Pressure-controlling deaggregating synthetic method for lithium iron phosphate positive electrode material

A positive electrode material, lithium iron phosphate technology, applied in the direction of phosphate, phosphorus oxyacid, phosphorus compound, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

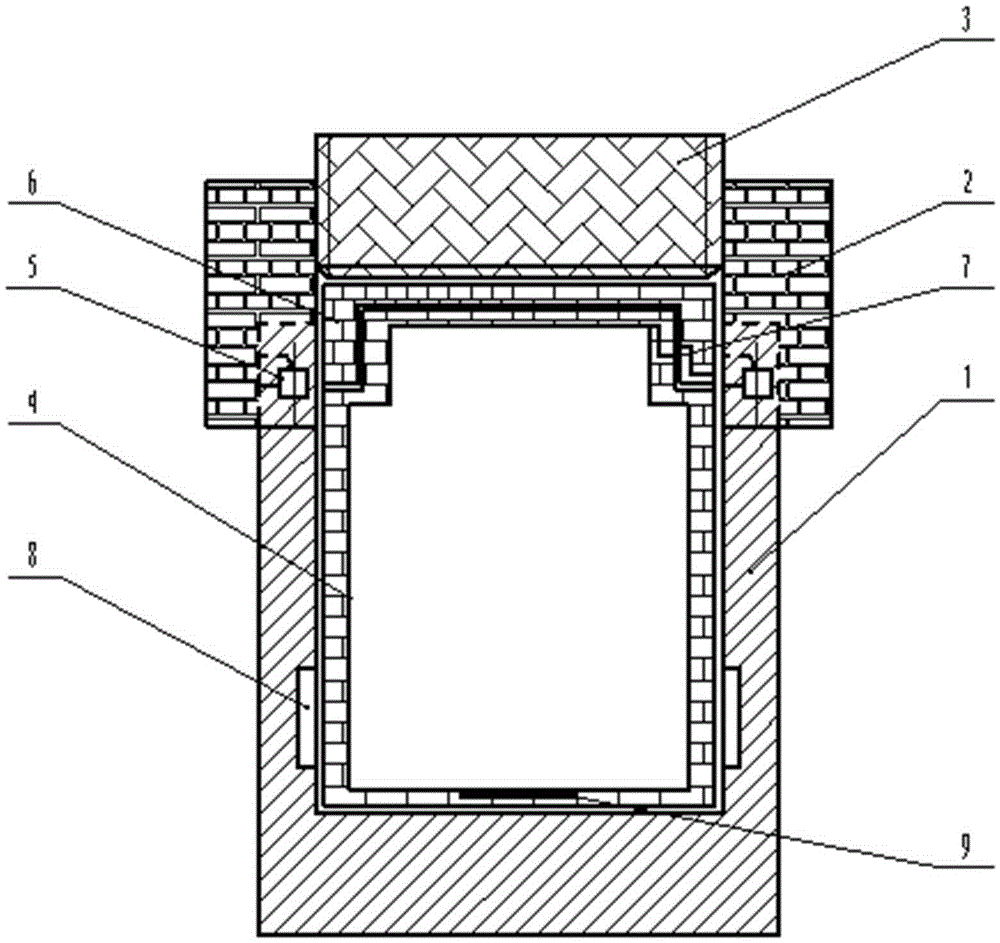

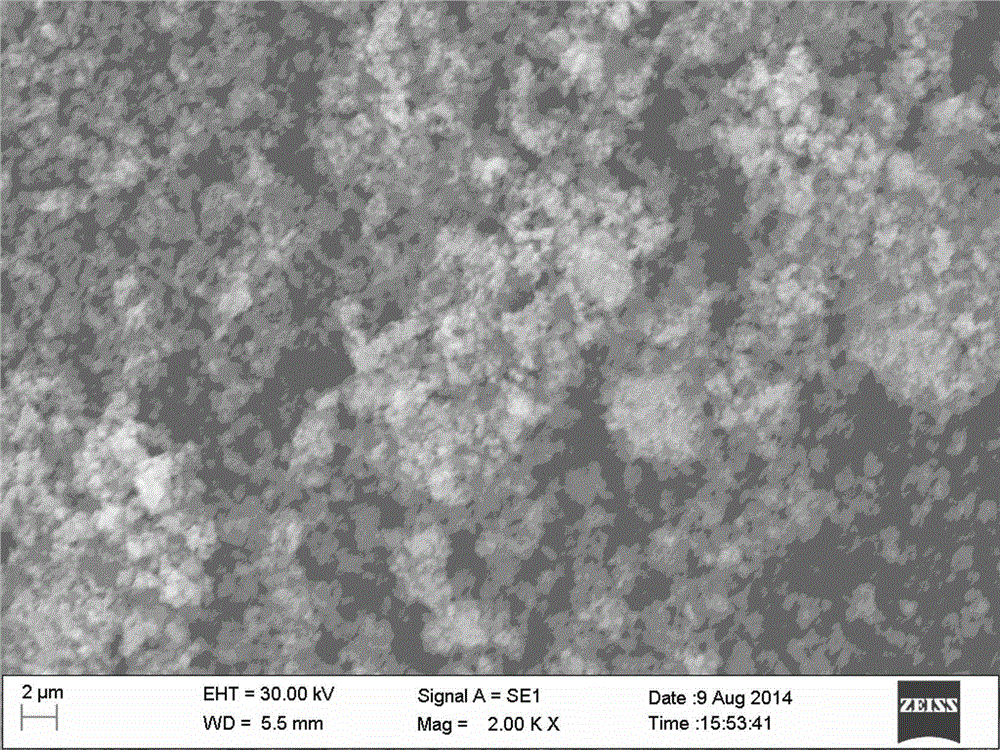

[0021] 1) The analytically pure FePO 4 2H 2 After removing water at high temperature, O is added to the inner body (4) of the ultrasonic-assisted microwave reactor, and Li is added according to the molar ratio of Li:Fe=1.02:1. 2 CO 3 , and then add Vc aqueous solution with a concentration of 20% according to the ratio of the total volume ratio of 1:0.5, and turn on ultrasonic assistance (9) and microwave (8) heating at the same time, control the temperature of the material at 50°C for 10 minutes, and form precursor A. Precursor A was sintered at 300°C for 30 minutes under the protection of nitrogen in a rotary furnace, and then rapidly cooled to obtain powder precursor B;

[0022] 2) After weighing the precursor B and putting it into the inner body (4) of the ultrasonic-assisted microwave reactor, weigh the glucose aqueous solution with a concentration of 50% according to the mass ratio of 1:0.2, and after turning on the ultrasonic auxiliary for 5 minutes, turn off the ultra...

