Heat radiator

A heat dissipation device and base technology, which is applied in the field of heat conduction, can solve the problems of increasing process complexity, difficulty in adapting to lightweight, and increasing the weight of heat dissipation devices, and achieve the effects of improving heat transfer efficiency, good temperature uniformity, and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solution will be described in further detail below in conjunction with the accompanying drawings.

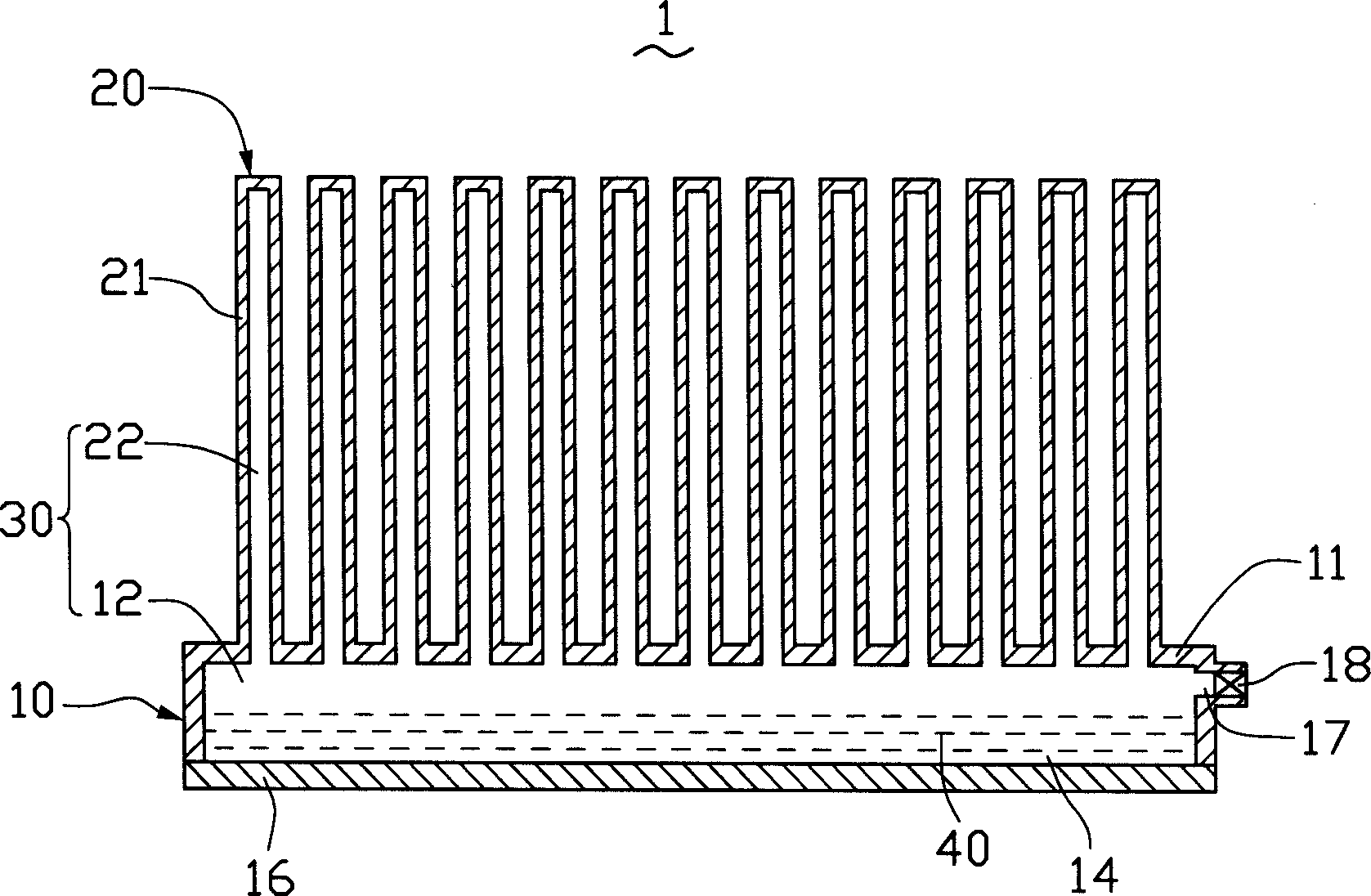

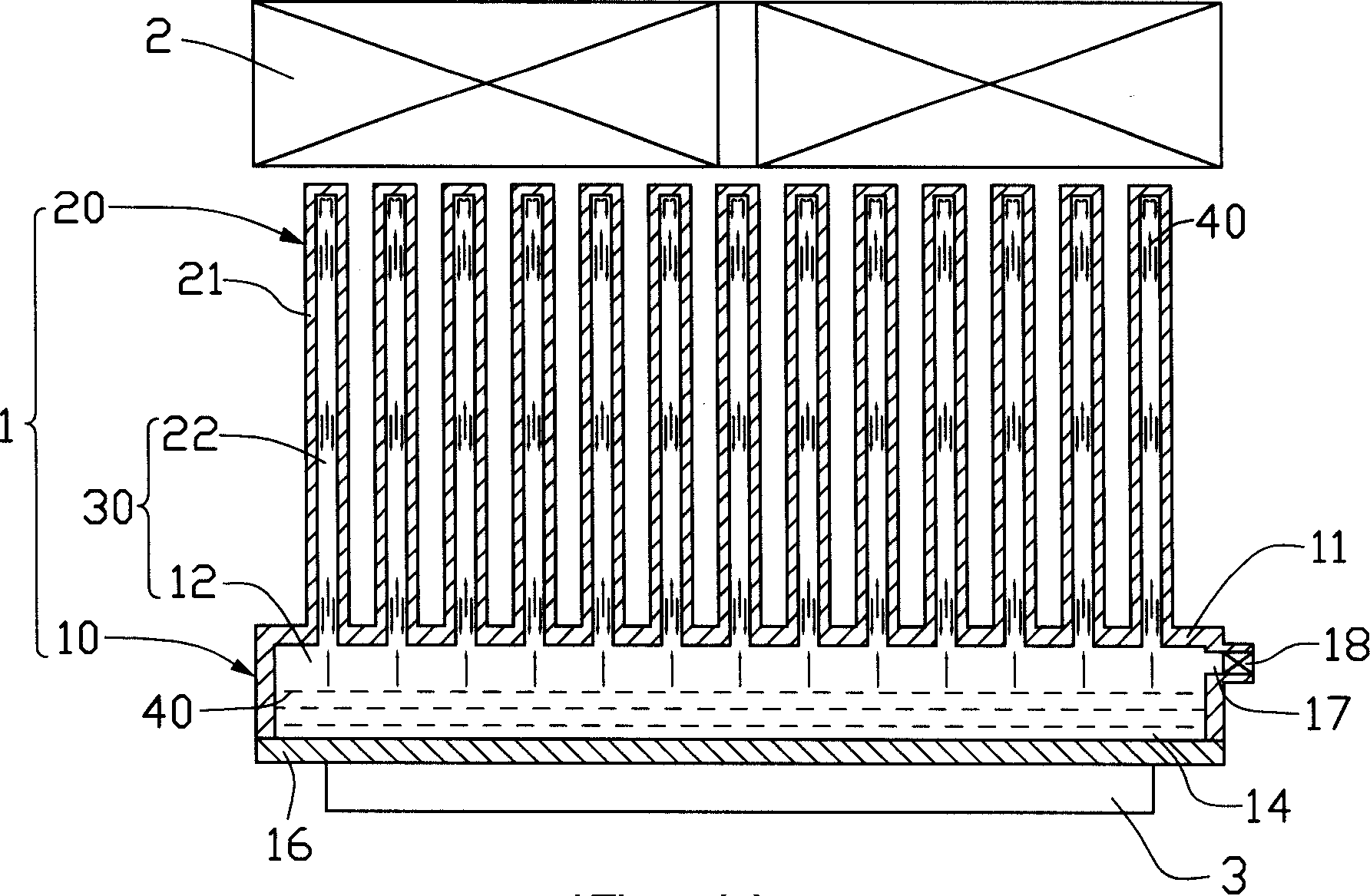

[0023] see figure 1 , is a heat dissipation device 1 provided by an embodiment of the technical solution, which includes: a base 10 and a plurality of fins 20 connected to the base 10 . Wherein the base 10 has a first cavity 12, the plurality of fins 20 has a second cavity 22 respectively, the second cavities 22 of the plurality of fins 20 are respectively connected with the first cavity of the base 10 12 communicate with each other, so that the base 10 and the plurality of fins 20 form a hollow sealed cavity 30 . The hollow sealed cavity 30 is filled with a working fluid 40 .

[0024] The base 10 further includes a housing 11 , an opening 14 defined on the housing 11 opposite to the plurality of fins 20 , and a cover 16 sealingly fitted with the opening 14 . The shell 11 and the cover 16 of the base 10 can be made of different materials according to diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com