Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50 results about "Titanium(II) oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

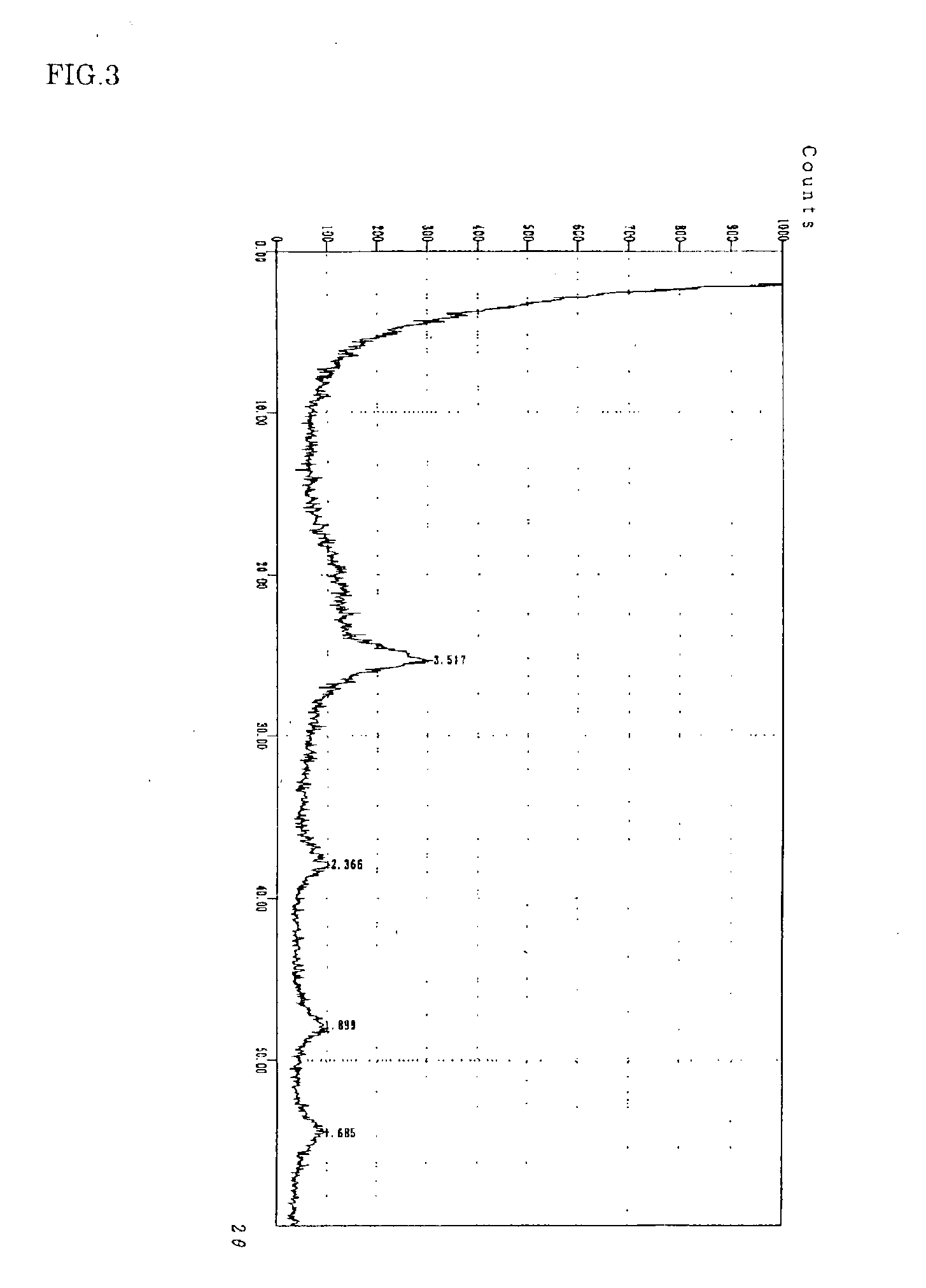

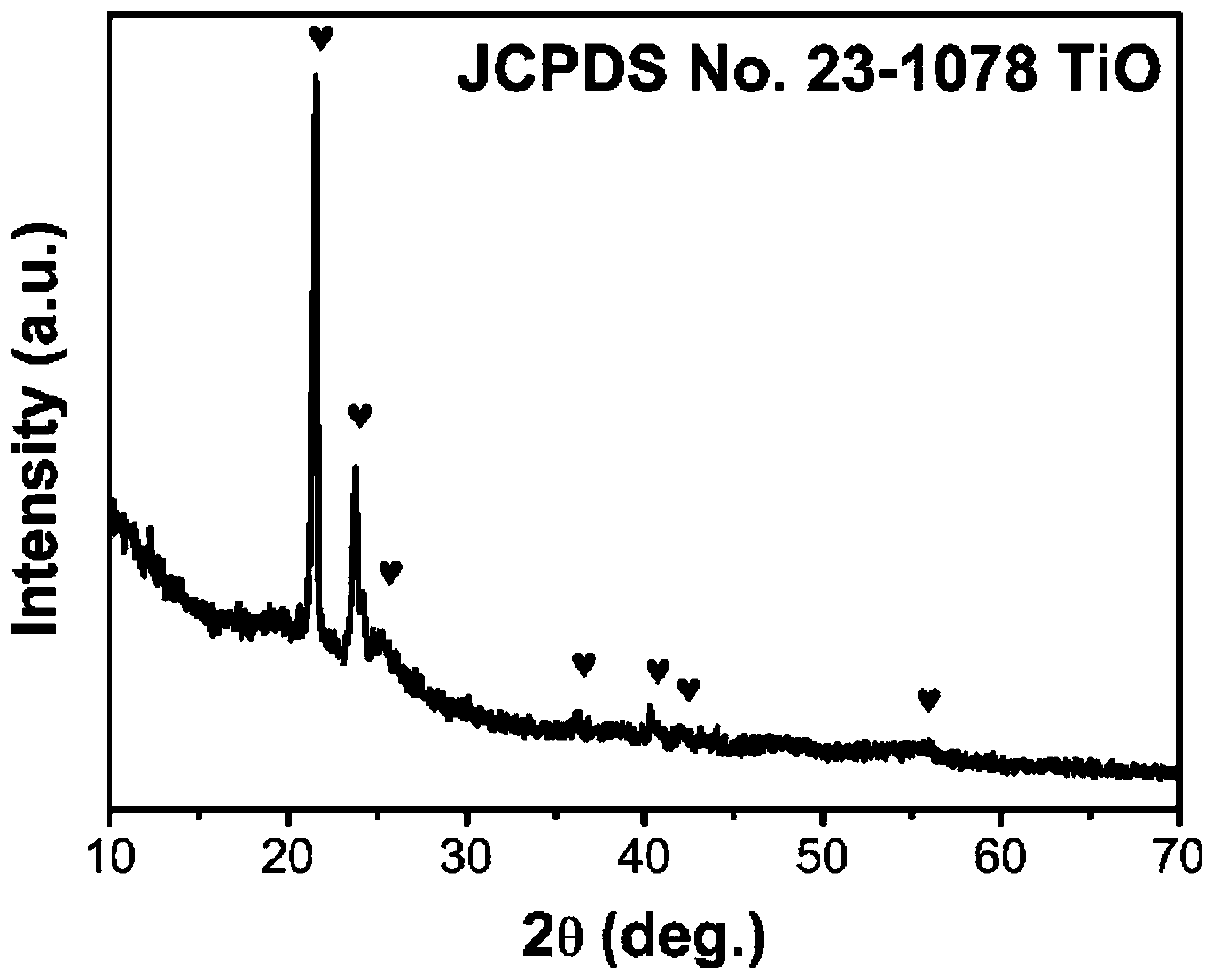

Titanium(II) oxide (TiO) is an inorganic chemical compound of titanium and oxygen. It can be prepared from titanium dioxide and titanium metal at 1500 °C. It is non-stoichiometric in a range TiO0.7 to TiO1.3 and this is caused by vacancies of either Ti or O in the defect rock salt structure. In pure TiO 15% of both Ti and O sites are vacant. Careful annealing can cause ordering of the vacancies producing a monoclinic form which has 5 TiO units in the primitive cell that exhibits lower resistivity. A high temperature form with titanium atoms with trigonal prismatic coordination is also known. Acid solutions of TiO are stable for a short time then decompose to give hydrogen...

Double silver low-emissivity and solar control coatings

InactiveUS20060147727A1Reduce infrared emissivityMinimal reduction in visible transmittanceLiquid surface applicatorsGlass/slag layered productsLow emissivityMechanical stability

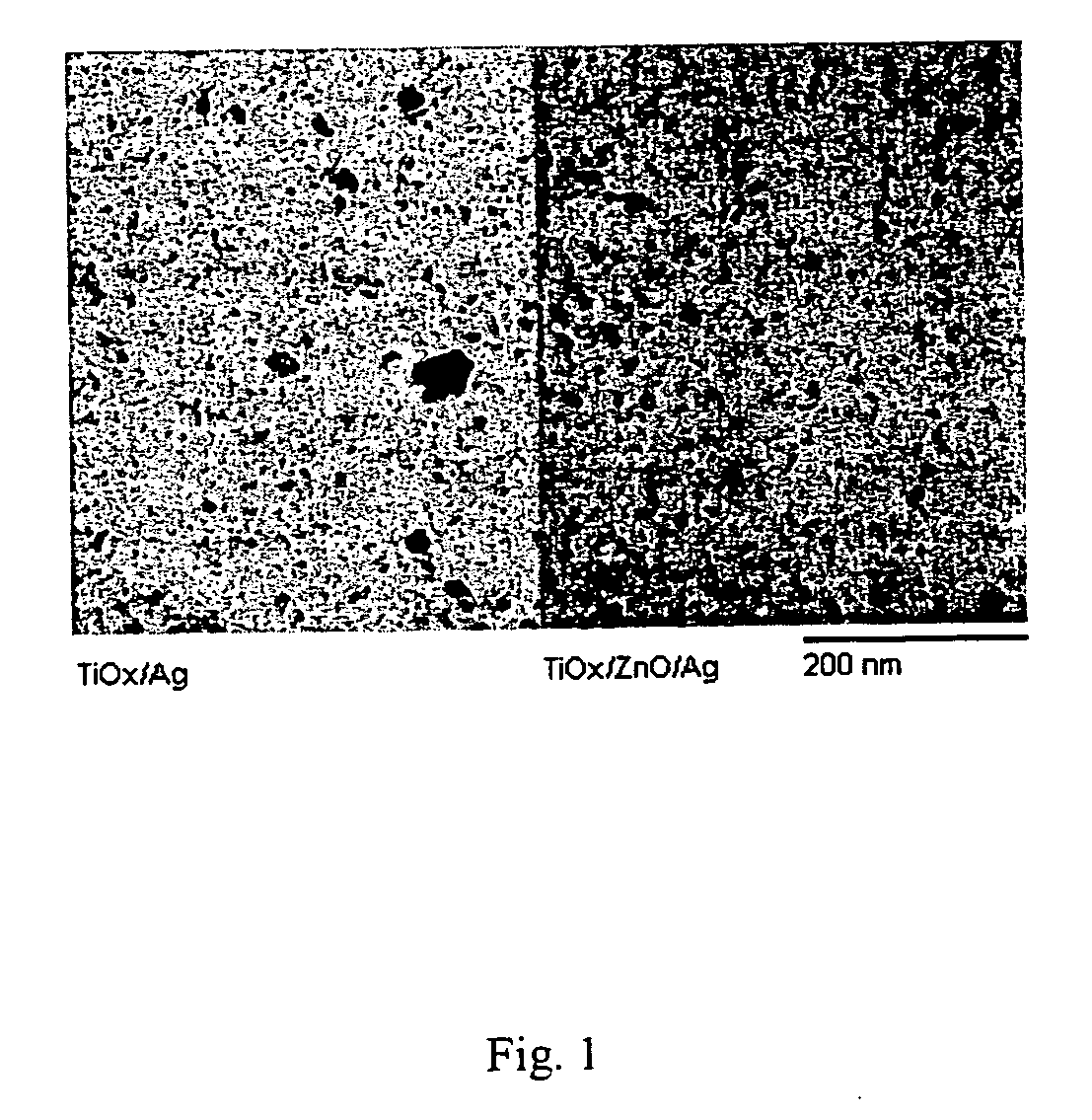

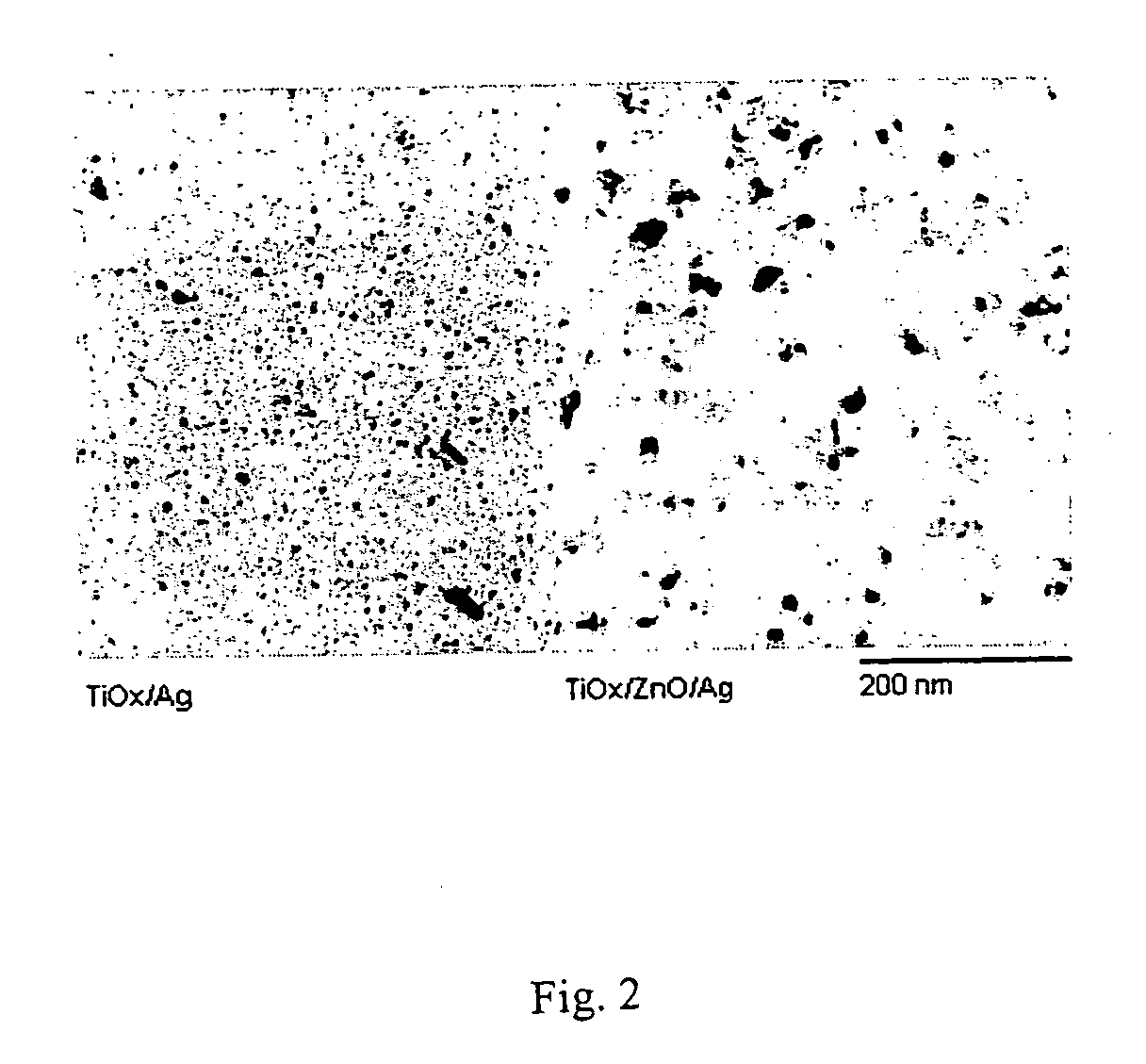

A low-emissivity multilayer coating includes, in order outward from the substrate, a first layer including a layer containing titanium oxide, a layer containing silicon nitride, or a sublayer layer containing titanium oxide in combination with a sublayer containing silicon nitride; a second layer including Ag; a third layer including at least one layer selected from titanium oxide layers and silicon nitride layers; a fourth layer including Ag; and a fifth layer including silicon nitride. The color of the coatings can be varied over a wide range by controlling the thicknesses of the layers of titanium oxide, silicon nitride and Ag. A diffusion barrier of oxidized metal protects relatively thin, high electrical conductivity, pinhole free Ag films grown preferentially on zinc oxide substrates. Oxygen and / or nitrogen in the Ag films improves the thermal and mechanical stability of the Ag. Dividing the first layer of titanium oxide, the Ag layers, and / or the third layer with a sublayer of oxidized metal can provide greater thermal and mechanical stability to the respective layers.

