Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

86 results about "Thiophosphoric Acid Esters" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation of phosphorothioate and boranophosphate oligomers

InactiveUS6160109AHigh diastereomeric excessLow costSugar derivativesOrganic-compounds/hydrides/coordination-complexes catalystsOligomerDiastereomer

Owner:MCGILL UNIV +1

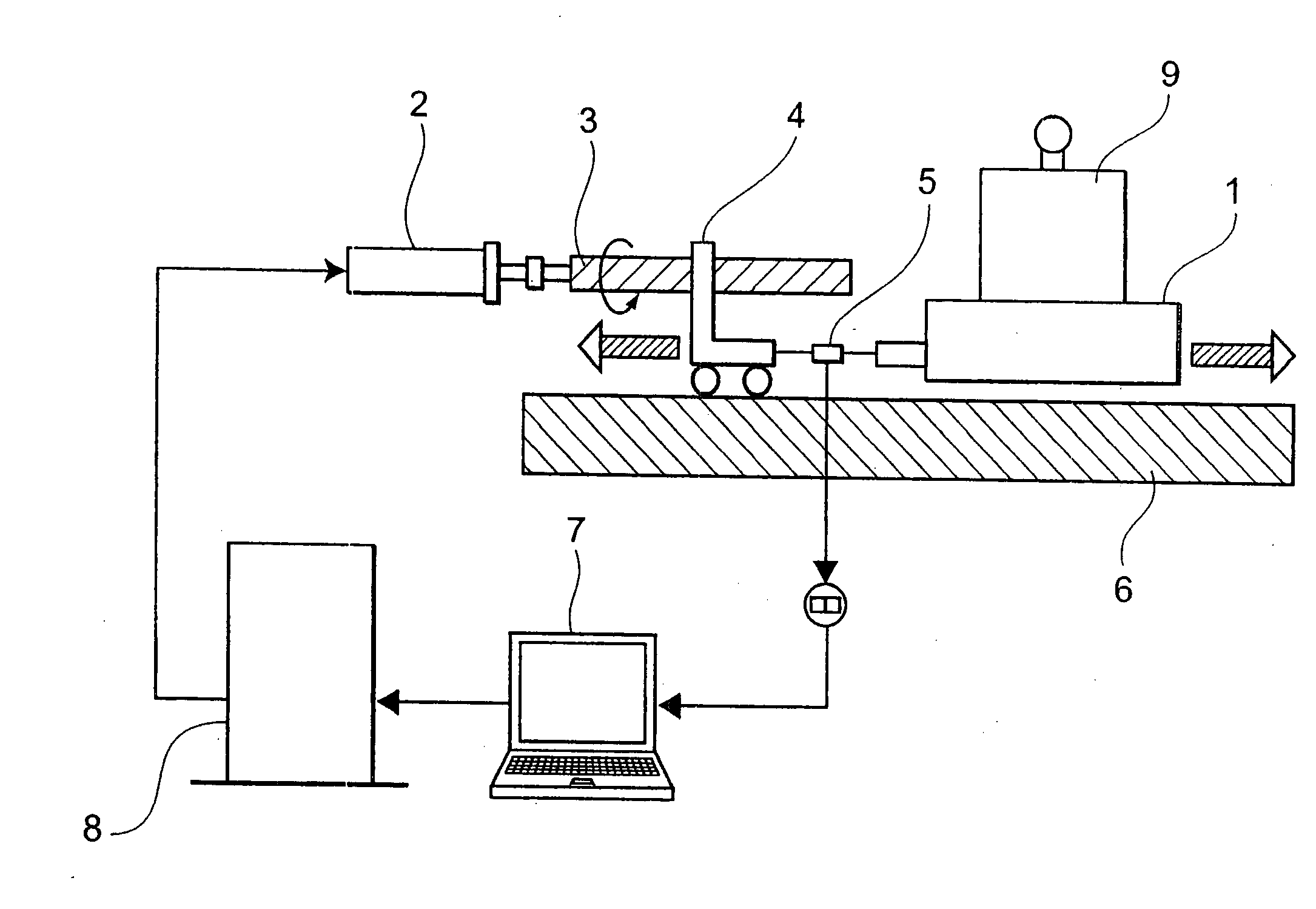

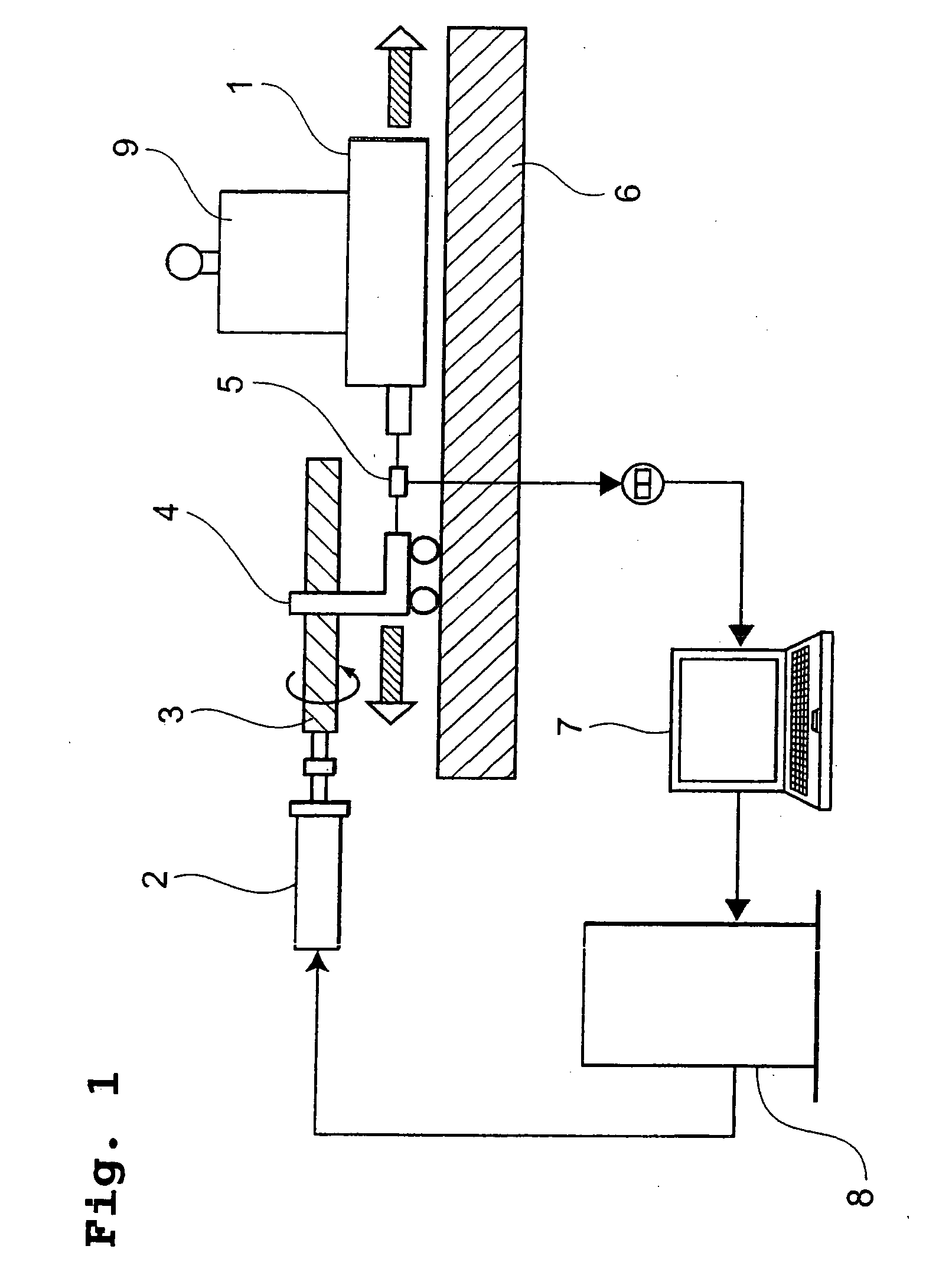

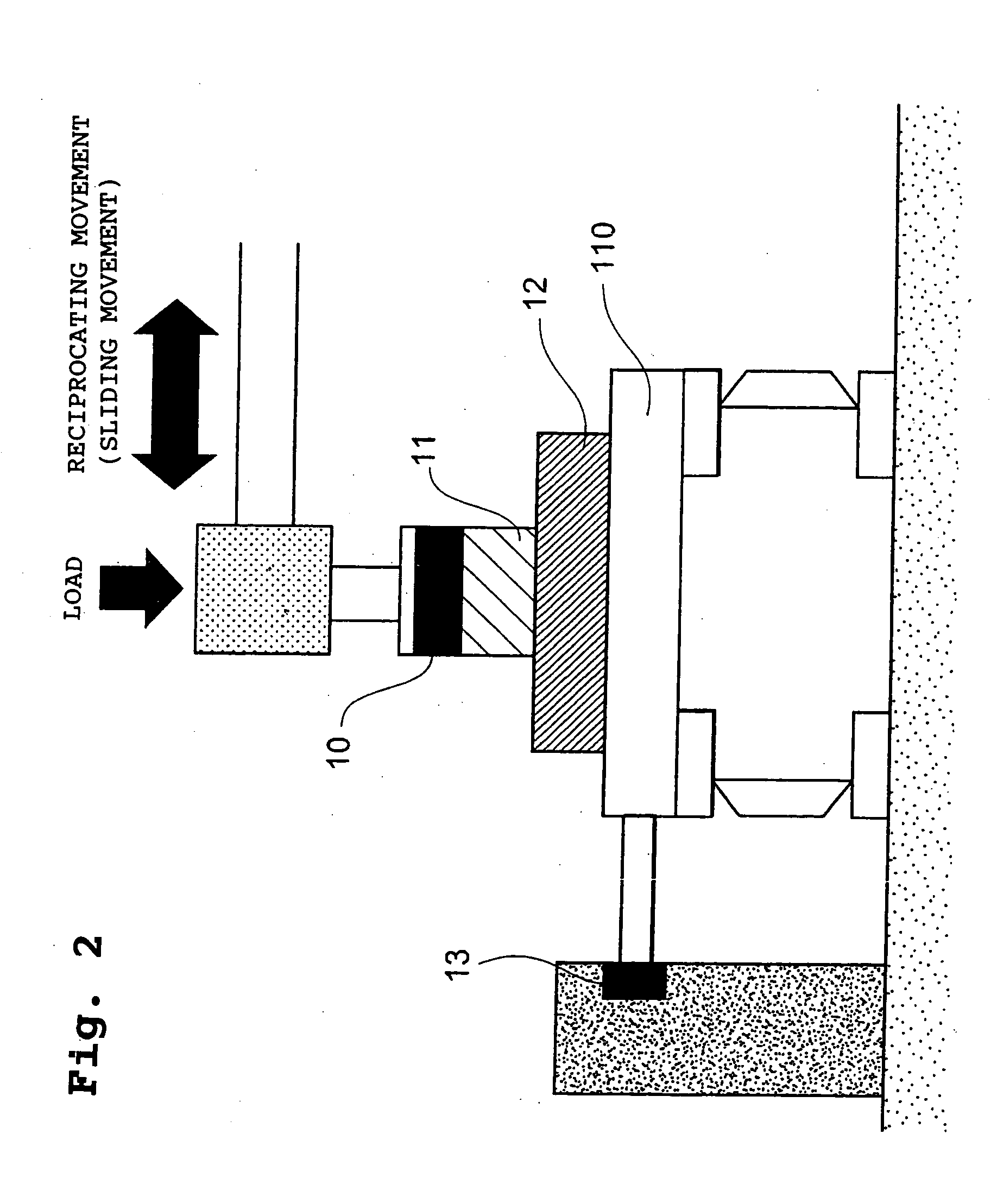

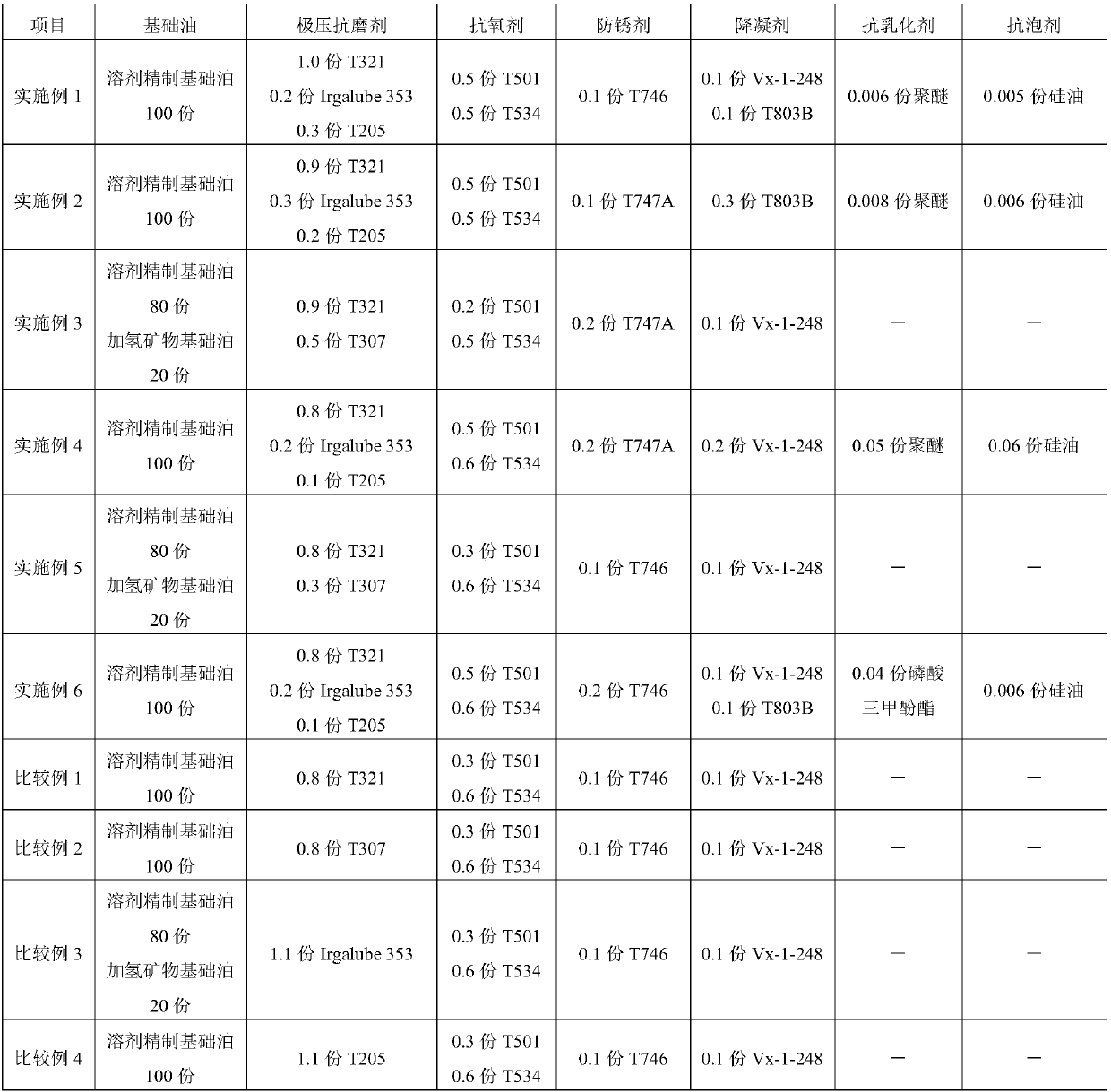

Lubricative Composition for Industrial Machinery and Equipment

InactiveUS20080058235A1Excellent in sludge resistance and extreme pressure propertyMaintain good propertiesGroup 5/15 element organic compoundsAdditivesViscosity indexCarboxylic acid

A lubricative composition for industrial machinery and equipment which comprises a base oil selected from among mineral oils, fats and oils, synthetic oils and mixture of two or more of them, and at least one additive selected from among the following components (A) to (D): component (A): (A-1) a phosphorus-containing carboxylic acid and / or (A-2) a thiophosphoric ester, component (B): a dispersant viscosity index improver, component (C): (C-1) a specific amidocarboxylic acid compound and / or (C-2) a specific carboxylic acid compound, and component (D): an ester oiliness improver. The composition is favorable as a lubricating oil composition and useful as a gear oil composition, a lubricating oil composition for paper machines or a lubricating oil composition for slide guides, a hydraulic oil, or the like.

