Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

146 results about "Uniform property" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In the mathematical field of topology a uniform property or uniform invariant is a property of a uniform space which is invariant under uniform isomorphisms. Since uniform spaces come as topological spaces and uniform isomorphisms are homeomorphisms, every topological property of a uniform space is also a uniform property. This article is (mostly) concerned with uniform properties that are not topological properties.

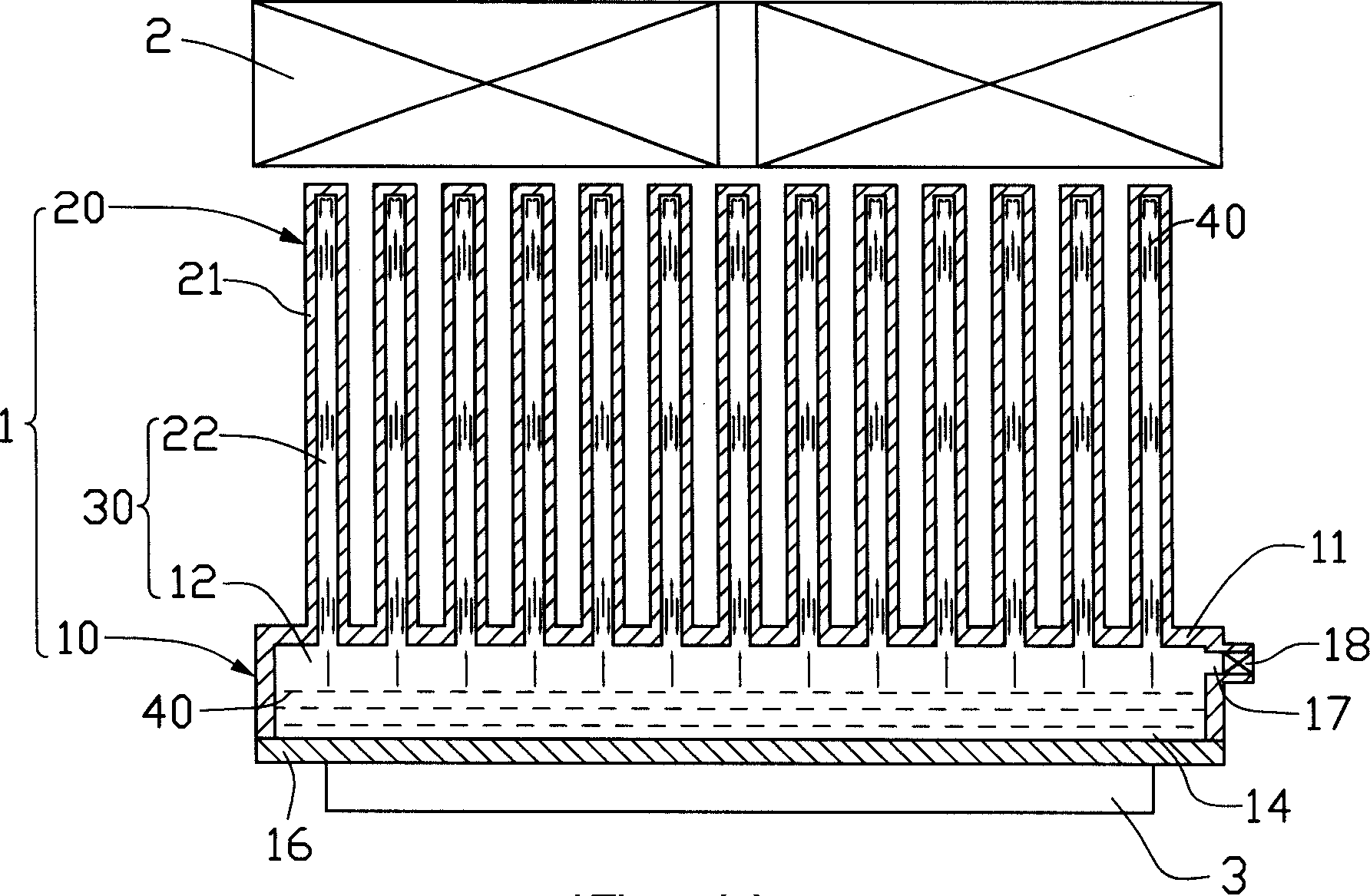

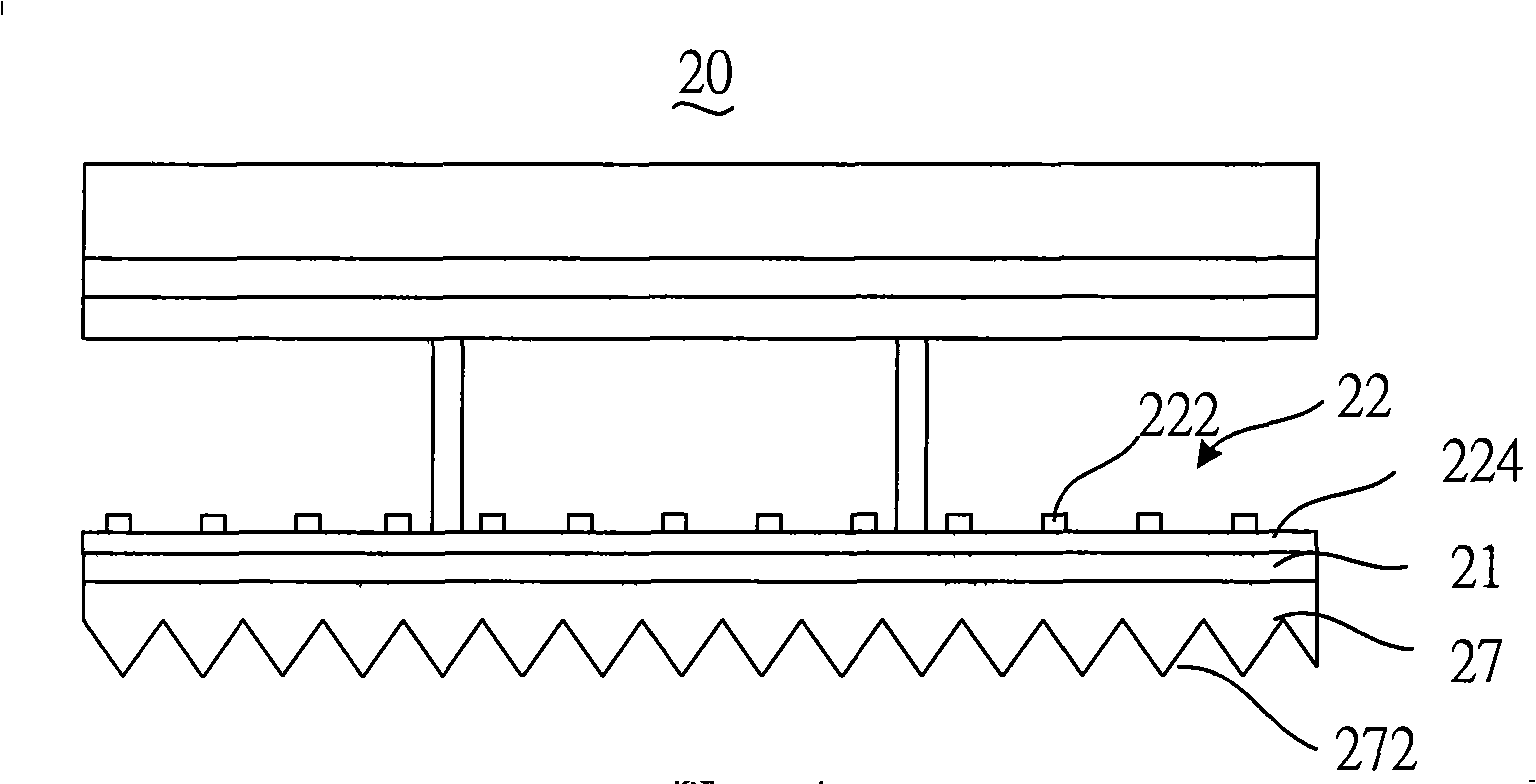

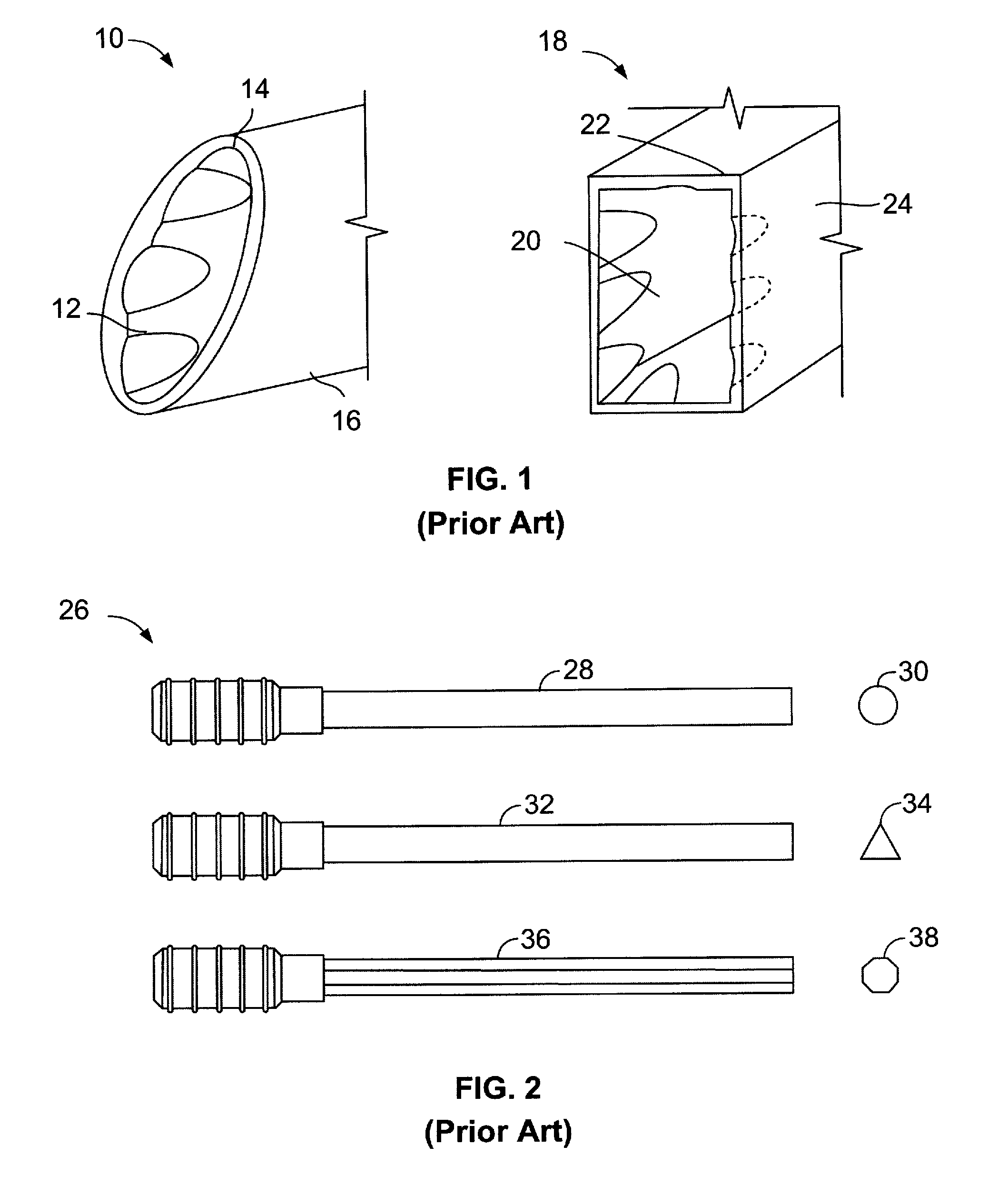

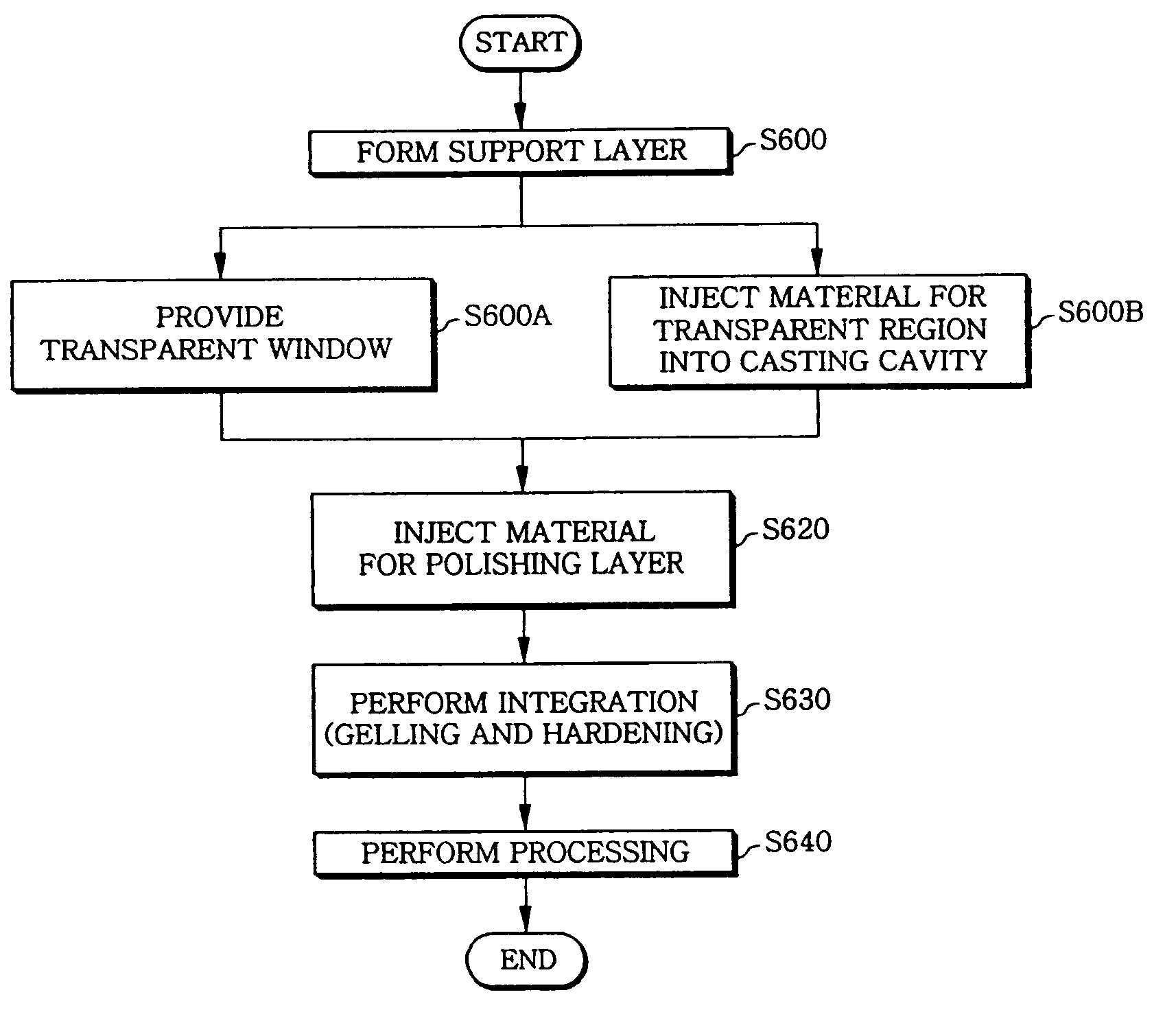

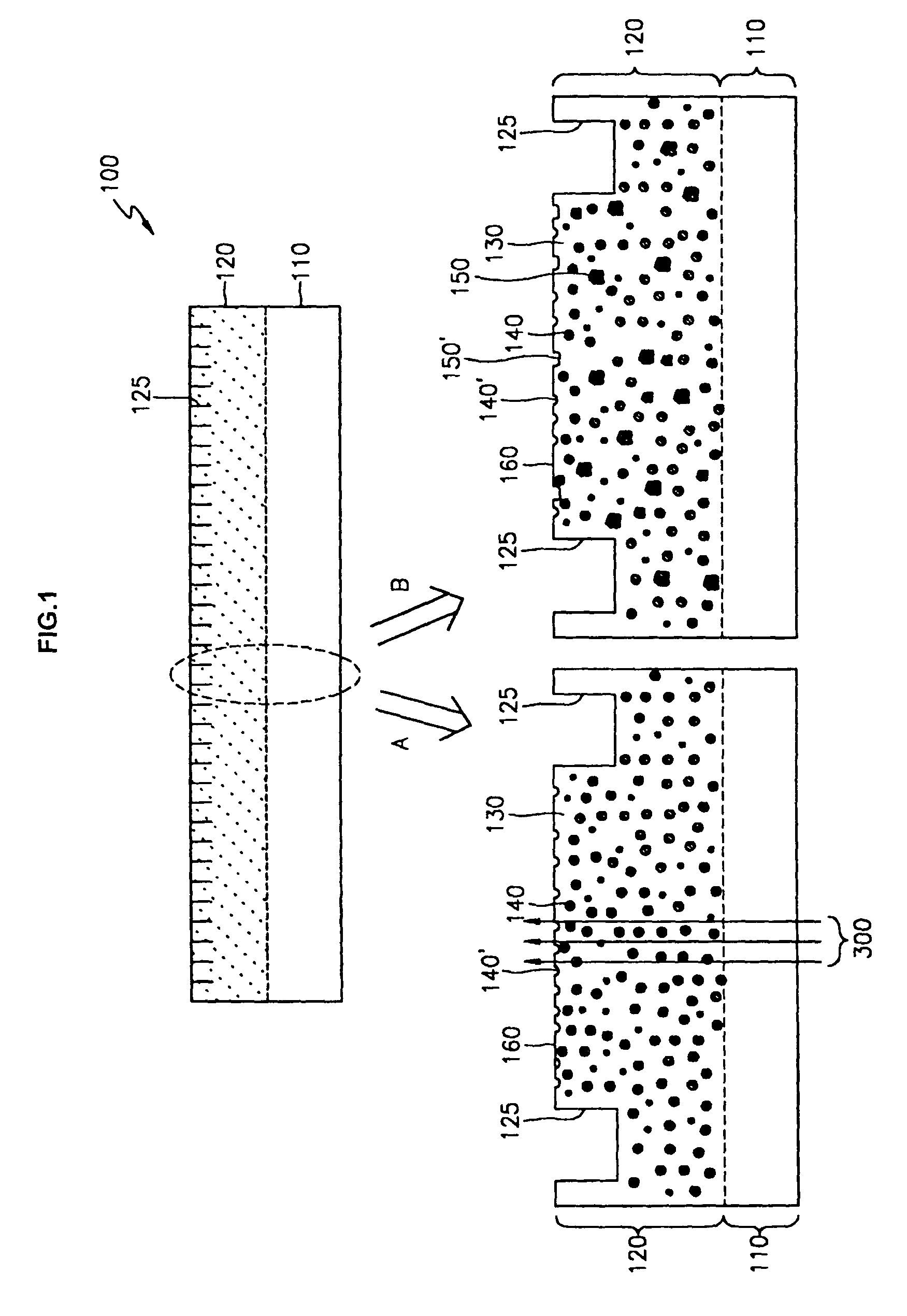

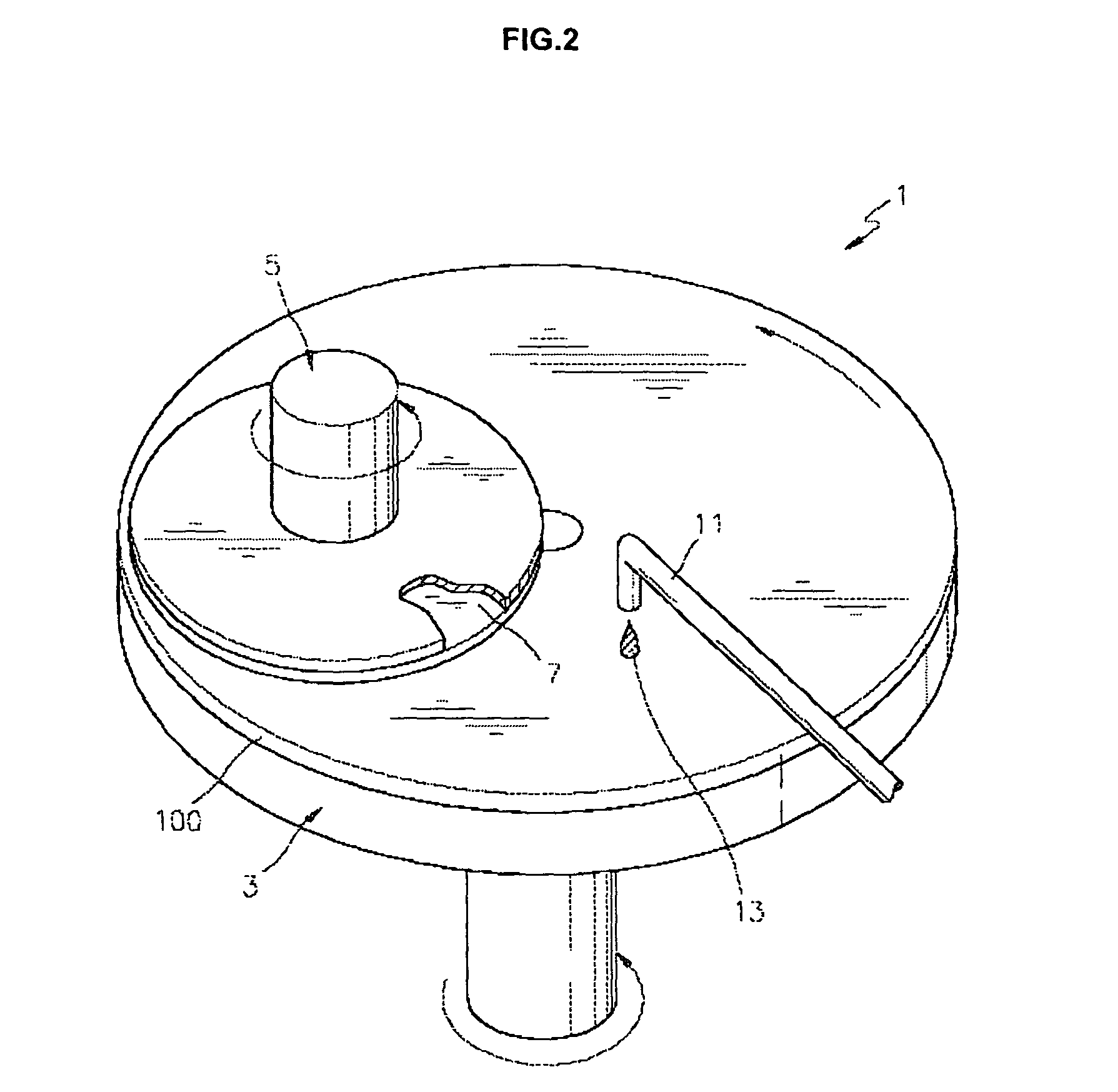

Integral polishing pad and manufacturing method thereof

InactiveUS7029747B2Improve planarization efficiencyEasy to manufactureSemiconductor/solid-state device manufacturingTraffic signalsAdhesiveHardness

