Titanium monoxide semiconductor ceramic and preparation method thereof

A technology for preparing titanium monoxide and ceramics, which is applied in the field of semiconductors, can solve problems such as difficulty in preparing titanium monoxide, difficulty in synthesizing titanium monoxide, and slow temperature rise and fall, so as to reduce production costs and energy consumption, and reduce equipment costs. Ingredient stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

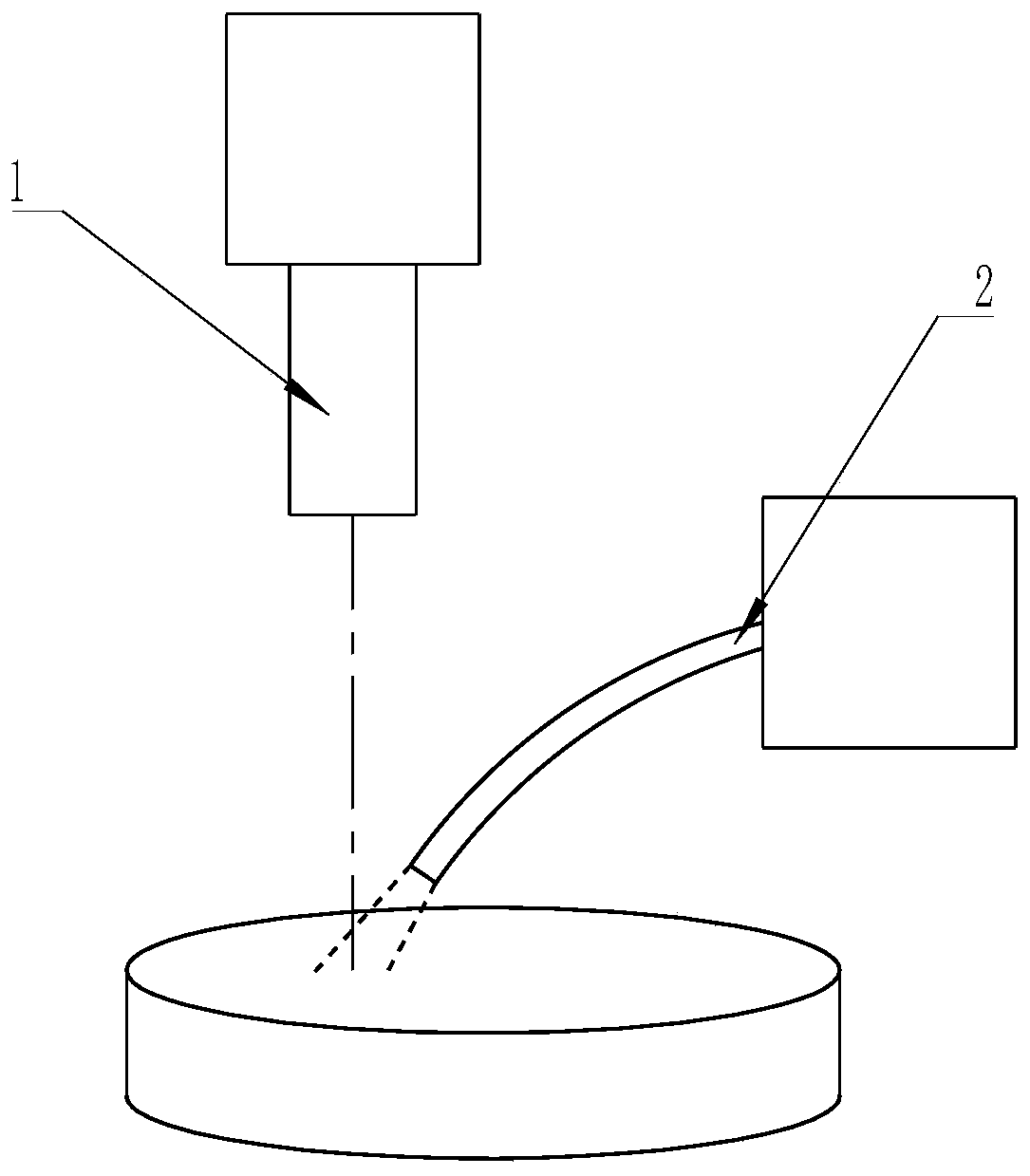

Method used

Image

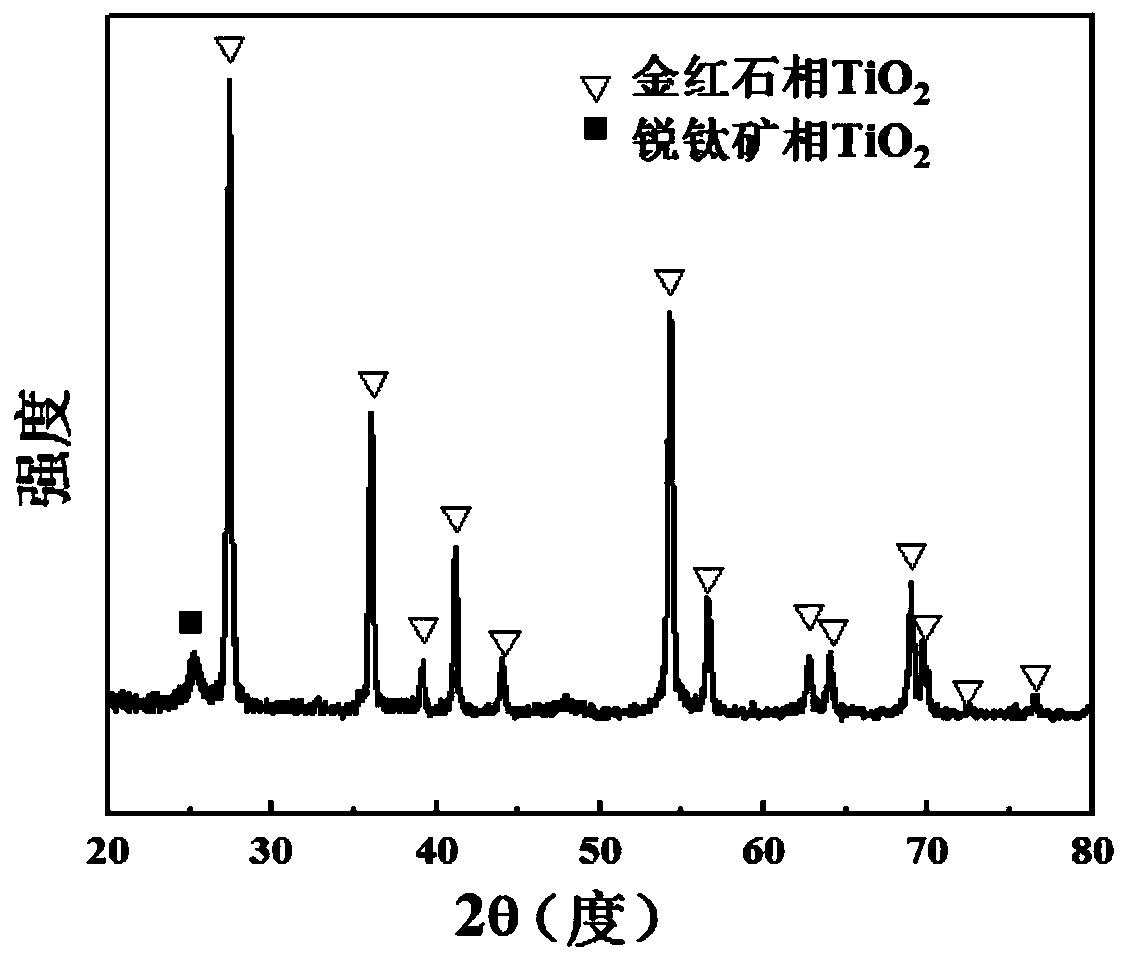

Examples

Embodiment 1

[0028] This embodiment provides a method for preparing a titanium monoxide semiconductor ceramic, the method comprising the following steps:

[0029] S1, take 0.03mol tetrabutyl titanate and 0.03*1.5mol citric acid hydrate according to stoichiometric ratio, dissolve citric acid hydrate in 20mL deionized water to obtain citric acid aqueous solution, and then disperse tetrabutyl titanate under ultrasonic dispersion The ester was dissolved in aqueous citric acid to obtain a mixed solution.

[0030] S2, constantly stirring the mixed solution, and adding ammonia water to the mixed solution to adjust the pH to 5 to form a sol, adding 10 mL of ethylene glycol as a combustion aid to the sol, and aging at 15°C for 24 hours , the aged sol was placed in a water bath at 100°C for a chemical reaction for 1 hour to obtain a wet gel.

[0031] S3, drying the wet gel in an oven at 180° C. for 2 hours to volatilize the organic solvent to obtain a xerogel, and grind the xerogel in air to obtain...

Embodiment 2

[0035] This embodiment provides a method for preparing a titanium monoxide semiconductor ceramic, the method comprising the following steps:

