Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Does not affect reactivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

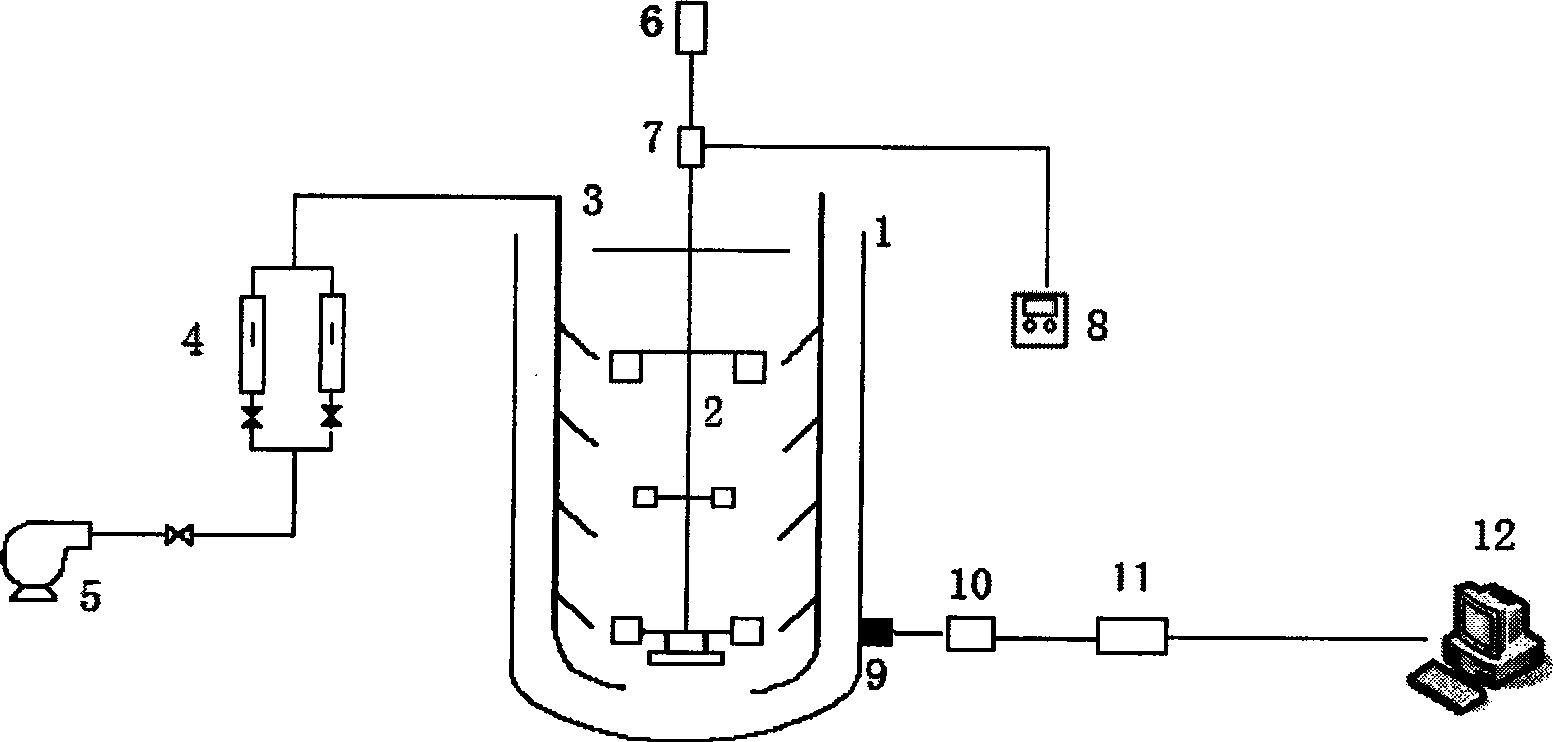

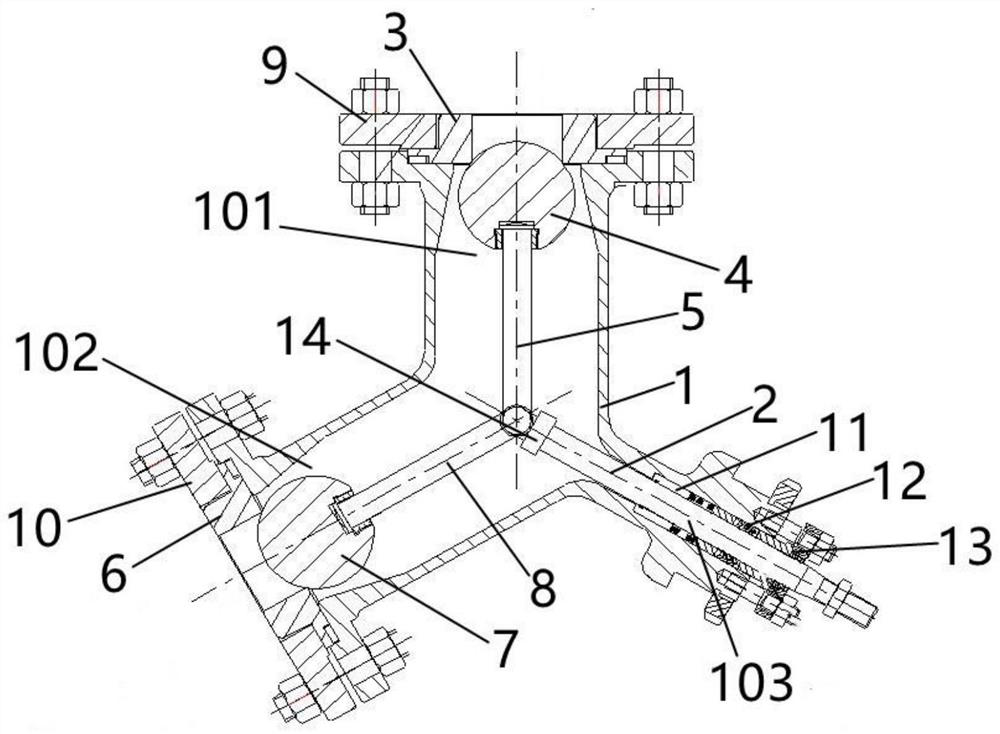

Sound wave monitoring device and method for fluidized bed reactor

ActiveCN1544140ASensitive fault monitoringThe phenomenon of reunion is obviousMaterial analysis using sonic/ultrasonic/infrasonic wavesChemical/physical processesFluidized bedAcoustic wave

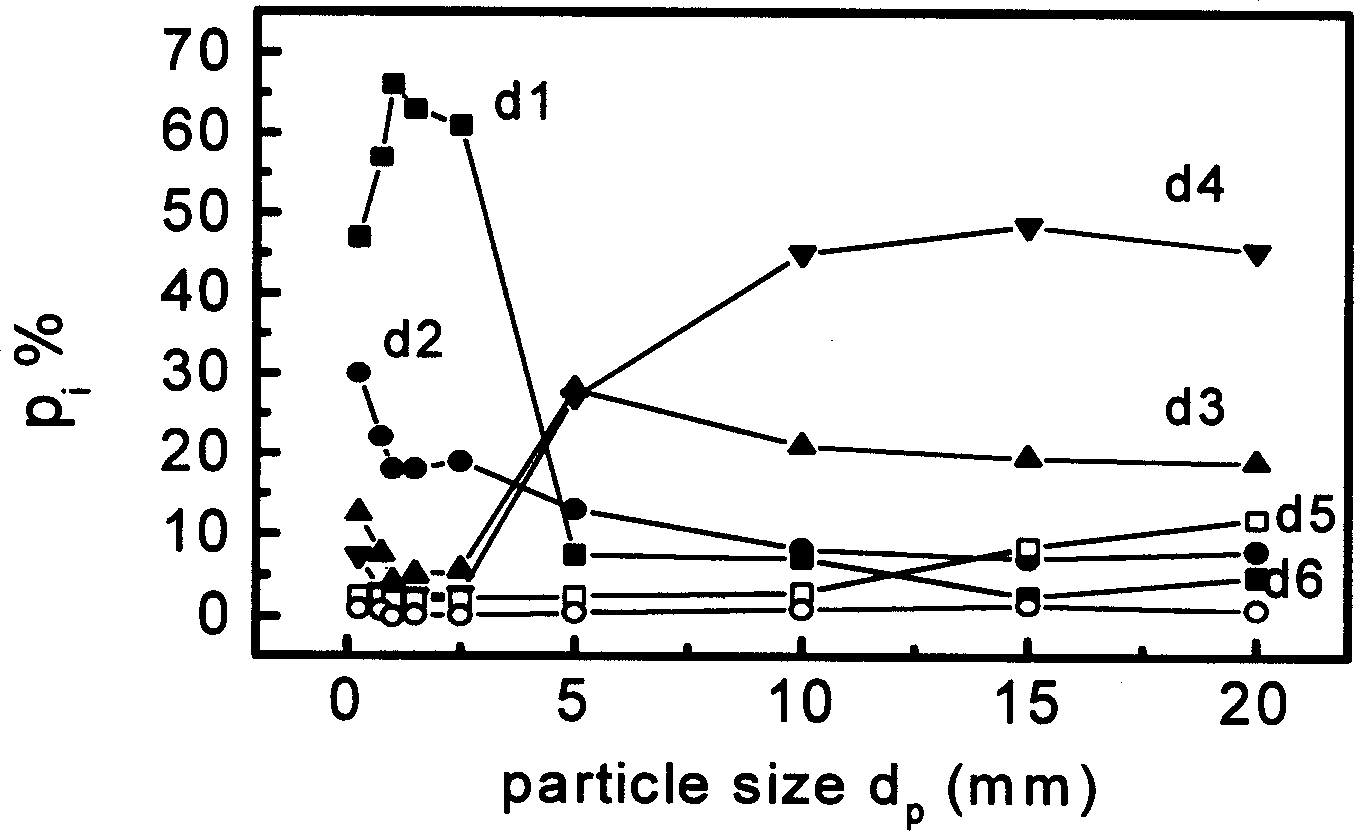

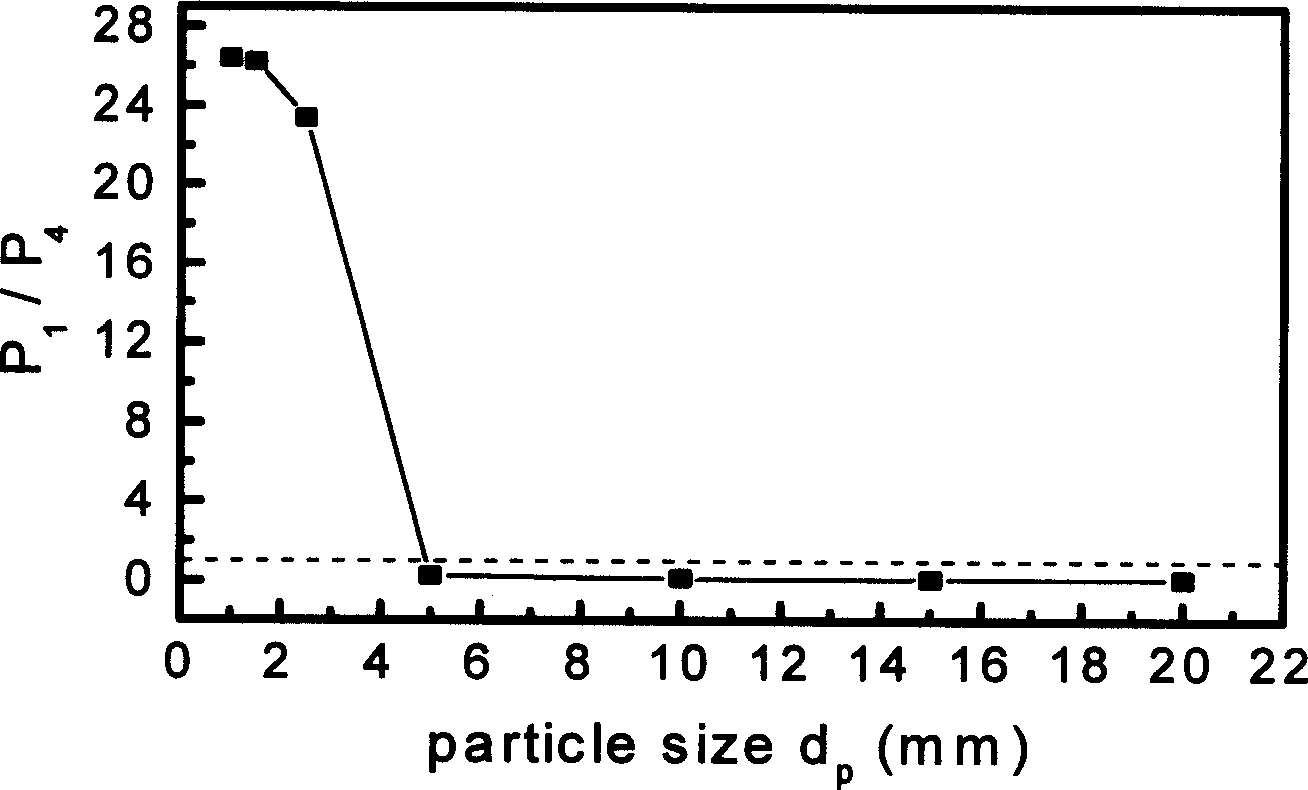

The invention discloses a fluid bed reactor sound-wave monitoring device and method, where the device includes receiving device, amplifying device, signal collecting device and signal processing device; the method includes the following steps: a, receiving sound signal transmitted in the fluid bed reactor; b, analyzing the sound signal, to select the parameters like frequency f, amplitude A, energy E, energy partition Pi in each frequency segment, etc; the practice proves that it has characters of sensitivity, safety and environmental protection, facility and shortcut, etc, can in time and accurately make on-line analysis on the information in the fluid bed (fluid situation, reaction situation, particle size distribution, flow pattern distribution, etc) during the producing practice, and can control production parameters by analyzing result.

Owner:CHINA PETROLEUM & CHEM CORP +1

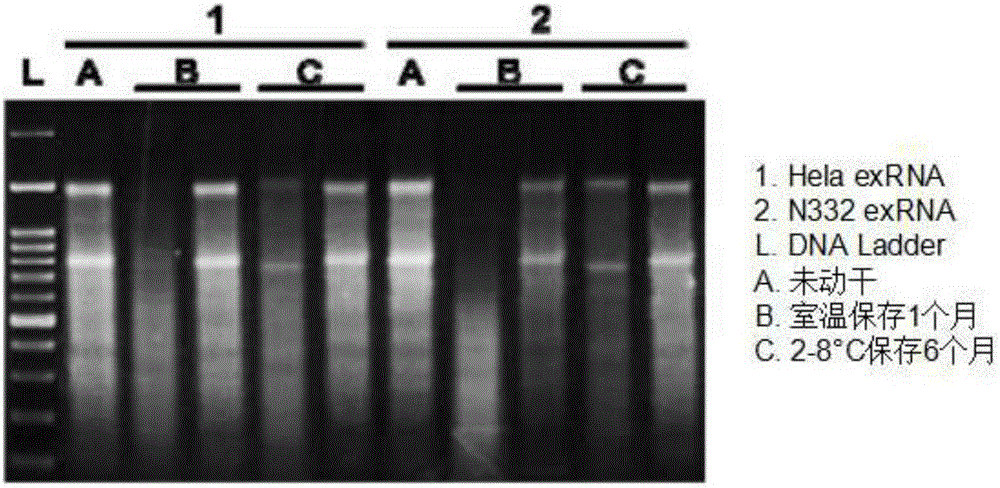

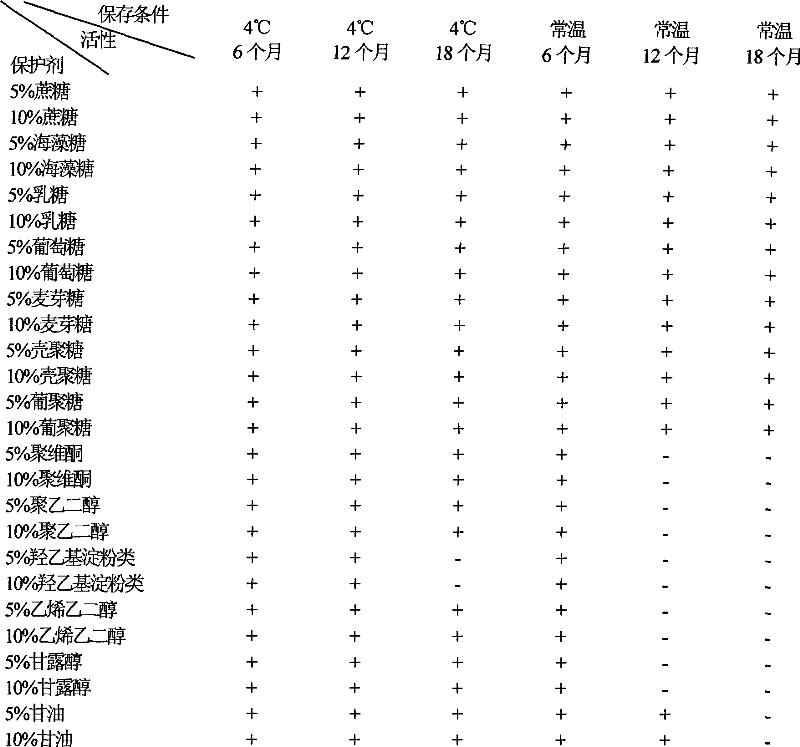

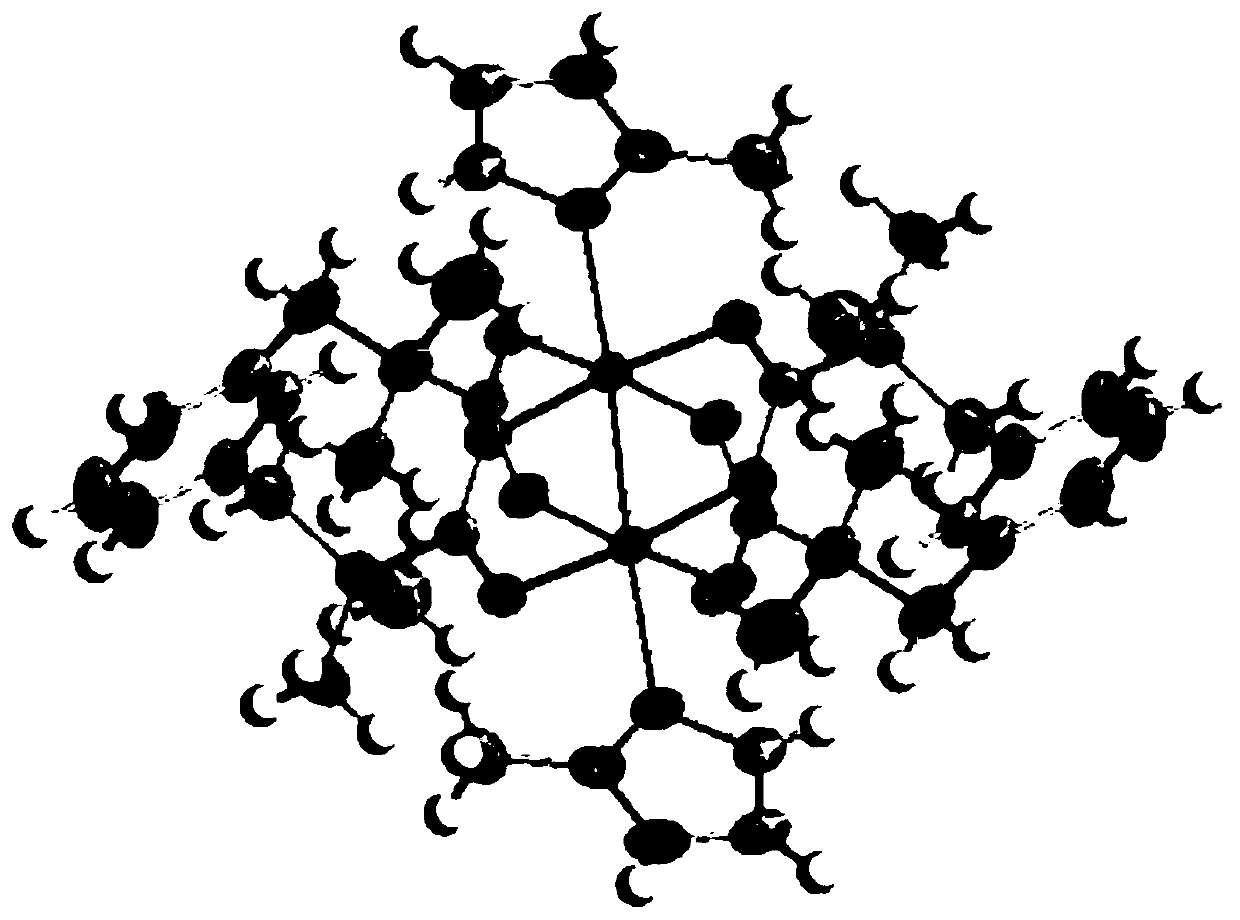

RNA protective agent, kit, application and preservation method

ActiveCN106065400AImprove structural stabilityImprove biological activityDNA preparationPreservation methodsEnzyme

