Method for preparing zinc cyanide nanomaterials by using non-toxic raw materials

A nano-material, zinc cyanide technology, applied in the field of green preparation, can solve the problem of toxic reaction time and achieve the effect of short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

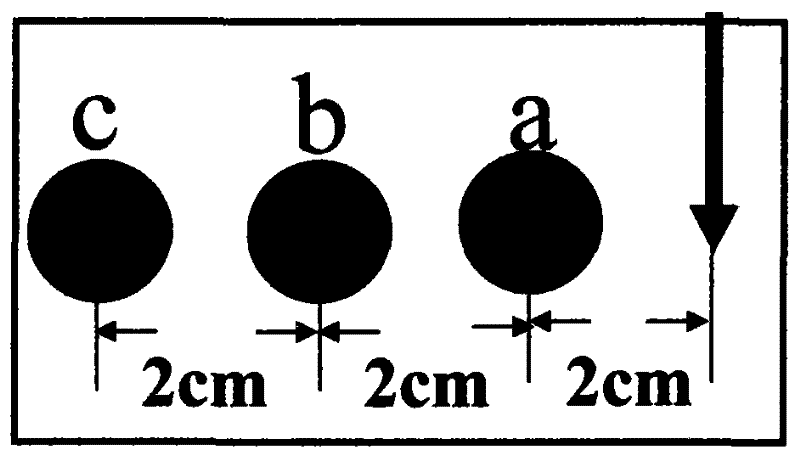

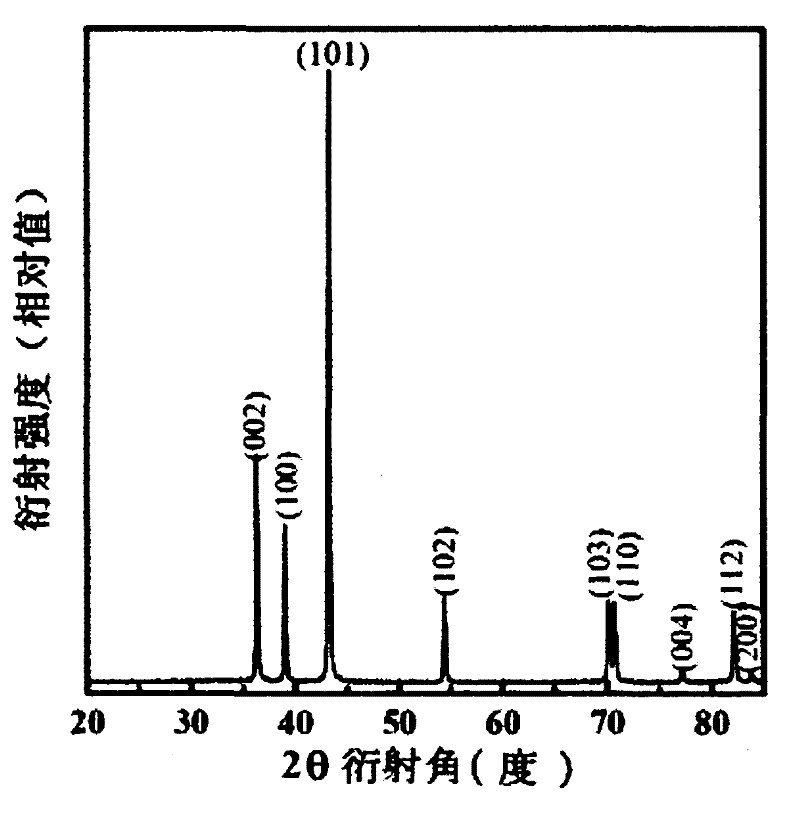

Embodiment 1

[0032] Zinc particles with a particle size of 1 micron to 1 mm are pressed into shape at a pressure of 1 MPa to 2 GPa. The pressed block is used as raw material, the pressure of argon is 0.05Mpa, the cathode used is graphite, and the volume of the studio is about 70dm 3 , add 25 milliliters of ethanol as carbon source, the electric current that produces electric arc discharge is 100A, and voltage is 12~28V. The distance between the zinc raw material and the arc starting point is 2 cm, that is, placed with figure 1 Shown at a. After the arc is extinguished, put in the air for passivation, the passivation time is 5 hours, and the hexagonal zinc / cubic zinc cyanide nanopowder material is deposited on the water cooling wall. image 3 It is the X-ray diffraction spectrum of the hexagonal zinc / cubic zinc cyanide nanopowder material deposited on the water wall, and the diffraction peak marked as zinc in the figure. The small peak at about 21° is zinc cyanide. Figure 4 It is a sca...