Owner:AGC FLAT GLASS NORTH AMERICA INC

Titanium oxide - aluminum oxide composite carrier, preparation method and application thereof

ActiveCN1689702AEasy to prepareThe reaction temperature is easy to controlCatalyst carriersCatalyst activation/preparationAluminateTitanium oxide

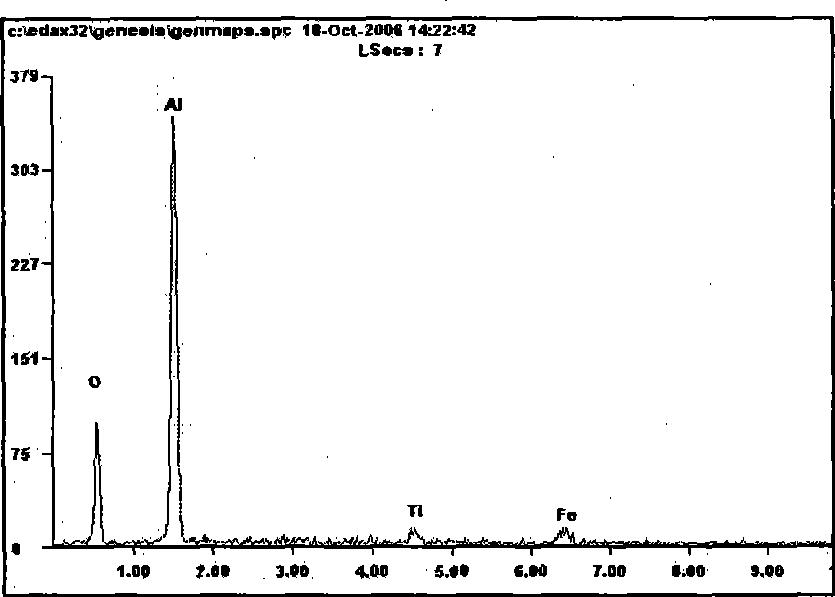

The present invention discloses one kind of composite titania-alumina carrier and its preparation process and application. The composite carrier contains titania in 10-50 wt% and in anatase and / or rutile form and contains alumina in alpha-Al2O3 form. The composite carrier has acid surface and total acid amount of 0.6-8 A / g / sq cm. The preparation process includes the following steps: mixing titanium tetrachloride solution and AlCl3.6H2O crystal through stirring and diluting, mixing with sodium meta-aluminate solution to obtain aluminum titanium hydroxide precipitate, ageing, filtering, washing, drying, crushing, kneading, and roasting at 800-1200 deg.c to obtain the carrier. The composite carrier is used in selective hydrogenation and is favorable to reducing side product 'green oil' and prolonging the life of catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of forming anodic titanium oxide layers having dual-color appearance and article having the same

InactiveUS20130075262A1Easily color-coatedMaintain its metallic lusterDuplicating/marking methodsSurface reaction electrolytic coatingTitaniumTitanium oxide

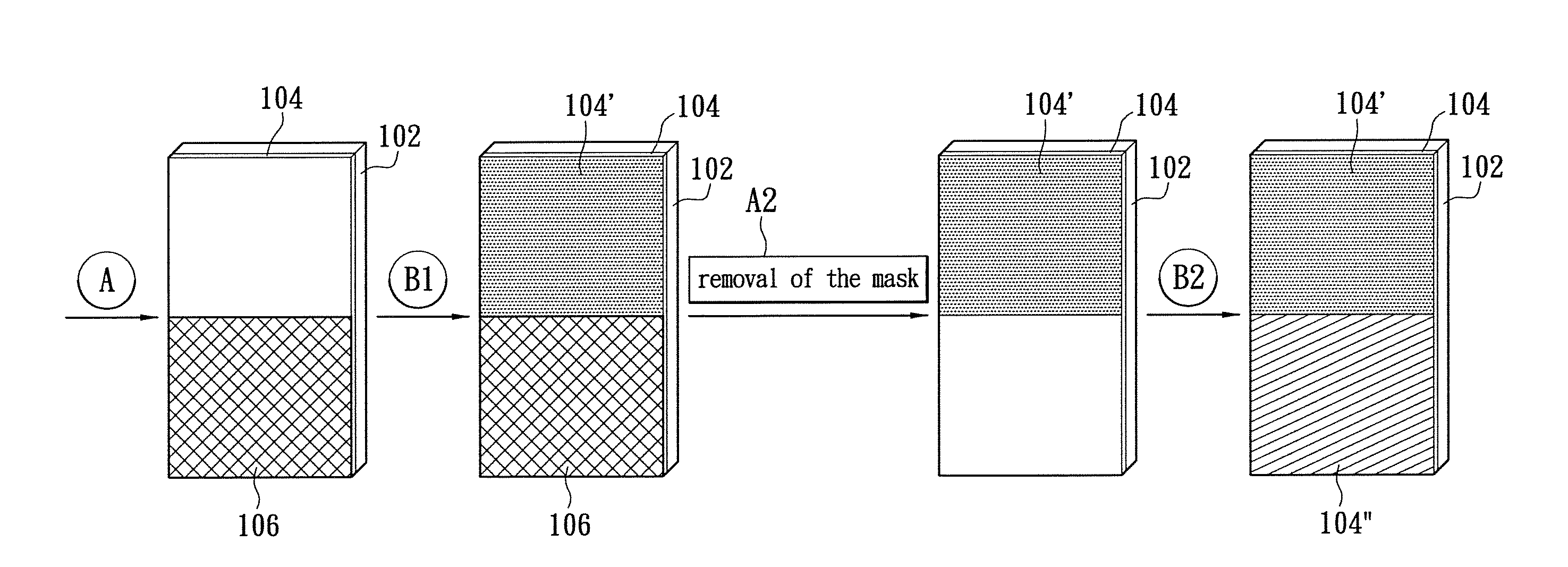

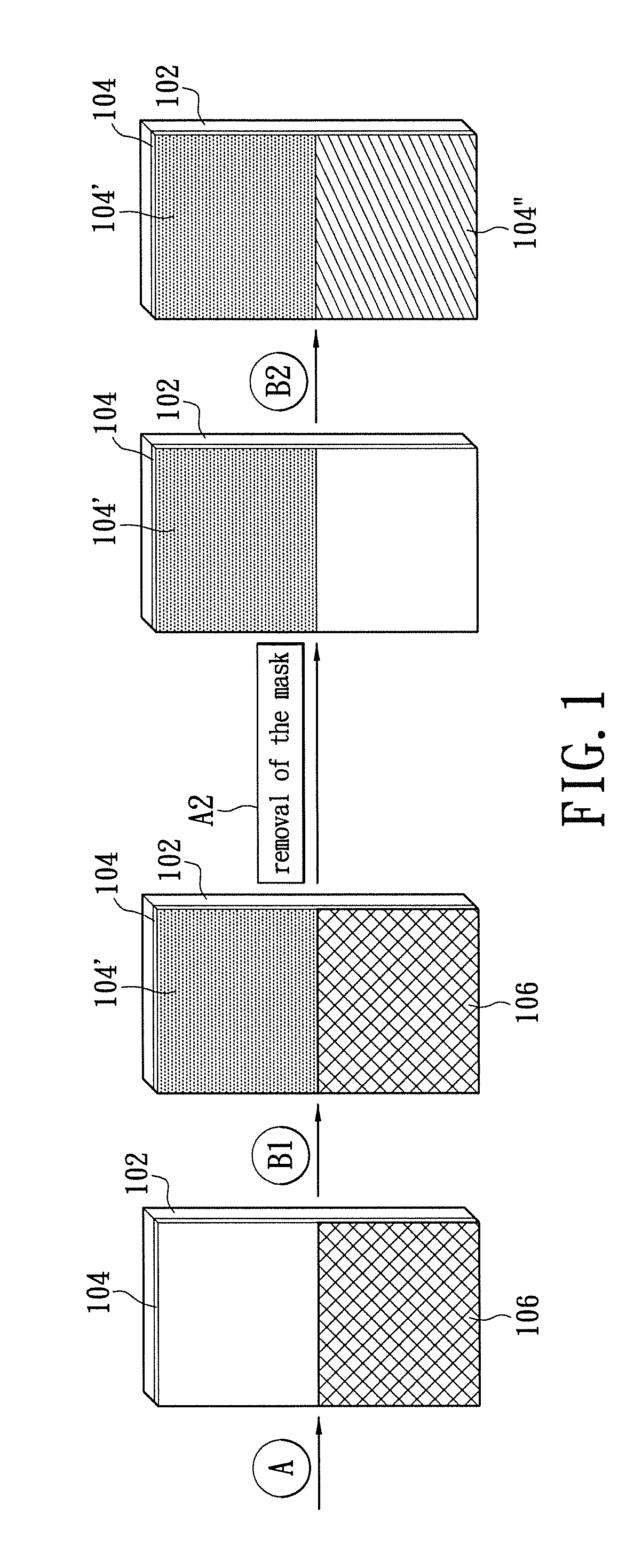

A method of forming anodic titanium oxide layers having dual-color appearance includes the following steps: providing a cleaned substrate; depositing a titanium film on the substrate; forming a mask of a desired pattern covering a portion of the substrate; carrying out a first anodization by immersing the substrate in an electrolytic solution as anode; applying a first direct-current voltage to produce a first titanium oxide layer; removing the mask; carrying out a second anodization by immersing the substrate in the electrolytic solution as anode; applying a second direct-current voltage having a value smaller than that of the first voltage to produce a second titanium oxide layer; and cleaning the coated substrate. The instant disclosure also includes an article made by the above method.

Owner:CATCHER TECH

Metal oxide/silica composite, and a cosmetic preparation comprising thereof

InactiveUS6949248B2Effect is not lostBiocideHeavy metal active ingredientsSilica particleUv protection

The object of this invention is to provide a UV protective powder, and a cosmetic preparation in which the dispersibility of metal oxide is kept at a high level, and the UV protection activity and transparency of the preparation are satisfactorily maintained.A metal oxide / silica composite wherein metal oxide particles whose primary particle diameter is 1-1000 nm are co-dispersed finely with silica particles, and the metal oxide particles exist substantially as primary particles in the composite. The composite is preferably obtained by mixing (1) a dispersion comprising a silica sol where silica particles have a primary particle diameter of 1-150 nm, and (2) fine particles of metal oxide whose primary particle diameter is 1-1000 nm, or a sol of the same metal oxide, and the metal oxide existing as fine particles or a sol preferably consists of one, or two or more selected from a group consisting of titanium oxide, zinc oxide and cerium oxide. Also a cosmetic preparation comprising thereof is provided.