Owner:NIPPON OIL CORP

Inhibiting corrosion caused by aqueous aldehyde solutions

Aldehydes useful as H2S sulfide scavengers may be corrosive to some metals such as steel, iron and aluminum, but the corrosive effect of the aldehydes may be mitigated by employing a corrosion inhibitor selected from the group consisting of a di-basic soluble phosphate salt, a tri-basic soluble phosphate salt, a phosphate ester, a thiophosphate ester, a thioamine, and combinations thereof.

Owner:BAKER HUGHES INC

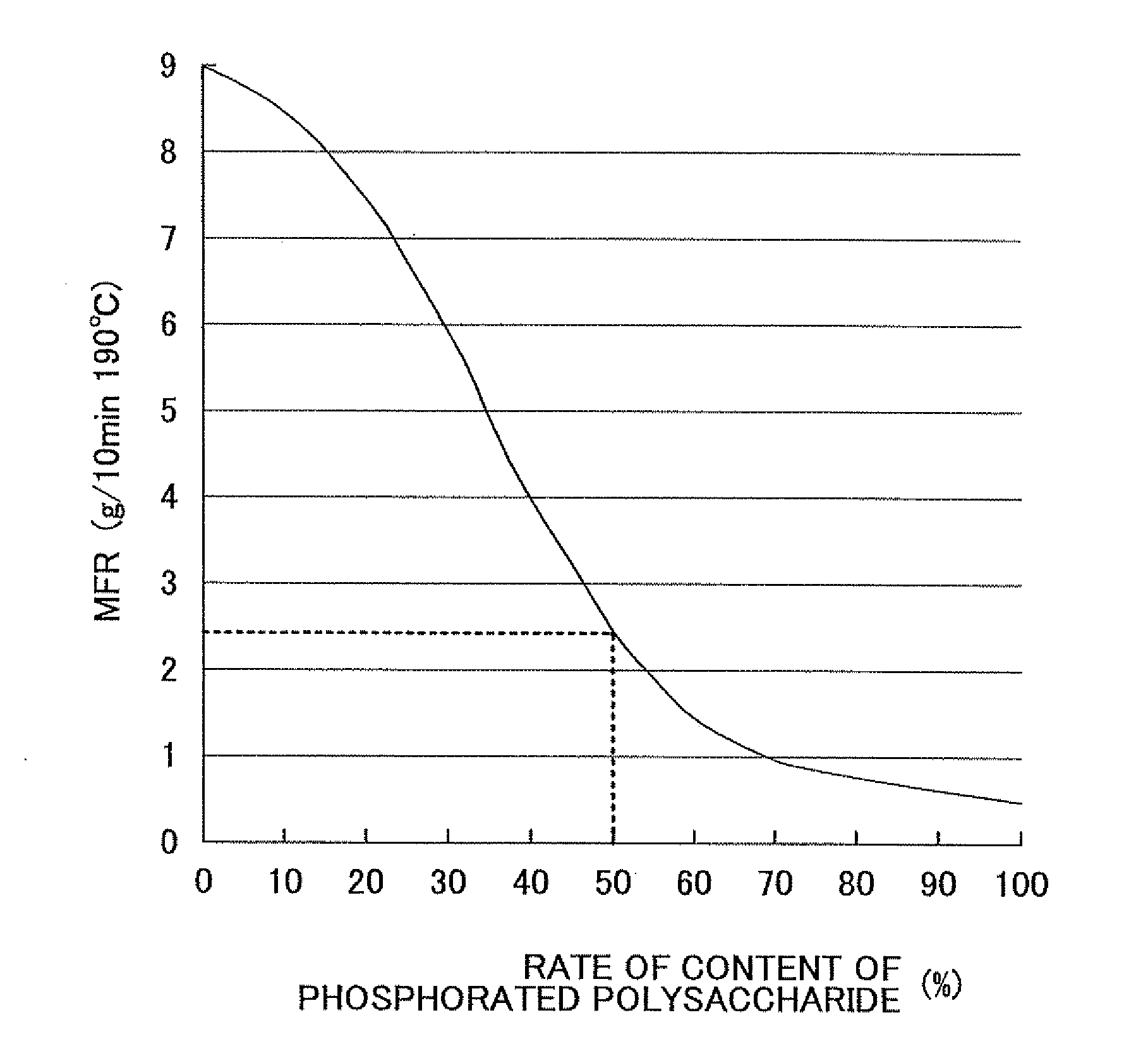

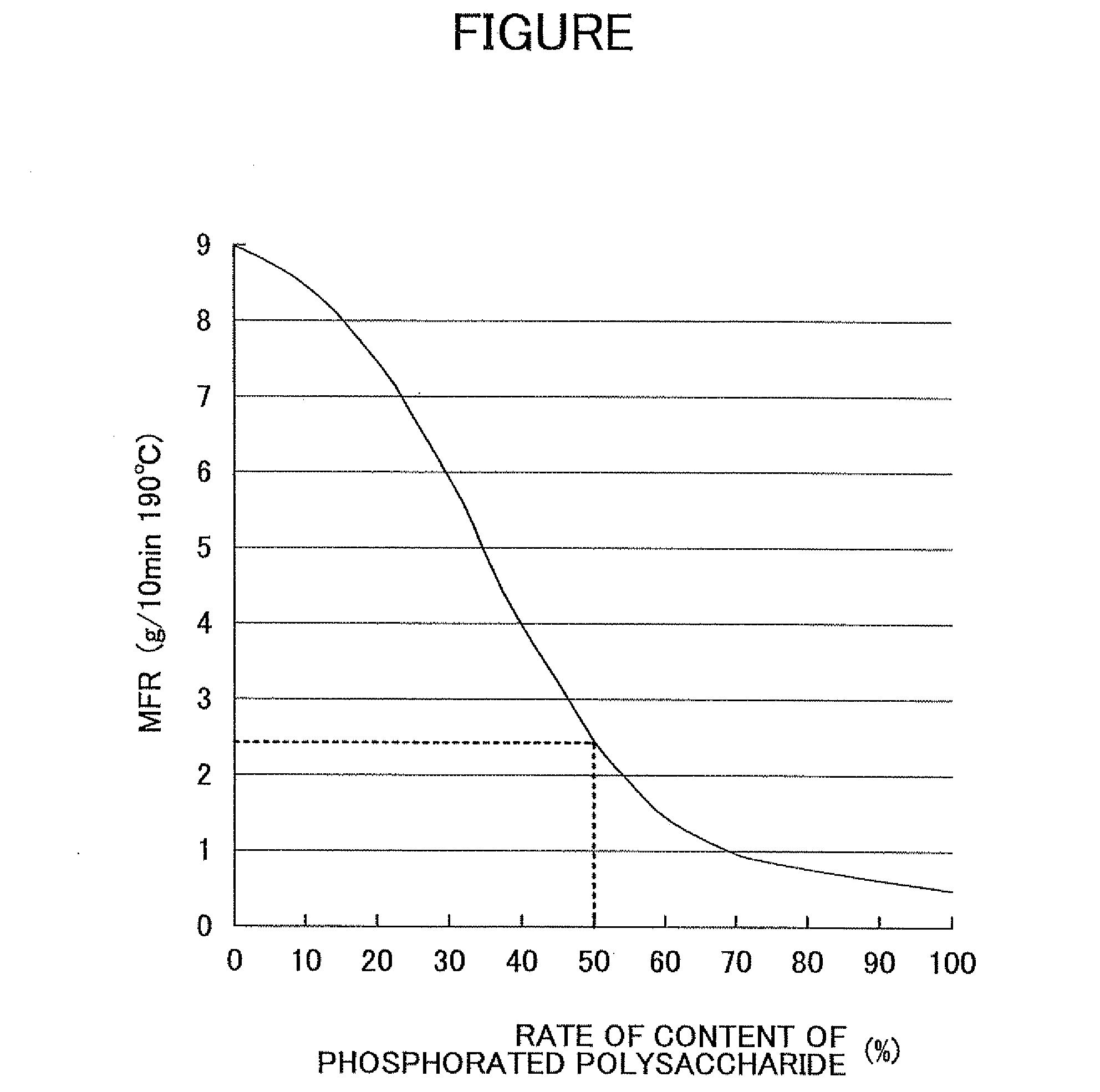

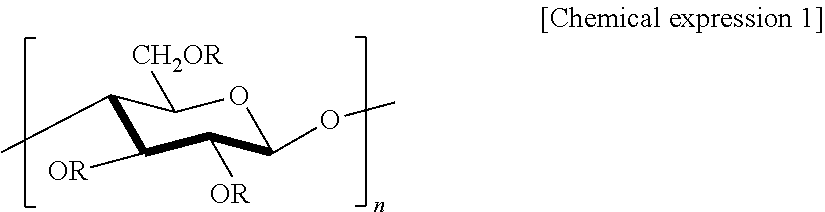

Fire retardant resin composition

InactiveUS20110105649A1Increase chanceReduce environmental impactIon-exchange process apparatusImpression capsPhosphoric Acid EstersSide chain

A disclosed fire retardant resin composition includes a thermoplastic resin and a fire retardant. The fire retardant is formed of phosphorated polysaccharide that is formed by attaching thiophosphoric acid ester or phosphoric acid ester to a side chain of natural polysaccharide.

Owner:RICOH KK

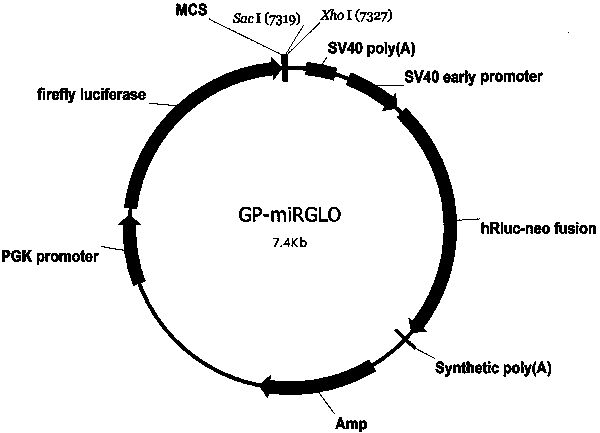

Small interfering nucleic acid, composition and application

ActiveCN111139242AEnhanced inhibitory effectSignificant clinical significanceOrganic active ingredientsGenetic material ingredientsSense strandRibose

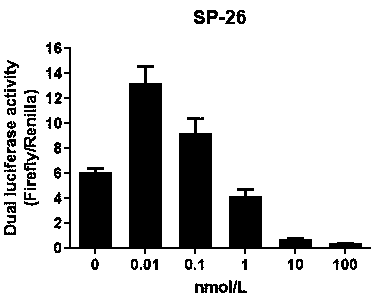

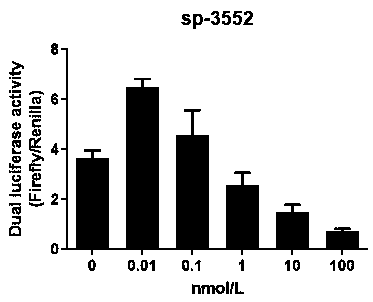

The invention discloses small interfering nucleic acid as well as a composition and application thereof. The invention claims to protect siRNA, which is PP-1758, PP-17660, PP-20091, PP-20163, SP-26, SP-179, SP-2013, SP-2867, SP-3169, SP-3552, MG-83, NP-208 or NP-241, wherein a part of nucleotides of the positive-sense strand are 2 '-O-methyl ribonucleotides, and a part of phosphate groups are thiophosphate groups. The invention provides brand new siRNA and a composition thereof. The brand new siRNA and the composition thereof can effectively prevent and / or treatment novel coronavirus.

Owner:SUZHOU GENEPHARMA

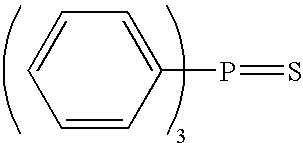

Polyurea-based grease additive composition

InactiveCN102504921AGood high temperature performanceImprove water resistanceLubricant compositionAntioxidantPolymethyl methacrylate

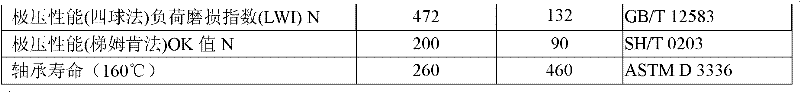

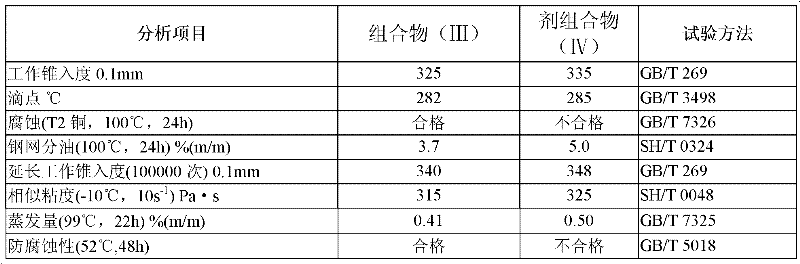

The invention relates to a polyurea-based grease additive composition. Components and percentage content of the polyurea-based grease additive composition are that: base oil is mineral oil and synthetic oil or blending oil of the mineral oil and the synthetic oil, and the content of the base oil is from 71% to 91.5%; a thickening agent is composed of a common reactant of isocyanate, fatty amine and alicyclic amine, and the content of the thickening agent is from 6% to 12%; an antioxidant uses amine antioxidants, and the total content of the antioxidant is from 0.5% to 3%; an extreme-pressure agent uses a mixture of sulfurized isobutylene, dialkyl group dithiophosphate and dialkyl group dithiocarbamic acid, and the total content of the extreme-pressure agent is from 0.5% to 5%; the content of an antirusting agent is from 0.5% to 3%; an antiwear agent is triphenyl thiophosphate and thiophosphoric acid ester or a mixture of the triphenyl thiophosphate and the thiophosphoric acid ester, and the total content of the antiwear agent is from 0.5% to 3%; and tackifier is polyisobutene and polymethyl methacrylate or a mixture of the polyisobutene and the polymethyl methacrylate, and the total content of the tackifier is from 0.5% to 3%. Due to the fact that appropriate raw material proportion is selected and used, grease has good high-temperature performance, a dropping point is higher than 260 DEG C, and the polyurea-based grease additive composition has a good water-resisting property, high and low temperature resistance and extreme pressure anti-wear performance, and can be applied to lubrication of each key running part of a continuous casing machine.