Owner:KPX CHEM

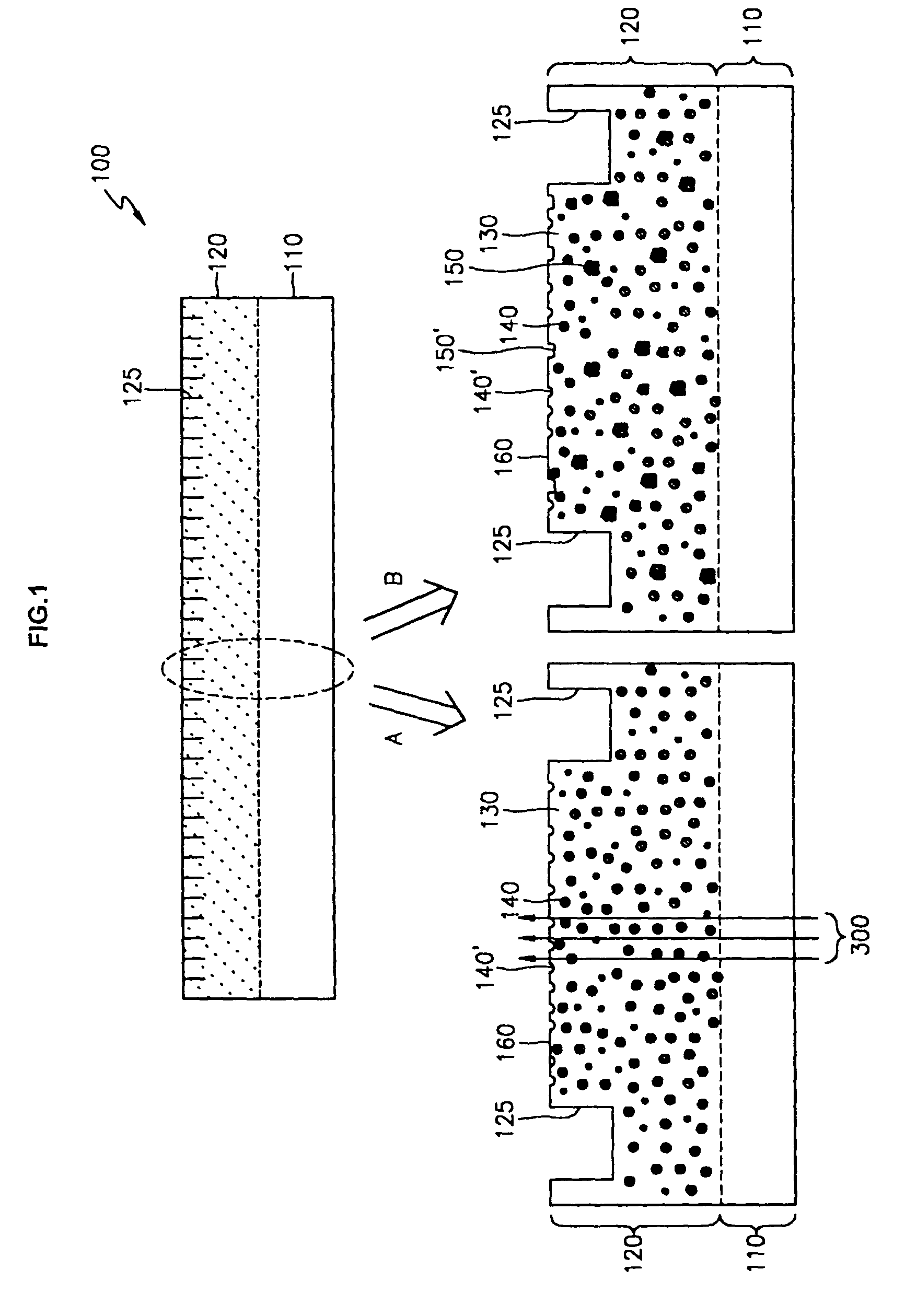

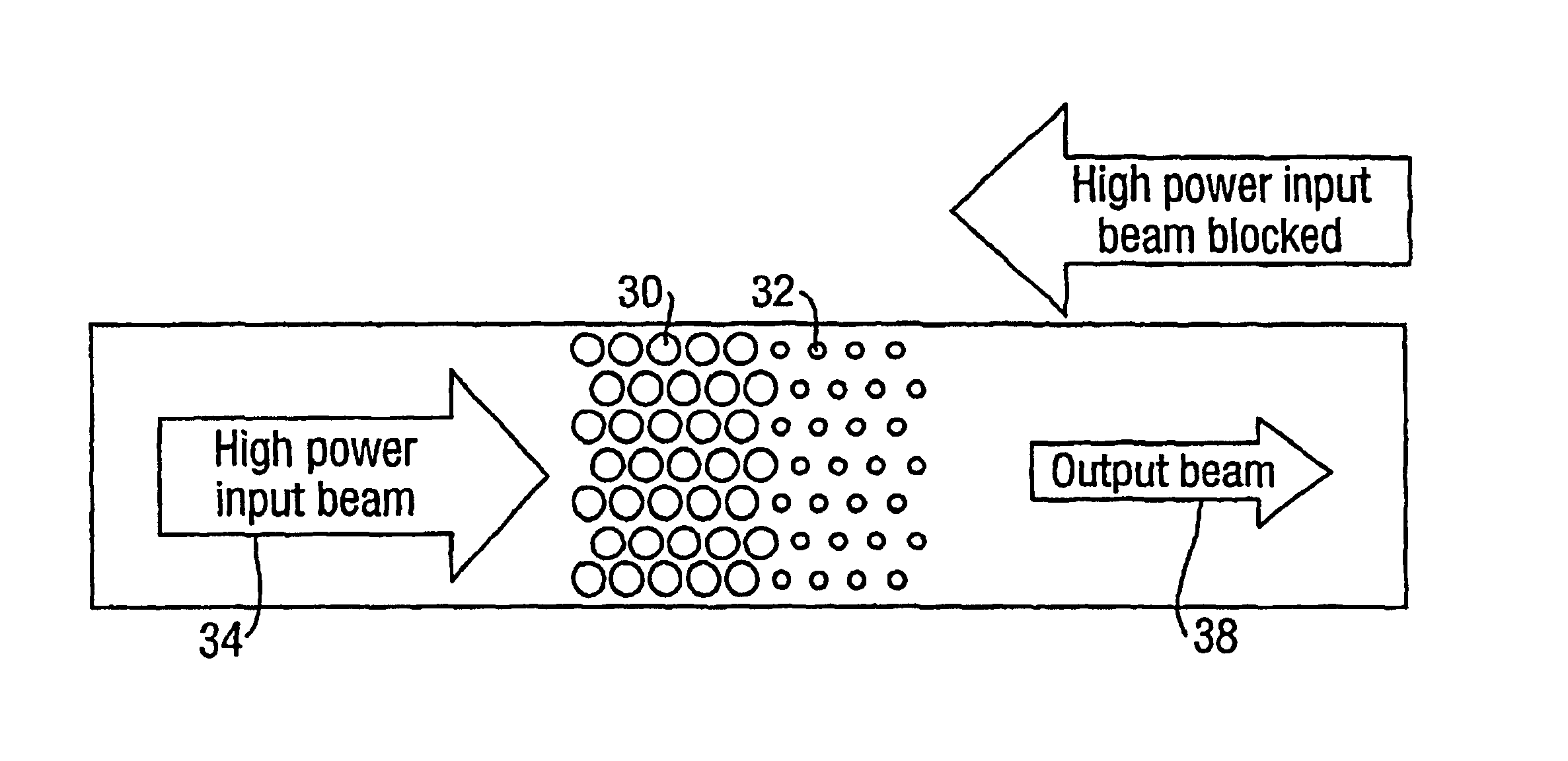

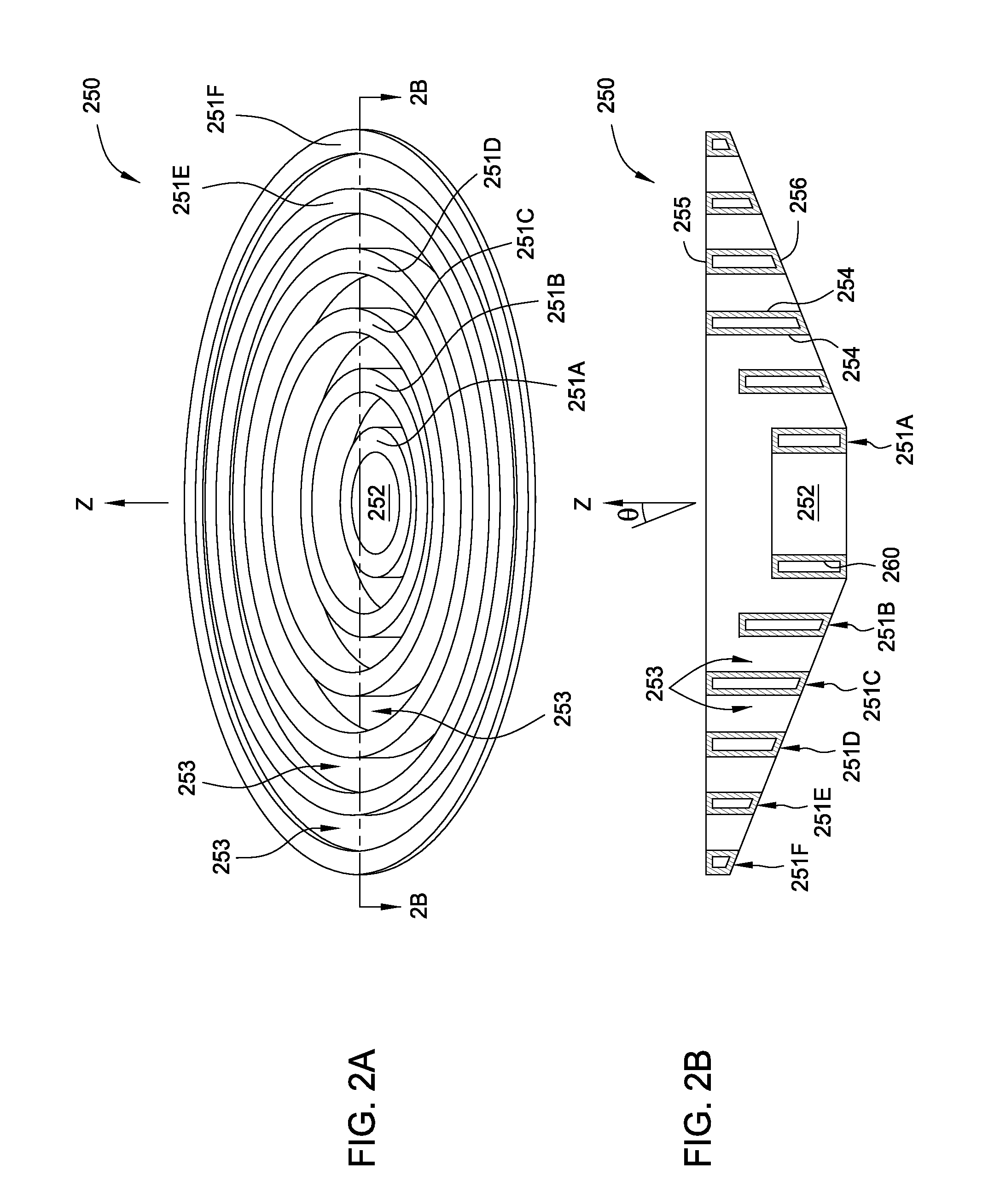

Optical device

InactiveUS6888994B2Non-linear effectEasy lithographic reproductionPolycrystalline material growthAfter-treatment detailsPhotonic bandgapRefractive index

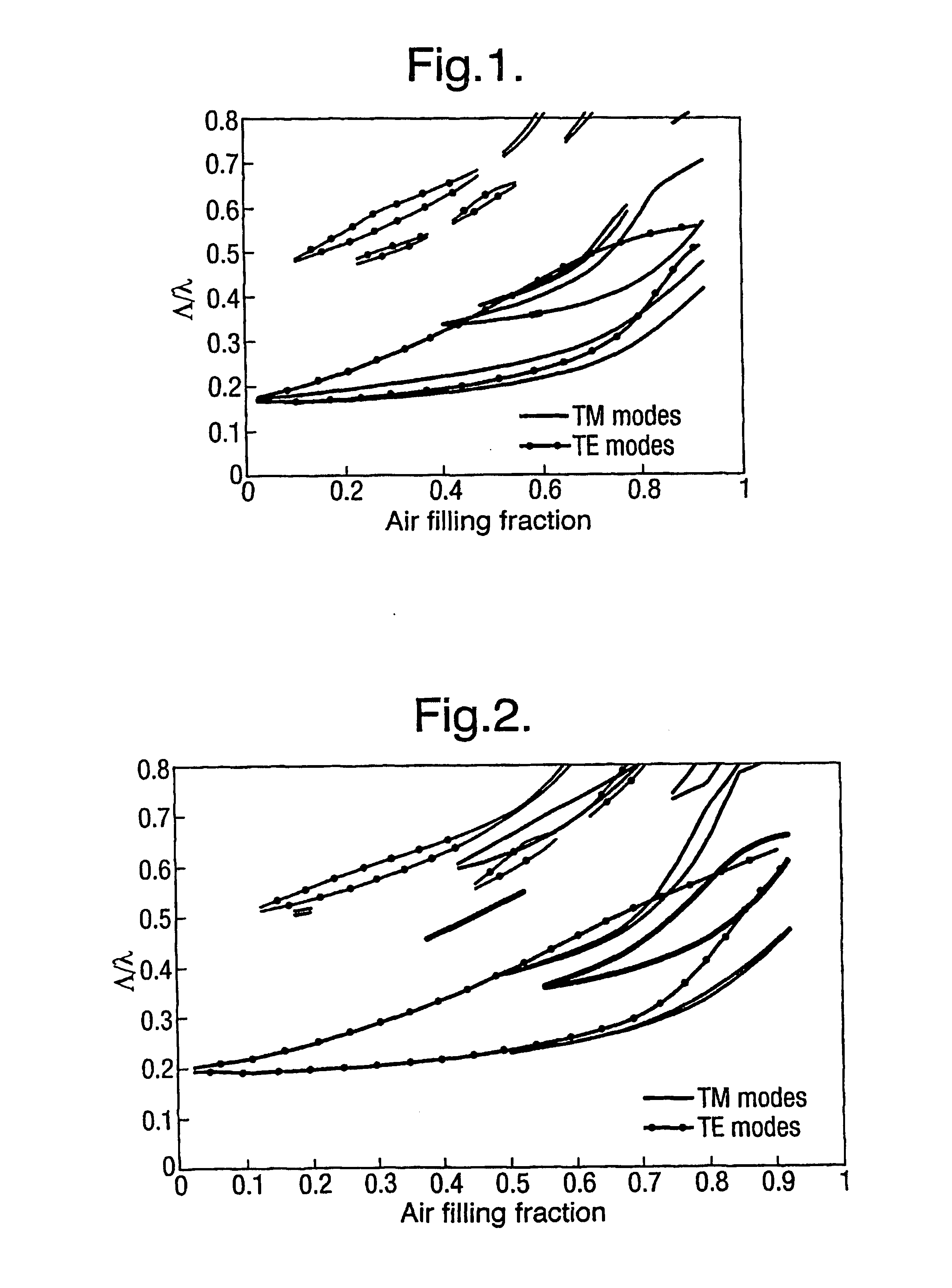

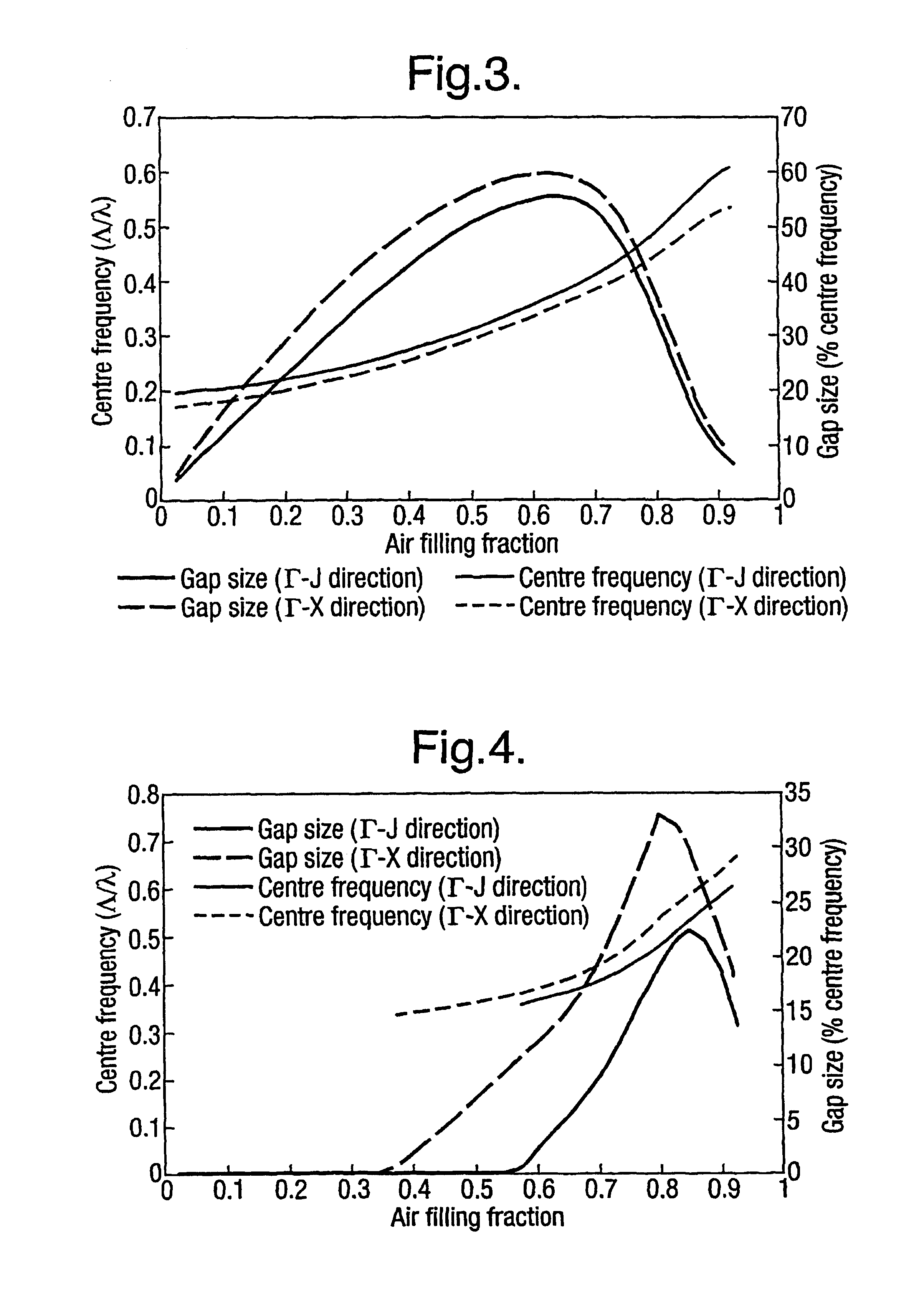

In order to create an optical device with a photonic band gap extending in two dimensions and with very uniform properties in any direction and for any polarisation state, to within 1%, air holes are etched within a substrate of low refractive index material such silicon oxynitride or silica glass. The ratio of air hole area to the remainder of the substrate is low, being less than 35%. The air holes define a quasicrystal structure, having twelve fold symmetry, being based on a square-triangle system. In another development, an etched substrate with a regular crystal structure or quasicrystal structure exhibits a non-linear refractive index. Two adjacent areas in such a substrate have different lattice properties, or have defects in the lattices, to create a unidirectional transmission path (diode action). A further beam of light may be used to modulate the transmission path by reason of the non-linear refractive index.

Owner:NANOGAN

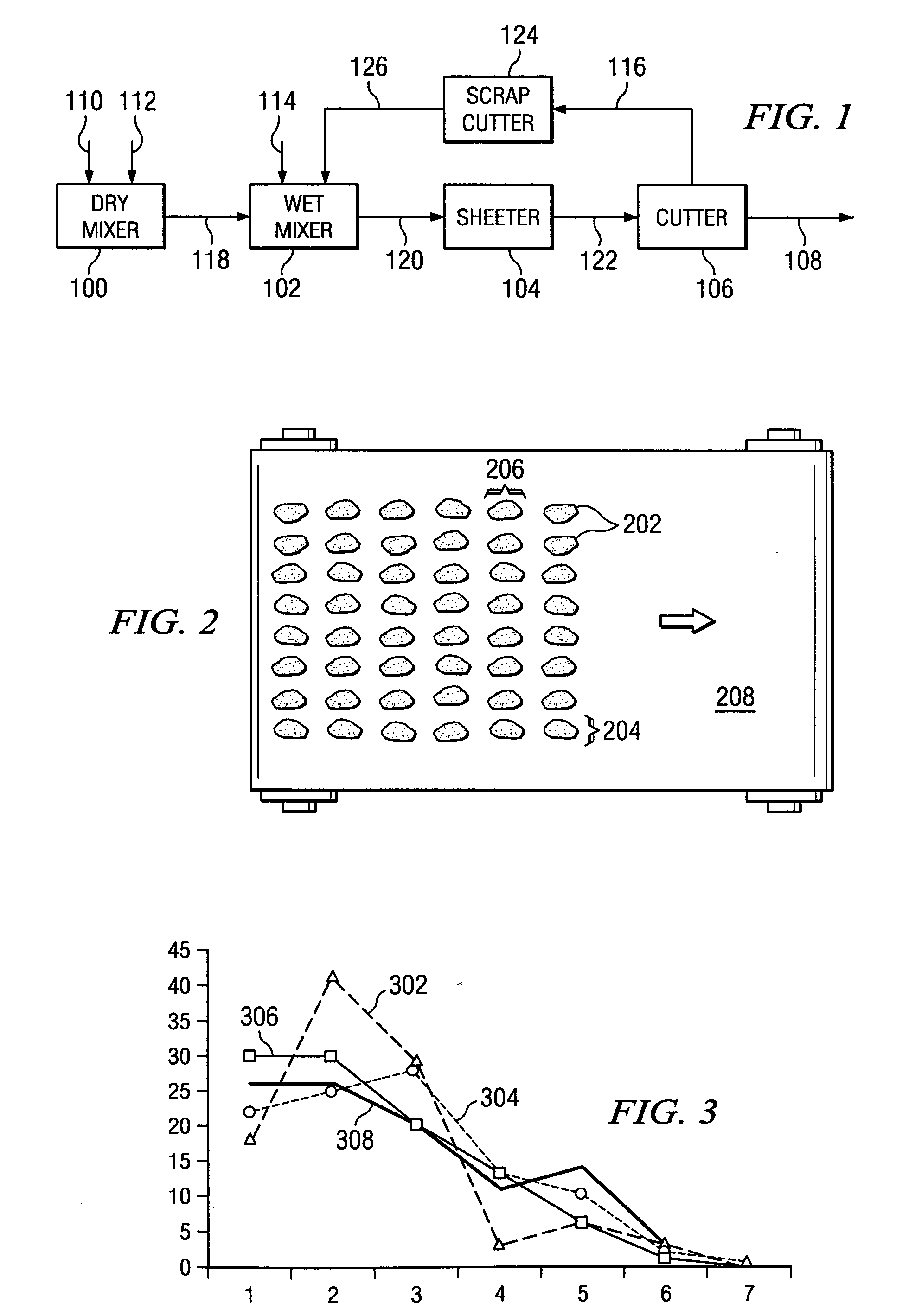

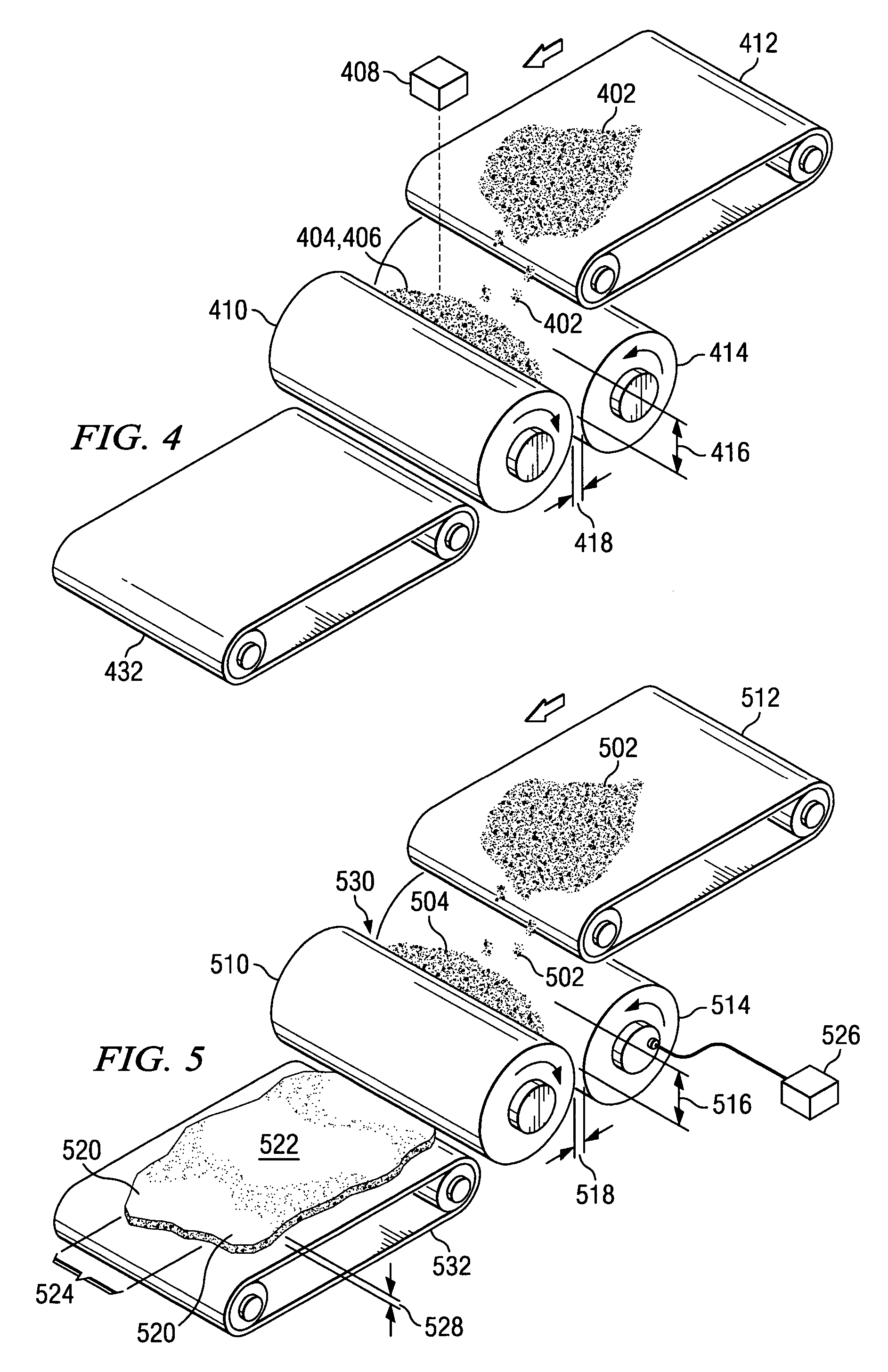

Method for sheeting and processing dough

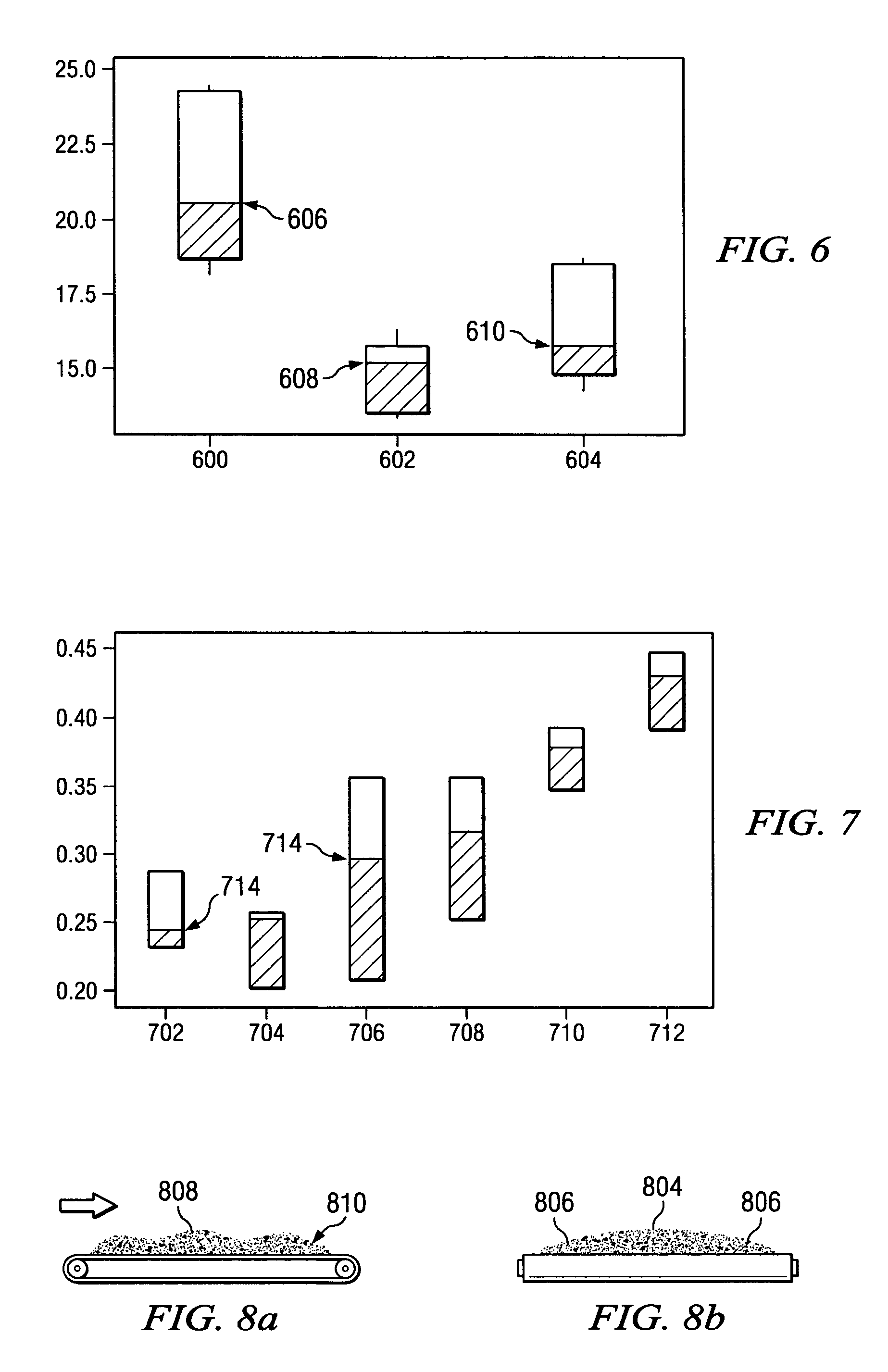

InactiveUS20060034988A1Improve consistencyGood composition uniformityDough treatmentDough-sheeters/rolling-machines/rolling-pinsAdditive ingredientEngineering

An improved method to produce a dough sheet having improved uniform properties in a high-speed manufacturing environment. In accordance with one embodiment of the present invention, the dough sheeting system comprises improved control of dough particles in the sheeter nip, and improved control of dough properties across the width of the dough sheet including, but not limited to, uniform thickness, uniform work input, uniform moisture content, uniform emulsifier content, and uniform dry ingredient content. In a preferred embodiment, the improvements described herein enable the high-speed production of stackable chip products. Improved mixing and control of process conditions in dry and wet upstream mixers enable such production.

