Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68results about How to "Reduce nodulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High grade non- oriented silicon steel and method for manufacturing same

ActiveCN101333620AReduce furnace roll nodulesReduce energy consumptionTemperature control deviceSheet steelElectrical steel

The invention discloses a high-brand non-oriented silicon steel as well as a manufacturing method, which are mainly characterized in that: chemical constituents thereof include, in weight percent: Si: 2.5 to 3.5 percent, Al: 0.5 to 1.5 percent, C<=0.004 percent, Mn: 0.10 to 1.50 percent, P<=0.02 percent, S<=0.005 percent, N<=0.002 percent, B<=0.005 percent, B / (C+N)=0.5-2.0; and the manufacturing method mainly includes: heating a casting billet to above 1100DEG C in a heating furnace, carrying out rolling, normalizing, acid washing and cold rolling after heat preservation, with the reduction rate of between 70 and 78 percent, and annealing, with d.p. equal to -25 to -40DEG C. The non-oriented silicon steel and the manufacturing method can make electric steel sheets and strips with excellent performance, and can reduce furnace roller nodulations and energy consumption in production, and further reduce the production cost.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for controlling and treating bottom roller dross of carbon sleeve furnace

ActiveCN101906529AReduce running speed varianceReduce nodulationFurnace typesHeat treatment process controlDrossDew point

The invention discloses a method for controlling and treating bottom roller dross of a carbon sleeve furnace. The possibility of dross occurrence is reduced by effective preventive measures for controlling the brushing current of a brush roller, reducing the use of a severely-oxidized transition strip, controlling appropriate furnace pressure, dew point and hydrogen content according to the difference of process speeds and process temperatures, periodically adjusting the rotating speed of a furnace roller, reducing running speed difference between the furnace roller and band steel, controlling the temperature raising and lowering rates of process temperature transformation during steel transformation and the like. Simultaneously, different treatment methods are used according to different dross states, so that treatment time is shortened greatly. The problems of long treatment time, single treatment method, no distinguished treatment according to different dross states, grinding of all furnace bottom rollers during treatment, damage to the furnace bottom rollers without dross, effect on service life and the like are solved, the plate surface quality of a cold-rolled and annealed product is enhanced and product percent of pass is increased.