Owner:CHINA PETROLEUM & CHEM CORP

Oil film bearing lubricating oil with high water separation performance

The invention relates to an oil film bearing lubricating oil with high water separation performance. The invention is characterized in that the oil film bearing lubricating oil comprises the following materials of: bi-polyisobutene succimide, phytic acid, 6-tert-butyl-3-methyl phenol, triphenyl thiophosphate, dialkyl pentasulfide, triazole octadecylamine salt, di(2, 4-ditert-butyl phenyl) pentaerythritol biphosphite ester, butyl isooctylphosphate laurylamine salt, dodecene hydrocarbon butane diacid, oxozone trimethylene derivates of amine, petroleum acid polyether ester, polyacrylic ester, oil-soluble polyether macromolecular compound, bisphenyl propyl dimethyl siloxane and base oil. The product has excellent water separation performance and good extreme-pressure abrasion resistance, and can meet the special requirements of working conditions of humidity and wateriness.

Owner:CHINA PETROLEUM & CHEM CORP

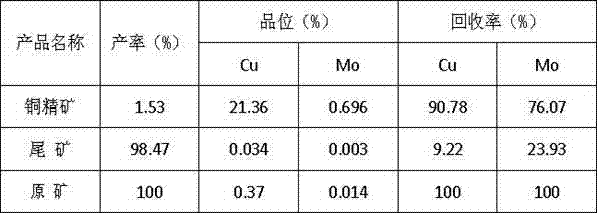

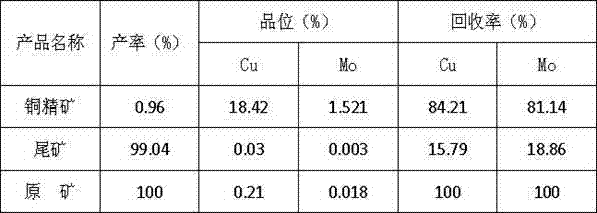

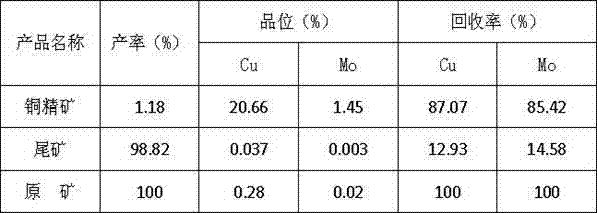

Composite collecting agent for bulk floatation of copper sulfide molybdenum ores

The invention discloses a composite collecting agent for bulk floatation of copper sulfide molybdenum ores. The collecting agent is a stable oily product which is formed by mixing 50%-70% of thiocarbamic acid ester, 2%-10% of thiophosphoric acid ester, 10%-30% of mixed non-polar hydrocarbon oil and 10%-20% of terpene alcohol. The collecting agent has the advantages that the thiocarbamic acid ester has the selective chelation on the exposing active points, such as copper and molybdenum, on the surfaces of minerals, the thiophosphoric acid ester has the selective adsorption function on the copper-containing minerals, the non-polar hydrocarbon oil can be adsorbed on the surface of the copper sulfide molybdenum ores through the Van der Waals force, and the terpene alcohol is a solution medium and has good air bubble property, so under the synergistic effect of the thiocarbamic acid ester, the thiophosphoric acid ester, the mixed non-polar hydrocarbon oil and the terpene alcohol, a good ore selection index can be obtained, and the agent mechanism is simplified; the collecting agent is used at the ore slurry temperature of 5-35 DEG C, and the usage amount is between 80-160g / t according to the change of the contents of usable minerals in the ores.

Owner:KUNMING METALLURGY INST

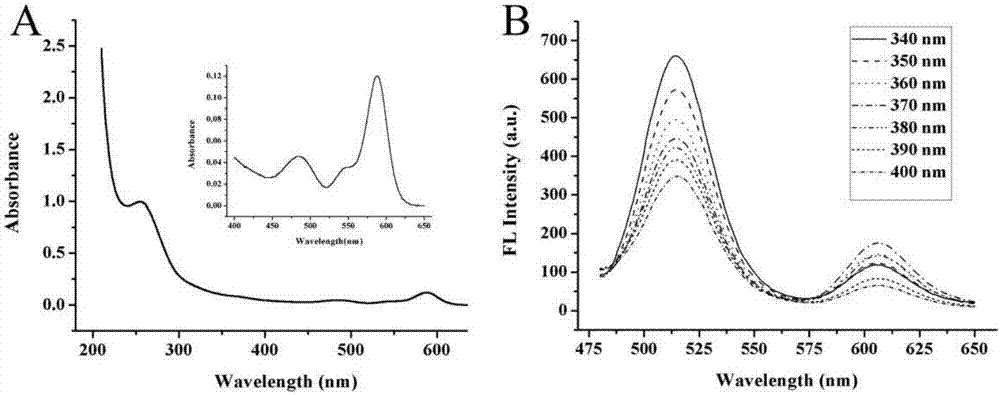

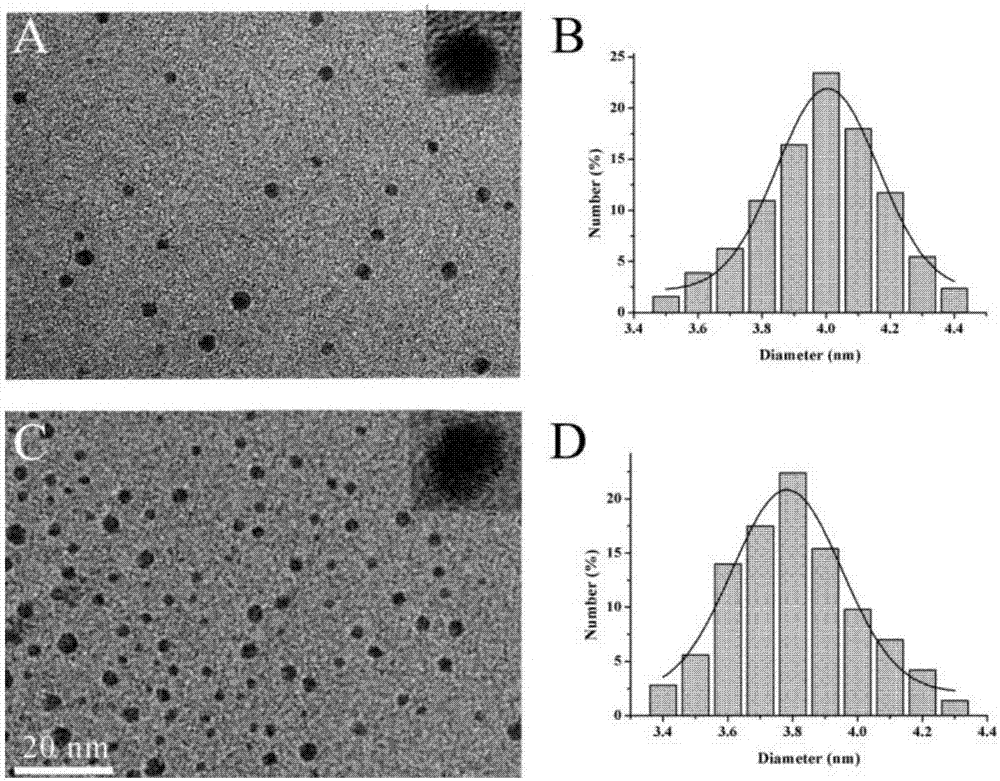

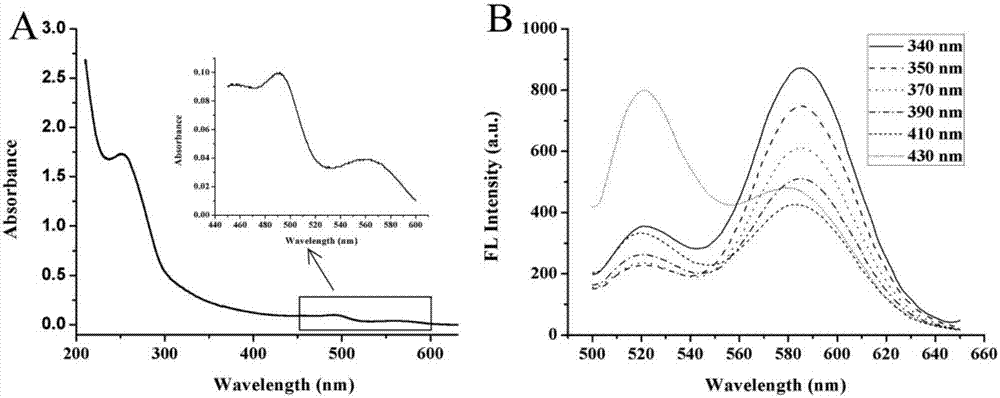

Method for synthesizing dye modified DNA (Deoxyribonucleic Acid) functionalized cadmium-containing quantum dots and application of quantum dots

ActiveCN107353903AThe synthesis method is simpleEasy to synthesizeMicrobiological testing/measurementFluorescence/phosphorescenceTumor targetTumor targeting

The invention discloses a method for synthesizing dye modified DNA (Deoxyribonucleic Acid) functionalized cadmium-containing quantum dots and an application of the quantum dots. According to the quantum dots, DNA, of which one end is modified with a dye and the other end is modified with thiophosphate, is connected to surfaces of the quantum dots through strong interaction between sulfur and cadmium. During the synthesis of the quantum dots, the dual-modified DNA is added as a co-stabilizer of the quantum dots so as to obtain a quantum dot probe. The quantum dot probe has extensive use in the aspect of ratio fluorescence, can be used for achieving accurate detection on nucleic acids, proteins, micromolecules and metal ions and has an important application value in the aspects of DNA hybridization and nano-material self-assembly. Meanwhile, as a whole body, the probe can be applied to the aspects of cell recognition, tumor targeted detection and the like as a fluorescence imaging probe. Compared with other dual-fluorescence-emission nano-materials, the probe has the advantages that the preparation method is simple, chemical modifications such as coupling are not required, and the probe has considerable advantages in the aspects of synthesis and purification processes, stability and other properties.

Owner:WUHAN UNIV

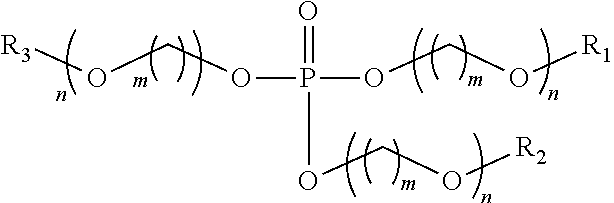

Lubricant composition

InactiveUS20090016652A1Improve efficiencyPrevent penetrationOrganic chemistryBearing componentsHigh concentrationThiocarbamate

The lubricant composition of this invention comprises a base oil and an additive, which is at least one selected from the group consisting of an organic sulfonate, a carboxylate, a thiocarbamate and a thiophosphoric acid ester salt. The lubricant composition can effectively suppress hydrogen embrittlement-caused flaking of an element, such as a rolling bearing, a sliding bearing, a gear, a ball thread, a linear guide, a linear bearing, a cam and various joints in a high concentration hydrogen environment. The invention provides also a rolling bearing, a sliding bearing, a gear, a ball thread, a linear guide, a linear bearing, a cam and various joints using the lubricant composition.

Owner:KYODO YUSHI CO LTD

Environment-friendly type lubricating oil additive

InactiveCN104974825AImprove wear resistanceImprove extreme pressure performanceAdditivesToluidineActive agent

An environment-friendly type lubricating oil additive is composed of the following raw materials in parts by weight: 7 to 12 parts of castor oil polyoxyethylene ether, 3 to 6 parts of molybdenum disulfide colloid, 2 to 7 parts of n-octadecanoic acid, 4 to 8 parts of critic acid, 6 to 13 parts of molybdenum dialkyldithiophosphate, 4 to 8 parts of butyl oleate, 3 to 6 parts of tackifier, 5 to 8 parts of o-toluidine / m-toluidine, 6 to 8 parts of methyl citrate, 4 to 7 parts of triphenyl phosphorothionate, 6 to 12 parts of sulfurized isobutylene, 5 to 8 parts of benzotriazole amine, 2 to 6 parts of n-butyl acetate, 1 to 4 parts of p-methoxyl styrene, 8 to 16 parts of linoleic acid, 4 to 6 parts of methanol, 7 to 13 parts of polyethylene glycol monomethyl ether, 4 to 7 parts of magnesium silicate, and 4 to 6 parts of fluorine surfactant. The provided environment-friendly type lubricating oil additive can improve the wear-resistant performance, extreme pressure resistant performance, and oxidation resistant performance of lubricating oil, has the advantages of convenient operation and environment-friendliness, and is according with the green and environment-protection requirements.

Owner:QINGDAO WENSHENG AUTOMOBILE COMPONENTS & PARTS

Preparation method of functional lubricating oil

ActiveCN103897772AImprove dispersion stabilityImprove anti-friction and anti-wear propertiesAdditivesHydration reactionThio-

The invention discloses a preparation method of functional lubricating oil, which comprises the following steps: 1) respectively dissolving zinc acetate and thioacetamide into water to prepare solutions; 2) carrying out hybrid reacting of the zinc acetate solution and the thioacetamide solution with dialkyl phosphorodithioate and hydrazine hydrate, and separating, washing and drying the obtained precipitate to obtain the nanometer zinc sulfide modified by the dialkyl phosphorodithioate; 3) stirring and mixing nanometer molybdenum disulfide and nanometer borate with a coupling agent to obtain the coupling agent modified nanometer composite powder; and 4) adding the nanometer zinc sulfide modified by the dialkyl phosphorodithioate obtained in the step 2) in base oil, adding the coupling agent modified nanometer composite powder obtained in the step 3) in the base oil, and successfully blending to obtain the lubricating oil. The functional lubricating oil disclosed by the invention is excellent in antifriction and abrasive resistance, high in bearing capacity, and has a repairing function on the abraded surface.