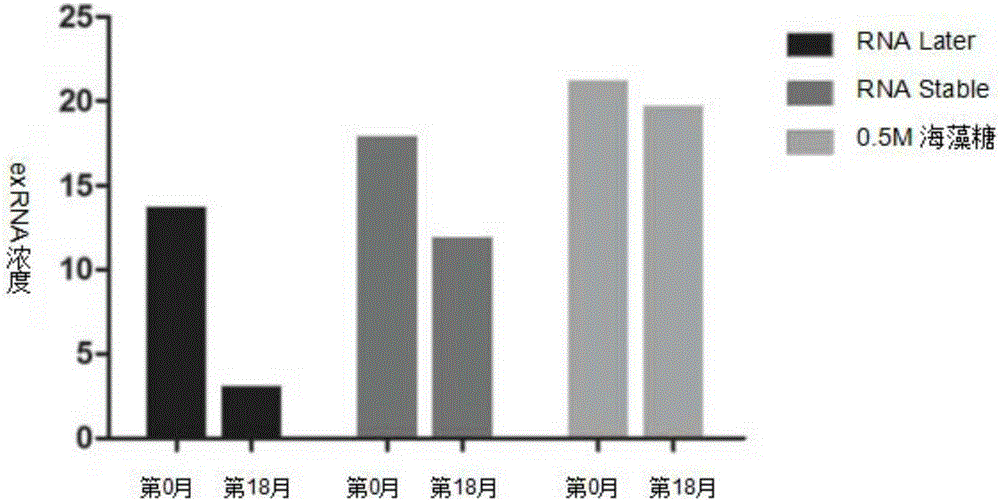

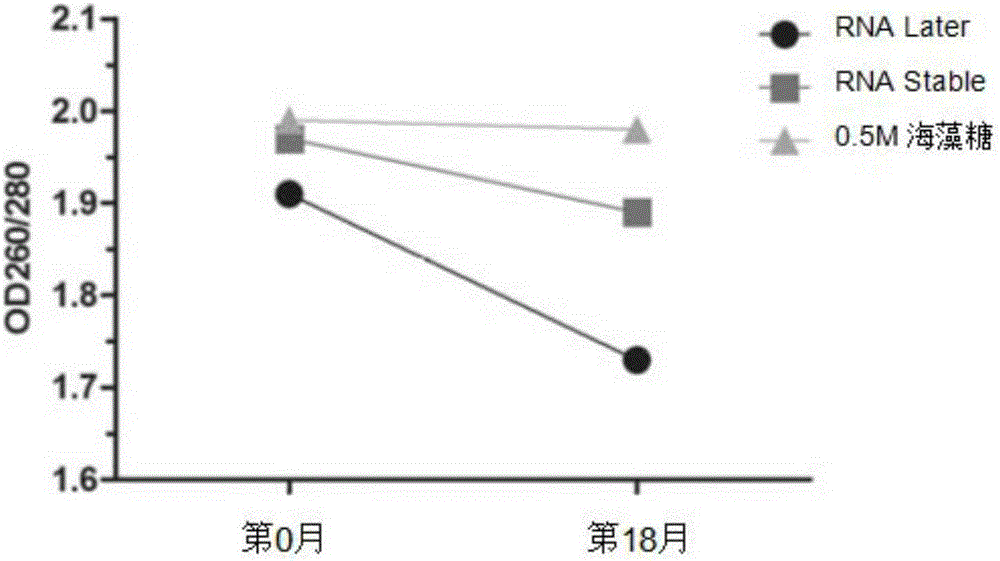

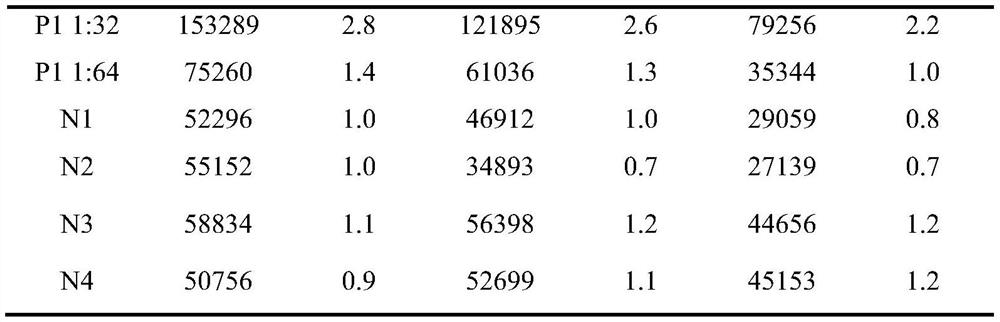

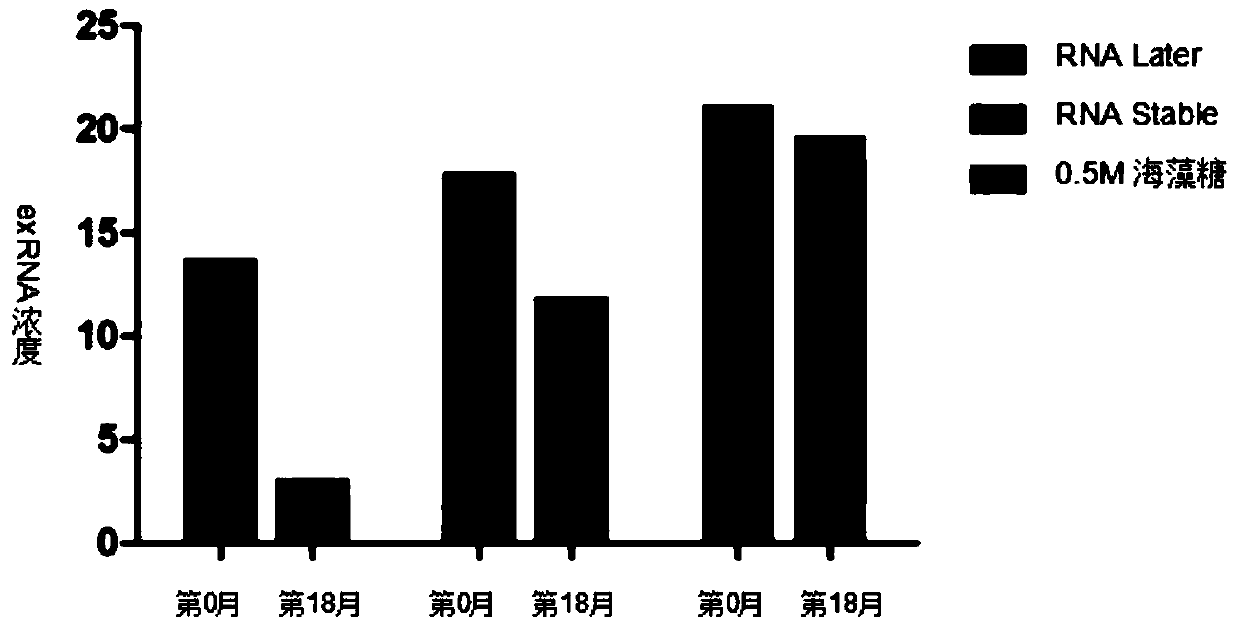

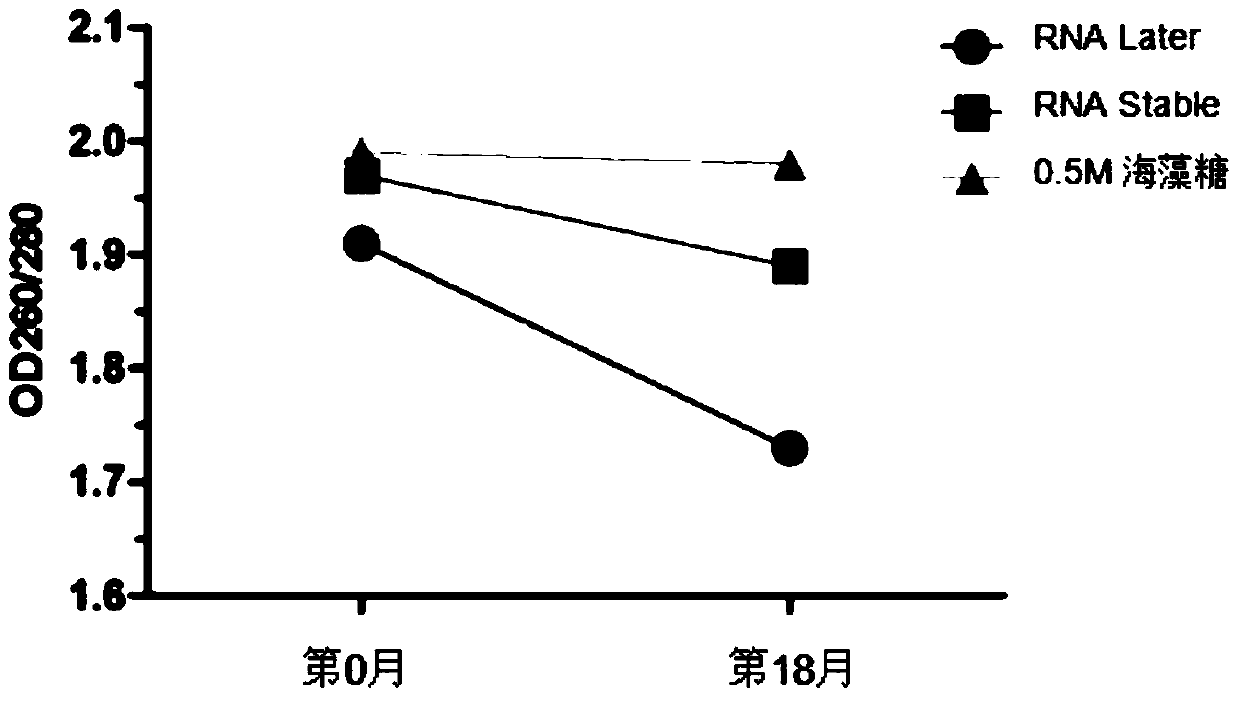

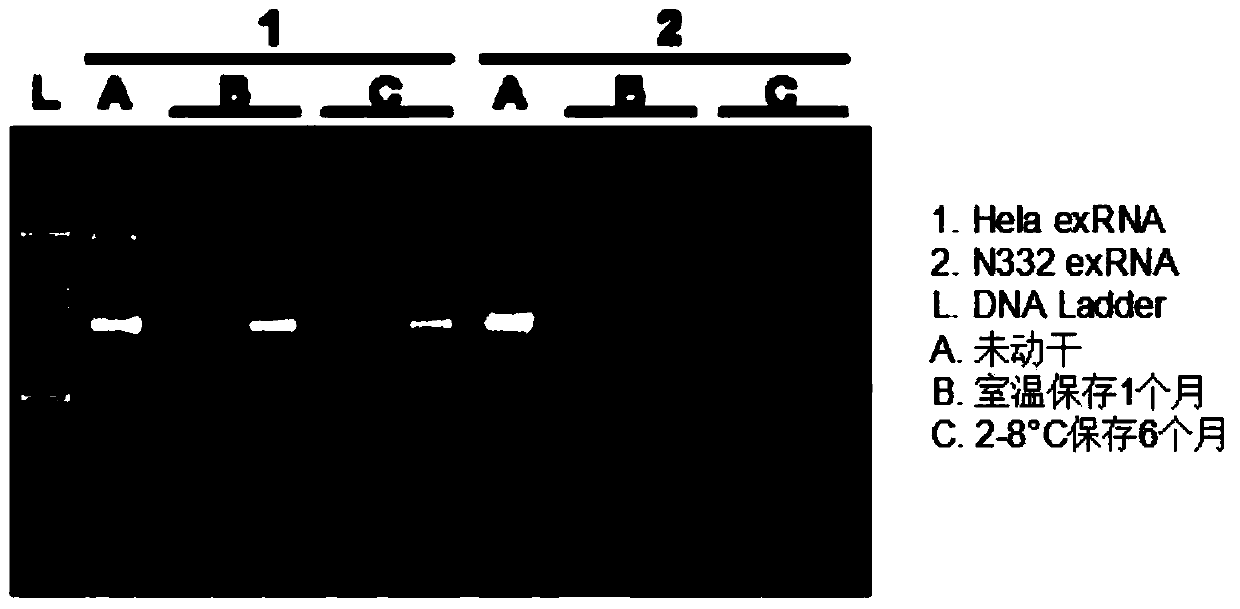

The invention provides an RNA protective agent, a kit containing the protective agent, application and a preservation method of RNA. The protective agent contains a trehalose solution with a concentration of 0.27M-1M. The protective agent provided by the invention can achieve the effects of long preservation time, temperature insensitivity and wide range of use temperature, an extracellular RNA sample treated by the protective agent has no influence to cDNA synthesis, PCR reaction and enzyme activity in sequencing and bank building. The protective agent provided by the invention can efficiently solve the RNA degradation, pollution and other problems encountered during long-term preservation or use of exRNA, and especially has important significance for preservation, repeated use and long-distance transportation of extracellular microRNA.

Owner:上海晟燃生物科技有限公司

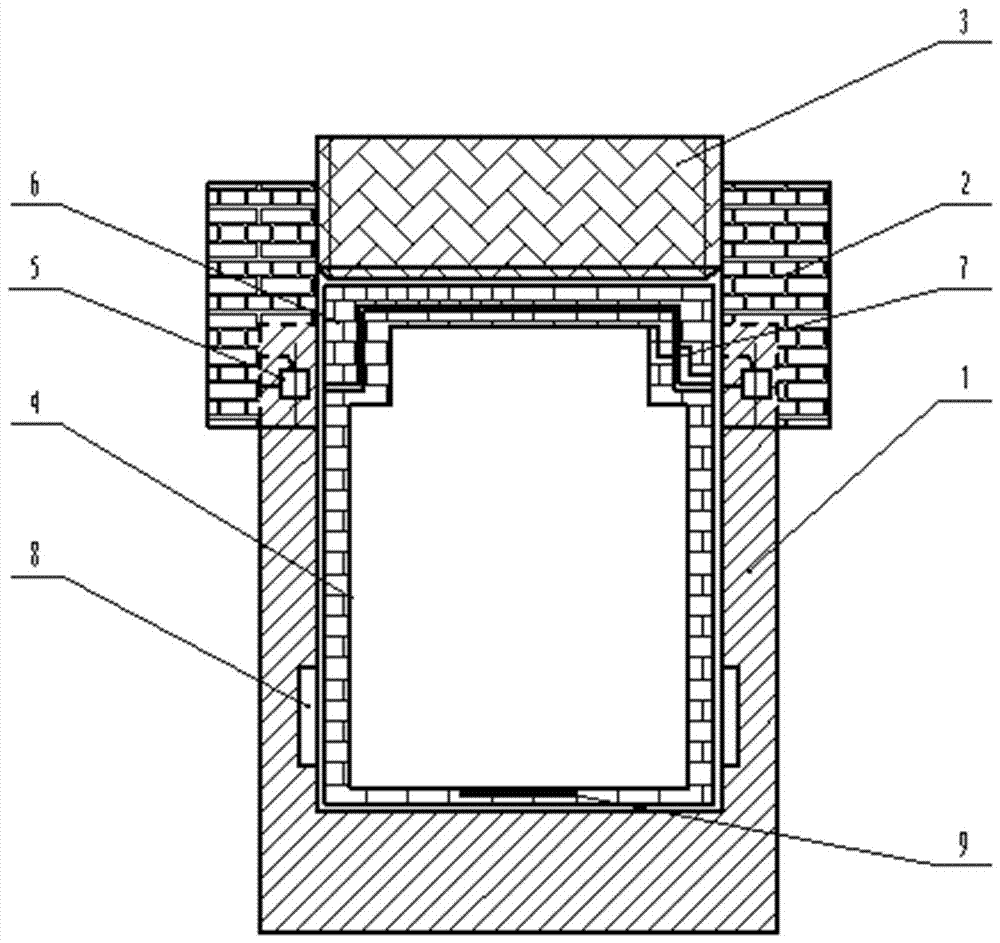

Production method of ferrotitanium

InactiveCN102392133AGranularity requirements are relaxedDoes not affect reactivitySmelting processFerrosilicon

The invention relates to a production method of ferrotitanium. The production method is characterized by comprising the following steps: carrying out arc strike by using ferrum-contained raw material to form a molten pool; putting titanium-containing raw material and lime into a refined electric furnace; carrying out electric-arc heating; in the melting process, adding ferrosilicon into the refined electric furnace to prepare slag and iron; adding the ferrum-containing raw material, lime and aluminum into the refined electric furnace to react with the slag, wherein the alloy generated in the reaction process sink and the slag floats up in the reaction process, and slag and iron are separated until reaction is finished; deslagging, and continuously smelting to finish the whole smelting process; and cutting off power supply, cooling and finishing to obtain the ferrotitanium. The production method has the advantages that requirement on the granularity of each raw material is not strict, processing procedures are reduced, the labor intensity of workers is lowered, the safety coefficient in the ferrotitanium production can be improved, the product recovery rate is improved, aluminum consumption is lowered, and production cost is lowered; and different models of ferrotitanium are produced, thereby breaking through a pattern that a single method can be used for smelting limited models of ferrotitanium.