Owner:ANGANG STEEL CO LTD

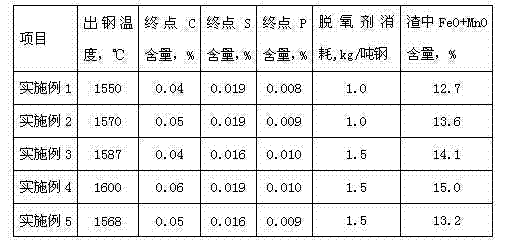

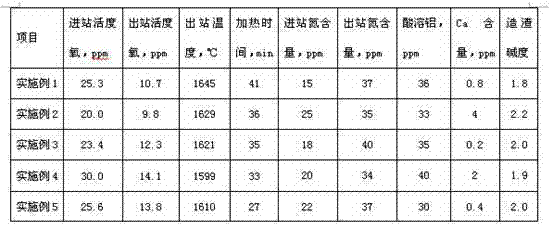

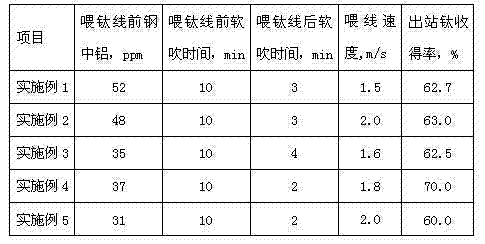

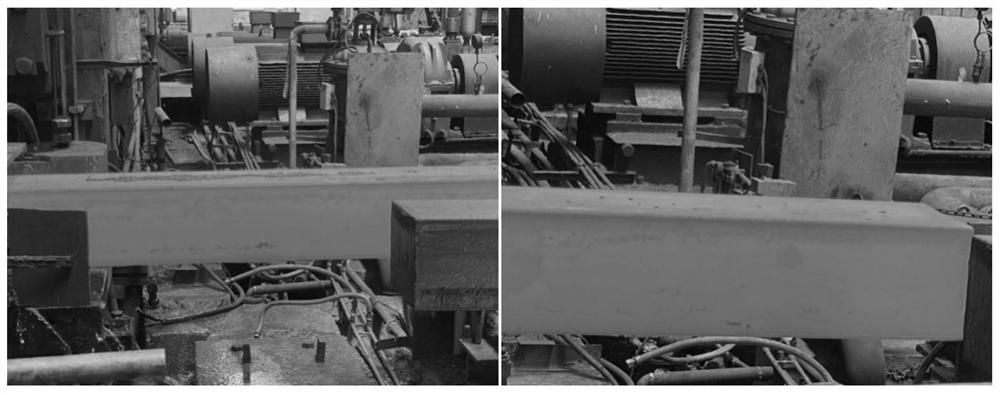

Titanium-containing solder wire steel production method capable of alleviating continuous casting nozzle clogging

InactiveCN104259414AReduce nodulationIncrease the number of continuous pouring furnacesManufacturing convertersProcess efficiency improvementSteelmakingTitanium

The invention discloses a titanium-containing solder wire steel production method capable of alleviating continuous casting nozzle clogging and belongs to the technical field of steel making. The titanium-containing solder wire steel production method capable of alleviating the continuous casting nozzle clogging includes processing steps that (1) smelting in a top-bottom combined blowing converter, to be specific, using low-sulfur molten iron and high-quality waste steel to blow; (2) refining in an LF furnace; (3) performing titanium alloying in an LF furnace, to be specific, softly blowing molten steel for 10 minutes, and feeding low-aluminum low-nitrogen 70Ti iron-packaged core to the molten steel to perform the titanium alloying after finishing soft blowing; (4) protecting casting in the whole process. The titanium-containing solder wire steel production method capable of alleviating the continuous casting nozzle clogging is aimed to solve the continuous casting water feed nozzle and submerged nozzle clogging problem for the titanium-containing solder wire steel production; the titanium-containing solder wire steel production method capable of alleviating the continuous casting nozzle clogging alleviates the nozzle clogging degree through optimizing the steel making, refining and continuous casting techniques, improves the continuous casting furnace number and cast blank yield and effectively lowers the production cost.

Owner:HEBEI IRON AND STEEL

Method for smelting low-carbon aluminium-killed steel and method for continuously casting low-carbon aluminium-killed steel

The invention provides a method for smelting low-carbon aluminium-killed steel, comprising the following steps: carrying out primary smelting by adopting a converter top and bottom combined blowing way, and then tapping molten steel obtained by the primary smelting into a steel ladle; blocking slag and predeoxidising in the tapping process, wherein the slag is blocked to ensure that the total content of FeO and MnO which enter the steel ladle is 3-5wt% of the molten steel entering the steel ladle, and the predeoxidising operation comprises the step of adding ferro-aluminium deoxidizer into the molten steel and can ensure that the oxygen content of the molten steel is 10-100ppm; carrying out primary aluminium feeding on the molten steel in the steel ladle before the molten steel in the steel ladle is refined after tapping is completed; refining the molten steel after the primary aluminium feeding is completed, and carrying out secondary aluminium feeding in the refining process; and removing impurities floating on the liquid surface of the molten steel. The invention also provides a method for continuously casting the low-carbon aluminium-killed steel, comprising the following steps: pouring the molten steel obtained by adopting the method for smelting the low-carbon aluminium-killed steel into a crystallizer, and continuously pulling and cooling. By adopting the method for smelting the low-carbon aluminium-killed steel, the purity of the molten steel can be obviously improved, and the accretion in the continuous casting process can be reduced.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

Method for smelting ultra-low-carbon steel by using single-nozzle refining furnace

The invention relates to a smelting method of ultra-low-carbon steel, which is an operating method for decarburizing by using a single-nozzle refining furnace. The invention is a smelting method for smelting ultra-low-carbon steel by using the single-nozzle refining furnace. The method is used for smelting the ultra-low-carbon steel with C of being less than or equal to 20ppm, and adjusts the inserting depth of a single-nozzle furnace dipping pipe, lance position of an oxygen lance, vacuum degree, oxygen supplying flow and eccentric bottom-blown argon of a steel ladle to stir molten steel under the vacuum condition by controlling the initial conditions of the thickness of a tapping slag layer, the temperature of arrived molten steel, the content of arrived carbon and the like so as to achieve the purpose of decarburization. The method has the following advantages that: 1. the treatment time of the molten steel is short, the refractory material consumption is low, and the scaffolding of the dipping pipe is little; and 2. the smelting time is short, the splashing is little, the consumption of sealing rings is less, the corrosion of the steel ladle is not serious, the cost is low and the operation is simple.