Owner:DEVON ENERGY CORP

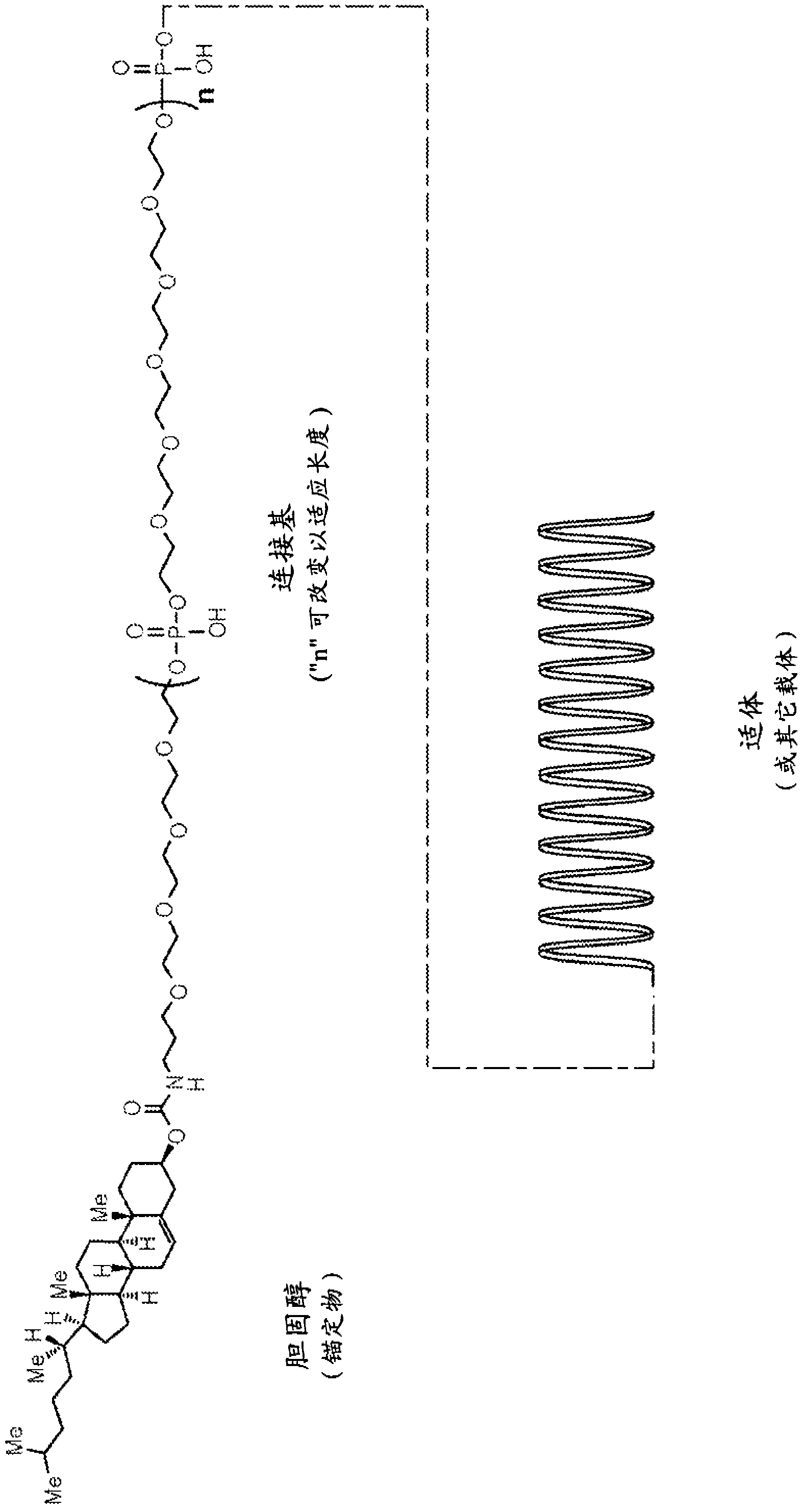

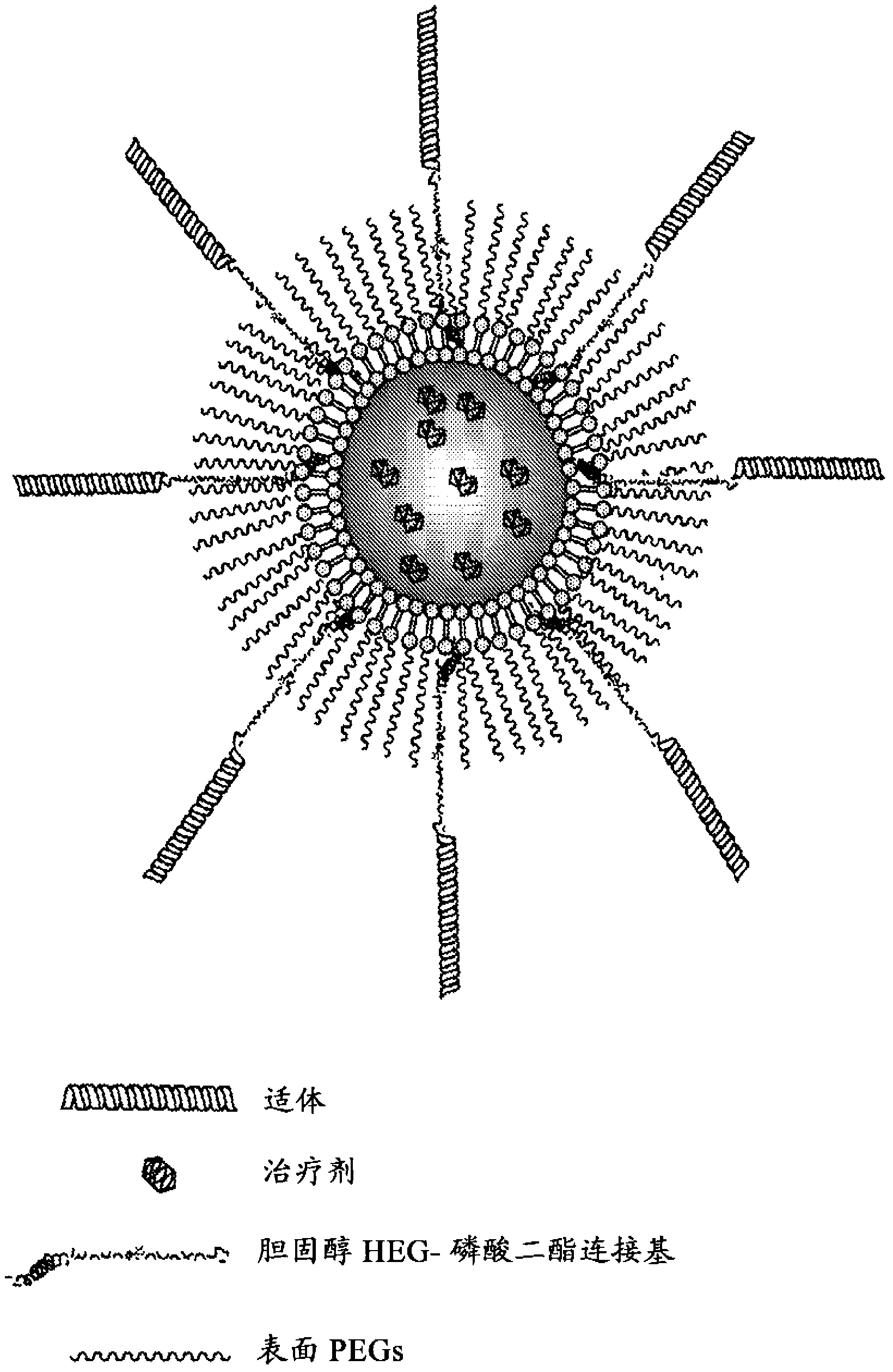

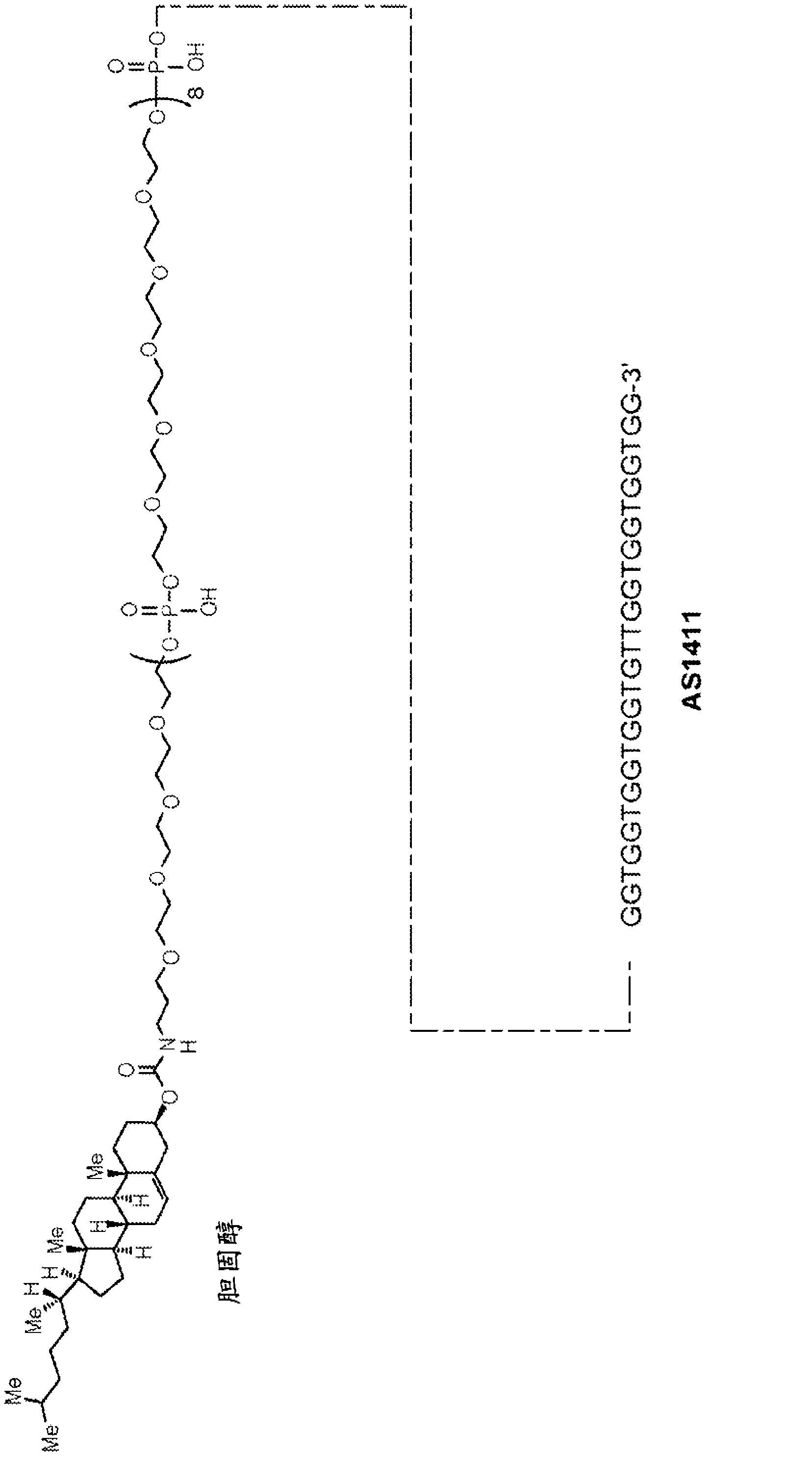

Aptamer conjugates for targeting of therapeutic and/or diagnostic nanocarriers

InactiveCN103269722AEasy to synthesizeComposite autoRadioactive preparation carriersNMR/MRI constrast preparationsDiseaseNanocarriers

Owner:MALLINCKRODT INC

Lubricating oil composition

The present invention relates to a lubricating oil composition comprising lubricating oil base oil in combination with: (a) one or more substituted phenyl -naphthylamines; (b) one or more anti-wear additives, preferably ashless thiophosphates ; and (c) an additional base oil component selected from bright stock oil, polyalkylene glycols (PAGs) , alkyl naphtalenes, alkyl benzenes and natural and synthetic esters such as diesters and polyolesters, preferably bright stock oil. In another aspect the present invention provides the use of the lubricating oil composition to lubricate a combination of a gas turbine and a steam turbine.

Owner:SHELL INT RES MAATSCHAPPIJ BV

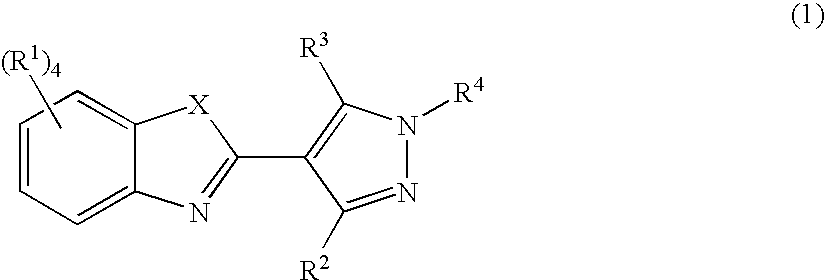

Pyrazolylbenzothiazole derivatives and their use as therapeutic agents

Pharmaceutical pyrazolybenzothiazole compositions of formula (1) are provided. The compositions may be pharmaceutically acceptable salts. R1, R2 and R3 at each occurrence are independently selected from amino, aminosulfinyl, aminosulfonyl, aryl, azido, halogen, heteroalkyl, heteroaryl, hydrazinyl, hydrocarbyl, hydrogen, hydroxyl, nitro, nitroso, phosphate, phosphinate, phosphonate, phosphonium, phosphorothioate, phosphoryl, sulfamoyl, sulfate, sulfinic acid, sulfonamido, sulfonate, sulfonic acid, sulfonyl, sulfoxido, thiol, thioureido, and ureido, and R4 is selected from hydrogen, heteroalkyl, heteroaryl, and hydrocarbyl.

Owner:DERMIRA CANADA

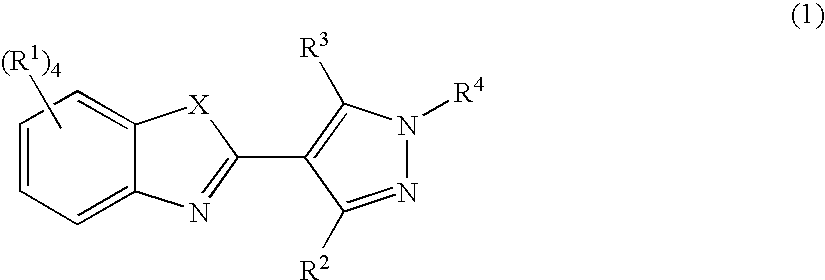

Specific marking method for 5-hydroxymethyluracil on DNA (deoxyribonucleic acid)

ActiveCN111088252AAvoid errorsAccurate identificationMicrobiological testing/measurementDNA/RNA fragmentationChemical reactionThio-

The invention discloses a specific marking method for 5-hydroxymethyluracil on DNA (deoxyribonucleic acid) and belongs to the technical field of molecular biology. The specific marking method comprises the following steps: transferring gamma-thiophosphate to 5-hmU from 5-O-thiotriphosadenine by using 5-hmU separated from bacteriophage M6 of pseudomonas aeruginosa so as to generate 5-thiophosphoricacid methyluracil, representing the generated 5-thiophosphoric acid methyluracil by using a liquid chromatogram-tandem mass spectrometry method, and marking sulfydryl through crosslinking chemistry,so as to achieve specific marking on 5-hydroxymethyluracil on DNA. By adopting the method disclosed by the invention, defects that a great amount of detection samples are needed, chemical reaction conditions are harsh, the reaction efficiency is low, and the like, can be effectively overcome.