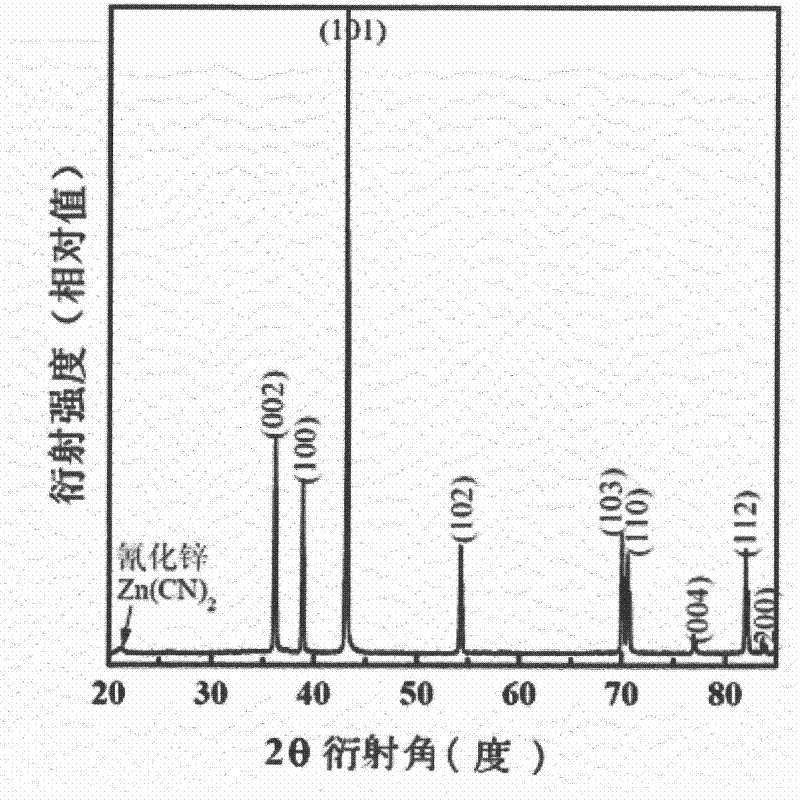

Embodiment 2

[0034] Zinc particles with a particle size of 1 micron to 1 mm are pressed into shape at a pressure of 1 MPa to 2 GPa. The pressed block is used as raw material, the pressure of argon is 0.05Mpa, the cathode used is graphite, and the volume of the studio is about 70dm 3 , adding 25 ml of alcohol as a carbon source, the current of arc discharge is 60A, and the voltage is 12-28V. The distance between the zinc raw material and the arc starting point is 2 cm, that is, placed with figure 1 Shown at a. After the arc is extinguished, put in the air for passivation, the passivation time is 5 hours, and the hexagonal zinc / cubic zinc cyanide nanopowder material is deposited on the water cooling wall. Figure 5 It is the X-ray diffraction spectrum of the hexagonal zinc / cubic zinc cyanide nanopowder material deposited on the water wall, and the diffraction peak marked as hexagonal zinc in the figure. The small peak indicated by the arrow is cubic zinc cyanide. Figure 6 It is a scanni...

Embodiment 3

[0036] Zinc particles with a particle size of 1 micron to 1 mm are pressed into shape at a pressure of 1 MPa to 2 GPa. The pressed block is used as the raw material, the argon pressure is 0.05Mpa, the cathode used is graphite, 25ml of alcohol is added as the carbon source, the arc discharge current is 100A, and the voltage is 12-28V. The distance between the zinc raw material and the arc starting point is 6 cm, that is, place the figure 1 Shown at c. After the arc is extinguished, put in the air for passivation, the passivation time is 5 hours, and the cubic zinc cyanide / hexagonal zinc nanopowder material deposited on the water wall. Figure 9 It is the X-ray diffraction spectrum of the zinc cyanide / zinc nanopowder material deposited on the upper cover, and the diffraction peak marked as cubic zinc cyanide is shown in the figure. The small peak indicated by the arrow is hexagonal zinc. It is clear that cubic zinc cyanide is the main product. Figure 10 It is a scanning ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com