Owner:北京北科三泰科技发展有限公司

High Ca, silicon-free aluminum calcium iron alloy for deoxidising of molten steel and its preparation method

The invention discloses calcium-aluminium- ferrum alloy for steel- melting and deoxidizing, the weight proportion of them is as follows: 15% C21C 7 / 06 C22C 33 / 04 C22C 33 / 06 0 6 1 2007 / 7 / 16 101086029 2007 / 12 / 12 100475980 2009 / 4 / 8 2009 / 4 / 8 2009 / 4 / 8 Guo Qingcheng Liaoning 117100 Guo Qingcheng Fan Songtao

Owner:本溪铸新冶炼有限公司

CrNiMo round steel for wind power gear and preparation method

InactiveCN112522615AImprove purityReduce and stabilize superheatProcess efficiency improvementElectric furnaceGear wheelContinuous caster

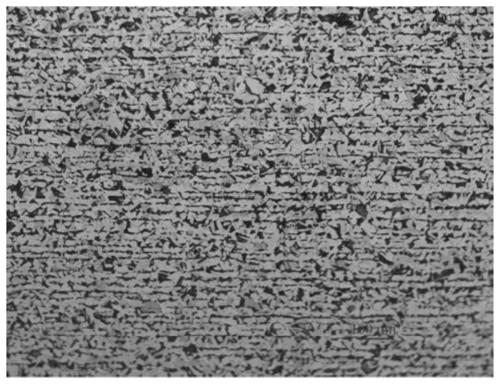

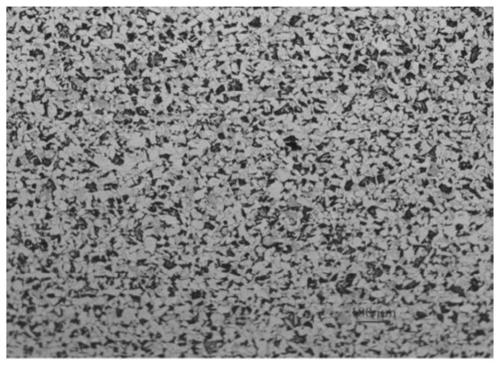

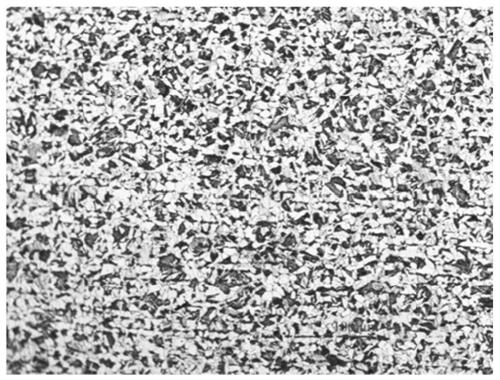

The invention discloses CrNiMo round steel for a wind power gear and a preparation method. The CrNiMo round steel comprises the following ingredients in parts by weight: 0.15%-0.21% of C, 0.17%-0.37%of Si, 0.50%-0.90% of Mn, 1.50%-1.80% of Cr, 1.40%-1.70% of Ni, smaller than or equal to 0.20% of Cu, smaller than or equal to 0.025% of P, smaller than or equal to 0.025% of S, 0.25-0.35% of Mo, smaller than or equal to 0.0020% of O, 0.025-0.040% of Al and 0.0080-0.0120% of N. The preparation method comprises the steps of electric furnace smelting, LF refining, VD vacuum degassing, five-machine five-flow arc-shaped continuous casting machine and rolling, the preparation method is easy to operate and high in production efficiency, the prepared round steel has the advantages of being low in oxygen content, narrow in through hardening band, high in purity, accurate in component control, light in strip shape, excellent in surface quality and the like, and various technical requirements of steel for wind power gears are completely met.