Owner:SHISEIDO CO LTD

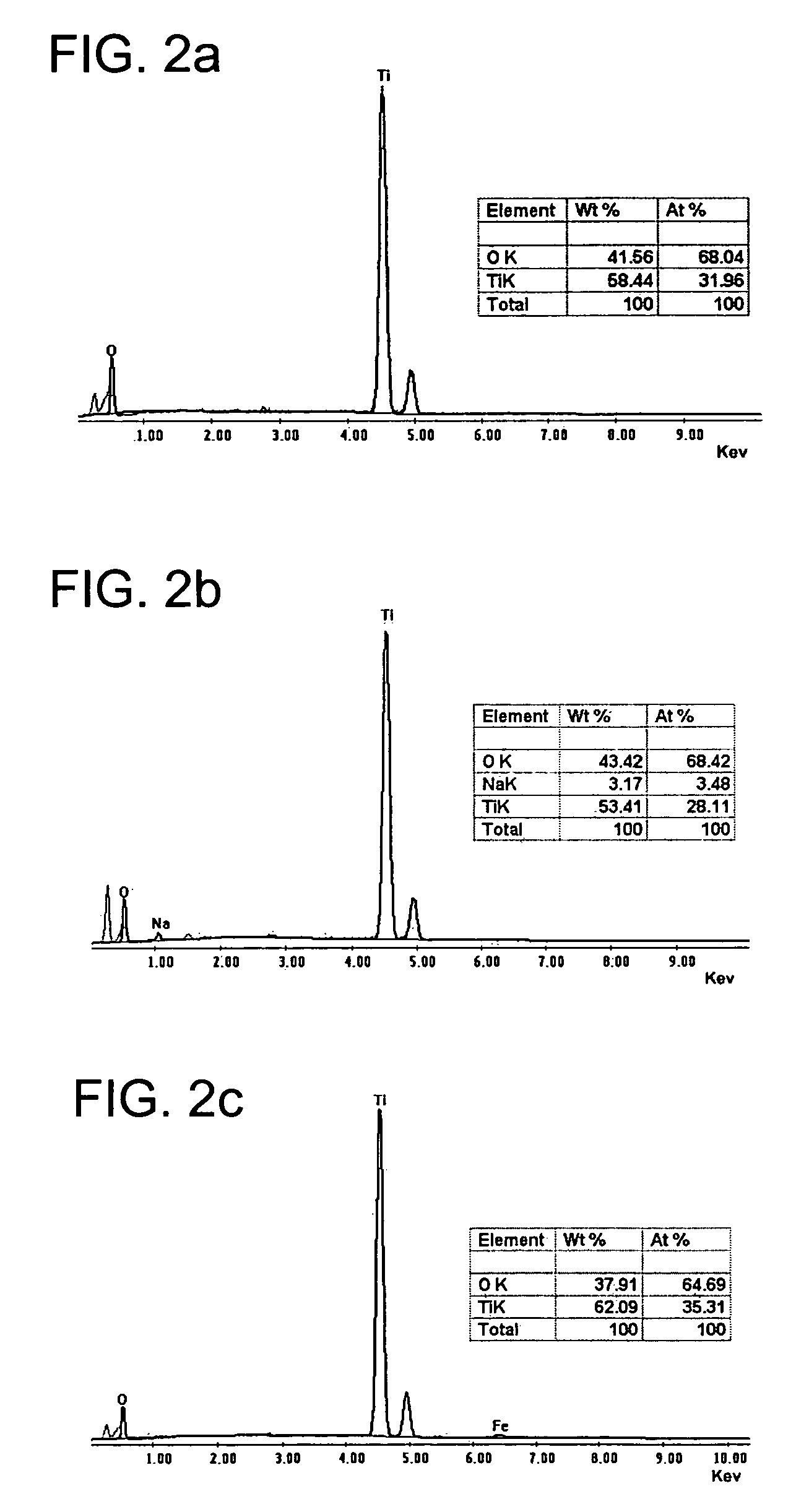

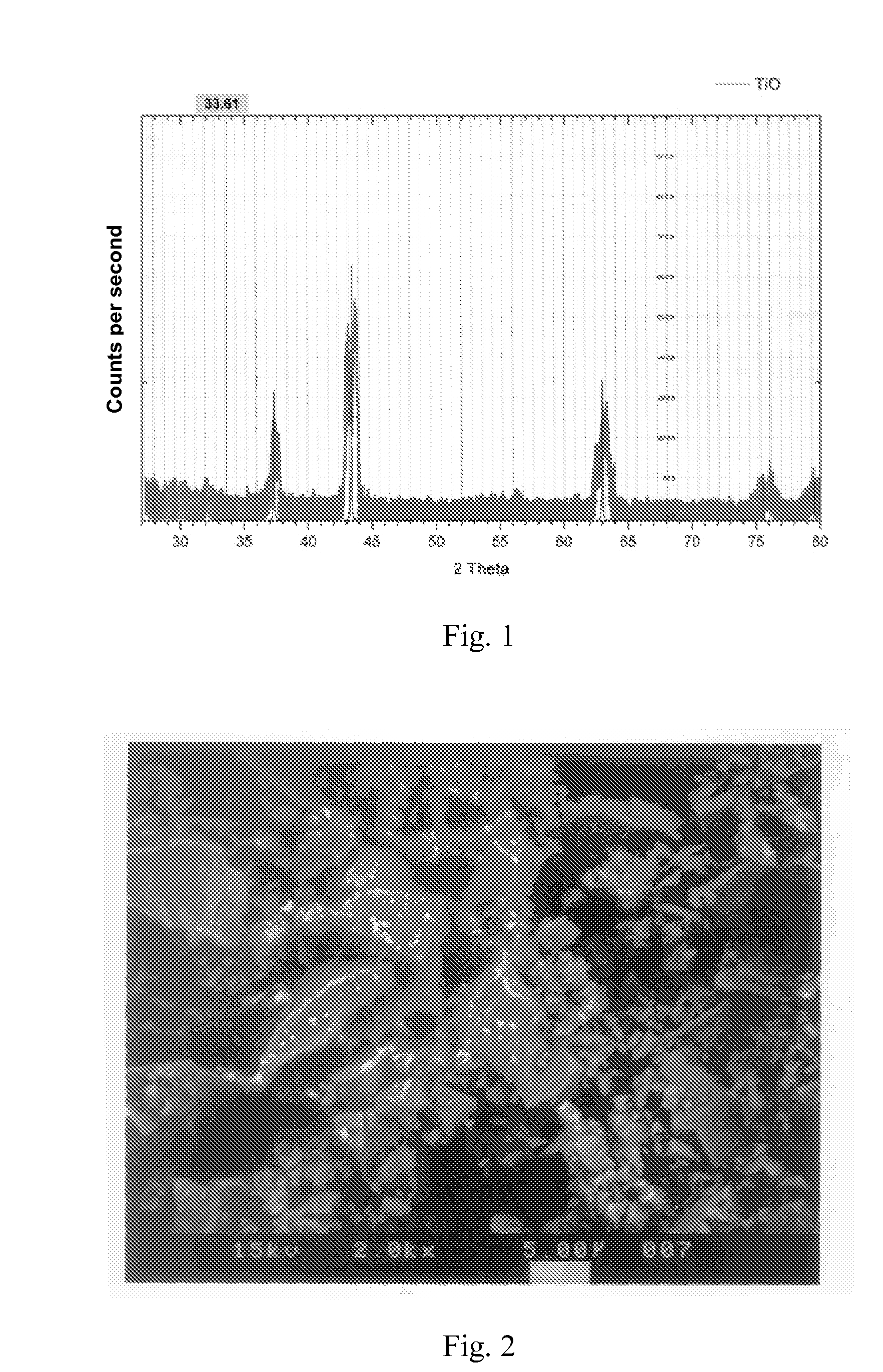

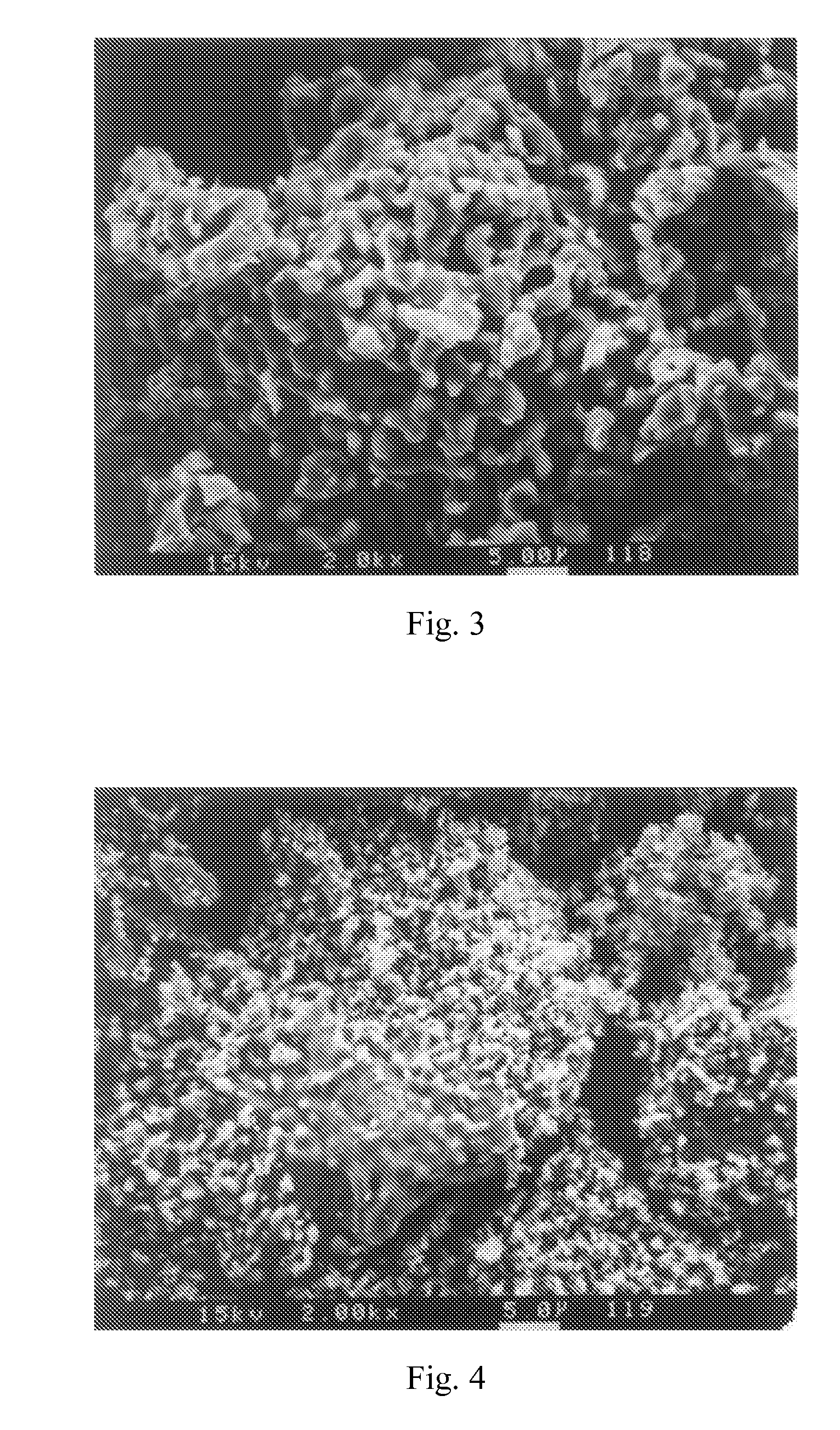

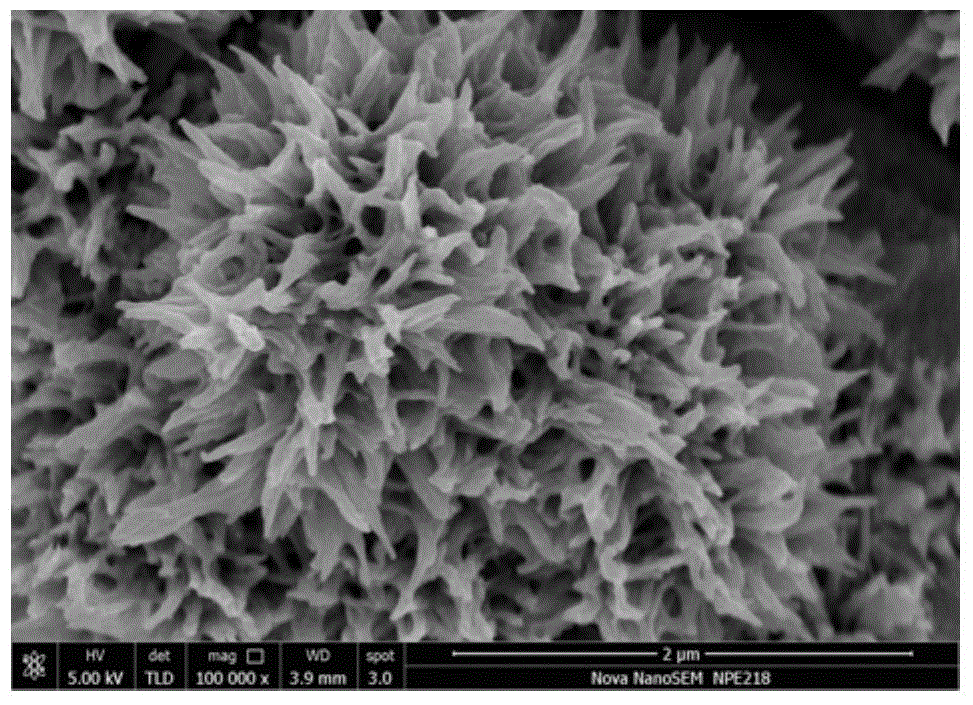

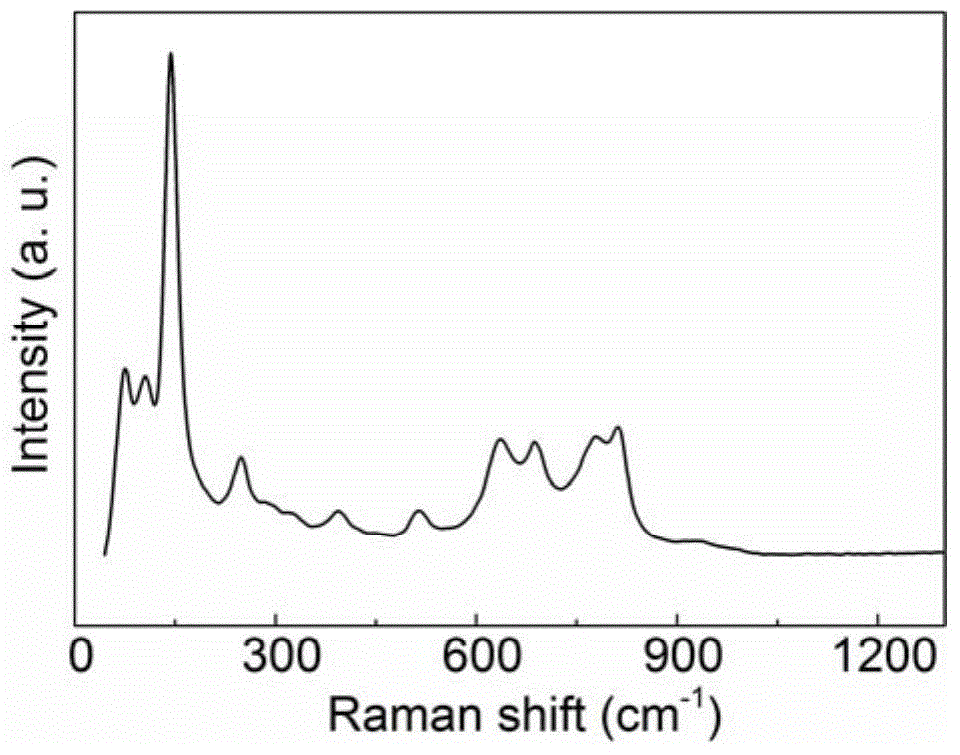

Nanostructured titanium oxide material and its synthesis procedure

ActiveUS7645439B2Stable structureHigh areaMaterial nanotechnologyTitanium suboxidesNanowireNanostructure

Owner:INST MEXICANO DEL GASOLINEEO

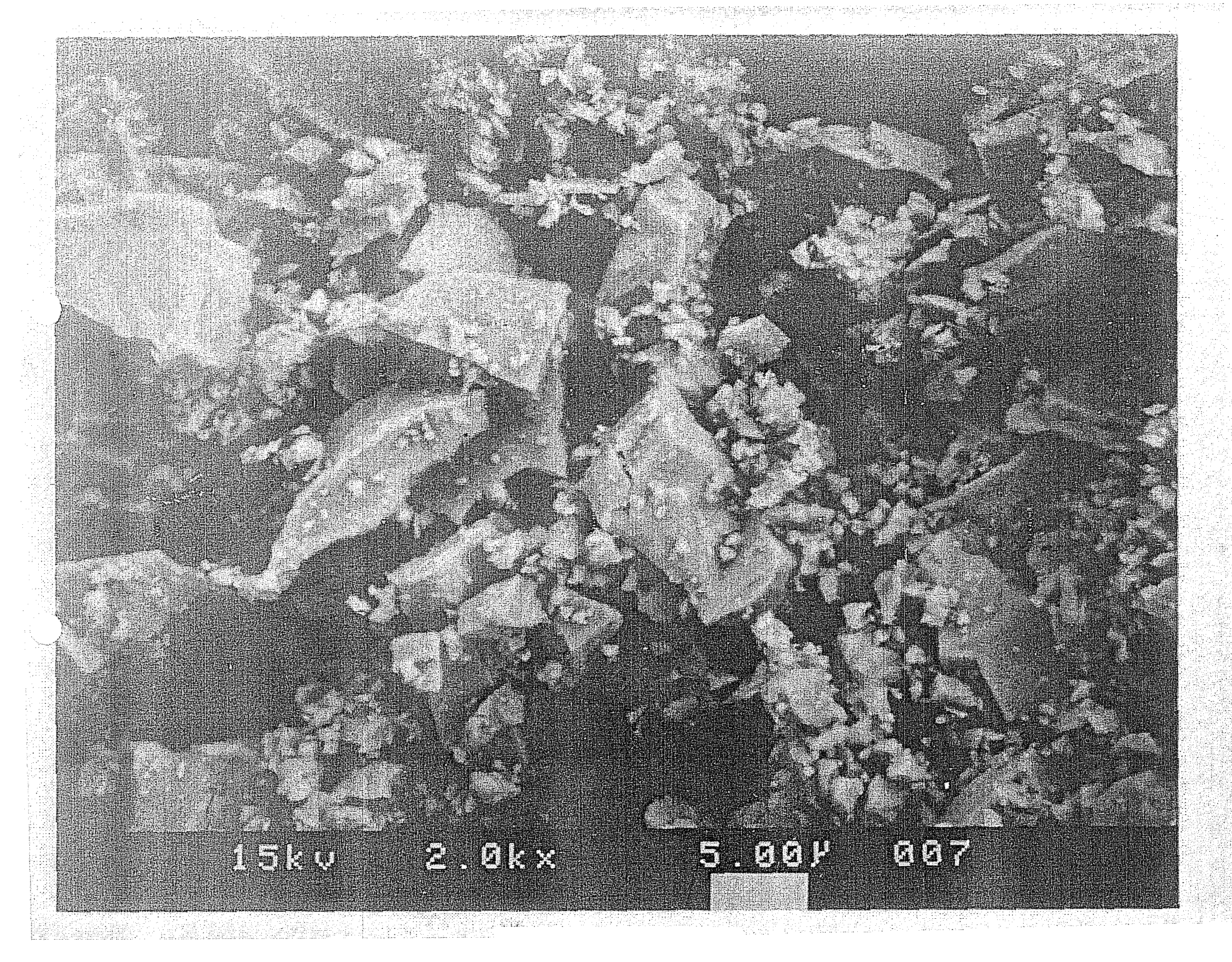

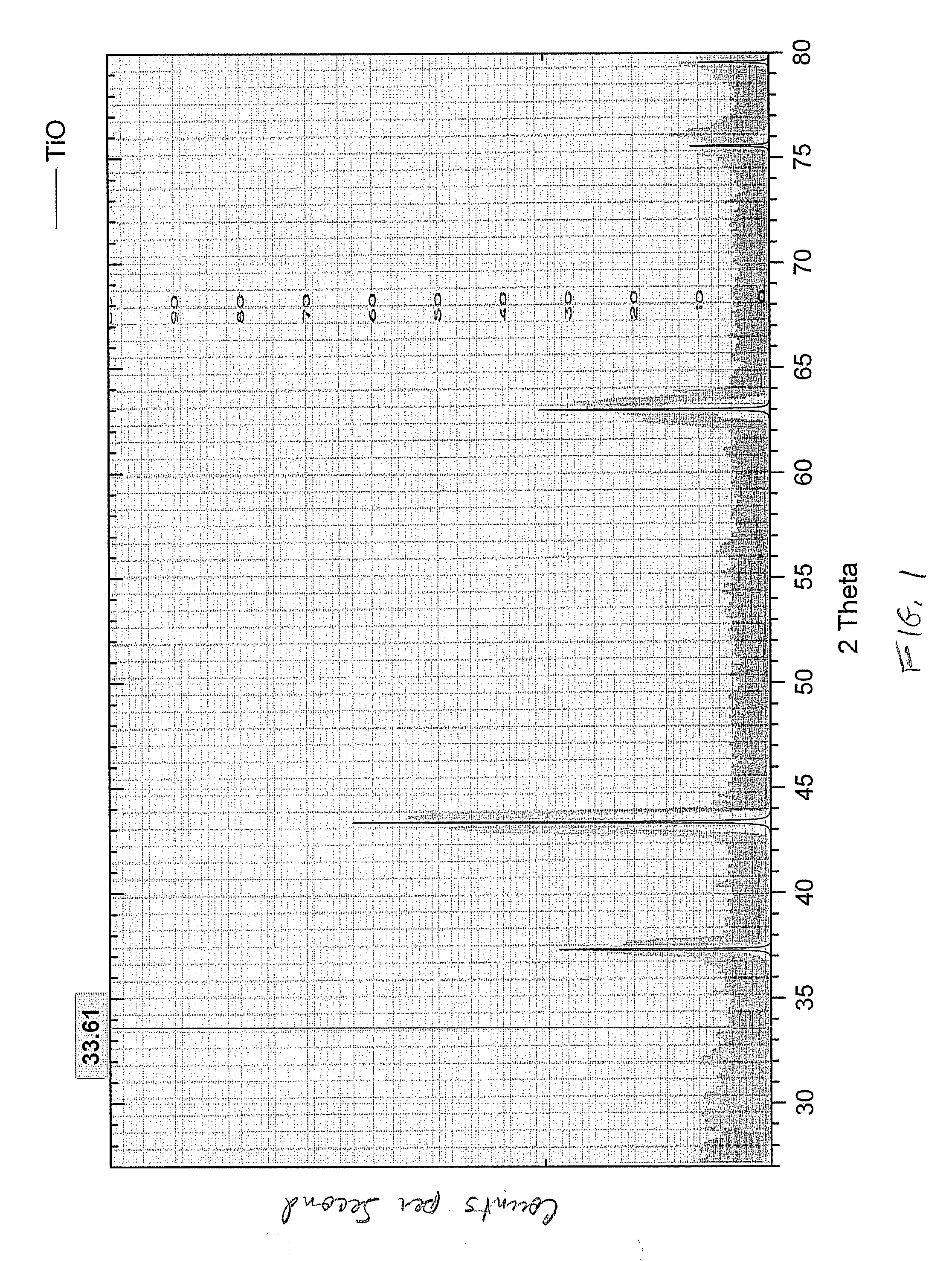

Production of high-purity titanium monoxide and capacitor production therefrom

The present invention relates to high-purity titanium monoxide powder (TiO) produced by a process of combining a mixture of titanium suboxides and titanium metal powder or granules; reacting the mixture at a temperature above about 1200° C.; and fragmenting the body to form TiO particles suitable for application as e.g., capacitors. The TiO product is unusually pure in composition and crystallography, highly dense, and can be used for capacitors and for other electronic applications. The method of production of the TiO is robust, does not require high-purity feedstock, and can reclaim value from waste streams associated with the processing of TiO electronic components.