[0036] S1, take 0.03mol tetrabutyl titanate and 0.03*1.5mol citric acid hydrate according to stoichiometric ratio, dissolve citric acid hydrate in 20mL deionized water to obtain citric acid aqueous solution, and then disperse tetrabutyl titanate under ultrasonic dispersion The ester was dissolved in aqueous citric acid to obtain a mixed solution.

[0037] S2, constantly stirring the mixed solution, and adding ammonia water to the mixed solution to adjust the pH to 5.5 to form a sol, adding 10 mL of ethylene glycol as a combustion aid to the sol, and aging at 20°C for 24 hours , the aged sol was placed in a water bath at 100° C. for a chemical reaction with a reaction time of 1.5 h to obtain a wet gel.

[0038] S3, drying the wet gel in an oven at 180° C. for 3 hours to volatilize the organic solvent to obtain a dry gel, and grind the d...

Embodiment 3

[0041] This embodiment provides a method for preparing a titanium monoxide semiconductor ceramic, the method comprising the following steps:

[0042] S1, take 0.03mol tetrabutyl titanate and 0.03*1.5mol citric acid hydrate according to stoichiometric ratio, dissolve citric acid hydrate in 20mL deionized water to obtain citric acid aqueous solution, and then disperse tetrabutyl titanate under ultrasonic dispersion The ester was dissolved in aqueous citric acid to obtain a mixed solution.

[0043] S2, constantly stirring the mixed solution, and adding ammonia water to the mixed solution to adjust the pH to 6 to form a sol, adding 10 mL of ethylene glycol as a combustion aid to the sol, and aging for 24 hours at 25° C. , the aged sol was placed in a water bath at 100°C for a chemical reaction, the reaction time was 2h, and a wet gel was obtained.

[0044] S3, drying the wet gel in an oven at 180° C. for 4 hours to volatilize the organic solvent to obtain a xerogel, and grind the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com