Owner:ZENITH STEEL GROUP CORP +1

Large-section aluminum-containing hot-rolled H-shaped steel and manufacturing method thereof

PendingCN110438397AImprove mechanical propertiesImprove low temperature resistanceNear net shapeImpurity

The invention discloses large-section aluminum-containing hot-rolled H-shaped steel and a manufacturing method thereof. Chemical components of the hot-rolled H-shaped steel comprise, by weight percent, 0.11-0.14% of C, 0.18-0.25% of Si, 1.40-1.50% of Mn, smaller than or equal to 0.025% of P, smaller than or equal to 0.008% of S, 0.040-0.050% of V, 0.012-0.02% of Ti, 0.040-0.050% of Al and the balance iron and trace impurity. The manufacturing method of the steel comprises the steps of molten iron pre-desulfuration, converter smelting, LF refining, near-net-shape beam bank continuous casting and rolling. According to the steel and the method, by means of vanadium-titanium composite microalloying, meanwhile, an aluminum element is used in cooperation, the refined crystalline strengthening and dispersion strengthening effect is achieved, and the comprehensive mechanical performance of the large-section H-shaped steel is improved. In the production process, the beam blank single-point flange non-equilibrium full-protection continuous casting technology is adopted, the cleanness degree of the molten steel is controlled strictly, scaffolding of a water opening is reduced, the inclusion content is low, the low-temperature impact performance of rolled materials is stable, and the yield is high.

Owner:SHANDONG IRON & STEEL CO LTD

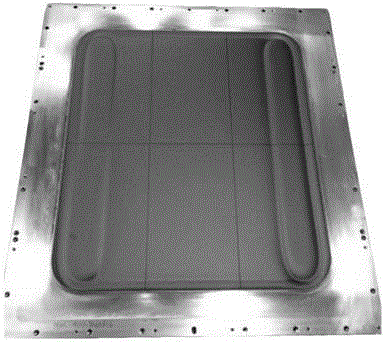

Pressureless sintering method for TFT-grade ITO target

ActiveCN105294072AReduce nodulationShorten the production cycleCompression moldingHigh volume manufacturing

The invention relates to a pressureless sintering method for a TFT-grade ITO target. The method includes the specific steps that ultra-high-activity ITO nanopowder is selected, the pelleted ITO powder is subjected to compression molding, the molding pressure ranges from 25 MPa to 80 MPa, and the holding time ranges from 15 seconds to 300 seconds; the ITO powder is subjected to isostatic cool pressing reinforcing, the isostatic pressing pressure ranges from 180 MPa to 300 MPa, and the holding time ranges from 300 seconds to 1,200 seconds; then the ITO power is directly placed in a sintering furnace, atmosphere is introduced, the ITO powder is divided into multiple segments for temperature rise and holding at certain temperature rise rate, and the ITO powder is cooled to room temperature at certain rate to complete sintering. The method is characterized in that the ITO powder pelleted by adding a molding agent is subjected to compression molding, and after isostatic cool pressing reinforcing, the ITO powder is directly placed in the sintering furnace to be sintered. Through the design of the sintering manufacturing procedure, an original degreasing process is fused into a sintering process, and the two processes are conducted in the sintering furnace together. Compared with the technology with the independent degreasing procedure, degreasing equipment is omitted, equipment investment is reduced, more energy is saved, the sintering period is shortened by about 40%, production efficiency is improved, and the method is suitable for mass production.

Owner:GUANGXI CRYSTAL UNION PHOTOELECTRIC MATERIALS CO LTD

Method for smelting ultra-low-carbon steel by using single-nozzle refining furnace

The invention relates to a smelting method of ultra-low-carbon steel, which is an operating method for decarburizing by using a single-nozzle refining furnace. The invention is a smelting method for smelting ultra-low-carbon steel by using the single-nozzle refining furnace. The method is used for smelting the ultra-low-carbon steel with C of being less than or equal to 20ppm, and adjusts the inserting depth of a single-nozzle furnace dipping pipe, lance position of an oxygen lance, vacuum degree, oxygen supplying flow and eccentric bottom-blown argon of a steel ladle to stir molten steel under the vacuum condition by controlling the initial conditions of the thickness of a tapping slag layer, the temperature of arrived molten steel, the content of arrived carbon and the like so as to achieve the purpose of decarburization. The method has the following advantages that: 1. the treatment time of the molten steel is short, the refractory material consumption is low, and the scaffolding of the dipping pipe is little; and 2. the smelting time is short, the splashing is little, the consumption of sealing rings is less, the corrosion of the steel ladle is not serious, the cost is low andthe operation is simple.