Owner:READING ALLOYS

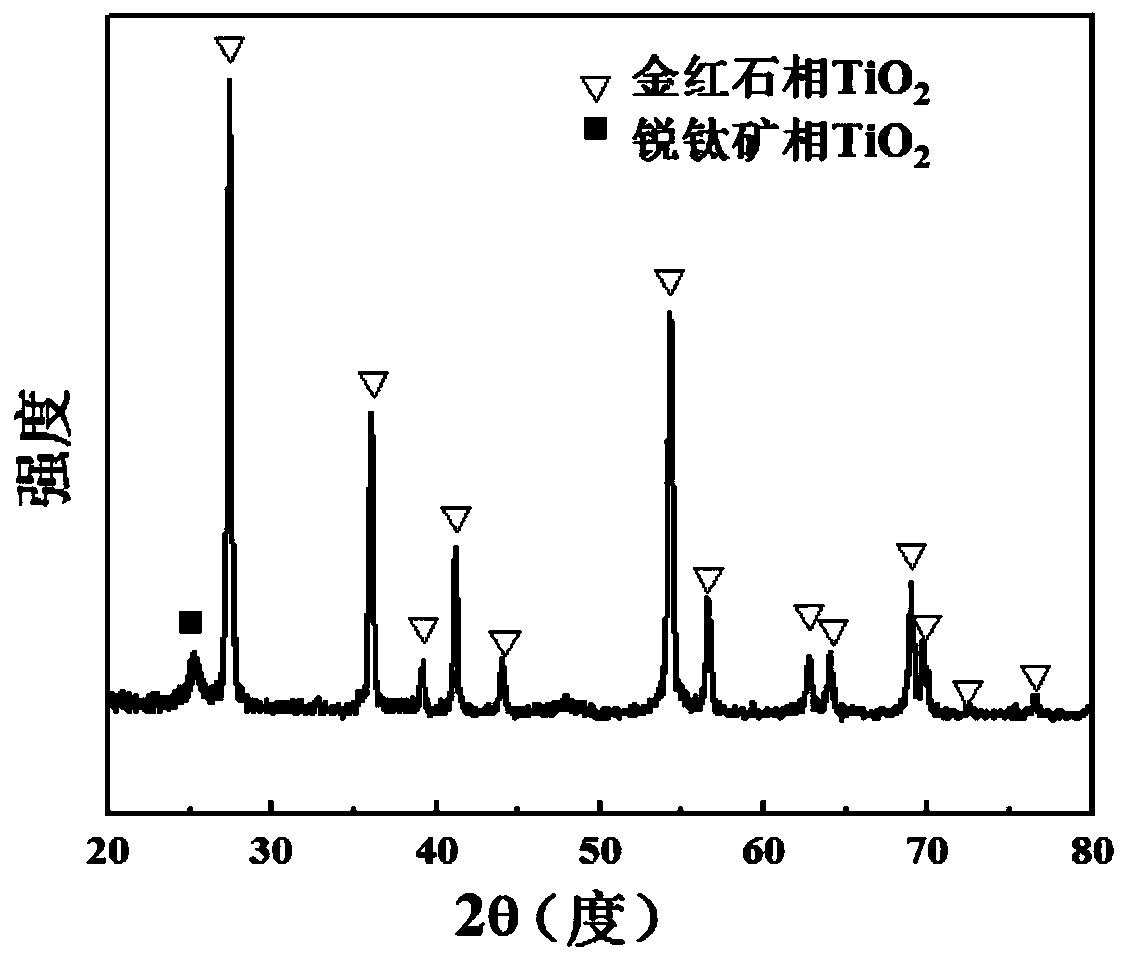

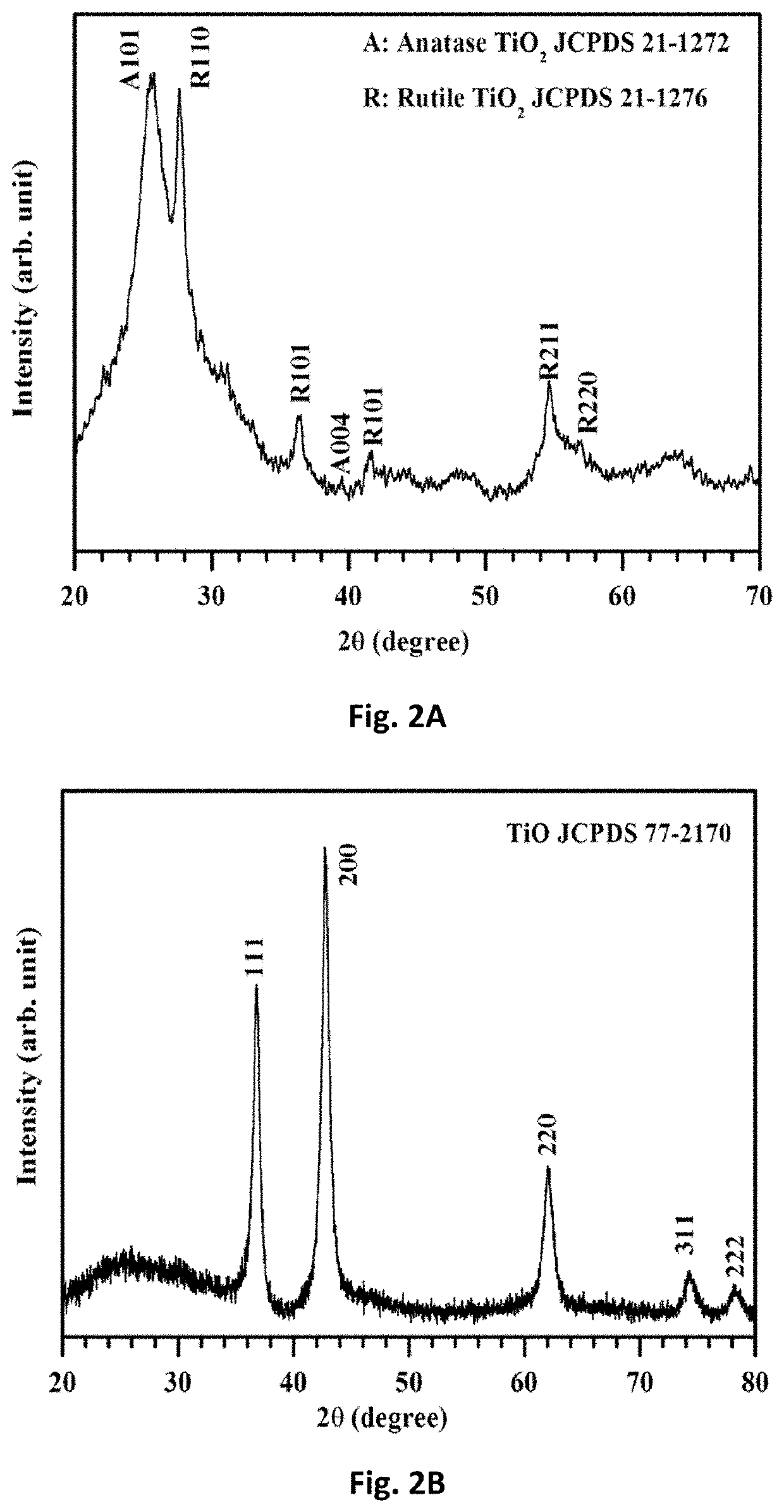

Titanium oxide/tungsten oxide nano-composite film on surface of metallic titanium, preparation and application

ActiveCN104801295AHigh purityGood photocatalysisMetal/metal-oxides/metal-hydroxide catalystsComposite filmSurface oxidation

The invention relates to a titanium oxide / tungsten oxide nano-composite film on the surface of metallic titanium, preparation and an application. The metallic titanium is cleaned and etched, then the metallic titanium is impregnated in an oxidation liquid containing peroxotungstic acid sol and hydrogen peroxide and is kept for a period of time at a certain temperature, a titanic acid and peroxotungstic acid containing nano-film formed through crystal in-situ growth and deposition is obtained, and finally, the titanium oxide / tungsten oxide nano-composite film on the surface of the metallic titanium is obtained through calcination; the film mainly comprises a titanium dioxide and tungsten trioxide compound with a nanobelt structure, the nanobelt width is in a range from 10 nm to 150 nm, and the length is in a range from 0.5 mu m to 20 mu m; the mass percentage of titanium oxide is in a range from 1% to 99.5%, and titanium oxide mainly adopts a rutile or anatase crystalline phase; the mass percentage of tungsten oxide is in a range from 0.5%-99%, and tungsten oxide mainly adopts a hexagonal or monoclinic crystal phase. Compared with the prior art, the preparation is simple and easy and is suitable for large-scale industrial production; the prepared titanic oxide film has important application value in the related fields of photoelectrocatalysis, metal corrosion prevention, electrochemical sensing and the like.

Owner:SHANGHAI JIAO TONG UNIV

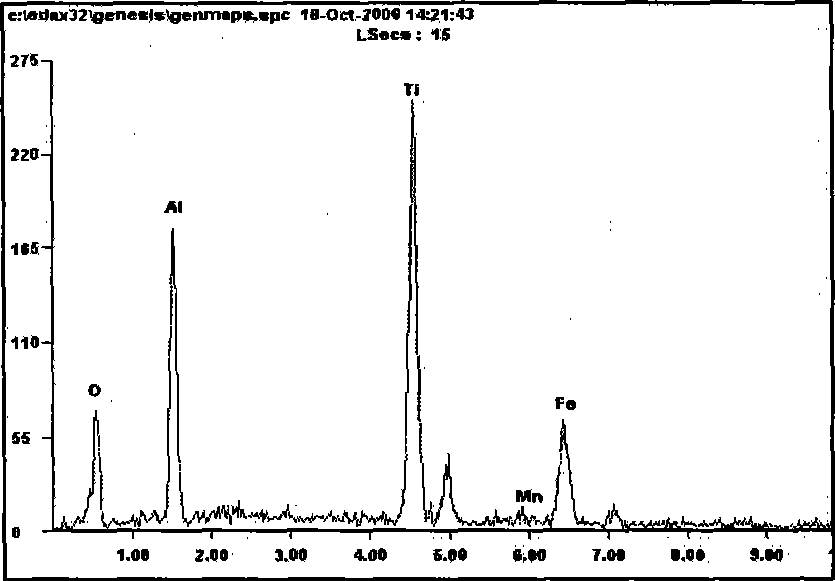

Molten steel deoxygenation method for thinning solidification structure

The invention provides a hot metal deoxidation method of a refinement and solidification structure, which comprises the following steps: proper amount of carbon powder, ferromanganese, ferrosilicon and other alloys are added into the molten steel to carry out deoxidizing and alloying. The method is characterized in that: before deoxidizing and alloying, proper amount of SiAlFe alloy is added to carry out pre-deoxidizing, the oxygen activity of the molten steel is controlled between 50 multiplied by 10<-6> and 100 multiplied by 10<-6> through pre-deoxidizing and deoxidizing and alloying and the temperature is controlled over 1550 DEG C; then proper amount of ferrotitanium is added to carry out final deoxidizing and aluminum content and titanium content of the steel deoxidized are respectively 0.003 percent to 0.012 percent and 0.015 percent to 0.050 percent. Under the conditions without changing the technique flow of steelmaking, adding equipment and increasing cost, the solidification structure of carbon steel can be obviously refined and isometric crystal proportion can be improved to more than 80 percent. Therefore, harmful function of alumina foreign impurities is eliminated, generation of large particles of single titanium oxide is avoided and blockage of a water gap is reduced.

Owner:ANGANG STEEL CO LTD

Titanium oxide production process

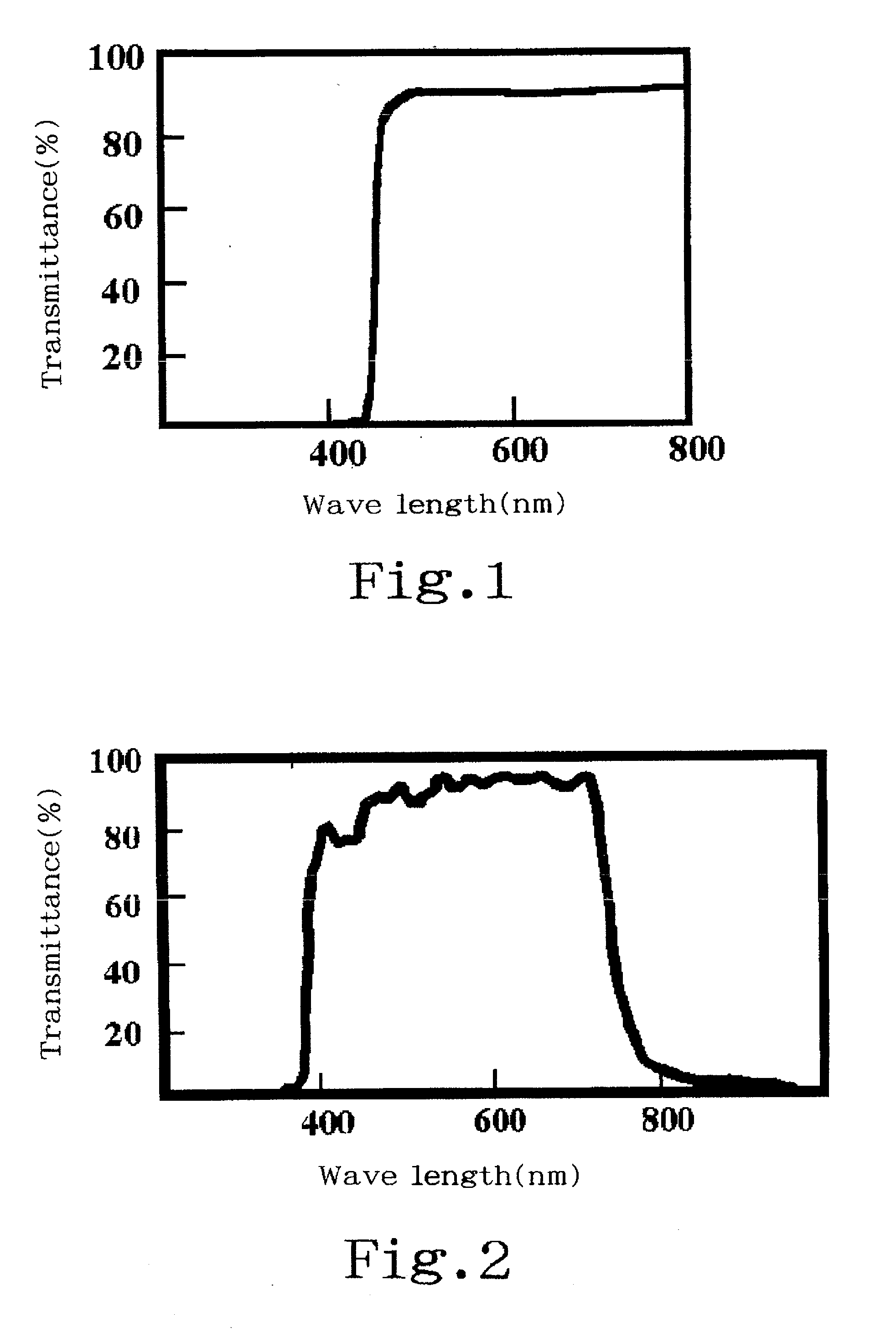

InactiveUS20030068268A1Easy to produceImprove photocatalytic activityMaterial nanotechnologyCatalyst activation/preparationTitanium hydroxideTitanium

A process for producing a titanium oxide is provided which comprises the steps of (i) reacting a titanium compound with ammonia in an amount exceeding the stoichiometric amount necessary to convert the titanium compound to a titanium hydroxide or reacting a titanium compound with a base at pH of from about 2 to about 7, to obtain a reaction product and (ii) calcining the obtained product. The titanium oxide exhibits a high photocatalytic activity by visible light radiation.

