Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Magnesium-aluminum oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

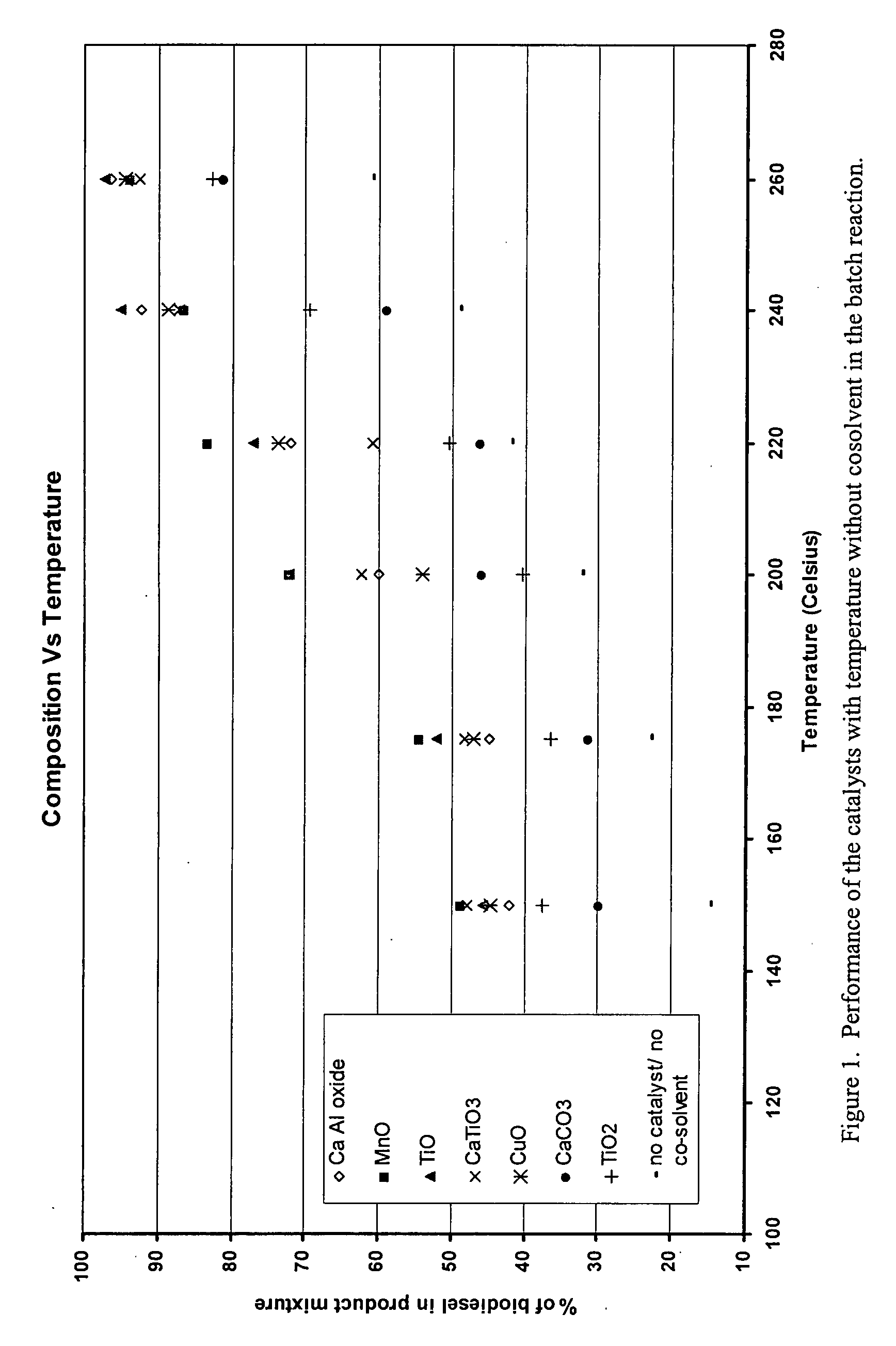

Green biodiesel

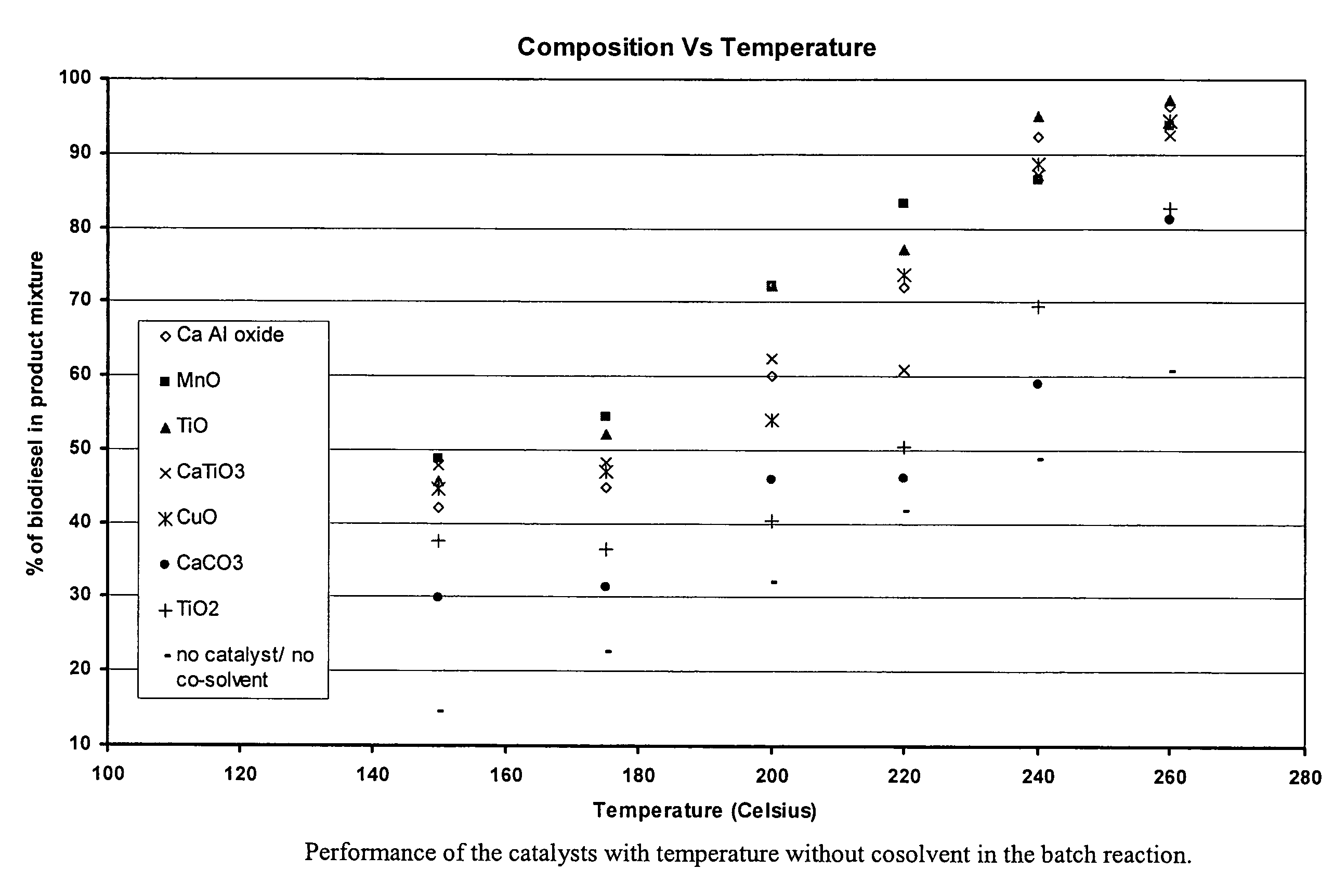

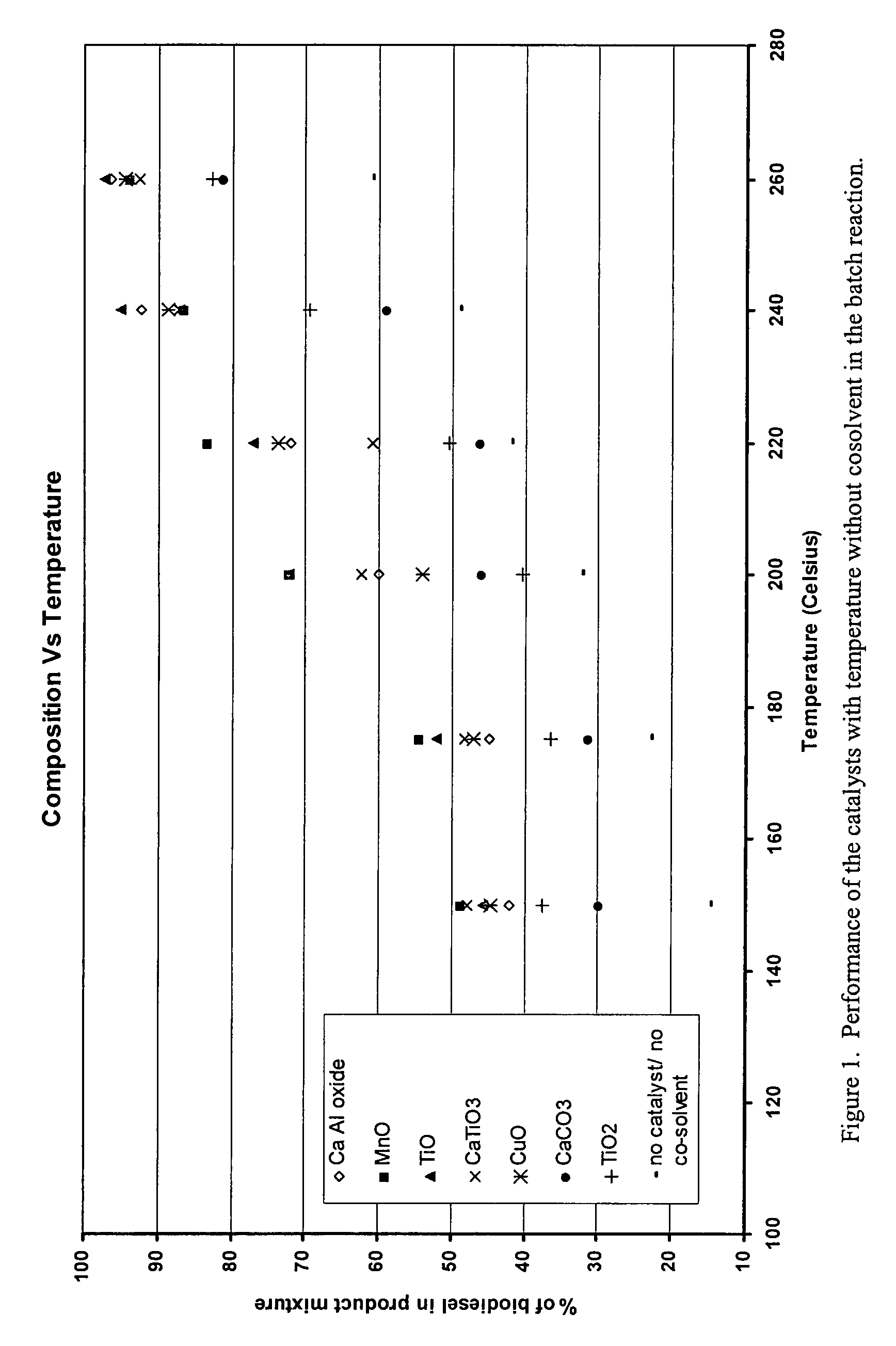

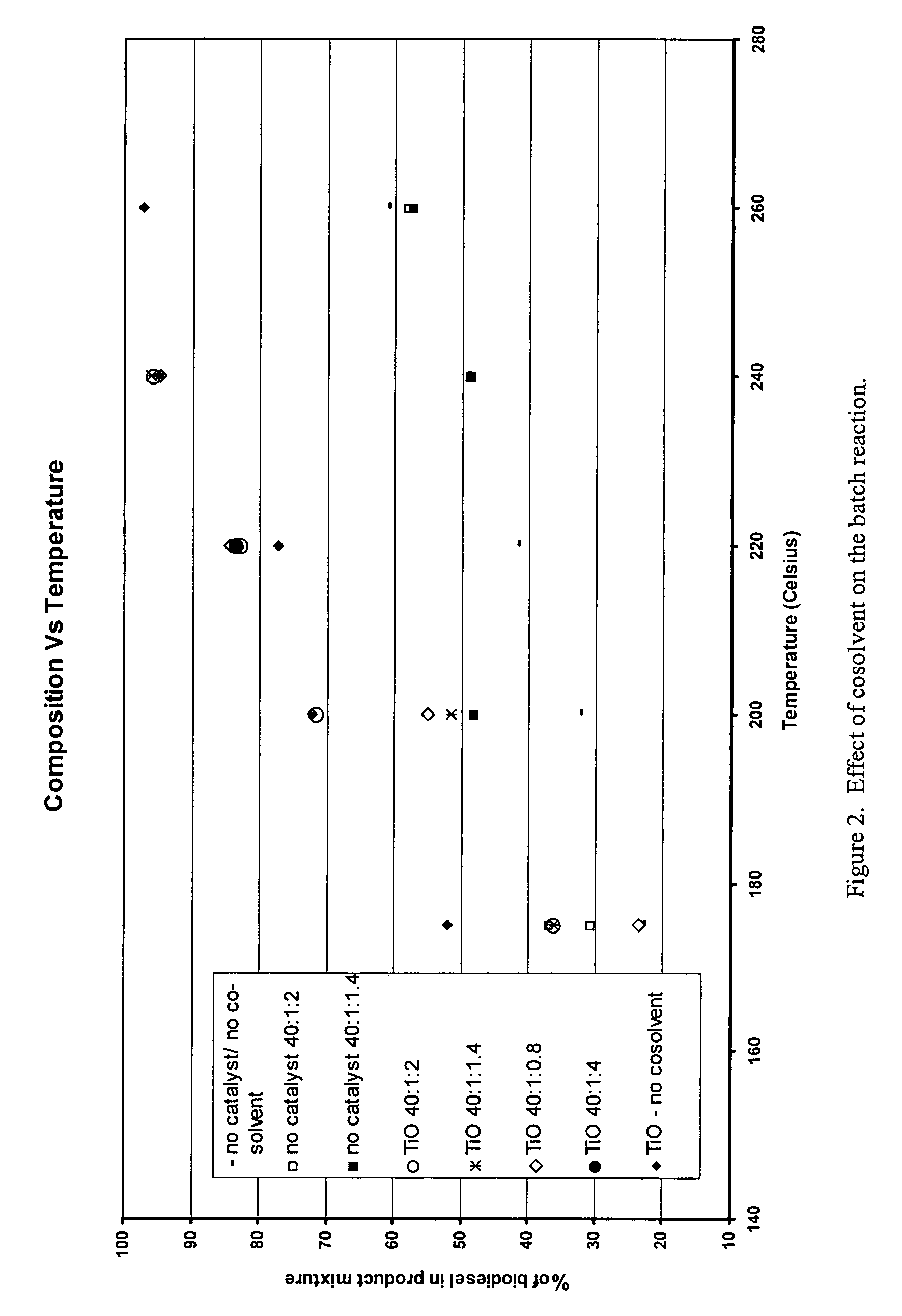

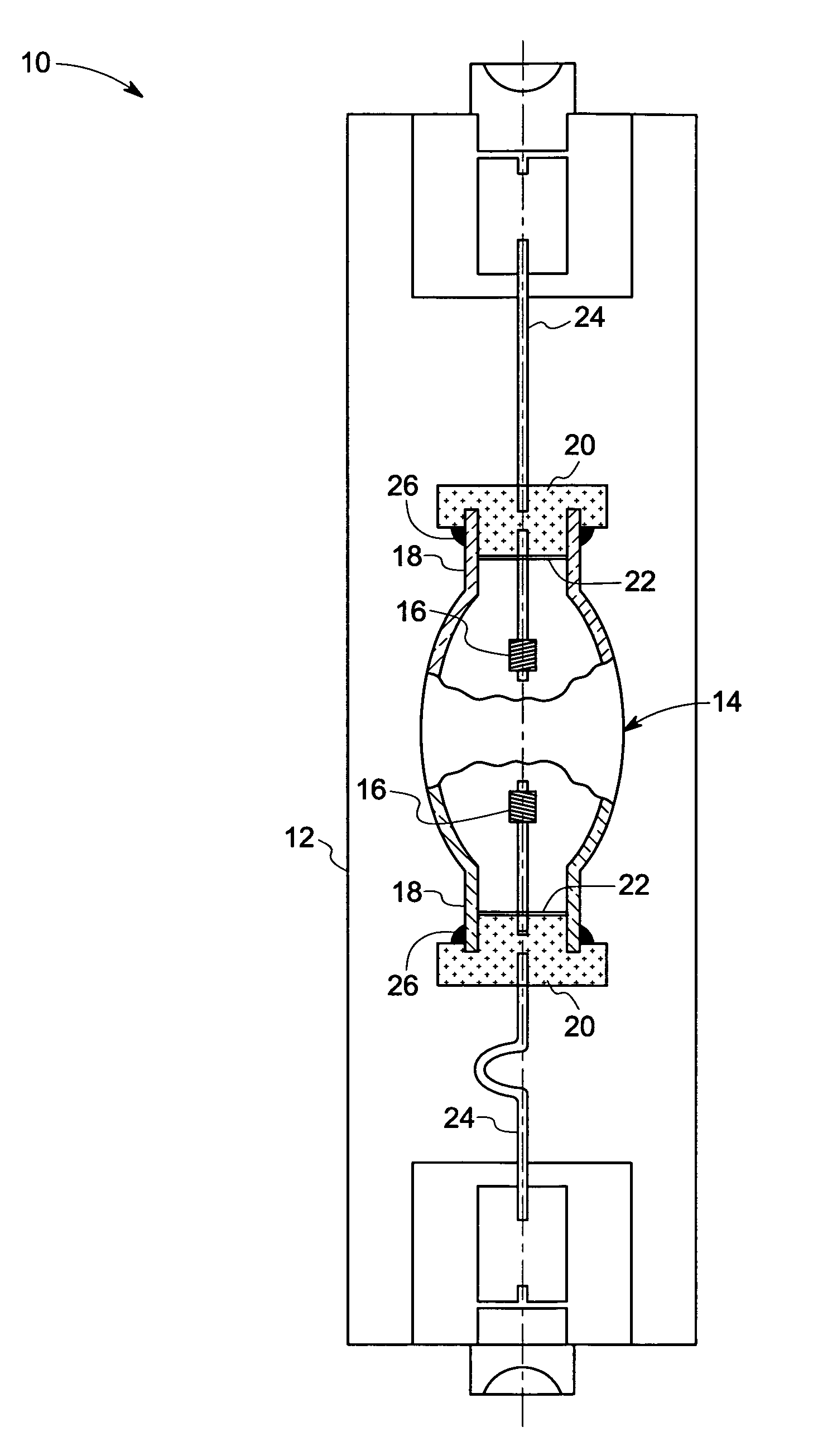

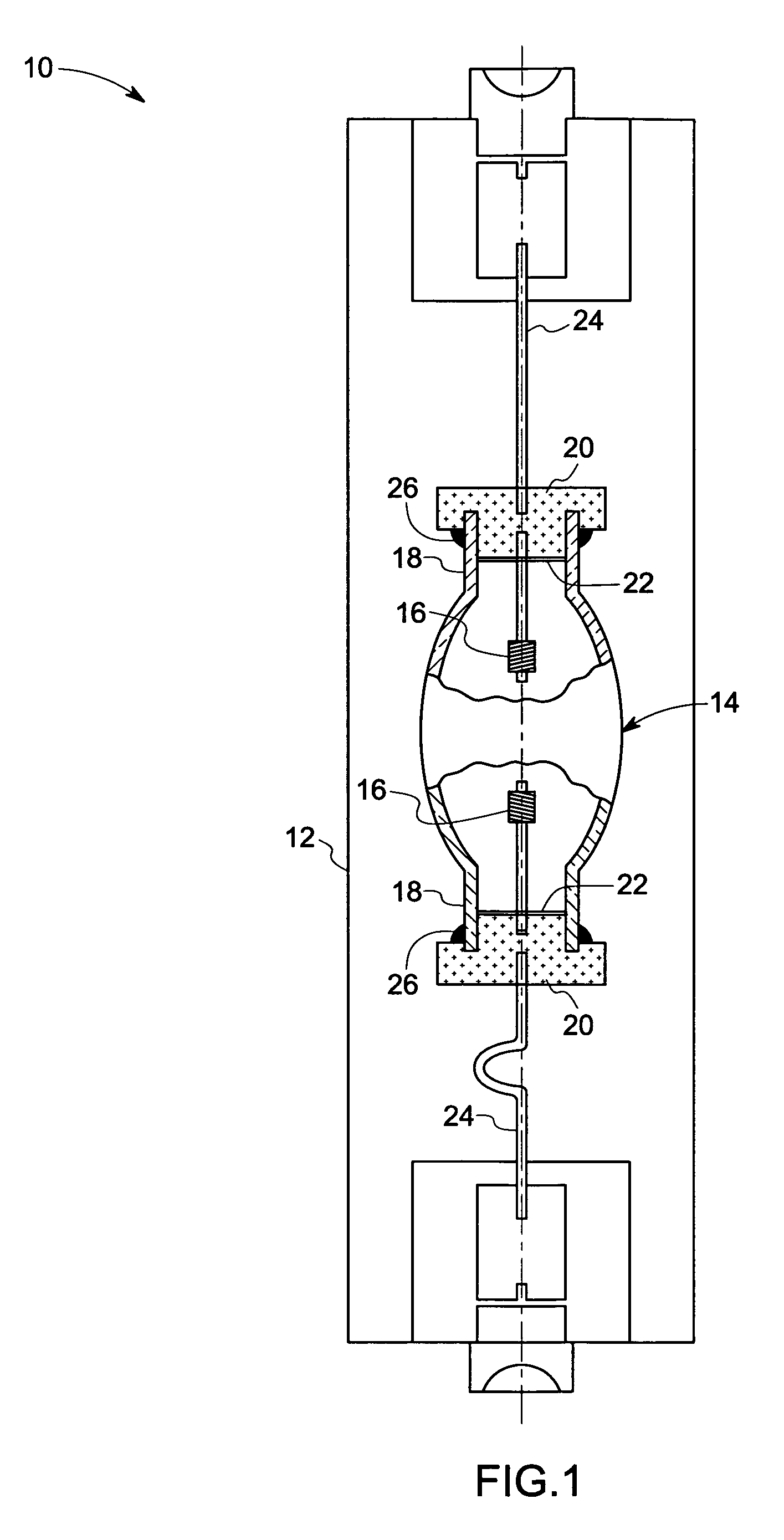

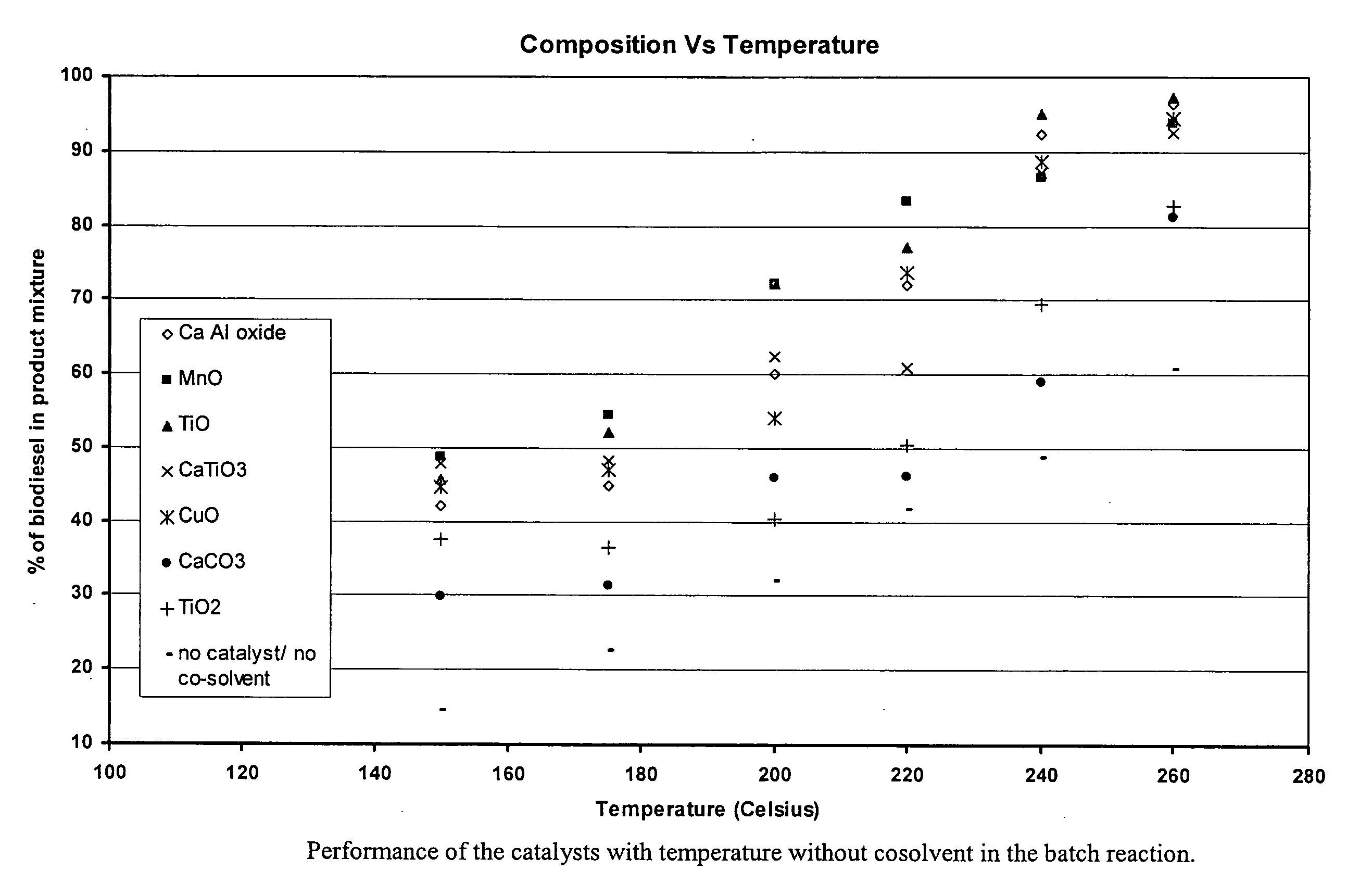

InactiveUS7563915B2Reduce wasteSignificant energyFatty oils/acids recovery from wasteFatty acid esterificationCalcium silicateBiodiesel

Methods for improved manufacture of green biodiesel focus on the selection and use of one or more solid metallic oxide base catalyst(s) selected from the group consisting of calcium oxide (CaO), calcium aluminum oxide (CaO—Al2O3), calcium titanate (CaTiO3), barium titanate (BaTiO3), magnesium aluminum oxide (MgO—Al2O3), zinc oxide (ZnO), copper (II) oxide (CuO), nickel oxide (NiO), manganese oxide (MnO), titanium oxide (TiO), vanadium oxide (VO), cobalt oxide (CoO), iron oxide (FeO), chromite (FeCr2O4), hydrotalcite (Mg6Al2(CO3)(OH)16.4(H2O), magnetite (Fe3O4), magnesium silicate and calcium silicate.

Owner:PENN STATE RES FOUND

Electrically conductive cermet and method of making

An electrically conducting cermet comprises at least one transition metal element dispersed in a matrix of at least one refractory oxide selected from the group consisting of yttria, alumina, garnet, magnesium aluminum oxide, and combinations; wherein an amount of the at least one transition metal element is less than 15 volume percent of the total volume of the cermet. A device comprises the aforementioned electrically conducting cermet.