Owner:CITIC JINZHOU METAL

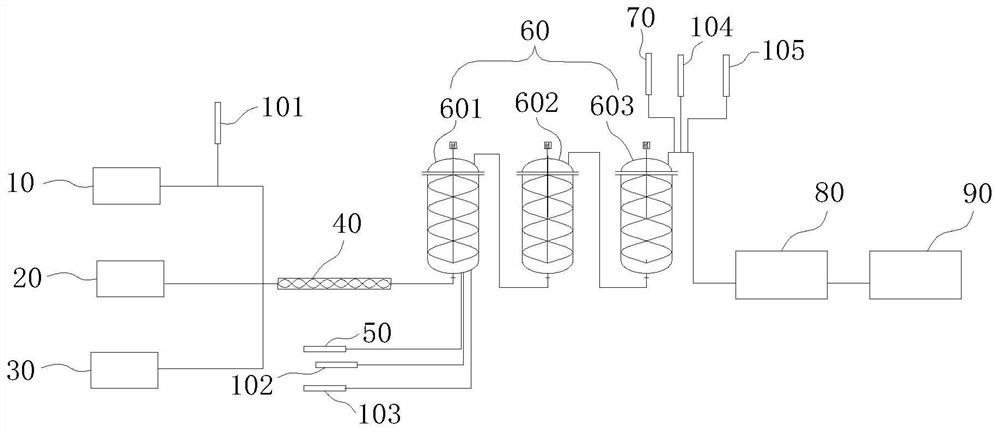

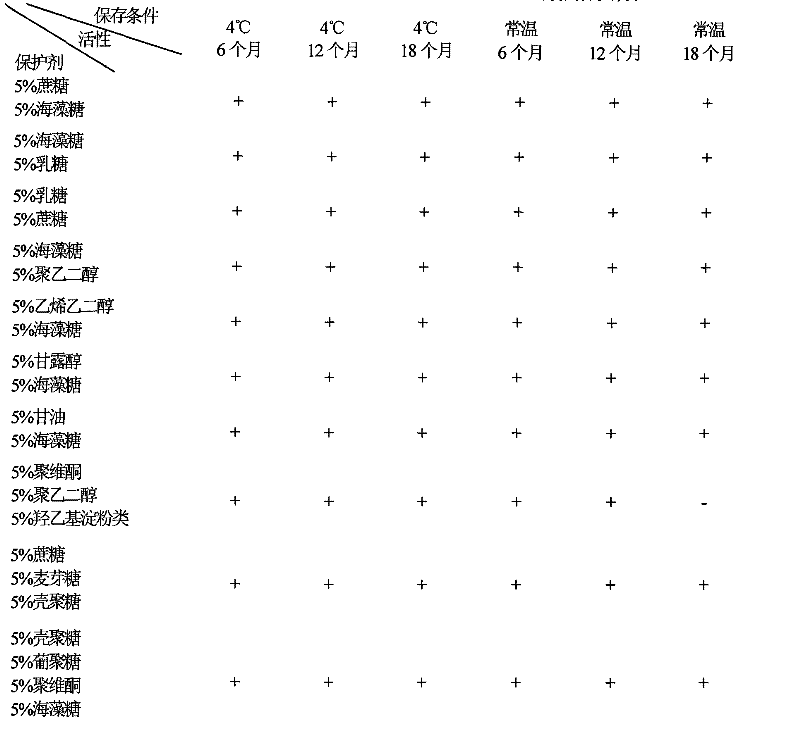

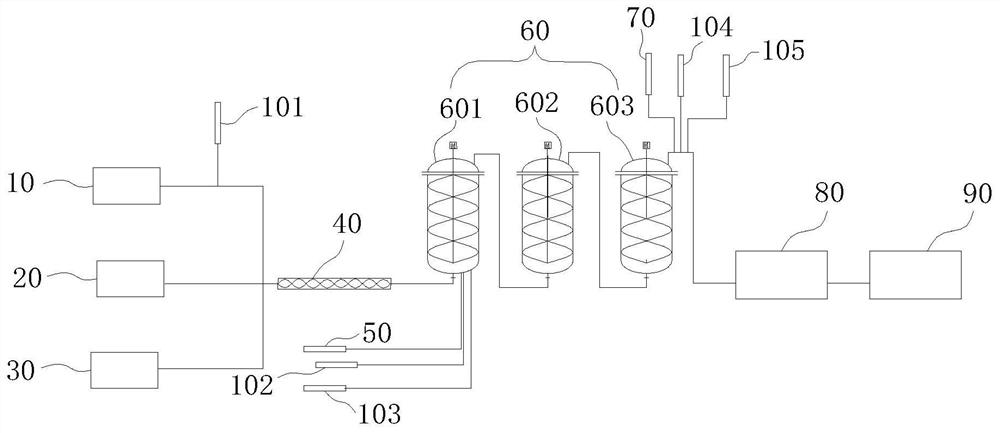

Continuous preparation process of nickel-series butadiene rubber and rare earth-series butadiene rubber

The invention relates to a continuous preparation process of nickel-series butadiene rubber and rare earth-series butadiene rubber. The method comprises the steps: continuously introducing butyl oil and one of a nickel-series catalyst and a rare earth-series catalyst into a polymerization reaction unit of a polymerization device for polymerization reaction, to obtain a nickel-series or rare earth-series butadiene rubber solution, then introducing the rubber solution into a coagulation unit for coagulation, and thus obtaining the nickel-series or rare earth-series butadiene rubber, wherein thebutyl oil comprises a butadiene monomer and a solvent, the content of an oxygen-containing compound of the butyl oil is less than or equal to 20 mg / kg, and the water value of the butyl oil is less than or equal to 50 ppm. When the nickel-series butadiene rubber is prepared, the introduction of the rare earth-series catalyst is stopped, and the butyl oil and the nickel-series catalyst are introduced into the polymerization reaction unit; when the rare earth-series butadiene rubber is prepared, the introduction of the nickel-series catalyst is stopped, and the butyl oil and the rare earth-seriescatalyst are introduced into the polymerization reaction unit. Therefore, the flexible switching production of the nickel-series butadiene rubber and the rare earth-series butadiene rubber can be realized on the same polymerization device under the condition of not stopping to clean the kettle.

Owner:ZHEJIANG TRANSFAR SYNTHETIC MATERIAL CO LTD

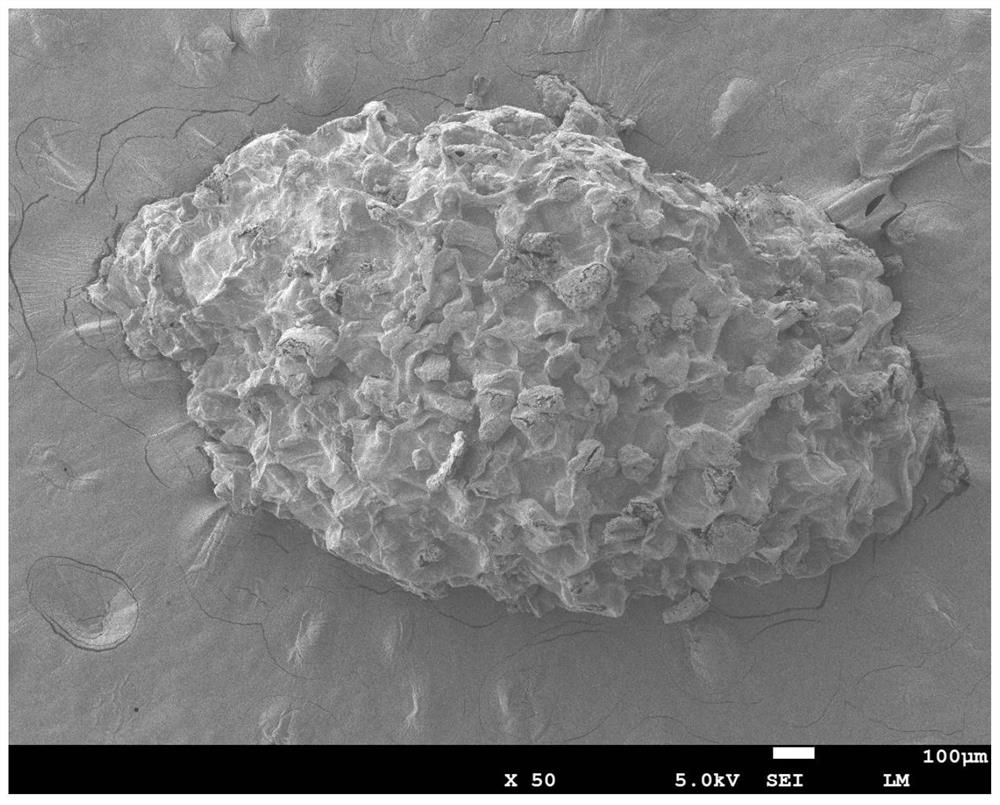

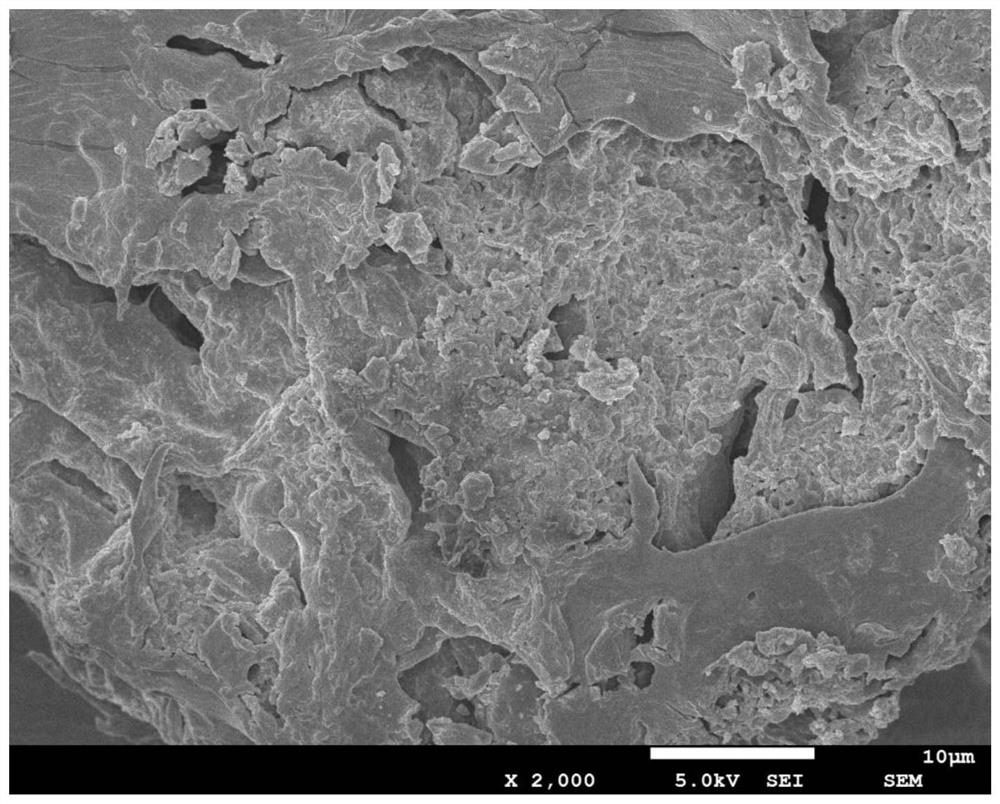

Green synthetic magnetic composite nanomaterial, preparation method and application thereof

PendingCN112755963AImprove mechanical propertiesHigh strengthOther chemical processesWater contaminantsFerrous saltsAdsorption effect

The invention discloses a green synthetic magnetic composite nano material which is characterized by being prepared from the following components in parts by mass: ellipsoidal solid particles prepared by self-assembly, ferrous sulfate heptahydrate, a green tea extracting solution, tea residues and calcium alginate in a ratio of 1:(4-6):(0.6-0.8):(1.8-2.5). The invention also discloses a preparation method and application of the composite nanomaterial. According to the method, ferrous salt is taken as a raw material, calcium alginate is taken as a coating agent, a green tea extracting solution is taken as a reducing agent and a dispersing agent, and the calcium alginate-coated nano-iron composite material is synthesized in a green manner by controlling reaction conditions and the material adding amount and is applied to rapid removal of Cr<6+> and methylene blue in a water body. The nanomaterial has the advantages of being wide in raw material source, simple and convenient in synthesis method, stable in material performance, wide in application range, good in pollutant adsorption effect, free of secondary pollution and the like, can be suitable for emergency treatment of pollutants in large-volume environmental water bodies, and can also be used for deep purification of general domestic sewage, environmental water bodies and drinking water bodies.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

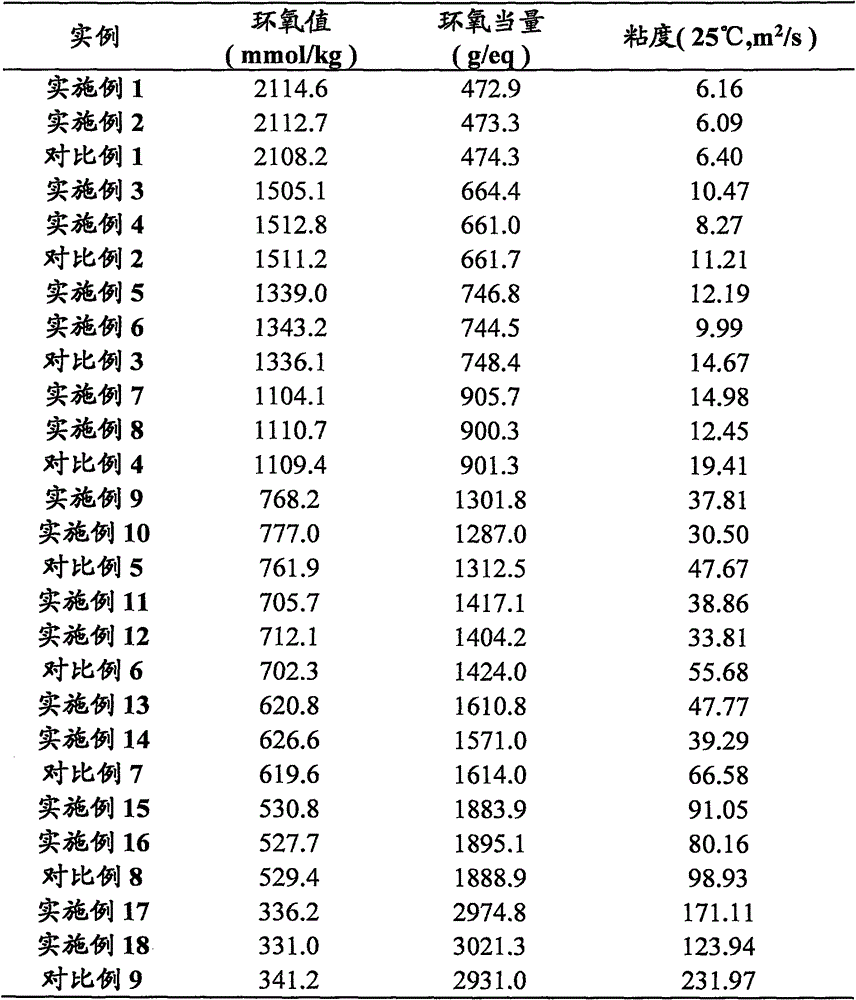

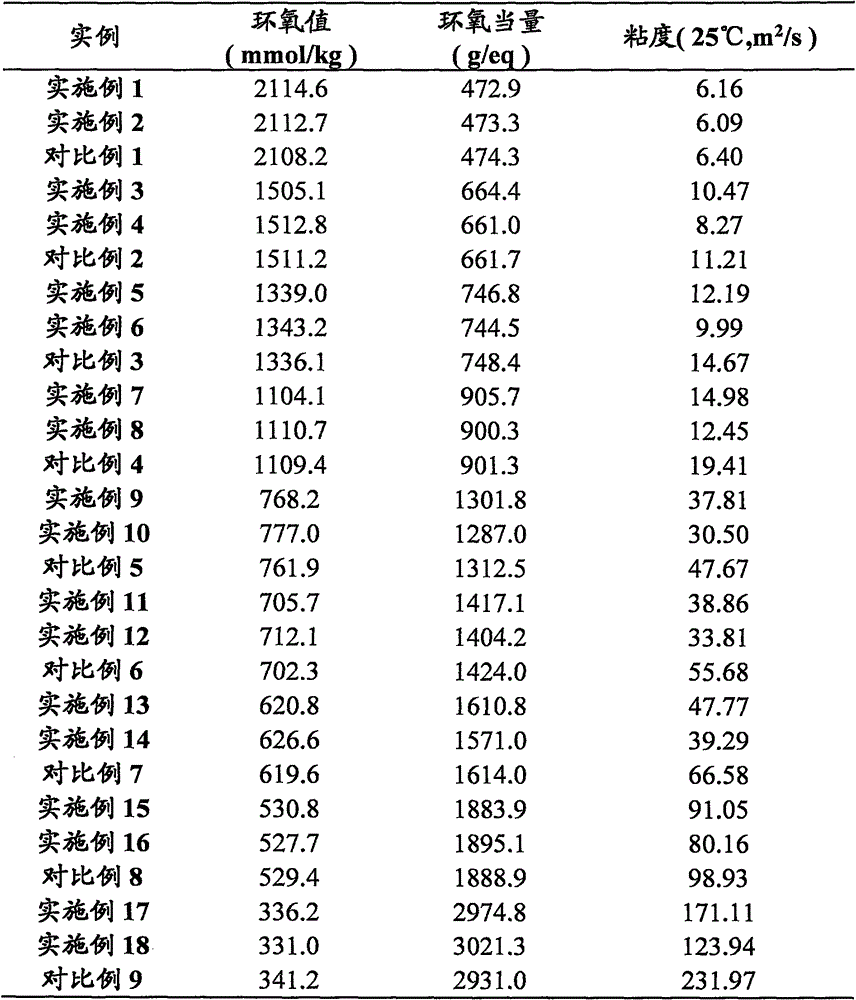

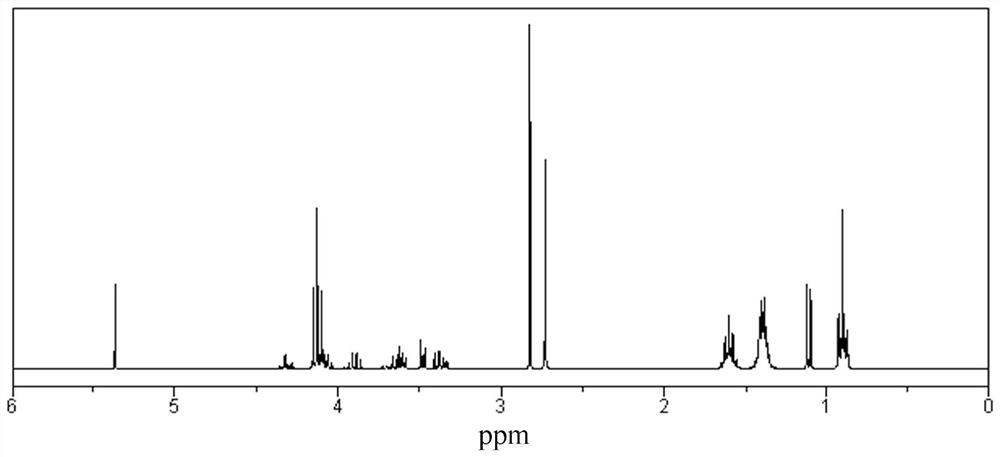

Modifying method of solid epoxy resin

ActiveCN105061728ALower limit of kinematic viscosityDoes not affect physical stabilityOxygenViscosity

The invention discloses a modifying method of solid epoxy resin, and especially relates to a modifying method for reducing the viscosity of the solid epoxy resin. The method comprises the following steps: carrying out mixing melting on base resin and bisphenol A under an oxygen isolation condition to obtain a molten material, adding a catalyst and a compound additive containing a phenolic hydroxyl group, and reacting to obtain modified solid epoxy resin. The modifying method reduces the viscosity of the epoxy resin, and widens the viscosity range of the epoxy resin under a fixed epoxy equivalent condition in order to enlarge the application range of the epoxy resin.