Owner:FRITO LAY NORTH AMERICA INC

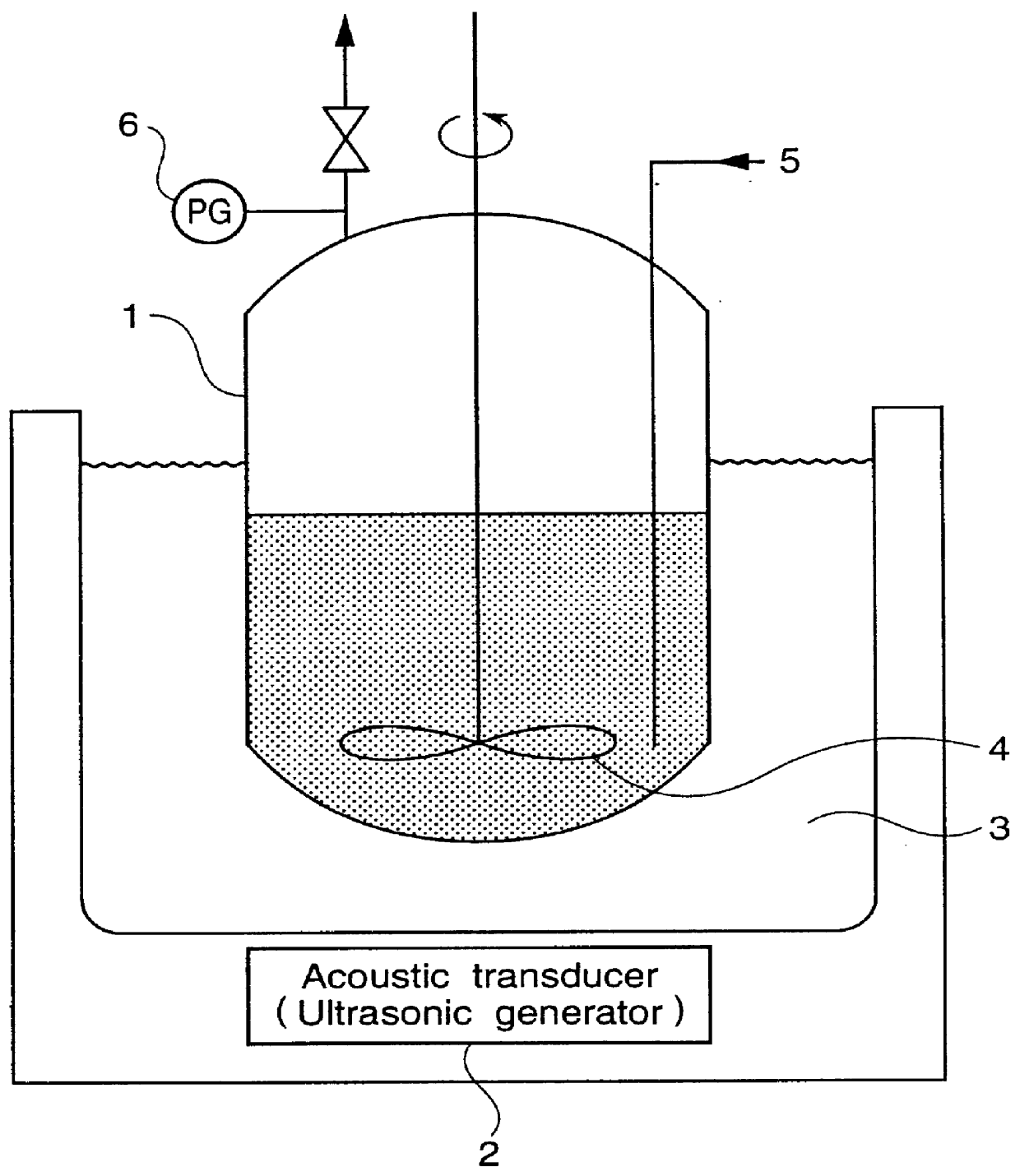

Prepolymerized solid catalyst, process for preparing the same, and process for heterogeneous polymerization of olefins

InactiveUS6060416AGood effectSmall particle sizeOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationPolymer sciencePolyolefin

A high-performance prepolymerized solid catalyst is prepared by polymerizing an olefin onto an olefin polymerization catalyst in a heterogeneous system under irradiation with an elastic wave, wherein the olefin is prepolymerized in an amount of not less than 0.1 g based on 1 mmol of a transition metal contained in the olefin polymerization catalyst. The elastic wave is preferably an ultrasonic wave. In a process for heterogeneous polymerization of an olefin, an olefin is subjected to slurry polymerization or gas phase polymerization in the presence of the prepolymerized solid catalyst. In a process for heterogeneous polymerization of an olefin, an olefin may be polymerized onto the olefin polymerization catalyst in a heterogeneous system under irradiation with an elastic wave to prepare polyolefin. Therefore, the heterogeneous polymerization of an olefin can be stably conducted and polyolefins of uniform property and high quality can be obtained.

Owner:MITSUI CHEM INC

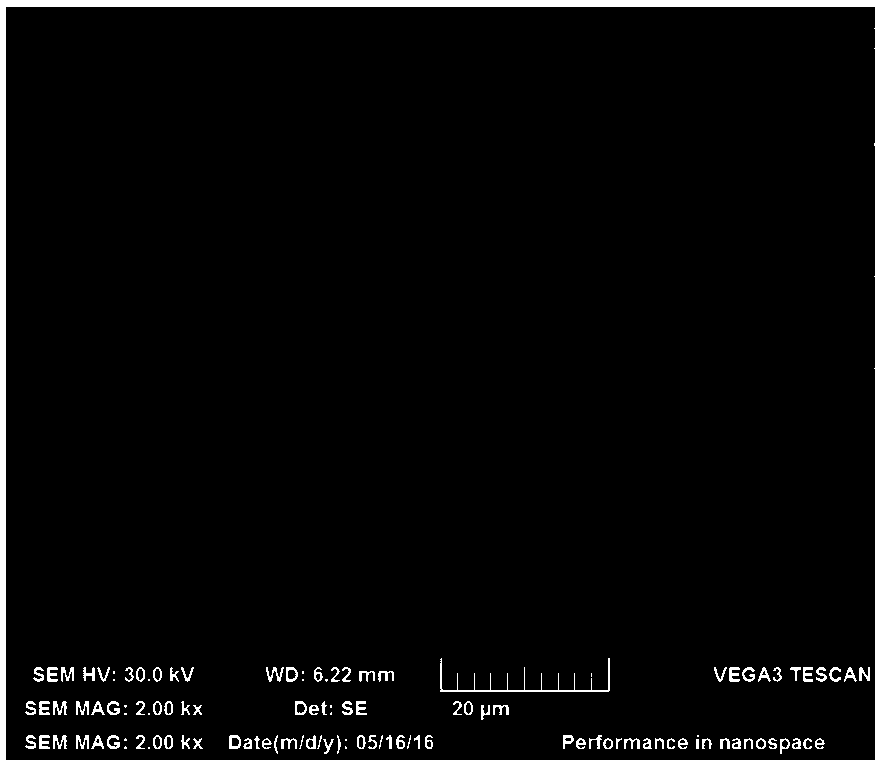

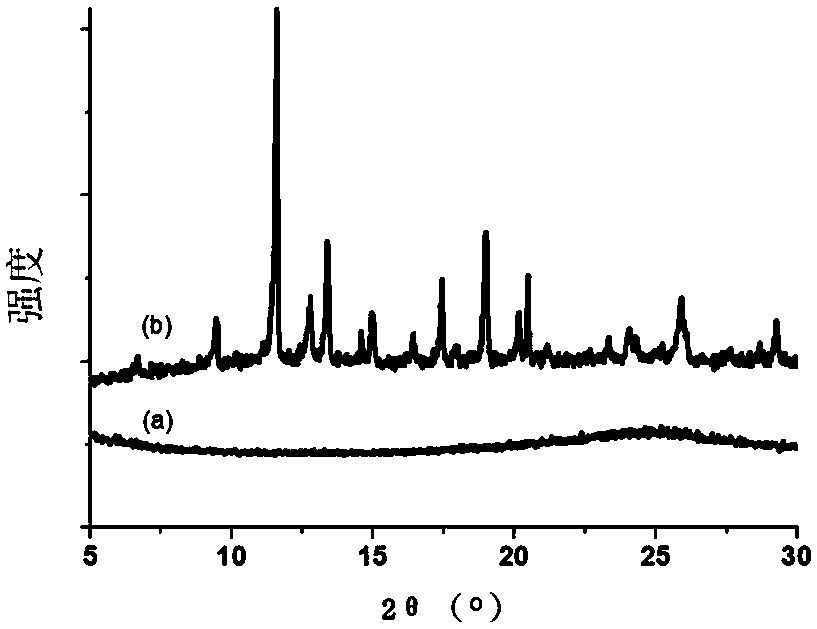

Graphene-metal organic framework composite material, and preparation method and application thereof

ActiveCN107871617AReduce "chalking"Process stabilityHybrid capacitor electrodesHybrid/EDL manufacturePorous grapheneCapacitance

The invention discloses a graphene-metal organic framework composite material, and a preparation method and application thereof. The composite material includes graphene and a metal organic frameworkcompound. The graphene is three-dimensional porous graphene. The metal organic framework compound is uniformly grown in an internal pore structure of the three-dimensional porous graphene. The preparation method includes the steps of (1) preparing a three-dimensional porous graphene aerogel; (2) preparing a three-dimensional porous graphene aerogel containing a metal organic framework material precursor solution; and (3) preparing a graphene-metal organic framework composite material. The application includes applications as electrode materials, adsorbents, or catalysts. The graphene-metal organic framework composite material has the advantages of good conductivity, good capacitance performance, uniform properties, stable structure, high cycle service life, and the like. The preparation method is simple in process and low in cost, and can prepare a graphene-metal organic framework composite material with the controllable shape and pore structure and excellent product performance.

Owner:NAT UNIV OF DEFENSE TECH

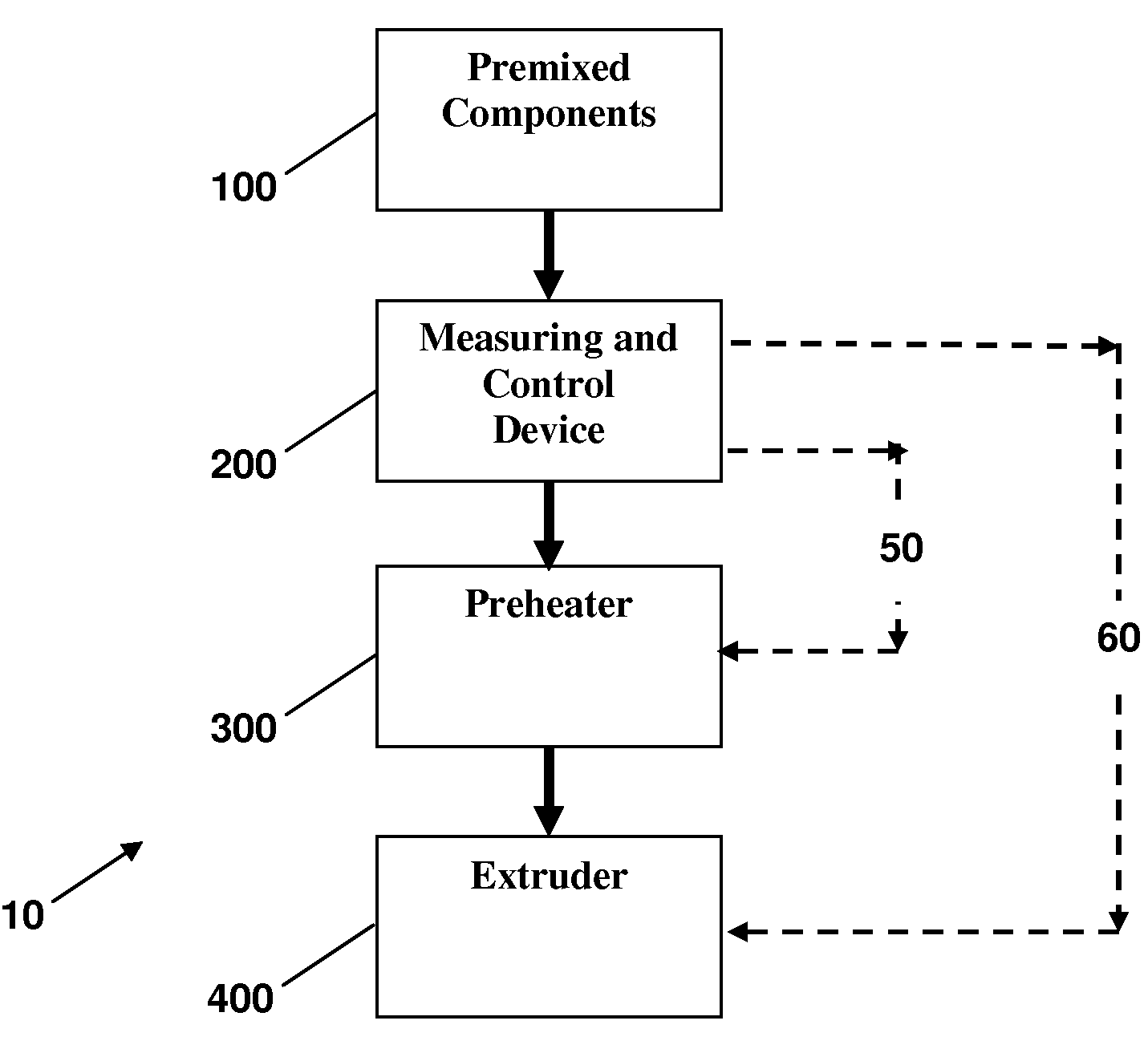

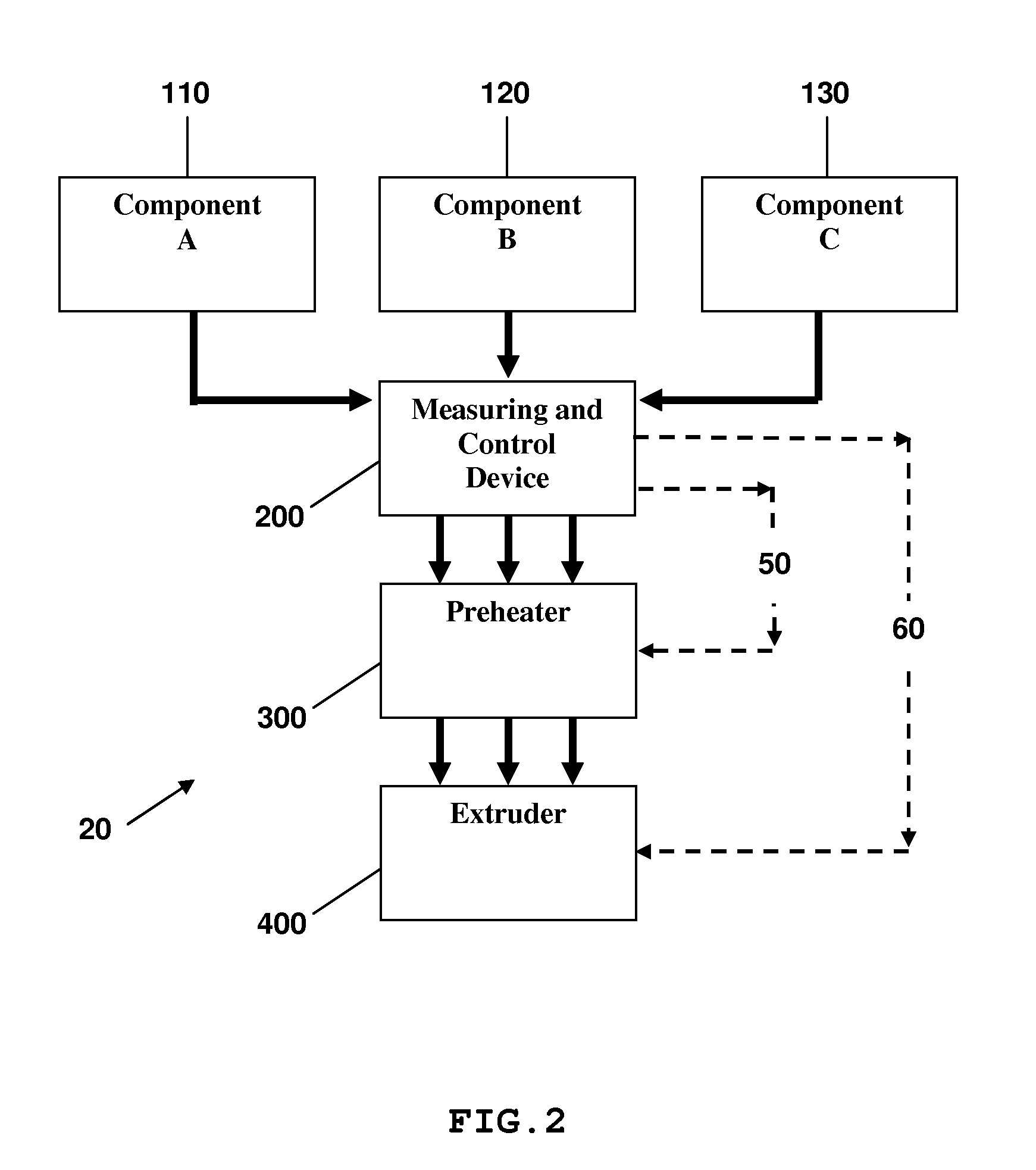

System and method for manufacturing composite materials having substantially uniform properties

InactiveUS20080197523A1Limited lifeImprove moisture resistanceTailstocks/centresConfectioneryUniform propertyMaterials science

A system and method for manufacturing composite material components having substantially uniform properties comprising means to control the metering of constituent composite material components during manufacture. The resulting composite material components may, for example, be used in the construction of decking systems, railing, porches, fences, stairs, or other similar or suitable applications that may benefit from aesthetically pleasing appearances.

