Method of forming anodic titanium oxide layers having dual-color appearance and article having the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

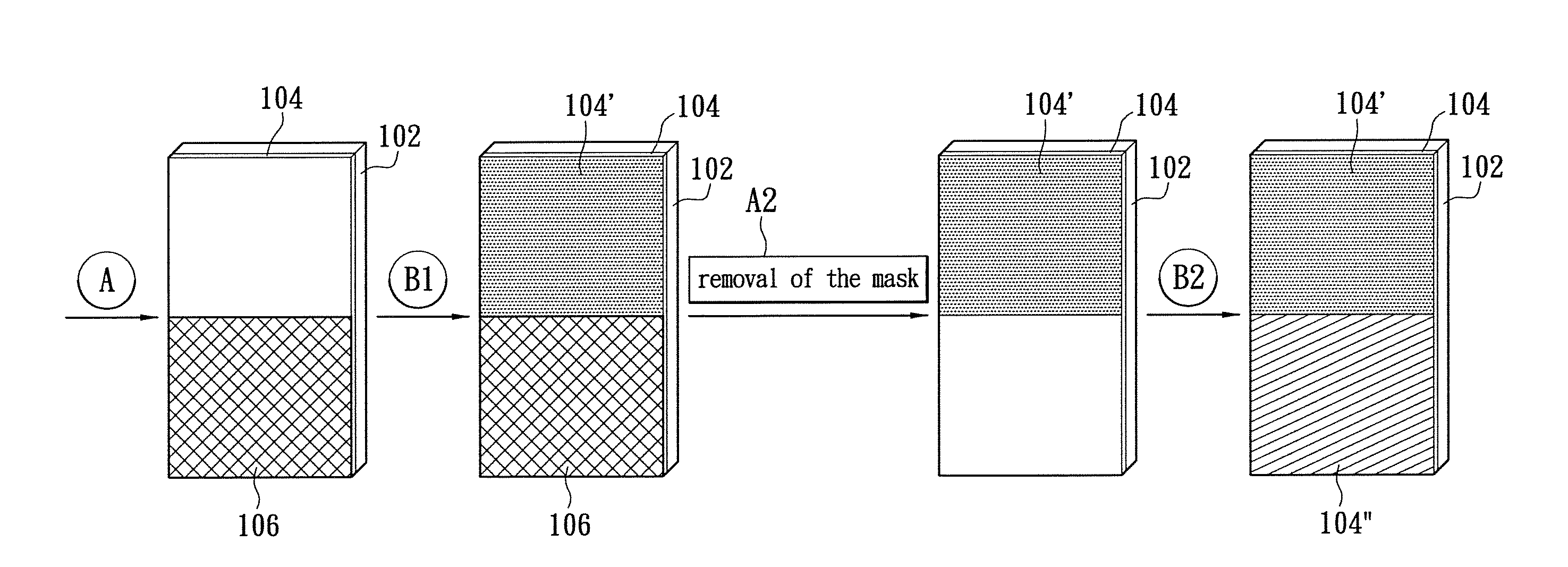

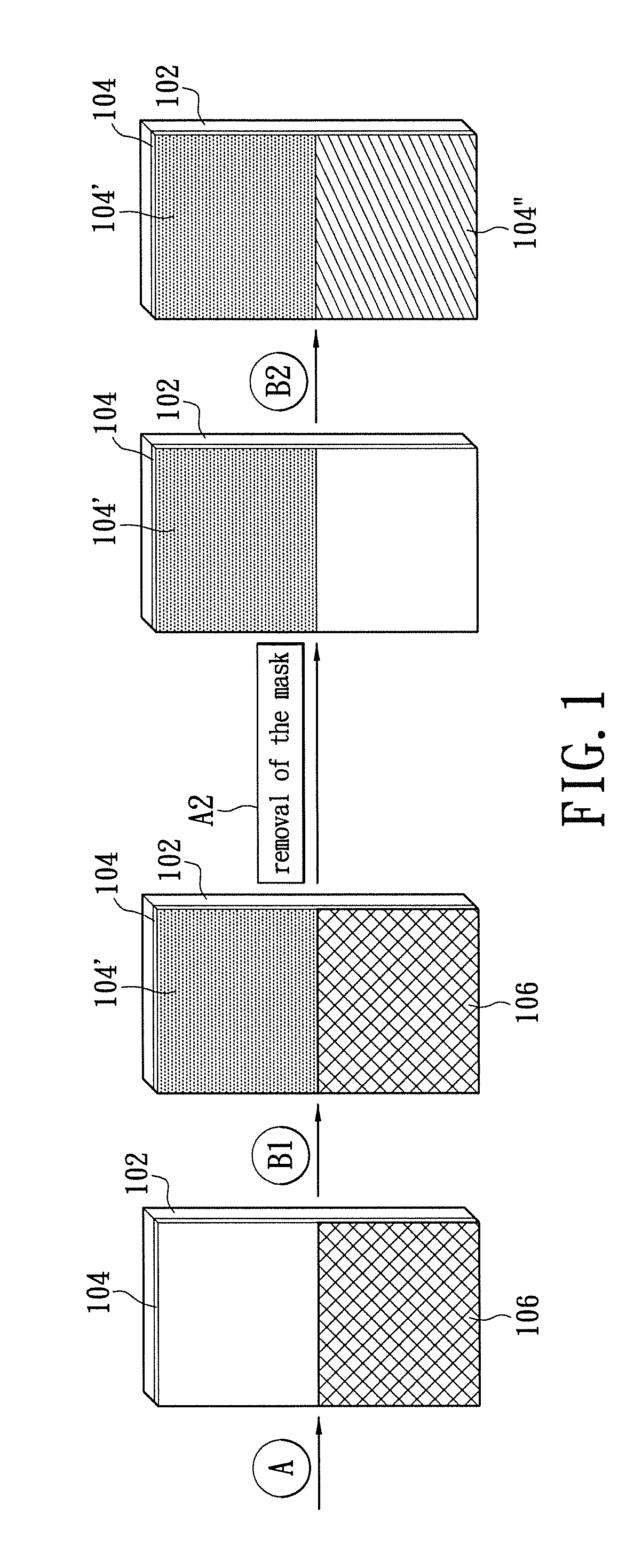

[0018]Please refer to FIG. 1, which shows a step-by-step illustration of the method in forming anodic titanium oxide layers having dual-color appearance of the instant disclosure. The present method can be broken into a preparation process A, a first anodizing B1, removal of the mask A2, and a second anodizing B2. Each different stage is explained in details hereinbelow.

[0019][Preparation Process A]

[0020]Please refer to FIGS. 1 and 2, with FIG. 2 showing a flowchart listing the steps of the preparation process A of the instant disclosure. In step A11, a substrate 102 is provided. The substrate 102 is mainly made of metallic material and can be a metal housing, such as aluminum, aluminum alloy, stainless steel, or magnesium alloy housing. The substrate 102 may also be a non-metallic housing as well.

[0021]Then, for step A12 regarding the metal housing, the substrate 102 may first be cleaned prior to anodic treatment. Generally speaking, the cleaning process includes degreasing, acid w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com