Owner:GENERAL ELECTRIC CO

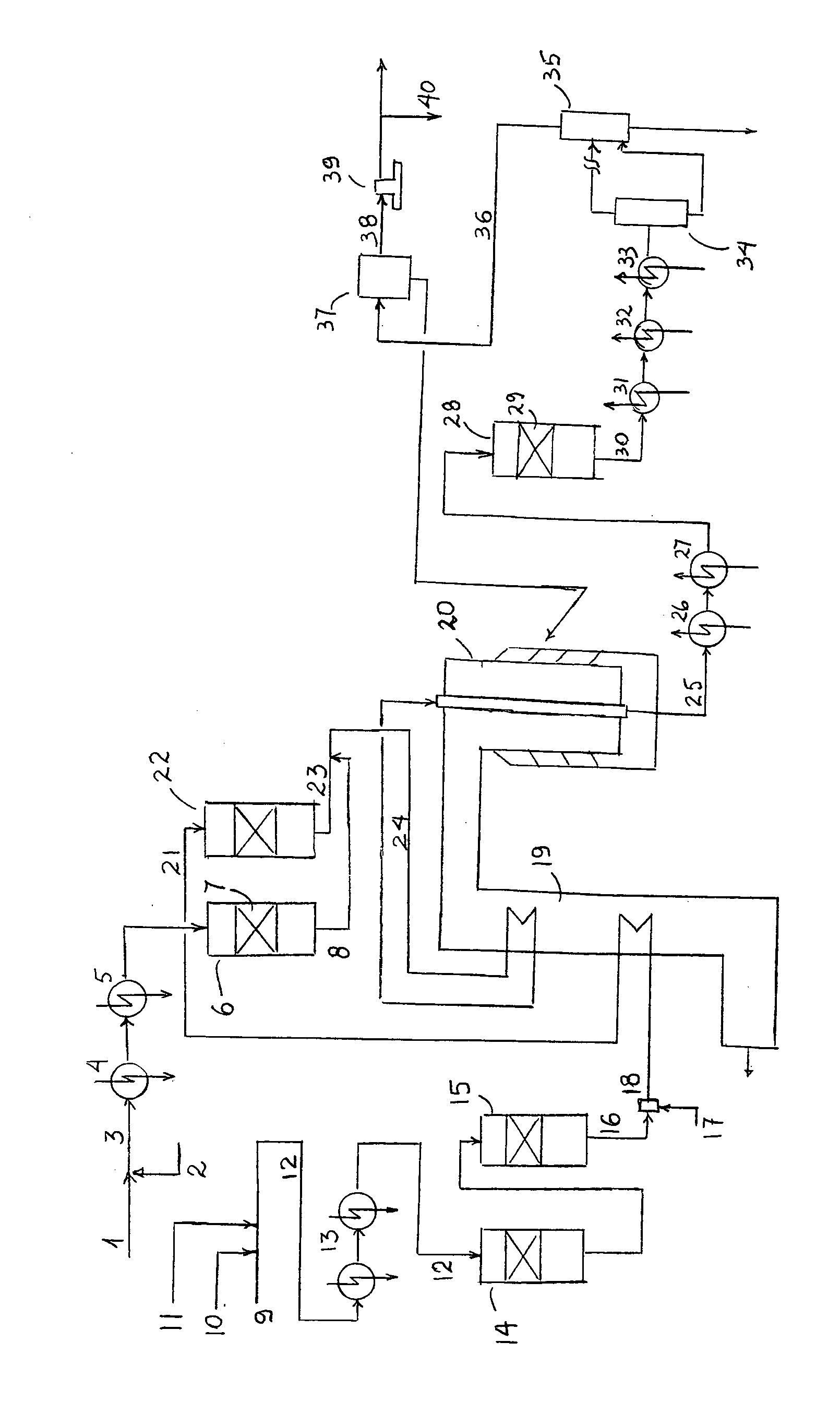

Process for the production of hydrogen

Process for the removal of organic and / or inorganic sulfur from an ammonia stream by passing said stream through a fixed bed of sulfur absorbent in a sulfur absorber and withdrawing a sulfur-free ammonia stream, wherein said sulfur absorbent is a catalyst having a total nickel content in reduced form in the range 10 wt % to 70 wt % with the balance being a carrier material selected from the group of alumina, magnesium alumina spinel, silica, titania, magnesia, zirconia and mixtures thereof.

Owner:HALDOR TOPSOE AS

Green Biodiesel

InactiveUS20070282119A1Significant energySignificant processing timeFatty oils/acids recovery from wasteFatty acid esterificationCalcium silicateBiodiesel

Methods for improved manufacture of green biodiesel focus on the selection and use of one or more solid metallic oxide base catalyst(s) selected from the group consisting of calcium oxide (CaO), calcium aluminum oxide (CaO—Al2O3), calcium titanate (CaTiO3), barium titanate (BaTiO3), magnesium aluminum oxide (MgO—Al2O3), zinc oxide (ZnO), copper (II) oxide (CuO), nickel oxide (NiO), manganese oxide (MnO), titanium oxide (TiO), vanadium oxide (VO), cobalt oxide (CoO), iron oxide (FeO), chromite (FeCr2O4), hydrotalcite (Mg6Al2(CO3)(OH)16.4(H2O), magnetite (Fe3O4), magnesium silicate and calcium silicate.