Owner:SUMITOMO CHEM CO LTD

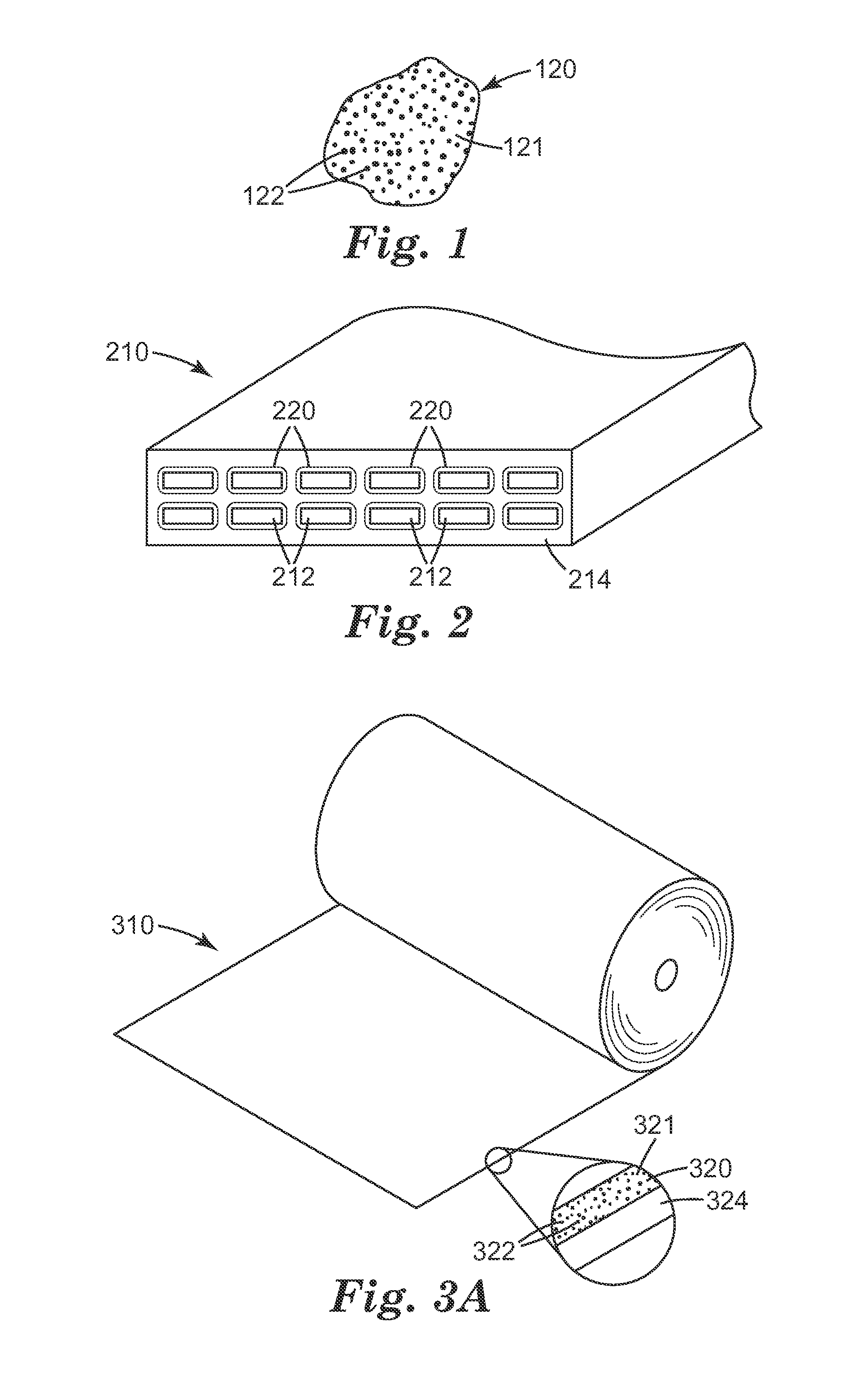

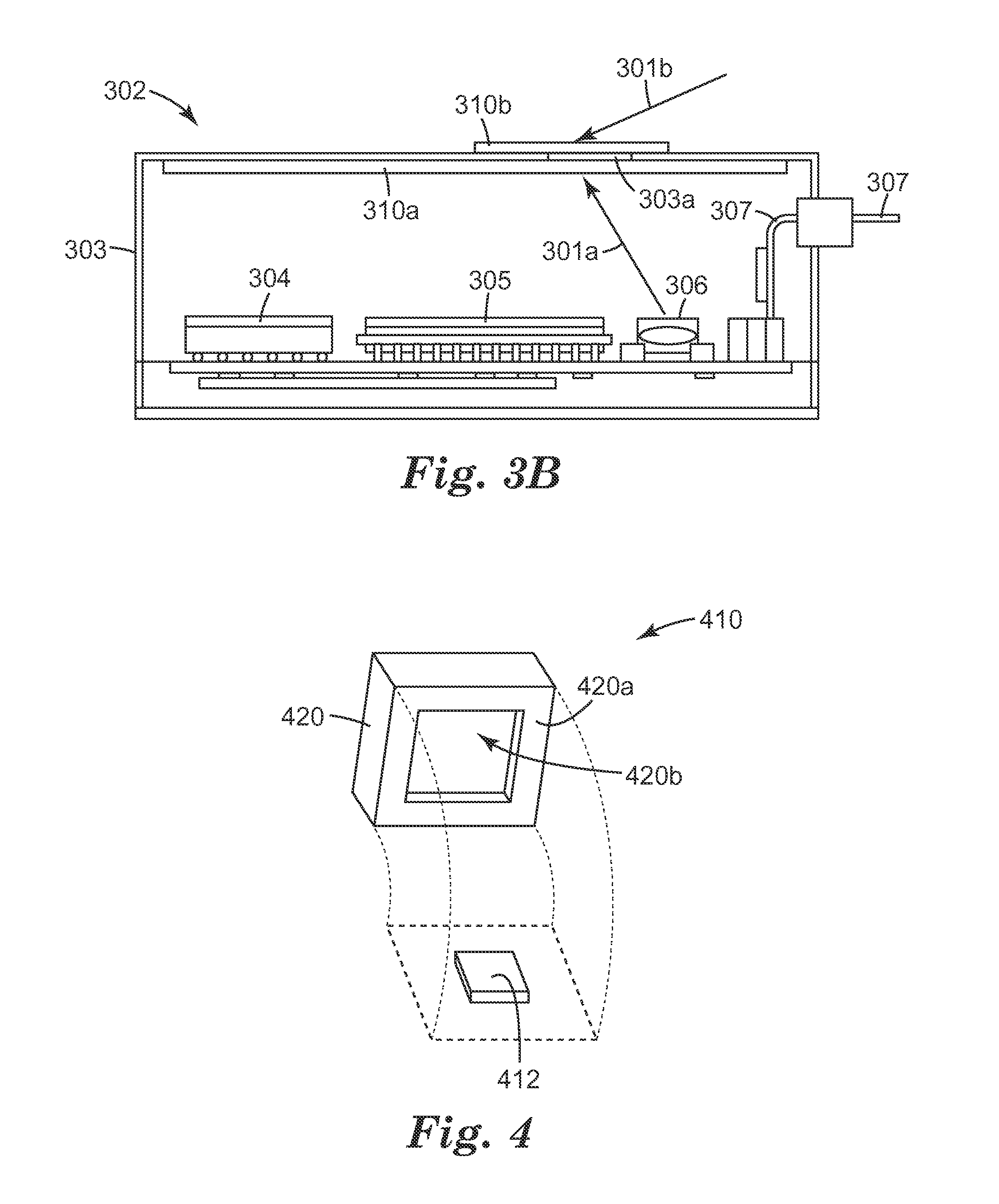

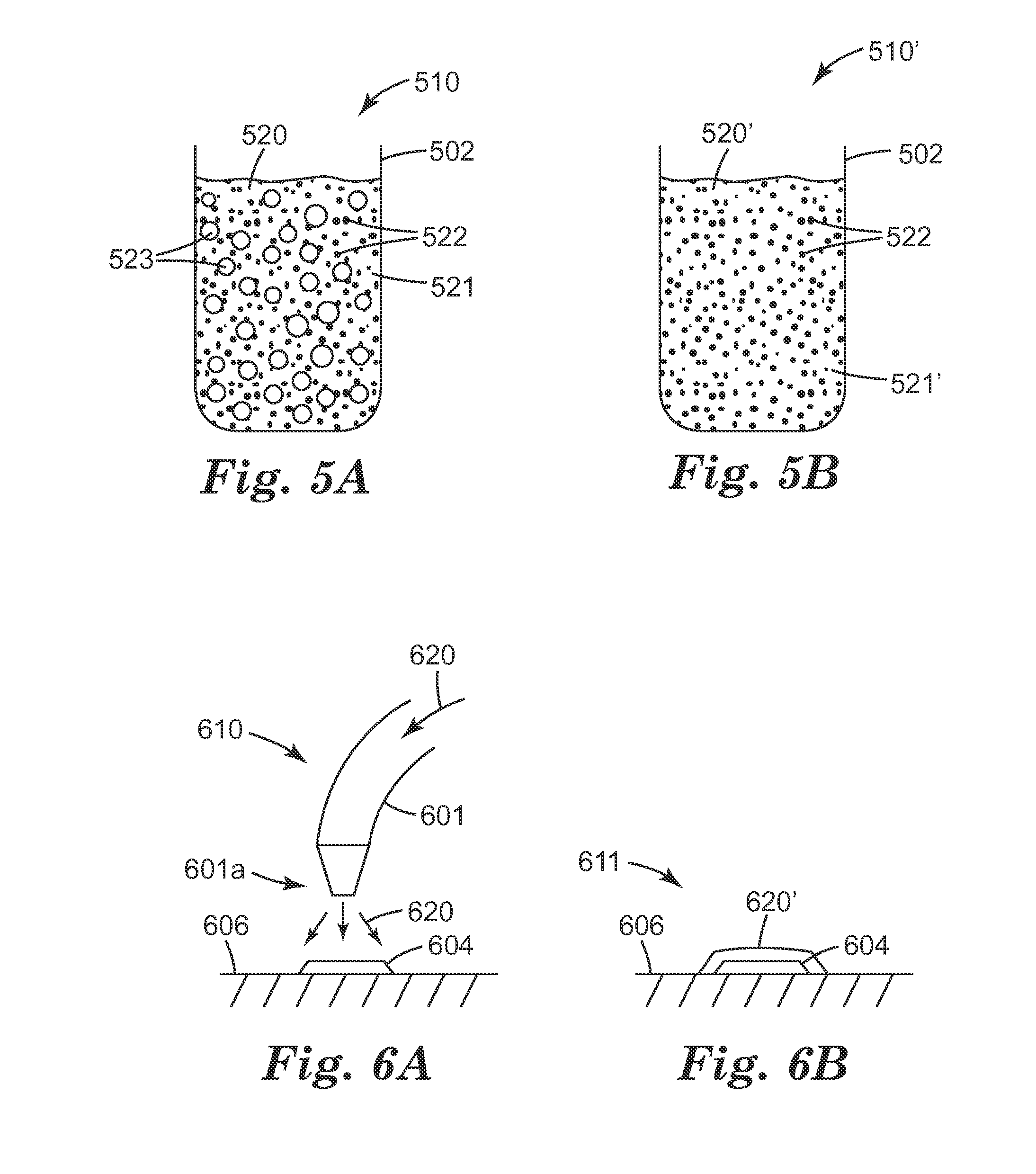

Electromagnetic Interference (EMI) Shielding Products Using Titanium Monoxide (TIO) Based Materials

ActiveUS20160309628A1Reduce electromagnetic interferenceMagnetic/electric field screeningElectromagnetic interferenceTitanium

Compositions (120), which may be in the form of flexible films, molded bodies, or printable inks, can incorporate ceramic particles (122) comprising titanium monoxide (TiO) for purposes of electromagnetic interference (EMI) shielding at megahertz through gigahertz frequencies. One or more additional ceramic particles can also be included. The compositions comprise a composite material (120) which includes the ceramic particles (122) dispersed within a matrix material (121), such as a polymer. Methods associated with such compositions are also described.

Owner:3M INNOVATIVE PROPERTIES CO

Preparation method of lithium titanate material

The invention belongs to a lithium battery material, and concretely relates to a preparation method of a lithium titanate material. The method comprises the following steps: 1, adding tetrabutyl titanate into anhydrous ethanol, and uniformly stirring to form a titanium alcohol solution; 2, adding lithium acetate into the titanium alcohol solution, and uniformly stirring to form a mixed solution; 3, adding titanium monoxide powder into the mixed solution, and carrying out low-temperature ultrasonic treatment for 1-2 h to obtain a suspension; 4, spraying the suspension into a constant-temperature reaction kettle, sealing, depositing, decompressing and cooling to obtain coated titanium monoxide particles; and 5, putting the coated titanium monoxide particles into the sealed reaction kettle, carrying out constant-pressure standing for 1-3 h, then introducing water vapor, carrying out a sealed pressurization reaction for 2-3 h, relieving the pressure, and carrying out sealed sintering so asto obtain lithium titanate particles. The problem that an existing lithium titanate material is poor in electrical conductivity is solved; and titanium monoxide is used as an inner core, and lithiumtitanate is used as a surface coating layer, so it is guaranteed that the prepared material has oxygen deficiency, the mobility of electrons is improved, and the electrical conductivity is improved.

Owner:江苏众钠能源科技有限公司

Production of high-purity titanium monoxide and capacitor production therefrom

The present invention relates to high-purity titanium monoxide powder (TiO) produced by a process of combining a mixture of titanium suboxides and titanium metal powder or granules; heating and reacting the compacted mixture under controlled atmosphere to achieve temperatures greater than about 1885° C., at which temperature the TiO is liquid; solidifying the liquid TiO to form a body of material; and fragmenting the body to form TiO particles suitable for application as e.g., capacitors. The TiO product is unusually pure in composition and crystallography, highly dense, and can be used for capacitors and for other electronic applications. The method of production of the TiO is robust, does not require high-purity feedstock, and can reclaim value from waste streams associated with the processing of TiO electronic components.

Owner:READING ALLOYS

Preparation method of high-purity titanium monoxide

PendingCN111762813ADoes not affect granularityDoes not affect reactivityTitanium oxides/hydroxidesTitanium(II) oxideTitanium oxide

The invention provides a preparation method of high-purity titanium monoxide and belongs to the technical field of preparation of titanium monoxide. The preparation method comprises the steps that: high-purity titanium powder and high-purity titanium dioxide are prepared into powder with the granularity of 600-1000 meshes according to the mass ratio of 53: 47, and the powder is mixed; the preparedpowder is put into a specially-made aluminum oxide crucible, and the crucible is put into a calcining furnace; and under the condition of vacuum degree, calcining is performed for 4-8 hours at the high temperature of 1250-1400 DEG C to obtain the high-purity titanium monoxide. According to the method for preparing the high-purity titanium monoxide, the low-valence metal oxide is prepared from themetal and the metal high-valence oxide, and therefore, pollution of impurity metal is avoided.

Owner:宁夏中科欧德科技有限公司

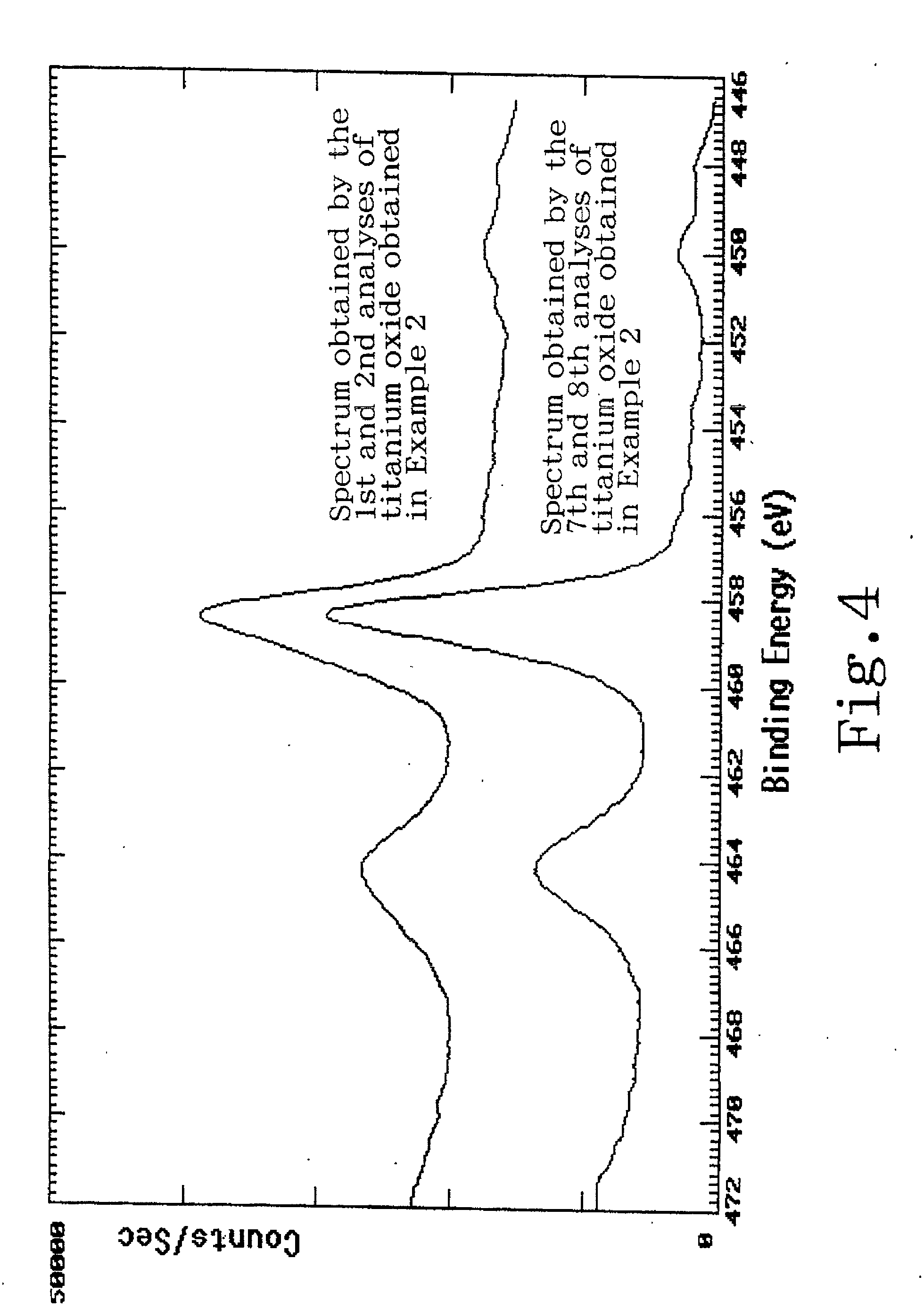

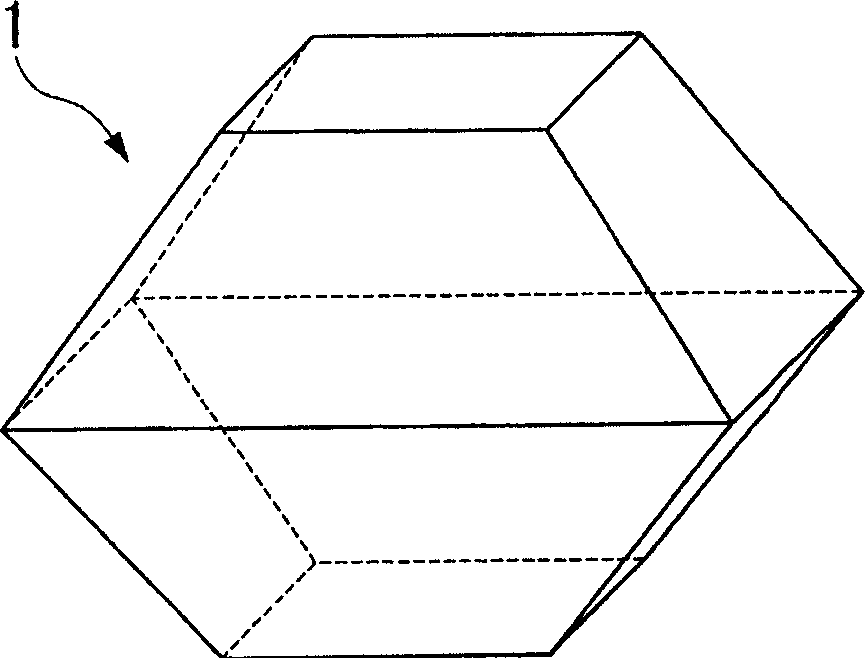

Particulate titanium oxide, method and apparatus for manufacturing the same, and treatment methods using such titanium oxide

