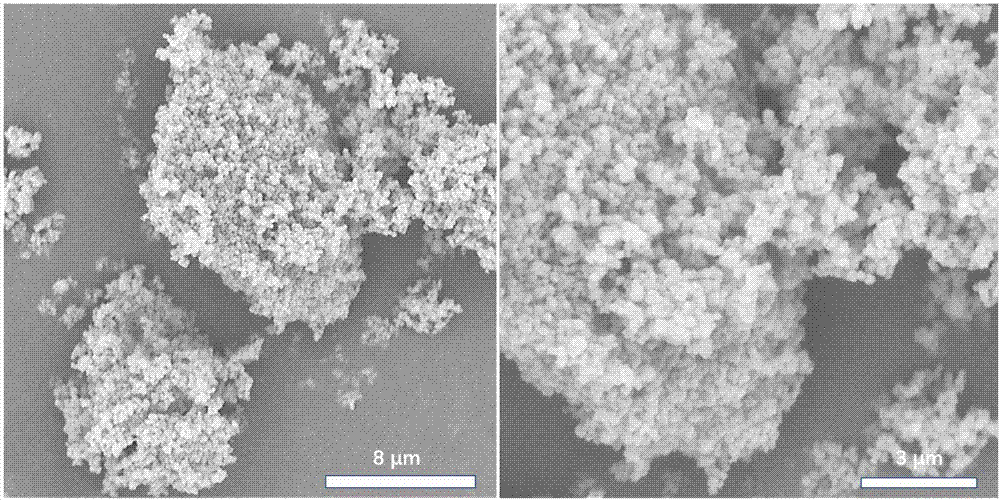

Method for preparing zinc cyanide nanomaterials by using non-toxic raw materials

InactiveCN101780967BShort reaction timeEnergy based chemical/physical/physico-chemical processesMetal cyanidesGraphiteProcess conditions

The invention provides a method for preparing zinc cyanide nanomaterials by using non-toxic raw materials, which adopts improved technological conditions and preparation technology that uses arc discharge to generate plasma, zinc granule and graphite as anode consumption components, and the graphite as cathode. The preparation is carried out in atmosphere of argon and ethanol; after the preparation, vacuumizing is carried out immediately; then air is insufflated for passivating for 1-300 hours, and finally powder depositing on a working chamber wall is collected. By using the method, zinc cyanide of nanometer size and zinc cyanide / zinc nano powder materials can be obtained steadily in large bulk. The preparation method of the invention uses the non-toxic raw materials and has short reaction time, thus being a fast and environment-friendly preparation method.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A method for catalytic thermal decomposition to remove zinc cyanide complex

InactiveCN110090385BAvoid pollutionNo secondary pollutionDispersed particle separationPtru catalystPhysical chemistry

Owner:NORTHEASTERN UNIV LIAONING

A kind of preparation method of topicastat

The invention relates to a preparation method of topiroxostat, which comprises the following steps: reacting an initial raw material compound isoniazide disclosed as Formula (6) with a compound 4-cyano-pyridyl-N-oxide disclosed as Formula (5) to generate a triazole compound disclosed as Formula (4), reacting the triazole compound disclosed as Formula (4) in the presence of a copper catalyst (CuX), zinc cyanide (Zn(CN)2) and dimethylamino formyl chloride to generate a cyanotriazole compound disclosed as Formula (3), reacting the compound disclosed as Formula (3) in the presence of p-toluenesulfonic acid to generate a compound disclosed as Formula (2), and finally, alkalifying with inorganic alkali to obtain the target compound disclosed as Formula (1) (topiroxostat). The method is simple in operation and after-treatment, and greatly lowers the consumption of the zinc cyanide due to the use of the copper catalyst, so that the reaction conditions are milder, and the purity of the prepared product is high; and the method is suitable for industrial production.

