Zn/N double-doped titanium monoxide material and preparation method thereof

A titanium monoxide and double doping technology, applied in the field of photocatalytic materials, can solve the problems of photocatalyst wavelength absorption and poor activity, and achieve the effect of simple preparation process and high scientific research value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

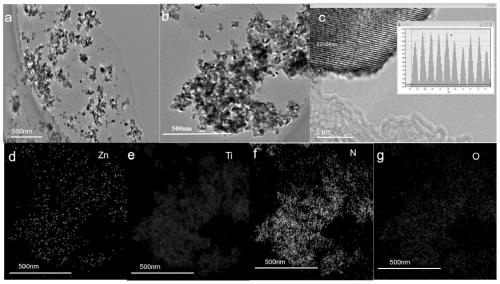

[0024] This embodiment provides a Zn / N double-doped titanium monoxide material, which contains Ti, C, N, Zn, and O elements.

[0025] The above-mentioned Zn / N double-doped titanium monoxide material (Zn / N-TiO) preparation method specifically includes the following steps:

[0026] Dissolve polyacrylonitrile in N,N-dimethylformamide, then add titanium dioxide (P25) and stir for 10 hours, then add zinc nitrate to the above solution and stir for 16 hours, then take an oil bath until the liquid is completely evaporated, where The molar ratio of polyacrylonitrile, titanium dioxide (P25) and zinc nitrate is 2:1:3, and the oil bath temperature is 180°C. The solid obtained in the oil bath was placed in a tube furnace, kept at 800°C for 4 hours under the condition of ammonia gas, and then lowered to room temperature, and a Zn / N double-doped titanium monoxide material was obtained. The doping ratio of Zn was 3%, and the doping ratio of N is 8%.

[0027] Using a field emission scanning ...

Embodiment 2

[0030] This embodiment provides an N-doped titanium monoxide material containing Ti, C, N, and O elements.

[0031] The above-mentioned N-doped titanium monoxide material (N-TiO) preparation method specifically comprises the following steps:

[0032] Polyacrylonitrile is dissolved in N, N-dimethylformamide, then add titanium dioxide (P25) and stir after 10 hours, oil bath until liquid is completely volatilized, wherein the molar ratio of polyacrylonitrile, titanium dioxide (P25) is 2: 1. The temperature of the oil bath is 180°C. The solid obtained in the oil bath was placed in a tube furnace, kept at 800° C. for 4 hours under the condition of ammonia gas, and then lowered to room temperature to obtain N-doped titanium monoxide material.

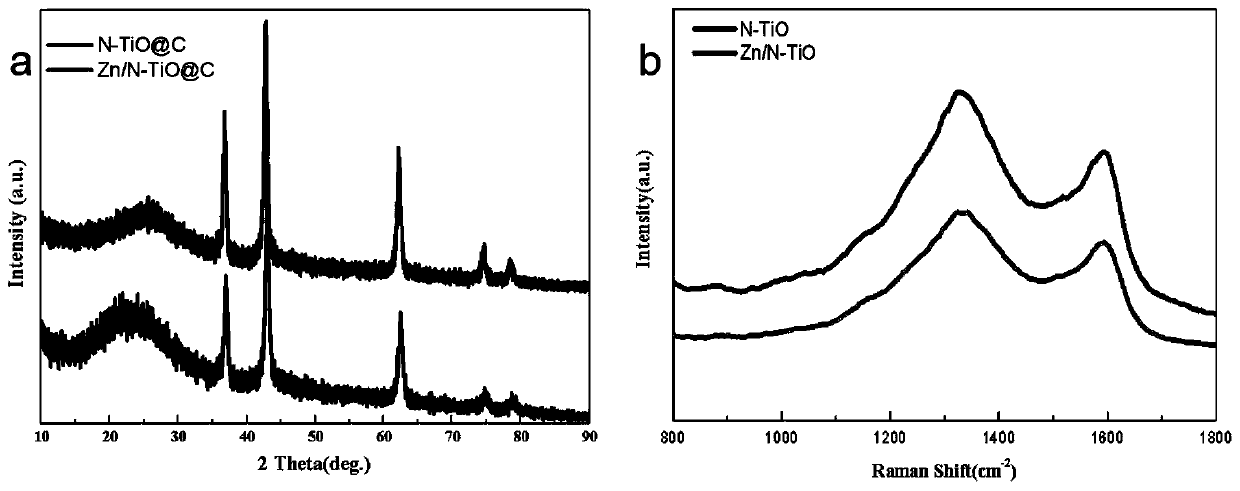

[0033] The products Zn / N-TiO@C and N-TiO@C obtained in Example 1 and Example 2 were tested respectively by using an X-ray diffractometer (model: Burker-AXS D8, manufacturer: Bruker Company, Germany), and the results are shown in Fig. As sho...

Embodiment 3

[0036] The obtained Zn / N double-doped titanium monoxide material was tested for photocatalytic reduction of carbon dioxide.

[0037] Take by weighing 10mg of the Zn / N-TiO prepared by the above-mentioned Example 1 and the N-TiO photocatalyst prepared by Example 2 respectively in a sample bottle, and add 10mL of an aqueous solution of triethanolamine (the aqueous solution of triethanolamine, by volume ratio Calculate, where triethanolamine: water is 1:4), then control the power to 60W, the frequency is 40KHz to conduct ultrasound for 10min, after exhausting through the vacuum pump, fill in carbon dioxide gas to 80kpa, after a period of time, place it in a 300W xenon lamp (with 400 or 700nm cut-off filter) for carbon dioxide reduction test. The role of triethanolamine is as a sacrificial agent for sacrificing holes, thereby facilitating the combination of electrons and carbon dioxide to generate carbon monoxide, methane and ethane.

[0038] Use gas chromatography (model: GC7900,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com