Owner:JIANGSU KUMHO YANGNONG CHEM CO LTD +1

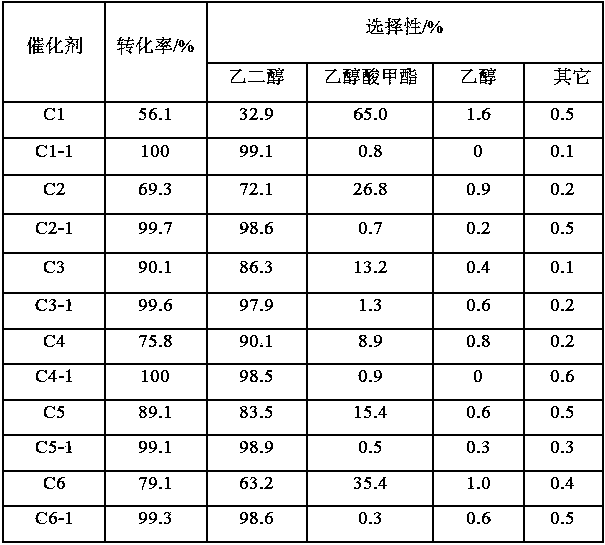

High-stability copper-based catalyst for preparing ethylene glycol by hydrogenating dimethyl oxalate and preparation method of high-stability copper-based catalyst

InactiveCN108144647AReduce adsorptionIncreased resistance to hydrophilic substancesOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsCopperDimethyl oxalate

The invention discloses a high-stability copper-based catalyst for preparing ethylene glycol by hydrogenating dimethyl oxalate and a preparation method of the high-stability copper-based catalyst. Thecatalyst is prepared from the following components by weight percent: 10 to 50 percent of metal copper, 38 to 89.8 percent of carrier, 0.1 to 2 percent of additives, and 0.1 to 10 percent of hydrophobic groups. The catalyst is designed according to the characteristic of the dimethyl oxalate raw material containing trace water, an inorganic oxide is used as a catalyst carrier, and the non-modifiedcopper-based catalyst is prepared according to a conventional catalyst preparation method; and the hydrophobic groups are grafted onto the surface of the non-modified copper-based catalyst by adopting a heating refluxing method, an ultrasonic method or a fumigation method, thereby preparing the hydrophobic modified copper-based catalyst. By virtue of the hydrophobic treatment on the surface of the catalyst, a hydrophobic micro environment is built on the surface of the catalyst, so that the absorption of impurities such as trace water on the surface of the catalyst is selectively reduced, thewater resistance and acid resistance of the catalyst can be effectively improved, and the stability of the catalyst is greatly improved on the premise of not influencing the reaction activity of thecatalyst.

Owner:河南能源集团研究总院有限公司

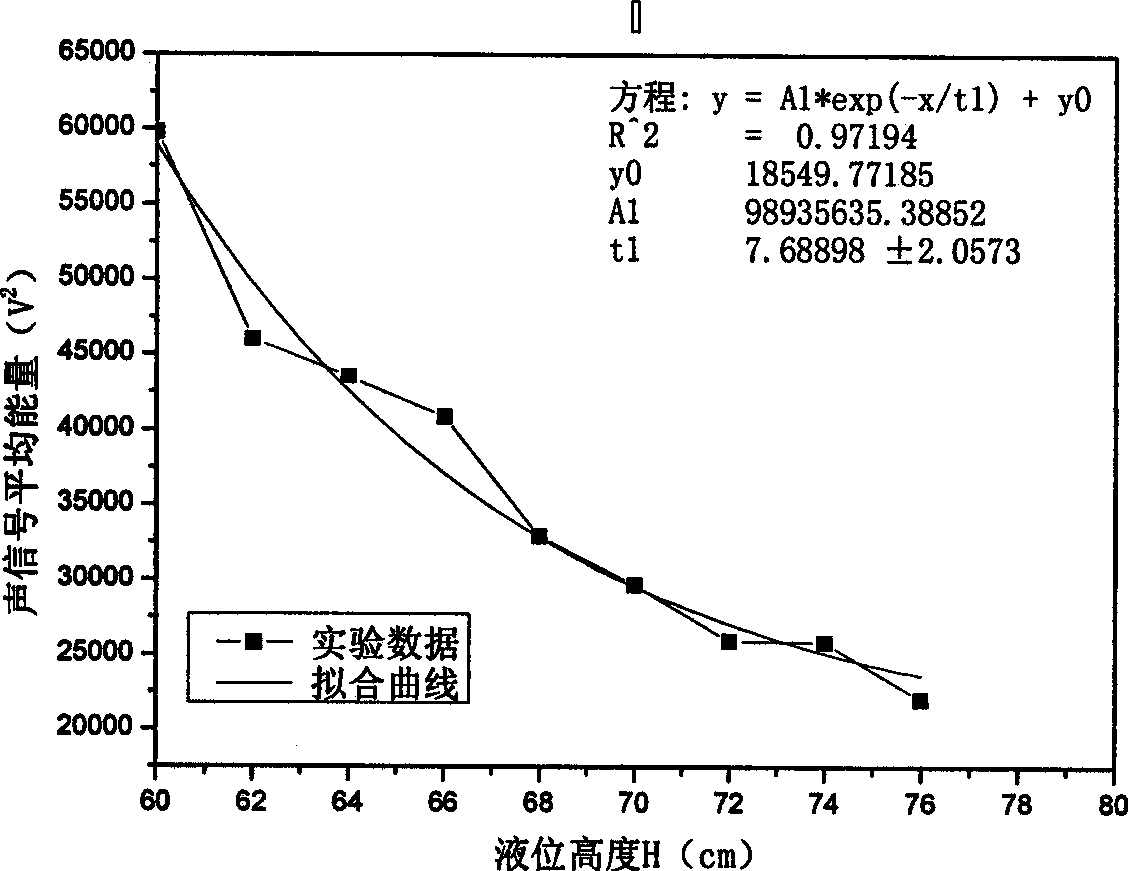

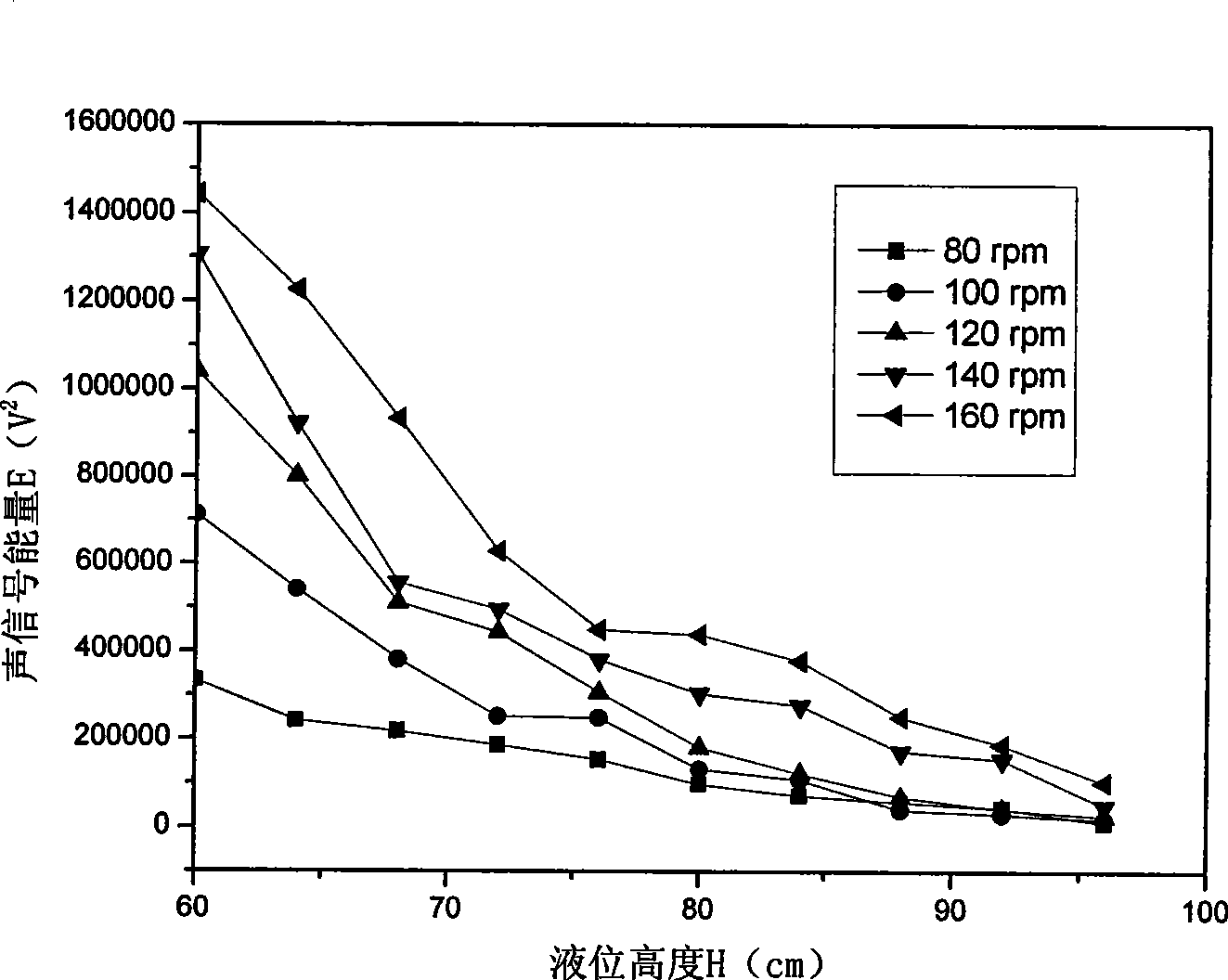

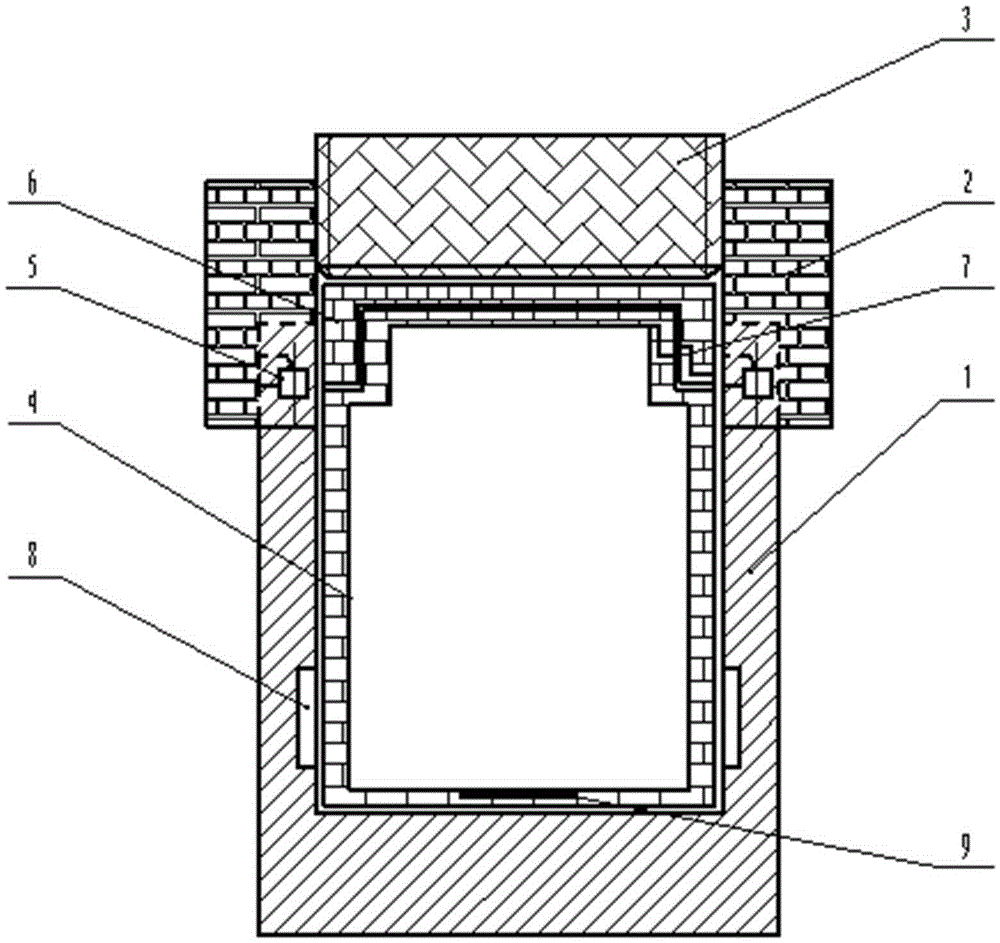

Method for detecting liquid height in stirred tank reactor

InactiveCN101532865AEasy to useDoes not affect movementMachines/enginesLevel indicatorsLiquid heightAcoustic emission

The invention discloses a method for detecting the liquid height in a stirred tank reactor, including the following steps: (1)arranging an acoustic emission signal received device at the outer wall of the reactor; (2)receiving the acoustic emission signal in the stirred tank reactor; (3)selecting the average energy E of the acoustic emission signal at the wall of the stirred tank reactor as the characteristic variables; (4) judging the liquid height in the stirred tank reactor by the characteristic energy E of the acoustic emission signal stirred tank al at the wall of the stirred tank reactor according to the forecast model or standard curve of the predetermined characteristic variables E and the liquid height in the reactor. The acoustic emission signal received device for the method is non-inserted, and has convenient installation, safety and environment protection, sensitive response, accurate measure, wide application range and the like.

