Nano-composite electroplating solution, preparing method of nano-composite electroplating solution and zinc alloy electroplated part

A nano-composite, electroplating solution technology, applied in fasteners, electrolytic coatings, sliding fastener components, etc., can solve problems such as poor corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a kind of preparation method of nanocomposite electroplating solution, comprises the following steps:

[0042] Cuprous cyanide, zinc cyanide, sodium cyanide, sodium carbonate, potassium sodium tartrate, ammonium chloride and nano-SiO 2 Mix with water to obtain the above nanocomposite electroplating solution. In the present invention, cuprous cyanide, zinc cyanide, sodium cyanide, sodium carbonate, potassium sodium tartrate, ammonium chloride and water are preferably prepared to obtain the first mixed solution, and then a small amount of mixed solution is mixed with dispersant and silicon dioxide to obtain The second mixed solution is ultrasonically dispersed after being stirred and mixed, and finally the second mixed solution is added to the first mixed solution to obtain a nanocomposite electroplating solution. The nanocomposite electroplating solution that makes according to the above method is the nanocomposite electroplating soluti...

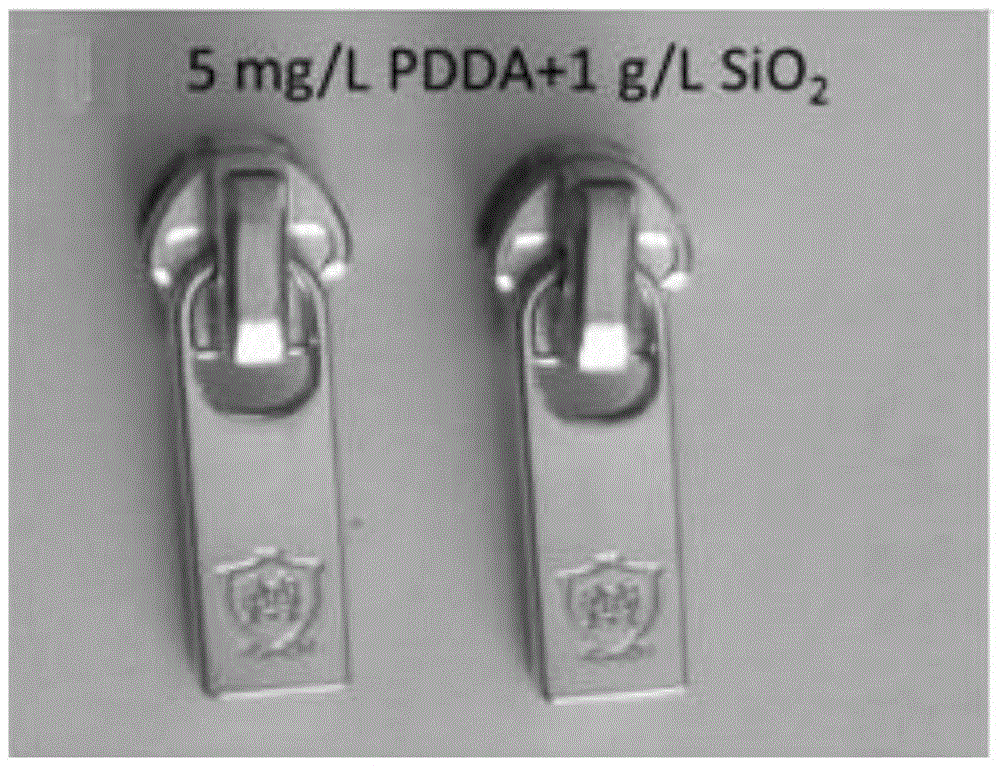

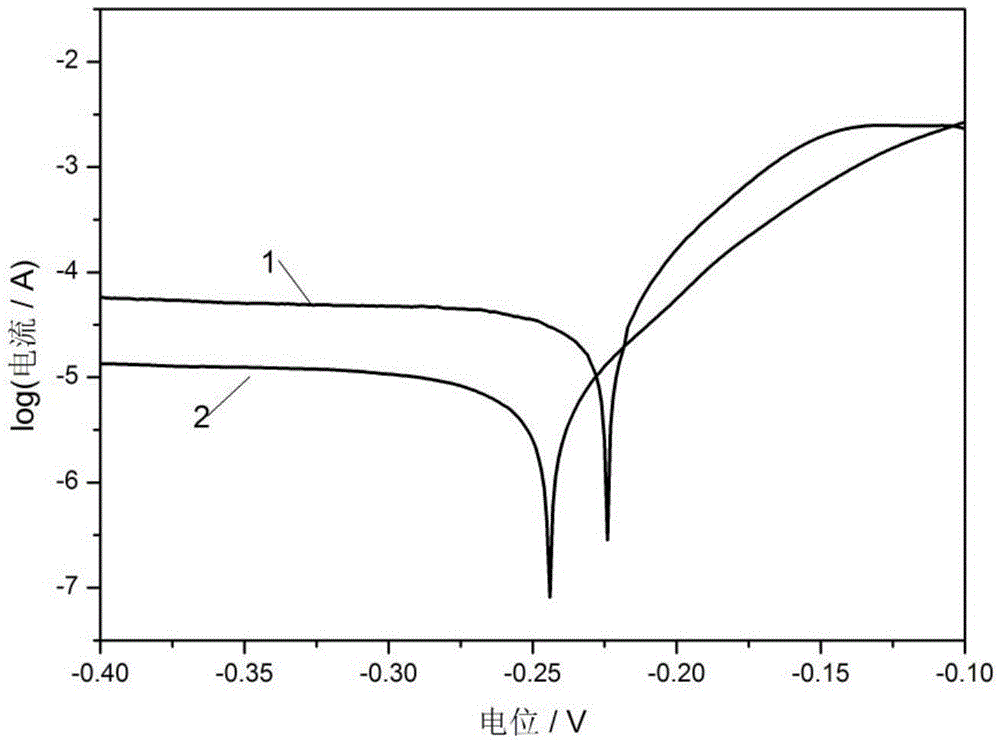

Embodiment 1

[0055] Preparation of nanocomposite electroplating solution: wherein, the concentration of cuprous cyanide is 25g / L, the concentration of zinc cyanide is 11g / L, the concentration of sodium cyanide is 47g / L, the concentration of sodium carbonate is 30g / L, and the concentration of sodium potassium tartrate is 10g / L, ammonium chloride concentration is 6g / L, nano-SiO 2 Particle size is 15±5nm, nano SiO 2 The concentration is 1g / L, and the PDDA concentration is 5mg / L.