Owner:于宗光

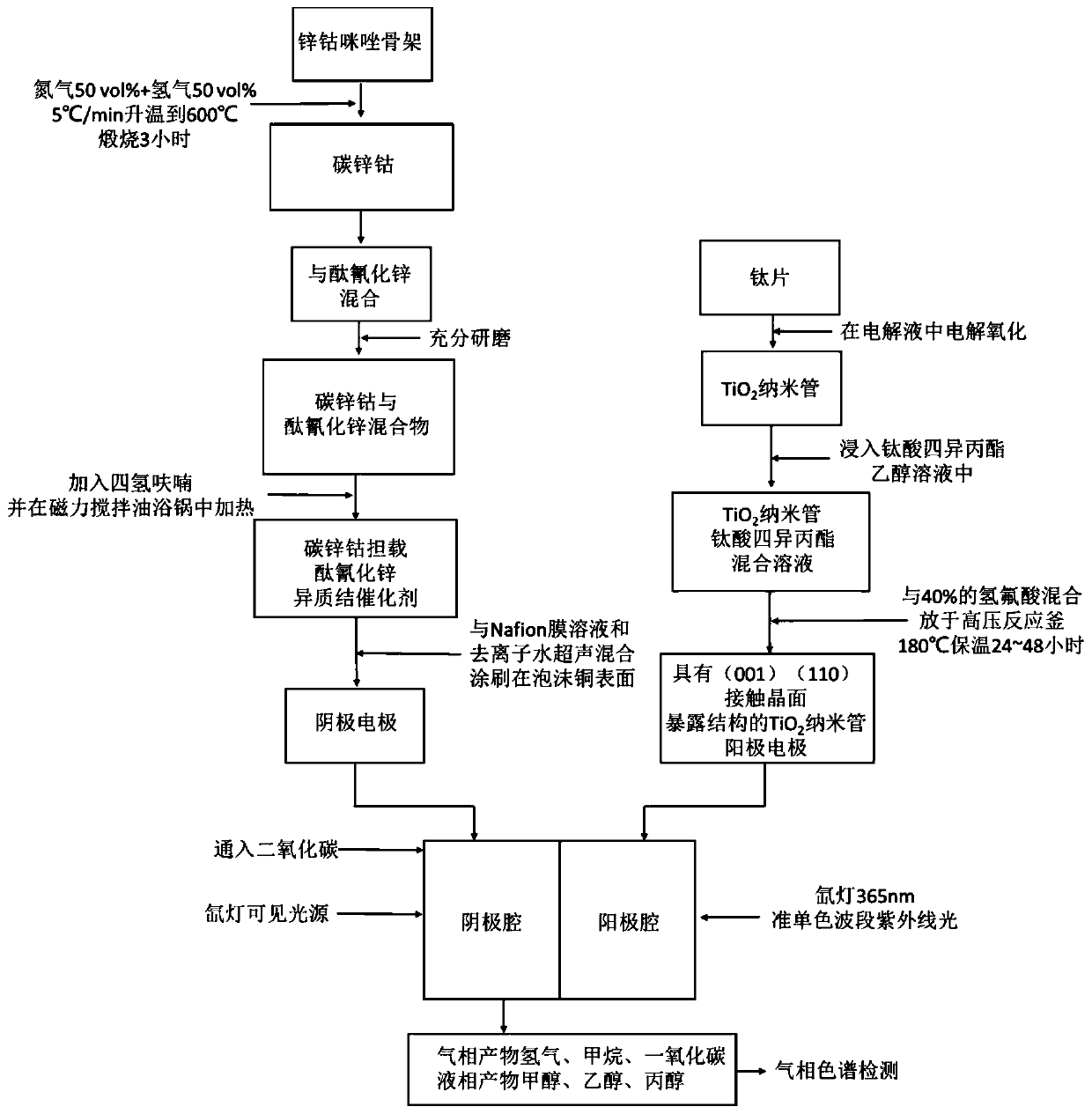

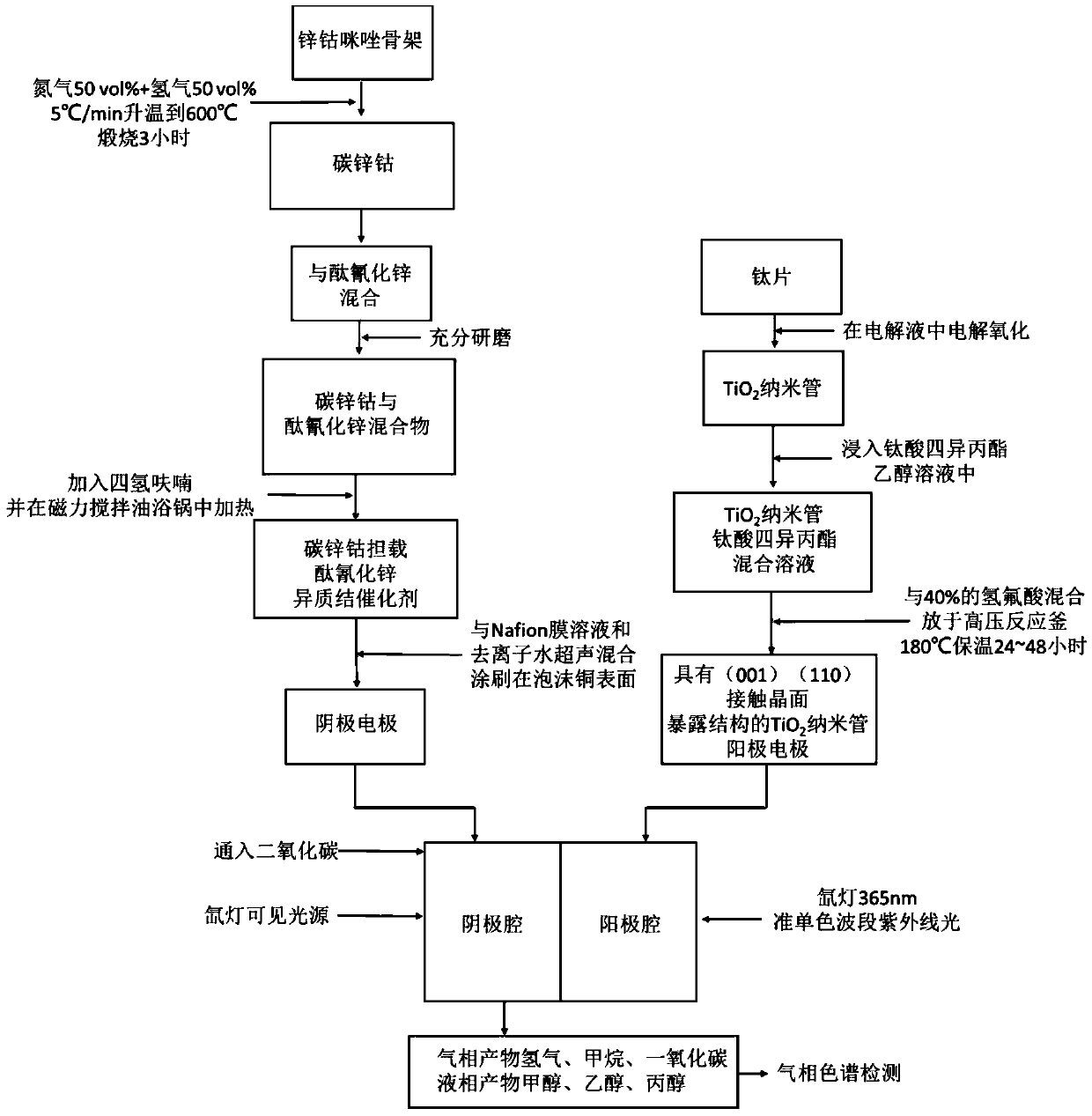