Owner:CRANE BUILDING PRODS

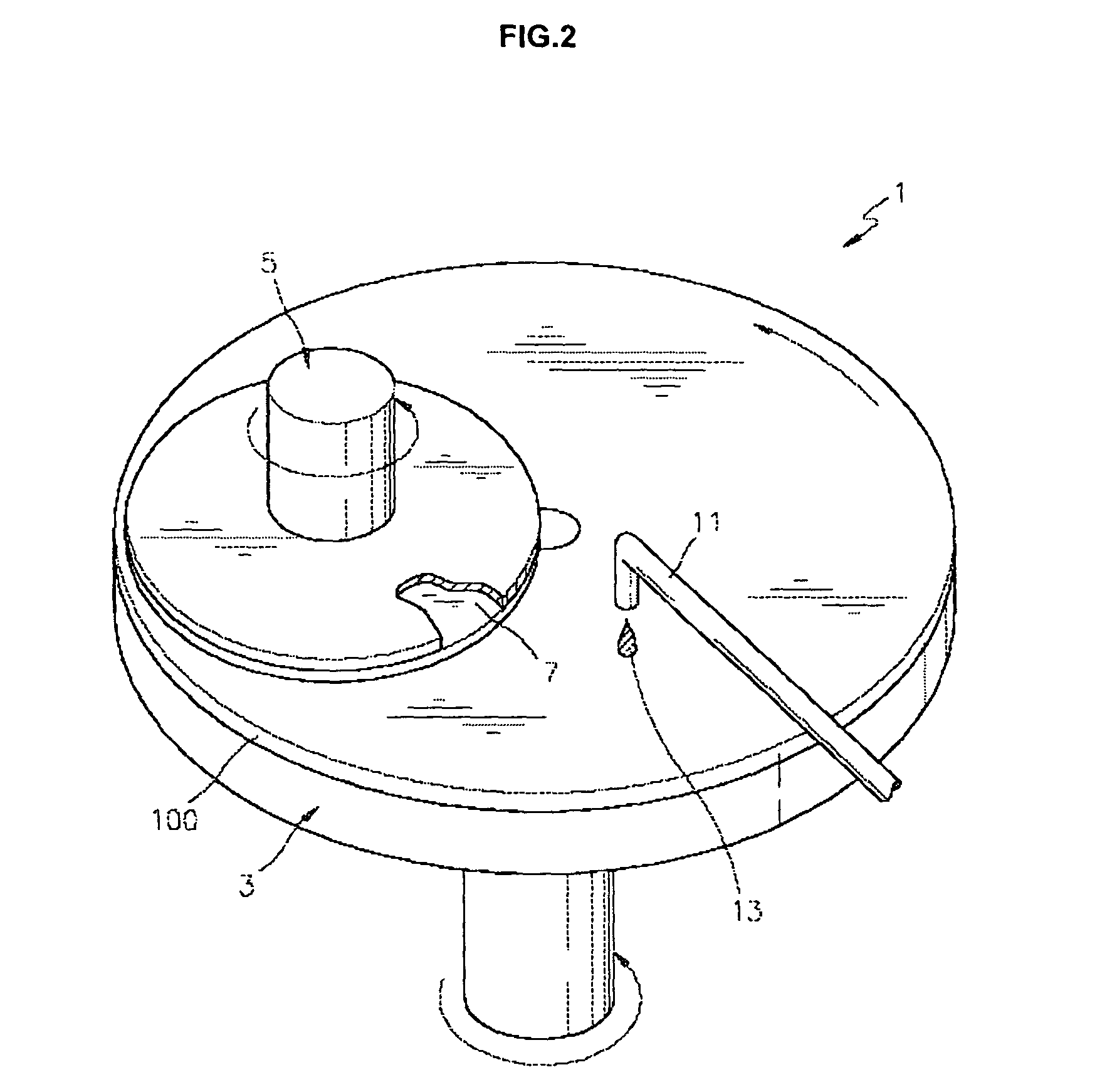

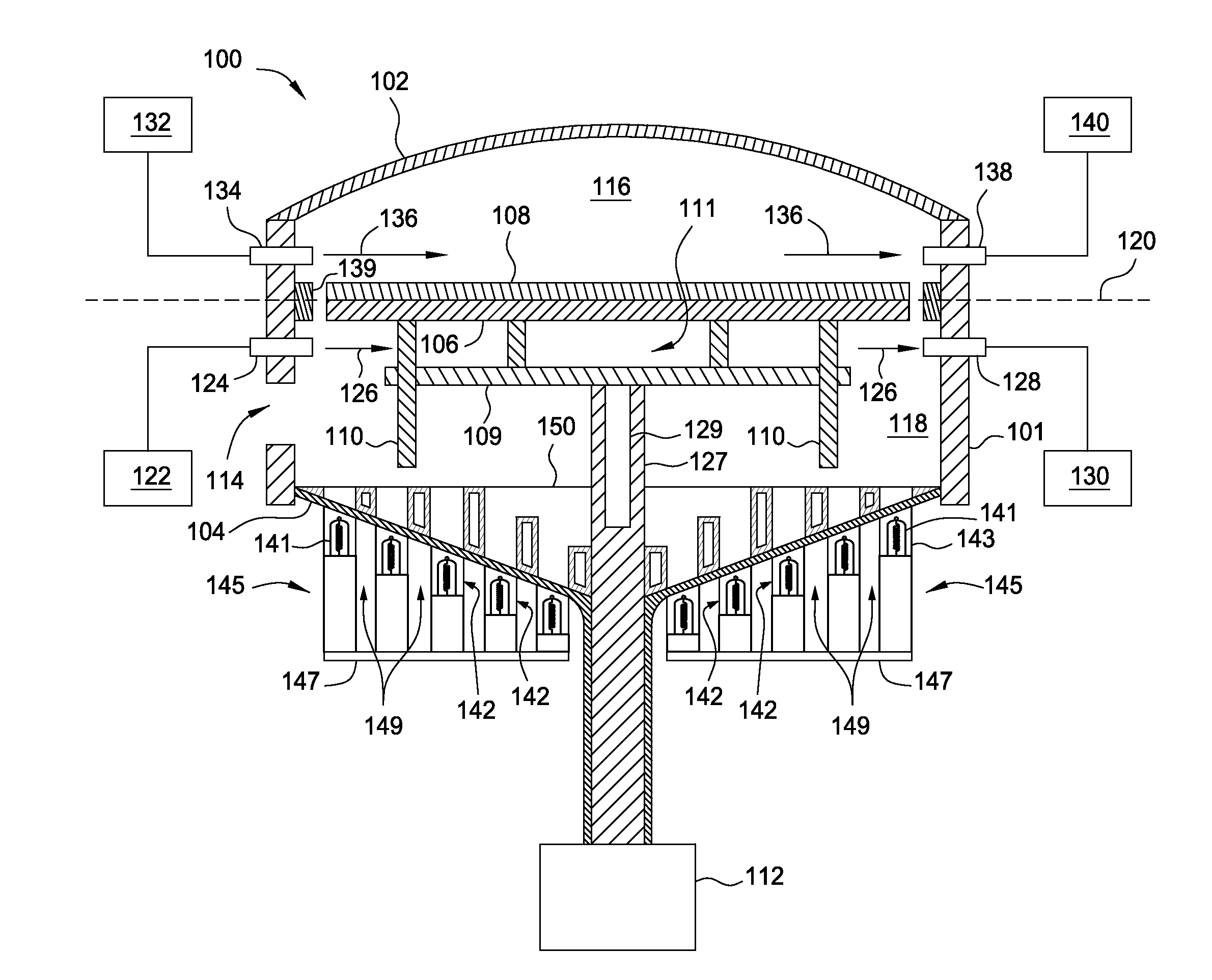

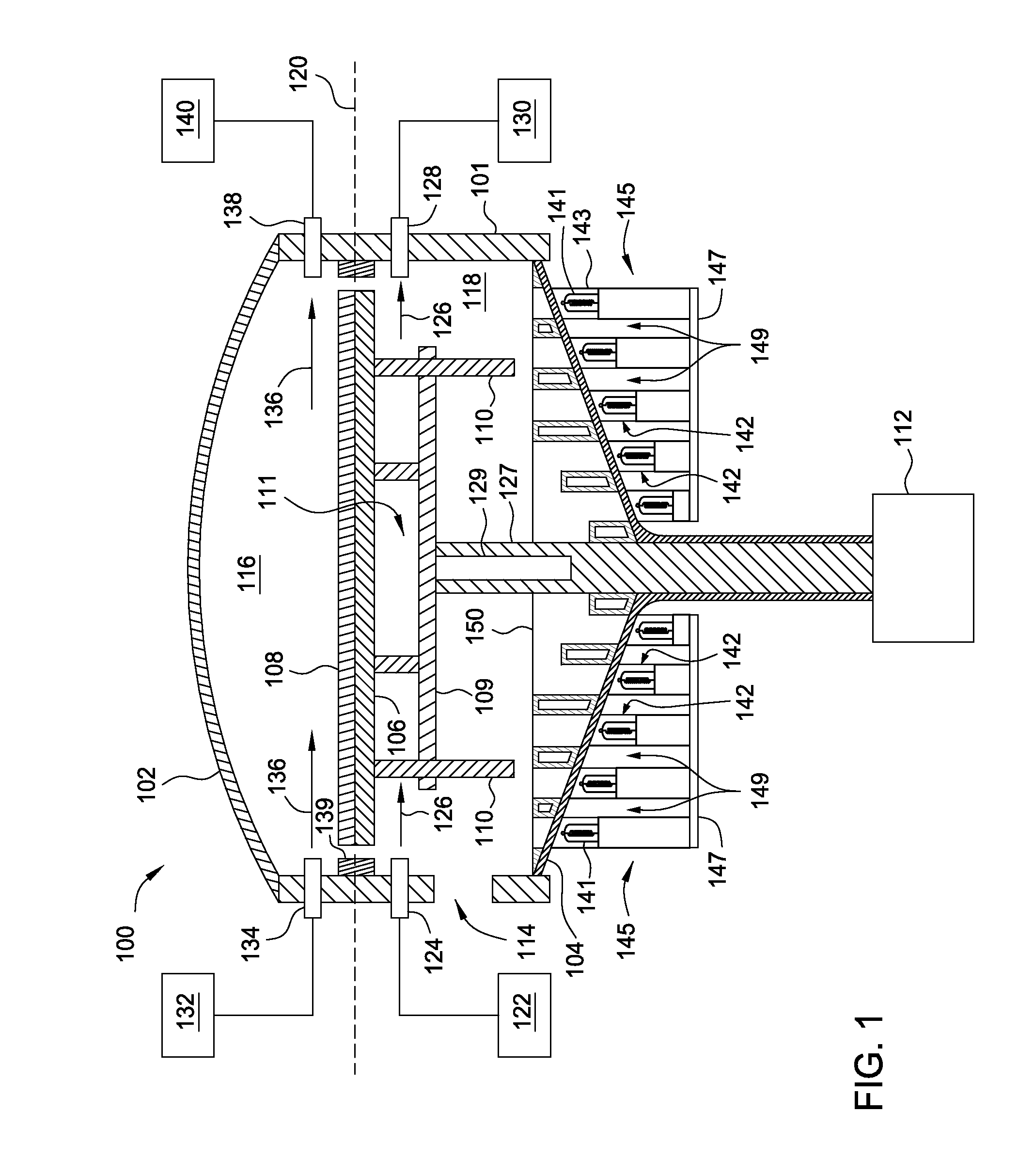

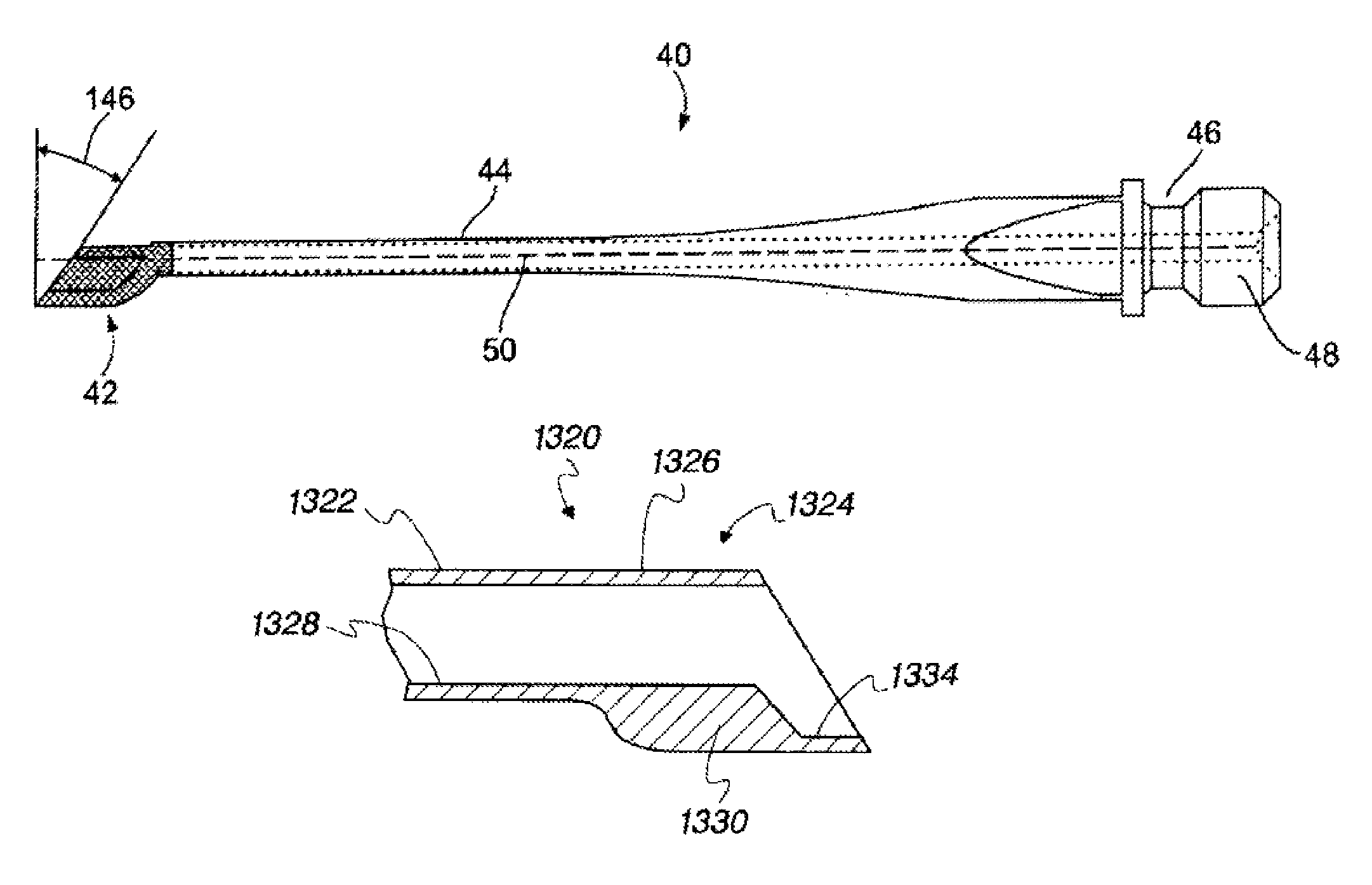

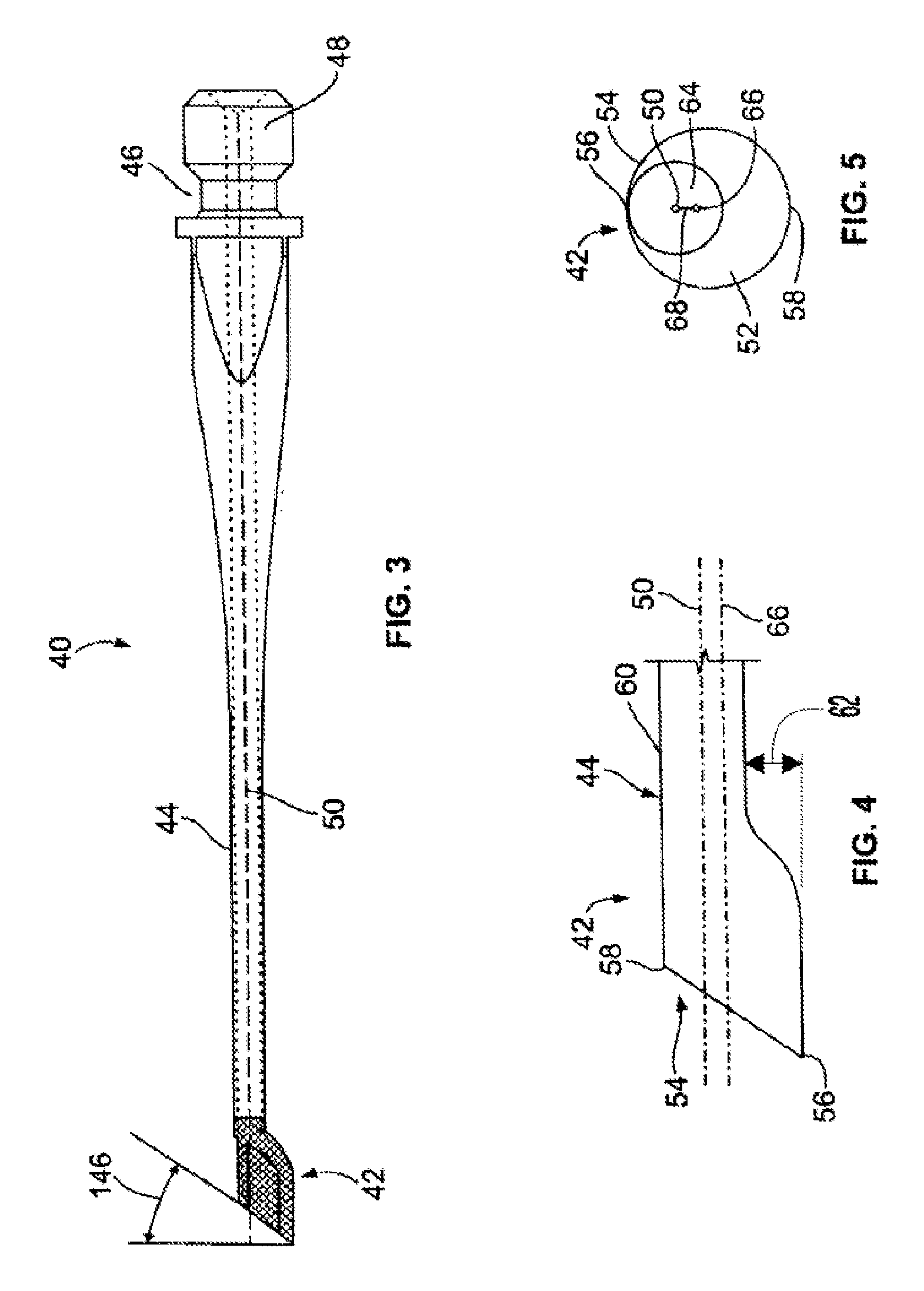

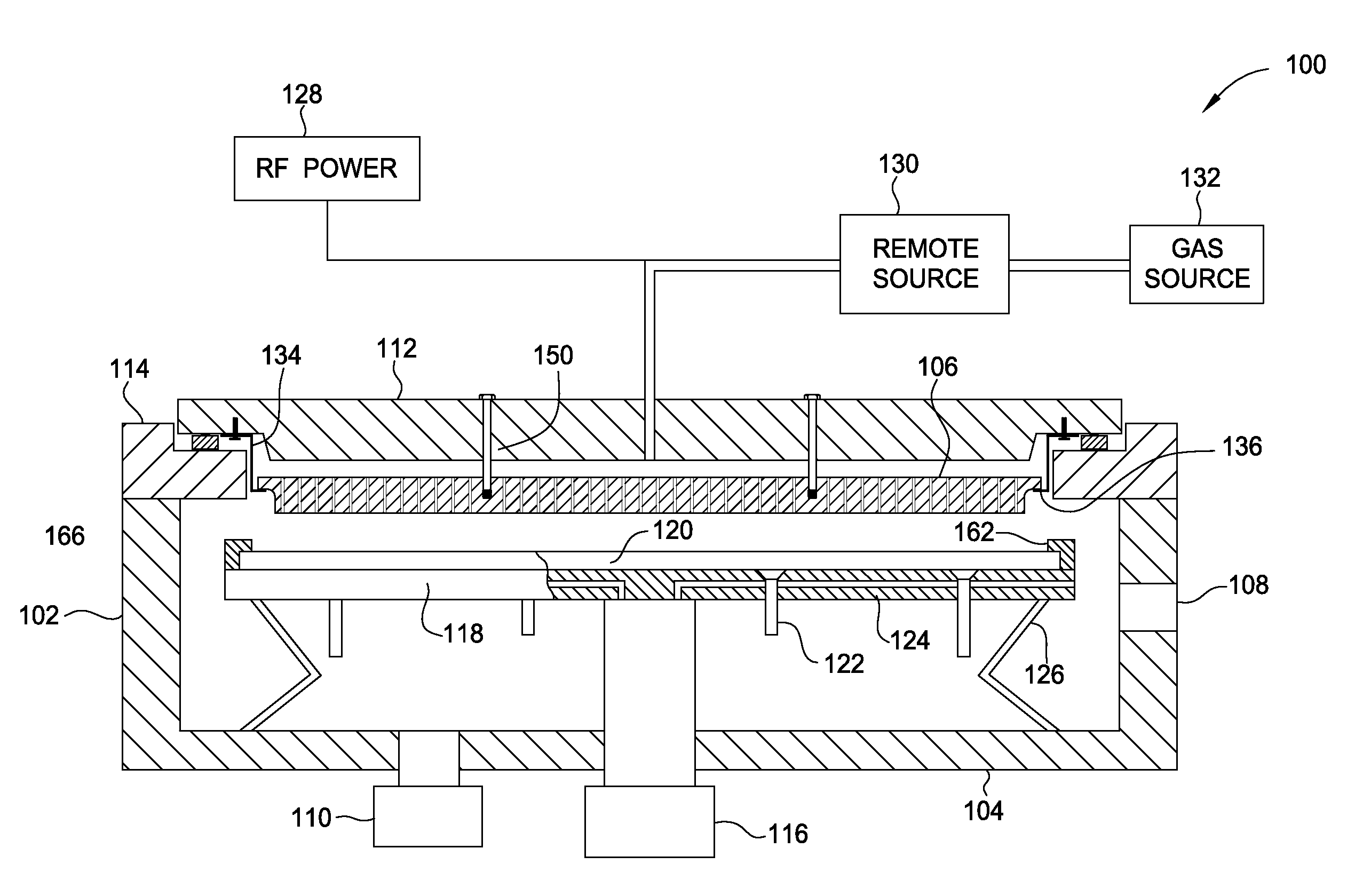

Optics for controlling light transmitted through a conical quartz dome

InactiveUS20130284095A1Influence heatingInfluence temperature distributionMirrorsSemiconductor/solid-state device manufacturingLight pipeEngineering

Embodiments described herein generally relate to apparatus for heating substrates. The apparatus generally include a process chamber having a substrate support therein. A plurality of lamps is positioned to provide radiant energy through an optically transparent dome to a substrate positioned on the substrate support. A light focusing assembly is positioned within the chamber to influence heating and temperature distribution on the substrate and to facilitate formation of a film on a substrate having uniform properties, such as density. The light focusing assembly can include one or more reflectors, light pipes, or refractive lenses.

Owner:APPLIED MATERIALS INC

High-strength and high-conductivity heat-resistant Cu-Fe-Y-Mg alloy material with electromagnetic wave shielding performance and preparation method thereof

The invention discloses a high-strength and high-conductivity heat-resistant Cu-Fe-Y-Mg alloy material with electromagnetic wave shielding performance and a preparation method thereof, and the copperalloy comprises Cu, Fe, Mg and Y elements; and the mass percentage of Fe is greater than or equal to 5% and is smaller than the mass percentage of Cu, and the Fe is uniformly distributed in the alloymaterial. The copper alloy uses a large amount of inexpensive iron element in the composition design; due to the immiscibility of copper and iron in the molten state, the starting alloy is mainly copper in the smelting process, a small amount of iron is added for melting, and after melting, Cu-Fe master alloy is added in a master alloy manner, alloy elements yttrium and magnesium are jointly addedin the smelting, which acts as a modificator and promotes the uniform distribution of the iron phase in the copper matrix in the solidified state, so that the alloy product finally has uniform properties, electromagnetic wave shielding performance and high strength and high thermal conductivity. The copper alloy material is suitable for non-vacuum large-scale industrial manufacturing.

Owner:CENT SOUTH UNIV

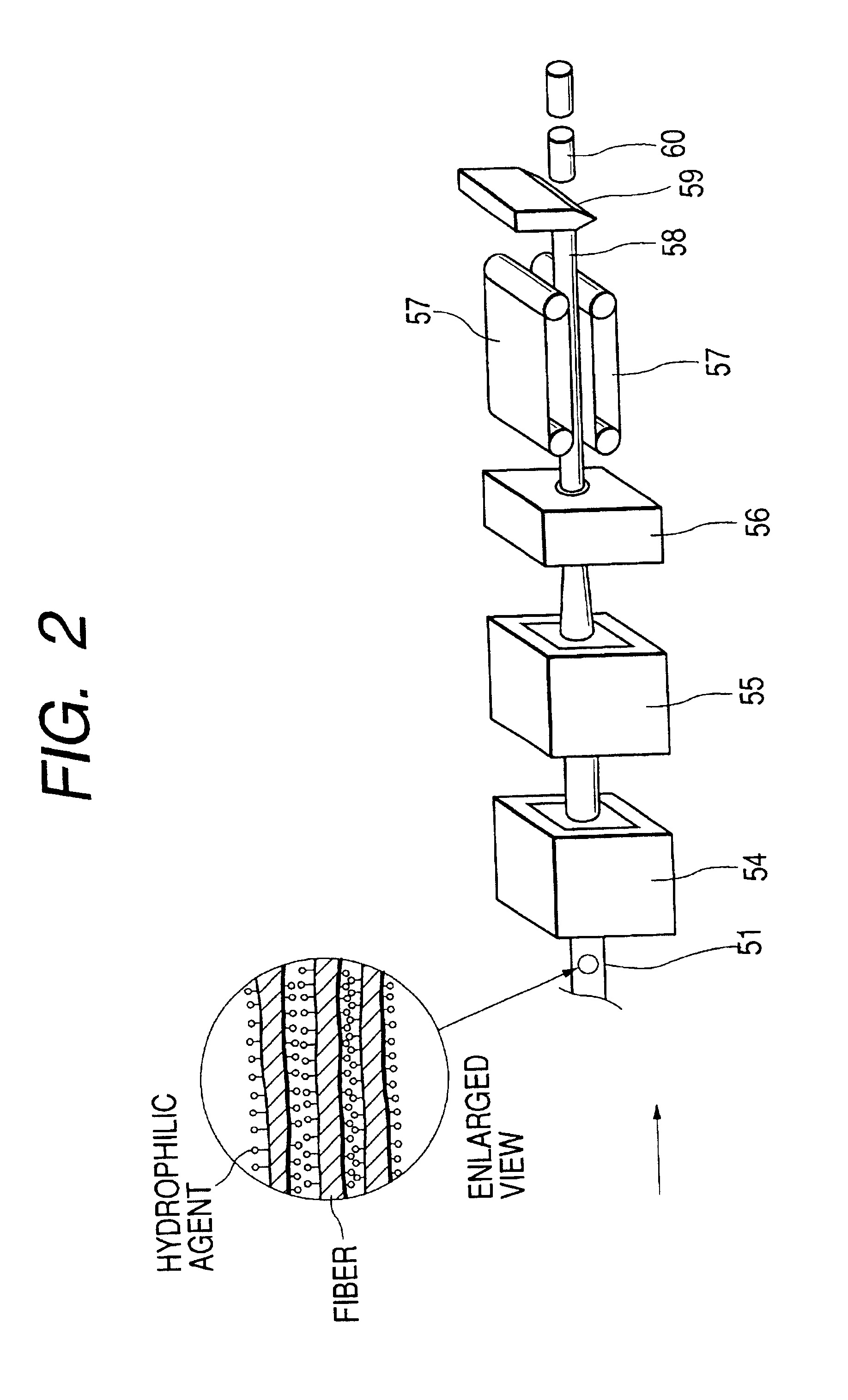

Method for manufacturing fiber aggregate, fiber aggregate, and liquid container using such fiber aggregate

InactiveUS6863762B2Enhancing uniform propertySmall stepMechanical working/deformationWood working apparatusSurface layerSingle fiber

A method for manufacturing a fiber aggregate formed by fiber having reforming surface comprises the steps of providing a fiber surface having thermoplastic resin at least on the surface layer thereof with a hydrophilic processing liquid containing polymer having a first portion with more hydrophilic group than the surface, and a second portion having interfacial energy different from that of the hydrophilic group, and interfacial energy substantially equal to the surface energy of the fiber; orientating the second portion toward the fiber surface, while orientating polymer to the side different from the surface of the first group; and forming a fiber absorber by heating the fiber having the reformed surface in the step of orientating polymer to thermally bond the contact points of fibers themselves. With this method of manufacture, it becomes possible to enhance the uniform property of the fiber aggregate still more, which is formed subsequent to making the property of such fiber aggregate uniform per unit of single fiber or small aggregate existing in any one of stages before the formation thereof.

Owner:CANON KK

Lycium ruthenicum Murr proanthocyanidin product and preparation method thereof

ActiveCN101982192AEfficient removalStable in natureAntinoxious agentsPlant ingredientsBetacyaninsProanthocyanidin

The invention relates to a lycium ruthenicum Murr proanthocyanidin product. The product is a pale purple pink powder product which is prepared from fresh lycium ruthenicum Murr as raw materials and contains 40% to 70% of oligomeric proanthocyanidins, 10% to 35% of high polymer procyanidins, and 10% to 40% of other impurities after being separated and purified. The invention also discloses a preparation method of the product. The invention adopts the membrane separation technique, has simple and quick method, not only avoids using toxicant organic reagent and acquires the product having stable and uniform property, but also efficiently lowers the producing cost and can adopt the raw materials of health care product which has an antioxidant function.