InactiveCN100582323CHigh crystallinityLarge specific surface areaPolycrystalline material growthTitanium dioxideSingle crystalOxygen

Titanium oxide grains of large specific area and high crystallinity with reduced internal defects, whose high photocatalytic activity as a photocatalyst is promising; and titanium oxide grains which even when heated at high temperature, exhibits low tendency of transformation to rutile crystal structure and exhibits low rate of sintering. As titanium oxide grains for composing a photocatalyst, use is made of those of the shape of a boxy polyhedron. The polyhedron constituting the titanium oxide grains is composed of one or more titanium oxide single-crystal polyhedrons. The crystallinity can be enhanced by causing the flatness ratio of single-crystal polyhedrons to fall within the range of 0.33 to 3.0. It is preferred that the polyhedron be a hexa to decahedron. The rutile transformation ratio R (700 to 24) is to be 7.5% or less while the rutile transformation ratio R (500 to 24) is to be 2.0% or less. Titanium oxide grains of the above configuration are produced through a process comprising feeding titanium tetrachloride vapor and oxygen into a synthetic tube of quartz glass and heating them from the exterior of the synthetic tube by means of an oxyhydrogen flame burner so as to effect thermal oxidation.

Owner:FUJIKURA LTD

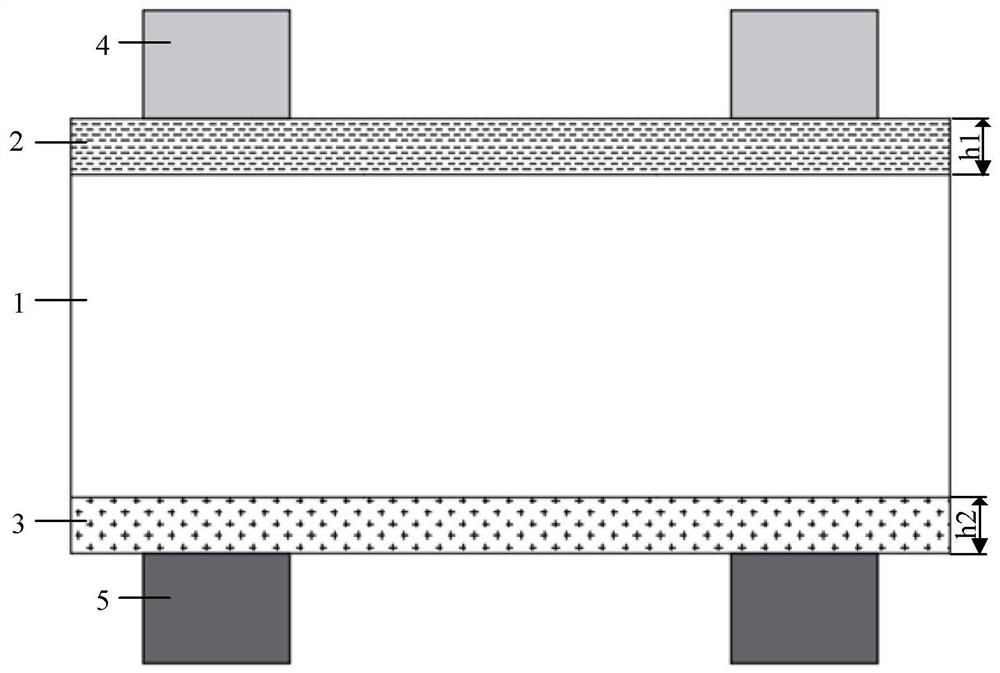

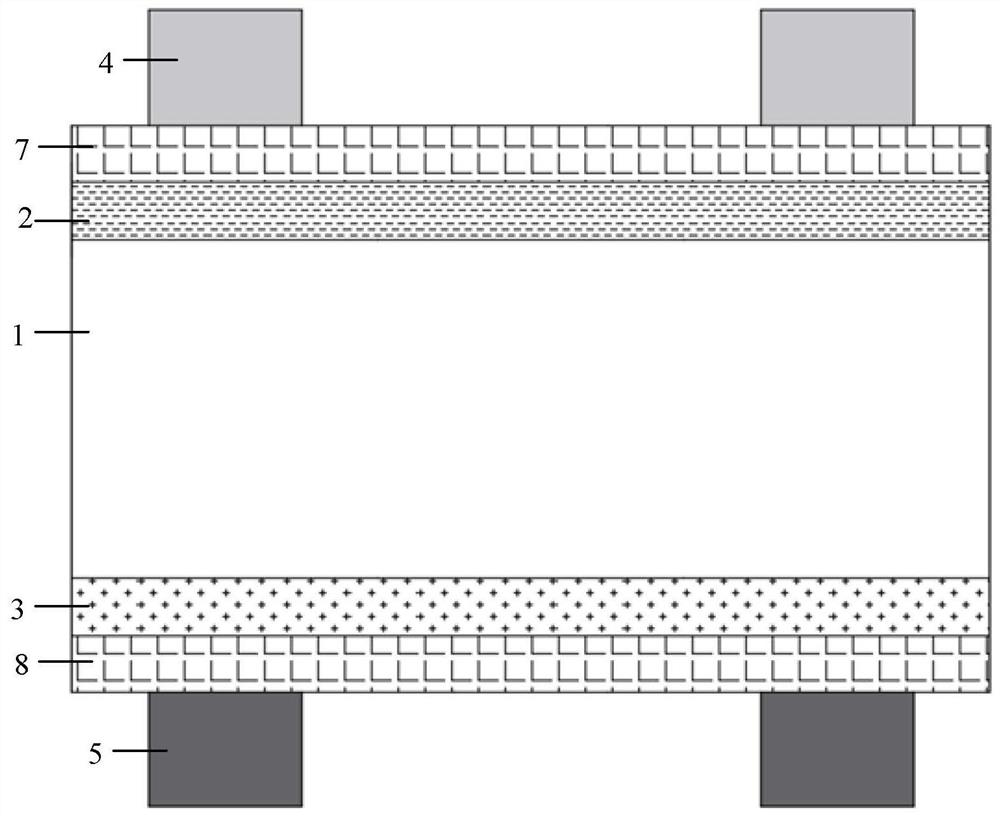

Solar cell, production method and photovoltaic module

ActiveCN112151626ASolution to short lifeReduce bring inFinal product manufactureSemiconductor devicesEngineeringSolar cell

The invention provides a solar cell, a production method and a photovoltaic module, and relates to the technical field of solar photovoltaics. The solar cell comprises a silicon substrate, a first titanium oxide layer, a second titanium oxide layer, a first electrode and a second electrode, wherein the first titanium oxide layer has electron selectivity, and the second titanium oxide layer has hole selectivity; the first electrode is located on the first titanium oxide layer; the second electrode is positioned on the second titanium dioxide layer; the first titanium oxide layer and the secondtitanium oxide layer are respectively positioned on a light-facing surface and a backlight surface of the silicon substrate; or the first titanium oxide layer and the second titanium oxide layer are respectively positioned in a first region and a second region of the backlight surface of the silicon substrate. The production process of the first titanium oxide layer and the second titanium oxide layer is less than or equal to 600 DEG C, the temperature is low, impurities are reduced, the service life of minority carriers is long, the cell structure is simplified, and the process is simplified.The first titanium oxide layer and the second titanium oxide layer can avoid direct contact between the silicon substrate and the electrodes, and the recombination rate is greatly reduced.

Owner:LONGI SOLAR TECH (TAIZHOU) CO LTD

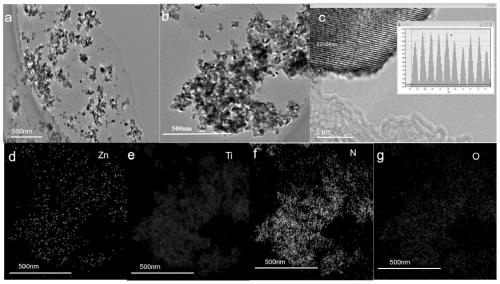

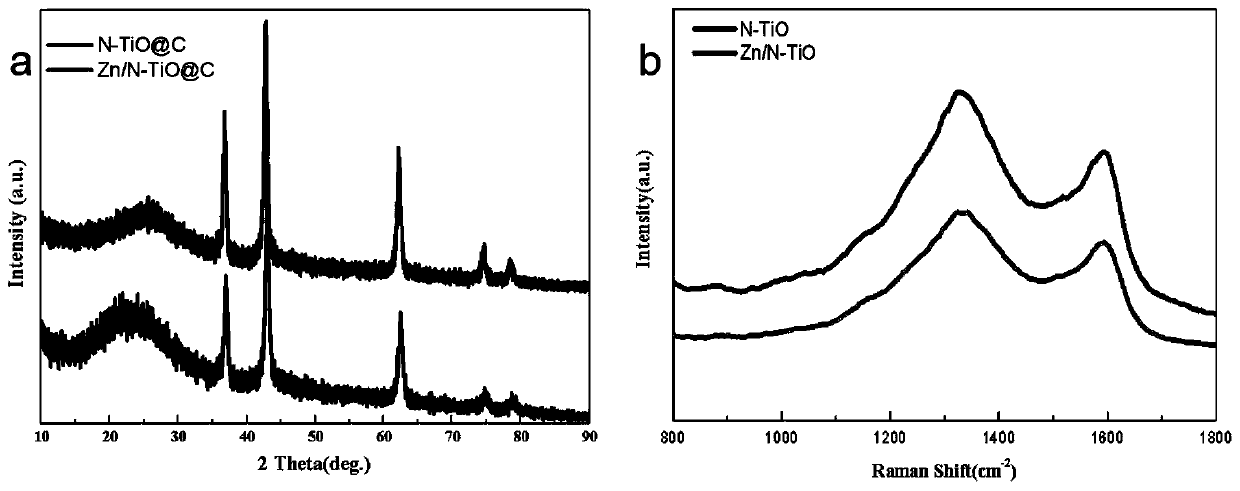

Zn/N double-doped titanium monoxide material and preparation method thereof

ActiveCN111558388ACo-dopingImprove photocatalytic performancePhysical/chemical process catalystsEnergy inputZinc nitrateTitanium oxide

The invention relates to a Zn / N double-doped titanium monoxide material and a preparation method thereof. The preparation method comprises the following steps: (1) dissolving polyacrylonitrile in N, N-dimethylformamide, adding titanium dioxide, performing stirring, and then adding zinc nitrate and stirring together; and (2) heating until the liquid is completely volatilized, carrying out high-temperature treatment on the obtained solid under the condition of ammonia gas, and cooling to obtain the Zn / N double-doped titanium monoxide material. Compared with the prior art, the Zn / N co-doped metaloxide material has the advantage that the photocatalytic performance of the Zn / N co-doped metal oxide material is effectively improved by combining the strong oxidation bridge effect among the metaloxide, carbon and heteroatoms.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Titanium monoxide nano-material and preparation method and application thereof

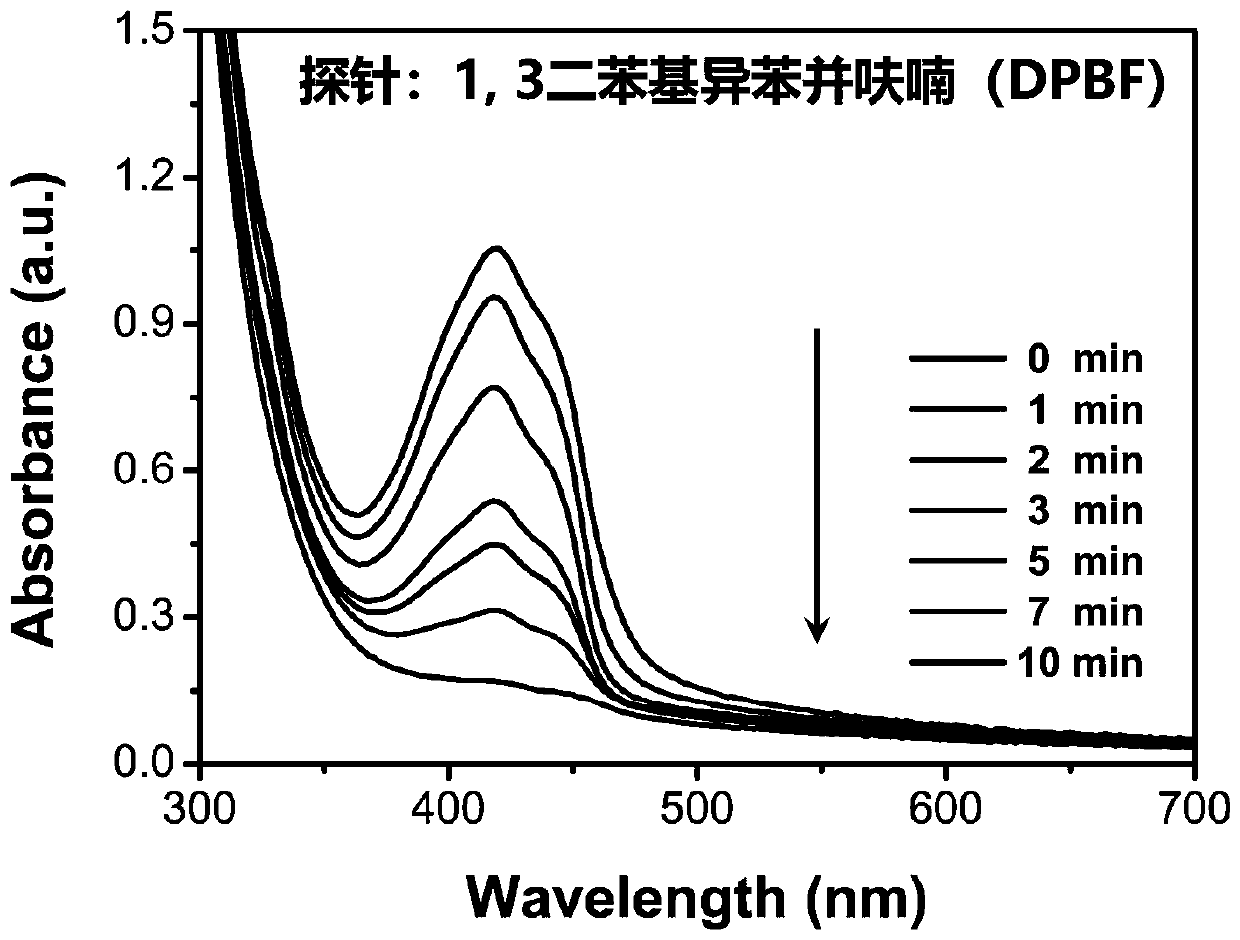

ActiveCN110882389ARegular shapeUniform sizeHeavy metal active ingredientsNanomedicineSonodynamic therapyTitanium

The invention discloses a titanium monoxide nano-material and a preparation method thereof. A hydrophobic titanium monoxide nano-material is prepared by a high temperature pyrolysis method; and then amphiphilic molecules are used for modification, so that a titanium monoxide nano-material aqueous solution with good dispersibility is obtained. The obtained titanium monoxide nano material can generate a large amount of active oxygen under an ultrasonic condition and can be effectively used for sonodynamic therapy of tumors; and the sonodynamic therapy effect is obviously superior to that of theexisting commercial nano material. In addition, the invention discloses application of a titanium monoxide nano material in an anti-tumor preparation.