Owner:PENN STATE RES FOUND

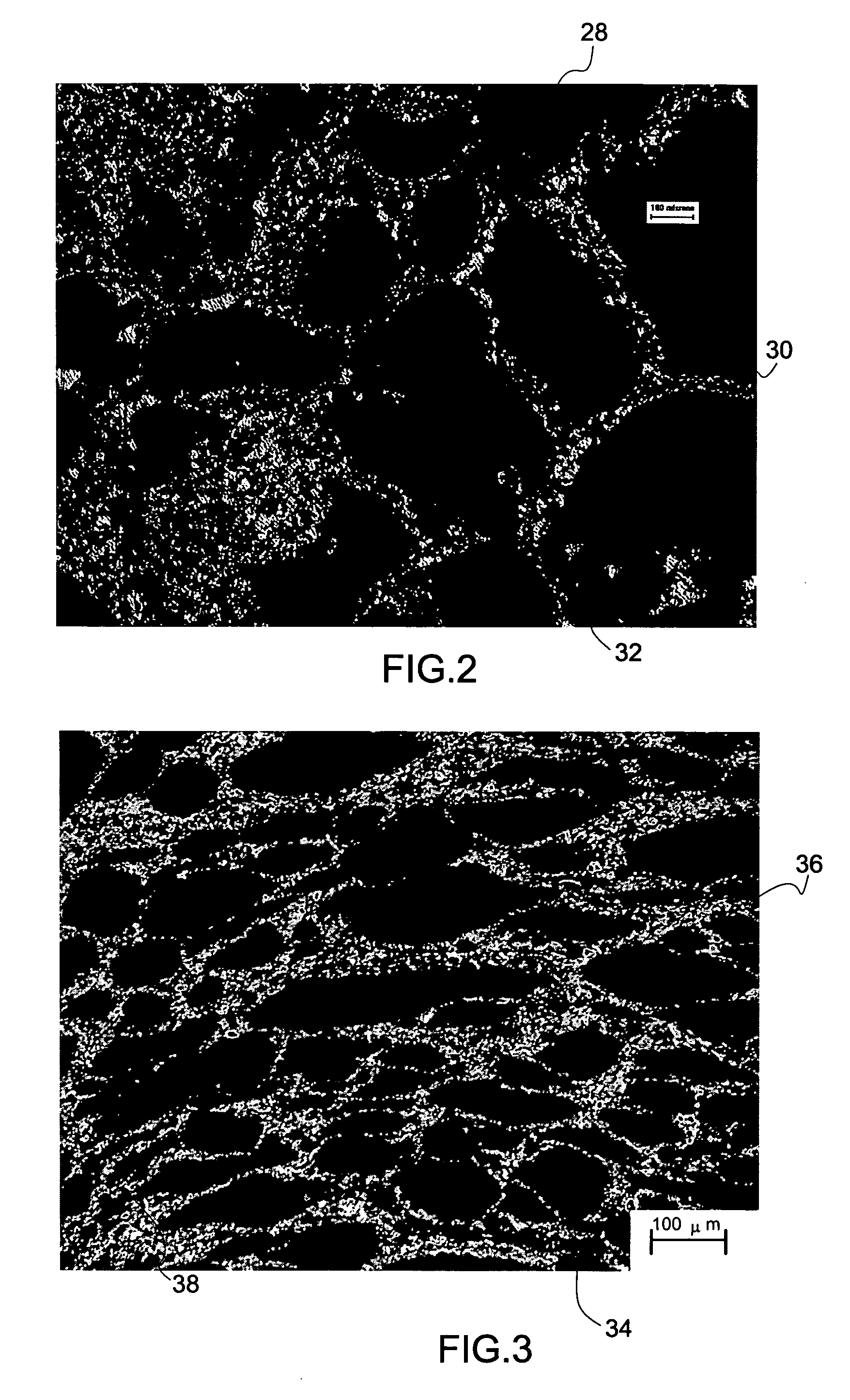

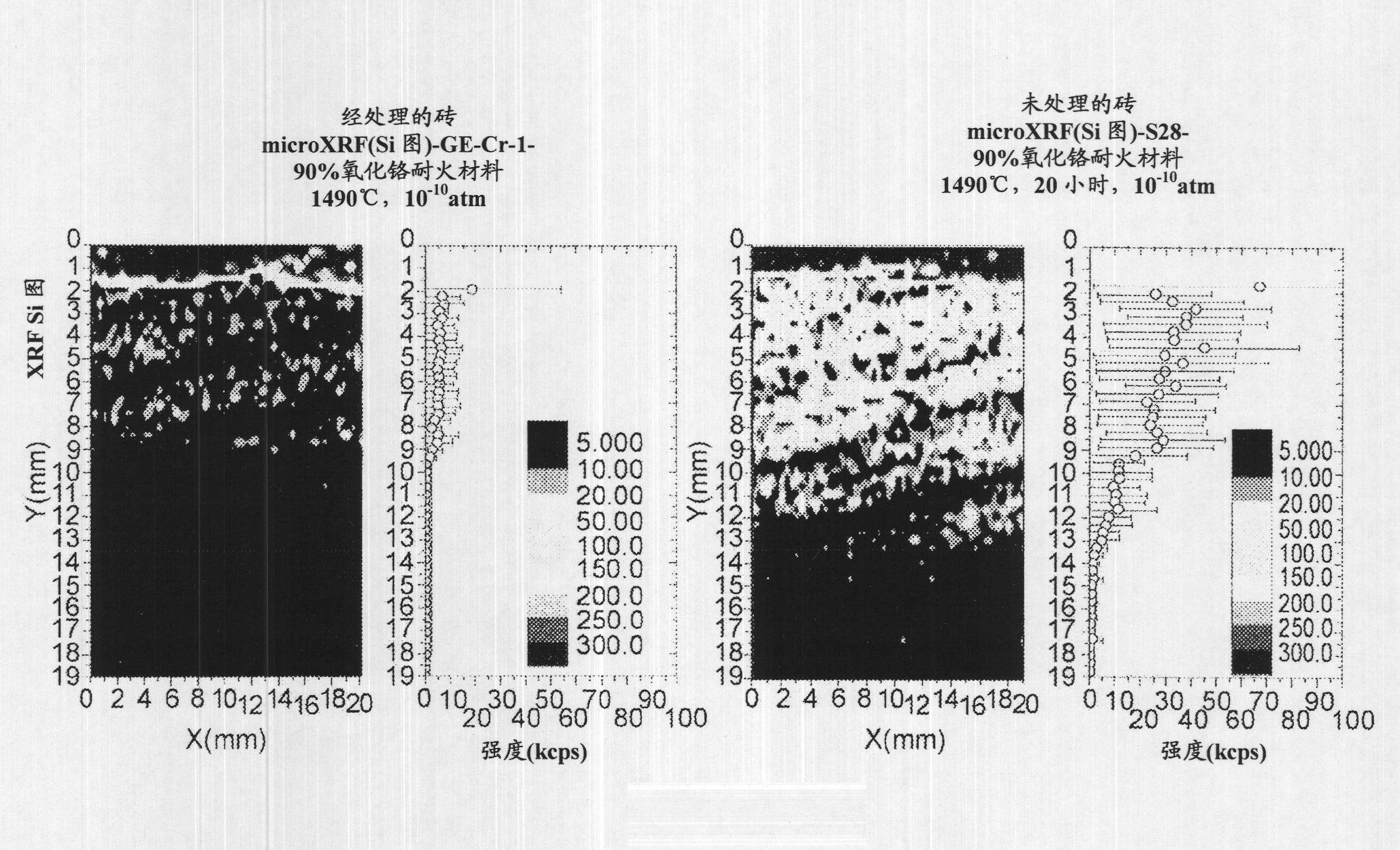

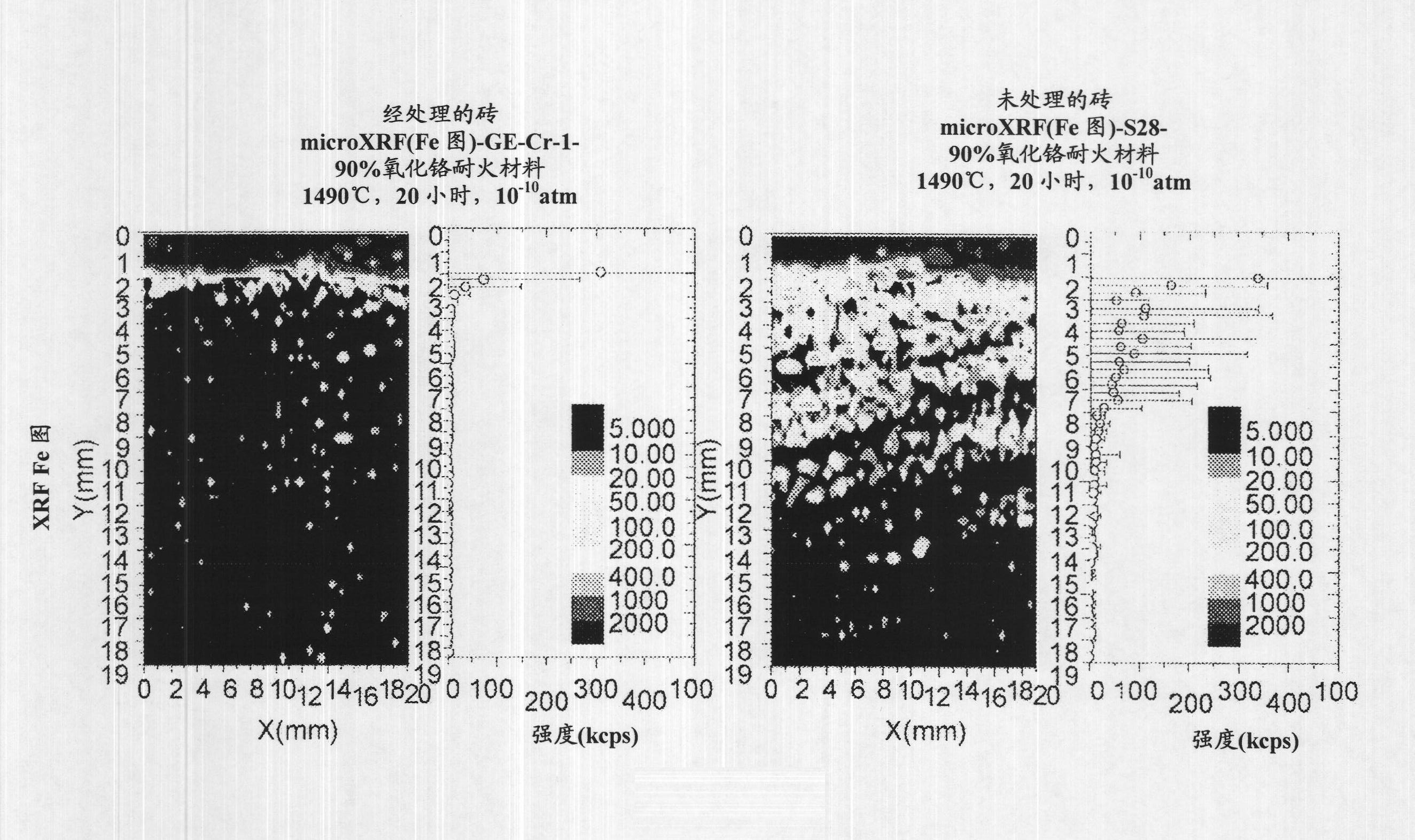

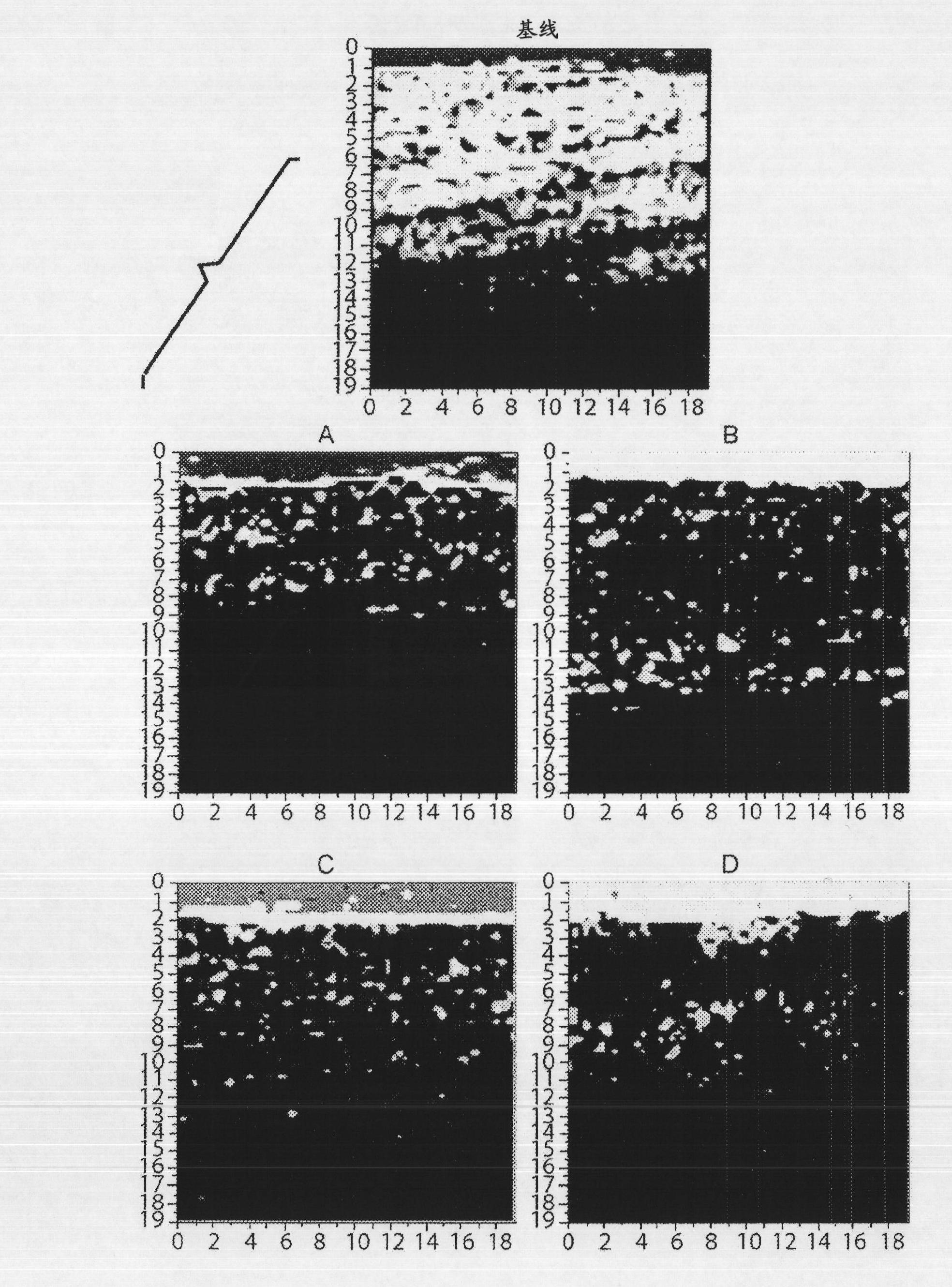

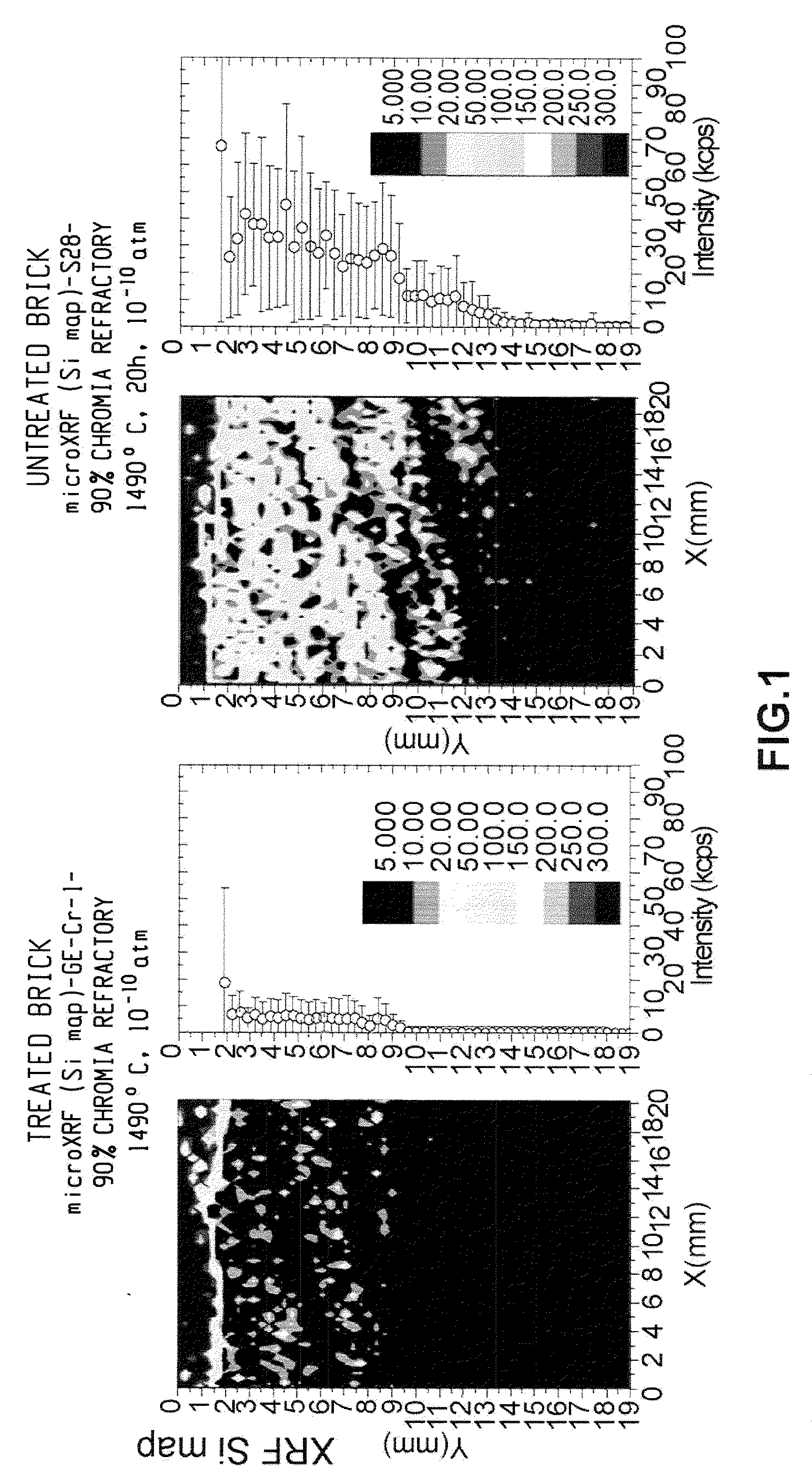

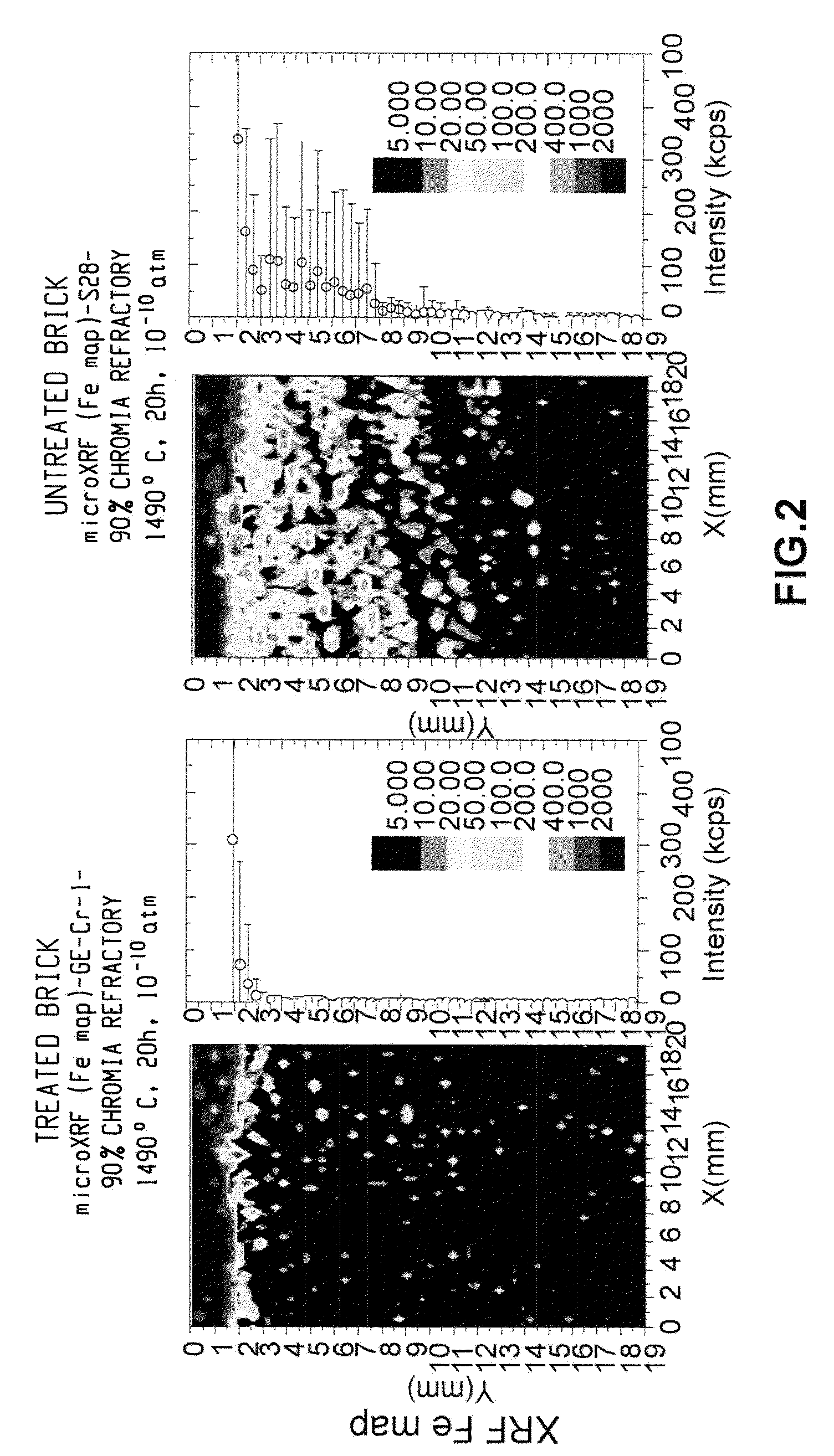

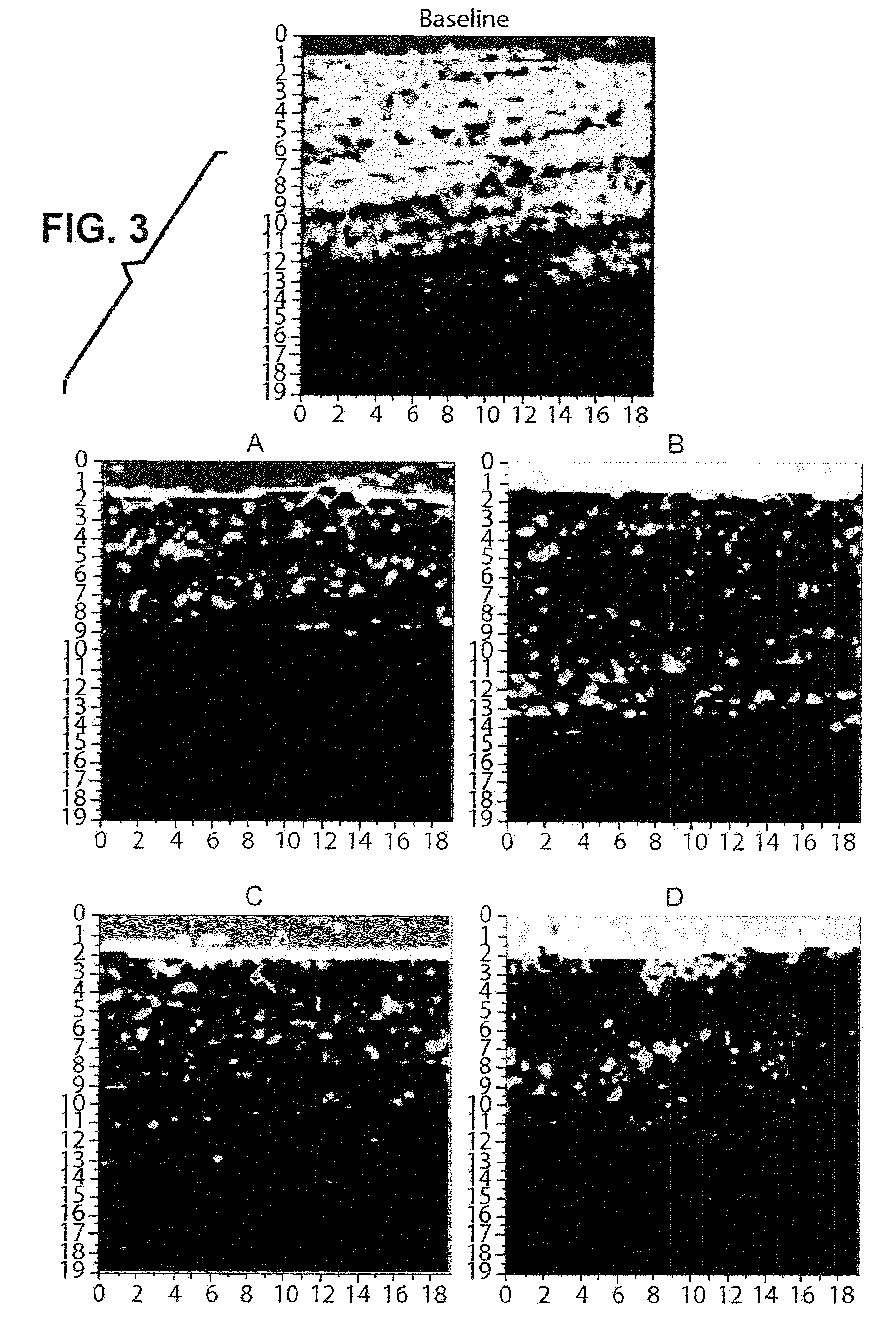

Treated refractory material and methods of making

InactiveCN101786894AExtend the lifespanImperviousMaterial nanotechnologyCeramicwareZirconateRare earth

A treated refractory material includes a refractory material having a plurality of pores, wherein the refractory material comprises aluminum oxide, silicon oxide, magnesium oxide, chromium oxide, zirconium oxide, titanium oxide, calcium oxide, fireclay, silicon carbide, tungsten, mullite, dolomite, magnesite, magnesium aluminum oxide, chromite, magnetite, or a combination comprising at least one of the foregoing; and a protective material disposed within the plurality of pores of the refractory material, wherein the protective material is selected from the group consisting of aluminum oxide, chromium oxide, silica, rare earth oxides, rare earth zirconates, titanium oxide, mullite, zirconium oxide, zirconium silicate, yttrium oxide, magnesium oxide, iron oxide, and blends thereof.

Owner:GENERAL ELECTRIC CO

Light hydrocarbon distillate selective dediene catalyst and method for preparing the same

InactiveCN1485411AReduce carbon depositionExtended service lifeRefining by selective hydrogenationActive componentSolid solution

A catalyst for selectively hydrogenating and dediolefinating for light hydrocarbon fractions, comprises 0.05í½1.0 wgtúÑ Pd as the active component and the carrier of magnesium aluminum oxide solid solution. In the magnesium aluminum oxide, the mol ration of Mg / Al is 1.0í½12.0. the catalyst also contains auxiliary agents selecting from Co, Mo, Ni and Wu. The catalyst is suitable for selectively hydrogenating and dediolefinating for light C4-C6 hydrocarbon fractions.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treated refractory material and methods of making

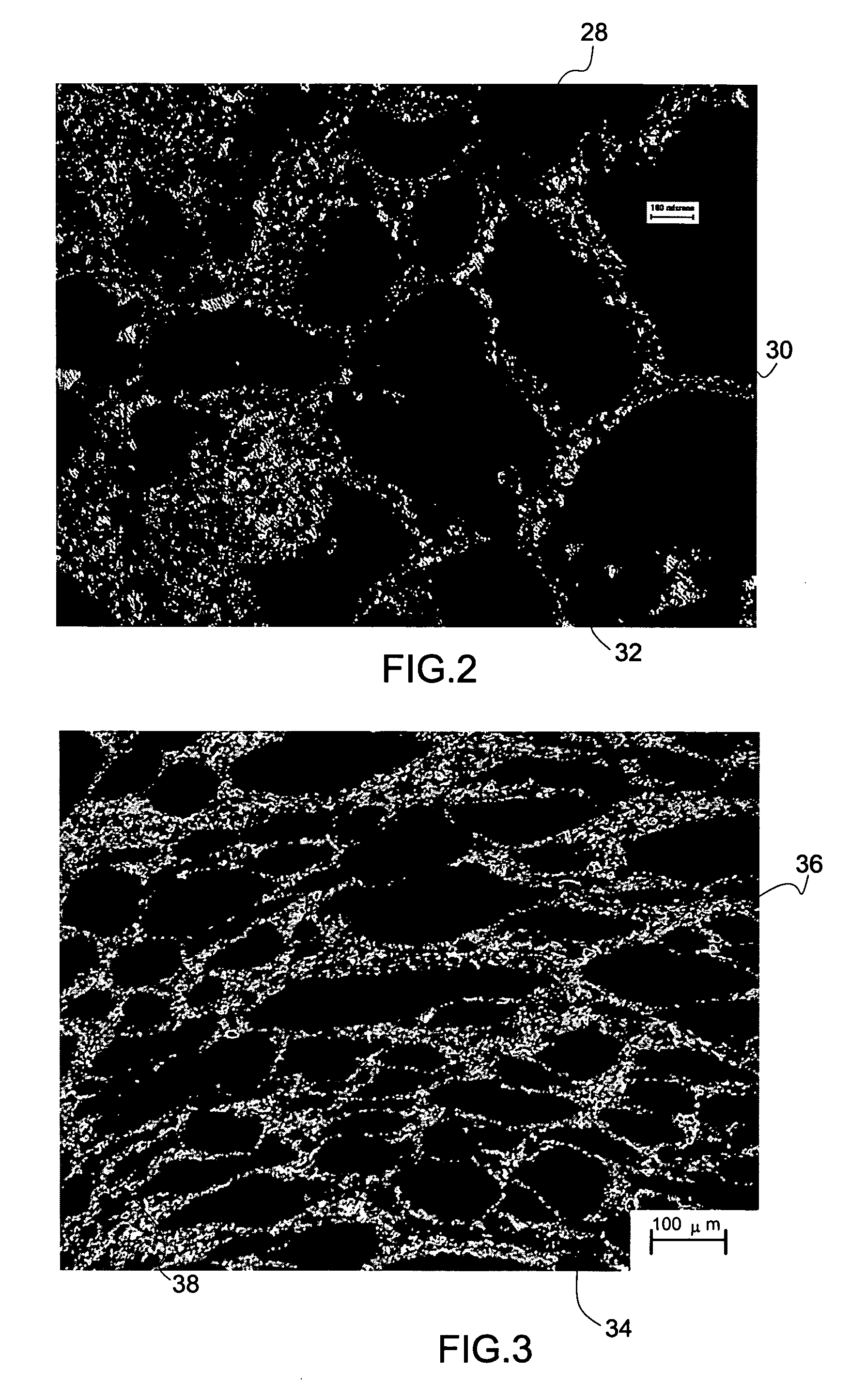

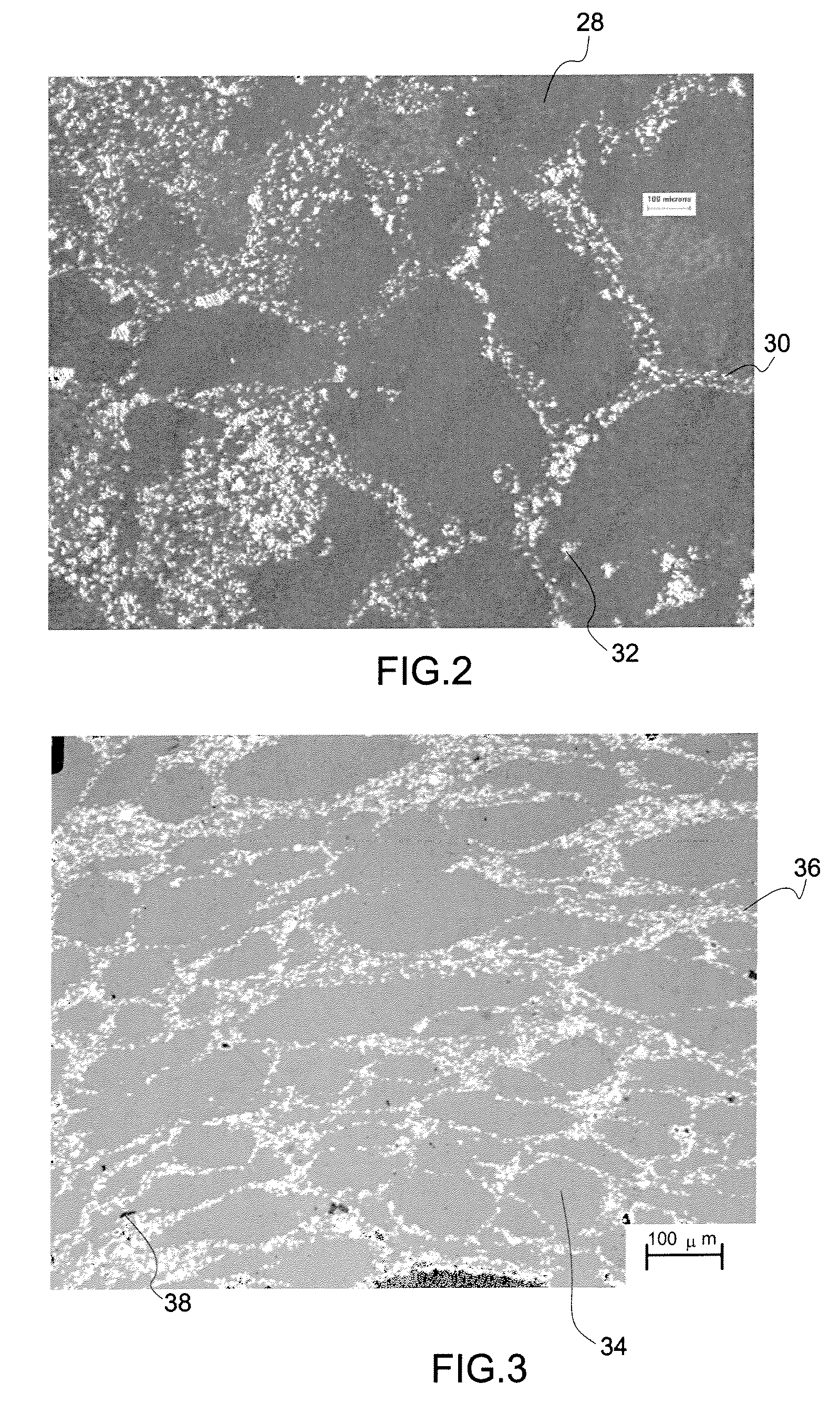

InactiveUS20090188347A1Extended service lifeProvide protectionMaterial nanotechnologyFurnace componentsMagnetiteZirconate