Owner:浙江启润生物科技有限公司

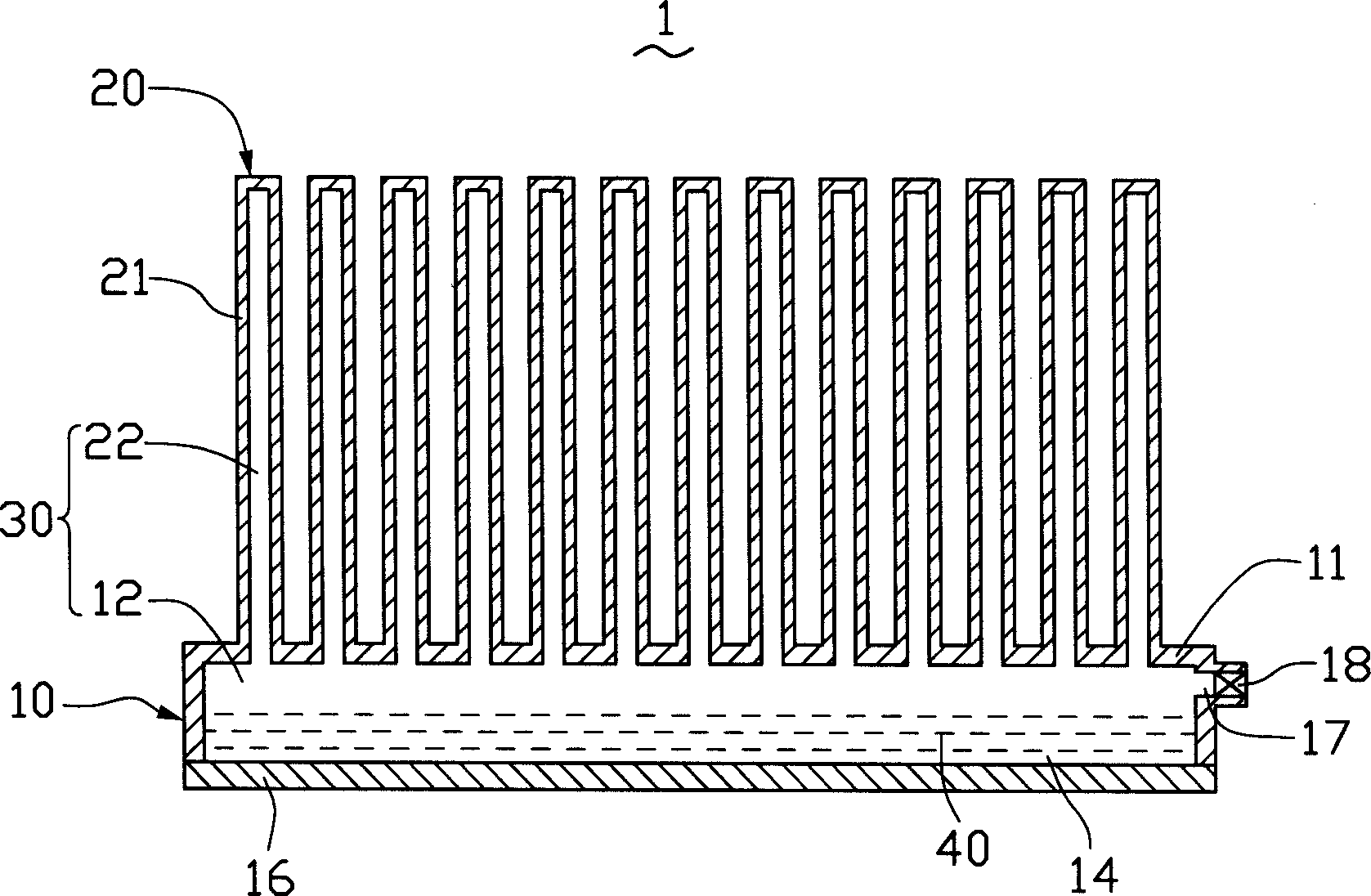

Heat radiator

InactiveCN1909771AReduce thermal resistanceImprove heat transfer efficiencyDigital data processing detailsSemiconductor/solid-state device detailsWorking fluidEngineering

The invention relates to a heat radiator, which comprises a base and several wings connected to the base, wherein said base has the first chamber; said wings both have one second chamber; the second chambers are through to the first chamber, to make the base and the wings form one hollow sealing chamber filled with working fluid. The invention arranges chambers in the base and wings, with better temperature uniform property, high heat adsorption amount and lower weight, to improve the heat emission efficiency.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

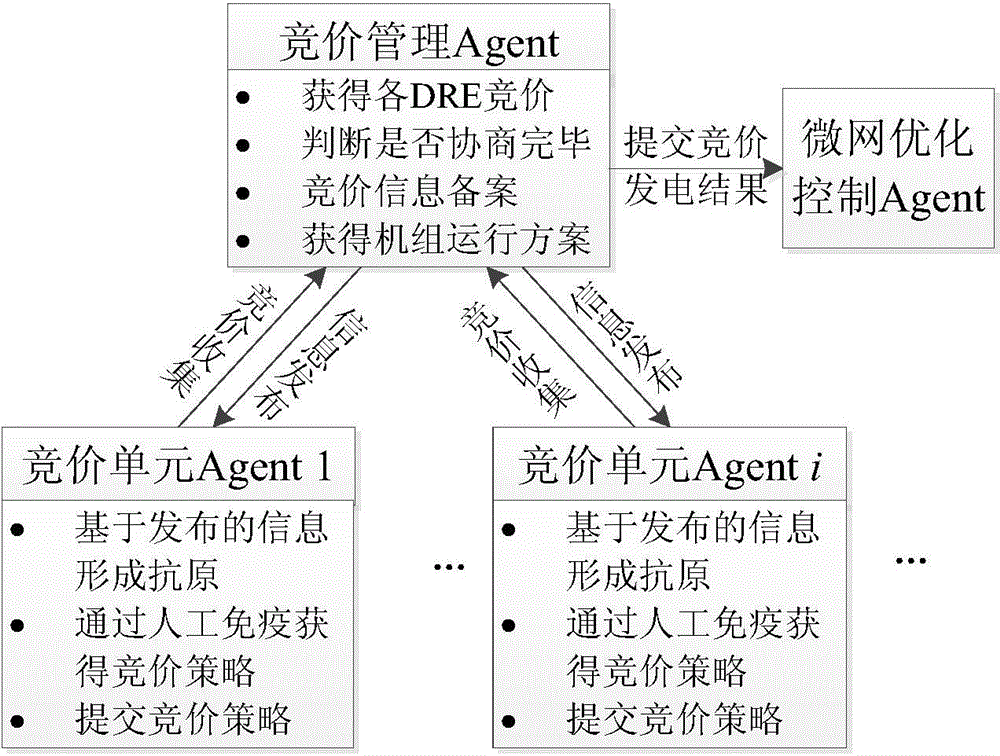

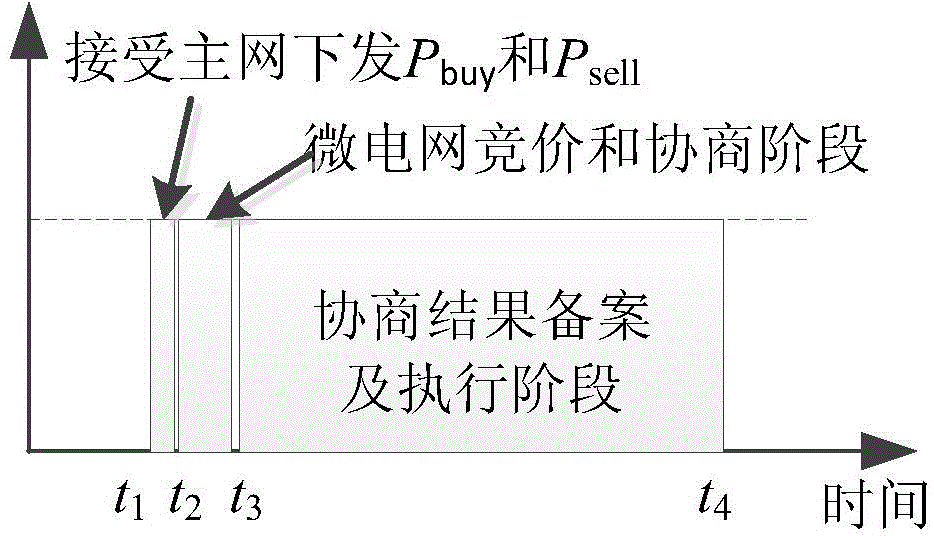

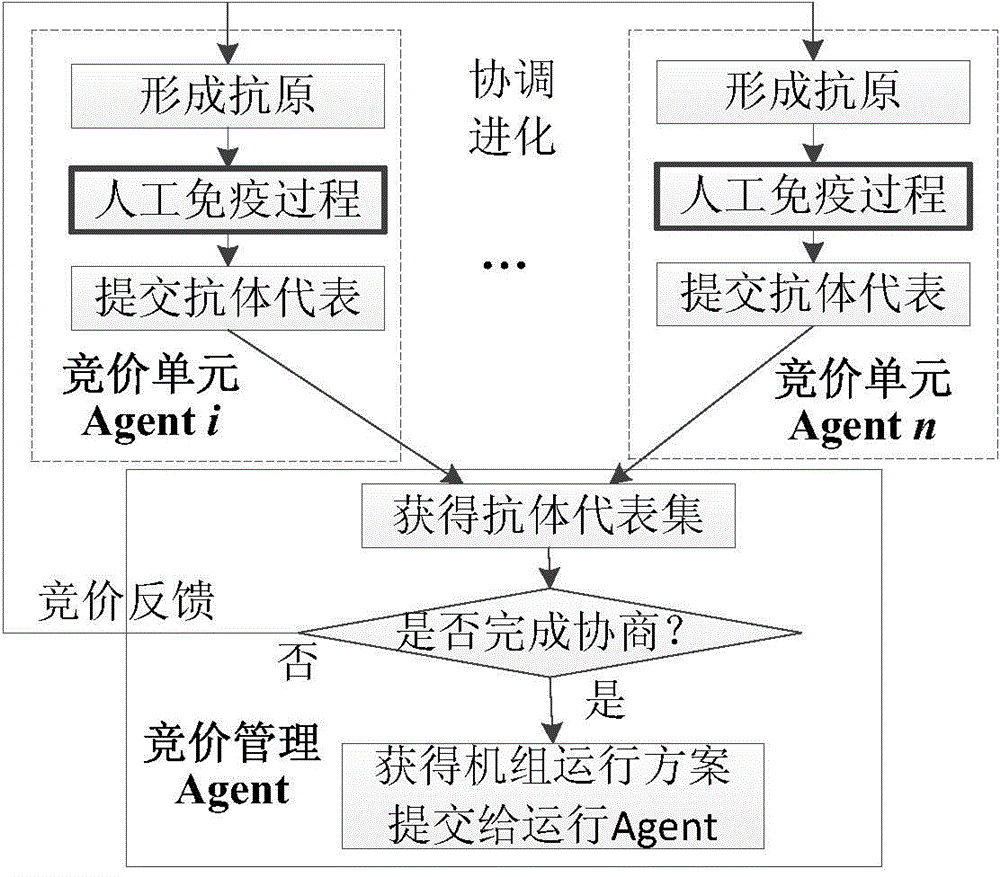

Operation optimization method for multi-agent-structure micro-grids

InactiveCN104392279ARealize commercial operationGeneration forecast in ac networkDc network circuit arrangementsElectricity priceControl system

The invention discloses an operation optimization method for multi-agent-structure micro-grids. The method comprises the steps that a micro-grid obtains electricity price Pbuy which is sold to users by a main grid in the next period and distributive energy purchase electricity price Psell; bidding-based micro-grid operation optimization calculation is performed; micro-grid distributive power supply achieves the quote function through unit bidding; bidding management agents assist to complete negotiation and optimization of units in the micro-grid; the bidding management agents send generation capacity bidding results of the units to the micro-grid control system, and the micro-grid control system performs micro-grid operation optimization based on bidding negotiation results. According to the method, the problems that prior operation modes cannot perform micro-grid internal benefit distribution during non-uniform properties of equipment in the micro grid or relating to public micro grids is solved, and achieving of the commercial operation of micro grids is facilitated.

Owner:TIANJIN UNIV

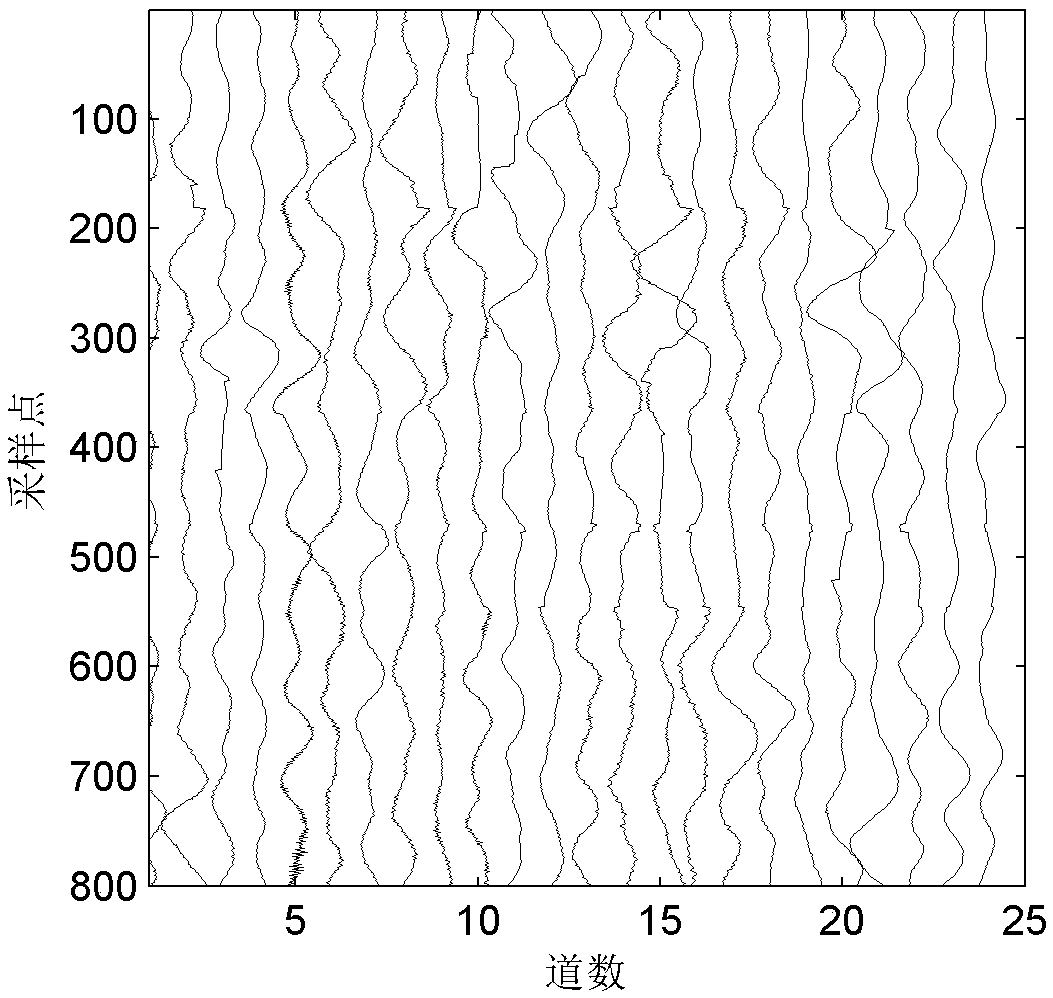

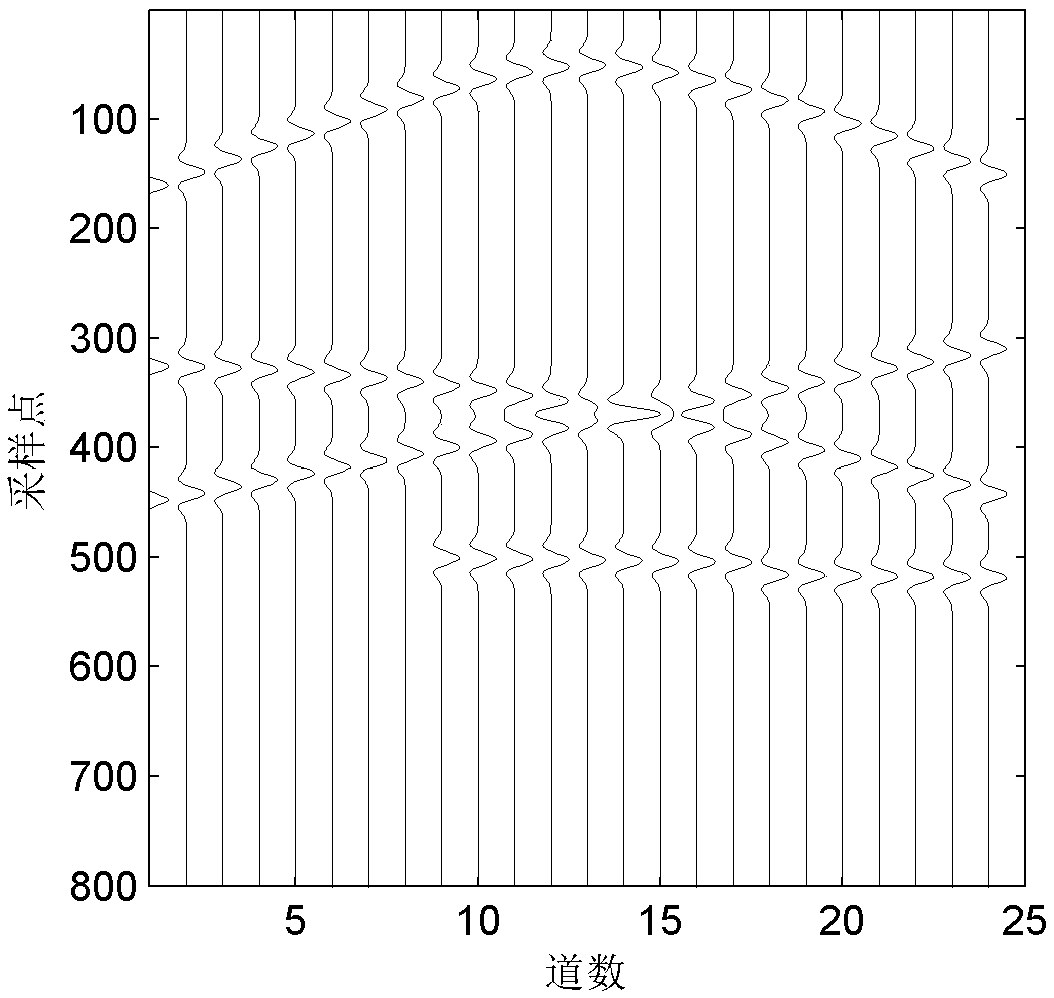

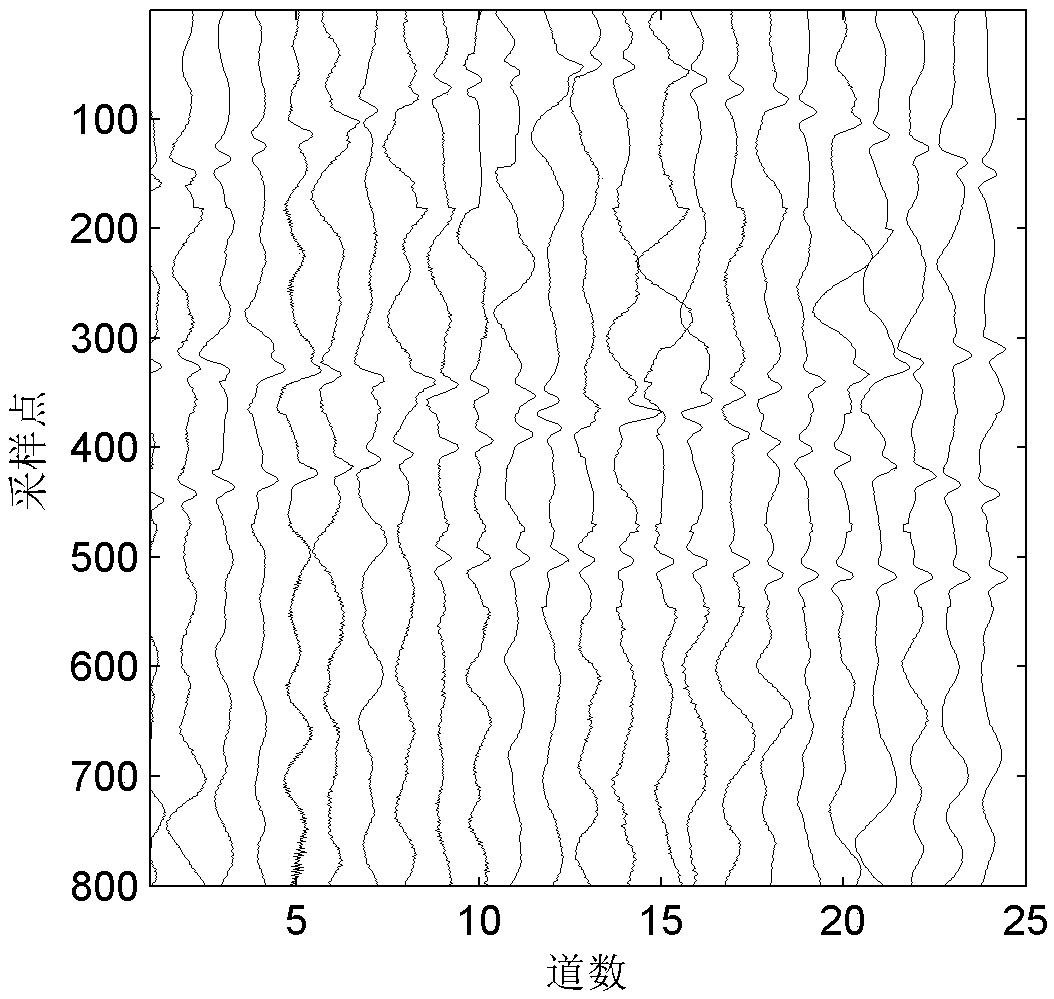

Block sparse compressed sensing-based desert seismic exploration random noise suppression method

ActiveCN107817527AReduce sparsityImprove sparsitySeismic signal processingImage resolutionRandom noise

The invention relates to a block sparse compressed sensing-based desert seismic exploration random noise suppression method and belongs to a method for eliminating the low-frequency random noise in the desert seismic exploration environment. The accurate positioning of effective signals is achieved through the research on the non-uniform property of the desert noise. The characteristic that a seismic signal structural block is sparse is fully considered by the block sparse compressed sensing algorithm, so that the purpose of random noise suppression in the desert area is achieved. According tothe invention, on the premise that the random noise in the desert area is reduced, the amplitude of effective reflection waves in seismic record can be effectively kept. The resolution of seismic data is improved. The method provides a favorable condition for the seismic data treatment of petroleum and natural gas exploration in the complex and variable desert environment.