Owner:ZHEJIANG UNIV

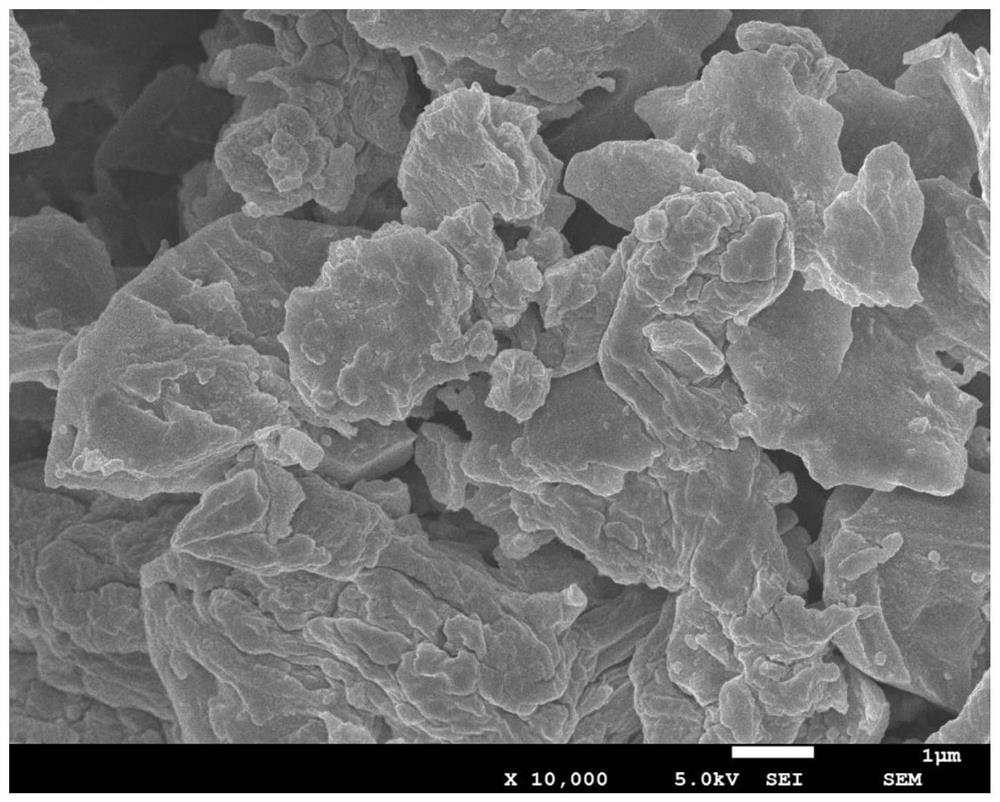

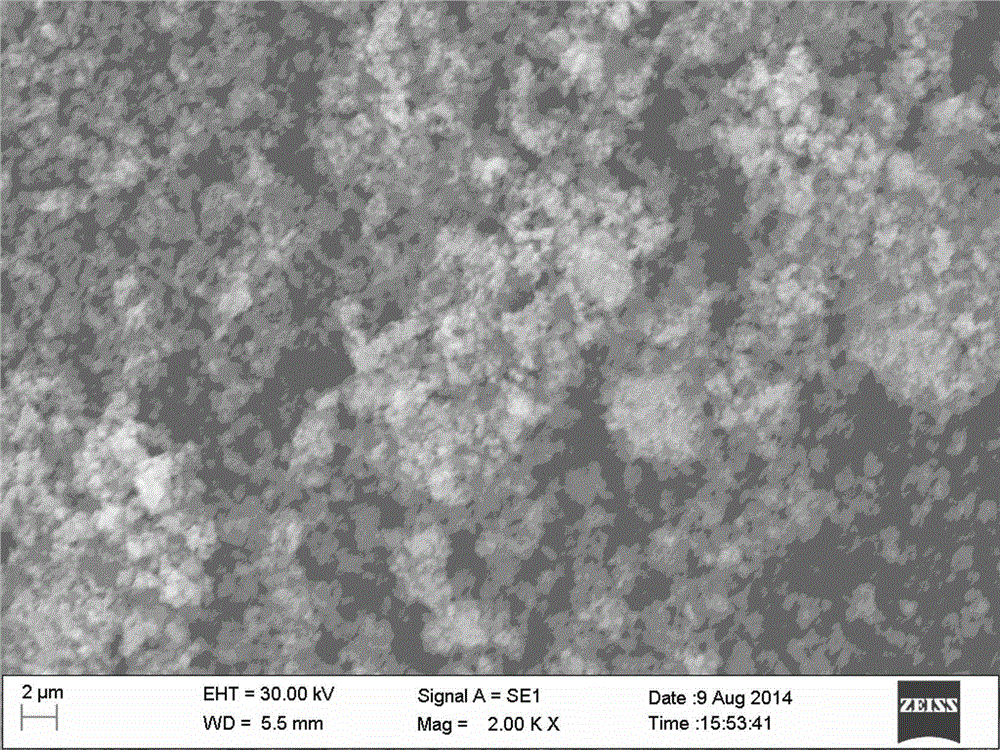

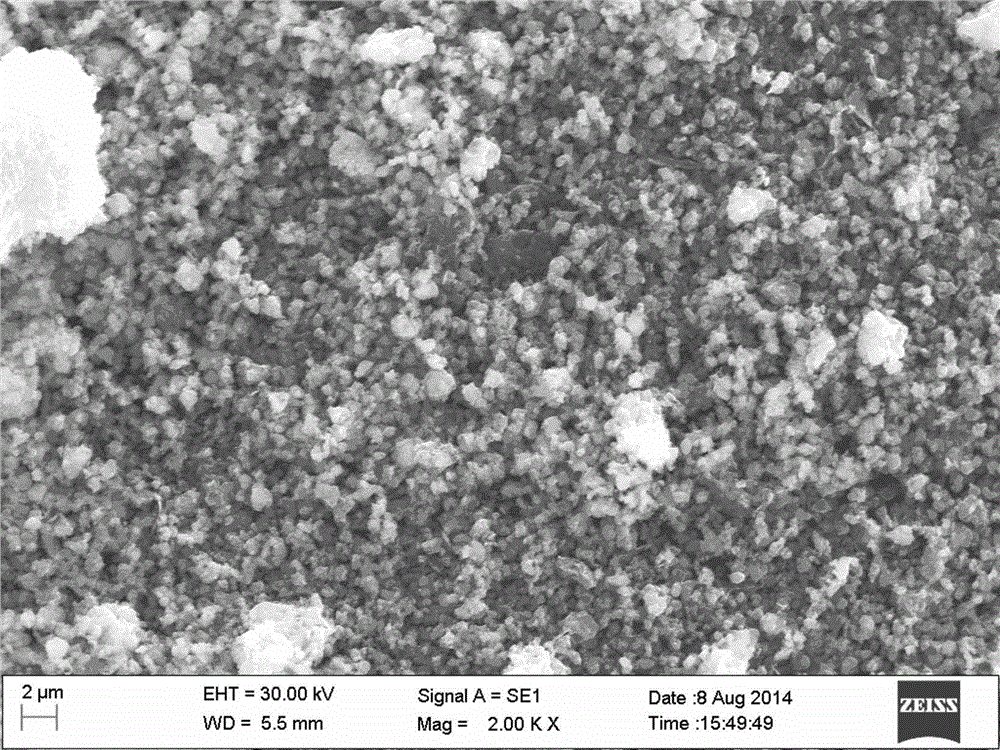

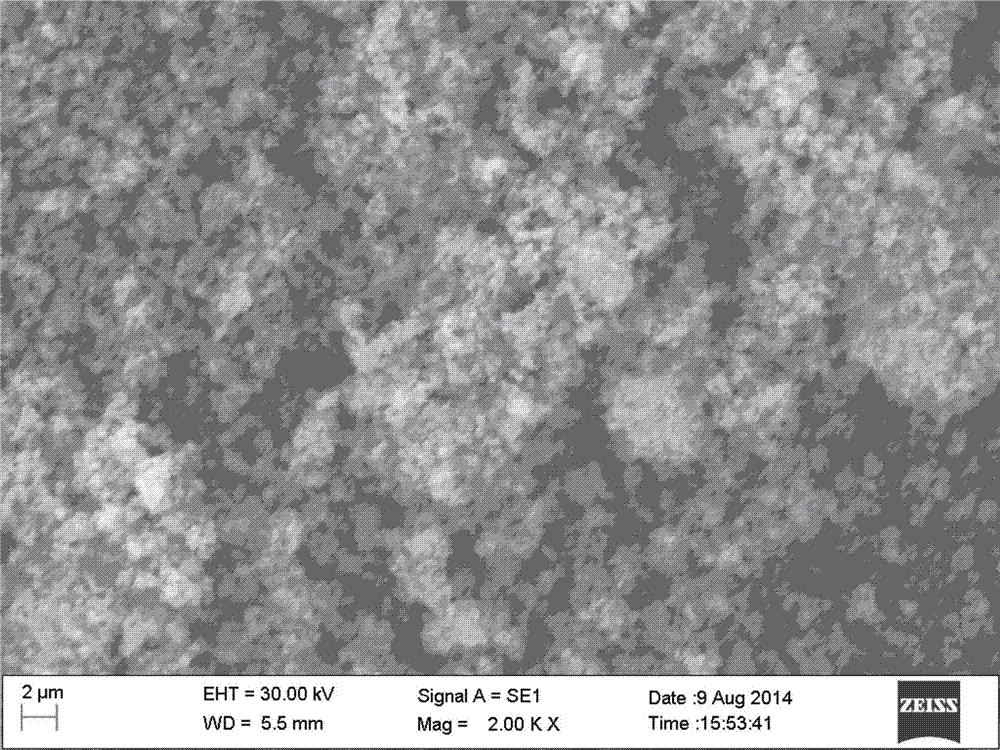

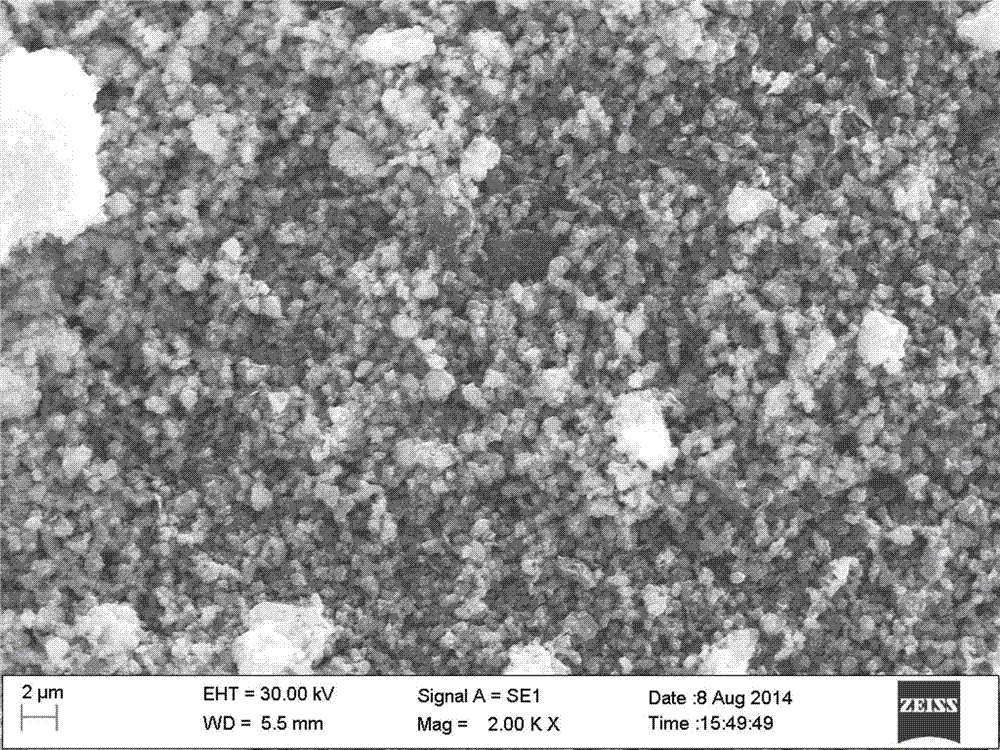

Pressure-controlling deaggregating synthetic method for lithium iron phosphate positive electrode material

ActiveCN105322167AGood directionGood dispersionPhosphatesCell electrodesElectro conductivityCell material

The invention aims to provide a pressure-controlling deaggregating synthetic method for a lithium iron phosphate positive electrode material. The method is suitable for the lithium iron phosphate positive electrode material with certain strength, with a coating layer on the surface of the material, and with small primary grain diameters. The pressure-controlling deaggregating synthetic method performs the reaction, uniform mixing and coating of the materials in gradient through an ultrasonic microwave reaction kettle; and a uniform reaction and a controllable process of the approximate nanoscale raw materials are finally realized. The prepared battery material is relatively high in particle uniformity and consistency; meanwhile, the powder is small in particles; and therefore, the lithium iron phosphate material is higher in the conductivity and the ion diffusion rate, and the electroelectroless performance of the material is greatly improved.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

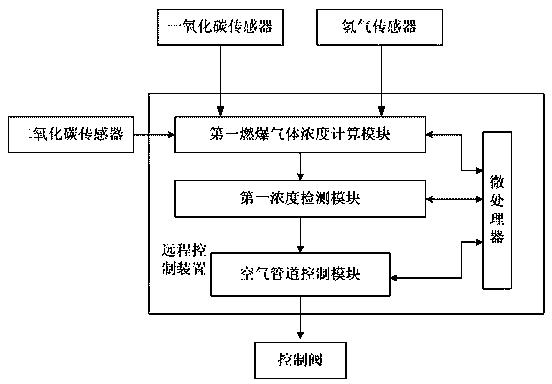

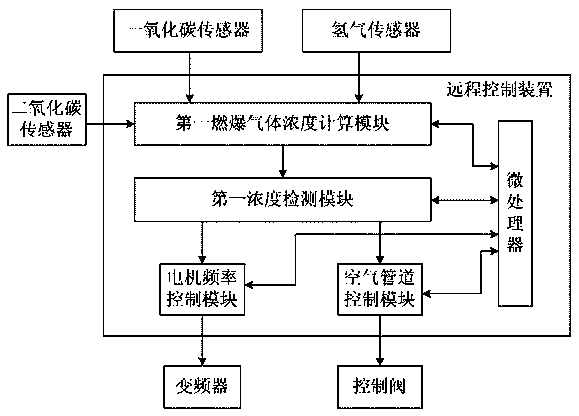

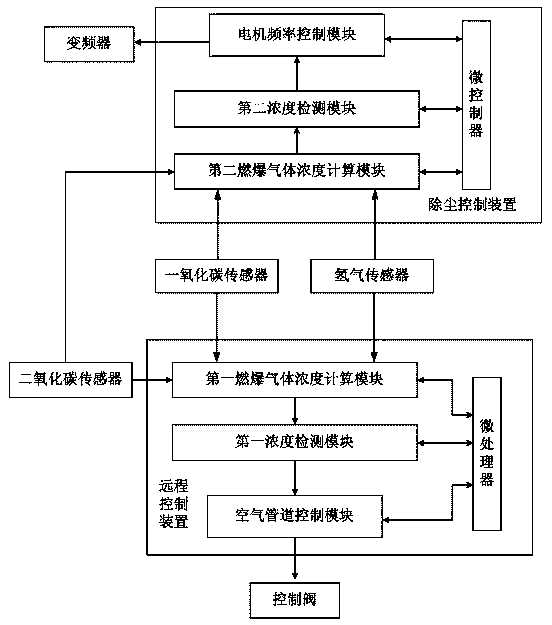

Combustion control method for copper refining and control system

The invention discloses a combustion control method for copper refining and a control system. The method comprises the steps of guiding pure oxygen for combusting natural gas in the whole refining process; in the reduction process, when the sum of the concentration of hydrogen gas, the concentration of carbon dioxide and the concentration of carbon monoxide is equal to or higher than the lower explosion limit, opening an air pipeline for guiding air for combusting the natural gas, and when the sum of the concentration of the hydrogen gas, the concentration of the carbon dioxide and the concentration of the carbon monoxide is lower than the lower explosion limit, closing the air pipeline and guiding the pure oxygen for combusting the natural gas. The control system comprises a combustion gun, a hydrogen gas sensor, a carbon monoxide sensor, a carbon dioxide sensor and a remote control device controlling the combustion mode. According to the invention, in the reduction process of copper refining, the air is guided for combusting the natural gas timely, protection to inert gas is improved, the temperature of waste gas can be lowered, the waste gas entering an underground flue is prevented from exploding, control is convenient, and the automation degree is high.

Owner:四川博鑫铜业有限公司

Catalyst for preparing propylene from butylene and preparation method thereof

InactiveCN106732765AGood choiceHigh yieldMolecular sieve catalystsBulk chemical productionMolecular sieveOrganic chemistry

The invention provides a catalyst for preparing propylene from butylene and a preparation method thereof. The preparation method comprises the following steps: mixing a CHA / AEI eutectic molecular sieve, a carrier raw material and sesbania cannabina powder, so that mixed powder is obtained; adding an inorganic acid solution into the mixed powder, and mixing; and mixing, kneading, carrying out extrusion moulding, drying at the temperature of 90-120 DEG C, and roasting for 2 hours at the temperature of 500-600 DEG C, so that the catalyst for preparing propylene from butylene is obtained. The catalyst for preparing propylene from butylenes, prepared by adopting the preparation method, can catalyze reaction for preparing propylene from butylene, and the propylene selectivity and yield are high.