Owner:XI AN JIAOTONG UNIV

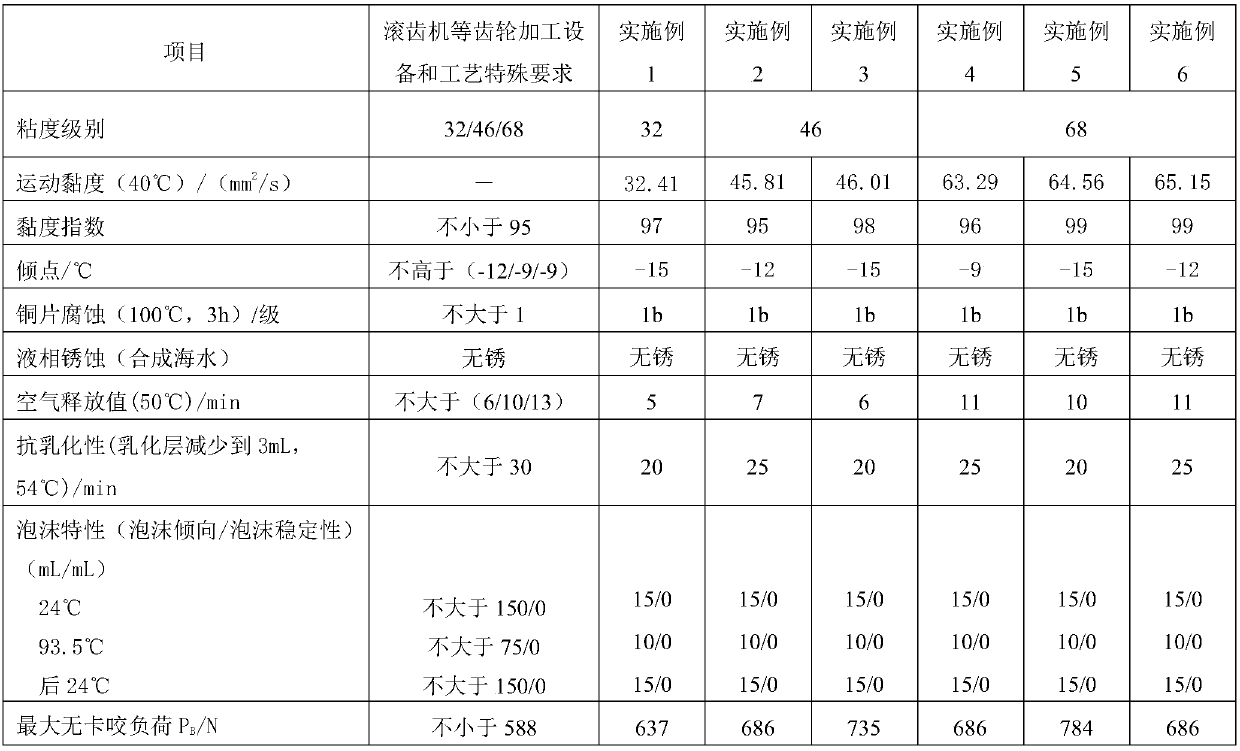

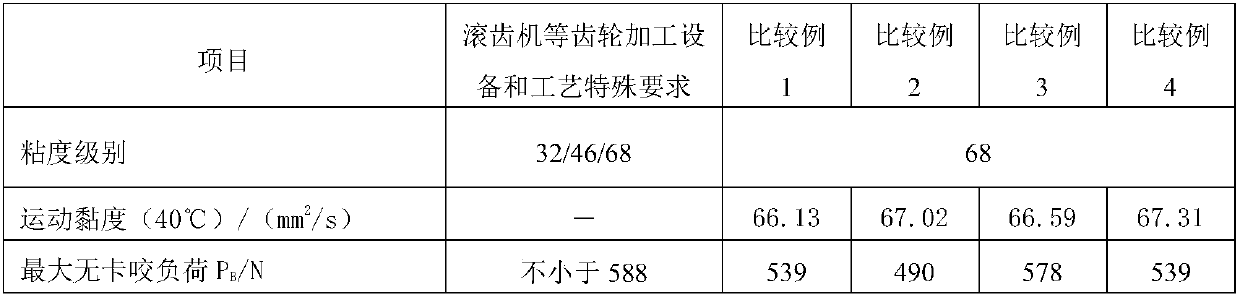

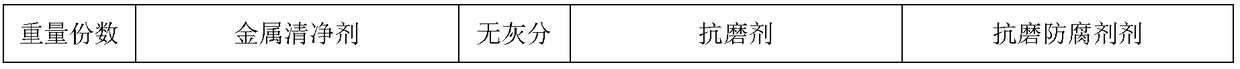

Special oil composition for gear hobbing machine and application of special oil composition

InactiveCN107603708AMeet the higher requirements of processing special working conditionsImprove compatibilityLubricant compositionHobbingPhosphate

The invention relates to special oil composition for a gear hobbing machine and an application of the special oil composition, and mainly solves the problems that hydraulic oil is polluted after leakoil enters a hydraulic system due to poor compatibility between oil for the gear hobbing machine and the hydraulic system of equipment and a tool is not protected ideally as a result of insufficient lubrication property of oil products in the prior art. The oil composition is prepared from the following components in parts by weight: a) 100 parts of mineral base oil, b) 0.1-10 parts of extreme-pressure anti-wear agent, c) 0.1-1.0 part of a pour point depressant, d) 0.01 to 0.5 parts of a rust inhibitor and e) 0.01 to 2.0 parts of an antioxidant; the extreme-pressure anti-wear agent is a mixture of at least one of sulfurized olefin, phenyl sulfide, sulfurized aliphatic acid ester or chlorinated paraffin and at least one of thiophosphoric acid diester amine salt, phosphate amine salt, phosphorothioate, zinc dialkyldithiophosphate salt or a derivative of the zinc dialkyldithiophosphate salt. With adoption of the technical scheme, the problems are better solved, and the extreme pressure anti-wear agent can be used in industrial production of the special oil composition for the gear hobbing machine.

Owner:CHINA PETROLEUM & CHEM CORP

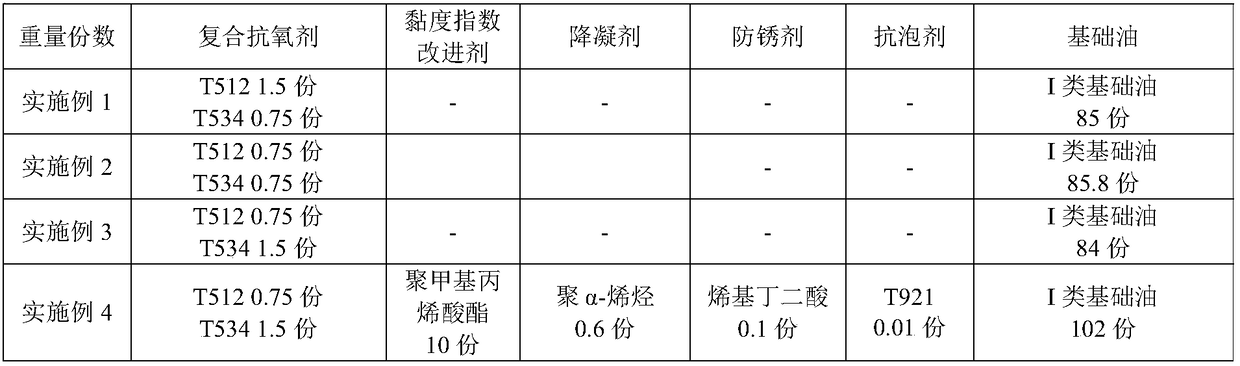

Diesel engine oil composition and application thereof

The invention relates to a diesel engine oil composition and application thereof, and mainly solves the problems of insufficient anti-wear and extreme pressure performance of internal combustion engine oil in the prior art. The diesel engine oil composition comprises the following components by weight: a) 2-5 parts of a metal detergent, which is formed by compounding a sulfonate and sulfurized alkyl phenolate; b) 1-5 parts of a polyisobutylene succinimide ashless dispersant; c) 1-3 parts of an anti-wear preservative, which is formed by compounding long chain primary alcohol based zinc dialkyldithiophosphate and primary alcohol based zinc dialkyl dithiophosphate; d) 0.5-3 parts of a composite antioxidant, which is formed by compounding an amine type antioxidant and a phenolic ester antioxidant; e) 0.5-3 parts of an antiwear agent, which is one of or compounded by several of phosphorothioates, thiocarbamates and antimony thiocarbamate; and f) 85-105 parts of base oil. The technical scheme adopted by the invention well solves the problems, and can be used in a vehicle diesel engine system.

Owner:CHINA PETROLEUM & CHEM CORP

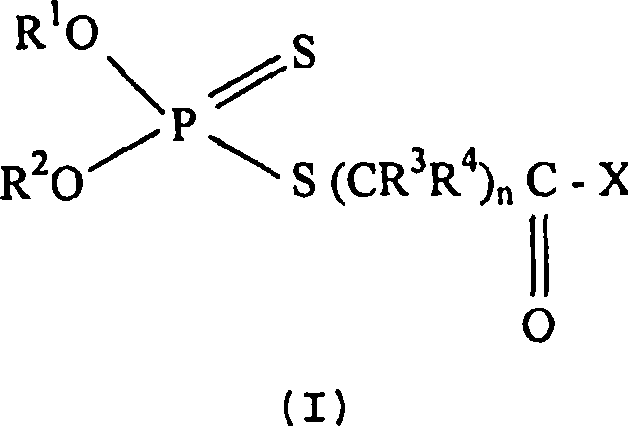

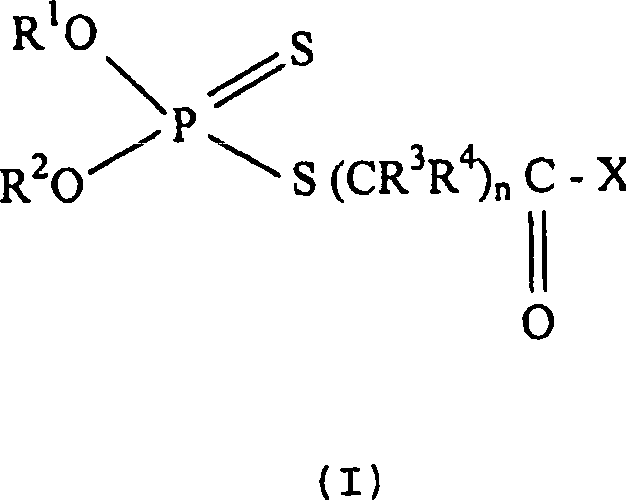

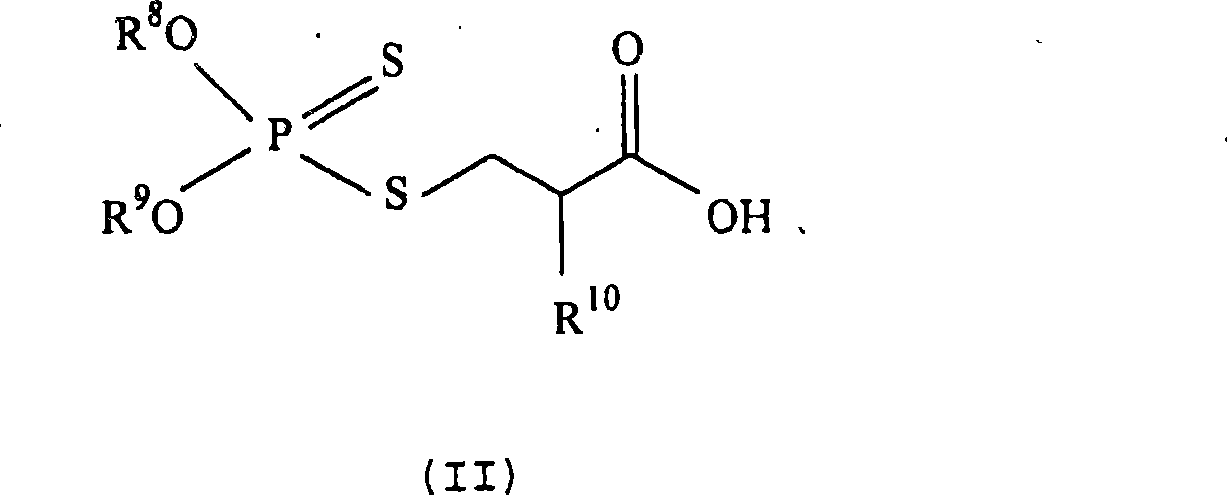

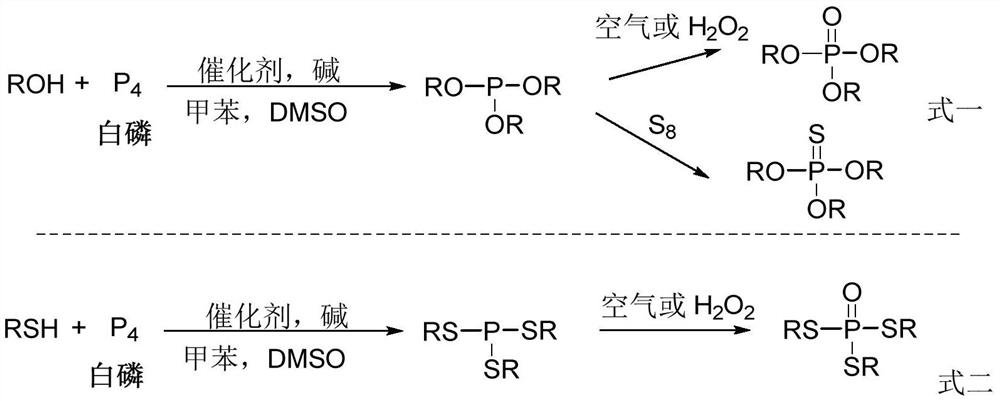

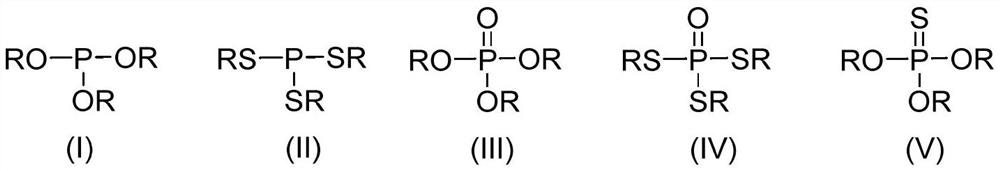

Method for preparing phosphate ester derivatives from white phosphorus

ActiveCN113004323ALower reaction costHigh yieldGroup 5/15 element organic compoundsPhosphoric Acid EstersPtru catalyst

A method for preparing phosphate ester derivatives from white phosphorus relates to the field of chemical engineering, and comprises the following steps: adding alkali, a catalyst, a white phosphorus solution, ROH or RSH (R represents alkyl or aromatic group) into a reaction container in an inert atmosphere, and heating and stirring the mixture in a mixed solvent of toluene and DMSO (dimethyl sulfoxide) to react for a certain time, so as to obtain three-coordinated phosphate ester derivatives; and 2) continuing to add H2O2, air or sulfur powder until the oxidation is completed, thereby obtaining the tetra-coordinated phosphate ester derivative. According to the method, chlorine, phosphorus trichloride and halogen are not needed, phosphite ester is directly prepared from elementary white phosphorus in an efficient, green and environment-friendly manner, and phosphate and thiophosphate can be directly prepared after oxidation. High pollution and high corrosivity of a traditional method are avoided in the whole process; meanwhile, white phosphorus is completely converted in the whole process, white phosphorus residues are avoided, and the post-reaction treatment process is safe.