Owner:JILIN UNIV

Method for manufacturing a tunnel junction magnetic sensor using ion beam deposition

InactiveUS20080152834A1Avoids target poisoningQuality improvementNanomagnetismNanoinformaticsOxygen ionsIon deposition

A method for forming a MgO barrier layer in a tunnel junction magnetoresistive sensor (TMR). The MgO barrier layer is deposited by an ion beam deposition process that results in a MgO barrier layer having exceptional, uniform properties and a well controlled oxygen content. The ion beam deposition of the barrier layer includes placing a wafer into an ion deposition chamber and placing Mg target into the chamber. An ion beam from an ion beam gun is directed at the target thereby dislodging Mg atoms from the target for deposition onto the wafer. Oxygen is introduced into the chamber by one or both of pumping molecular oxygen (O2) into the chamber and / or introducing oxygen ions into the chamber from a second ion beam gun. The use of ion beam deposition avoids oxygen poisoning of the Mg target, such as would occur using a more conventional plasma vapor deposition technique.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

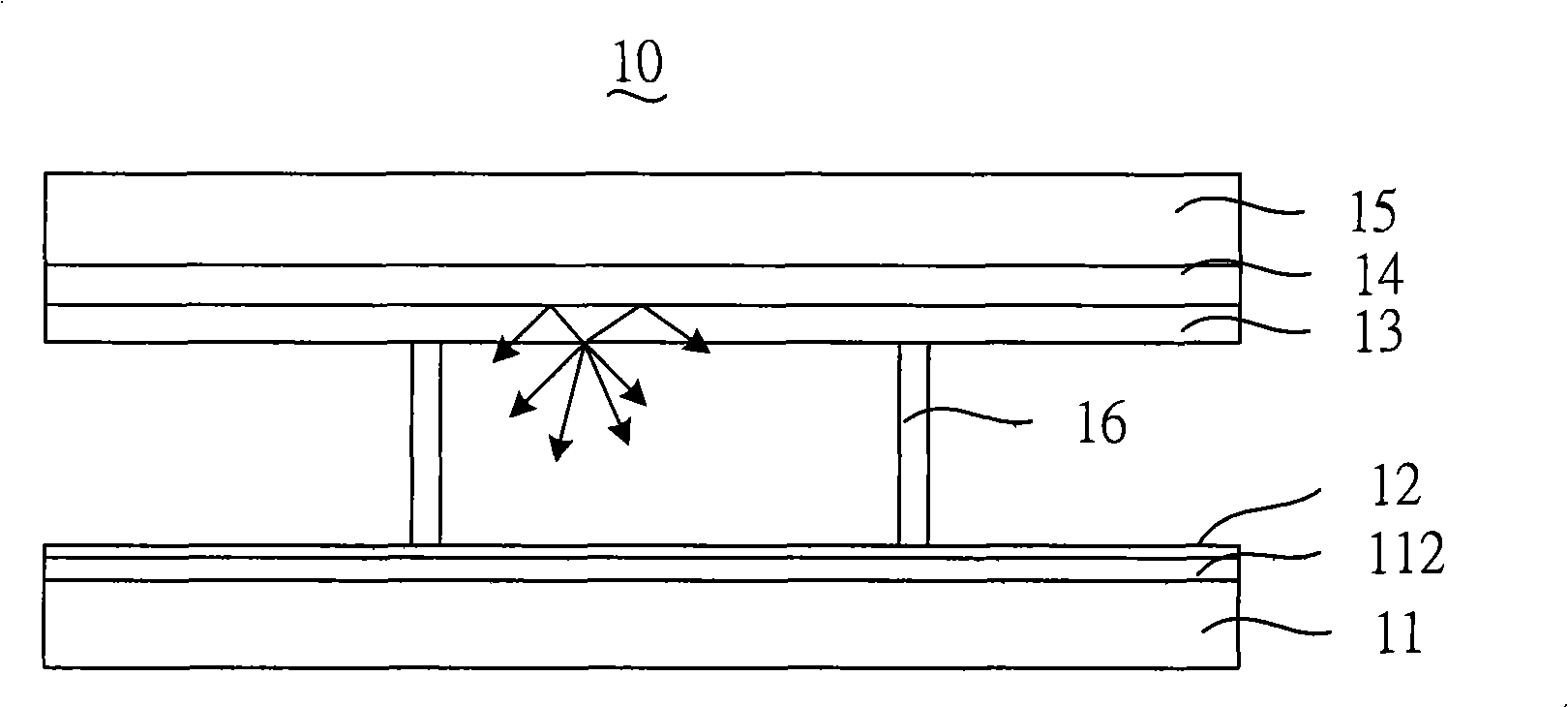

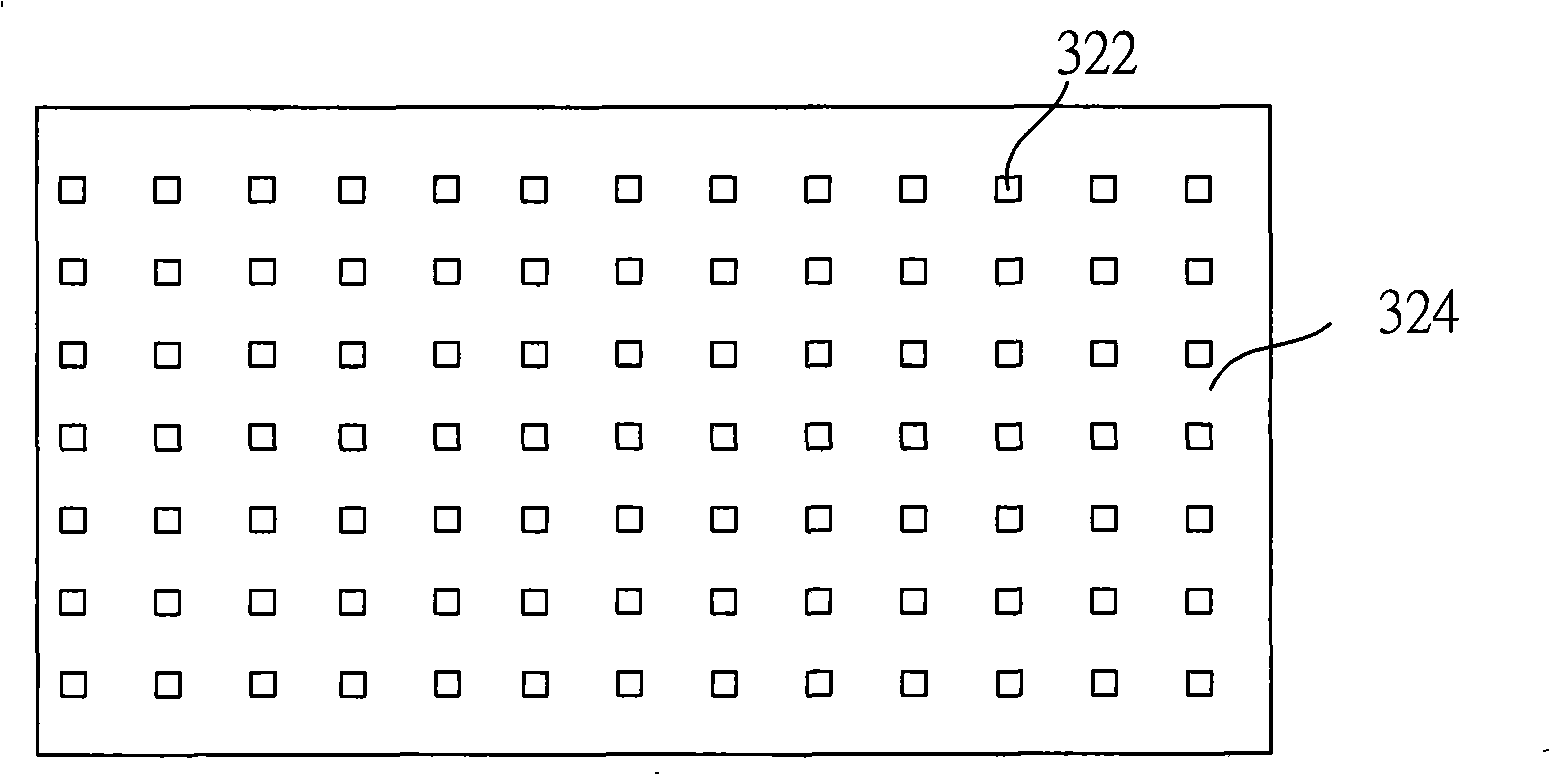

Field emission backlight

ActiveCN101285960AImprove uniformityCathode ray tubes/electron beam tubesElectroluminescent light sourcesCarbon nanotubeOptoelectronics

The invention relates to a field emission backlight, comprising an anode substrate, a cathode substrate and a fluorescent layer arranged on the anode substrate. A light reflecting layer is arranged between the anode substrate and the fluorescent layer; the cathode substrate is transparent; the cathode substrate is provided with a transparent conducting layer and an enphoric cathode; the enphotic cathode comprises a carbon nanotube; and emergent light of the field emission backlight has high-uniform property.

Owner:TSINGHUA UNIV +1

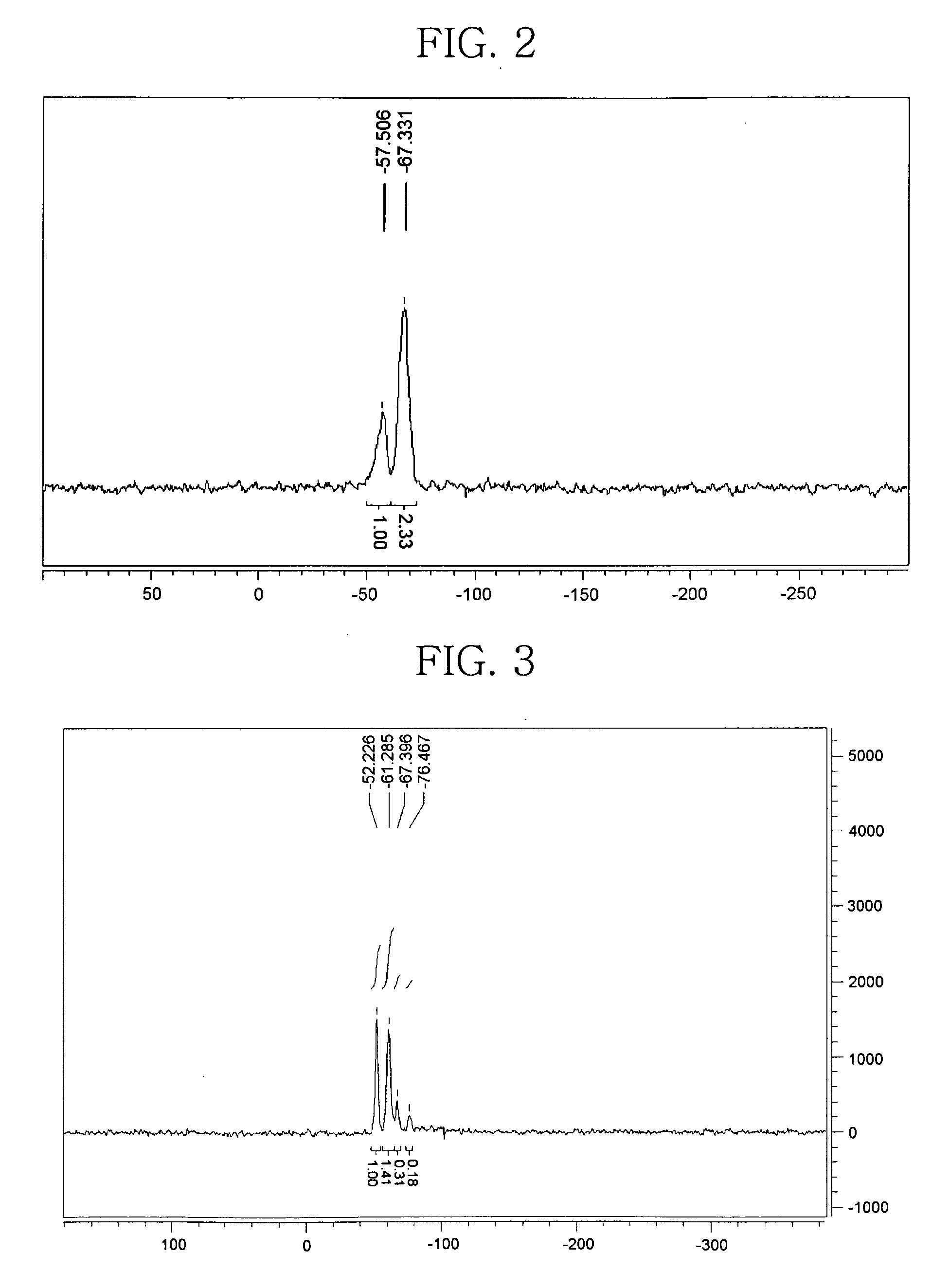

Composition and organic insulator prepared using the same

ActiveUS20080308793A1Improve electrical performanceReduce and prevent generationPlastic/resin/waxes insulatorsSolid-state devicesHysteresisHybrid material

Disclosed are a composition including a silane-based organic / inorganic hybrid material having a multiple bond and one or more organic metal compounds and / or one or more organic polymers, an organic insulator including the composition, an organic thin film transistor (OTFT) including the organic insulator and an electronic device including the OTFT. The organic insulator including the composition for preparing an organic insulator has increased charge mobility and an increased on / off current ratio, thus exhibiting improved properties, and the organic thin film transistor manifests uniform properties due to the absence of hysteresis.

Owner:SAMSUNG ELECTRONICS CO LTD

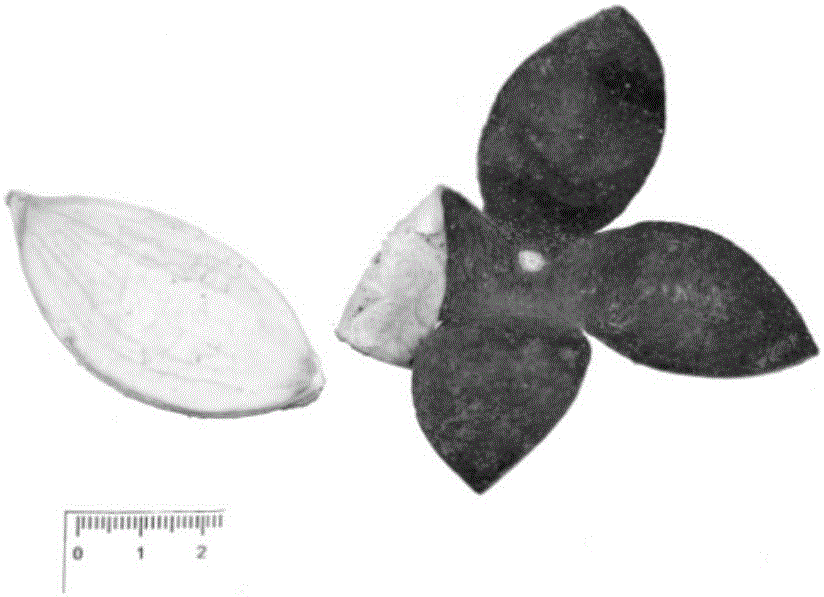

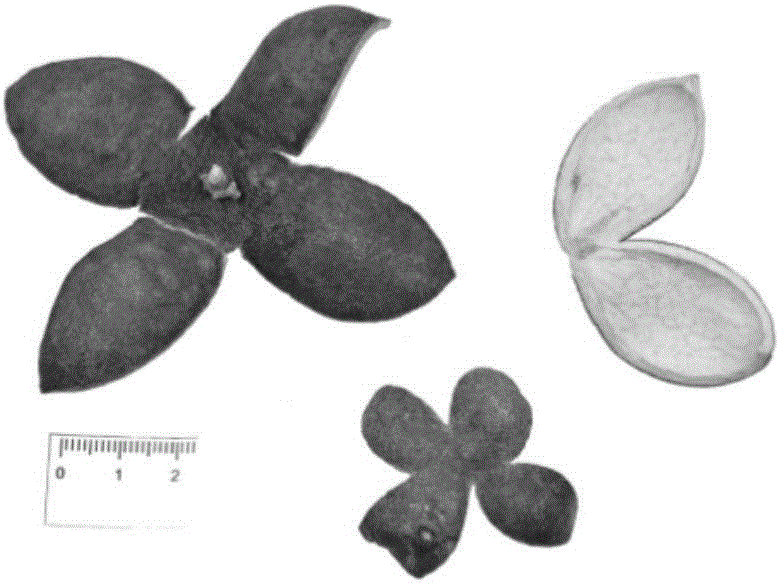

Apparatus and method for phacoemulsification

Owner:TAKAYUKI AKAHOSHI M D +1

Green tangerine orange peel reference extract and application thereof

ActiveCN106841433AQuality assuranceEasy to prepareComponent separationTangerine FruitDrugs preparations

The invention provides a green tangerine orange peel reference extract which is prepared by the following steps: carrying out multiple extraction on different sources or batches of green tangerine orange peel drug powders to obtain different sources or batches of green tangerine orange peel extracts, and blending the different sources or batches of green tangerine orange peel extracts to obtain the green tangerine orange peel reference extract. The green tangerine orange peel reference extract is blended from different sources or batches of extracts, thereby ensuring the consistency of different batches of green tangerine orange peel reference extracts. By selecting the representative drug as the raw material, the obtained product is representative, and can reflect the quality of the detected drug more visually when being used as the reference extract. The green tangerine orange peel reference extract has stable and uniform properties, and is convenient to use. The green tangerine orange peel reference extract can be used as the reference in the quality control of the green tangerine orange peel and drug preparations containing green tangerine orange peel, can be used for qualitative identification on the drug or traditional Chinese medicine preparation, and can also be used for semiquantitative and even quantitative analysis.

Owner:广州浩意万医药科技有限公司

Heat treatment process for bearing steel

The invention provides a heat treatment process for a bearing steel. According to the process, the technology measure of combination of quenching temperature increasing and an isothermal treatment is adopted to change the internal organizational structure of the steel so as to comprehensively improve the comprehensive properties of the chromium-containing bearing steel. The experiment results show that: the completely-austenitized chromium-containing bearing steel is subjected to isothermal quenching and tempering pretreatment, the treated carbide has characteristics of fine and uniform property, and dispersed distribution; with the refined austenite grains, the wear resistance of the steel is increased by more than 30%; the cold processing plasticity of the steel is improved, and the cutting property and the welding performance of the steel are substantially improved.

Owner:张莹

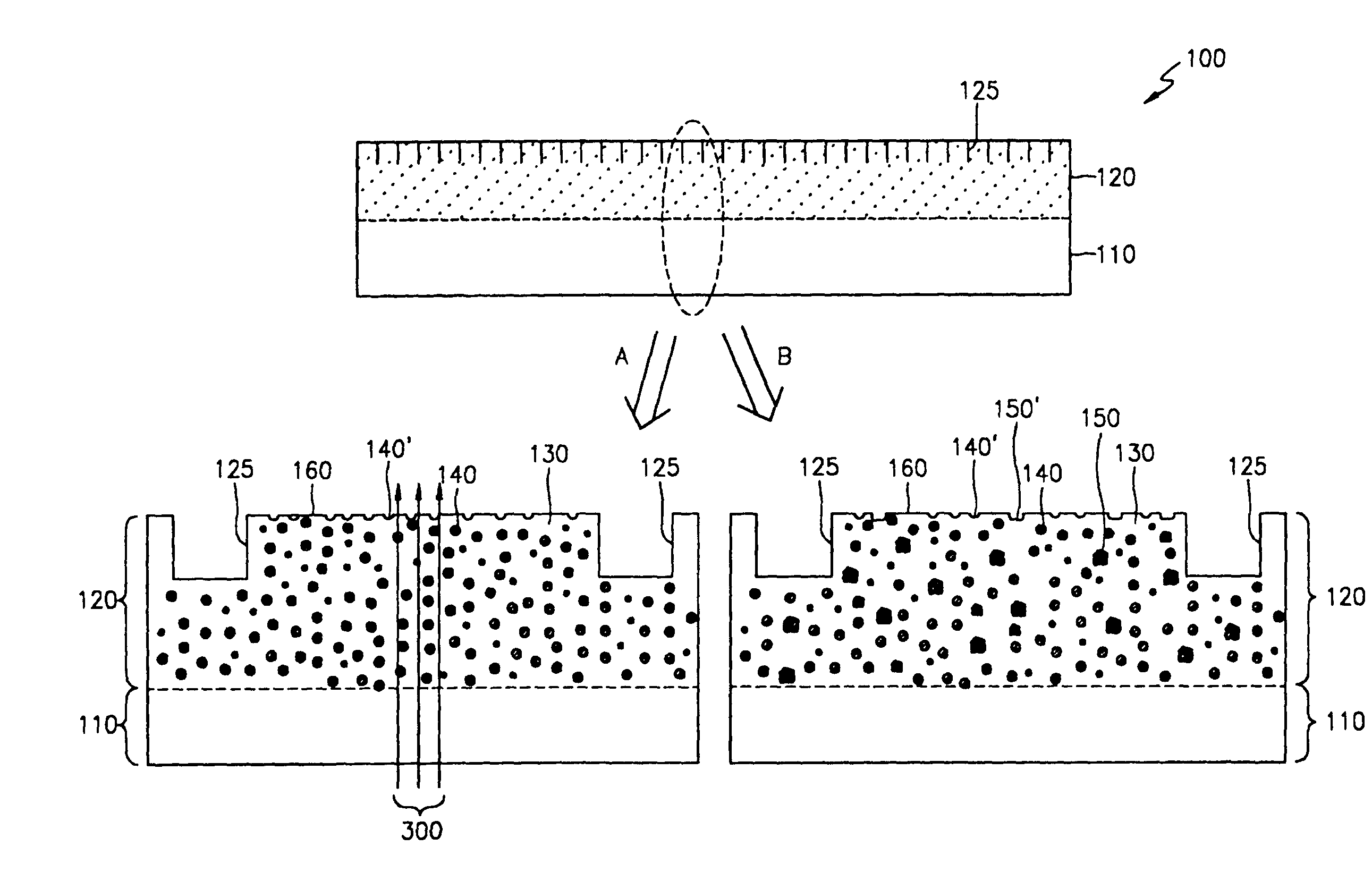

Integral polishing pad and manufacturing method thereof

InactiveUS20050260928A1Improve planarization efficiencyEasy to manufactureSemiconductor/solid-state device manufacturingTraffic signalsManufacturing technologyAdhesive

An integral polishing pad includes an elastic support layer and a polishing layer, which is formed on the elastic support layer and has a higher hardness than the elastic support layer. The elastic support layer and the polishing layer are made from materials chemically compatible with each other so that a structural border between the elastic support layer and the polishing layer does not exist. In addition, the integral polishing pad also includes a transparent region, which is transparent to a light source used to detect the surface state of an object being polished and integrated with the other elements of the integral polishing pad. The integral polishing pad has high planarization efficiency and uniform properties, and thus can be reliably used for polishing. In addition, the integral polishing pad prevents a congestion of a polishing slurry and facilitates delivery of the polishing slurry. The integral polishing pad does not need an adhesive for connecting elements or a process for bonding the elements, thereby simplifying manufacturing processes.

Owner:KPX CHEM

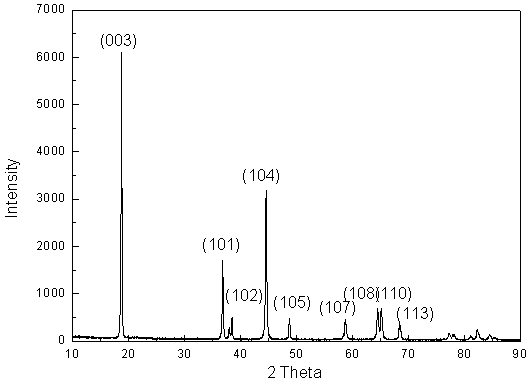

Catalyst for preparing aromatic hydrocarbons through directed conversion of CO2 and preparation method of catalyst

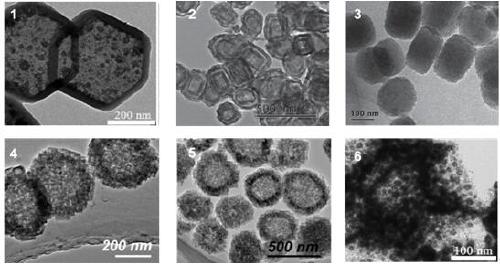

ActiveCN109985659AUniform compositionUniform structureHydrocarbon from carbon oxidesMolecular sieve catalystsSimple Organic CompoundsCore shell

The invention discloses a catalyst for preparing aromatic hydrocarbons through directed conversion of CO2, and relates to the technical field of catalytic hydrogenation. Metal oxide is adopted as a core, and a a molecular sieve is adopted as a shell so as to obtain the core-shell structure catalyst, wherein the metal ion center of the metal organic compound is one or more of Zn<2+>, Zr<2+>, Fe<3+>, Co<2+>, Ni<2+>, Cu<2+>, Cr<3+> and Mn<2+>, and the molecular sieve is one or more of ZSM-5, MCM-41, SAPO, MCM-22, USY and SBA-15. The catalyst for preparing aromatic hydrocarbons through directed conversion of CO2 has the characteristics of a uniform structure, uniform properties and precise regulation, the preparation process has simple procedures and high repeatability, and the prepared catalyst has the advantages of high conversion rate of CO2, high selectivity to aromatic hydrocarbons, a long service life, a wide application range and the like; and the prepared catalyst can be directly applied to preparation of aromatic hydrocarbons through directed conversion of CO2, and has an industrial value.

