Preservation method of loop-mediated isothermal amplification reaction reagent mixture

A loop-mediated isothermal, amplification reaction technology, applied in biochemical equipment and methods, microorganism determination/inspection, etc., can solve problems such as cumbersome operation steps, achieve simple operation, reduce storage and transportation costs, and facilitate practical operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

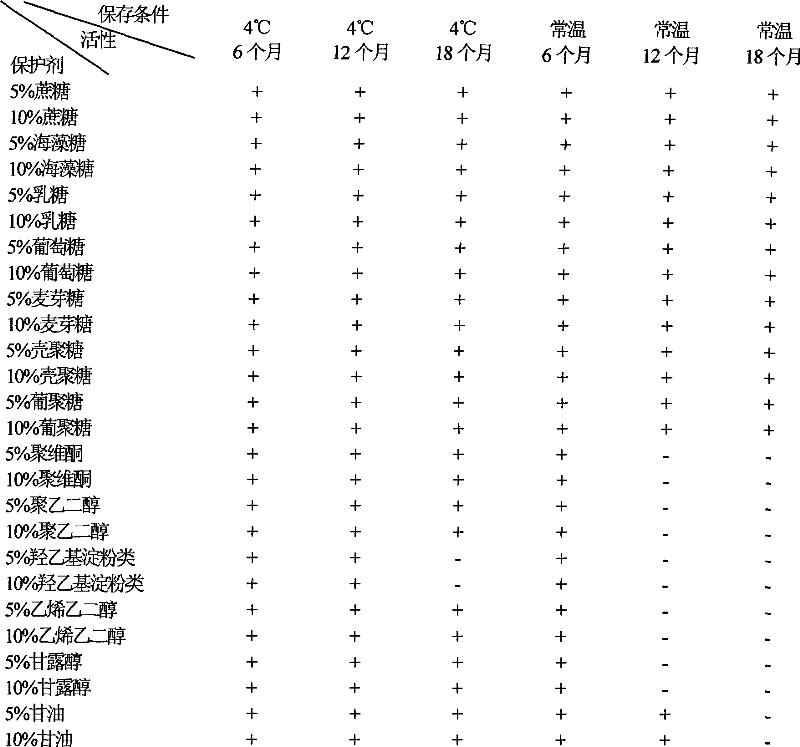

[0012] Embodiment 1. Vacuum drying treatment after adding different concentrations and different types of dry protection agents to the LAMP reaction reagent mixture

[0013] Mix 3744 μL of the mixture of various LAMP reaction reagents except the nucleic acid of the test sample (including 1.6 μM each of LAMP primers FIP and BIP, 0.2 μM each of primers F3 and B3, 1.4 mM each of dATP, dTTP, dGTP and dCTP, MgCl 2 6mM, Betaine 1M, Tris-HCl 20mM, KCl 10mM, MgSO 4 2mM, (NH 4 ) 2 SO 4 10mM, TritonX-1000.1%, BstDNA polymerase 1248U, AMV reverse transcriptase 19.5U) in 26 1.5mL centrifuge tubes according to 144μL per tube, as shown in the first column of Table 1 (26 rows in total) Concentration and type Add dry protectant to each 1.5mL centrifuge tube, mix well, then divide the mixture in each 1.5mL centrifuge tube into 6 0.2mL centrifuge tubes according to the amount of 24μL, and then divide the packed The 0.2ml centrifuge tube with the mixture is placed in a low-temperature vac...

Embodiment 2

[0014] Example 2. Rapid air-drying after adding different concentrations and different types of drying protectants to the LAMP reaction reagent mixture

[0015] Mix 3744 μL of the mixture of various LAMP reaction reagents except the nucleic acid of the test sample (including 1.6 μM each of LAMP primers FIP and BIP, 0.2 μM each of primers F3 and B3, 1.4 mM each of dATP, dTTP, dGTP and dCTP, MgCl 2 6mM, Betaine 1M, Tris-HCl20mM, KCl10mM, MgSO4 2mM, (NH 4 ) 2 SO 4 10mM, BSA100μg / mL, Bst DNA polymerase 1248U, AMV reverse transcriptase 19.5U) were divided into 26 1.5mL centrifuge tubes according to 144μL per tube, according to the first column of Table 2 (a total of 26 rows) Concentration and type Add dry protectant to each 1.5mL centrifuge tube, mix well, then divide the mixture in each 1.5mL centrifuge tube into 6 0.2mL centrifuge tubes according to the amount of 24μL, and then divide the packed The 0.2ml centrifuge tube with the mixture is placed in a normal temperature air d...

Embodiment 3

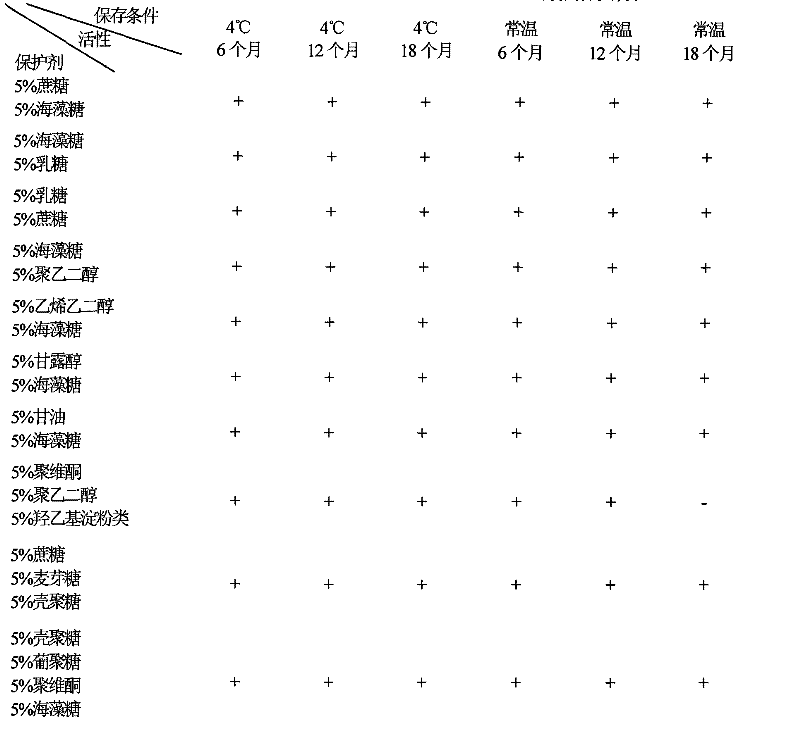

[0016] Example 3. Vacuum drying treatment after adding two or more drying protectants to the LAMP reaction reagent mixture

[0017] Mix 1440 μL of the mixture of various LAMP reaction reagents except for the nucleic acid of the test sample (including 1.6 μM each of LAMP primers FIP and BIP, 0.2 μM each of primers F3 and B3, 1.4 mM each of dATP, dTTP, dGTP and dCTP, 1 M betaine, Tris-HCl 20mM, KCl10mM, MgSO 4 8mM, (NH 4 ) 2 SO 4 10mM, TritonX-1000.1%, BstDNA polymerase 480U, AMV reverse transcriptase 7.5U) in 10 centrifuge tubes of 1.5mL according to 144μL per tube, as shown in the first column of Table 3 (10 rows in total) Concentration and type Add dry protectant to each 1.5mL centrifuge tube, mix well, then divide the mixture in each 1.5mL centrifuge tube into 6 0.2mL centrifuge tubes according to the amount of 24μL, and then divide the packed Place the 0.2ml centrifuge tube of the mixture in a low-temperature vacuum freeze dryer (HetoDrywinne, Denmark), control the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com