Dispersing and spraying automatic continuous production system of electrode paste of power battery

A technology of electrode slurry and power battery, which is applied to battery electrodes, shaking/oscillating/vibrating mixers, circuits, etc. It can solve problems such as easy powder dropping, breakage, poor consistency, and small elastic space of the coating, so as to improve the coating quality. Cloth consistency, reduce production cost, reduce the effect of internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is a detailed description of the automatic continuous production system for dispersion, coating, and coating of power battery electrode slurry according to the present invention with reference to the accompanying drawings and specific examples.

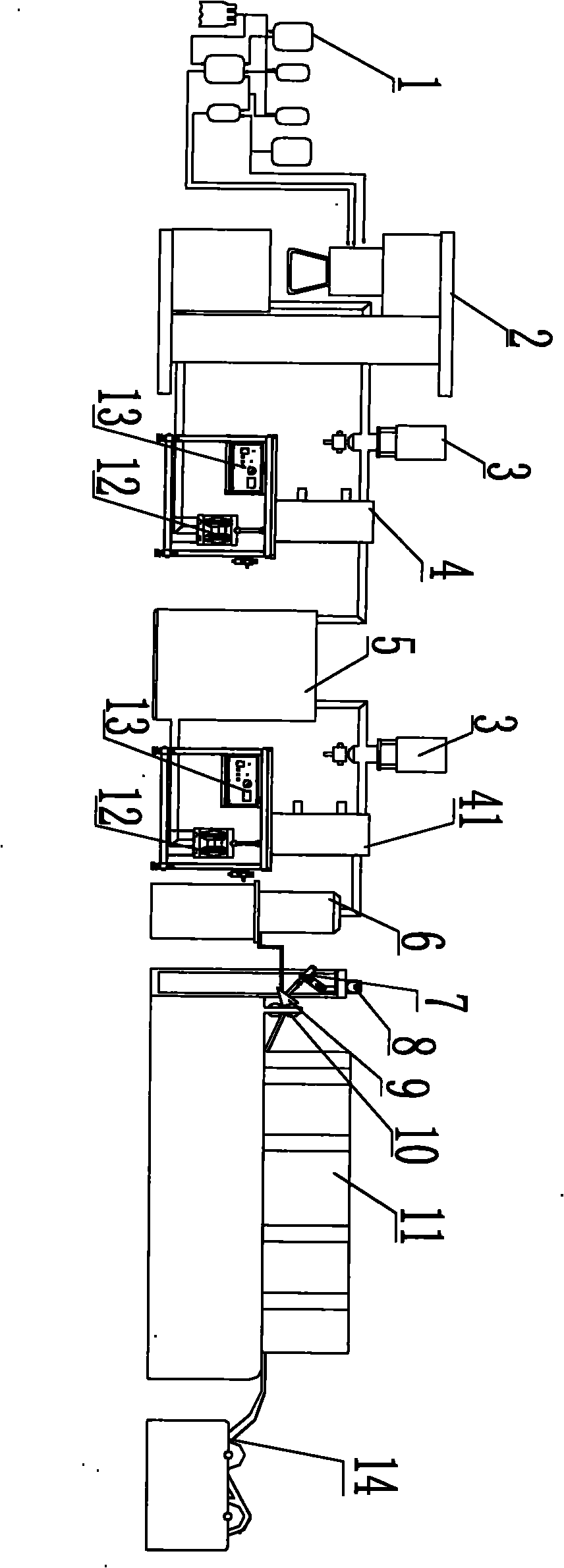

[0020] Automated continuous production system for power battery electrode slurry dispersion coating, such as figure 1 As shown, it includes a batching device 1 , an initial stirring device 2 , a slurry dispersing device 4 , a filtering device 6 and a coating device 11 . The batching device 1 is connected to the initial stirring device 2 through pipelines, and the batching device 1 prepares the electrode slurry material according to the set ratio, and then enters the initial stirring device 2 for preliminary stirring. The initial mixing device 2 may be a stellar mixer. The initial stirring device 2 is connected to the slurry dispersing device 4 through pipelines, and the slurry initially stirred by the initial sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com