Owner:XIAMEN UNIV

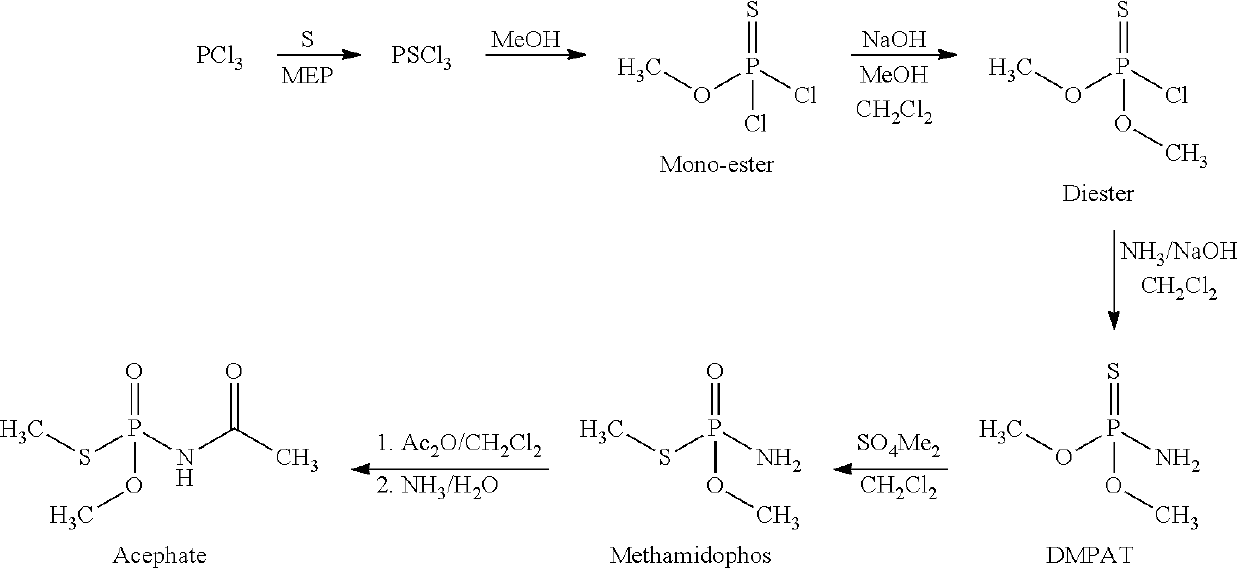

Process for preparation of o, o-dimehyl phosphoramidothioate and n-(methoxy-methylsulfanylphosphoryl) acetamide

ActiveUS20200024293A1BiocideGroup 5/15 element organic compoundsPhosphoric Acid EstersAcetic anhydride

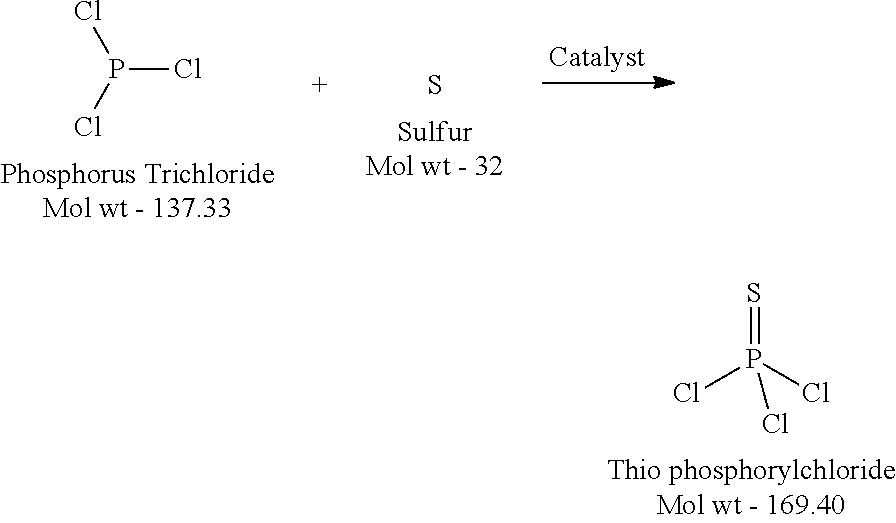

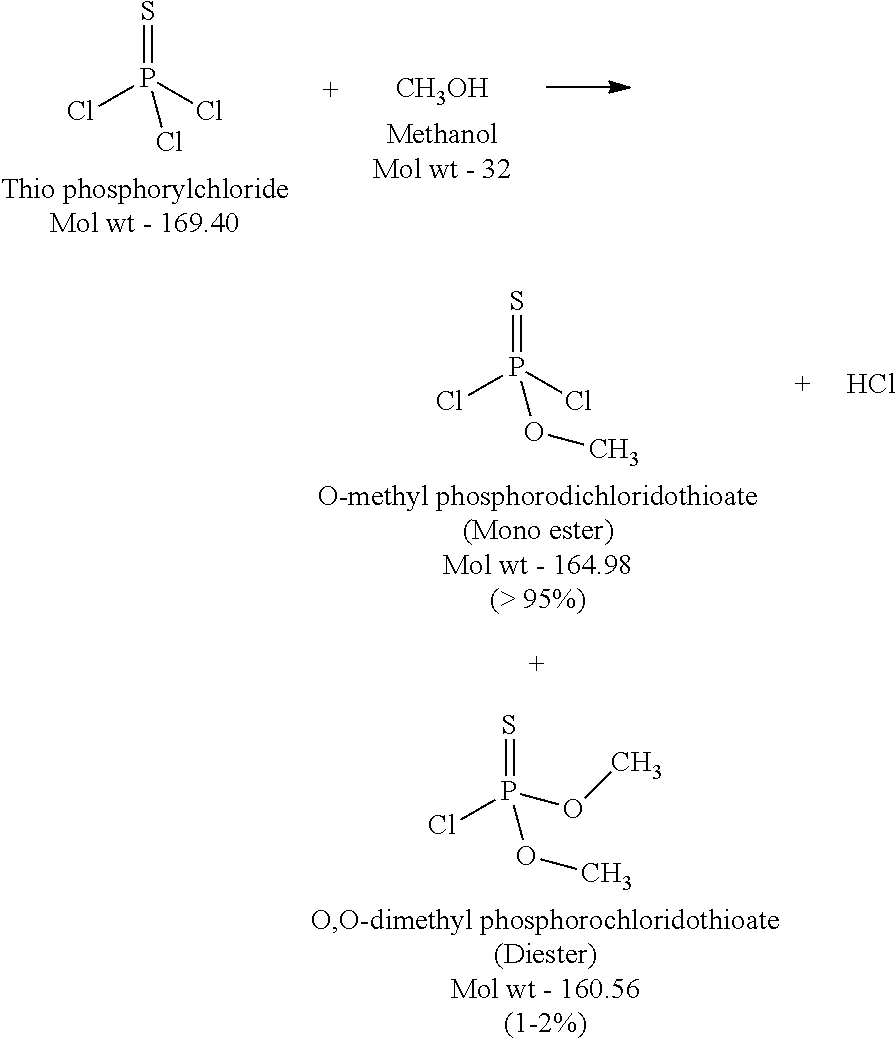

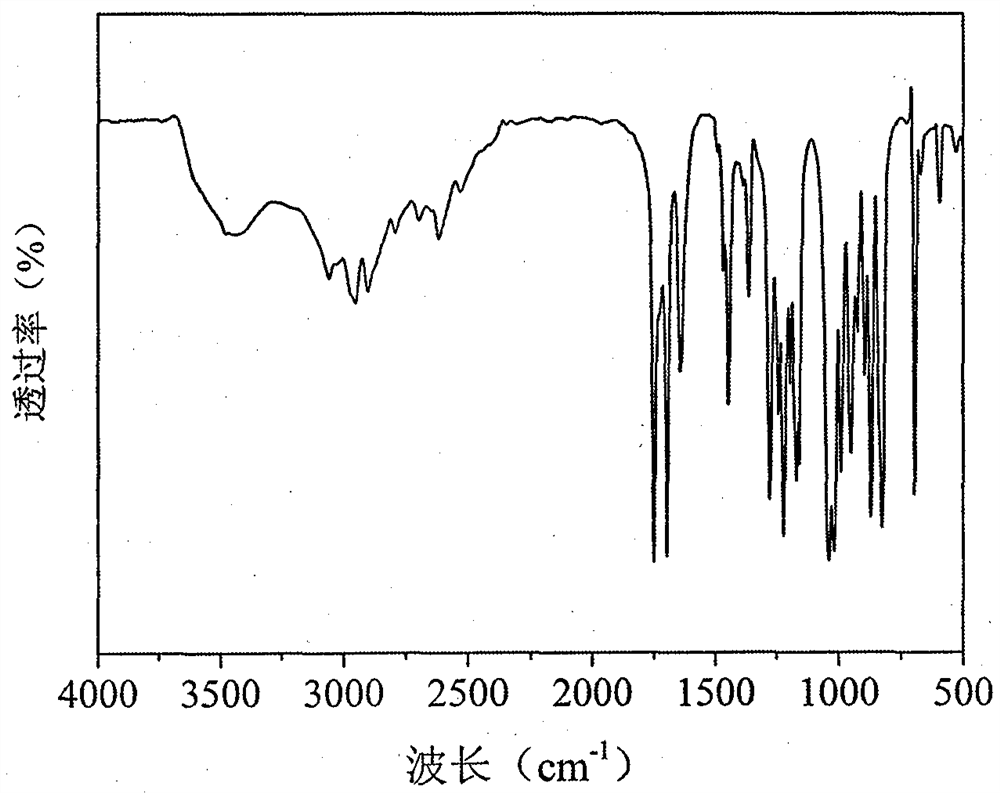

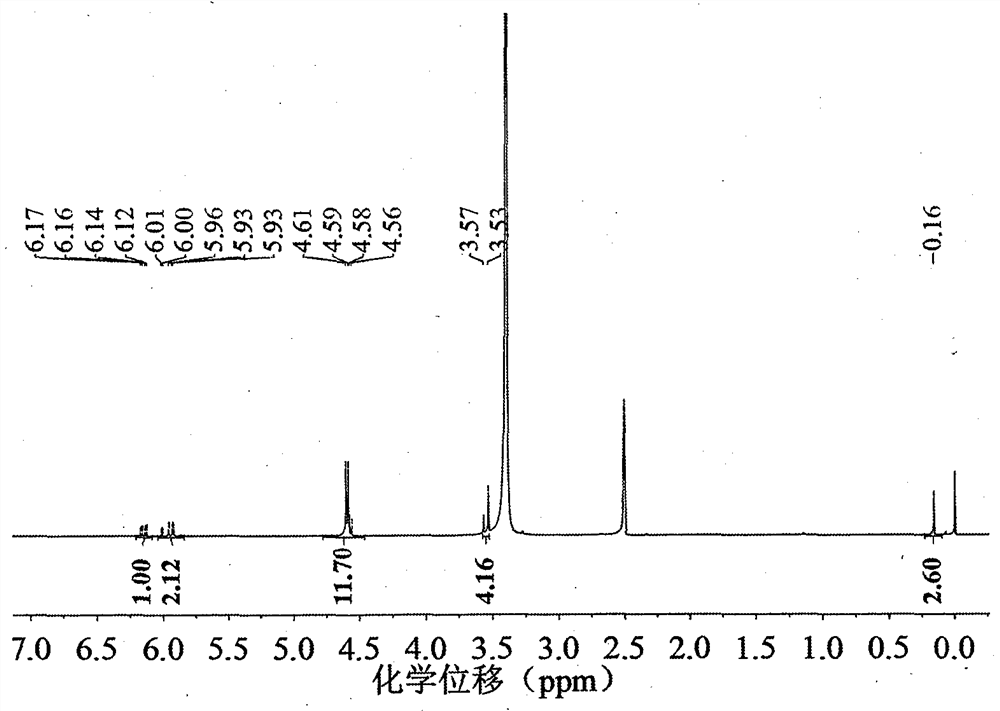

Preparation of O,O-dimethyl phosphoramidothioate and O,O-dimethyl phosphoroamidothioate. A process of making O,O-dimethyl phosphoroamidothioate is described including reacting sulfur with PCl3 to form PSCl3, reacting the PSCl3 formed with methanol to form O-methyl phosphorodichloridothioate, and reacting the O-methyl phosphorodichloridothioate formed with methyl lye to form O,O-dimethyl phosphorochloridothioate in solution in CH2Cl2, and reacting the O,O-dimethyl phosphorochloridothioate formed with sodium hydroxide and ammonium hydroxide to form O,O-dimethyl phosphoroamidothioate in solution in CH2Cl2. Reacting the O,O-dimethyl phosphoroamidothioate formed with catalytic dimethyl sulfate to form methamidophos, and reacting the methamidophos formed with acetic anhydride to form N-(methoxy-methylsulfanylphosphoryl) acetamide is also described. Throughout the process, the O,O-dimethyl phosphorochloridothioate and the O,O-dimethyl phosphoroamidothioate formed are maintained in solution in CH2Cl2 at all times.