Owner:PETROCHINA CO LTD +1

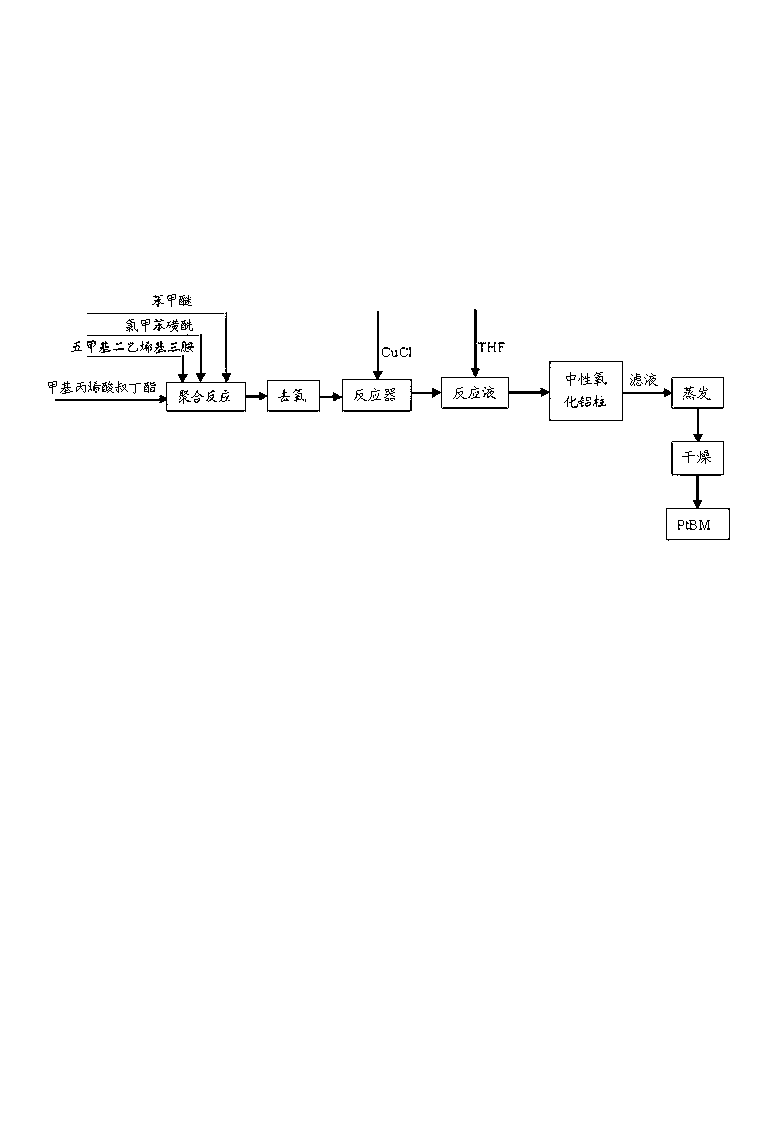

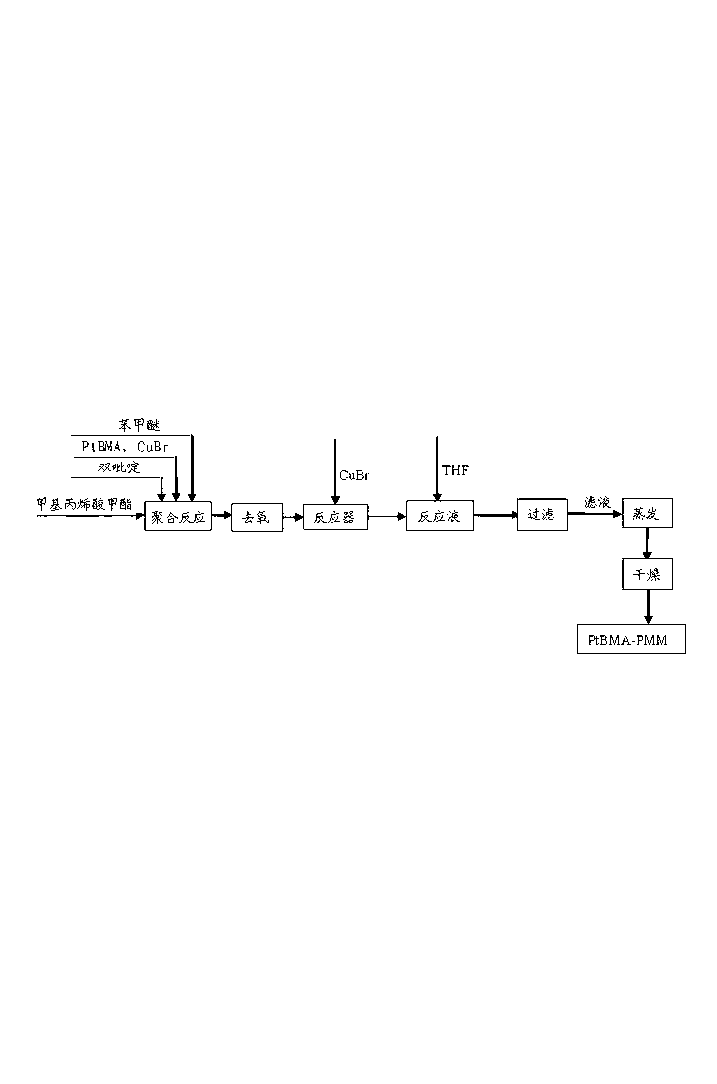

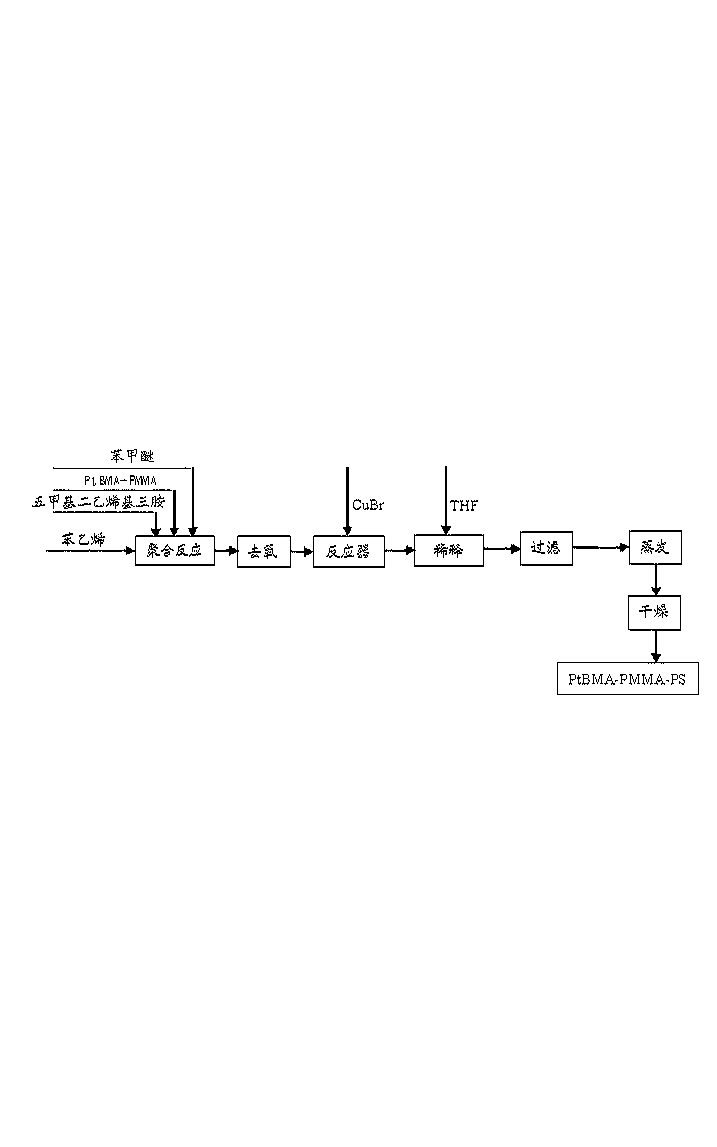

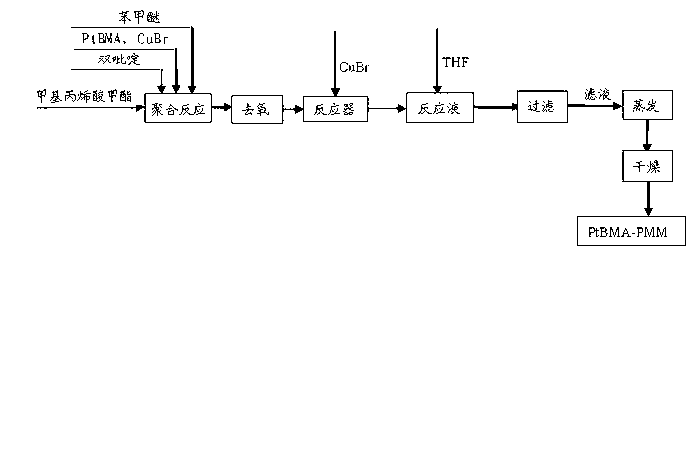

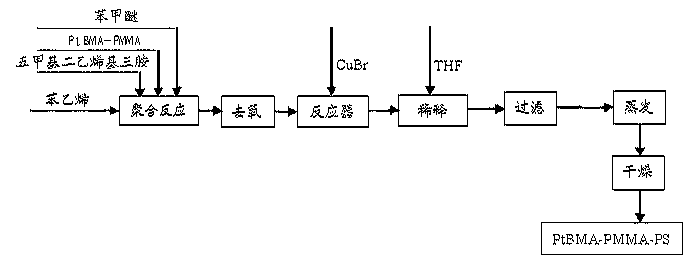

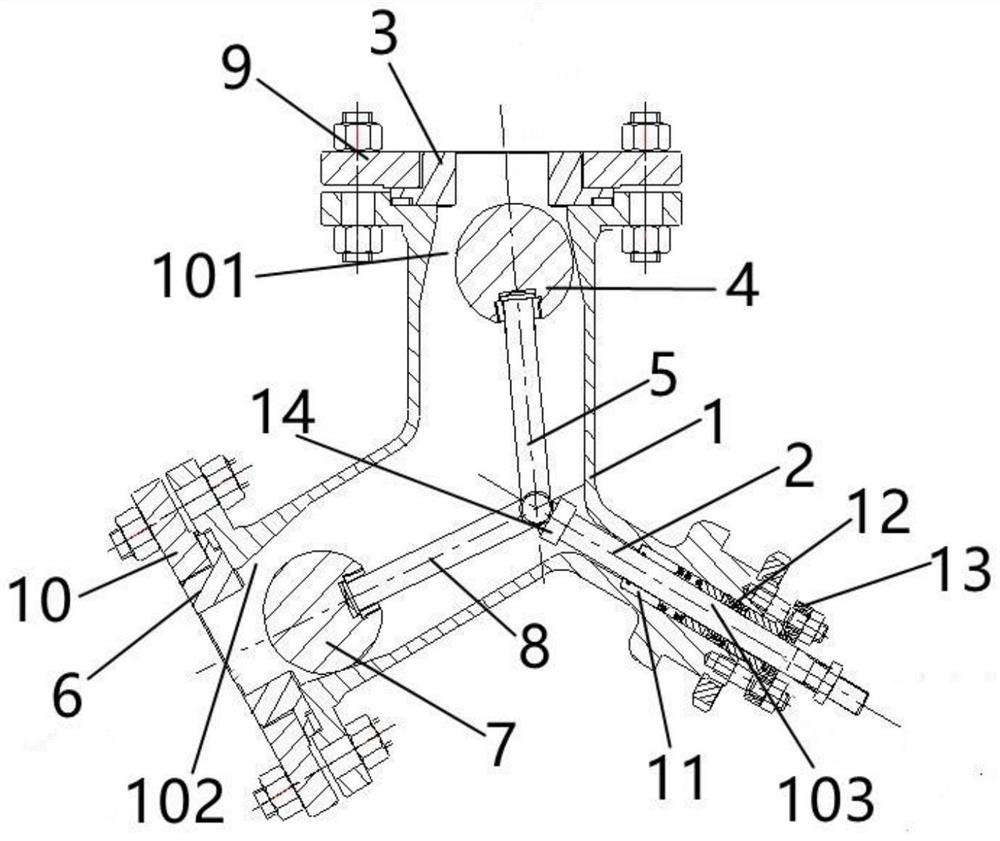

Preparation method of triblock polymers with suspension nanometer zero-valent irons

InactiveCN102702452AHigh reactivityGood suspensionOther chemical processesPolymethyl methacrylateAtom-transfer radical-polymerization

The invention discloses a preparation method of triblock polymers with suspension nanometer zero-valent irons. The preparation method comprises the steps of utilizing an atom transfer radical polymerization(ATRP) method to synthetize triblock polymers of poly(t-butyl methacrylate), polymethyl methacrylate and polrvinyl benzene, hydrolyzing the poly(t-butyl methacrylate) to prepare polymethacrylicacid using trifluoroacetic acid, and finally sulfonating the polrvinyl benzene to prepare polystyrolsulfon acid using sulfuric acid acetyl. The method improves the original three-step reaction into aone-step reaction in the synthetic process of the polymers, thereby reducing the operation steps, reducing the consumption of raw materials, improving reaction stability and improving the productivity of aimed compounds; and adding trifluoroacetic acid in a hydrolysis process, so that the hydrolysis process is thorough and the reactivity and the suspension property of products are improved. The experiment results show that the triblock polymers comprise functional groups in required target products, the molecular weight can reach about 100 thousand, and the stabilization time of suspension effects of nanometer zero-valent irons can reach more than two months.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

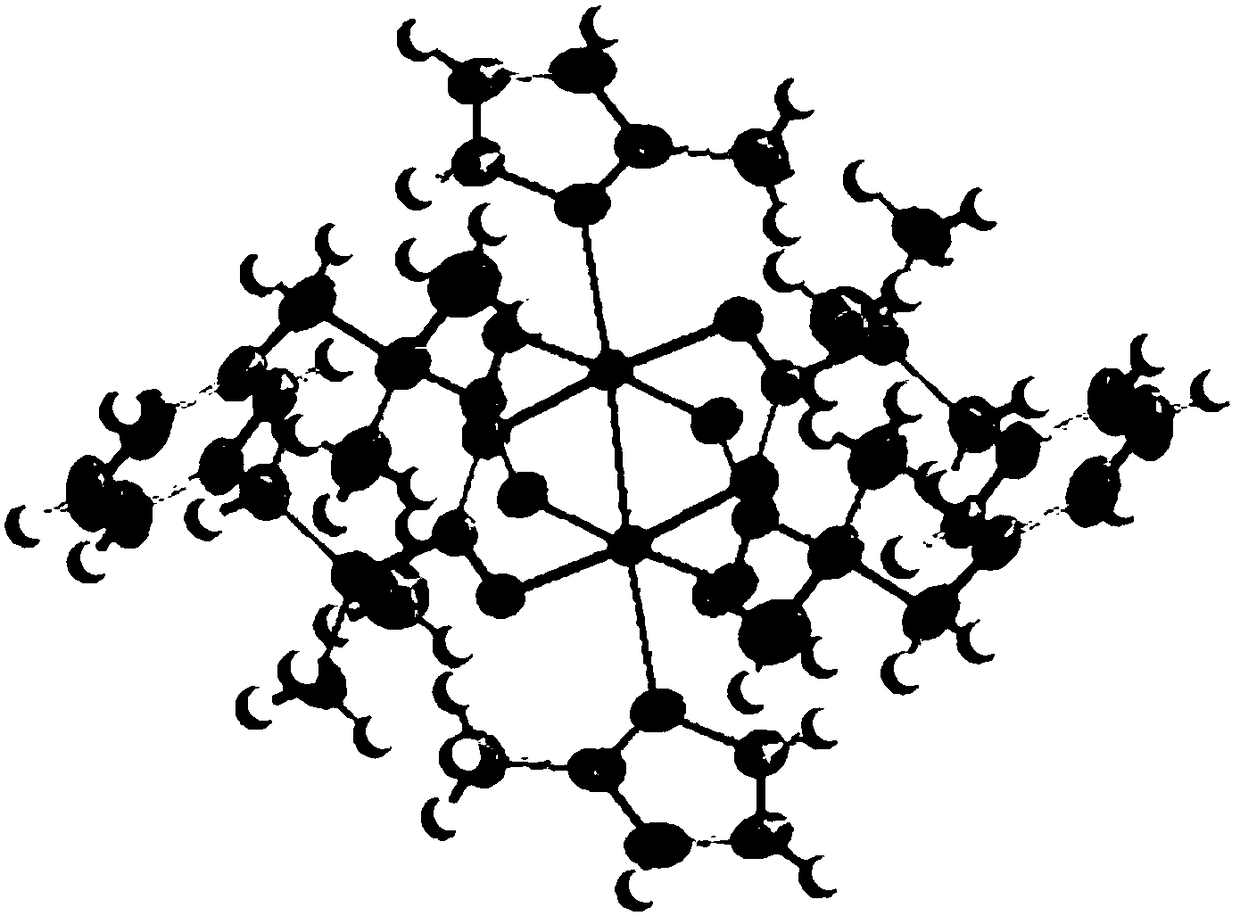

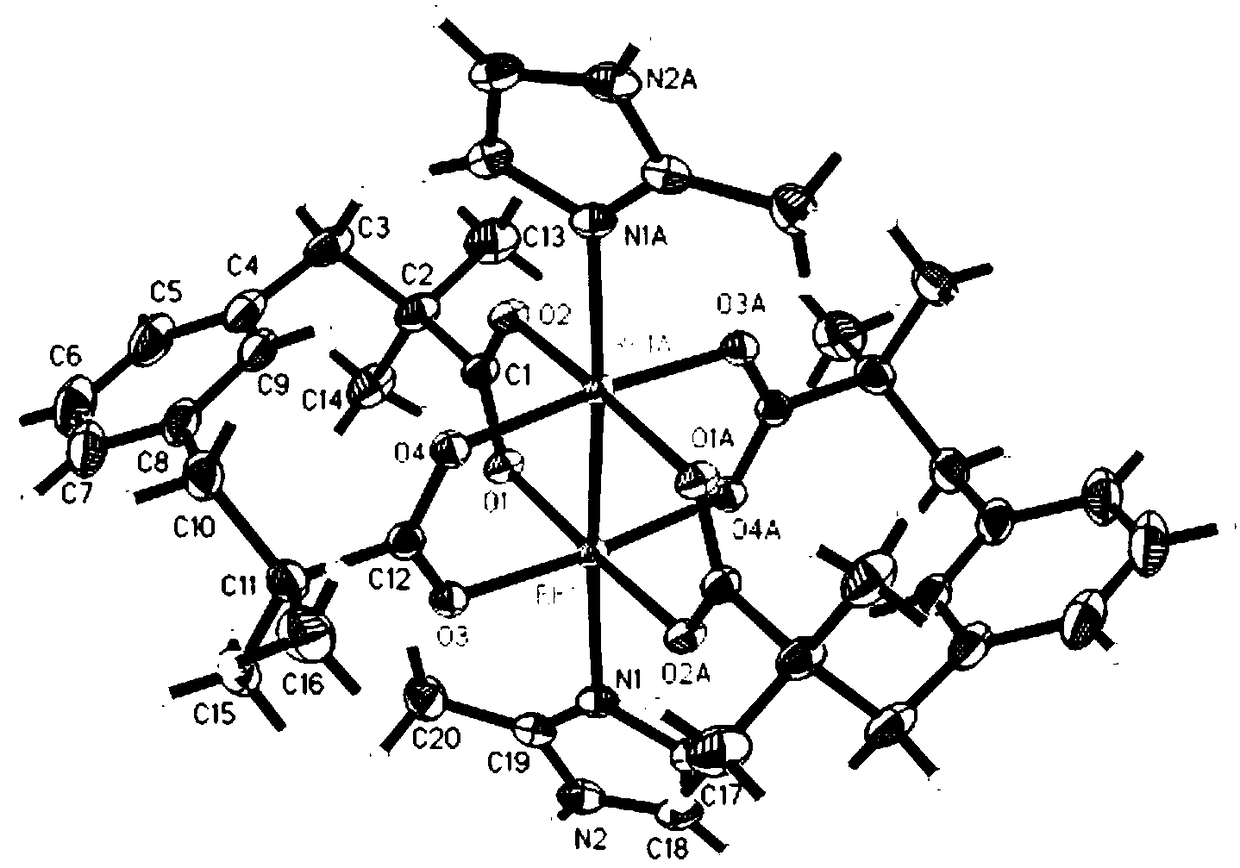

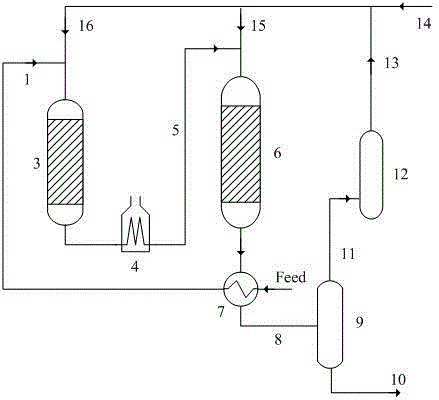

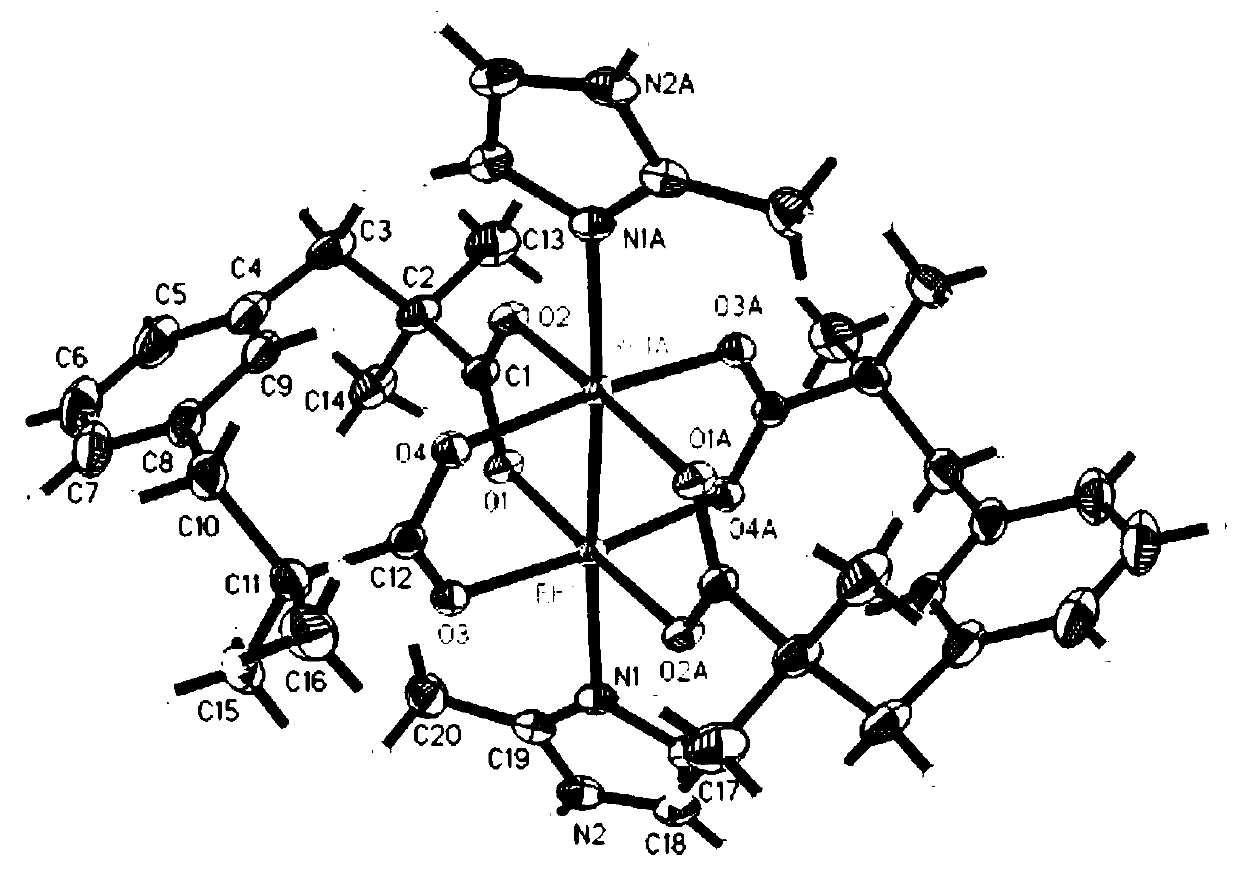

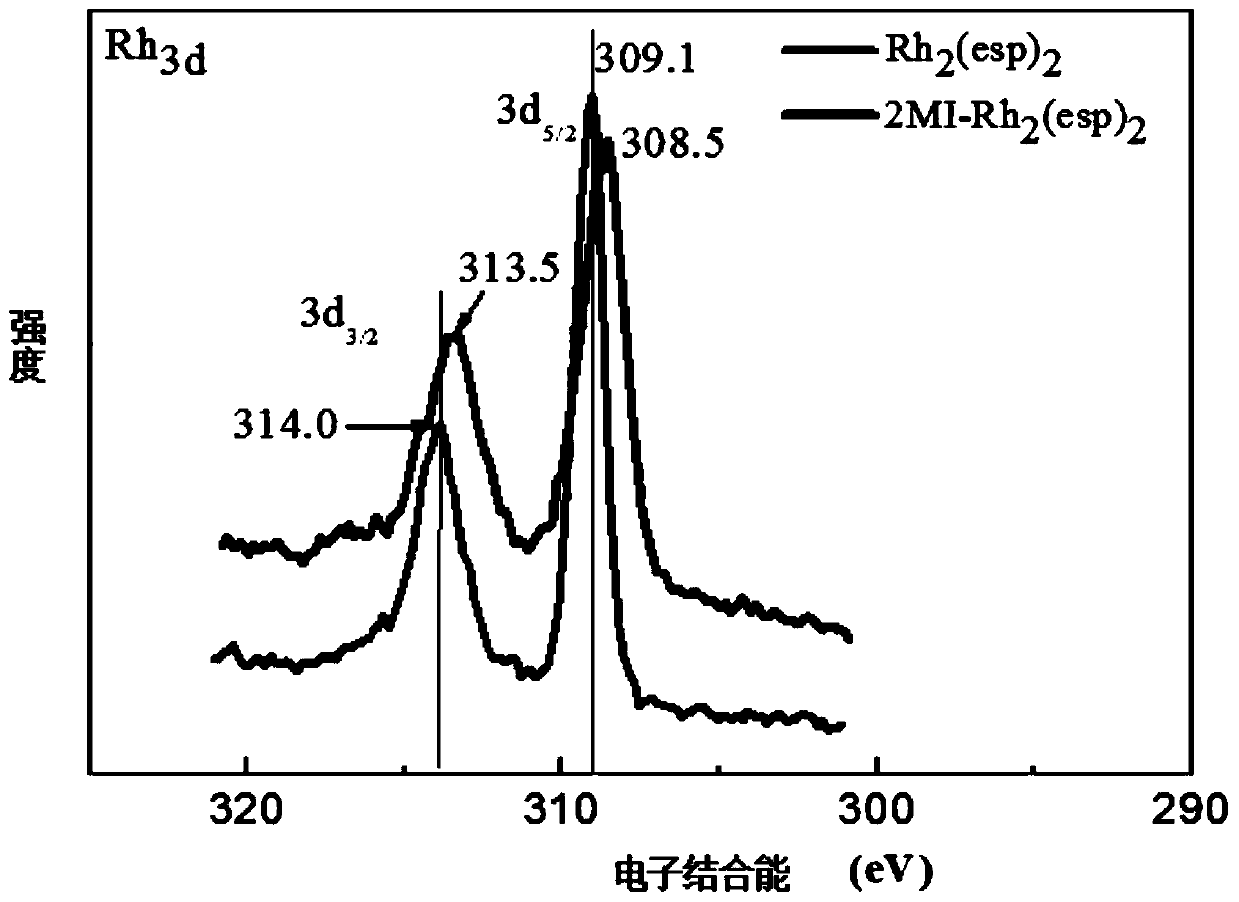

Immobilized binuclear rhodium metal complex catalyst and preparation method and application thereof