A treated refractory material includes a refractory material having a plurality of pores, wherein the refractory material comprises aluminum oxide, silicon oxide, magnesium oxide, chromium oxide, zirconium oxide, titanium oxide, calcium oxide, fireclay, silicon carbide, tungsten, mullite, dolomite, magnesite, magnesium aluminum oxide, chromite, magnetite, or a combination comprising at least one of the foregoing; and a protective material disposed within the plurality of pores of the refractory material, wherein the protective material is selected from the group consisting of aluminum oxide, chromium oxide, silica, rare earth oxides, rare earth zirconates, titanium oxide, mullite, zirconium oxide, zirconium silicate, yttrium oxide, magnesium oxide, iron oxide, and blends thereof.

Owner:GENERAL ELECTRIC CO

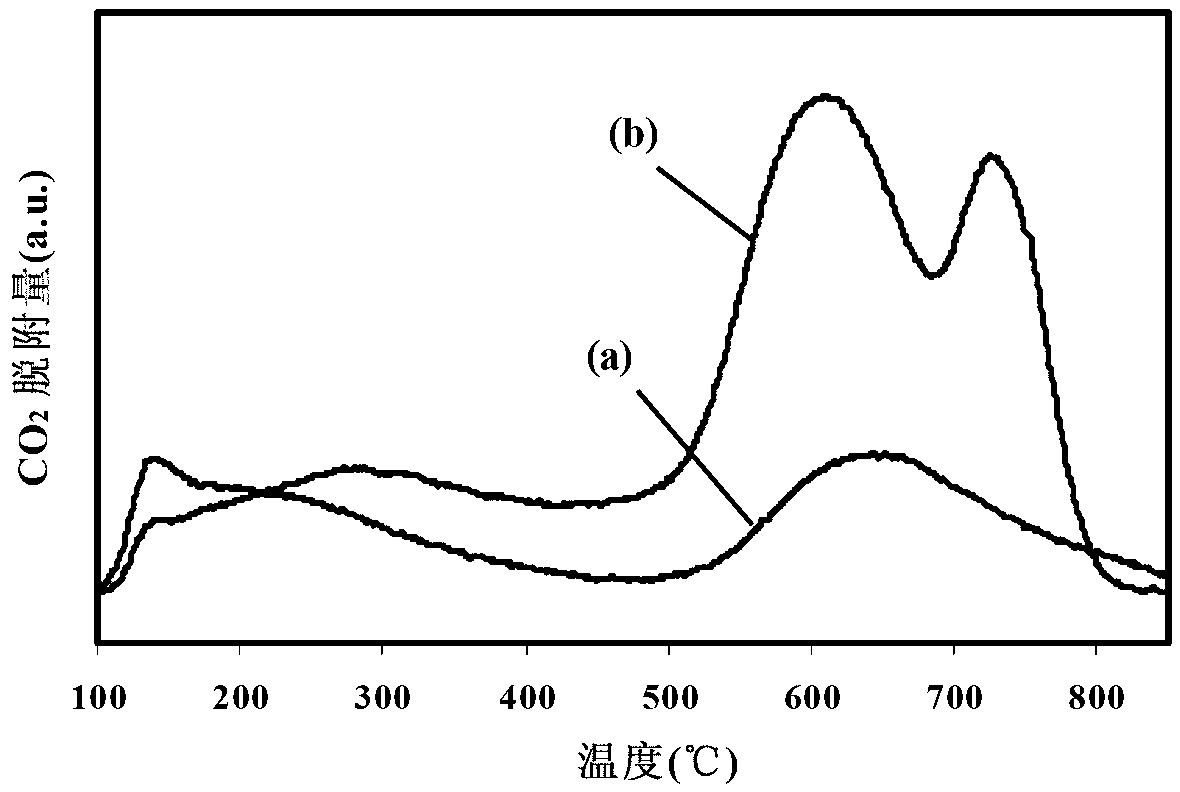

Preparation and application of solid super alkali catalyst

InactiveCN103212398AEasy to prepareHigh catalytic activityCarboxylic acid nitrile preparationOrganic compound preparationTube furnaceNitrogen atmosphere

The invention provides a preparation method of a composite metal-oxide-based solid super alkali catalyst. According to the method, magnesium nitrate and aluminum nitrate with a molar ratio of [1:1]-[7:1] are prepared into a solution; 1mol / L of NaOH or KOH is used for regulating the pH to 10-12; refluxing is carried out for 12-72h; a precipitate is washed by using water with different amounts; the precipitate is dried, and is heated to 400-700 DEG C in a tube furnace under a nitrogen atmosphere; roasting is carried out for 1-5h, such that the solid super alkali catalyst with K or Na mass content of 1-20% is obtained. According to the solid super alkali catalyst preparation method, synthesizing and modification are carried out simultaneously, wherein modification object K or Na and carrier magnesium-aluminum oxide are simultaneously produced during the roasting process, such that time and energy consumption are saved. When the catalyst is applied in a Knoevenagel condensation reaction, catalyst dose is low, reaction conditions are mild, and catalytic activity is high. The catalyst can be repeatedly used through centrifugal separation.