Owner:北京北科三泰科技发展有限公司

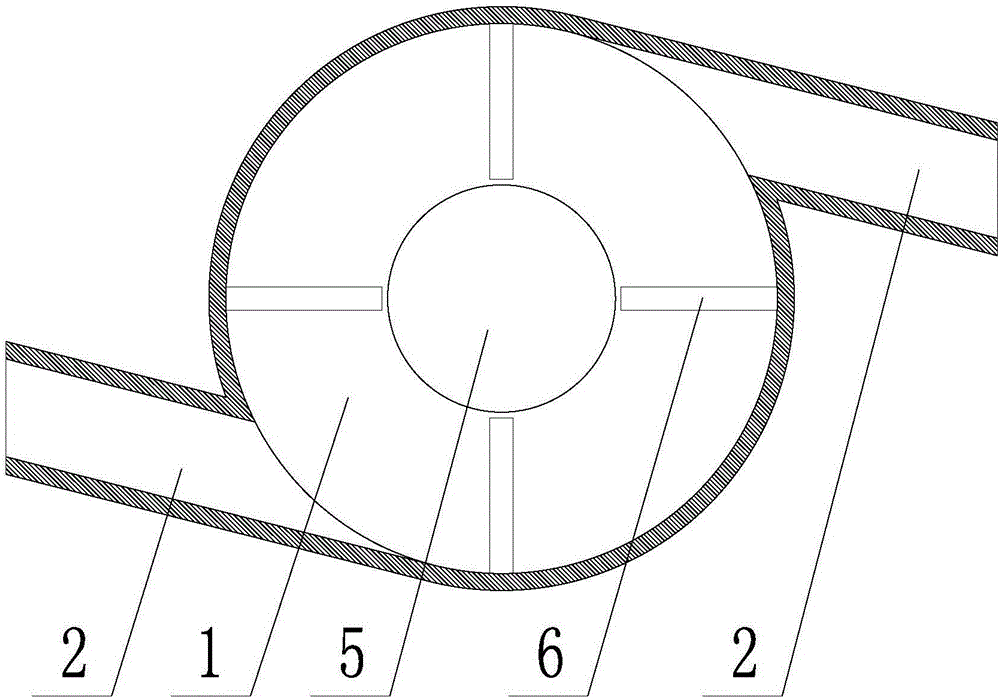

Nozzle flow rotating generation device and nozzle flow rotating continuous casting method

The invention discloses a nozzle flow rotating generation device and a nozzle flow rotating continuous casting method. The device comprises a cylinder type flow rotating generator and a cylinder type flow rotating tundish; the cylinder type flow rotating generator is mounted in a traditional continuous casting tundish, and an inner cavity of the traditional continuous casting tundish is communicated with an immersion type nozzle through the cylinder type flow rotating generator; the cylinder type flow rotating tundish has two mounting modes; according to the first mode, the cylinder type flow rotating tundish and the traditional continuous casting tundish are used in a cooperated manner, the cylinder type flow rotating tundish is mounted on the outer portion of the traditional continuous casting tundish, and the traditional continuous casting tundish is communicated with the immersion type nozzle through the cylinder type flow rotating tundish; and according to the second mode, the cylinder type flow rotating tundish is independently used, and a nozzle of a steel ladle is communicated with the immersion type nozzle directly through the cylinder type flow rotating tundish. The method comprises the steps that before continuous casting, according to the continuous casting technology, the nozzle flow rotating generation device is selected, then, the device and the traditional continuous casting tundish are assembled, during continuous casting, under the effects of molten steel gravity and tangent line entrances, molten steel generates rotating flowing, and molten steel in the immersing type nozzle generates rotary flowing.