InactiveCN108295902AThe method of synthesizing ZIF-8 is simple and quickLarge specific surface areaCatalyst carriersOrganic chemistrySelf assembleRoom temperature

The invention discloses a preparation method and application of an immobilized binuclear rhodium metal complex catalyst. The immobilized binuclear rhodium metal complex catalyst is prepared from a metallic organic framework ZIF-8 which is formed by Zn<2+> and 2-methylimidazole and serves as a carrier as well as Rh[2](esp)[2] which is axially modified by the 2-methylimidazole and is distributed onthe carrier ZIF-8. The preparation method comprises the following steps: enabling a mixed system containing the Rh[2](esp)[2], the 2-methylimidazole and a solvent to be subjected to reaction under theroom temperature condition to form the Rh[2](esp)[2] axially modified by the 2-methylimidazole, and then, adding the Zn<2+> into the mixed system to be subjected to reaction at room temperature to obtain the immobilized binuclear rhodium metal complex catalyst. The 2-methylimidazole is adopted as an organic ligand for synthesizing the ZIF-8, is self-assembled with zinc ions to form the metallic framework of the ZIF-8, and is in axial coordination with the Rh[2](esp)[2]; and after coordination, not only the reaction activity of the Rh[2](esp)[2] is not affected, but the reaction selectively for catalytic synthesis of N-H propane compounds is improved, and the universality is realized.

Owner:SHANGHAI NORMAL UNIVERSITY

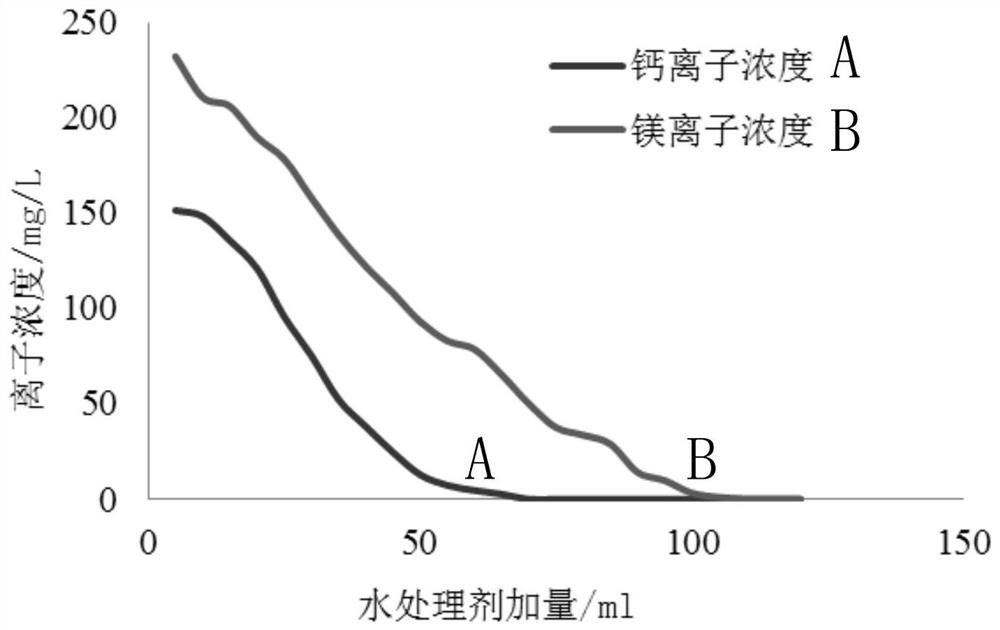

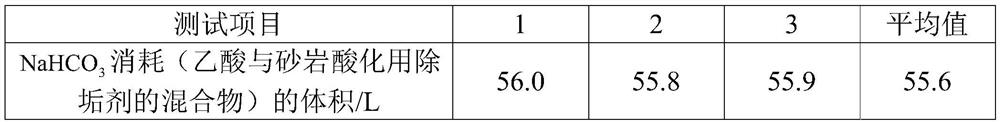

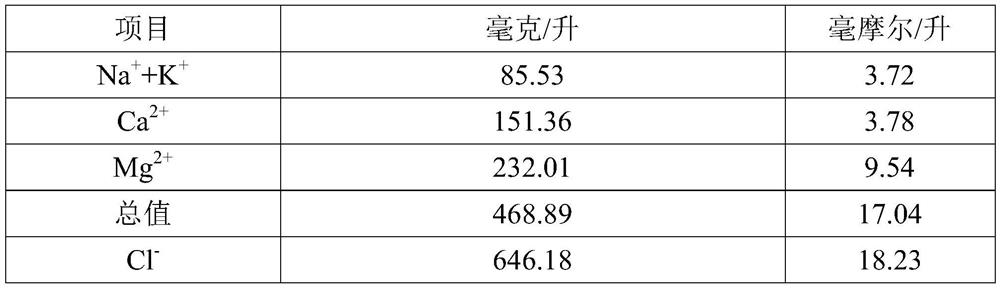

Descaling agent for sandstone acidification and preparation method thereof

InactiveCN112342002AEfficient removalDoes not affect reactivityDrilling compositionChemical structureDescaling agent

The invention discloses a descaling agent for sandstone acidification and a preparation method of the descaling agent. The descaling agent is a polymer formed by copolymerizing a monomer A and a monomer B in a molar ratio of 1: 1, wherein the chemical structural formula of the monomer A is shown in the description, the chemical structural formula of the monomer B is shown in the description, the weight-average molecular weight of the polymer is 1000-1300g / mol, and the molecular weight distribution coefficient of the polymer is 1.1-1.2. The descaling agent for sandstone acidification is a sulfonic group-containing polymer, can be directly added into a prepared acidification working solution for use, and can effectively remove calcium and magnesium ions in the acidification process without influencing the reaction or interaction among the acidification working solution, acid-erodible minerals and acid-soluble substances. Besides, the preparation method of the anti-scaling agent is simple, the anti-scaling agent is prepared by adding an initiator step by step under a low-temperature condition to initiate copolymerization, the preparation cost is low, and the anti-scaling agent has a good market prospect.

Owner:CNPC BOHAI DRILLING ENG +1

Ultraviolet cured wood paint and preparation method thereof

Owner:HUIZHOU CHANGRUNFA PAINT

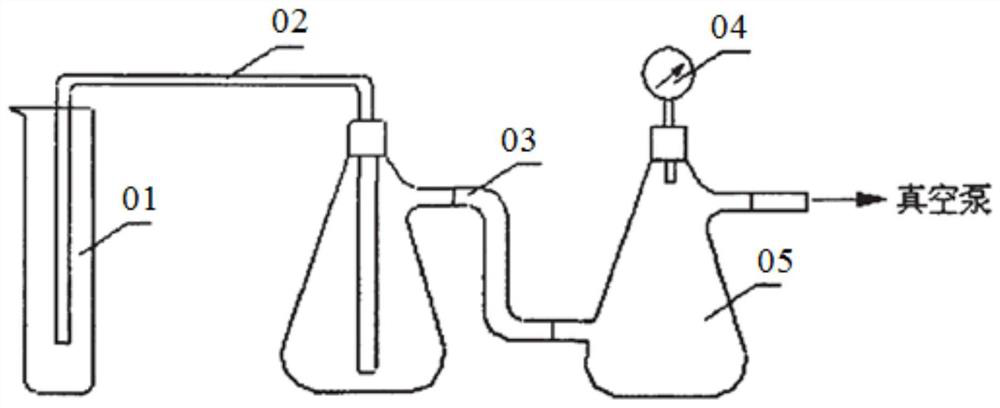

Preservation method of loop-mediated isothermal amplification reaction reagent mixture

InactiveCN101591703BActive and stableLow costMicrobiological testing/measurementRoom temperatureQuarantine

The invention discloses a preservation method of a loop-mediated isothermal amplification reaction reagent mixture. The preservation method realizes long-term preservation of the loop-mediated isothermal amplification reaction reagent mixture at normal temperature or room temperature by adopting the following steps: adding a specific drying protective agent in the loop-mediated isothermal amplification reaction reagent mixture; and then carrying out vacuum drying or quick air drying of the mixture at a temperature lower than 80 DEG C. The preservation method has the advantages of low cost, simple operation and stable persistent activity of dried loop-mediated isothermal amplification reaction reagent mixture at the normal temperature, and the like. Therefore, the preservation method can effectively promote the application of loop-mediated isothermal amplification technology in the fields of medical treatment, inspection and quarantine, and the like, as well as the popularization of loop-mediated isothermal amplification kits.

Owner:YELLOW SEA FISHERIES RES INST CHINESE ACAD OF FISHERIES SCI

Single-stage series diesel oil hydrofining method

ActiveCN103059978AReasonable temperature distributionFully playTreatment with hydrotreatment processesPtru catalystPhysical chemistry

The invention discloses a hydrofining method. The method consists of: mixing diesel oil with hydrogen, introducing the mixed gas into a first reactor, leaving the mixed gas and a hydrofining catalyst to undergo a contact reaction under a low temperature and a high space velocity, with the catalyst taking metal Mo and Co as active components, and having an average pore size of 20-40 angstroms and a total acid amount of 0.2-1.0mmol / g; and leaving the effluent of a first reactor to enter a second reactor, letting the effluent and a hydrofining catalyst to undergo a contact reaction under a high temperature and a low space velocity, with the catalyst taking metal W and / or Mo and Ni as active components, and having an average pore size of 40-70 angstroms and a total acid amount of 1.0-3.0mmol / g. The method employs appropriate catalysts according to different reaction types, and is in favor of lowering the catalyst cost without influencing reaction activity. The method provided in the invention can be used for producing diesel oil with a sulfur content of less than 50 micrograms / g.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solid-supported binuclear rhodium metal complex catalyst and its preparation method and application

InactiveCN108295902BFixed capacity can be adjustedThe method of synthesizing ZIF-8 is simple and quickCatalyst carriersOrganic chemistryPtru catalystZinc ion

Owner:SHANGHAI NORMAL UNIVERSITY

Preparation method of triblock polymers with suspension nanometer zero-valent irons

InactiveCN102702452BHigh reactivityGood suspensionOther chemical processesPolystyreneAtom-transfer radical-polymerization

The invention discloses a preparation method of triblock polymers with suspension nanometer zero-valent irons. The preparation method comprises the steps of utilizing an atom transfer radical polymerization(ATRP) method to synthetize triblock polymers of poly(t-butyl methacrylate), polymethyl methacrylate and polrvinyl benzene, hydrolyzing the poly(t-butyl methacrylate) to prepare polymethacrylic acid using trifluoroacetic acid, and finally sulfonating the polrvinyl benzene to prepare polystyrolsulfon acid using sulfuric acid acetyl. The method improves the original three-step reaction into a one-step reaction in the synthetic process of the polymers, thereby reducing the operation steps, reducing the consumption of raw materials, improving reaction stability and improving the productivity of aimed compounds; and adding trifluoroacetic acid in a hydrolysis process, so that the hydrolysis process is thorough and the reactivity and the suspension property of products are improved. The experiment results show that the triblock polymers comprise functional groups in required target products, the molecular weight can reach about 100 thousand, and the stabilization time of suspension effects of nanometer zero-valent irons can reach more than two months.

Owner:INST OF HYDROGEOLOGY & ENVIRONMENTAL GEOLOGY CHINESE ACAD OF GEOLOGICAL SCI

A kind of modification method of solid epoxy resin

The invention discloses a modifying method of solid epoxy resin, and especially relates to a modifying method for reducing the viscosity of the solid epoxy resin. The method comprises the following steps: carrying out mixing melting on base resin and bisphenol A under an oxygen isolation condition to obtain a molten material, adding a catalyst and a compound additive containing a phenolic hydroxyl group, and reacting to obtain modified solid epoxy resin. The modifying method reduces the viscosity of the epoxy resin, and widens the viscosity range of the epoxy resin under a fixed epoxy equivalent condition in order to enlarge the application range of the epoxy resin.

Owner:JIANGSU KUMHO YANGNONG CHEM CO LTD +1

Synthesis method of tetrahydrofuran-3-formaldehyde

InactiveCN112375050ALow costHigh yieldOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystFormylation reaction

The invention discloses a synthesis method of tetrahydrofuran-3-formaldehyde, which comprises the steps of S1, mixing 2,5-dihydrofuran, a rhodium-carbon catalyst, a phosphine ligand cocatalyst and a polymerization inhibitor, and carrying out hydroformylation reaction under the action of water gas; and S2, after the reaction is completed, taking out the reaction liquid, and carrying out reduced pressure distillation to obtain tetrahydrofuran-3-formaldehyde. By adopting the rhodium-carbon catalyst, the cost can be reduced, the polymerization inhibitor is introduced, the side reaction of dimerization of 2,5-dihydrofuran can be prevented, the reaction selectivity is improved, the solvent-free reaction is adopted in the whole reaction system, the post-treatment process is further simplified while the production capacity is improved, the catalyst is favorably recycled and reused at the same time, the obtained product has high purity and high yield, and the method is very suitable for industrial large-scale production.

Owner:DALIAN JOIN KING FINE CHEM CO LTD

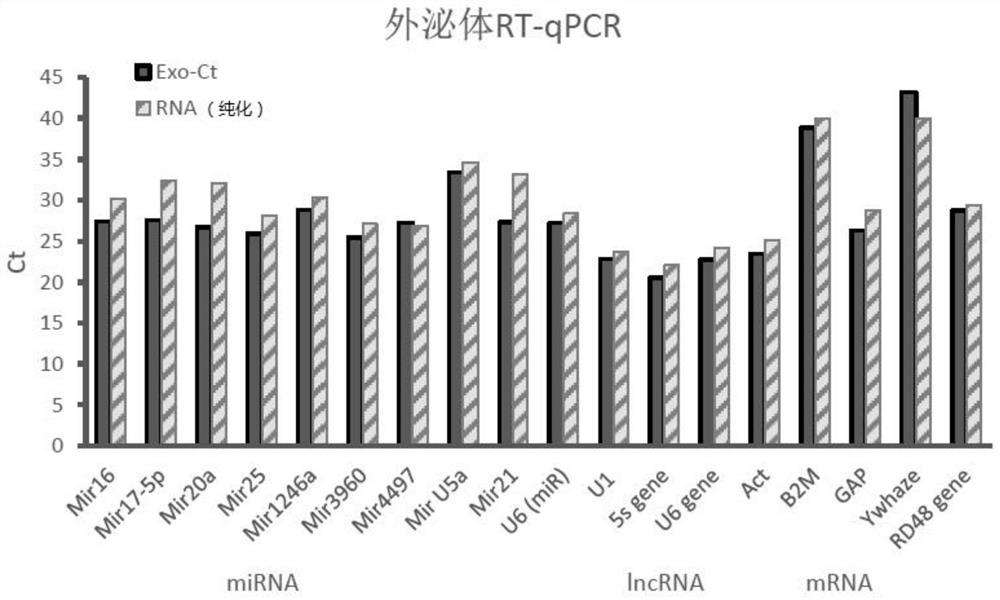

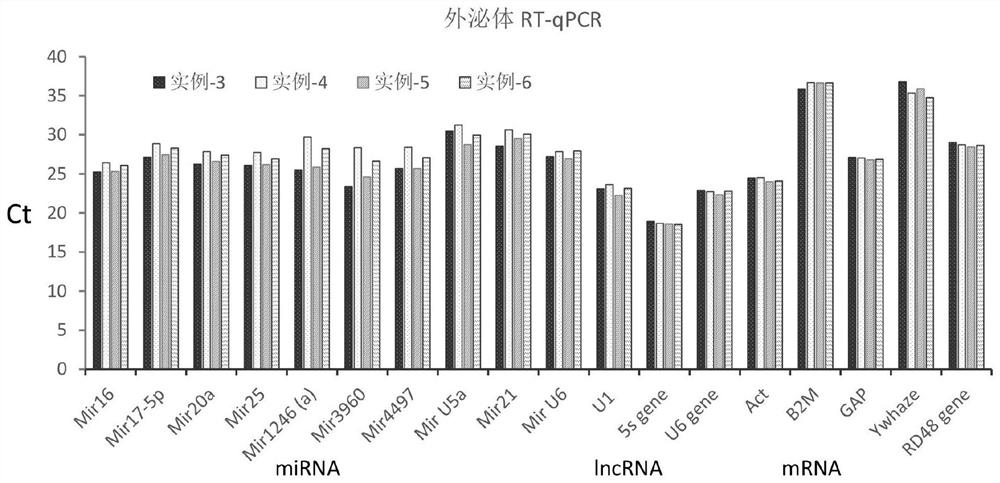

Method for detecting nucleic acid molecules in exosomes

PendingCN113151398AThe detection method is simpleGood Ct valueMicrobiological testing/measurementExosomeTranscriptional response

The invention relates to a method for simply, conveniently and quickly detecting nucleic acid molecules in exosomes. The method comprises the following steps: cracking the exosomes in a sample to release the nucleic acid molecules of the exosomes; and performing reverse transcription reaction: after the exosomes are cracked, the nucleic acid molecules are not extracted, or after the nucleic acid molecules are extracted, reverse transcription reaction of all RNA is carried out, namely RT-For-All, so that all RNA in the exosomes is simultaneously subjected to reverse transcription in the same reaction; and a reverse transcription buffer comprising a universal adapter (e.g., miRNA Adapter) and a random primer is used in the reverse transcription reaction. The invention also provides a kit for detecting the nucleic acid molecules in the exosomes. Contained components are released by directly dissolving the exosomes, RNA and DNA do not need to be extracted, and reverse transcription of all RNA is directly carried out in the same reverse transcription reaction. Various RNA and DNA can be detected from trace exosomes.

