Preparation method of self-doped Fe-n-C oxygen reduction electrocatalyst by salting out thermal polymerization of animal blood

An electrocatalyst and thermal polymerization technology, applied in the field of electrocatalysis, to achieve the effects of increased specific surface area, excellent electrocatalytic performance, and increased pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Take about 500mL of fresh pig blood in a 1L beaker, heat and dry in a drying oven at 80°C until constant weight.

[0046] (2) Crush the dried fresh pig blood, pass through a 200-mesh sieve, and take about 1.00 g of the under-sieved powder into the corundum ark.

[0047] (3) Put the corundum ark in a tube furnace for high-temperature pyrolysis, at a heating rate of 10°C / min, high-temperature pyrolysis at 900°C for 60 minutes, and cool to room temperature.

[0048] (4) The pyrolyzed material was pulverized and fully washed with a large amount of mixed solution of deionized water and ethanol, and then freeze-dried (19Pa, -50°C) to obtain a catalyst.

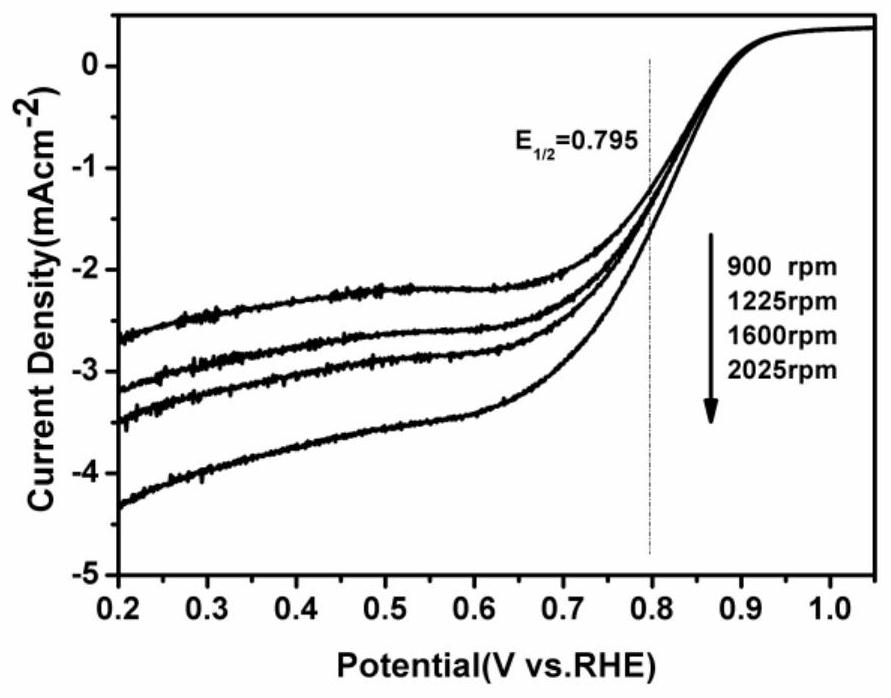

[0049] (5) Electrocatalytic performance test: Weigh 9 mg of the prepared catalyst and a 2.0 mL centrifuge tube with an electronic balance, add 0.99 mL of absolute ethanol and 0.01 mL of 5% Nafion ethanol solution, and sonicate for 20 min-60 min to form a uniform dispersion. Take 10ul of dispersion liquid and drop-coat it...

Embodiment 2

[0052] (1) Take about 500mL of fresh pig blood in a 1L beaker to which 200mL of 50g / L sodium chloride solution has been added in advance, stir and let stand for 30min.

[0053] (2) Boil the pig blood after salting out in a 2.5L beaker with water for 20min, take it out and dry it at 80°C.

[0054] (3) Put the corundum ark in a tube furnace for high-temperature pyrolysis, at a heating rate of 10°C / min, high-temperature pyrolysis at 900°C for 60 minutes, and cool to room temperature.

[0055] (4) The pyrolyzed material was pulverized and fully washed with a large amount of mixed solution of deionized water and ethanol, and then freeze-dried (19Pa, -50°C) to obtain a catalyst.