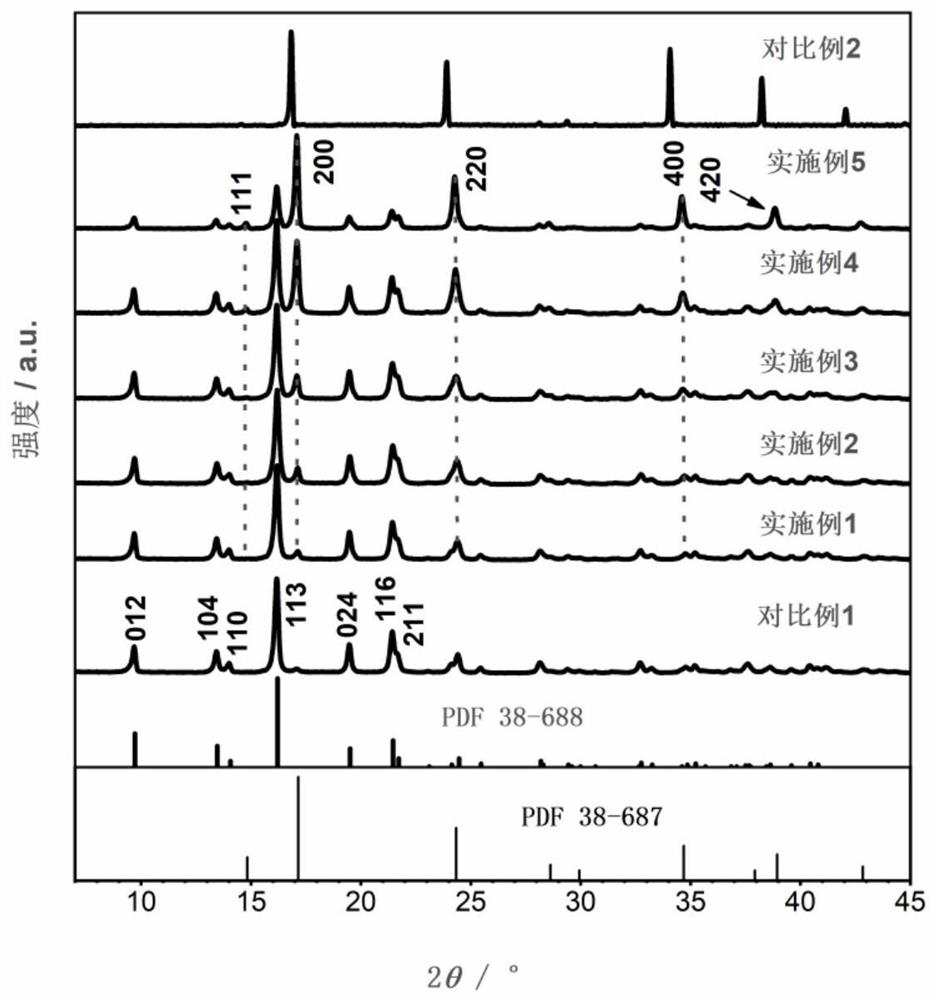

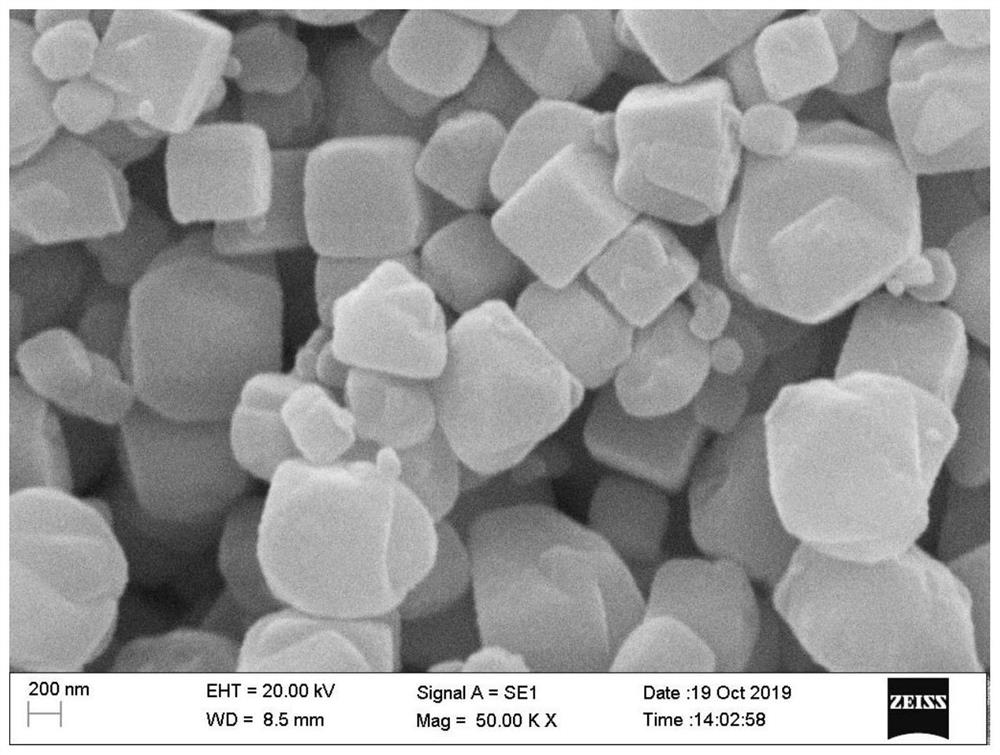

Carbon-zinc-cobalt-supported zinc phthalocyanide heterojunction catalyst for double-light reduction of co 2 Methods

