Microwave solidification preparation technology of lithium ion anode-cathode material

A microwave curing and cathode material technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problem of uniformity of distribution affecting the performance uniformity of finished products, etc., to increase the depth of microwave transmission, prevent sedimentation, and facilitate uniform nucleation and nucleation. The effect of uniform growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

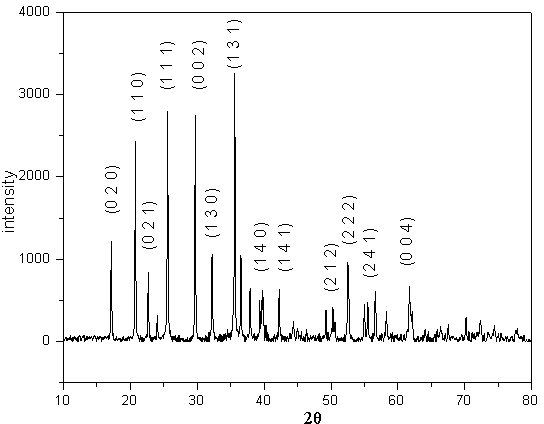

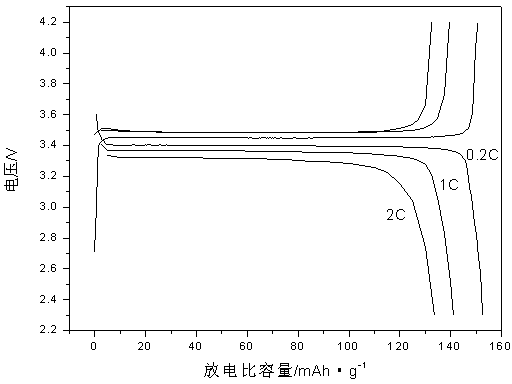

[0028] Preparation of lithium iron phosphate material:

[0029]Weigh 114.72kg, 28.98kg, and 18.132kg of iron phosphate, lithium carbonate, and glucose after drying, put them into a mixing tank, add 70L of distilled water, and then turn on the mixer to stir at high speed. After stirring for 2 hours, pump the slurry to the colloid mill to feed mouth, adjust the gear gap to 2 μm, and finely crush the slurry obtained by stirring to obtain a viscous fluid slurry. After high-temperature compounding at 150°C in a microwave compounding furnace protected by nitrogen, a cake-shaped powder material full of pores is obtained. , collect all the powder materials and transfer them into a rotary sintering furnace, pre-flow nitrogen for 30 minutes, and then sinter at 700°C for 6 hours. After the materials are cooled with the furnace, they are ground and sieved to obtain the lithium iron phosphate cathode material. The charge and discharge performance test of this example: mix the obtained carb...

Embodiment 2

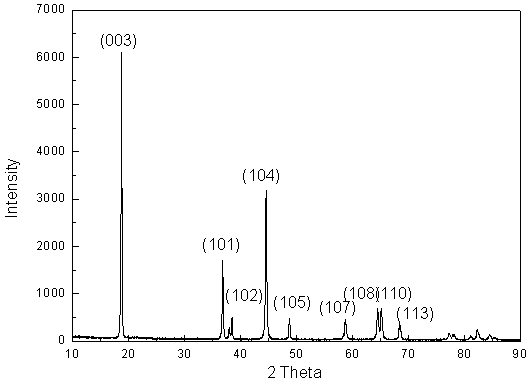

[0034] Preparation of nickel cobalt lithium manganese oxide material:

[0035] After nickel hydroxide cobalt manganese was vacuum-dried as the precursor for 30min, the mass was weighed under cooling, and the precursor and lithium salt were weighed according to the reaction ratio of 1: 1.15 in the molar ratio of precursor and lithium ion, and a total of 80.794kg was added, and 40kg of Deionized water, and then put it into the stirring equipment and mix for 2 hours. After the stirring is completed, pump the slurry to the colloid mill, adjust the gap between the colloid mill to 2 μm, carry out pulverization and refinement, and put the obtained viscous slurry into a microwave oven. Under certain conditions, the temperature range of the microwave equipment is adjusted to 120°C for instant curing, and finally a block material with a porous structure inside is obtained, and then the material is transferred into a sagger. Set the muffle furnace program to 800°C, and sinter for 15 hour...

Embodiment 3

[0040] Preparation of lithium nickel manganese oxide material

[0041] Accurately weigh 12.6kgLi2CO3, 9.8kgNiO and 42.9kgMnO2 and place them in a stirring tank, add 22.7L of distilled water as a dispersant, and after stirring for 2 hours, use an emulsifier to emulsify the obtained slurry to obtain a viscous fluid. The material was transferred to a microwave oven for rapid drying. The dried material was placed in a sagger and calcined at 850°C for 5 hours in an air atmosphere. After calcination and cooling, transfer the material into a stirring tank, continue to add NiO according to the ratio of the introduced nickel content to the existing nickel content of 0.15:0.40, and add 30L distilled water as a dispersant at the same time, and repeat the above operation after stirring for 2 hours. The dried material was placed in a sagger, calcined at 850°C for 10h in air atmosphere, and then annealed at 600°C for 10h. After the material is cooled with the furnace, it is ground and sie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com