Embodiment 2

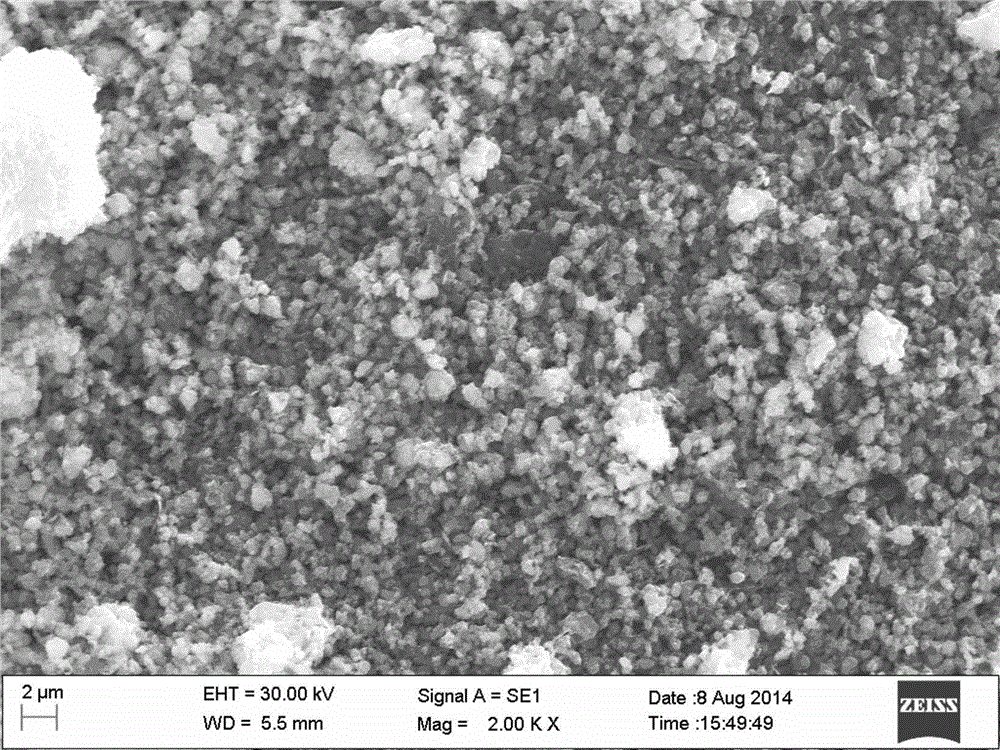

[0029] 1) The analytically pure FePO 4 2H 2 After removing water at high temperature, O is added to the inner body (4) of the ultrasonic-assisted microwave reactor, and Li is added according to the molar ratio of Li:Fe=1.02:1. 2 CO 3, and then add Vc aqueous solution with a concentration of 30% according to the ratio of the total volume ratio of 1:0.6, and turn on ultrasonic assistance (9) and microwave (8) heating at the same time, control the temperature of the material at 40°C for 10 minutes, and form precursor A. Precursor A was sintered at 300°C for 30 minutes under the protection of nitrogen in a rotary furnace, and then rapidly cooled to obtain powder precursor B;

[0030] 2) After weighing the precursor B and putting it into the inner body (4) of the ultrasonic-assisted microwave reactor, weigh the glucose aqueous solution with a concentration of 40% according to the mass ratio of 1:0.2, and after turning on the ultrasonic assist for 5 minutes, turn off the ultrasoni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com