Owner:HUNAN UNIV

Electric heating tube manufacturing process

InactiveCN105246181AImprove pressure resistanceExtended service lifeHeating element shapesElectrical resistance and conductanceManufacturing technology

The invention discloses an electric heating tube manufacturing process, which relates to the technical field of electric heating tube manufacturing. The process comprises steps: decontamination and impurity removal are carried out; an electric heating wire is manufactured; resistance of the electric heating wire is measured; a conductive rod is riveted on the electric heating wire; the electric heating wire penetrates through a seamless steel tube, and filling of G3 high-temperature magnesium aluminum oxide powder is carried out; in a condition of 3000 to 3500V / mit, high voltage detection is carried out; tube narrowing is carried out, and the diameter of the seamless steel tube is narrowed to 12mm from 14mm; the resistance of the electric heating wire is measured again, and requirements are reached; second-time high voltage test is carried out in a condition no lower than 2800V / mit; drying and annealing are carried out; and test is carried out according to drawing requirements, and after qualification, a tube sealing nozzle is sealed with silicone oil. The electric heating tube manufactured by the above process has the advantages of high voltage resistance, long service life and hard damage.

Owner:TANGZHOU QIANGMING ELECTROTHERMAL APPLIANCE CO LTD

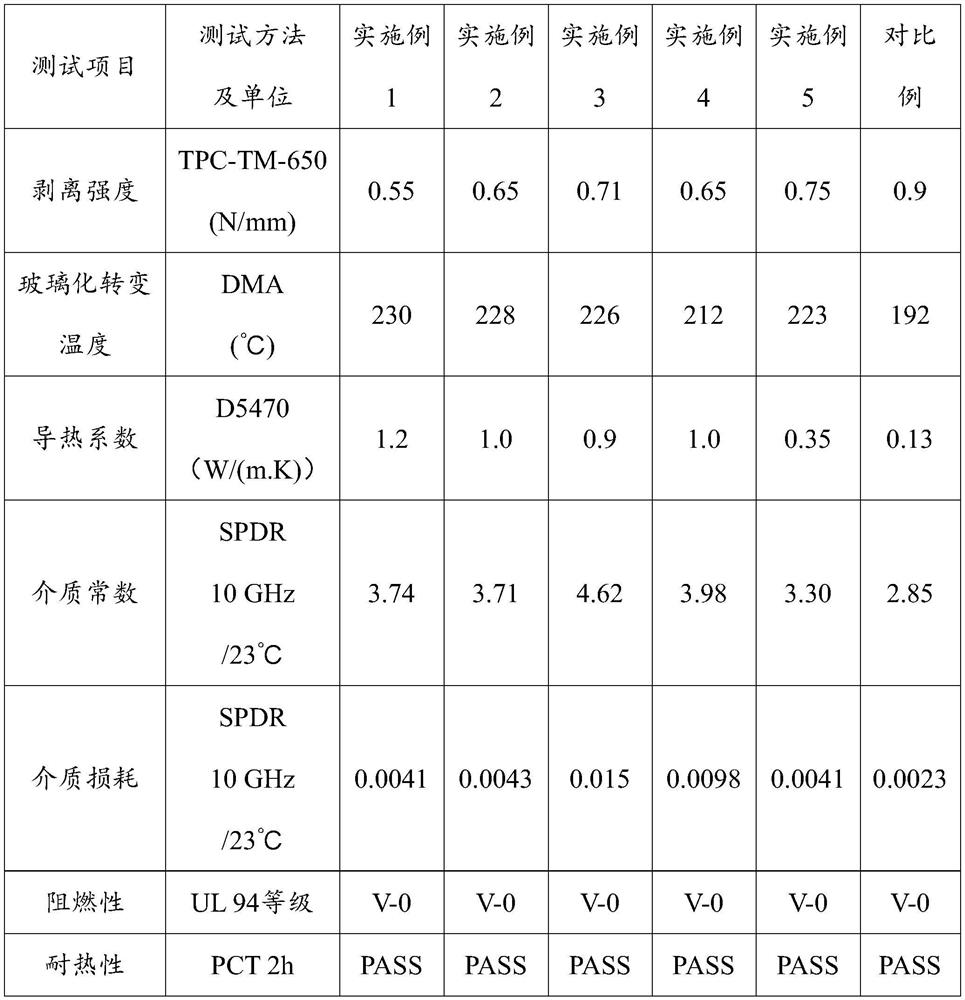

Resin composition, preg, laminated board, preg production method, laminated board production method and use of laminated board

ActiveCN111635626AImprove thermal conductivityMeet needsLamination ancillary operationsSynthetic resin layered productsCarbide siliconPolymer science

Owner:AAC TECH NANJING

Electrically conductive cermet and devices made thereof

An electrically conducting cermet comprises at least one transition metal element dispersed in a matrix of at least one refractory oxide selected from the group consisting of yttria, alumina, garnet, magnesium aluminum oxide, and combinations; wherein an amount of the at least one transition metal element is less than 15 volume percent of the total volume of the cermet. A device comprises the aforementioned electrically conducting cermet.

Owner:GENERAL ELECTRIC CO

Heterogeneous catalyst for preparing isophorone, preparation and applications thereof

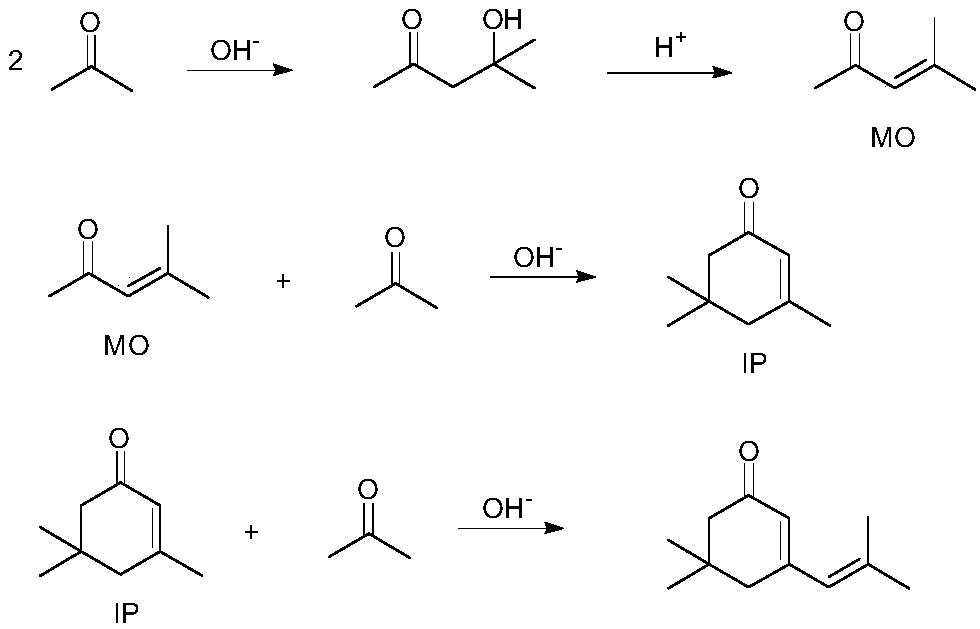

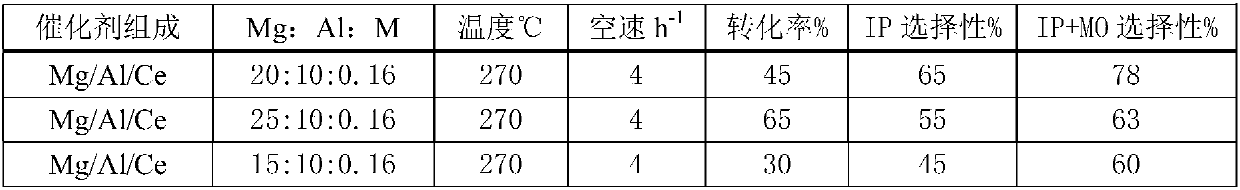

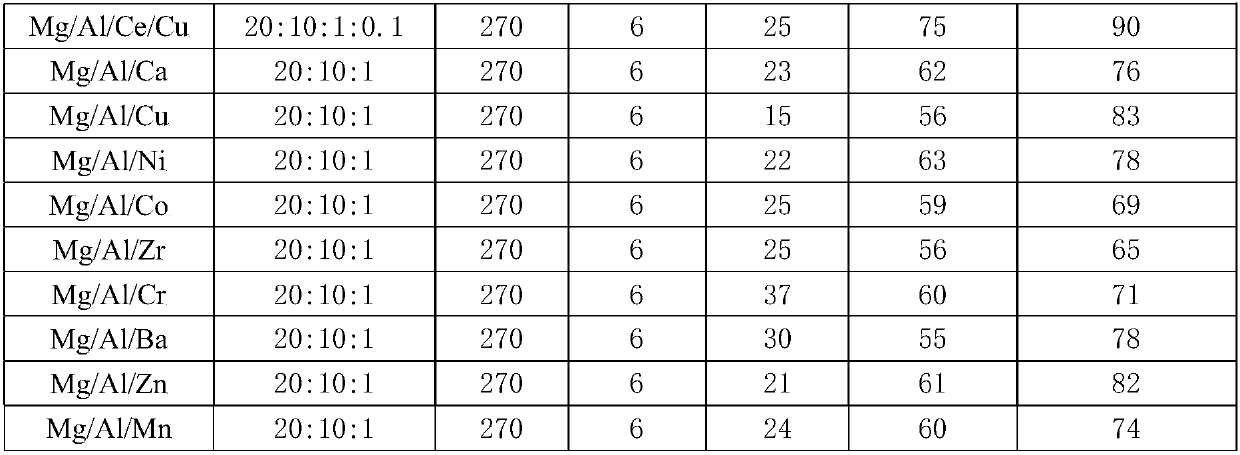

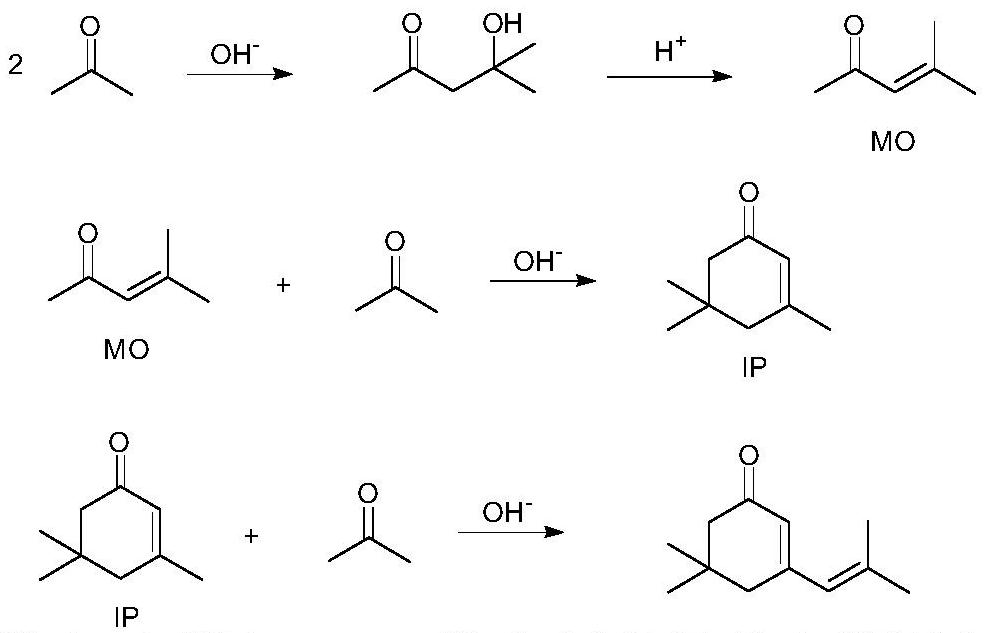

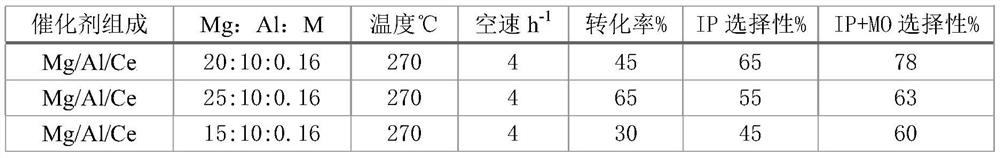

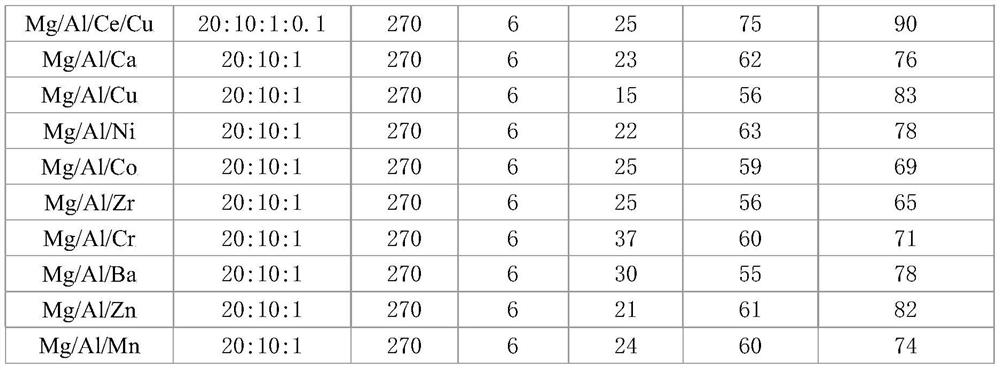

ActiveCN109926040AEasy to prepareLow priceOrganic compound preparationCarbonyl compound preparationIsophoroneMesityl oxide

The present invention provides a method for preparing a heterogeneous catalyst in the presence of a templating agent, wherein the heterogeneous catalyst is used for preparing isophorone through acetone condensation, and is a modified composite oxide (MgO-Al2O3-M<x+>Ox / 2) based on a magnesium aluminum oxide. The preparation method comprises: weighing a certain amount of a mixed salt, dissolving ina certain amount of water, adding a certain amount of a templating agent, adding a certain amount of a precipitating agent to the mixed salt solution in a dropwise manner at a certain temperature, aging, filtering, washing, drying, and calcining to obtain the catalyst. Compared with the catalyst in the prior art, the catalyst of the present invention has advantages of simple preparation method, low price, low bulk density, high activity, high selectivity and good stability. According to the present invention, in the reaction for preparing isophorone through acetone condensation, the reaction temperature is 250-300 DEG C, the mass space velocity of acetone is 1-8 h<-1> under normal pressure, the conversion rate of acetone is up to 45%, the isophorone selectivity is 75%, the mesityl oxide and isophorone selectivity is 90%, and the technology is suitable for the industrial production of isophorone.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

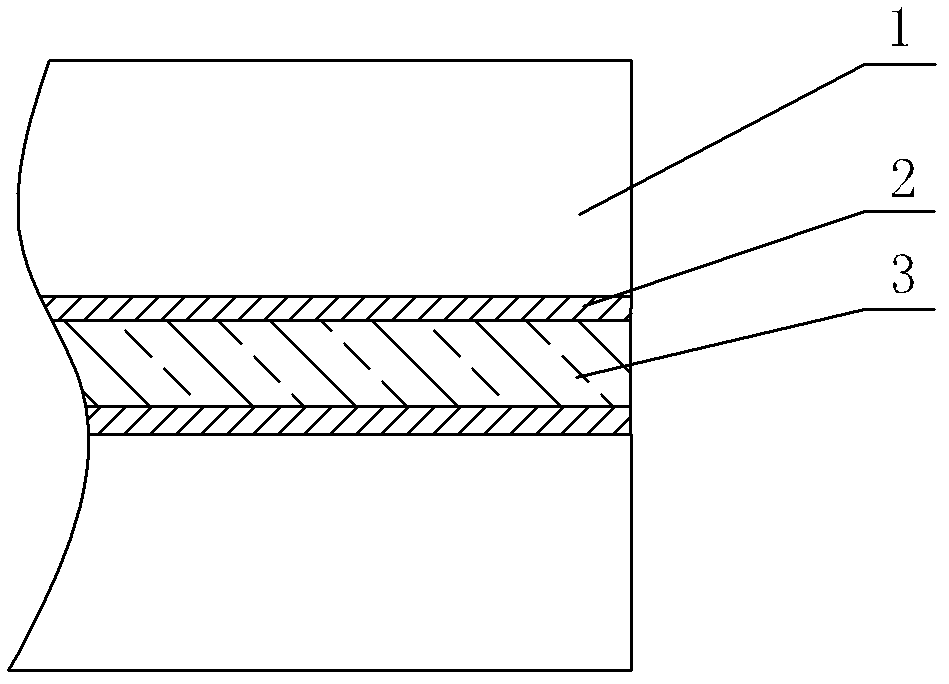

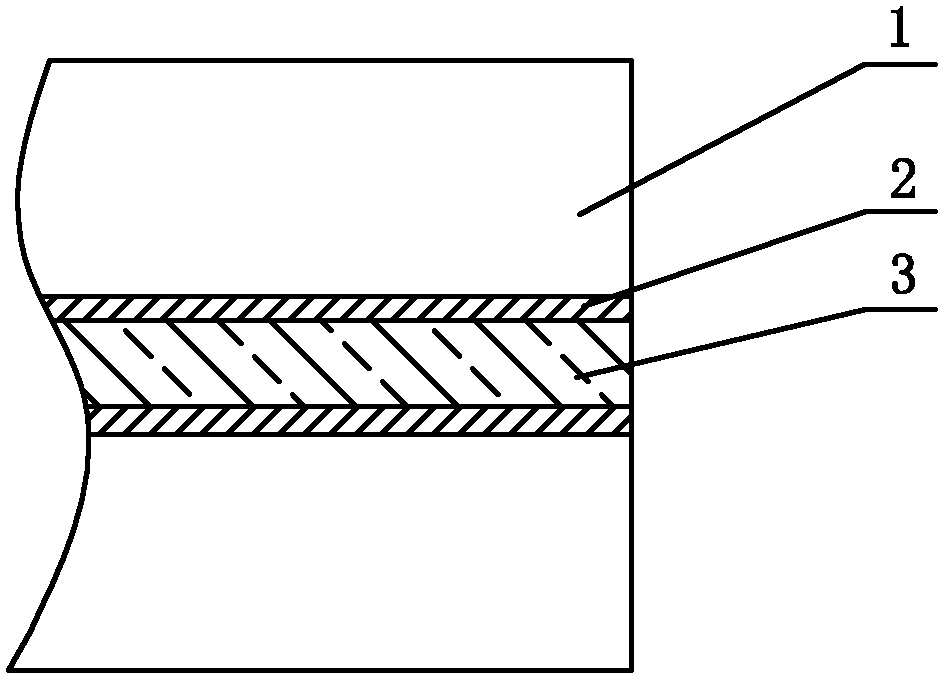

Calcium silicate composite fireproof door core plate

InactiveCN102425362AHigh bonding strengthImprove integrityFireproof doorsDoor leavesFiberCalcium silicate