ActiveCN109402652BReduce side effectsImprove separation efficiencyElectrolytic organic productionElectrode shape/formsHeterojunctionLiquid product

The present invention relates to CO 2 The gas conversion and utilization technology aims to provide a carbon-zinc-cobalt-supported zinc phthalocyanide heterojunction catalyst for double-light reduction of CO 2 Methods. Including: porous carbon-zinc-cobalt-supported zinc phthalocyanide heterojunction catalyst as the coating material of the cathode electrode, TiO 2 The anode electrode is made of nanotubes; the dual-light reactor adopts a transparent cavity, and the cathode electrode and the anode electrode are respectively installed, and the middle is separated by a Nafion film; the anode electrode is irradiated by the 365nm quasi-monochromatic band light of the xenon lamp, and the cathode electrode is irradiated by the visible light of the xenon lamp; Add saturated NaCl aqueous solution, add saturated NaHCO in the cathode chamber 3 aqueous solution, the CO 2 into the cathode chamber for double photoreduction reaction; the liquid products in the cathode chamber include methanol, ethanol and propanol, and the gaseous products in the cathode chamber include H 2 、CH 4 and CO. The present invention improves the CO 2 The selectivity of the reduction to liquid alcohol products; the separation efficiency of photogenerated electron-holes is improved and their recombination is inhibited, so that the double photoreduction of CO 2 The overall conversion efficiency of the reaction was increased by 50%.

Owner:ZHEJIANG UNIV

A beneficiation method for comprehensive recovery of combined silver and copper from low-grade manganese-bearing ores

ActiveCN111411224BAchieve chemical dissociationLow costProcess efficiency improvementManganeseSilver ion

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Manganese-doped modified zinc-ion battery cathode active material and its preparation method and application

ActiveCN111732112BImprove cycle performanceImprove cycle stabilityIron cyanidesSecondary cellsZinc compoundsManganese doping

The invention relates to a manganese-doped and modified zinc-ion battery cathode active material and its preparation method and application. The cathode active material comprises manganese zinc ferricyanide, and the X-ray diffraction spectrum of manganese zinc ferricyanide is at diffraction angle 2θ=9.68 °, 13.42°, 14.00°, 14.78°, 16.16°, 17.08°, 19.46°, 21.42°, 21.64°, 24.26°, 34.60° and 38.82° have absorption peaks, and the 2θ error is ±0.2; preferably, ferricyanide Manganese zinc is prepared by a method comprising the following steps: the zinc salt solution, the manganese salt solution and the ferricyanide ion solution are blended and then reacted. The positive electrode active material of the invention can improve the performance of the zinc ferricyanide positive electrode active material, and obviously improve the cycle stability of the positive electrode material.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for synthesizing 1-(2-fluorobenzyl)-1h-pyrazolo[3,4-b]pyridine-3-formamidine hydrochloride Method for synthesizing 1-(2-fluorobenzyl)-1h-pyrazolo[3,4-b]pyridine-3-formamidine hydrochloride](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/5fa76047-38cf-4cba-93e0-3e1d8ba116ca/US20140309425A1-20141016-C00001.png)

![Method for synthesizing 1-(2-fluorobenzyl)-1h-pyrazolo[3,4-b]pyridine-3-formamidine hydrochloride Method for synthesizing 1-(2-fluorobenzyl)-1h-pyrazolo[3,4-b]pyridine-3-formamidine hydrochloride](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/5fa76047-38cf-4cba-93e0-3e1d8ba116ca/US20140309425A1-20141016-C00002.png)

![Method for synthesizing 1-(2-fluorobenzyl)-1h-pyrazolo[3,4-b]pyridine-3-formamidine hydrochloride Method for synthesizing 1-(2-fluorobenzyl)-1h-pyrazolo[3,4-b]pyridine-3-formamidine hydrochloride](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/5fa76047-38cf-4cba-93e0-3e1d8ba116ca/US20140309425A1-20141016-C00003.png)