Owner:NORTHEASTERN UNIV

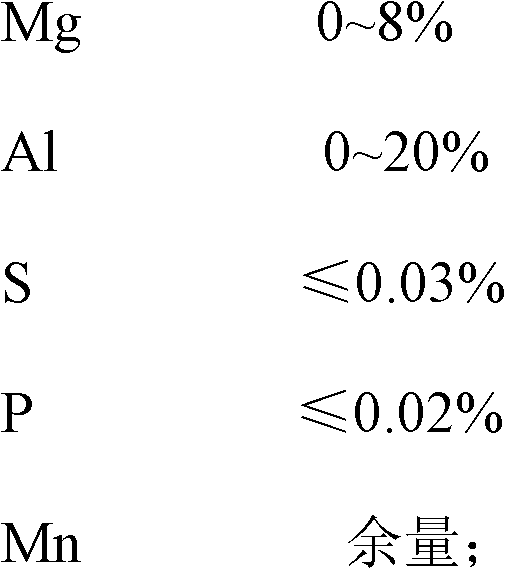

Compressing double deoxidizer for steelmaking and preparation method thereof

The invention aims at disclosing a compressing double deoxidizer for steelmaking, which, by weight percentage, comprises 5-20% of Ca, 0-8% of Mg, 0-20% of Al, less than 0.03% of S, less than 0.02% of P, 2-10% of binder and balanced Mn. The invention further aims at disclosing a preparation method of the compressing double deoxidizer for the steelmaking, raw materials are added in the binder after mixed according to the proportion and evenly mixed, the mixed raw materials are put in a compression molding press with the pressure less than 20T for pressing, the stoving temperature is set to be 60-120 DEG C to dry a compressed double deoxidizer block for 15-60min, and a dried compressed double deoxidizer block is cooled and packaged to obtain the needed compressing double deoxidizer for the steelmaking.

Owner:CHANGZHOU MAOSHENGTE ALLOY PROD +1

Low-temperature pulverization inhibitor for sintered ore

InactiveCN102605176AReduce the problem of continuous cycle enrichmentReduce the pulverization rate of low temperature reductionKirchhoff's circuit lawsCarboxymethyl starch

The invention relates to a smelting assistant for steel works, namely a low-temperature pulverization inhibitor for sintered ore. The low-temperature pulverization inhibitor is prepared by mixing carboxymethyl starch, boric acid, silicon micropowder and a permeate agent in designated proportion; compared with CaCl, Cl ion drag-in quantity is reduced more than 50%, the low-temperature pulverization inhibitor can not generate a replacement reaction with K and Na alkali metals in a furnace charge, therefore, the problem of continuous and circulating enrichment of KCl (kirchhoff's circuit laws) and NaCl in a blast furnace is solved, the reactivity of coke is restrained, the melting loss reaction is reduced, the heat intensity of the coke is ensured, low temperature reduction pulverization rate of the sintered ore is reduced, the destructive effect of the alkali metal on the coke and the blast furnace is basically solved, the furnace condition is smooth, and the output is increased.

Owner:通化耐博新材料股份有限公司

Ito sputtering target and method for manufacturing same, ito transparent electroconductive film, and method for manufacturing ito transparent electroconductive film

ActiveCN106460161AHigh strengthReduce arcingConductive layers on insulating-supportsVacuum evaporation coatingIndiumArea ratio

The present invention relates to a sputtering target characterized by being a sintered compact comprising In, Sn, O, and unavoidable impurities, the sintered compact containing Sn in an atomic ratio Sn / (In + Sn) of 1.8% to 3.7% (excluding 3.7%), the average crystal grain size of the sintered compact being in the range of 1.0-5.0 [mu]m, vacancies having a major-axis diameter of 0.1-1.0 [mu]m constituting an area ratio of 0.5% or less, the sintered compact having two phases including an indium oxide phase and a tin-oxide-rich phase, the area ratio of the tin-oxide-rich phase being 0.1-1.0%, and 95% or more of the tin-oxide-rich phase being present at grain boundary triple points. The present invention makes it possible to provide an ITO sputtering target suitable for forming a transparent electroconductive film and which has a low tin oxide content and enables a low-resistance film to be obtained even at low temperature, the sputtering target having a small grain size, high density, and high strength, and making it possible to reduce the occurrence of arcing or nodules.

Owner:JX NIPPON MINING & METALS CO LTD

High-purity steel and production process

ActiveCN112795728AImprove abilitiesImprove joining efficiencyProcess efficiency improvementSlagArgon flow