Owner:JE & NA BIOTECH CO LTD

Preparation method for self-active lithium titanate material

ActiveCN111137916AImprove conductivityRealization of electron-hole structureAlkali titanatesCell electrodesAlcoholEthylic acid

The invention discloses a preparation method for a self-active lithium titanate material. The preparation method comprises the following steps: step 1, adding lithium acetate into absolute ethyl alcohol, and carrying out uniform stirring for 1-3 hours so as to obtain a lithium alcohol solution; step 2, adding titanium monoxide powder into the lithium alcohol solution, and carrying out low-temperature ultrasonic treatment for 2-4 hours so as to obtain a mixed turbid liquid; step 3, uniformly spraying the mixed turbid liquid into a sealed reaction kettle, carrying out standing for 1-2 hours at aconstant temperature, and carrying out decompressing and cooling so as to obtain coated titanium monoxide particles; step 4, adding the coated titanium monoxide particles into a mold, and carrying out a constant-temperature and constant-pressure reaction for 2-4 hours so as to obtain a primary lithium titanate plate; and step 5, soaking the primary lithium titanate plate into tetrabutyl titanate,carrying out low-temperature ultrasonic treatment for 3-5 hours, then carrying out an extrusion reaction for 2-4 hours in a humid environment, and carrying out sintering so as to obtain the self-active lithium titanate material. According to the invention, the problem of poor conductivity of lithium titanate is solved; and titanium monoxide is used as an inner core, and lithium titanate is endowed with oxygen deficiency by utilizing the oxygen deficiency of the titanium monoxide, so an electron-hole structure of the lithium titanate is realized, and the overall conductivity and activity are greatly improved.

Owner:江苏众钠能源科技有限公司

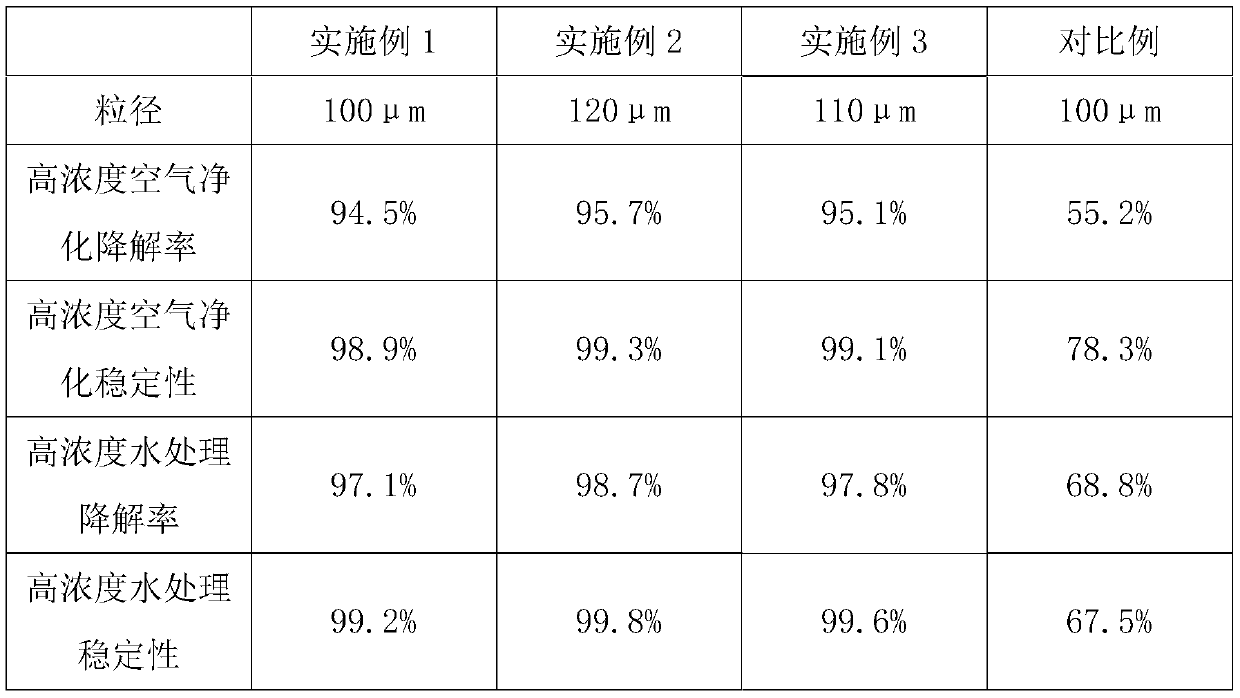

Preparation method of high-activity photocatalytic particles

InactiveCN110841618ASolve the problem of low quantum yieldHigh activityGas treatmentPhysical/chemical process catalystsTitanium(II) oxidePhotocatalytic degradation

The invention belongs to the field of photocatalysis, and particularly relates to a preparation method of high-activity catalytic particles, and the high-activity catalytic particles are prepared by wrapping the surface of nano titanium monoxide with n-butyl titanate and hydrolyzing and converting into titanium dioxide to form multi-titanium photocatalytic particles which take titanium monoxide asa core and titanium dioxide as a wrapping layer. The problem that the quantum yield of titanium dioxide particles is low is solved, the titanium monoxide serves as an inner layer, the titanium dioxide serves as the wrapping layer, the formed titanium oxide particles have the oxygen deficiency characteristic, the activity of the titanium dioxide on the surface is greatly improved, and the photocatalytic degradation efficiency is effectively improved.

Owner:绍兴市梓昂新材料有限公司

Zirconium titanate-based solid solution carrier material for motorcycle exhaust catalyst carrier

InactiveCN101698156ALow costWell mixedCatalyst carriersDispersed particle separationZirconium hydrideCerium(IV) oxide

The invention relates to a zirconium titanate-based solid solution carrier material for a motorcycle exhaust catalyst carrier, which mainly consists of titanium oxide, zirconium oxide and a stabilizer; the mixing ratio by parts by weight is as follows: 10-45 parts of the zirconium oxide, 10-45 parts of the titanium oxide and 1-10 parts of the stabilizer; and the stabilizer is one or two of yttrium oxide, lanthanum oxide, cerium oxide, copper oxide and barium oxide, and the stabilizer exists in the form of zirconium titanate solid solution. The zirconium titanate-based solid solution carrier material has the advantages that as a metal oxide-doped zirconium titanate composite oxide with cheap price is used as the carrier material of a three-way catalyst, a valuable Rh metal can be saved and the cost of the product can be reduced. The using effect proves that the transformation efficiency of a catalyst prepared by the carrier material to main pollutants of NOx, HC and CO can be more than 90%.

Owner:CHINA SPECIAL TYPE FLIER RES INST

Preparation method of efficient titanium-based photocatalyst

InactiveCN110860282AHigh yieldHigh activityGas treatmentPhysical/chemical process catalystsPolyvinyl alcoholFilm base

The invention belongs to the field of photocatalysis, and particularly relates to a preparation method of a high-efficiency titanium-based photocatalyst, which comprises the following steps: step 1, sequentially putting a base material into distilled water and anhydrous ethanol for ultrasonic cleaning for 20-30min, and performing drying to obtain a clean base material; 2, adding polyvinyl alcoholinto distilled water, stirring the substances uniformly to obtain a polyvinyl alcohol solution, then dipping the base material into the polyvinyl alcohol solution, then taking base material out, and performing drying to obtain a polyvinyl alcohol film; 3, spraying nano titanium monoxide powder on the surface of the polyvinyl alcohol film, and then spraying n-butyl titanate on the surface to obtaina multi-film base material; and 4, putting the multi-film base material into a sintering kettle, and carrying out sealed sintering for 2-5h to obtain the titanium-based photocatalytic film. The method provided by the invention solves the problem of low electron yield of existing nano titanium dioxide, utilizes the oxygen deficiency of titanium monoxide to form a multi-titanium structure with n-butyl titanate converted titanium dioxide, enhances the activity of the surface titanium dioxide, and effectively improves the photocatalytic efficiency.

Owner:绍兴市梓昂新材料有限公司

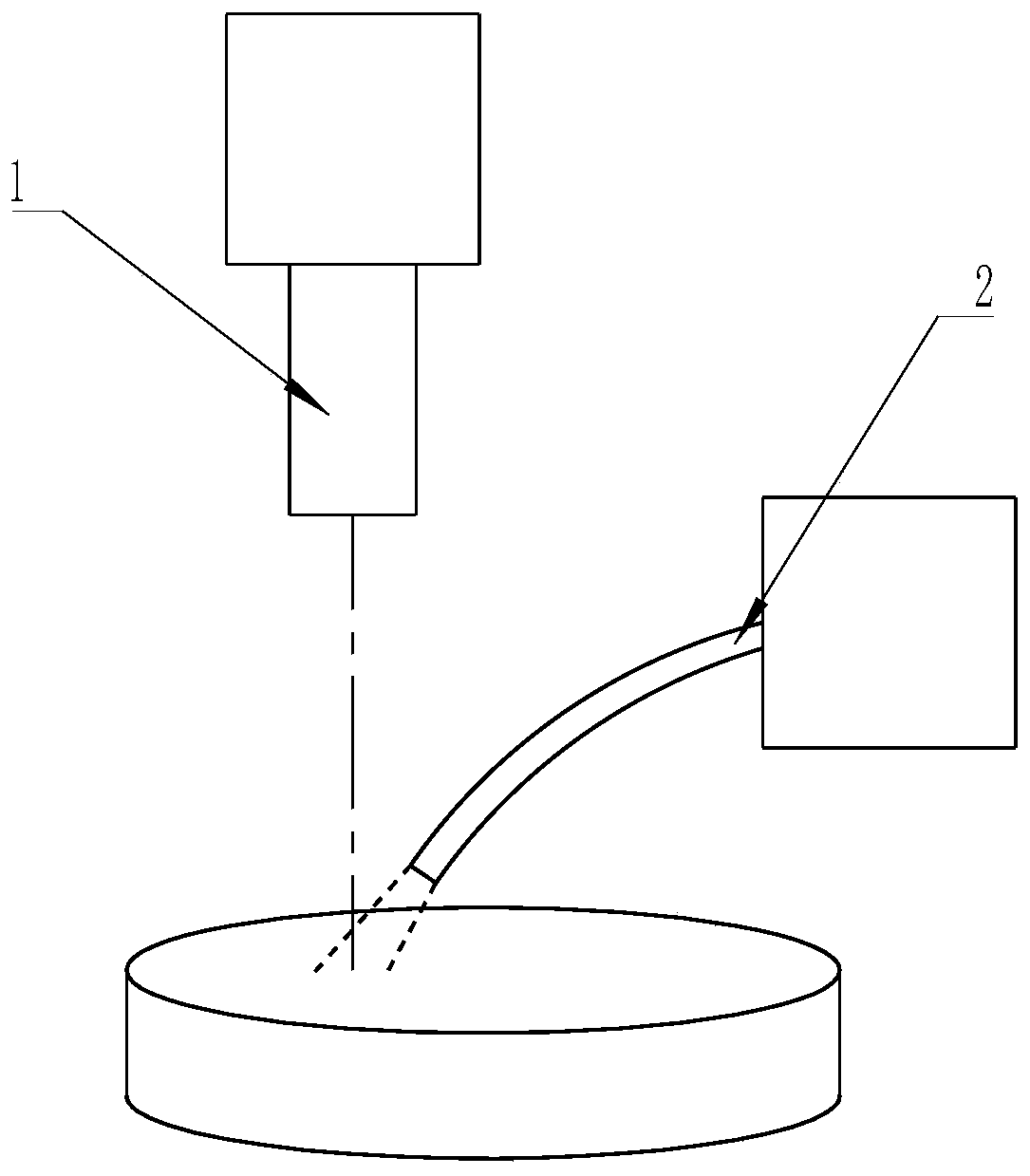

Titanium monoxide semiconductor ceramic and preparation method thereof

The invention relates to a titanium monoxide semiconductor ceramic and a preparation method thereof. The preparation method comprises the following steps: dissolving tetrabutyl titanate into a citricacid solution so as to obtain a mixed solution; adjusting the pH value of the mixed solution to form sol, putting a combustion improver into the sol, aging at the room temperature, and carrying out achemical reaction on the aged sol in a water bath pot so as to obtain wet gel; drying the wet gel in a drying oven so as to obtain dry gel, grinding the dry gel so as to obtain first powder, sinteringthe first powder in a muffle furnace, grinding the sintered first powder so as to obtain second powder, and pressing the second powder into round sheets by using a powder pressing machine; and scanning the round sheets with laser, and carrying out sintering, thereby obtaining the titanium monoxide semiconductor ceramic, wherein argon is used as a reaction protection gas in the scanning process. By adopting the technical scheme of the invention, the production cost and the energy consumption of the titanium monoxide semiconductor ceramic can be reduced.

Owner:HUBEI UNIV OF EDUCATION

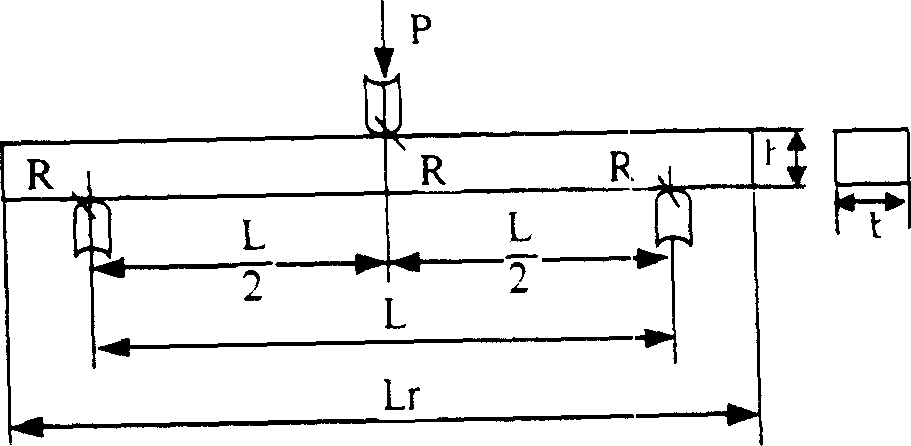

Titanium monoxide based metal ceramic gold-imitated material and its preparing process

The present invention relates to powder metallurgical technology, and is especially titanium monoxide-base cermet material and its preparation process. The present invention features that into the Fe-Cr alloy on titanium monoxide base with oxygen index of 0.8-1.2, one or several of Mo, Si and Ni elements in 0.1-20 5 are added. The titanium monoxide-base cermet gold-imitating material has chroma difference to 24K gold of 0.005-0.010, stable color in atmosphere, no color change after setting in gold corroding liquid at 25 deg.c for over 40 days, bending strength of 440-800 MPa, breaking toughness of 5.2-10.0 MNm-3 / 2. The titanium monoxide-base cermet gold-imitating material has excellent comprehensive performance.

Owner:CENT SOUTH UNIV

Particulate titanium oxide, method and apparatus for manufacturing the same, and treatment methods using such titanium oxide

InactiveCN1723304AEfficient preparationImprove decomposition efficiencyPolycrystalline material growthTitanium dioxideSingle crystalOxygen

Titanium oxide grains of large specific area and high crystallinity with reduced internal defects, whose high photocatalytic activity as a photocatalyst is promising; and titanium oxide grains which even when heated at high temperature, exhibits low tendency of transformation to rutile crystal structure and exhibits low rate of sintering. As titanium oxide grains for composing a photocatalyst, use is made of those of the shape of a boxy polyhedron. The polyhedron constituting the titanium oxide grains is composed of one or more titanium oxide single-crystal polyhedrons. The crystallinity can be enhanced by causing the flatness ratio of single-crystal polyhedrons to fall within the range of 0.33 to 3.0. It is preferred that the polyhedron be a hexa to decahedron. The rutile transformation ratio R (700 to 24) is to be 7.5% or less while the rutile transformation ratio R (500 to 24) is to be 2.0% or less. Titanium oxide grains of the above configuration are produced through a process comprising feeding titanium tetrachloride vapor and oxygen into a synthetic tube of quartz glass and heating them from the exterior of the synthetic tube by means of an oxyhydrogen flame burner so as to effect thermal oxidation.

Owner:THE FUJIKURA CABLE WORKS LTD

Free-standing, binder-free metal monoxide/suboxide nanofiber as cathodes or anodes for batteries

ActiveUS10886525B2Electrode thermal treatmentNegative electrodesMetal oxide nanoparticlesManganese oxide

A nanofiber mat comprises metal oxide nanoparticles distributed on surface of metal oxide nanofibers, wherein the nanofiber mat has a surface area at least 150 m2 / g, and the metal oxide is selected from titanium monoxide TiOx, wherein 0.65<x<1.25, niobium monoxide NbOx, wherein 0.982<x<1.008, vanadium (II) oxide VOx, wherein 0.79<x<1.29, iron (II) oxide FexO, wherein 0.833<x<0.957, manganese (II) oxide MnxO, wherein 0.848<x<1.000, titanium suboxide, TinO2n-1, wherein n>1, molybdenum suboxide, MonO3n-1, wherein n>1, MonO3n-2, wherein n>1, and vanadium suboxide, VnO2n-1, wherein n>1. Cathodes, anodes and batteries are made using the nanofiber mat. Processes for producing the metal oxide nanofiber mat and an electrode including it are also provided.

Owner:DREXEL UNIV

New method for producing high-quality high titanium slag

The invention discloses a new method for producing high-quality high titanium slag, which is characterized by comprising the process flows of pellet preparation by proportioning materials, quick melting, rolling reinforced reduction, and settlement separation. As the whole process is in a high-power running condition, the method shortens the process flow, not only greatly increases the yield, butalso can produce continuously and effectively inhibits the generation of titanium monoxide and titanium carbide generated by a quick reaction of titanium dioxide and carbon at the high temperature and a gradual reaction of the titanium dioxide and the carbon at the intermediate temperature; oxides of iron, silicon, manganese, aluminum and the like quickly finish oxidation-reduction reaction with the carbon at the intermediate temperature; the grade of a product is improved; and the content of titanium dioxide in the high titanium slag product reaches over 85 percent and is improved by over 10percent compared with that of the titanium dioxide in the high titanium slag product produced by the conventional method, and titanium-iron concentrate resources are saved by over 10 percent.