Owner:ARYSTA LIFESCIENCE INC

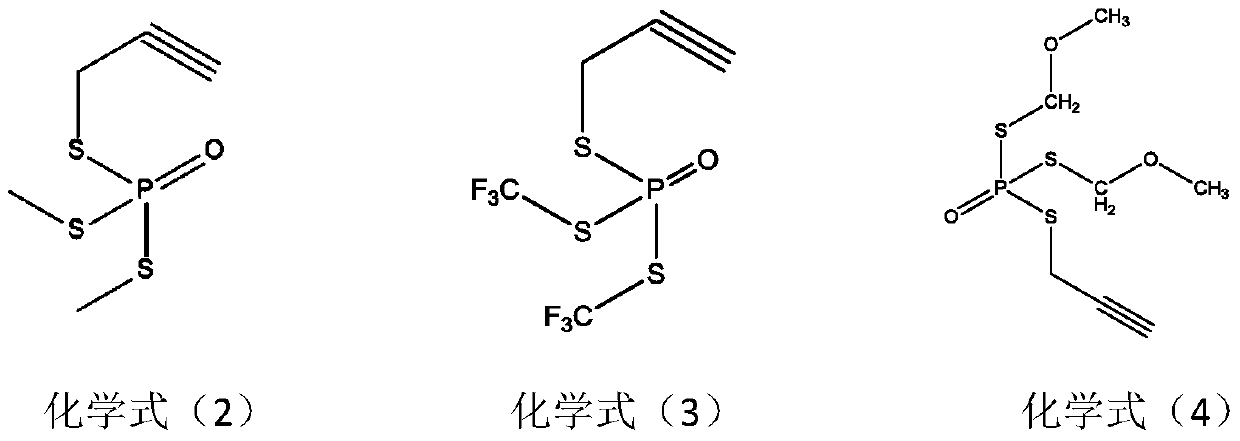

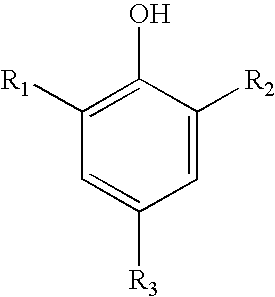

Reactive flame retardant vinyl organosilicon caged thiophosphate compound, and preparation method and application thereof

PendingCN112279873AGood symmetry of the cage ring structureGood char formationGroup 5/15 element organic compoundsEpoxyPolyester

Owner:SUZHOU UNIV OF SCI & TECH

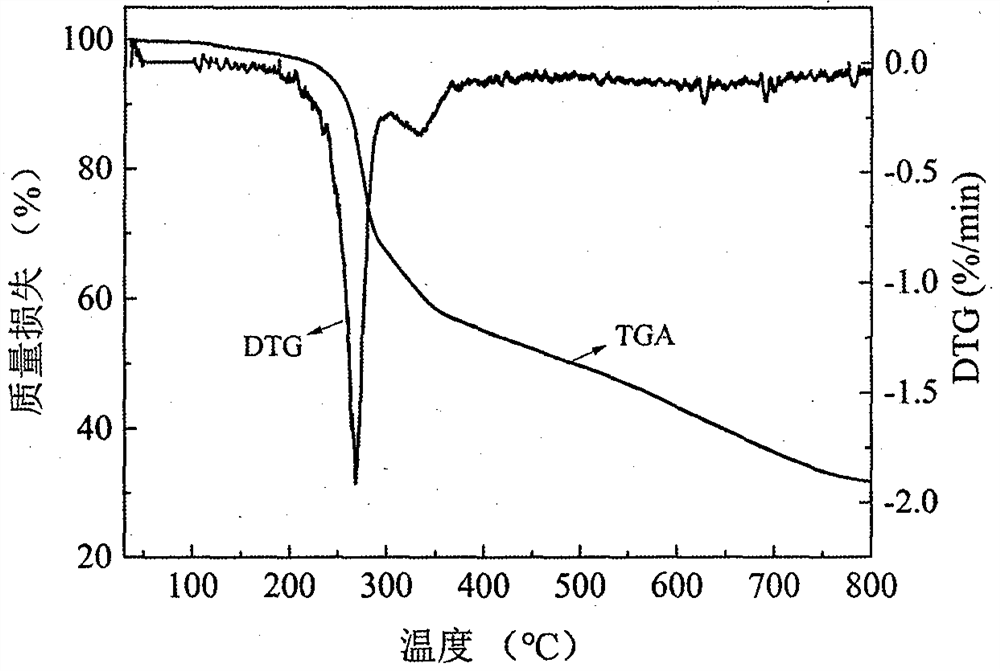

High-temperature lithium ion battery electrolyte and lithium ion battery

ActiveCN111048837AImprove high temperature performanceDoes not degrade low temperature performanceSecondary cellsOrganic electrolytesElectrolytic agentPhosphoric Acid Esters

The invention relates to a high-temperature lithium ion electrolyte and a battery containing the electrolyte. The electrolyte comprises an additive A, wherein the additive A is a thiophosphate compound containing alkynyl; different from common unsaturated phosphate ester at present, only one triple bond is reserved in the compound, and oxygen atoms are replaced by sulfur of the same group so thatthe impedance formed when the compound participates in positive electrode film formation is relatively small, the low-temperature performance of the battery is not influenced, and the compound has a lower oxidation potential and the compound is more easily oxidized at the positive electrode to participate in film formation, the damage effect of the electrolyte on the positive electrode at high temperature is prevented and the purpose of improving the high-temperature performance is achieved.

Owner:余姚市海泰贸易有限公司

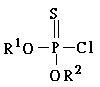

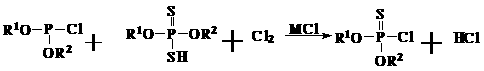

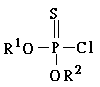

Waste residue-free preparation method of O,O-dialkyl thiophosphoryl chloride

InactiveCN103304596ASimple process routeMild reaction conditionsGroup 5/15 element organic compoundsPhosphorous acidMetal chloride

The invention discloses a waste residue-free preparation method of O,O-dialkyl thiophosphoryl chloride, which is characterized by comprising the following steps: by taking dialkyl chlorophosphite as an intermediate, performing chlorination with O,O-dialkyl phosphorodithioate under the effect of strong Lewis acid metal chloride to prepare O,O-dialkyl thiophosphoryl chloride with the structural general formula shown in the specification, wherein the chemical equation is shown in the specification. The method for preparing high-content O,O-dialkyl thiophosphoryl chloride, disclosed by the invention, has the advantages of simple process route, mild reaction conditions, simple after-treatment and low production cost, and is convenient for industrial transformation; and the method avoids or reduces pollution, strictly controls the process, saves after-treatment and prevents the generation of viscose waste sulfur residues.

Owner:秦小林

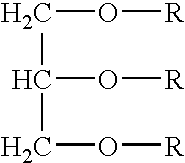

Vegetable Oil Lubricating Composition

A lubricating composition includes, in weight %, at least 90 percent of a vegetable oil, and an additive composition including:(a) about 1.5 to 2 percent triphenylphosphorothionate (TPPT),(b) about 0.1 to 3 percent hindered phenolic antioxidant,(c) about 0.05 to 0.25 percent 1-[di(phenyl)aminomethyl]tolutriazole, and(d) about 0.05 to 0.5 percent alkyl succinic acid half ester rust inhibitor.

Owner:VANDERBILT CHEM LLC

High-performance antirust cutting fluid

The invention discloses a high-performance antirust cutting fluid which comprises the following components in parts by weight: 10-15 parts of machine oil, 3-8 parts of thiophosphoric acid ester, 5-10 parts of antirust composition, 3-5 parts of bactericide, 1-2 parts of citric acid, 3-5 parts of sodium carbonate, 5-10 parts of emulsifier, and 20-30 parts of water. A working solution is a colorless transparent fluid, is free of nitrite, and facilitates environmental protection and human health; a 2-3% diluent can be used for common processing; a 4.5-5.5% diluent can be used for extreme pressure processing; an application scope is wide; oil mist is low; pungent odor does not exist; the single antirust time far exceeds a standard, and is greater than 220h; and the cutting fluid has excellent grinding settleability and excellent cooling, lubrication and cleaning properties.

Owner:QINGDAO CHENGTIAN WEIYE MACHINERY MFG

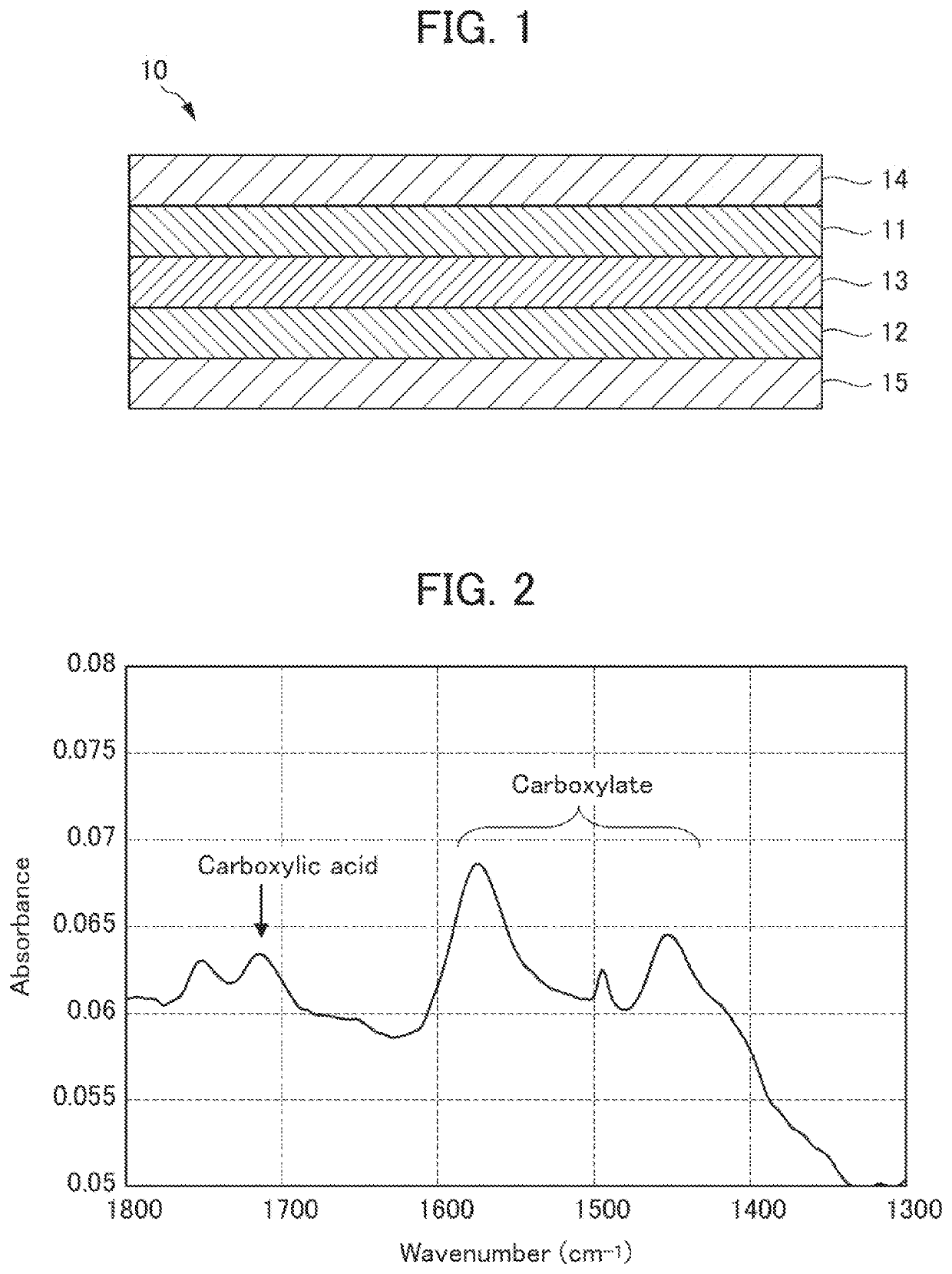

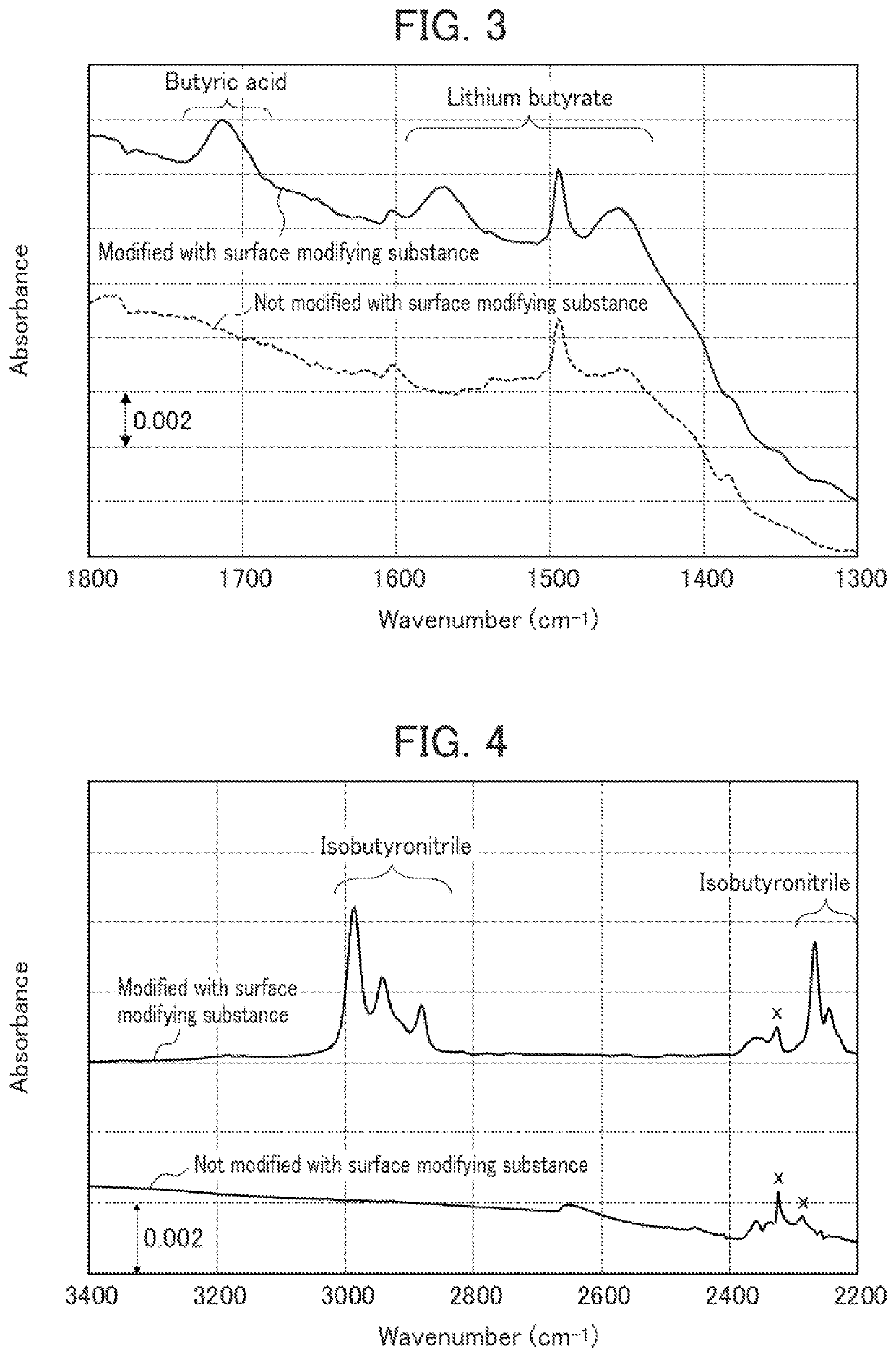

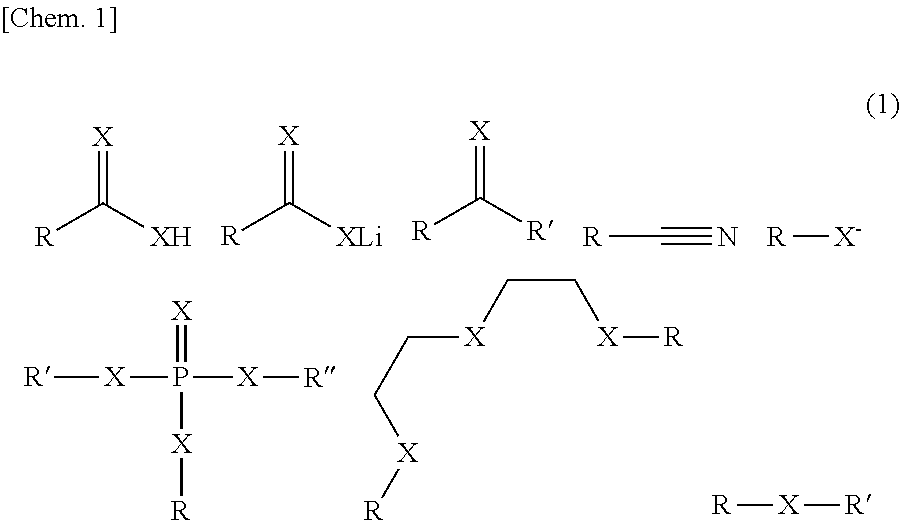

Electrode for solid-state battery and solid-state battery including same

PendingUS20220293956A1Avoid easy decompositionLower electrode resistanceSolid electrolytesFinal product manufactureThiocarboxylic acidPhosphoric Acid Esters