Owner:GUANGZHOU FULENGEN

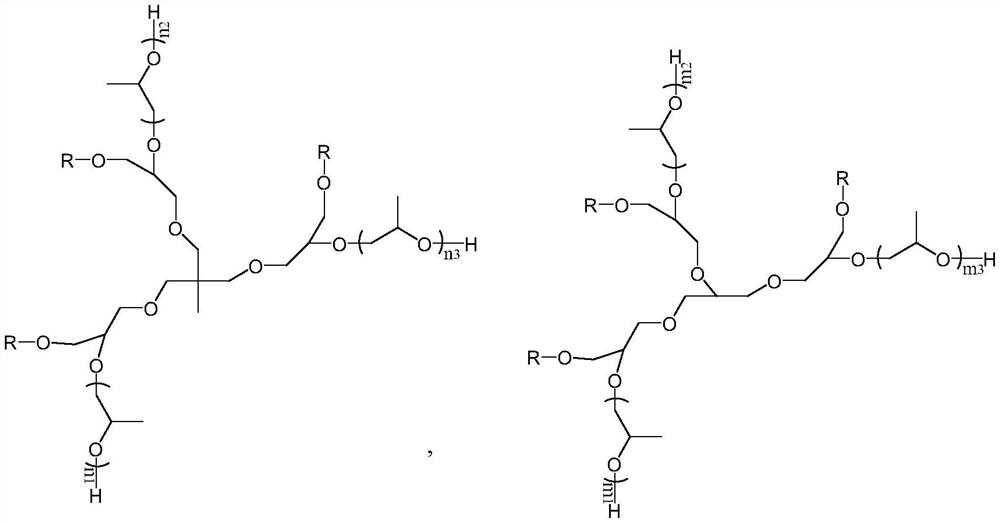

Citric acid triester modified polyether polyol and application thereof in polyurethane waterproof coating

InactiveCN113512189AEasily biodegradableLow viscosityPolyurea/polyurethane coatingsPolymer sciencePolyol

The invention relates to citric acid triester modified polyether polyol and application thereof in polyurethane waterproof coating, and belongs to the technical field of high polymer materials. According to the citrate modified polyether polyol, the citric acid triester is introduced into a polyether polyol molecular side chain through a chemical bond, and the preparation method of the citrate modified polyether polyol comprises the following steps: firstly, citric acid and alcohol react to prepare the citric acid triester, and then dianhydride acylation is performed to prepare anhydride acylated citric acid triester; and then reactions with triglycidyl ether and epoxypropane are conducted to prepare the citric acid triester modified polyether polyol. The citric acid triester is located on a molecular side chain of the polyether polyol, the reaction activity of the polyether polyol is not affected, meanwhile, the polyurethane material is endowed with excellent strength and elasticity, and the branched citric acid triester enables the polyether polyol to have low viscosity and have a good wrapping effect on a filler. The citric acid triester modified polyether polyol prepared by the invention has potential and wide application value in the field of polyurethane materials.

Owner:吴胜华

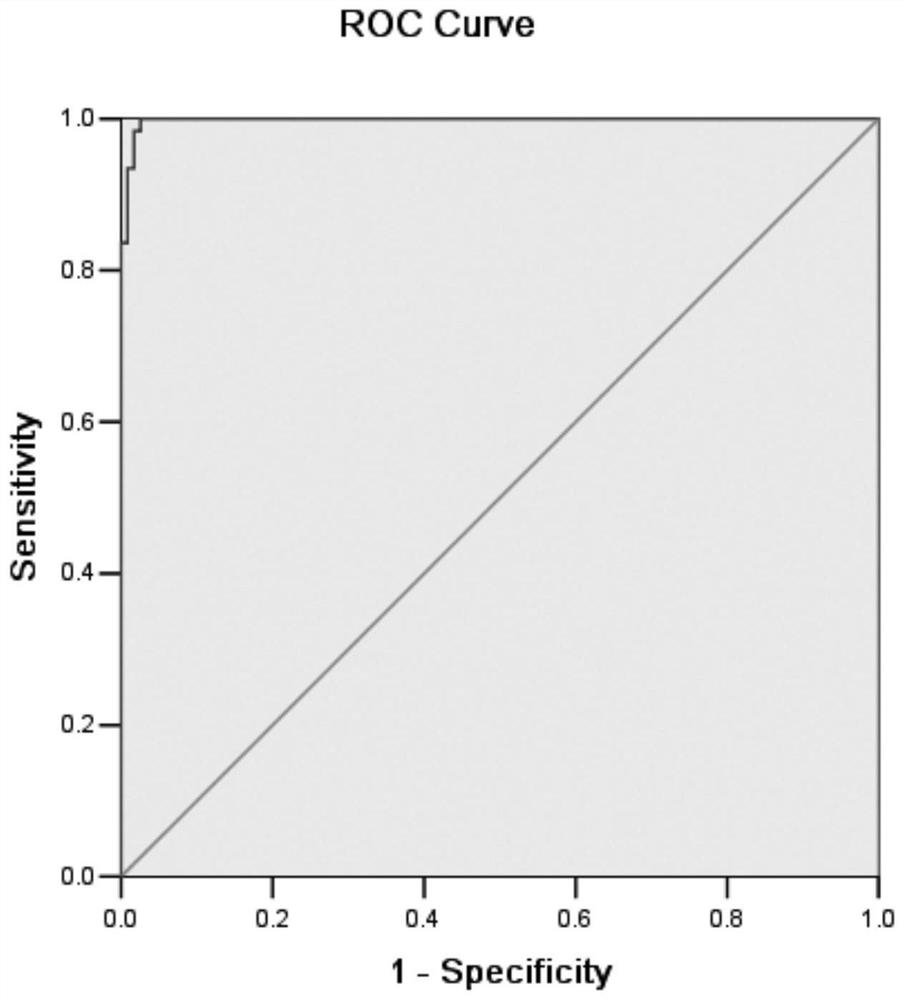

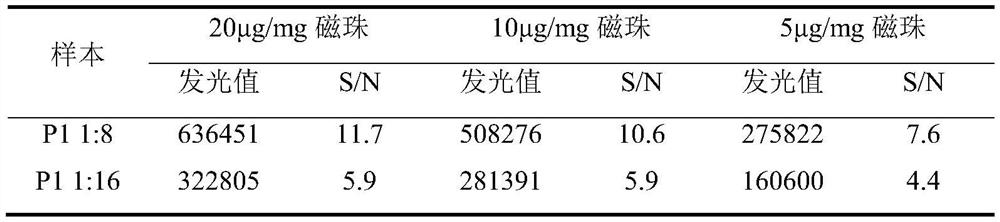

African swine fever virus magnetic particle chemiluminiscence antibody detection kit and application thereof

InactiveCN111796105AQuick checkAccurate detectionBiological testingImmunoassaysClassical swine fever virus CSFVSample dilution

The invention belongs to the technical field of immunoassay analysis, and particularly relates to an African swine fever virus magnetic particle chemiluminescence antibody detection kit and application thereof. The kit uses ASFV P30 recombinant protein as a magnetic particle conjugate, and uses goat anti-pig IgG marked by a chemiluminescence marker as a detection antibody. The kit is specificallycomposed of a magnetic particle suspension coupled with ASFV P30 recombinant protein, a reagent R, a calibration product, a quality control product, a sample diluent, a washing solution and a luminescent solution, wherein the reagent R is a diluted chemiluminescent marker labeled goat anti-pig IgG antibody working solution. The kit disclosed by the invention takes a magnetic particle chemiluminescence method as a detection technology, is combined with an alkaline phosphatase labeling technology, has the characteristics of high specificity, good sensitivity, excellent repeatability, strong stability and the like, and can be widely applied to basic ASFV detection.

Owner:LANZHOU INST OF VETERINARY SCI CHINESE ACAD OF AGRI SCI

A ribonucleic acid protecting agent, kit, application and preservation method

ActiveCN106065400BImprove biological activityAvoid damageDNA preparationMicrobiologyPreservation methods

The invention provides an RNA protective agent, a kit containing the protective agent, application and a preservation method of RNA. The protective agent contains a trehalose solution with a concentration of 0.27M-1M. The protective agent provided by the invention can achieve the effects of long preservation time, temperature insensitivity and wide range of use temperature, an extracellular RNA sample treated by the protective agent has no influence to cDNA synthesis, PCR reaction and enzyme activity in sequencing and bank building. The protective agent provided by the invention can efficiently solve the RNA degradation, pollution and other problems encountered during long-term preservation or use of exRNA, and especially has important significance for preservation, repeated use and long-distance transportation of extracellular microRNA.

Owner:上海晟燃生物科技有限公司

A kind of pressure-controlled deagglomeration synthesis method of lithium iron phosphate cathode material

ActiveCN105322167BGood directionGood dispersionPhosphatesCell electrodesMaterials scienceRaw material

The invention aims to provide a pressure-controlling deaggregating synthetic method for a lithium iron phosphate positive electrode material. The method is suitable for the lithium iron phosphate positive electrode material with certain strength, with a coating layer on the surface of the material, and with small primary grain diameters. The pressure-controlling deaggregating synthetic method performs the reaction, uniform mixing and coating of the materials in gradient through an ultrasonic microwave reaction kettle; and a uniform reaction and a controllable process of the approximate nanoscale raw materials are finally realized. The prepared battery material is relatively high in particle uniformity and consistency; meanwhile, the powder is small in particles; and therefore, the lithium iron phosphate material is higher in the conductivity and the ion diffusion rate, and the electroelectroless performance of the material is greatly improved.

Owner:SHANDONG GOLDENCELL ELECTRONICS TECH

Downward-expanding type emptying valve

PendingCN113898742ADoes not affect complete mixingDoes not affect reactivitySpindle sealingsLift valveMedicineEngineering

The invention discloses a downward-expanding type emptying valve which comprises: a valve body including a first valve cavity, a second valve cavity and a third valve cavity, wherein the first valve cavity, the second valve cavity and the third valve cavity are communicated; a guide rod which is located in the third valve cavity, wherein one end of the guide rod extends out of the end of the third valve cavity and is connected with a driving mechanism of the emptying valve; a first valve element assembly which is located in the first valve cavity and hinged to the guide rod; and a second valve element assembly which is located in the second valve cavity and hinged to the guide rod. A double-valve-element assembly is arranged, an upstream material opening and a downstream material opening can be sealed, and therefore, the good material mixing prevention effect is achieved; According to the downward-expanding type emptying valve, the first valve cavity and the second valve cavity are both arranged to be in the horn mouth shape, the surface of the valve element is arranged to be the arc-shaped face, the valve element and the valve rod are connected in a clearance fit mode, and during operation, the valve element can be self-aligned to rapidly and stably close a port of the valve cavity.

Owner:ZHEJIANG SUPCON FLUID TECH

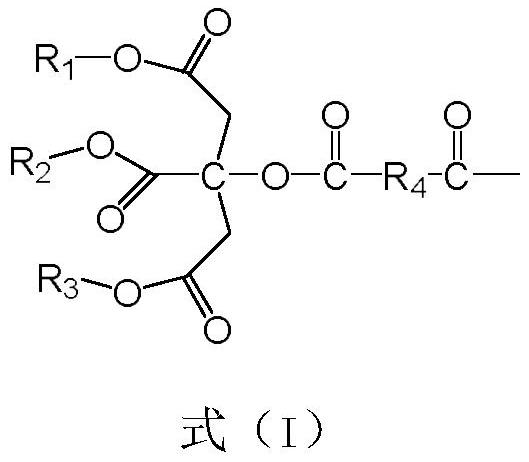

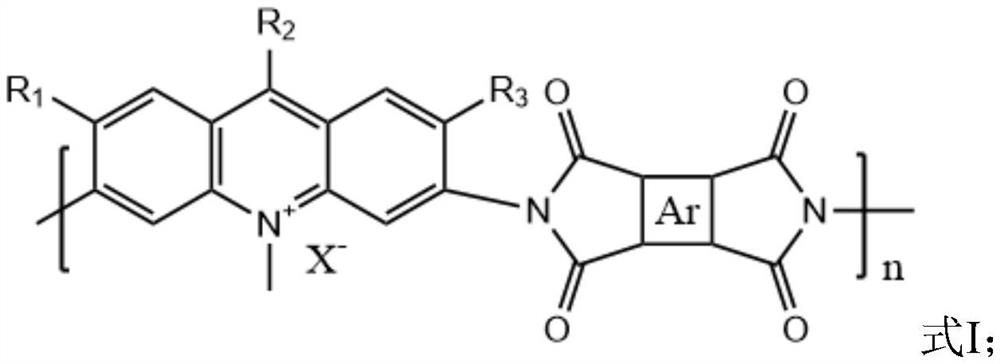

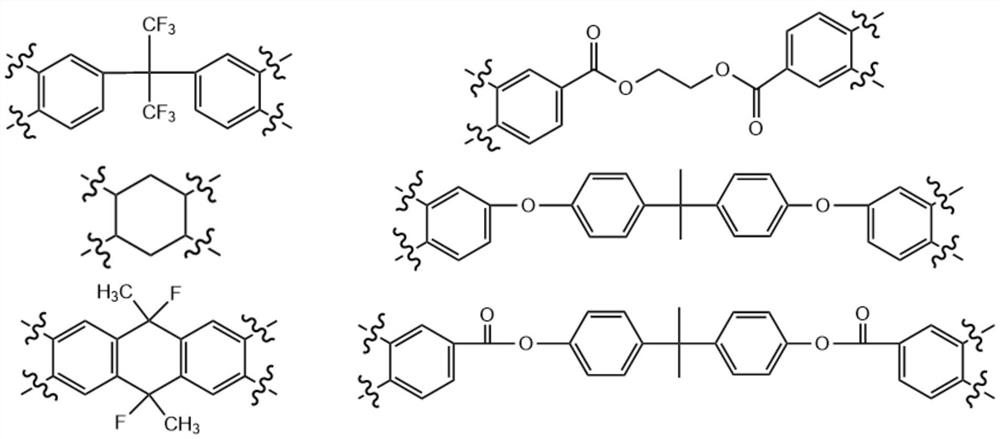

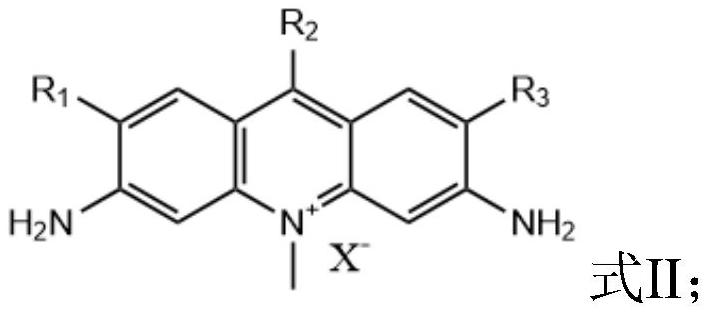

Polyimide containing pyridine quaternary ammonium salt structure, preparation method of polyimide, transparent polyimide film and preparation method of transparent polyimide film

ActiveCN114591504AHigh transparencyReduce charge transfer effectsPhotovoltaic energy generationPolymer scienceSolar battery

The invention relates to the technical field of high polymer materials, in particular to polyimide containing a pyridine quaternary ammonium salt structure, a preparation method of the polyimide, a transparent polyimide film and a preparation method of the transparent polyimide film, the polyimide containing the pyridine quaternary ammonium salt structure has the chemical structure shown in the formula I, X <-> is one or more selected from F <->, Cl <->, Br <-> and I <->; r1 and R3 are independently selected from alkyl with the carbon atom number of 1-5, and R2 is selected from hydrogen atom or phenyl; ar is a group selected from the following groups: wherein n is 50-150. According to the transparent polyimide film prepared by the preparation method disclosed by the invention, an aromatic heterocyclic structure containing pyridine quaternary ammonium salt is introduced into a diamine monomer, so that the planarity of a condensed ring is enhanced, charge transfer among molecules is weakened, the linear expansion coefficient is 10.9-18.9 ppm / K, the visible light transmittance at 550nm is 85-92%, the glass-transition temperature is 382-410 DEG C, and the thermodynamic property and the optical property are excellent; the method can be applied to the photoelectric fields of flexible transparent display substrate materials, optical transparent films or solar cell substrates and the like.

Owner:SHENZHEN HUAKE COMM TECH CO LTD

An underground cross-linked resin plugging agent prepared by seawater and its application

The invention provides an underground cross-linking type resin plugging agent prepared from seawater and application thereof. The underground cross-linking type resin plugging agent includes 3 wt% to7 wt% of sulfonated resol phenolic prepolymer, 2wt% to 4wt% of curing agent, 0.1wt% to 0.3wt% of coagulant, and the balance water. The sulfonated resol phenolic prepolymer sulfonate functional groupsimpart good water solubility of an anionic polymer in brine, and a phenoxy ether bond structure ensures the crosslinked body coating and water retaining capability. The cross-linking type resin plugging agent can be prepared from the seawater or saline with a higher degree of mineralization, can selectively enter a deep part of a high-permeability formation by general injection to delay the polycondensation and curing to form a thermosetting and thermal inertia resin gel which retains water highly. Under high temperature and high humidity formation conditions, the underground cross-linking type resin plugging agent can withstand formation differential pressure, water flow thrust and suction force of near-well zone negative pressure operation on the plugging agent for a long term.

Owner:PETROCHINA CO LTD

Continuous preparation process of nickel-based butadiene rubber and rare earth-based butadiene rubber

ActiveCN111848849BHigh activityRealize flexible switching productionPolymer scienceButadiene Dioxide

The invention relates to a continuous preparation process of nickel-based butadiene rubber and rare-earth-based butadiene rubber, comprising: continuously introducing butadiene oil and one of nickel-based catalysts and rare-earth-based catalysts into a polymerization reaction unit of a polymerization device for polymerization reaction to obtain nickel-based or rare-earth-based butadiene rubber glue, and then introduce the glue into the coagulation unit for coagulation to obtain nickel-based or rare-earth-based butadiene rubber, wherein butyl oil includes butadiene monomer and solvent, which contains The content of oxygen compounds is less than or equal to 20mg / kg, and the water value is less than or equal to 50ppm; Among them, when preparing nickel-based butadiene rubber, the introduction of rare earth catalysts is stopped, and butyl oil and nickel-based catalysts are introduced into the polymerization reaction unit; When using butadiene rubber, the introduction of nickel catalyst is stopped, and butyl oil and rare earth catalyst are introduced into the polymerization reaction unit. Therefore, the present invention can realize the flexible switching production of nickel-based butadiene rubber and rare-earth-based butadiene rubber on the same set of polymerization device without shutting down to clean the kettle.

Owner:ZHEJIANG TRANSFAR SYNTHETIC MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com