Owner:苏永山 +2

Free-standing, binder-free metal monoxide/suboxide nanofiber as cathodes or anodes for batteries

ActiveUS20210111390A1Electrode thermal treatmentNegative electrodesMetal oxide nanoparticlesManganese

A nanofiber mat comprises metal oxide nanoparticles distributed on surface of metal oxide nanofibers, wherein the nanofiber mat has a surface area at least 150 m2 / g, and the metal oxide is selected from titanium monoxide TiOx, wherein 0.65<x<1.25, niobium monoxide NbOx, wherein 0.982<x<1.008, vanadium (II) oxide VOx, wherein 0.79 <x <1.29, iron (II) oxide FexO, wherein 0.833<x<0.957, manganese (II) oxide MnxO, wherein 0.848<x<1.000, titanium suboxide, TiOnO2n-1, wherein n>1, molybdenum suboxide, MonO3n-1, wherein n>1, MonO3n-2, wherein n>1, and vanadium suboxide, VnO2n-1, wherein n>1. Cathodes, anodes and batteries are made using the nanofiber mat. Processes for producing the metal oxide nanofiber mat and an electrode including it are also provided.

Owner:DREXEL UNIV

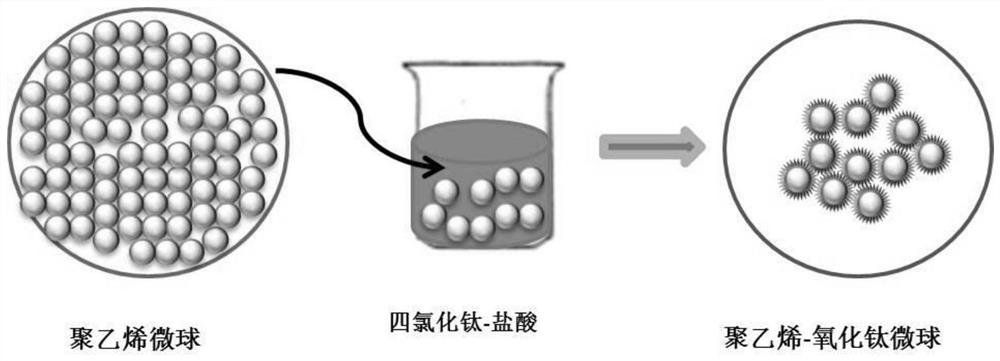

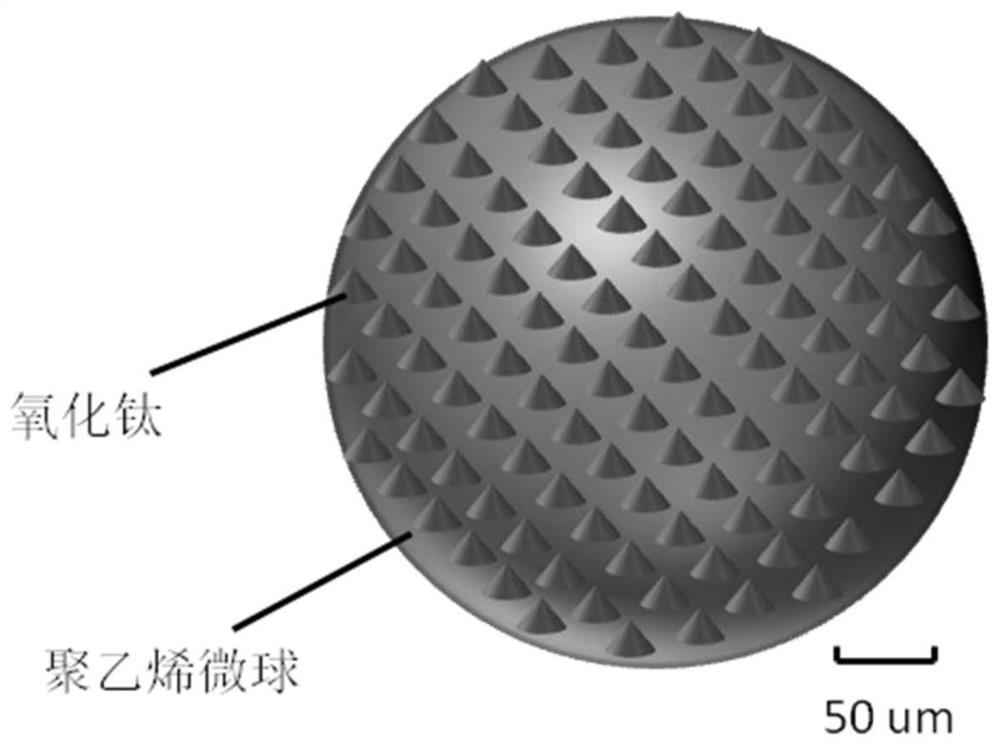

Polyethylene-titanium oxide micro-nano multi-level structure composite microsphere material and its application

ActiveCN109824934BUniform particle sizeShape controllableSkeletal/connective tissue cellsCoatingsMicrosphereMesenchymal stem cell

The invention discloses a polyethylene-titanium oxide micro-nano multi-level structure composite microsphere material and its application. The polyethylene-titanium oxide micro-nano multi-level structure composite microsphere material of the present invention is made by immersing polyethylene microspheres in tetrachloride In the titanium-hydrochloric acid mixture, stir and react in a constant temperature water bath at 60-100°C for 4-24h, wash, and dry to obtain the product. The microsphere has a stable structure and uniform size of 100-500 μm, and the titanium oxide nanorod has a length of 10-50 nm. Seeding human adipose-derived mesenchymal stem cells on the microspheres can promote the proliferation of stem cells and maintain the stemness of stem cells.

Owner:UNIV OF JINAN

A kind of preparation method of lithium titanate material

Owner:江苏众钠能源科技有限公司

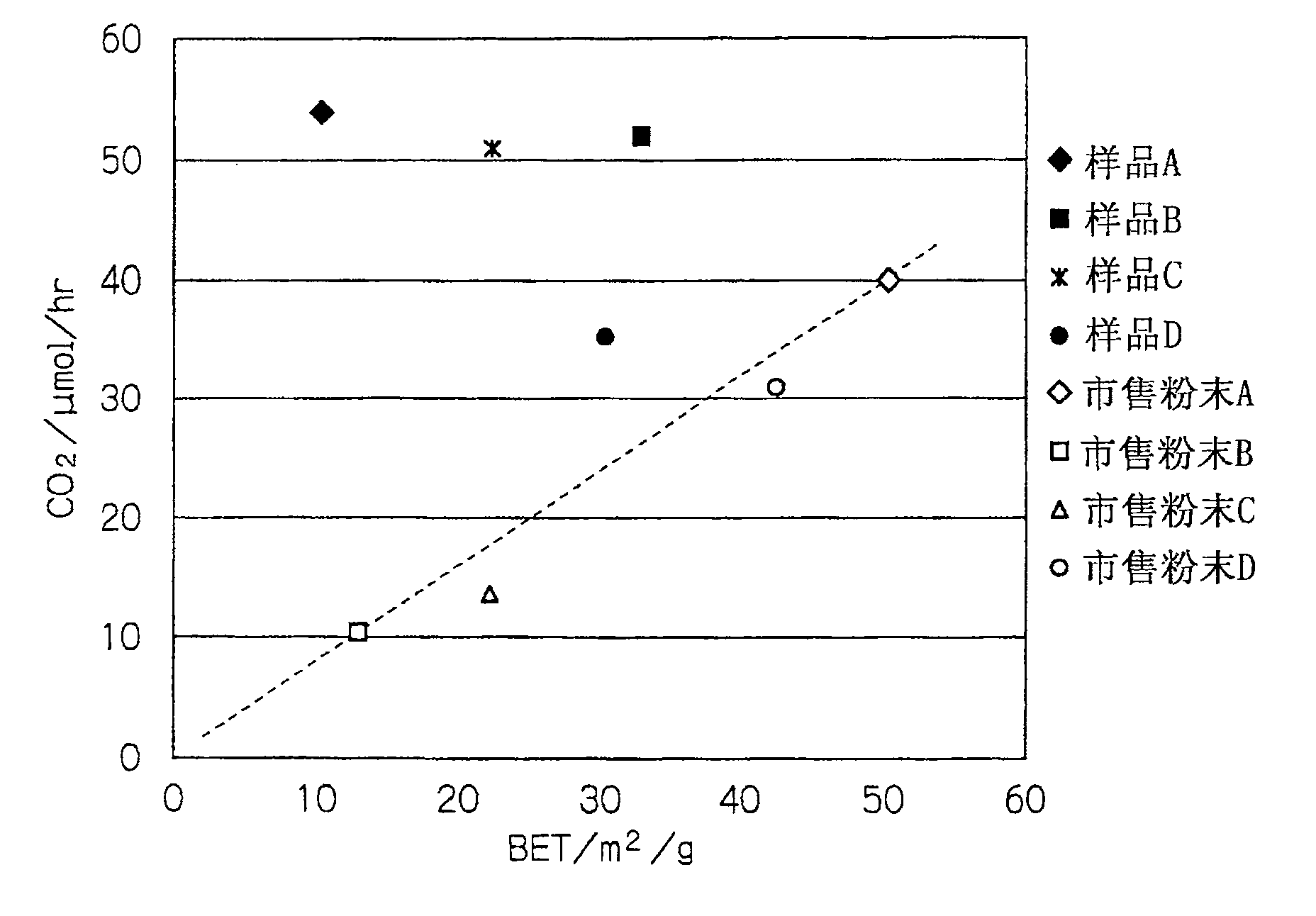

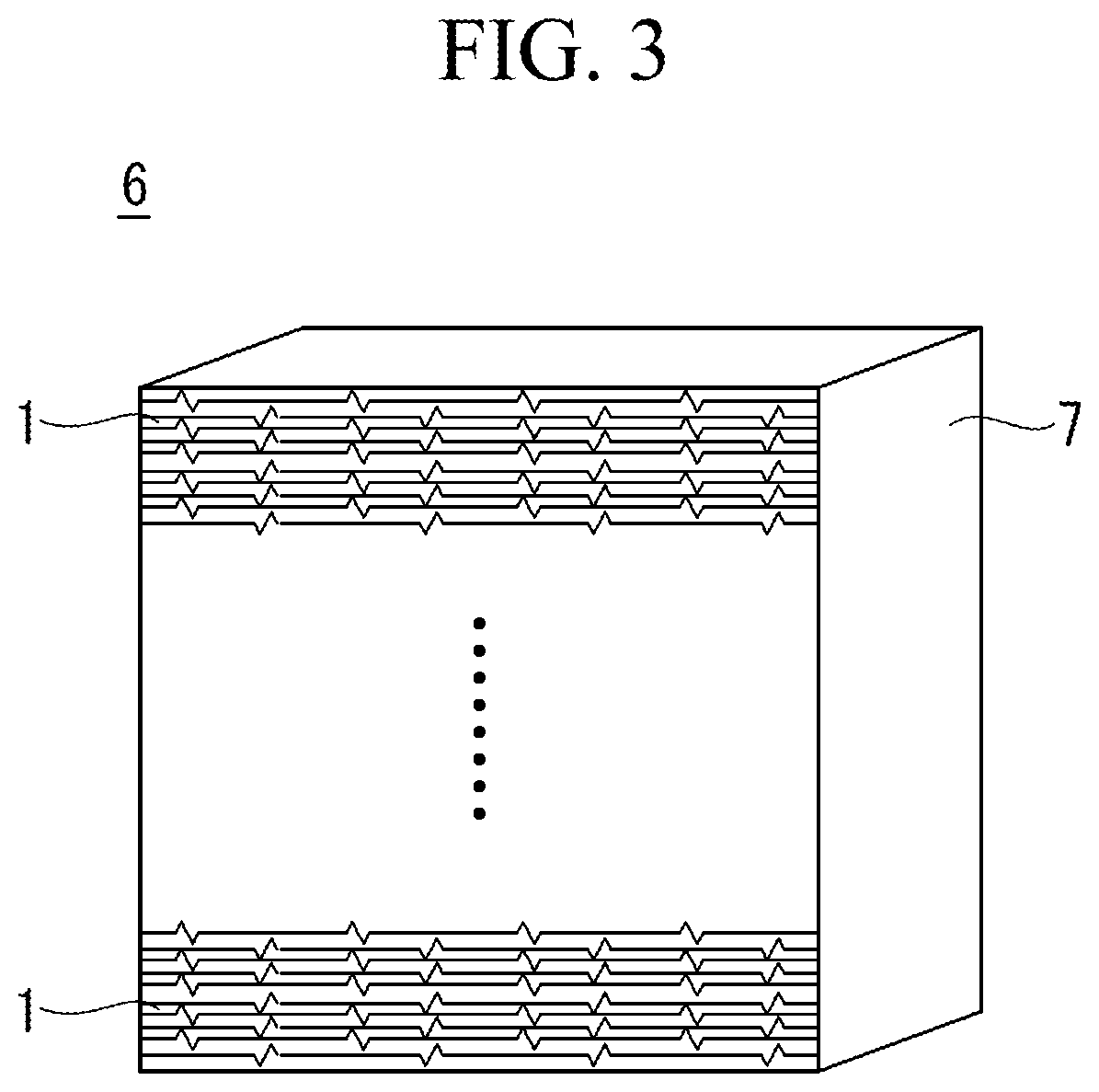

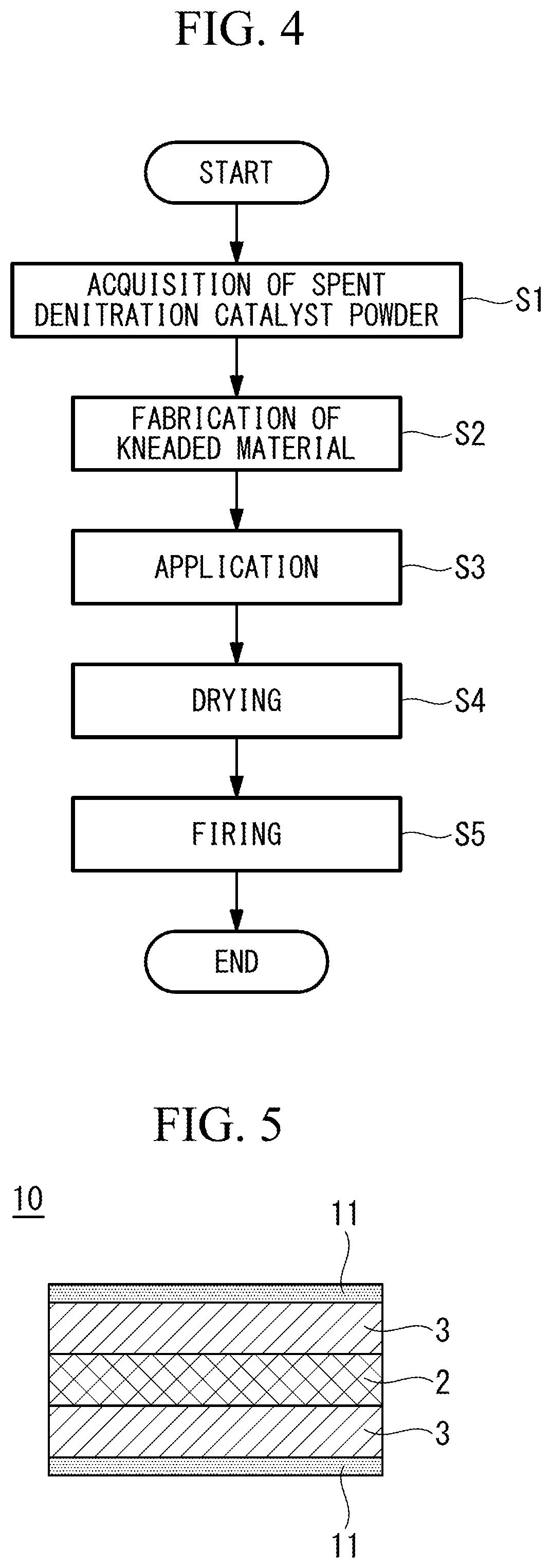

Regenerated denitration catalyst and method for manufacturing the same, and denitration apparatus

PendingUS20220126280A1Increase surface areaRestore performanceGas treatmentNitrogen preparationPtru catalystNitrogen oxides

It is an object to provide a regenerated denitration catalyst whose denitration performance is restored compared with a denitration catalyst before use, utilizing a spent denitration catalyst, and a method for manufacturing the same. In a regenerated denitration catalyst according to the present disclosure, a spent denitration catalyst including a first titanium oxide as a main component, and a second titanium oxide are mixed. The spent denitration catalyst is already used in a denitration reaction in which nitrogen oxides in a gas are decomposed into nitrogen and water using a reducing agent. The second titanium oxide has a larger specific surface area per unit weight than the first titanium oxide. A content of the second titanium oxide based on a total weight of the first titanium oxide and the second titanium oxide is preferably 10% by weight or more and 90% by weight or less.

Owner:MITSUBISHI HEAVY IND LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com