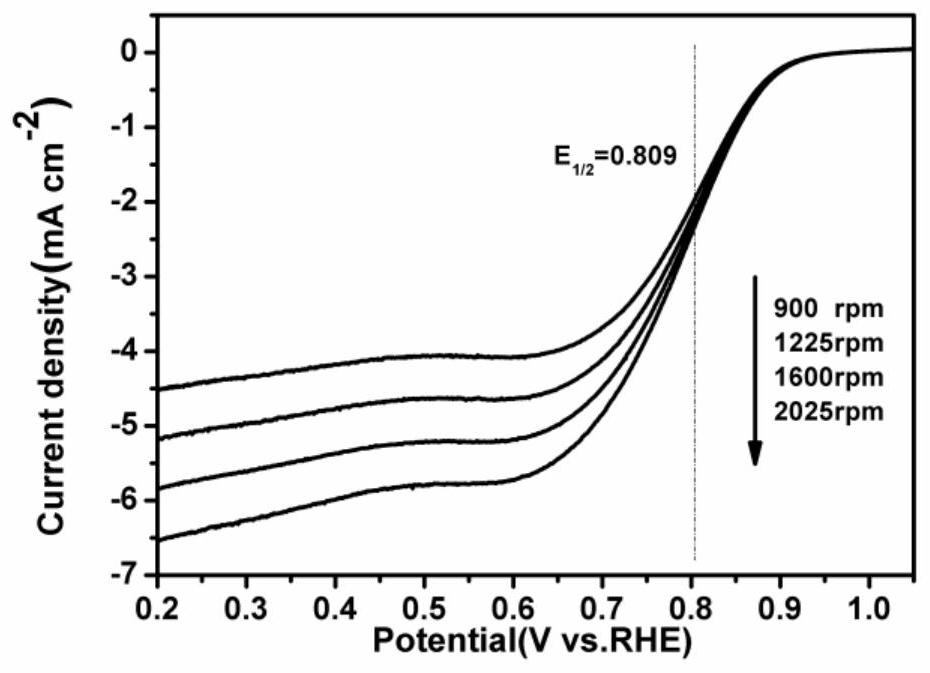

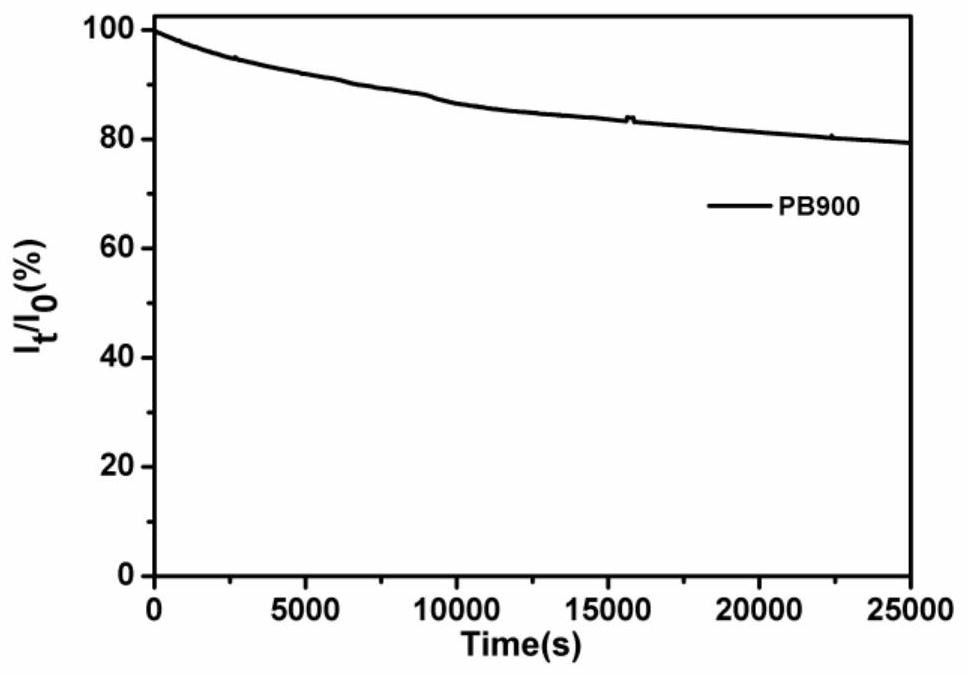

[0056] (5) Electrocatalytic performance test: perform the performance test according to the method described in step 5 in Example 1, and the specific oxygen reduction catalytic performance is as follows figure 2 As shown, the stability test as image 3 shown. At the same time, the electrocatalytic oxyg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| energy conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com