The invention relates to high-purity steel and a production process, and belongs to the technical field of steel production. The production process comprises the procedures of carrying out converter primary smelting, carrying out LF refining, carrying out VD vacuum treatment and carrying out continuous casting, the LF refining procedure comprises the following steps that (21) online bottom argon blowing is carried out when the steel enters a station, the argon flow is 120-140L / min, and the Ar pressure is 0.35-0.4MPa; (22) a slag former and a deoxidizing agent are added for first-time electrifying slagging, 6-level voltage is adopted, the current is 28000-30000A, the argon flow is 280-300L / min, the argon pressure is 0.35-0.4MPa, sampling is conducted after slagging is conducted for 8-12min through power transmission heating, and alloy is added to adjust components; the slag former comprises 4.5-7.2kg of calcite per ton of steel, 0.7-1.1kg of fluorite per ton of steel and 0.3-0.5kg of bauxite per ton of steel; and (23) after the components are adjusted, secondary electrifying is conducted, 4-level voltage is adopted, the current is 32000-34000 A, the argon flow is 70-90L / min, the Ar pressure is 0.3-0.35MPa and when the temperature of molten steel is greater than or equal to 1670 DEG C, a silicon-calcium wire is fed. The high-purity steel and the production process have the effects of reducing the impurity content in the molten steel and improving the purity of the molten steel.

Owner:天津荣程联合钢铁集团有限公司

Electrolysis device and method

ActiveCN106337193AImprove liquidityImprove heat transfer performanceElectrolysis componentsElectrolysisEddy current

The invention provides an electrolysis device and method. The electrolysis device comprises an electrolysis tank, at least one cathode in the electrolysis tank, multiple anodes arranged around the cathode in intervals and multiple air blowing pipes symmetrically arranged on the inner wall of the electrolysis tank, wherein bottom outlets of the air blowing pipes stretch out of the bottom surface of the electrolysis tank and are arranged along a horizontal direction. An electrolyte at the bottom of the electrolysis tank is stirred through gas and a gas outlet direction and a cathode center direction form an a certain angle in air blowing so that the electrolyte on the bottom produces eddy currents along a horizontal direction and the electrolyte in all zones in the electrolysis tank can circularly flow and thus heat transfer and mass transfer in the electrolysis tank are improved, inner temperatures and components are uniformed, product quality is improved and furnace conditions are improved.

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD

Device for restraining copper metallurgy smelting furnace from generating coking and use method

A device for restraining a copper metallurgy smelting furnace from generating coking and a use method, and belongs to the technical field of copper smelting. The device is characterized in that waste heat boiler outlet smoke is used for heating prepared-in high-concentration oxygen-rich secondary air through a heat exchange device, the secondary air mount is reduced, anthracite is prepared in copper concentrates, the smelting oxygen-rich air concentration is improved, and therefore coking in the smelting furnace and other hot boilers is restrained or controlled. The method is applicable to use of various copper metallurgy smelting furnaces, and the beneficial effects of being small in investment, low in running cost, easy to operate and the like are achieved.

Owner:CHIFENG FUBANG COPPER

Method for solving blockage of pouring nozzle of billet caster producing high carbon chromium bearing steel

The invention discloses a method for solving blockage of a pouring nozzle of a billet caster producing high carbon chromium bearing steel. The method includes LF refining, RH refining and a casting process. According to the method, calcium treatment operation is carried out in the middle of the LF refining. Calcium line addition is 0.10-0.35 kg / t steel. The content of molten steel Ca is controlledwithin 0.0010-0.0025 wt %. The sulfur content of the molten steel is less than or equal to 0.010 wt % before calcium treatment, otherwise the calcium treatment is delayed. Aluminum products are not added into the molten steel in the later period of the LF refining and the RH process. A slab section of the billet caster is less than or equal to 260mm*260mm. A tundish nozzle is an immersion nozzle,and an argon blowing stopper with holes is not needed to be used. The method solves the technical problems troubling the billet caster producing high carbon chromium bearing steel for a long time that the immersion nozzle is likely to be plugged, causing the billet caster to have accidents to stop pouring, the molten steel to return to a furnace or falls to the ground. The method reduces the production cost, improves the benefit of an enterprise and has excellent promotion and application value.

Owner:HANDAN IRON & STEEL GROUP +1

Anti-corrosion nodule-free sink roll

InactiveCN106637020AReduce coefficient of frictionImprove wear resistanceHot-dipping/immersion processesWear resistantEngineering

The invention discloses an anti-corrosion nodule-free sink roll which comprises a cylindrical roll body and roll shafts connected with the two ends of the roll body, wherein a spiral groove is formed in the surface of the roll body; the bottom of the spiral groove is arc-shaped; a wear-resistant coating is arranged on the surface of the spiral groove; the anti-corrosion nodule-free sink roll is further improved in that the wear-resistant coating on the surface of the spiral groove is a carbon tungsten alloy layer; and the roll body comprises an alloy sleeve, a metal-ceramic sleeve and a sealant layer, which are distributed from inside to outside in a radial direction in sequence. The anti-corrosion nodule-free sink roll has good corrosion resistance, solves the problem that nodules are formed on the surface of a conventional roll, and improves the product quality.