[0056] The preparation method is as follows: first configure the composition without dispersant and nano-SiO according to the ratio of the above components 2 Copper-zinc electroplating solution (preparation method is the same as comparative example 1), gets a small amount of electroplating solution and adds dispersant again, then adds nano-SiO 2 Particles, stirred for 10 minutes, ultrasonically dispersed for 60 minutes after mixing, and finally this containing dispersant and nano-SiO 2 A small amount of electrop...

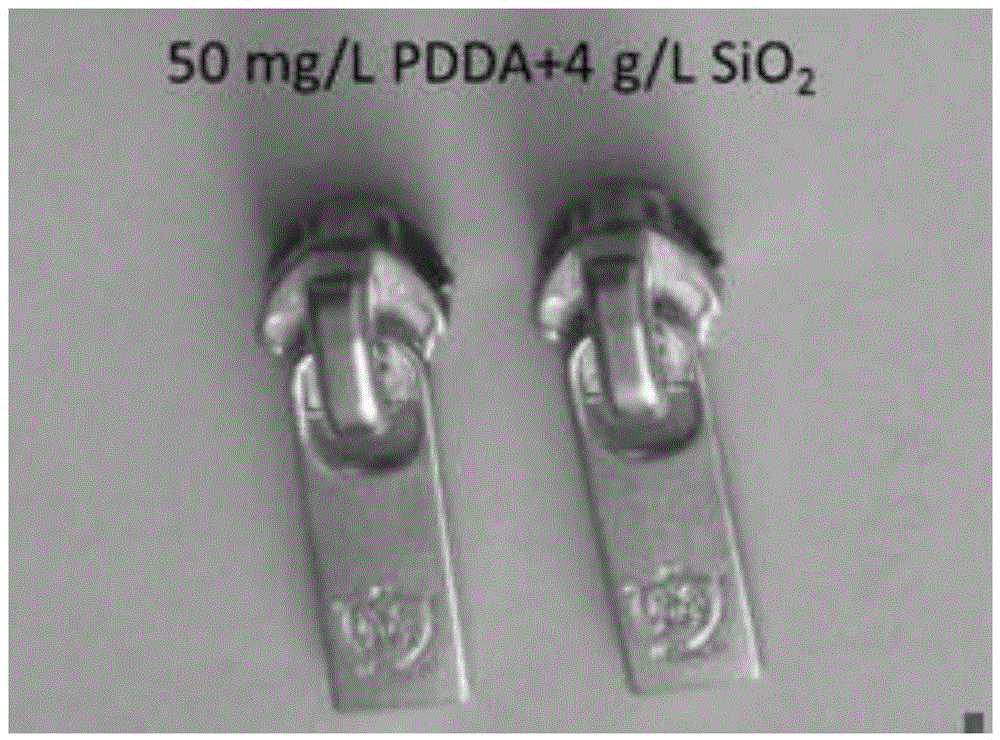

Embodiment 2

[0061] Prepare the nanocomposite electroplating solution with following proportioning according to the method in embodiment 1: cuprous cyanide concentration is 25g / L, and zinc cyanide concentration is 11g / L, and sodium cyanide concentration is 47g / L, and sodium carbonate concentration The concentration of sodium potassium tartrate is 30g / L, the concentration of potassium sodium tartrate is 10g / L, the concentration of ammonium chloride is 6g / L, and nano-SiO 2 Particle size is 15±5nm, nano SiO 2 The concentration is 4g / L, and the PDDA concentration is 50mg / L.

[0062] Put the prepared electroplating solution into the electroplating tank whose anode is a copper-zinc alloy plate, adjust the temperature controller to make the temperature in the tank 35°C, adjust the pH of the plating solution to 12 through a pH meter, and adjust the current valve so that the temperature of the electroplating solution is The current density is 0.5A / dm 2 , and then put the zinc alloy zipper head in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com