Owner:NANJING INST OF TECH

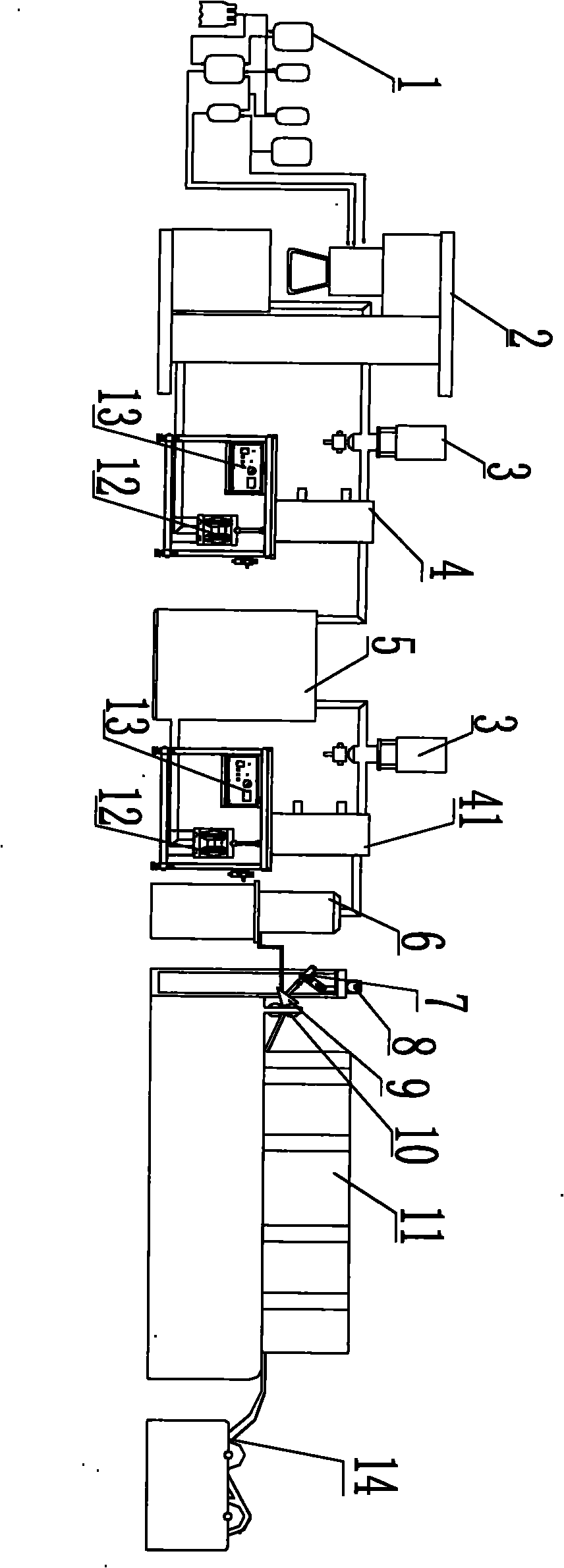

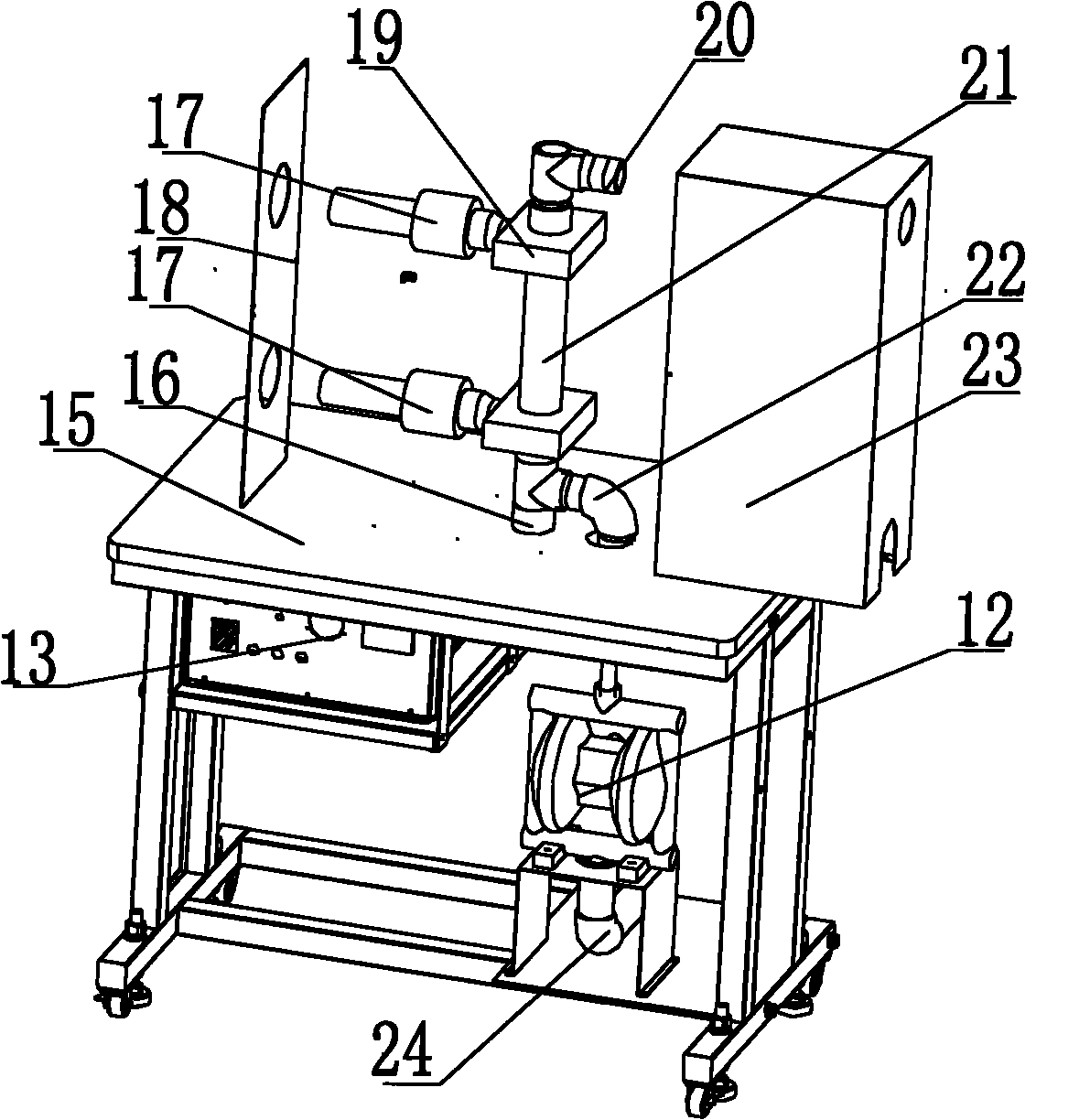

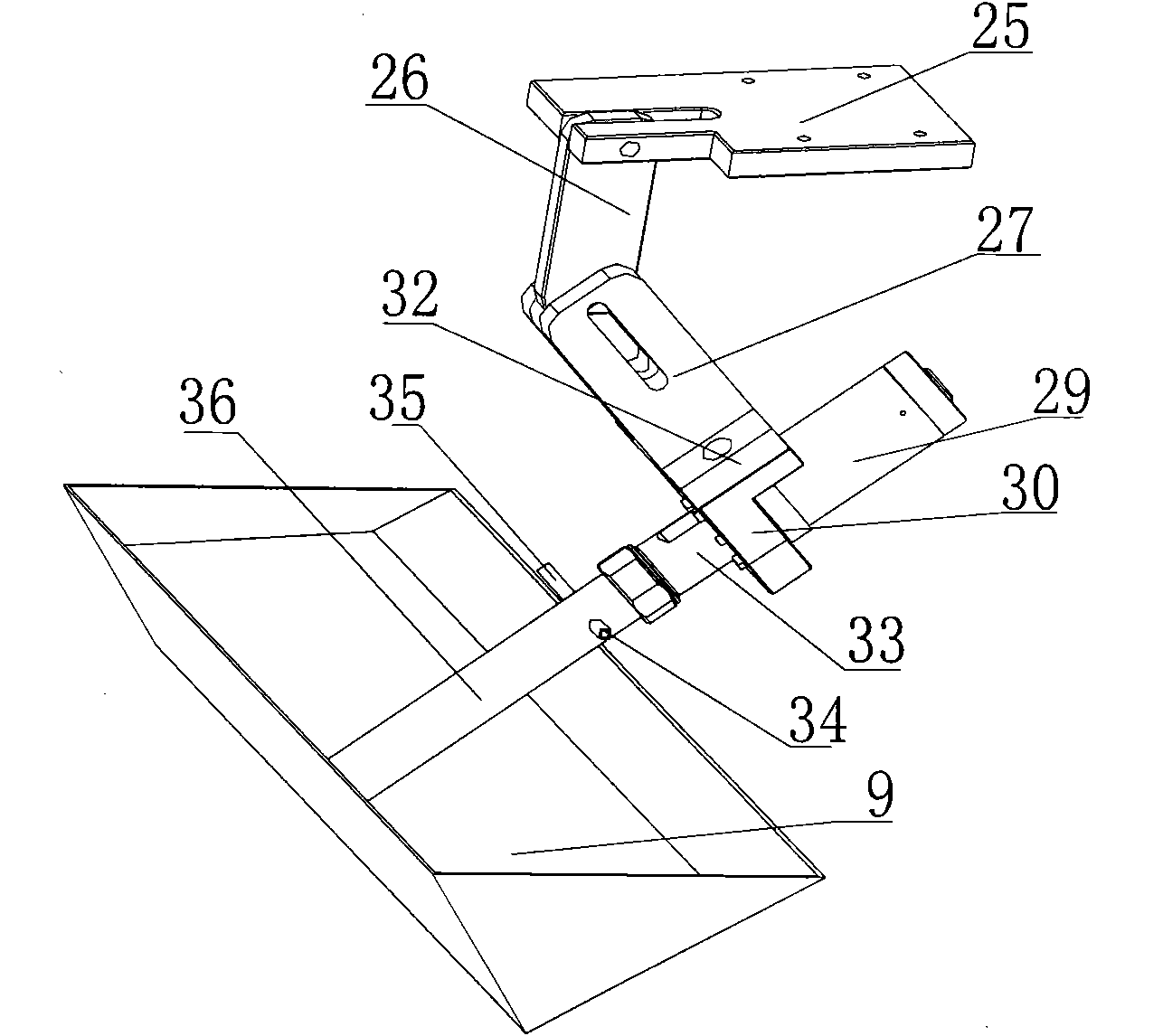

Dispersing and spraying automatic continuous production system of electrode paste of power battery

ActiveCN101966509AImprove consistencyEvenly dispersedLiquid surface applicatorsShaking/oscillating/vibrating mixersPower batteryLithium

The invention discloses a dispersing and spraying automatic continuous production system of electrode paste of a power battery, which comprises a proportioner, an initial stirring device, a paste dispersing device, a filtering device and a spraying device, wherein the proportioner is used for proportioning materials according to a set proportion, then the proportioned materials are transmitted into the initial stirring device for stirring, the initial stirring device is connected with the paste dispersing device which is connected with the filtering device, the filtering device is connected with the spraying device; and the paste dispersing device comprises a reaction pipe and at least one clamp type ultrasound processor, and the at least one clamp type ultrasound processor is clamped on the reaction pipe through a functional clamp. The invention has the advantages that small particles in the paste can be effectively dispersed uniformly by the two-stage ultrasound paste dispersing device so as to overcome phenomena of the agglomeration and the like; the sprayed electrode paste material is good in flexible and flat consistency, can effectively reduce the internal resistance and improve the property of the lithium ion power battery; and the spraying and adhering firm, flexible and flat consistency quality is improved, and the production cost can be effectively lowered.

Owner:GUANGZHOU NEWPOWER ULTRASONIC ELECTRONICS EQUIP

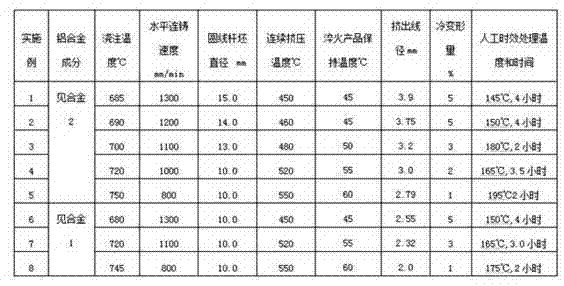

Process for producing aluminum alloy conductor

The invention provides a process for producing an aluminum alloy conductor, comprising the following steps: proportioning materials, melting, refining, carrying out horizontal continuous casting, cleaning, extruding continuously, quenching on line, carrying out small cold deformation stretching on line and ageing manually. By carrying out small cold deformation stretching on line and ageing manually according to the characteristics of continuous extrusion and large shearing deformation, the conduction with small textures, uniform properties and excellent surface quality is obtained. The process has the advantages of simple steps, convenience of operation, high yield and low production cost. The product produced by adopting the process has uniform properties and excellent surface quality. The process provided by the invention is used for producing the aluminum alloy conductor.

Owner:金龙电缆科技有限公司

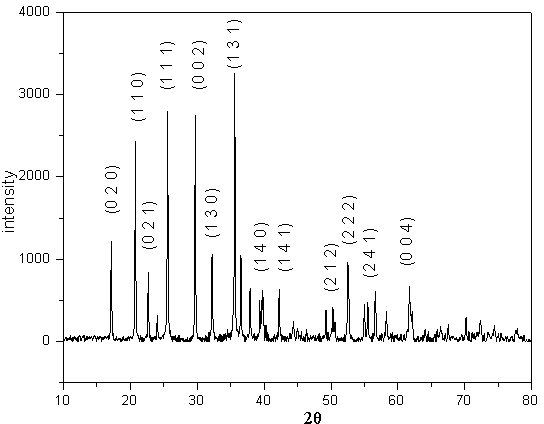

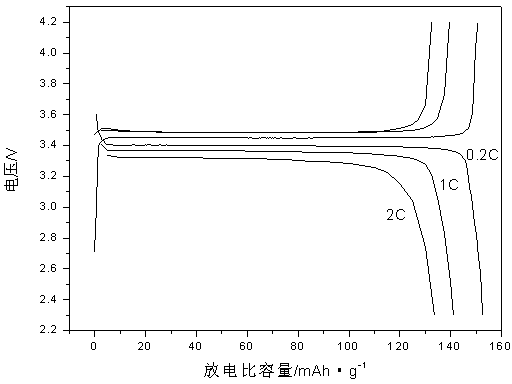

Microwave solidification preparation technology of lithium ion anode-cathode material

A microwave solidification preparation method of a lithium ion anode-cathode material comprises the steps of raw material pretreatment: sequentially adding reaction materials into a polar molecule solvent according to a particular reaction proportion, quickly stirring with stirring equipment to allow the materials to be mixed uniformly, controlling viscosity of the materials to ensure flowability of slurry, and realizing a refined and controllable particle size of the materials with a grinding and emulsification device to allow the obtained uniform slurry to be good in homogeneity and strong in microwave penetrating power, microwave chemical combination-instant solidification, dry material roasting: after collecting a dry material, putting the material into a high-temperature sintering furnace, precharging protective gas for 30-60min, roasting for 2-18h at 700-900 DEG C, or sintering for 1-5h at 300-600 DEG C, then roasting for 2-18h at 700-900 DEG C, and obtaining the lithium ion anode-cathode material with uniform properties and superior performances.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

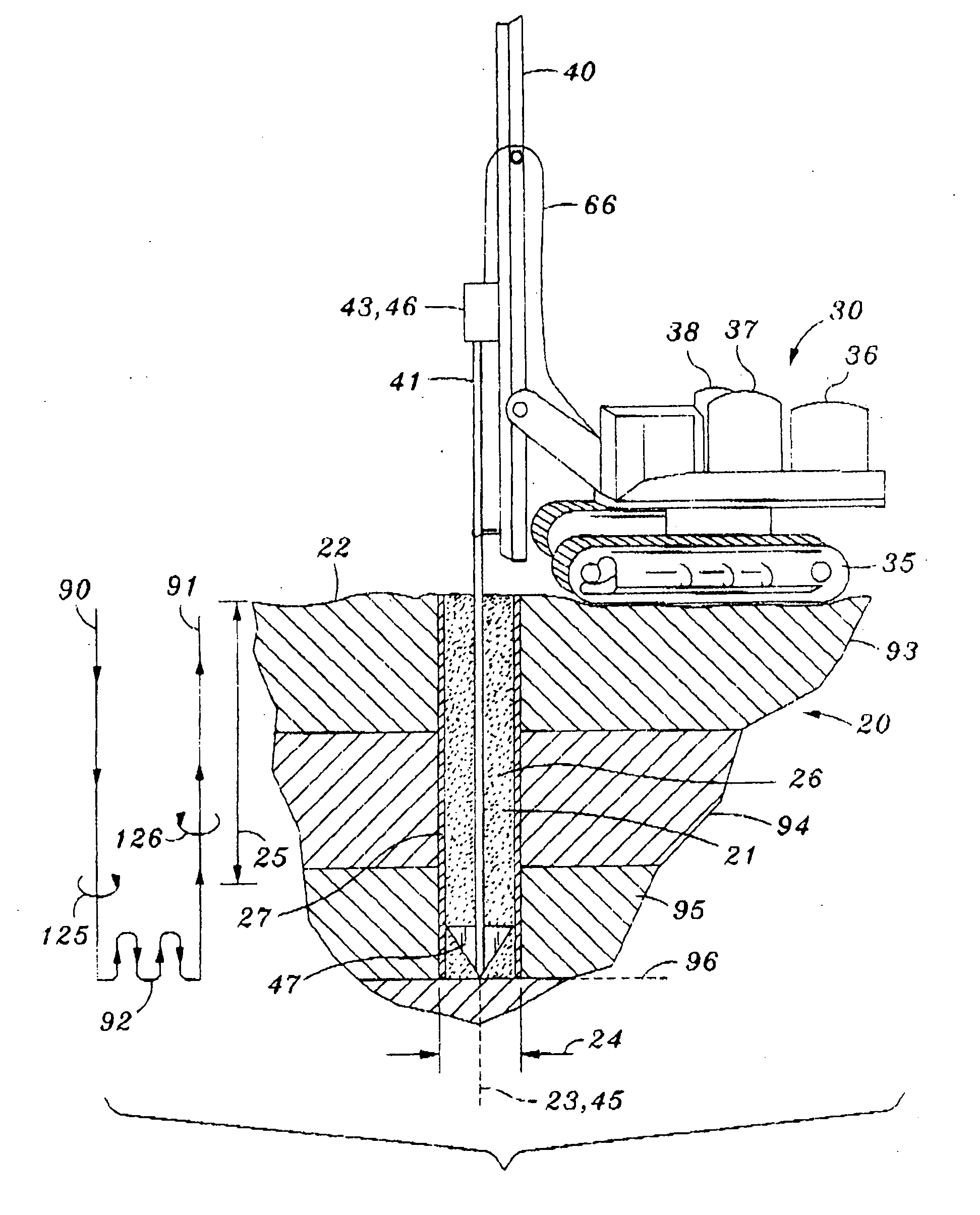

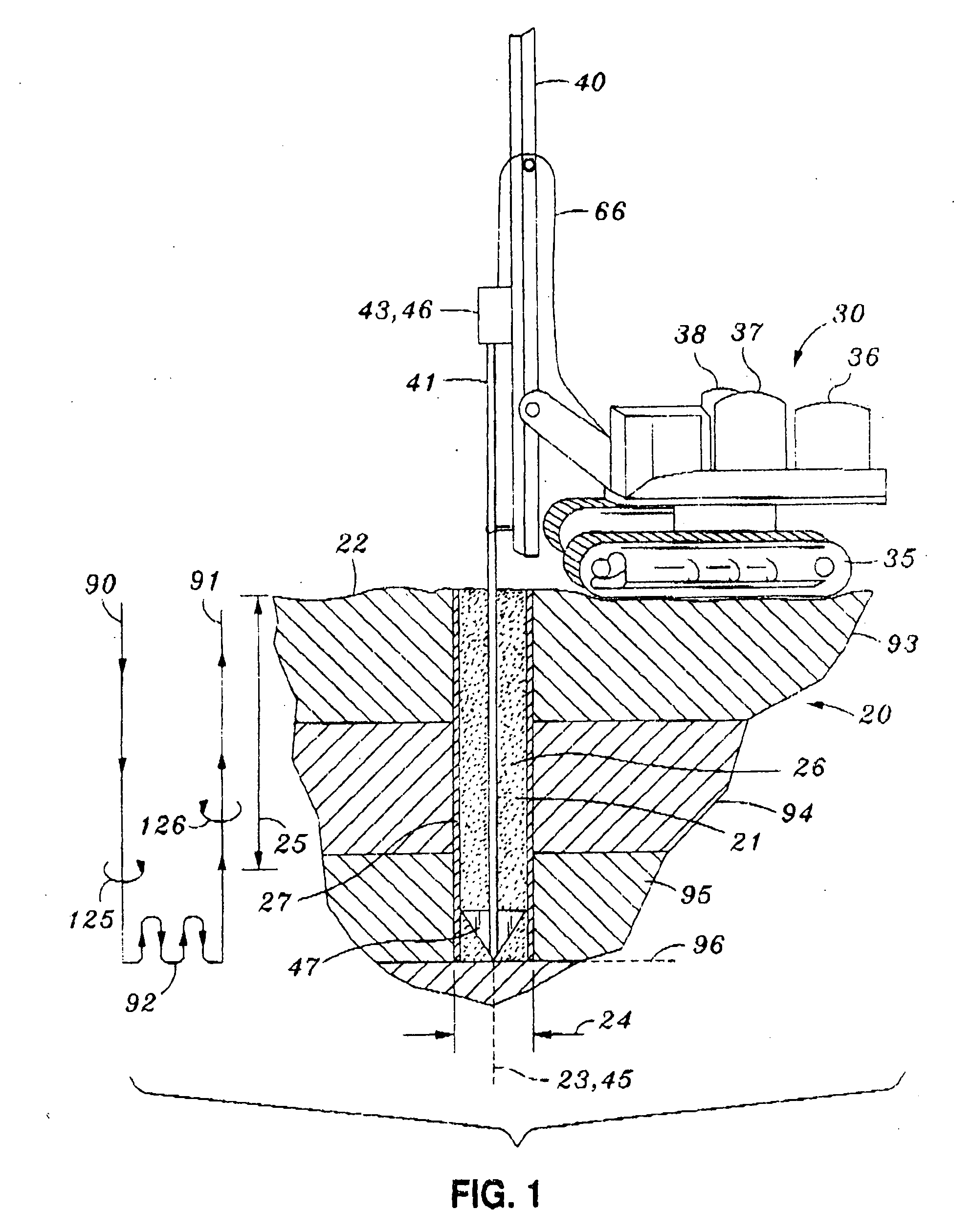

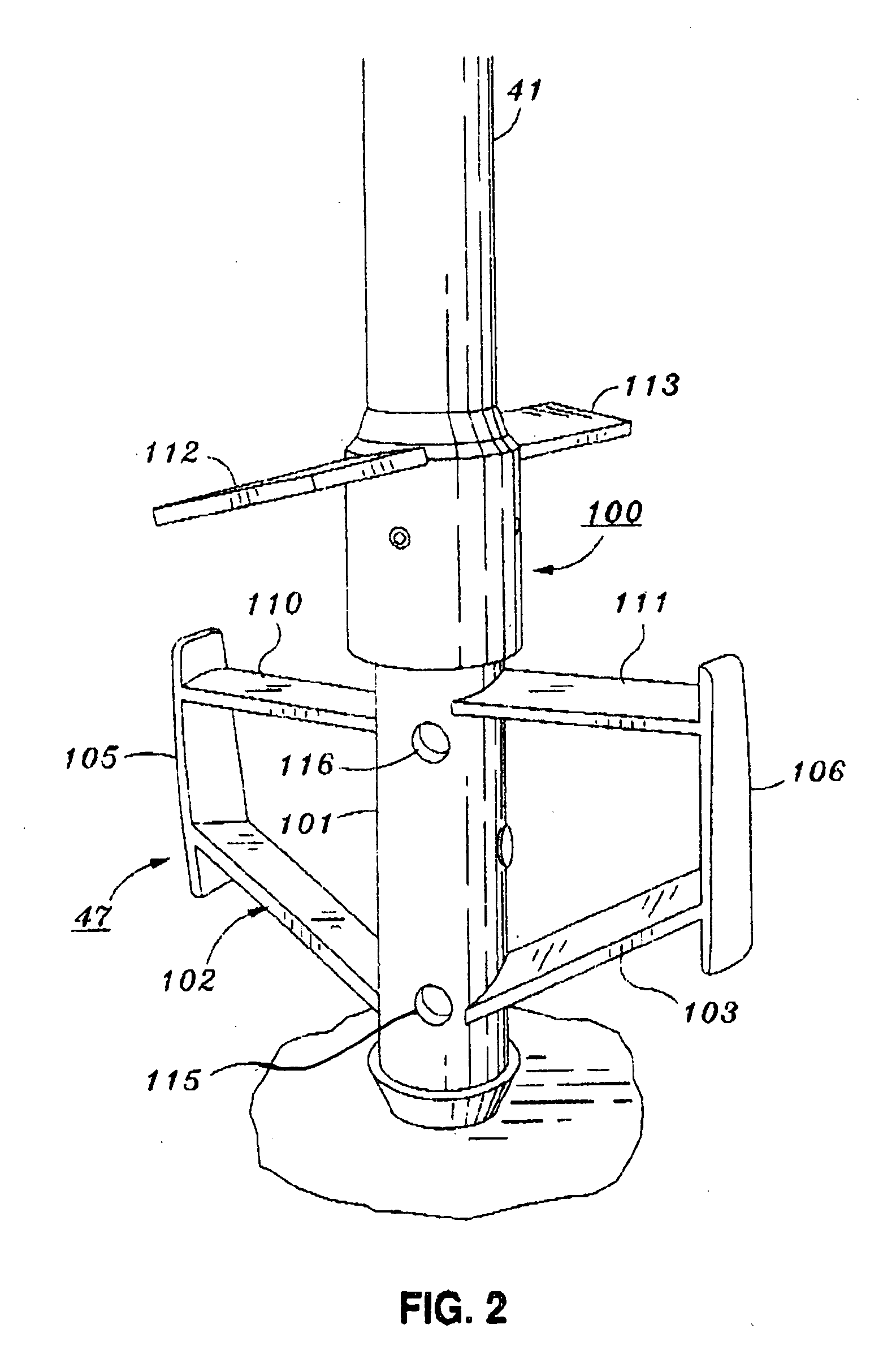

In-situ pilings with consistent properties from top to bottom and minimal voids

InactiveUS20070189859A1Promote escapeBulkheads/pilesSoil preservationUltimate tensile strengthUniform property

Owner:GUNTHER

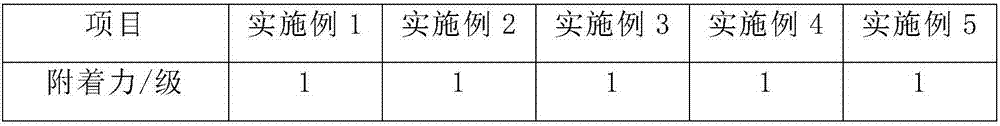

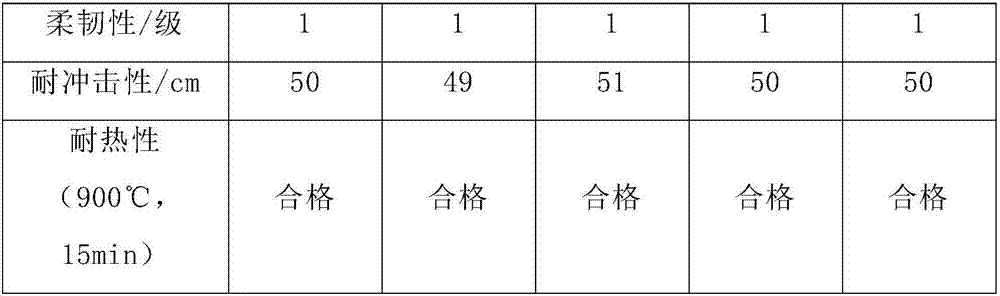

Wear-resistant high-temperature resistant coating having high adhesive force

InactiveCN107201168AImprove high temperature resistanceNon-foamingFireproof paintsAnti-corrosive paintsWear resistantInorganic pigments

The invention belongs to the technical field of equipment coating, and particularly relates to wear-resistant high-temperature resistant coating having high adhesive force. The coating includes silicone resin, a high-temperature resistant filler, aluminum paste, inorganic pigment, a film forming agent, nanometer zirconia ceramic micropowder, a curing agent and a solvent. The high-temperature resistant filler of the coating is quartz powder, mica powder or talcum powder, and the fineness of the filler is 700-800 meshes. The solvent is one of butyl acetate, xylene and n-butanol. The coating has uniform properties. An obtained coating layer of the coating is smooth, fine and good in adhesive force. The coating has excellent high-temperature resistance, good impact resistance, god wear resistance and good corrosion resistance. The coating is particularly suitable for surface protection of high-temperature motors, high-temperature electric resistance furnaces, and other devices.

