Preparation method of high-activity photocatalytic particles

A technology of photocatalytic particles and high activity, applied in the field of photocatalysis, can solve the problems of low quantum yield of titanium dioxide particles, achieve the effect of improving photocatalytic degradation efficiency, ensuring integrity and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

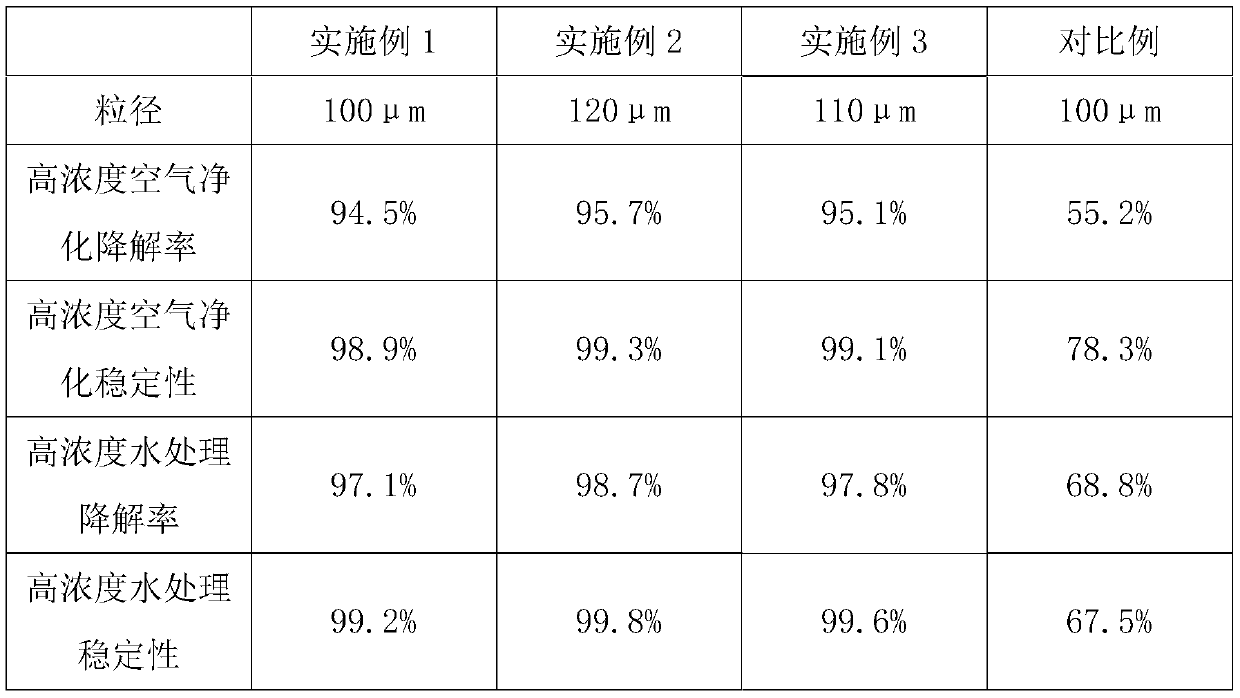

Examples

Embodiment 1

[0024] The invention discloses a preparation method of highly active photocatalytic particles. The highly active photocatalytic particles are coated on the surface of nanometer titanium monoxide by n-butyl titanate. It is converted into titanium dioxide by hydrolysis to form polytitanium photocatalytic particles with titanium monoxide as the core and titanium dioxide as the coating.

[0025] The method comprises the steps of:

[0026] Step 1, adding titanium monoxide to a ball mill, adding a small amount of distilled water to stir to form a slurry, and ball milling for 2 hours, then using hot nitrogen to seal and blow dry, and obtain nano-titanium monoxide after cooling;

[0027] Step 2, slowly adding nano-titanium monoxide to n-butyl titanate for low-temperature microwave reaction for 2 hours, stirring to form a suspension slurry;

[0028] Step 3, spray the suspension slurry and distilled water simultaneously in a constant temperature reaction kettle for constant temperature...

Embodiment 2

[0037] The invention discloses a preparation method of highly active photocatalytic particles. The highly active photocatalytic particles are coated on the surface of nanometer titanium monoxide by n-butyl titanate. It is converted into titanium dioxide by hydrolysis to form polytitanium photocatalytic particles with titanium monoxide as the core and titanium dioxide as the coating.

[0038] The method comprises the steps of:

[0039] Step 1, adding titanium monoxide to a ball mill, adding a small amount of distilled water to stir to form a slurry, and ball milling for 5 hours, then using hot nitrogen to seal and blow dry, and obtain nano-titanium monoxide after cooling;

[0040] Step 2, slowly adding nano-titanium monoxide to n-butyl titanate for low-temperature microwave reaction for 5 hours, and stirring to form a suspension slurry;

[0041] Step 3, spray the suspension slurry and distilled water simultaneously in a constant temperature reaction kettle for constant tempera...

Embodiment 3

[0050] The invention discloses a preparation method of highly active photocatalytic particles. The highly active photocatalytic particles are coated on the surface of nanometer titanium monoxide by n-butyl titanate. It is converted into titanium dioxide by hydrolysis to form polytitanium photocatalytic particles with titanium monoxide as the core and titanium dioxide as the coating.

[0051] The method comprises the steps of:

[0052] Step 1, adding titanium monoxide to a ball mill, adding a small amount of distilled water to stir to form a slurry, and ball milling for 4 hours, then using hot nitrogen to seal and blow dry, and obtain nano-titanium monoxide after cooling;

[0053] Step 2, slowly adding nano-titanium monoxide to n-butyl titanate for low-temperature microwave reaction for 4 hours, stirring to form a suspension slurry;

[0054] Step 3, spray the suspension slurry and distilled water in a constant temperature reaction kettle for 2 hours at a constant temperature, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com