To provide an electrode for a solid-state battery, capable of improving uniformity of electrode materials and suppressing decomposition of a solid electrolyte or an electrode active material by a binder or a solvent. An electrode for a solid-state battery including a solid electrolyte including sulfide and / or oxide, an electrode active material, a binder, and a conductive auxiliary agent, at least one of the solid electrolyte and the electrode active material having a surface being modified with a surface modifying substance, wherein the surface modifying substance is at least one selected from the group consisting of carboxylate, thiocarboxylate, carboxylic acid, thiocarboxylic acid, phosphate ester, thiophosphate ester, ketone, nitrile, alcohol, thiol, and ether.

Owner:HONDA MOTOR CO LTD

Water emulsifiable formulations

InactiveCN1767766AHigh flash pointReduce volatilityBiocideDead animal preservationPropylene carbonateCarbonate

A composition comprising an organic carbonate such as propylene carbonate and O,O-diethyl-O-(2-isopropyl-4-methyl-6-pyrimidinyl)phosphorothioate, S-[1,2-bis(ethoxycarbonyl)ethyl]O,O-dimethylphosphorodithioate, or 6,7,8,9,10, 10-hexachloro-1,5,5a,6,9,9a-hexahydro-6,9-methano-2,4,3-benzodioxathiepin-3-oxide, and methods thereof.

Owner:HUNTSMAN PETROCHEMICAL LLC

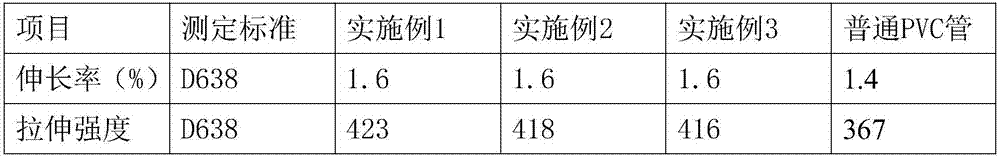

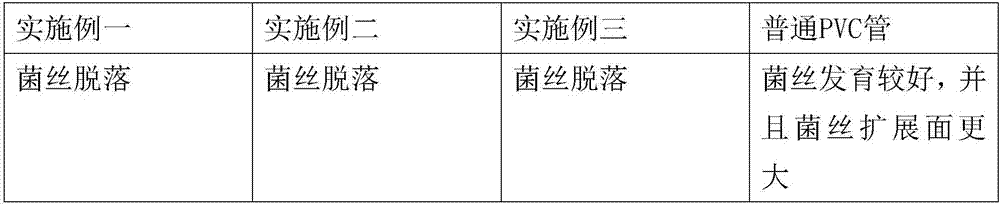

PVC (Polyvinyl Chloride) pipe and preparation technology thereof

The invention provides a PVC (Polyvinyl Chloride) pipe and a preparation technology thereof. The PVC pipe is prepared from the following components in parts by weight: 140 to 160 parts of PVC, 5 to 10 parts of DBP (Dibutyl Phthalate), 5 to 10 parts of ethyl cellulose, 3 to 3.5 parts of tribasic sodium phosphite, 0.5 to 2 parts of methyltin mercaptide, 0.1 to 0.15 part of stearic acid, 0.5 to 1 part of pearl micro-powder, 0.5 to 1 part of chitosan, 0.1 to 0.2 part of paraffin wax, 1.2 to 1.6 parts of talcum powder, 0.5 to 1 part of polyethylene polyamine, 2 to 6 parts of calcium carbonate, 2 to 8 parts of triethanolamine and 2 to 8 parts of thiophosphate. The PVC pipe provided by the invention has excellent tensile strength; the pearl micro-powder is added into materials and the content of micro-crystals in a molding process of the PVC pipe reaches 11 percent, so that the thermal stress of the pipe is greatly reduced; the pipe does not have a cracking phenomenon even being used for 10 years; the PVC pipe has very good antibacterial performance.

Owner:安徽博泰塑业科技有限公司

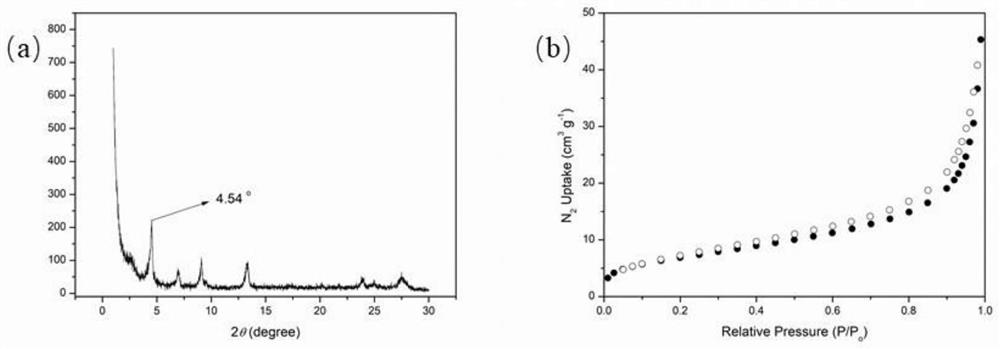

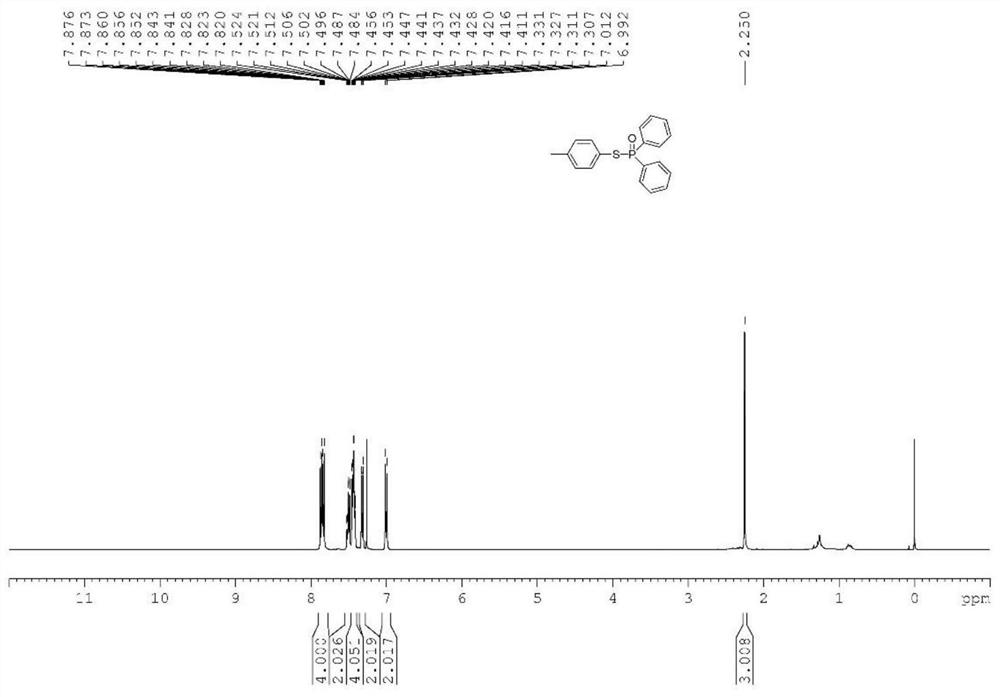

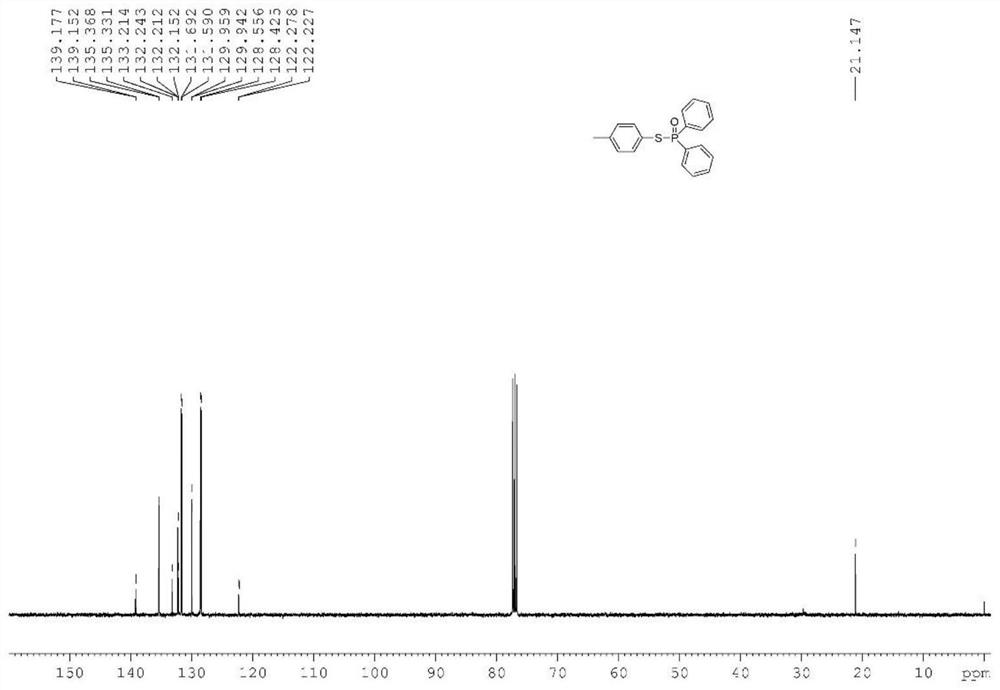

Photosensitive COFs catalyst and method for catalytic synthesis of thiophosphate derivatives

ActiveCN113713856AImprove stabilityHigh selectivityGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystPhosphine oxide

The invention provides a photosensitive COFs catalyst and a method for catalytic synthesis of thiophosphate derivatives. The photosensitive COFs catalyst takes 1,3,6,8-tetra(4-formylphenyl)pyrene and 1,1'-[1,4-phenylene bis(methylene)] bis(1-azacyclonium)salt as raw materials, and the photosensitive COFs catalyst is synthesized through a solvothermal method under the action of alkali. The preparation method comprises the following steps: by taking photosensitive COFs as a catalyst and taking a substituted phosphine oxide derivative and a thiol derivative as reactants, conducting reacting for 1-30 hours in an air or oxygen environment under the conditions of room temperature, existence of a solvent and illumination, removing the reaction solvent after the reaction is finished, and then obtaining the thiophosphate derivative by a column chromatography separation method or a recrystallization method. The reaction belongs to a heterogeneous catalytic reaction, the catalyst is good in stability, high in catalytic activity, high in reaction efficiency, capable of being recycled for multiple times, simple in synthesis process, high in product selectivity, few in by-product and environmentally friendly, and has a relatively strong industrial application prospect.

Owner:ZHONGYUAN ENGINEERING COLLEGE

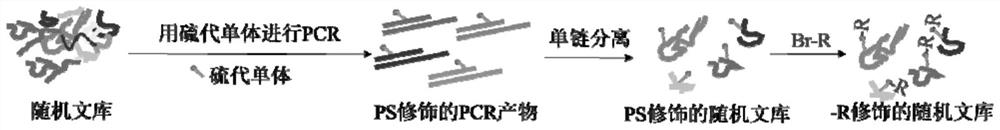

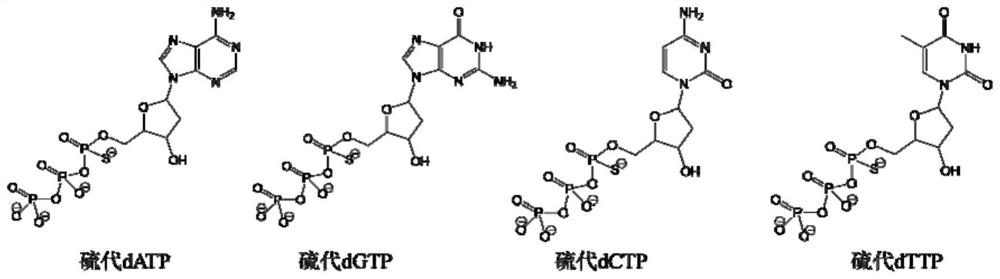

In-vitro screening method of nucleic acid aptamer, nucleic acid aptamer and kit for detecting target molecule

ActiveCN112410326AEasy to filterThe synthesis method is simpleMicrobiological testing/measurementScreening processAptamerThiophosphoric Acid Esters

The present invention provides an in-vitro screening method of a nucleic acid aptamer, which comprises: providing a random library having a thiophosphate group modification and a binding group modification, the binding group being suitable for binding to a target molecule, the thiophosphate group being bound to the binding group; and contacting the random library with a target, separating the random library combined with the target molecule, and taking the random library as a target nucleic acid aptamer obtained by screening. The random library is modified by the thiophosphate group and the binding group, the binding group generates affinity with a target, and the distance between the random library and the target is shortened, so that the random library is endowed with initial binding activity with the target, the random library and the target are easier to bind, and the nucleic acid aptamer is easier to successfully screen.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com