The invention discloses a calcium silicate composite fireproof door core plate, and belongs to the field of fireproof door core plates. The calcium silicate composite fireproof door core plate is characterized in that: a calcium silicate plate is compounded between two layers of inorganic soluble ceramic fiber plates, and a magnesium aluminum oxide cement layer is arranged between the inorganic soluble ceramic fiber plate and the calcium silicate plate. The fireproof door core plate body has a sandwiched composite structure formed by sticking the moisture-proof inorganic soluble ceramic fiber plate, the calcium silicate plate and the inorganic soluble ceramic fiber plate. The fireproof door core plate with the structure is characterized in that: because of the compound structure of the moisture-proof calcium silicate plate and the inorganic soluble ceramic fiber plates, the fireproof door core plate has the advantages of low volume density, high continuous high-temperature fireproof performance, energy conservation, consumption reduction, excellent sound insulation performance, high strength, high toughness, accurate size, and the like and can be easily processed; the steel plate can be easily embossed; and because all the materials are subjected to moisture-proof treatment, the fireproof door core plate has high durability.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

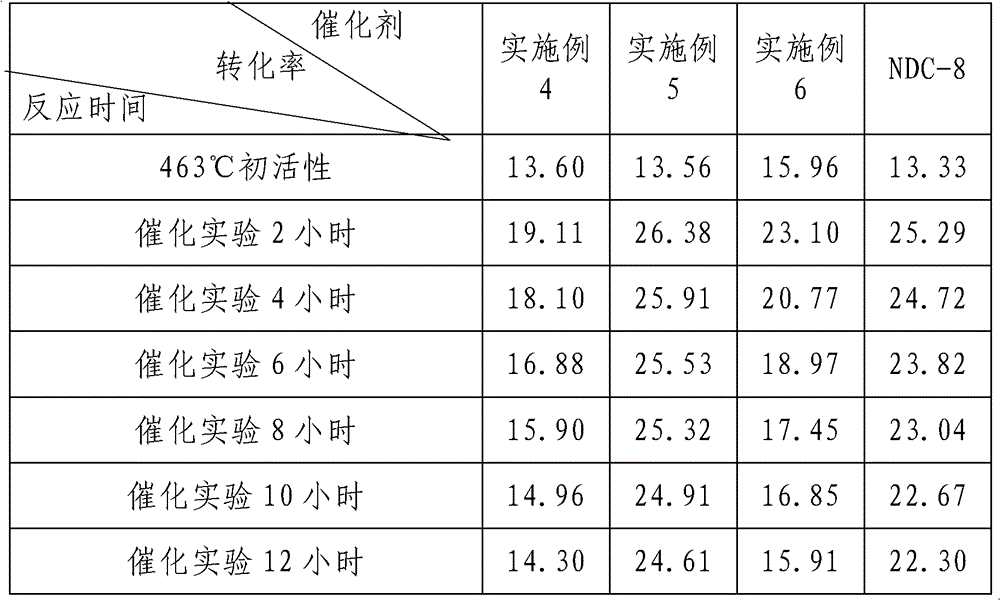

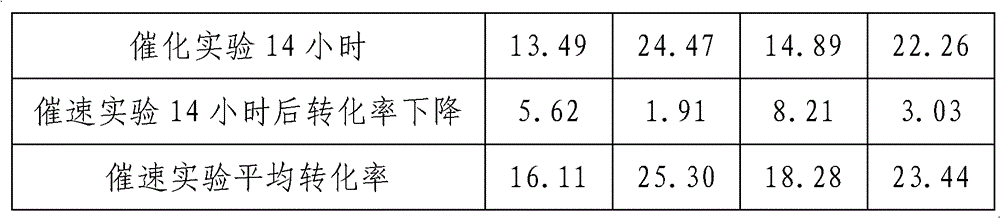

Preparation method of C10-C13 long-chain normal paraffin hydrocarbon dehydrogenation catalyst supporter

InactiveCN103055951AHigh reactivityImprove stabilityCatalyst carriersHydrocarbonsDehydrogenationOxide composite

The invention relates to a supporter for a C10-C13 long-chain normal paraffin hydrocarbon dehydrogenation catalyst, which is prepared by a co-impregnation preparation method by using ammonia water as a precipitating agent. The supporter is a magnesium aluminum oxide composite. The catalyst prepared from the supporter by a vacuum impregnation method comprises the following active components: 0.2-0.5% of Pt and 0.4-4.0% of Sn. The catalyst is mainly used for preparing monoolefines by dehydrogenating C10-C13 long-chain normal paraffin hydrocarbons. Compared with the catalyst prepared from the aluminum oxide supporter by the same method, the catalyst prepared from the magnesium aluminum oxide composite supporter has obviously higher reaction activity and stability; and compared with the commercial catalyst NDC-8, the catalyst prepared from the magnesium aluminum oxide composite supporter also has higher activity and stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Aluminum alloy hardened plating layer treatment process

The invention relates to an aluminum alloy hardened plating layer treatment process. The process includes the steps of: 1, polishing and cleaning the surface of an aluminum alloy workpiece, then daubing a base agent on the surface, wherein the base agent comprises 5-10 parts of aluminum chloride, 2-6 parts of magnesium chloride and 50-80 parts of a rosin solution; 2, heating the aluminum alloy surface obtained in step 1 at 300-400DEG C for 1h, and adding oxygen with an concentration of 60-70%; and 3, introducing sulfur oxide gas to the aluminum alloy piece obtained by step 2 under an oxygen insulation condition, and carrying out heating at 800-1000DEG C for 30h. According to the invention, by means of an accelerated oxidation process, a compact mixed layer of magnesium aluminum oxide and ferroferric oxide can be obtained on the aluminum alloy surface, compared with the aluminum oxide layer of common aluminum alloy, the surface has higher density, and the surface friction is also smaller.

Owner:ZHANGJIAGANG HUACHENG LOCOMOTIVE PRECISION PIPE MFG

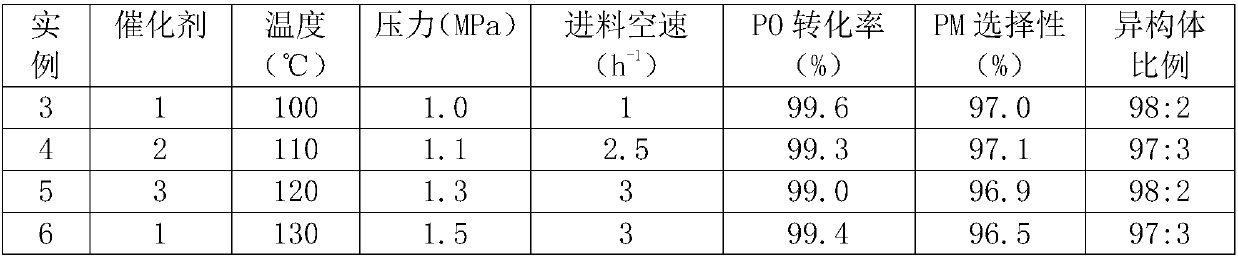

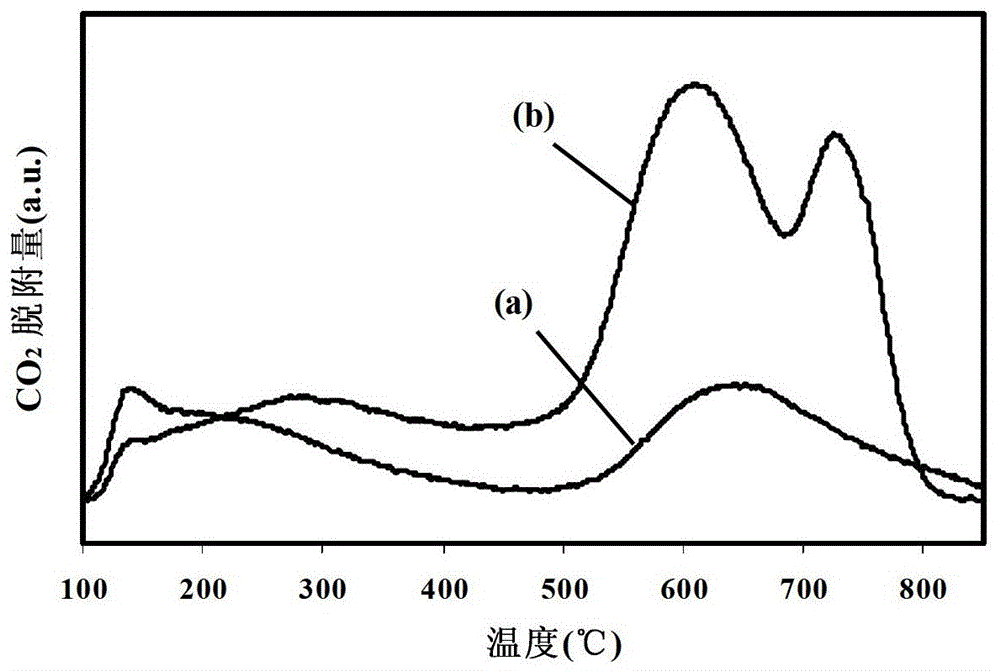

A preparation method of propylene glycol monoalkyl ether

ActiveCN109867589AIncrease alkalinityExtended service lifeEther preparation from oxiranesMetal/metal-oxides/metal-hydroxide catalystsAlcoholEther

The invention discloses a preparation method of propylene glycol monoalkyl ether. Propylene oxide and alcohol are used as raw materials and react under the catalysis of a modified magnetic solid basecatalyst to prepare the propylene glycol monoalkyl ether. The catalyst is obtained by taking nickel ferrite as a magnetic core, magnesium-aluminum oxide as a carrier and cesium as an active componentthrough transition metal modification. The method improves the reaction activity and selectivity, and alleviates the operation conditions; and the catalyst is long in service lifetime, easy to recoverand regenerate and low in production product, overcomes various defects in the prior art, and can be used for industrial production.

Owner:WANHUA CHEM GRP CO LTD

Nozzle coating for continuous casting of rare earth steel and preparation method of nozzle coating

ActiveCN114716850AReduce nodulationGuaranteed travelMelt-holding vesselsAnti-corrosive paintsContinuous castingAluminium

The invention discloses a nozzle coating for continuous casting of rare earth steel and a preparation method of the nozzle coating, belongs to the technical field of refractory materials, and solves the problem that a nozzle is nodulated and blocked in the current continuous casting process of the rare earth steel. The invention relates to a nozzle coating for continuous casting of rare earth steel, which comprises the following components: magnesium aluminum oxide and rare earth oxide, and the mass ratio of the magnesium aluminum oxide to the rare earth oxide is 83.3-94: 1.98-10; the magnesium-aluminum oxide is MgO.Al2O3 or takes MgO.Al2O3 as a main component, and contains a trace amount of MgO; the rare earth steel is steel containing rare earth cerium and / or lanthanum, and the type of the rare earth oxide is the same as that of rare earth in the rare earth steel. The nozzle coating can reduce nodulation of the submersed nozzle in the rare earth steel continuous casting process, so that the replacement frequency of the submersed nozzle is averagely reduced by more than 50%, and smooth operation of rare earth steel continuous casting is guaranteed.

Owner:CENT IRON & STEEL RES INST +1

Preparation and Application of a Solid Superbase Catalyst

InactiveCN103212398BEasy to prepareHigh catalytic activityCarboxylic acid nitrile preparationOrganic compound preparationTube furnaceNitrogen atmosphere

The invention provides a preparation method of a composite metal-oxide-based solid super alkali catalyst. According to the method, magnesium nitrate and aluminum nitrate with a molar ratio of [1:1]-[7:1] are prepared into a solution; 1mol / L of NaOH or KOH is used for regulating the pH to 10-12; refluxing is carried out for 12-72h; a precipitate is washed by using water with different amounts; the precipitate is dried, and is heated to 400-700 DEG C in a tube furnace under a nitrogen atmosphere; roasting is carried out for 1-5h, such that the solid super alkali catalyst with K or Na mass content of 1-20% is obtained. According to the solid super alkali catalyst preparation method, synthesizing and modification are carried out simultaneously, wherein modification object K or Na and carrier magnesium-aluminum oxide are simultaneously produced during the roasting process, such that time and energy consumption are saved. When the catalyst is applied in a Knoevenagel condensation reaction, catalyst dose is low, reaction conditions are mild, and catalytic activity is high. The catalyst can be repeatedly used through centrifugal separation.

Owner:HUNAN UNIV

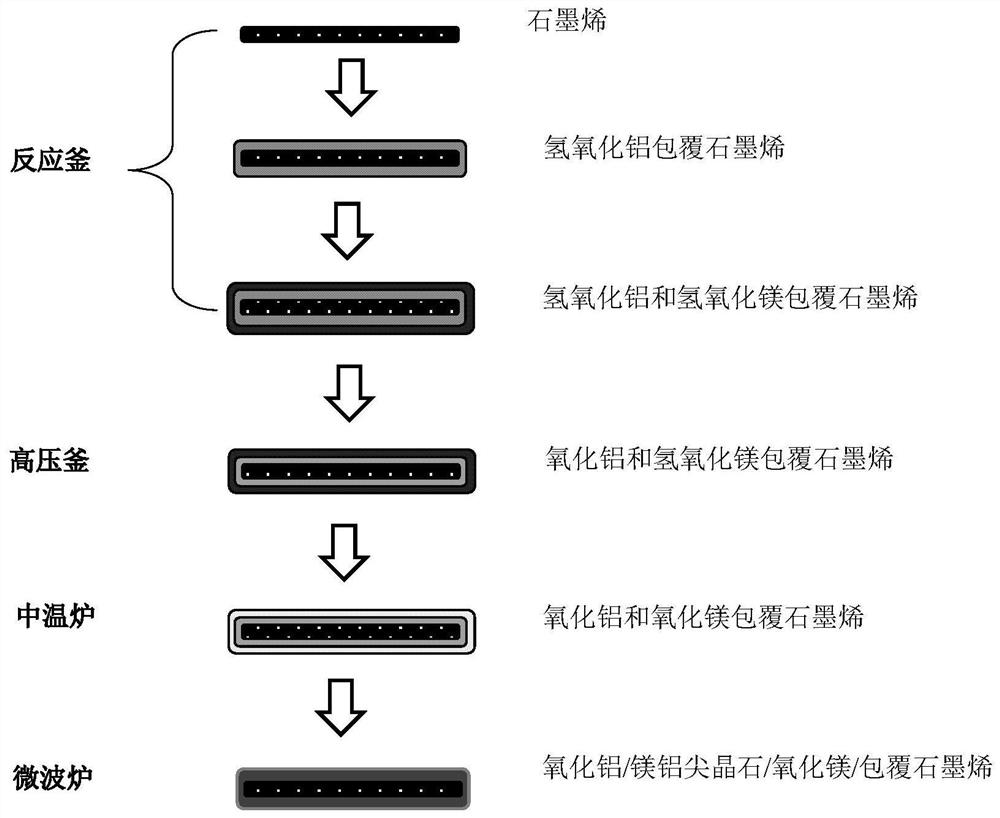

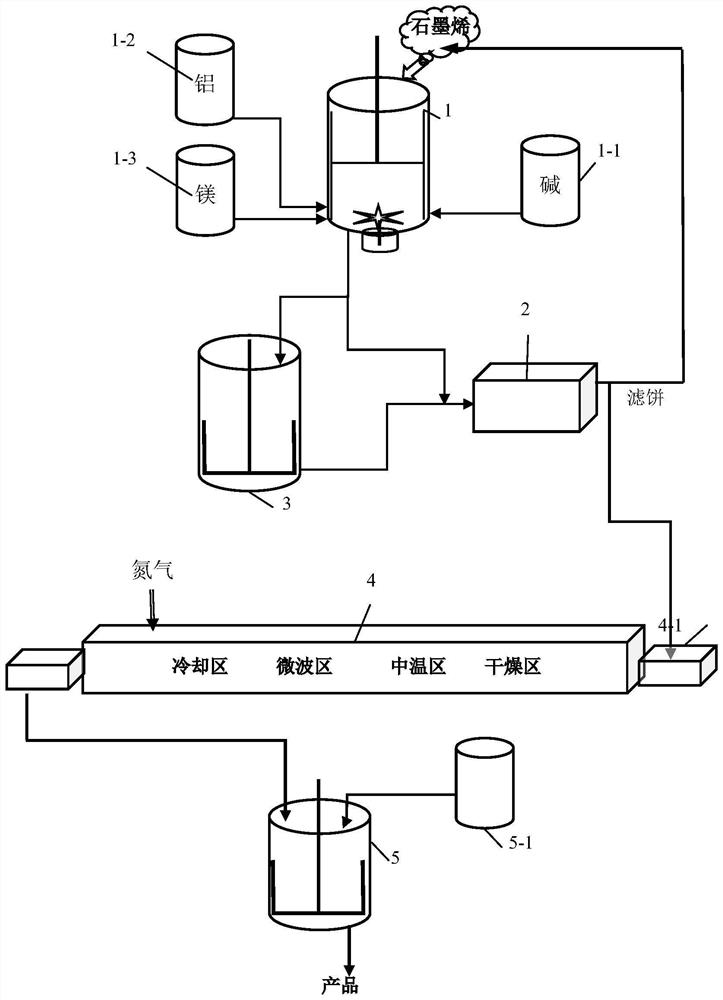

Production method of high thermal conductivity and insulation graphene for high polymer material and graphene

The invention discloses a preparation method of high-thermal-conductivity insulating graphene for a high polymer material and graphene. The method comprises the following steps: taking graphene oxide as a raw material to obtain uniformly dispersed graphene oxide slurry; the preparation method comprises the following steps: dissolving soluble aluminum salt, magnesium salt and alkali in deionized water to obtain an acid-base solution, and stirring and mixing a silane coupling agent, deionized water, acetic acid and ethanol to obtain a silane coupling agent reaction solution; pumping the graphene oxide slurry into an acid and alkali resistant reaction kettle, wherein the reaction kettle has stirring and jacket temperature control functions; an alkali solution is pumped in until the pH value is 6-9, and the temperature in the reaction kettle is 20-40 DEG C; the preparation method comprises the following steps: grinding and crushing sintered aluminum oxide / magnesium aluminate spinel / magnesium oxide coated graphene powder by adopting a heatable vertical stirring mill until the particle size is equal to the flake diameter of graphene, spraying a silane coupling agent reaction solution into the stirring mill, and continuously carrying out ball milling until the silane coupling agent reaction solution uniformly coats the surface of the powder, so as to obtain the silane coupling agent coated graphene powder. The product aluminum magnesium oxide and coupling agent modified graphene is obtained.