Owner:HEFEI MINGYOU HIGH TEMPERATURE TECH CO LTD

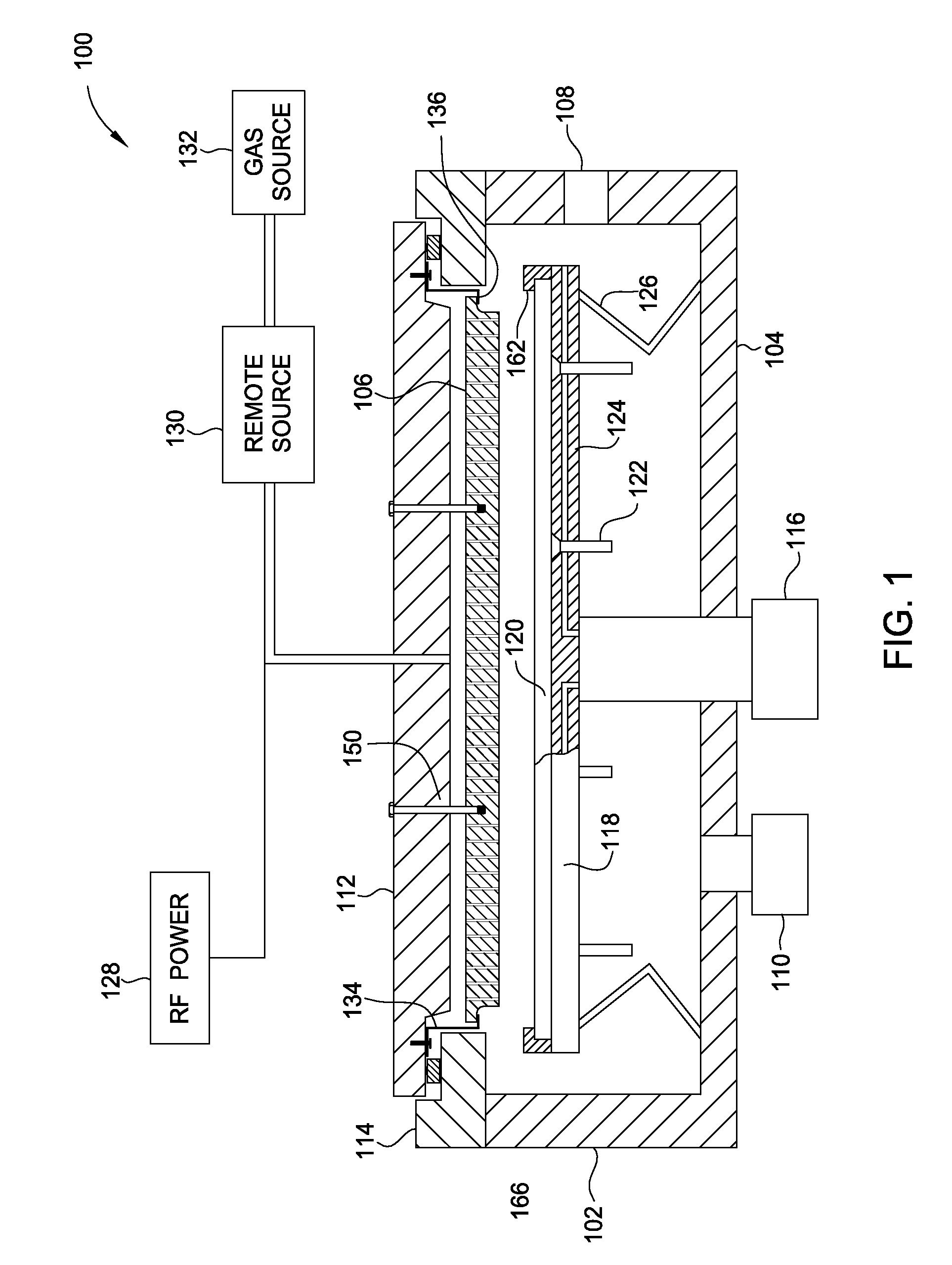

Showerhead and shadow frame

InactiveUS20100037823A1Uniform film propertyUniform propertyDust removalFire preventionEngineeringUniform property

The present invention generally relates to a gas distribution showerhead and a shadow frame for an apparatus. By extending the corners of the gas distribution showerhead the electrode area may be expanded relative to the anode and thus, uniform film properties may be obtained. Additionally, the expanded corners of the gas distribution showerhead may have gas passages extending therethrough. In one embodiment, hollow cathode cavities may be present on the bottom surface of the showerhead without permitting gas to pass therethrough. The shadow frame in the apparatus may also have its corner areas extended out to enlarge the anode in the corner areas of the substrate being processed and thus, may lead to deposition of a material on the substrate having substantially uniform properties.

Owner:APPLIED MATERIALS INC

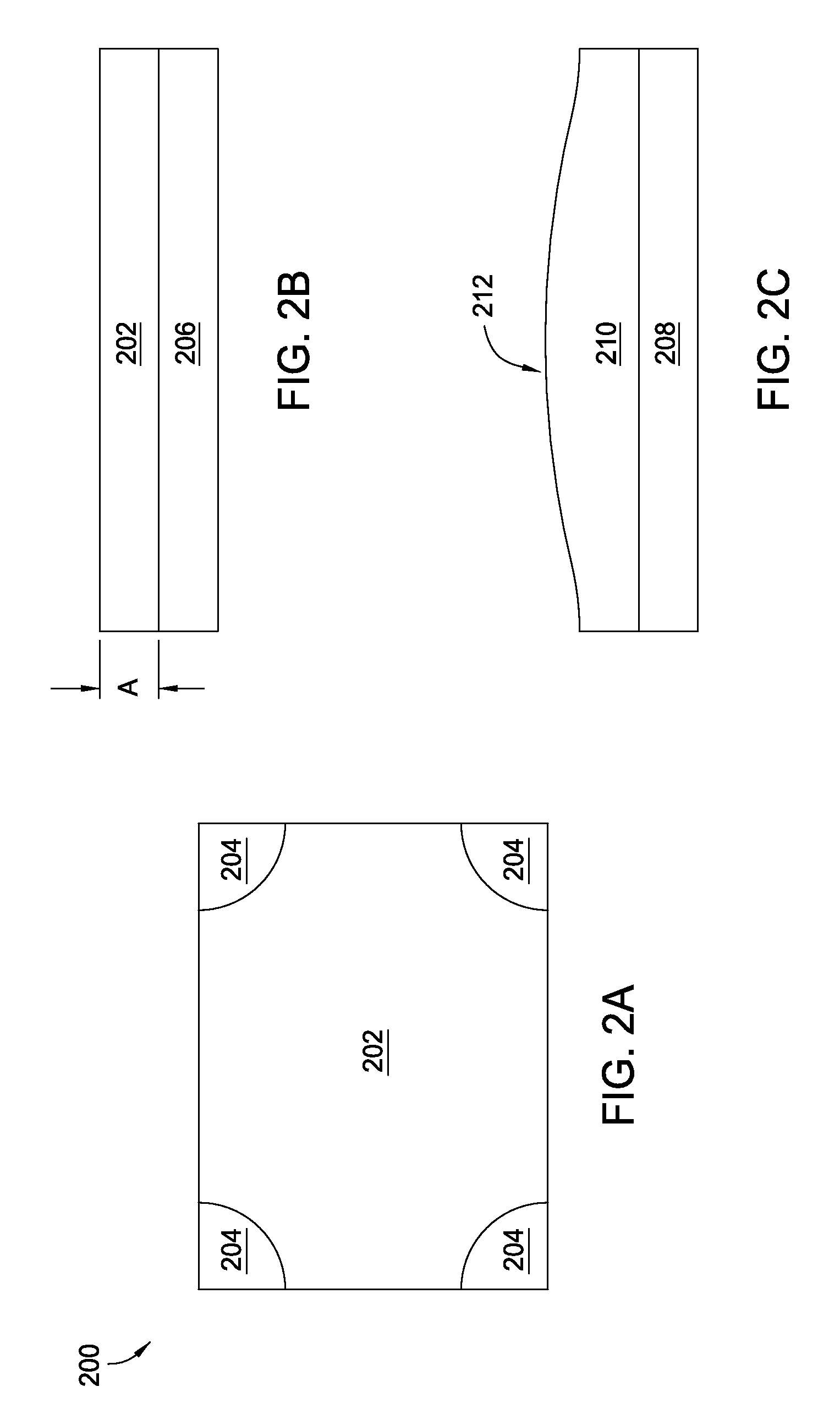

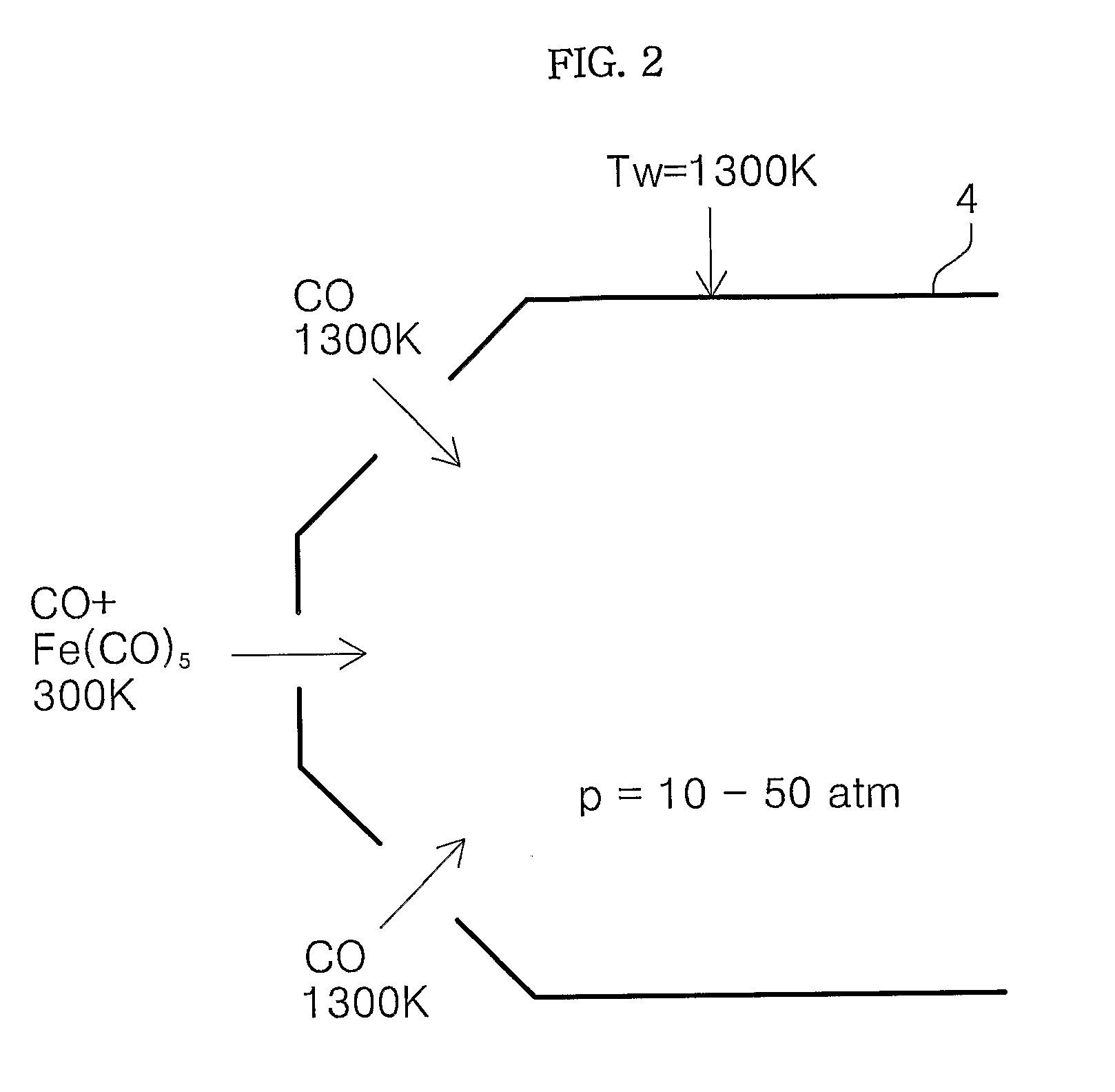

Method and Apparatus for Manufacturing Carbon Nano Tube

InactiveUS20080226535A1Uniform propertyHigh puritySpecific nanostructure formationMaterial nanotechnologyCarbon nanotubeProduct gas

The present invention relates to a method and apparatus for manufacturing a carbon nano tube, and more particularly, to a method and apparatus for manufacturing a carbon nano tube by which a carbon nano tube having a uniform property and high purity can be manufactured by uniformly raising a temperature of reaction gas, which includes a gaseous transition metal catalyst precursor compound and gaseous carbon compound contained in a hermetically closed reaction space, to the Boudouard reaction temperature. The method for manufacturing a carbon nano tube according to the present invention comprises the steps of preparing a reaction vessel including a substantially hermetic and compressible reaction space; supplying the reaction space with carbon nano tube reaction gas containing a gaseous carbon compound and a gaseous transition metal catalyst precursor compound; and compressing the reaction gas in the reaction space until a temperature of the carbon nano tube reaction gas supplied to the reaction space reaches a temperature equal to or greater than a minimum starting temperature of the Boudouard reaction and a temperature at which the transition metal catalyst precursor compound is thermally decomposed, thereby producing gas with carbon nano tube products suspended therein.

Owner:KOREA ADVANCED INST OF SCI & TECH

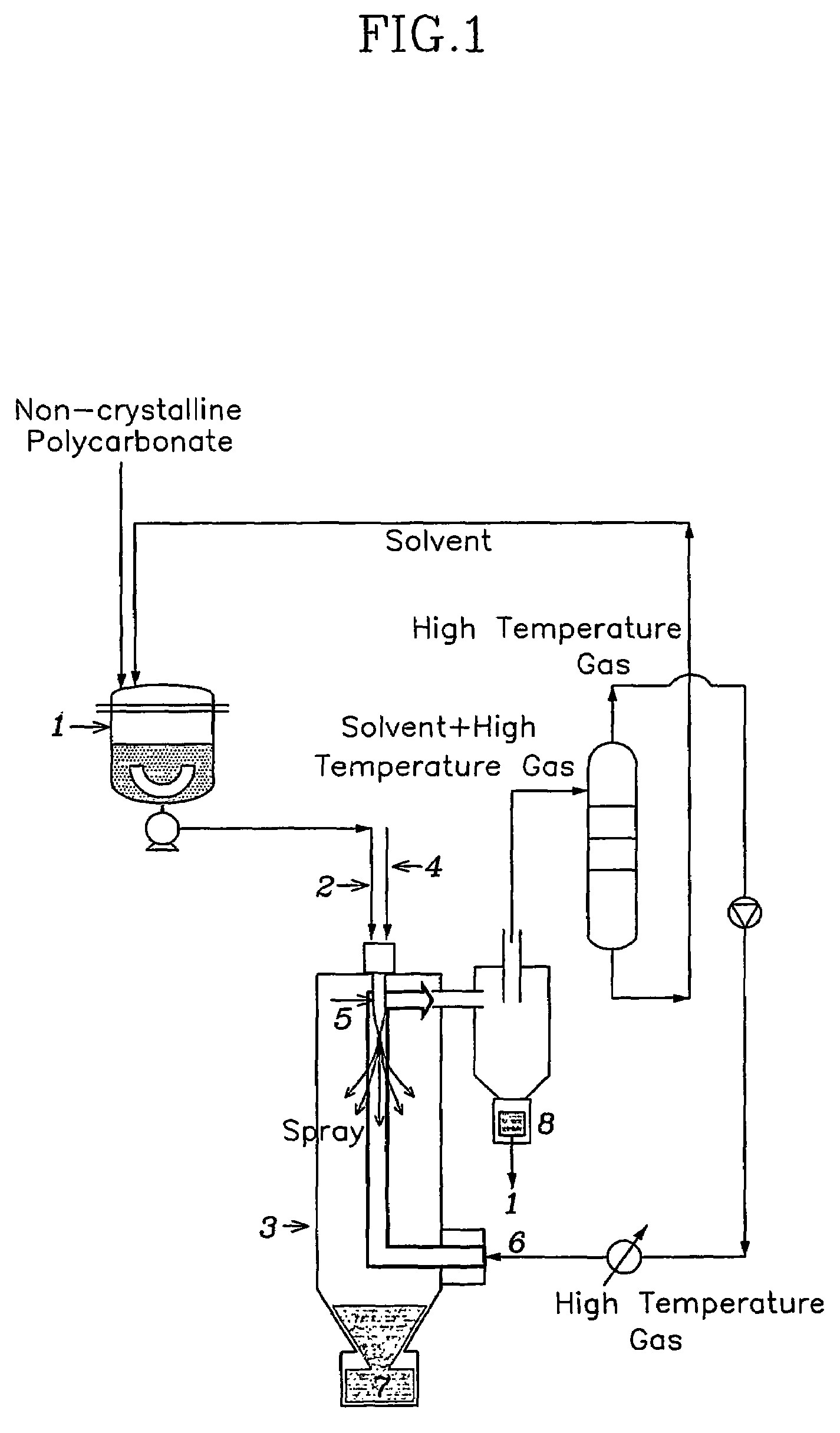

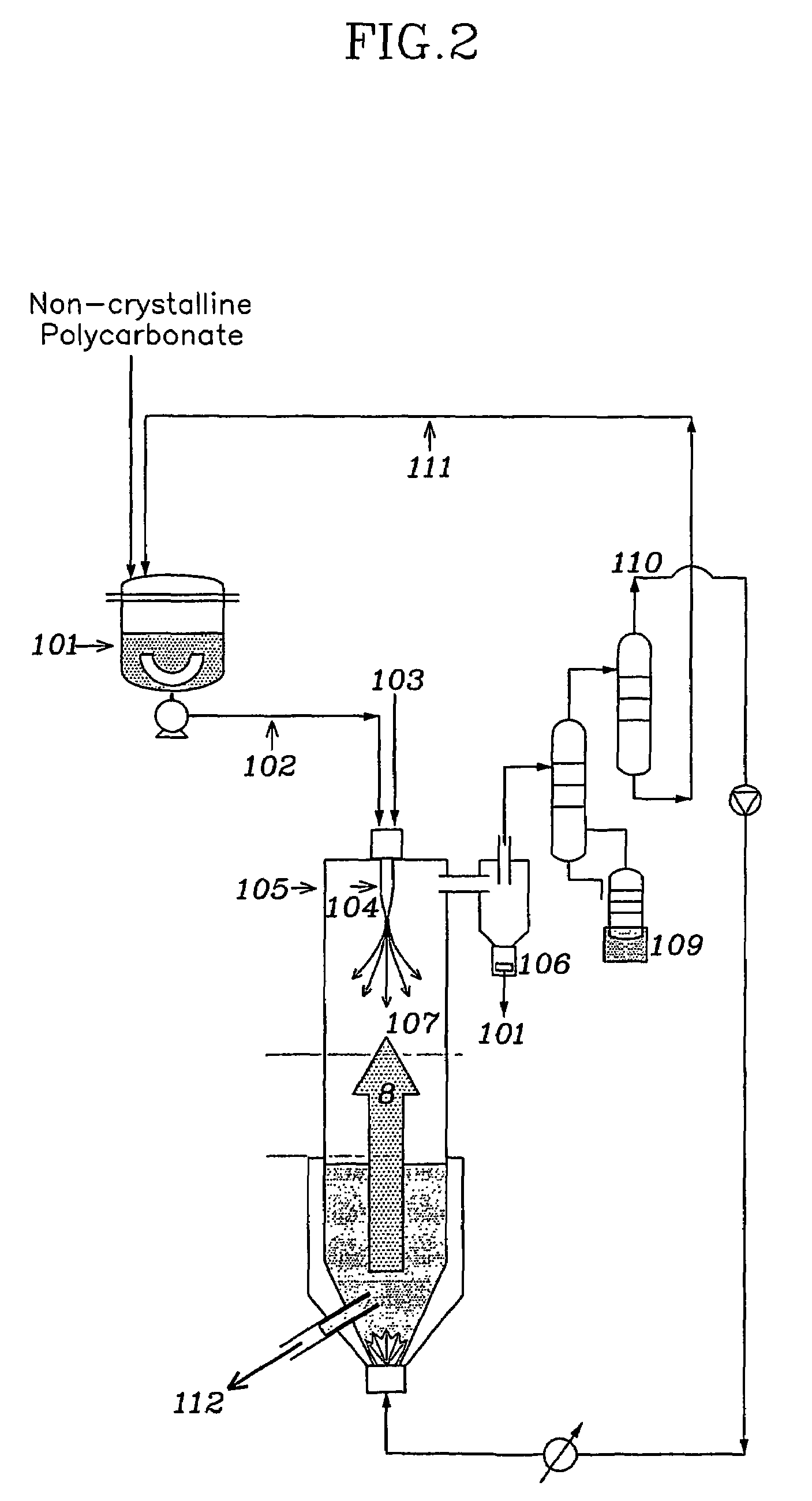

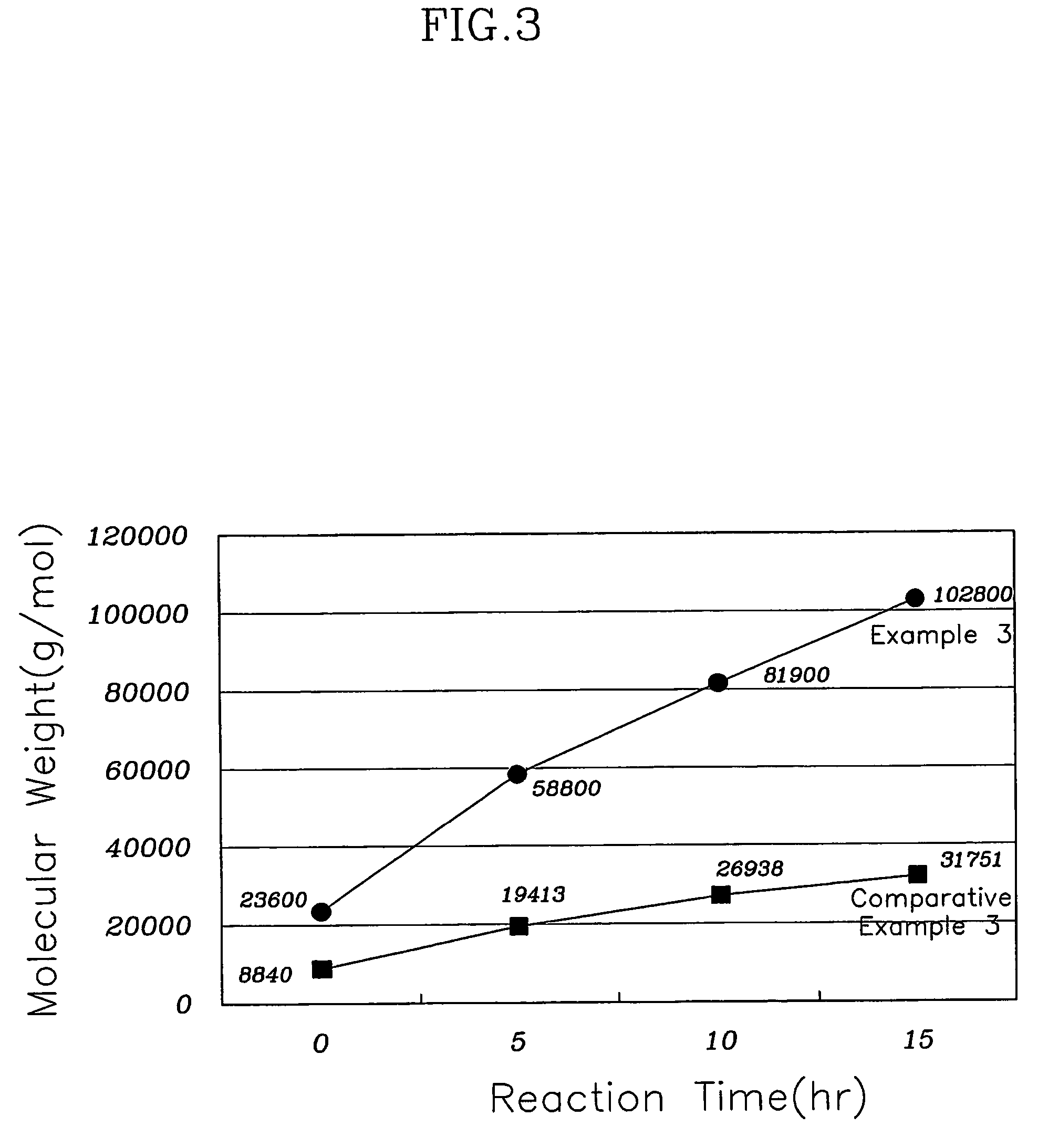

Preparation method of high molecular weight polycarbonate resin

InactiveUS7148312B2High molecular weightUniform physical propertiesChemical/physical/physico-chemical processesPolymer sciencePolycarbonate

The present invention relates to a method for the preparation of a high molecular weight polycarbonate resin, and more particularly to a method for preparing a high molecular weight polycarbonate resin using a solid state polymerization method after the preparation of a crystalline polycarbonate or-conducting the preparation of the crystalline polycarbonate and the solid state polymerization thereof simultaneously. According to the method for the preparation of a high molecular weight polycarbonate resin of the invention, it is possible to produce a high molecular weight polycarbonate resin having a narrow molecular weight distribution and uniform properties and that is applicable to injection and extrusion in large quantities with a low cost within a short time.

Owner:LG CHEM LTD

Novel low-cost wear-resistant pipe steel X65 steel plate and production method thereof

ActiveCN103725974AReduce manufacturing costGuaranteed mechanical propertiesWear resistantPetrochemical

The invention provides a novel low-cost wear-resistant pipe steel X65 steel plate which comprises the following chemical components in percentage by mass: 0.04-0.10% of C, 0.10-0.40% of Si, 1.40-1.60% of Mn, at most 0.02% of P, at most 0.015% of S, 0.015-0.060% of Als, 0.005-0.06% of Ti, 0.20-0.70% of Cr, 0.02-0.07% of V, and other Fe and residual elements. The production method comprises the following steps: converter smelting, LF (ladle furnace) refining, VD (vacuum degasser) vacuum treatment (optional), continuous casting, slow cooling of casting blank, heating, TMCP (thermomechanical rolling process) rolling, slow cooling, and hardening and tempering. By using the novel composite microalloying component design idea and simple effective process design, the method lowers the production cost of the steel plate, ensures the mechanical properties, ultrasonic flaw detection index and other indexes of the steel plate, and enhances the wear resistance of the steel plate. The steel plate produced according to the scheme has the advantages of uniform properties, excellent flaw detection quality and certain wear resistance, can be widely used in the fields of petrochemical industry, coal chemical industry, machine manufacturing and the like, and has favorable popularization meanings.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com