Composite collecting agent for bulk floatation of copper sulfide molybdenum ores

A composite collector, copper molybdenum sulfide technology, applied in flotation, solid separation and other directions, can solve the problems of weak selectivity, complicated preparation and addition steps, and weak collection capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

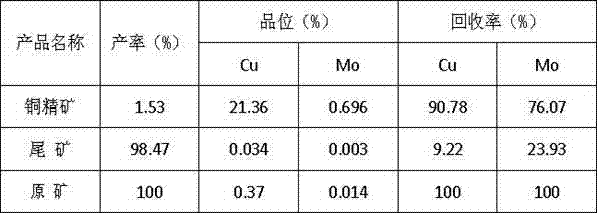

[0012] The raw ore contains 0.36% by mass of Cu, and 0.014% by mass of Mo, and 160 g / t of collector of the present invention is added. In this collector, thiocarbamate, phosphorothioate, mixed non-polar hydrocarbon The proportions of oil and terpene alcohols were 70%, 2%, 18%, and 20%, respectively. After flotation separation, the separation results in Table 1 were obtained.

[0013] Table 1 Mixed flotation separation index 1 of copper-molybdenum sulfide ore

[0014]

Embodiment 2

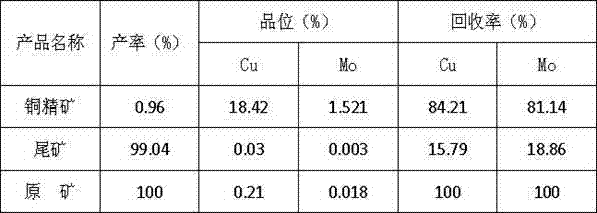

[0016] The raw ore contains 0.21% by mass of Cu and 0.018% by mass of Mo, and 80g / t of collector of the present invention is added, in which thiocarbamate, phosphorothioate, mixed non-polar hydrocarbon The proportions of oil and terpene alcohol were 65%, 5%, 20%, and 10% respectively. After flotation separation, the separation results in Table 2 were obtained.

[0017] Table 2 Separation index 2 of mixed flotation of copper-molybdenum sulfide ore

[0018]

Embodiment 3

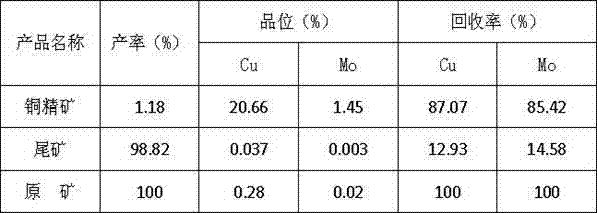

[0020] The raw ore contains 0.28% by mass of Cu and 0.02% by mass of Mo, and 130g / t of collector of the present invention is added. In this collector, thiocarbamate, phosphorothioate, and mixed nonpolar hydrocarbons The proportions of oil and terpene alcohol were 50%, 10%, 30%, and 10% respectively. After flotation separation, the separation results in Table 3 were obtained.

[0021] Table 3 Separation index 3 of mixed flotation of copper-molybdenum sulfide ore

[0022]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com