Owner:西安安聚德纳米科技有限公司

Medicine for treating gastropathy and preparation method thereof

InactiveCN101711772AShorten production timeHigh hardnessDigestive systemPill deliveryMagnesium stearateDicyclomine hcl

The invention relates to a medicine for treating gastropathy and a preparation method thereof in the field of the medical technology. The prescription of the medicine for treating the gastropathy comprises the following components by weight: 2 parts of hyoscine butylbromide, 2 parts of dicyclomine hydrochloride, 3 parts of sodium copper chlorophyllin, 350 parts of aluminium-magnesium hydroxide dried gel, 40 parts of magnesia, 60 parts of synthetic alumina-silicate, 10-25 parts of starch, 2-10 parts of pregelatinized starch, 15-30 parts of carboxymethyl starch sodium and 5-15 parts of magnesium stearate. The preparation method of the tablets of the medicine comprises the following steps: after sieving the hyoscine butylbromide, the dicyclomine hydrochloride, the aluminium-magnesium hydroxide dried gel, the magnesia, the synthetic alumina-silicate, the starch, the pregelatinized starch and the like respectively, putting into a mixer together, mixing evenly, putting the sodium copper chlorophyllin into a big beaker, pouring into the mixer after adding a right amount of distilled water and dissolving, then adding a right amount of distilled water, stirring into a soft material, putting the soft material into a granulator and drying into dry granules after sieving by a sieve mesh and granulating; and sieving the magnesium stearate and the carboxymethyl starch sodium respectively, putting into the mixer together with the dry granules and tabletting after mixing evenly.

Owner:张茂松

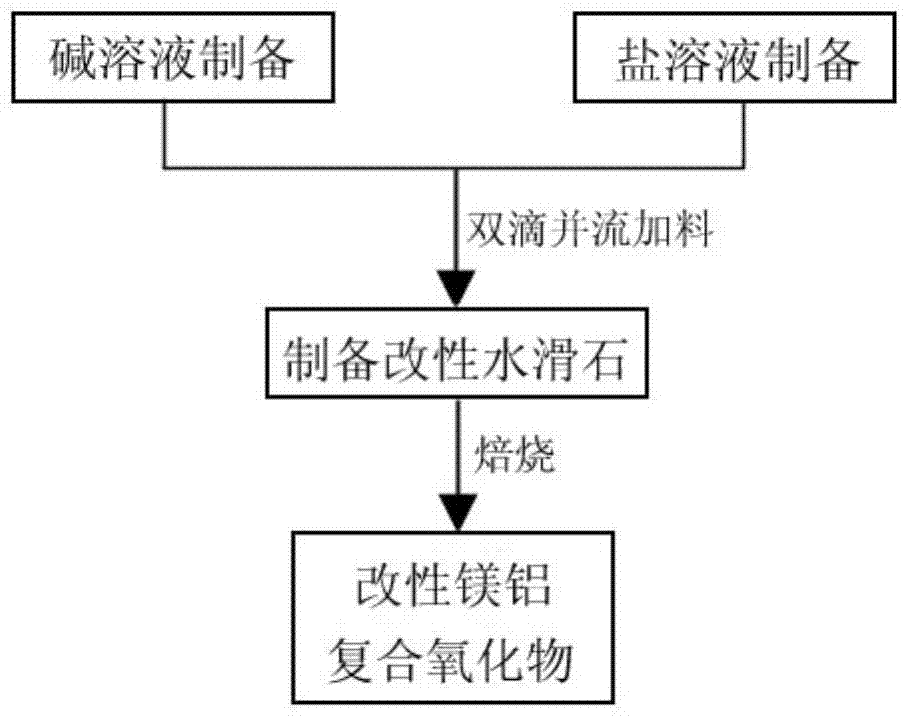

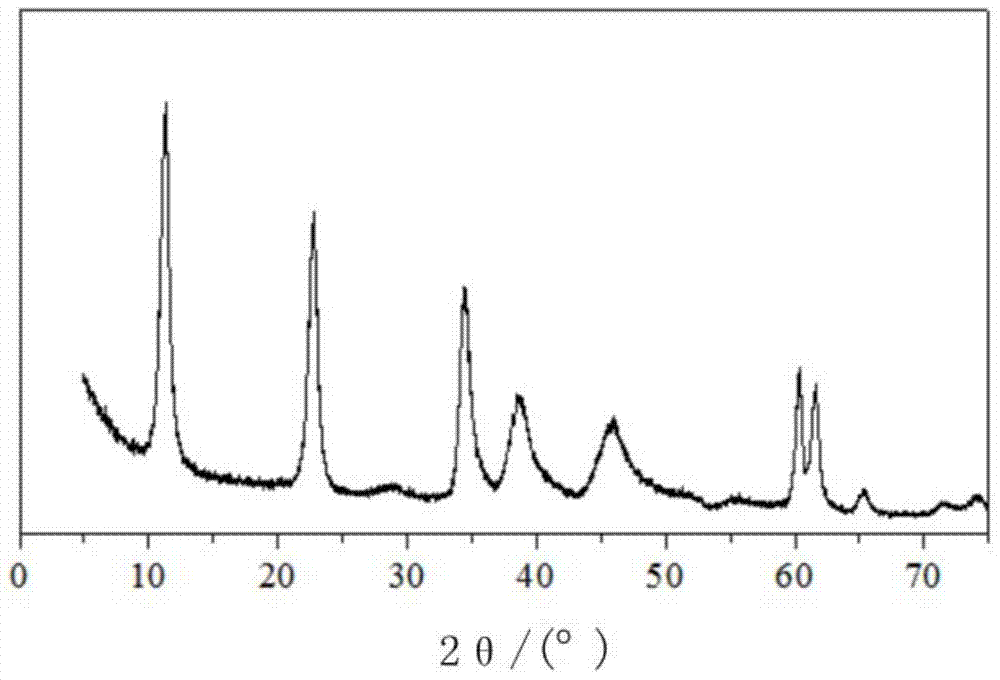

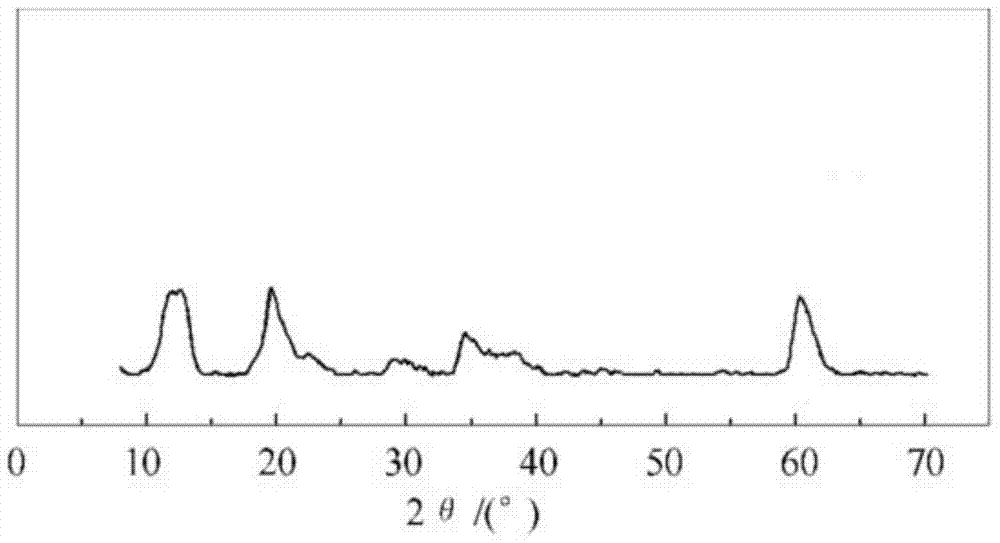

A modified magnesium-aluminum composite oxide catalyst for acetone condensation and its preparation method and application

ActiveCN104874386BImprove self-condensation reactivityHigh selectivityOrganic compound preparationCarbonyl compound preparationRare-earth elementIsophorone

The invention discloses a modified magnesium-aluminum composite oxide catalyst for acetone condensation, a preparation method and application thereof, and belongs to the technical field of acetone condensation. In the catalyst, the modified hydrotalcite is prepared by using a precipitant and a metal salt solution containing a rare earth element by a double-drop co-current co-precipitation method, and the modified magnesium-aluminum composite oxide catalyst is obtained after roasting. The catalyst is modified with rare earth components (La and Ce or Y and Ce) to modify the magnesium-aluminum composite oxide to effectively adjust the acid-base density and strength ratio of the catalyst surface, thereby improving its catalytic acetone self-condensation reaction activity and isotropic reaction. Selectivity of pherone. The modified catalyst achieves a single pass conversion rate of acetone of 35-42%, and a selectivity to isophorone of 72%-76%.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

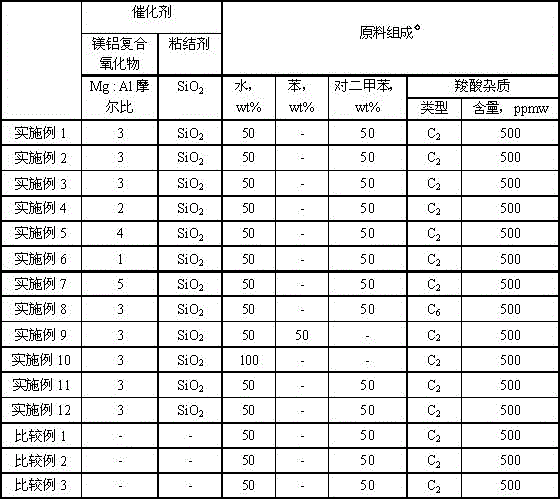

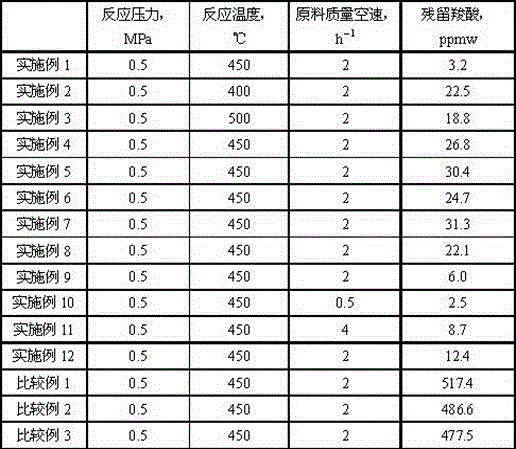

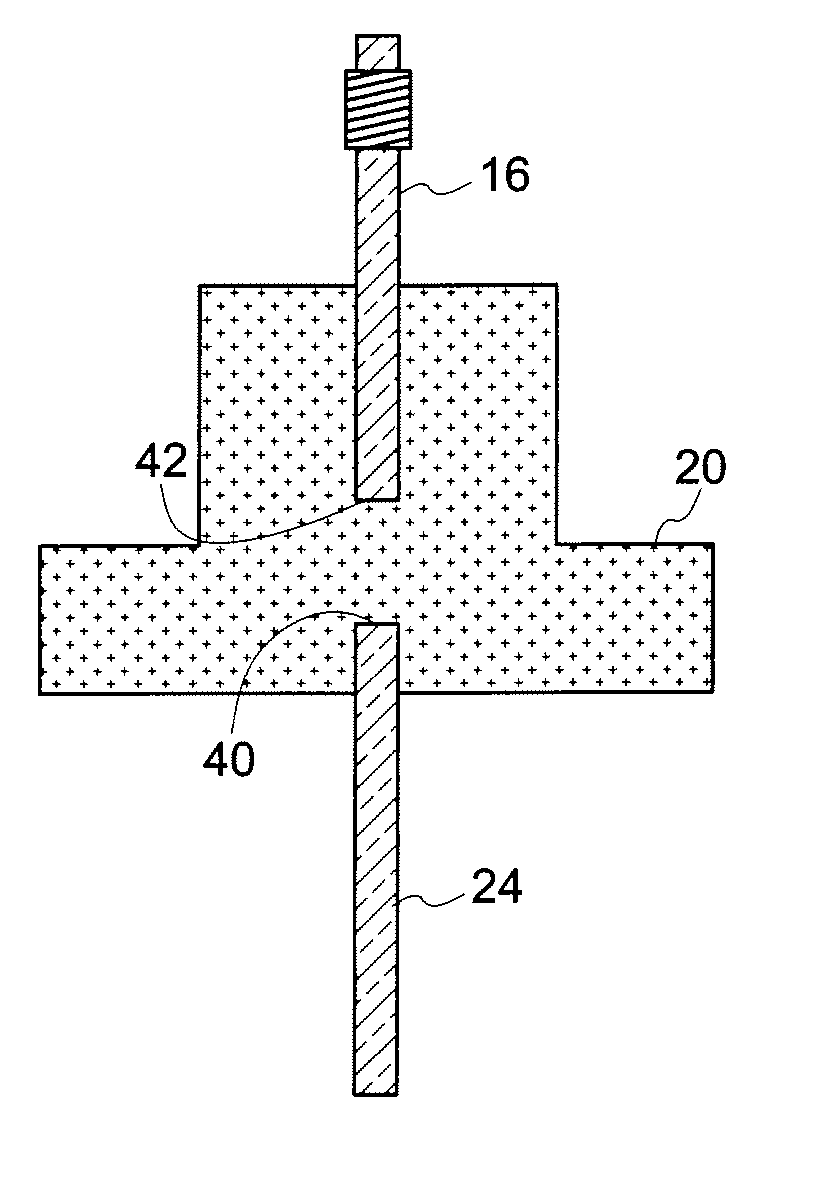

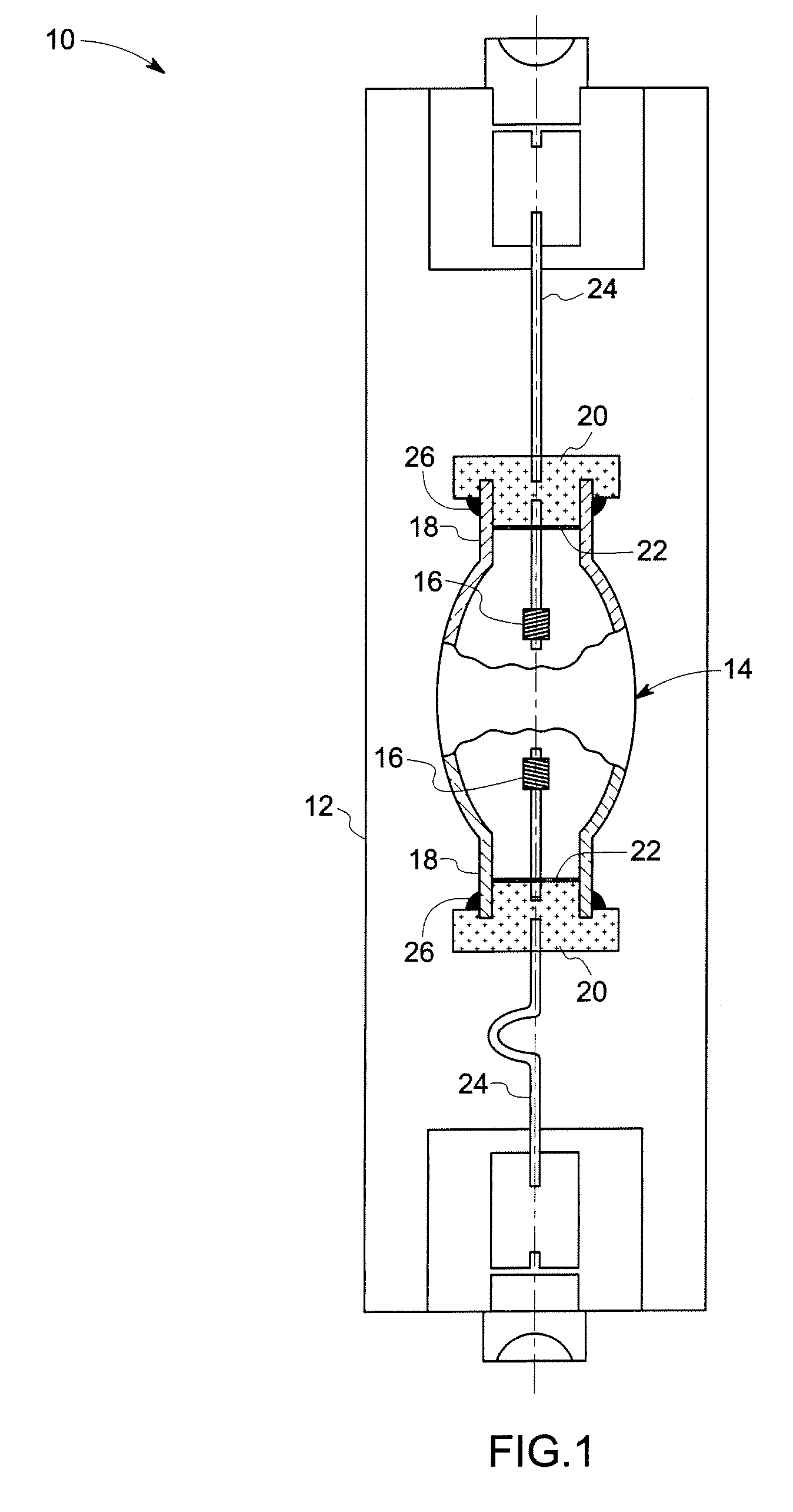

Method for removing carboxylic acid in water-containing raw material containing carboxylic acid impurities

Owner:CHINA PETROLEUM & CHEM CORP +1

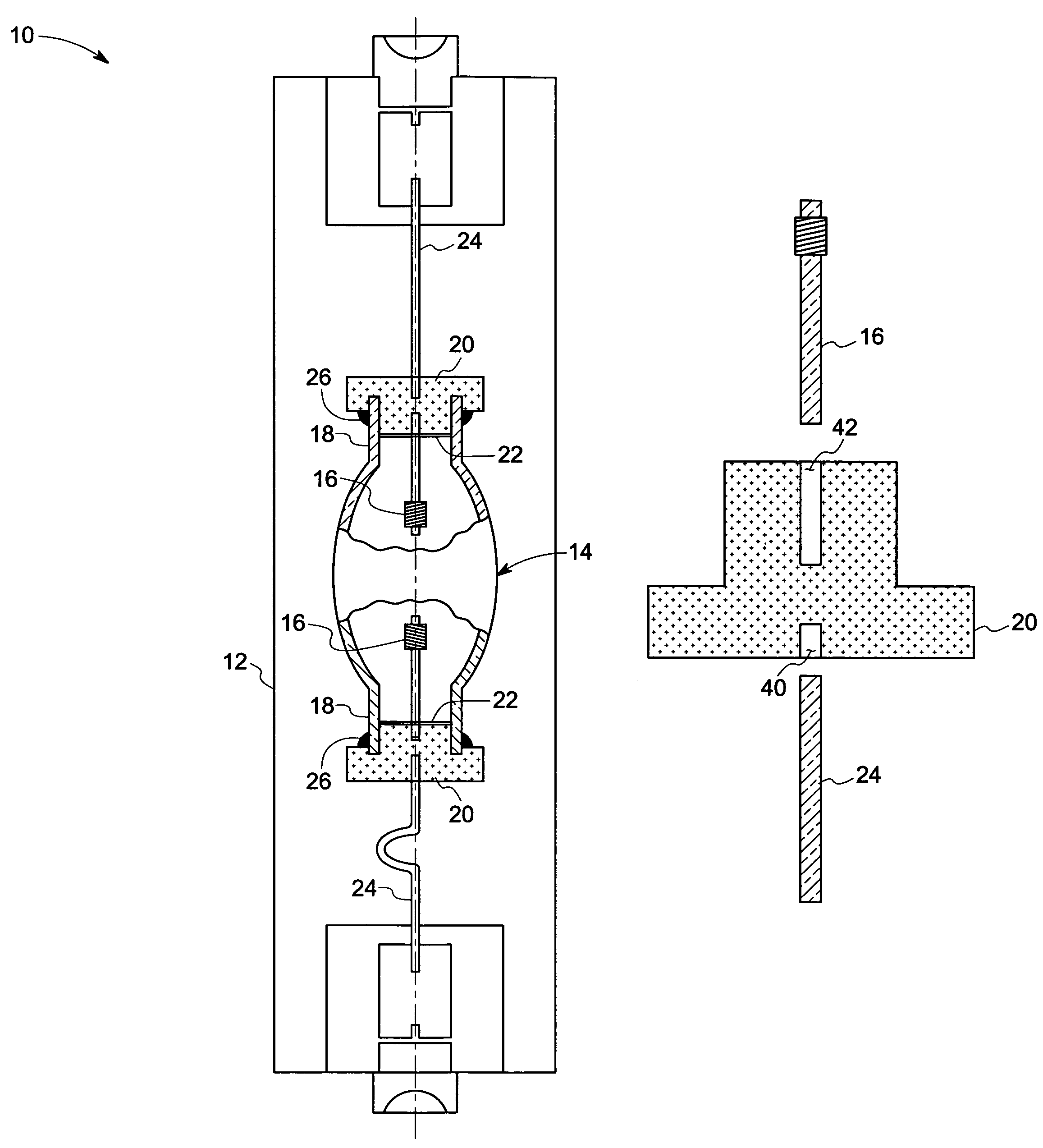

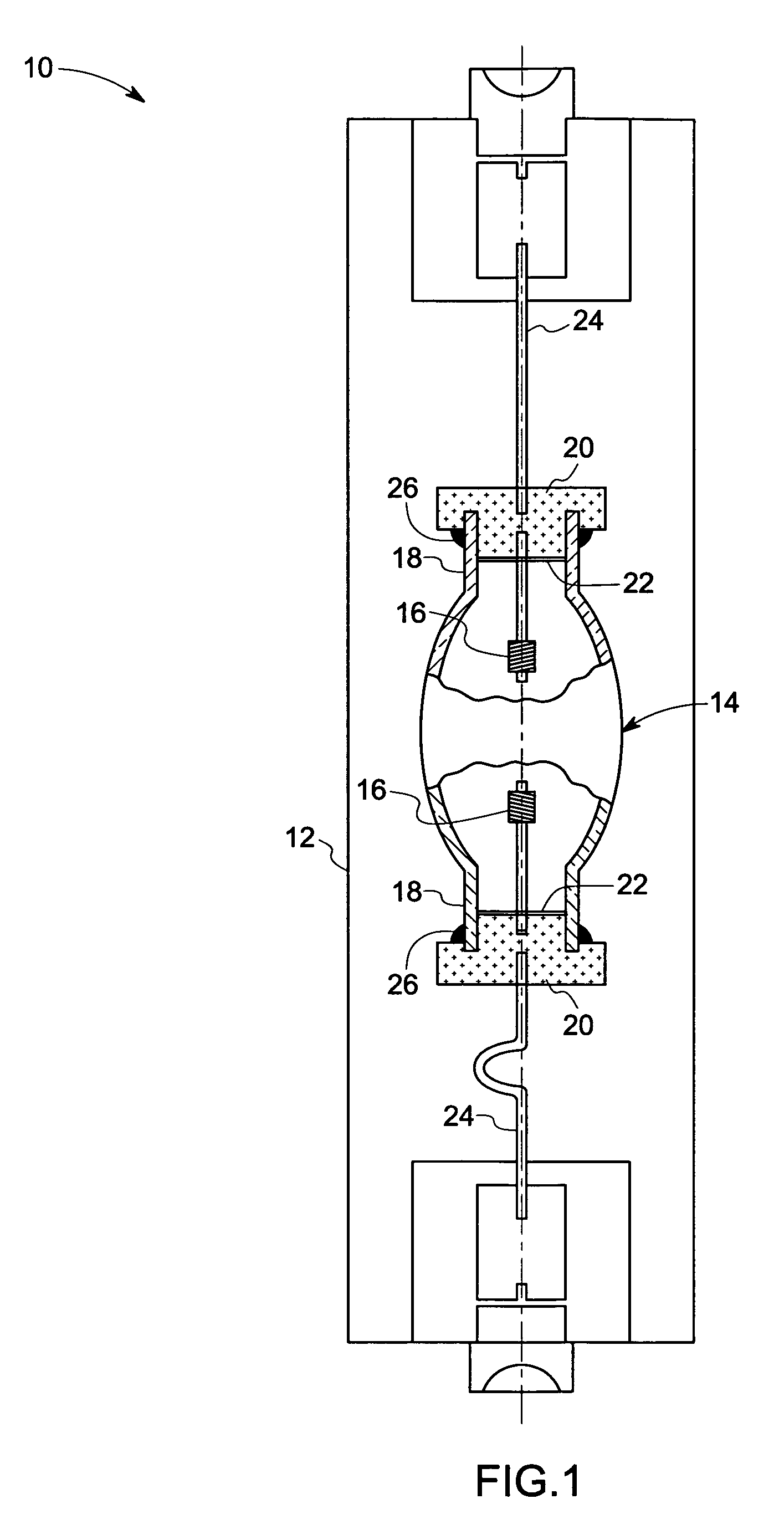

Electrically conductive cermet and method of making

InactiveUS20080112835A1Gas discharge lampsNon-conductive material with dispersed conductive materialRefractoryVolume percent

An electrically conducting cermet comprises at least one transition metal element dispersed in a matrix of at least one refractory oxide selected from the group consisting of yttria, alumina, garnet, magnesium aluminum oxide, and combinations; wherein an amount of the at least one transition metal element is less than 15 volume percent of the total volume of the cermet. A device comprises the aforementioned electrically conducting cermet.

Owner:GENERAL ELECTRIC CO

Light hydrocarbon distillate selective dediene catalyst and method for preparing the same

InactiveCN1224676CReduce carbon depositionExtended service lifeRefining by selective hydrogenationActive componentSolid solution

A catalyst for selectively hydrogenating and dediolefinating for light hydrocarbon fractions, comprises 0.05-1.0 wgt% Pd as the active component and the carrier of magnesium aluminum oxide solid solution. In the magnesium aluminum oxide, the mol ration of Mg / Al is 1.0-12.0. the catalyst also contains auxiliary agents selecting from Co, Mo, Ni and Wu. The catalyst is suitable for selectively hydrogenating and dediolefinating for light C4-C6 hydrocarbon fractions.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of heterogeneous catalyst for preparing isophorone and its preparation and application

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

A kind of preparation method of propylene glycol monoalkyl ether

ActiveCN109867589BHigh yieldHigh ratio of primary and secondary ethersEther preparation from oxiranesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystPropanediol

The invention discloses a preparation method of propylene glycol monoalkyl ether. Propylene oxide and alcohol are used as raw materials to react under the catalysis of a modified magnetic solid base catalyst to prepare propylene glycol monoalkyl ether. The catalyst uses nickel ferrite as the magnetic core, magnesium aluminum oxide as the carrier, and cesium as the active component, and is obtained through transition metal modification. The method improves the reaction activity and selectivity, eases the operating conditions, and at the same time, the catalyst has a long service life, is easy to recycle and regenerate, has low production cost, overcomes various defects in the prior art, and can be used in industrialized production.

Owner:WANHUA CHEM GRP CO LTD

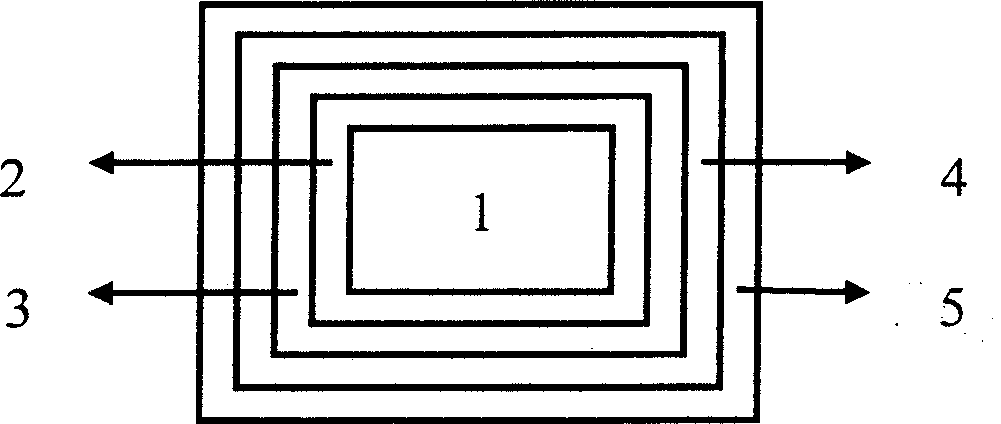

Cable processing technology

PendingCN114582560AImprove insulation performanceGuaranteed normal transmissionRubber insulatorsPlastic/resin/waxes insulatorsElectrical conductorCopper wire

The invention discloses a cable processing technology which comprises the following steps: preparing a conductor petal; preparing a conductor core; preparing an anti-interference layer: selecting raw materials including polyethylene, tinned broken copper wires, calcium stearate, conductive carbon black, nano aluminum oxide, magnesium, an adhesive, an antioxidant, methyl silicone oil, silicon dioxide, butylated hydroxytoluene and a thermal resistance mixture, and adding the polyethylene, the calcium stearate, the nano aluminum oxide, the magnesium, the silicon dioxide and the butylated hydroxytoluene into a mixing stirrer for stirring; after completion, tinned broken copper wires, conductive carbon black and a thermal resistance mixture are added into the mixing stirrer, the mixture is continuously added into the mixing stirrer, stirring is performed again, an adhesive, an antioxidant and methyl silicone oil are slowly added into the mixing stirrer in the stirring process, an anti-interference mixture is obtained, and the anti-interference mixture and a conductor core are both added into a plastic extruding machine; and preparing an outer protective layer. The preparation process is simple, and the prepared cable is resistant to magnetic interference, good in flame retardant effect and high in tensile property.

Owner:江苏恒康电力科技有限公司

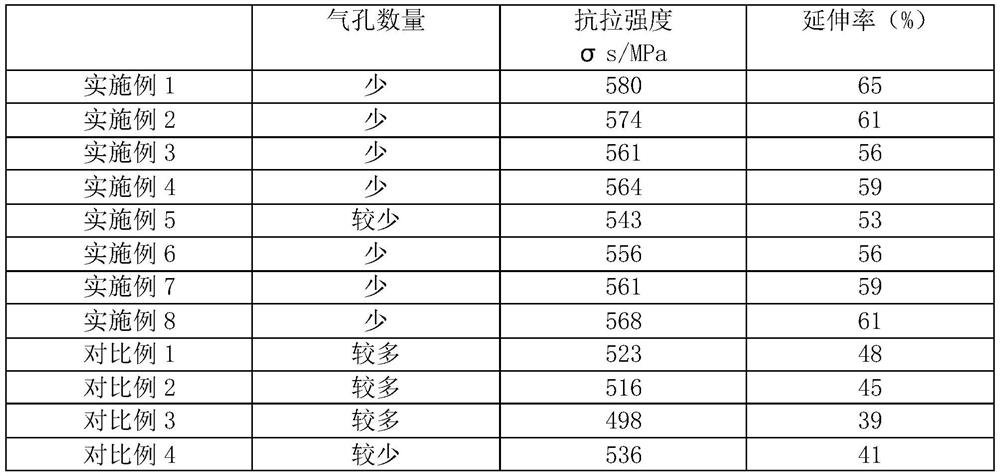

A flux cored wire

ActiveCN110539105BMitigate or eliminate the impactLess porosityWelding/cutting media/materialsSoldering mediaAl powderNiobium

The invention relates to a flux-cored welding wire, which includes a steel strip and powder filled inside the steel strip. The components contained in the powder and their mass percentages in the total amount of the powder are as follows: 35-50% rutile, 5-50% limestone 8%, graphite 0.4‑0.6%, alumina 5.5‑8.5%, magnesium alloy 3.5‑6.5%, fluoride 2‑5%, silicon manganese alloy 1.6‑2.8%, boron powder 4‑8%, chromium powder 3‑ 6%, nickel powder 2.5-3.5%, titanium powder 0.8-2%, aluminum powder 0.5-1.5%, niobium powder 0.1-0.5%, and the balance is iron powder. The invention has the effect of improving the porosity resistance performance when the flux-cored welding wire is welded with the parent metal.

Owner:常州长海焊材有限公司

Preparation process of 2,3,3,3-tetrafluoropropionic acid

InactiveCN108358771AAvoid corrosionReduce generationPreparation from carboxylic acid amidesMetal/metal-oxides/metal-hydroxide catalystsHydrolysisRaw material

The invention relates to a preparation process of 2,3,3,3-tetrafluoropropionic acid. According to the method, the 2,3,3,3-tetrafluoropropionic acid is prepared by taking waste liquor containing N,N-diethyl-2,3,3,3-tetrafluoropropylamide as a raw material and taking beryllium-doped magnesium aluminum oxide solid super base as a catalyst under a hydrolysis condition. The molar yield is 99 percent ormore.

Owner:佛山市飞程信息技术有限公司

Absorble magnesium alloy stent possessing double controlledly released coating layer and its preparation method

InactiveCN100488575CSolve the speed problemSolve coordination problemsStentsSurgeryCross-linkAcetic acid

An absorbabal Mg-alloy scaffold with double release-controllable coated layers is composed of a skeleton made of the Mg alloy WE43 containing Mg and one or more of Y, Nd, Zr, Yb, Er, Dy and Gd, a compact anticorrosive layer on the surface of skeleton and made of magnesium aluminum oxide or cerium oxide, a cross-linked compact madicine carrying layer on said anticorrosive layer and made of chitosan or collagen, a non-cross-linked medicine carrying layer on the first one and made of polylevolactic acid or polyhydroxyacetic acid, and a surficial release-controlling layer made of polylevelactic acid or polyhydroxyacetic acid. Its preparing process is also disclosed.

Owner:TIANJIN UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com