Owner:王秋林

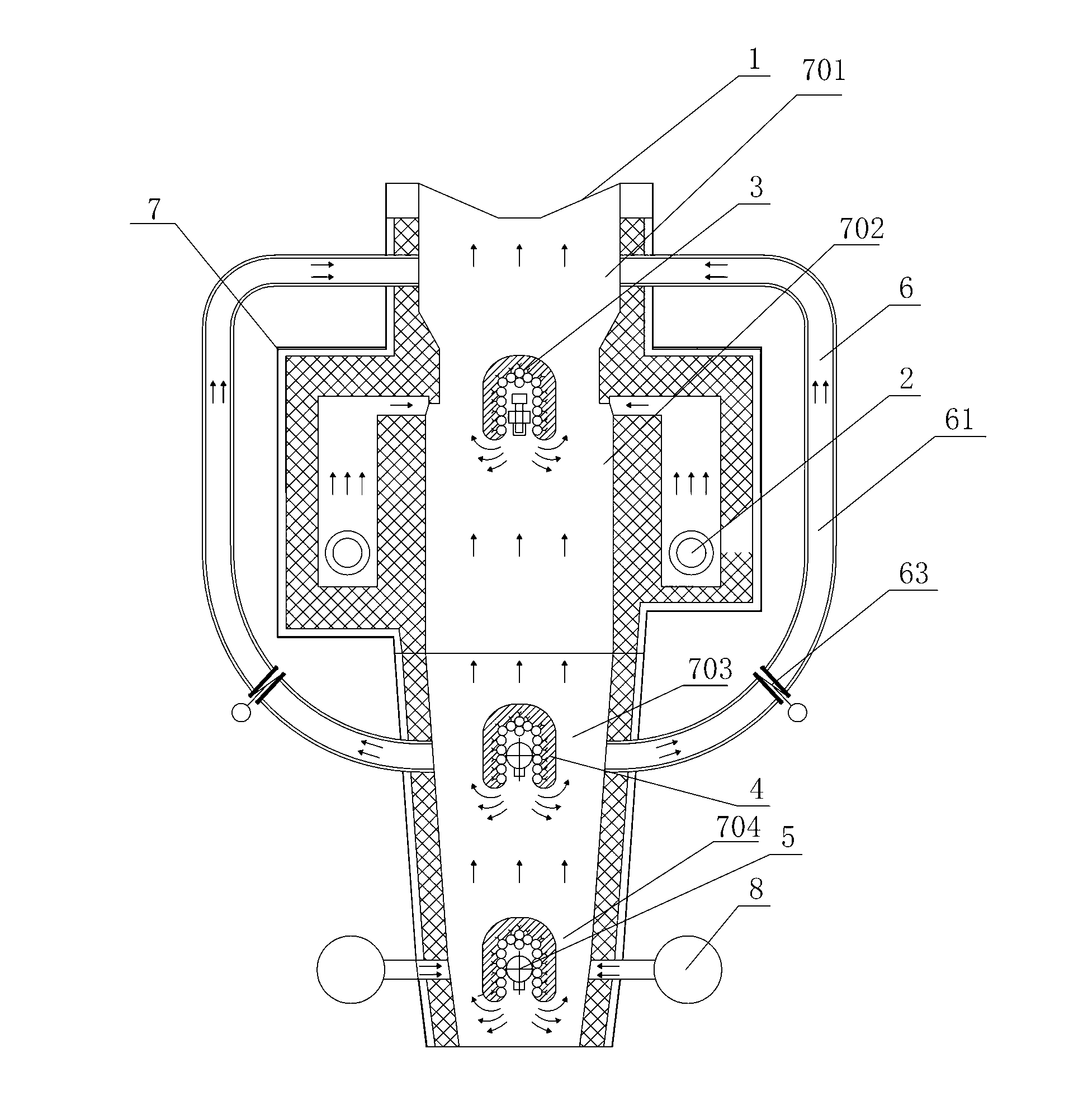

Electrical steel annealing and heating support method

ActiveCN104831053ARelieve pressureReduce lossFurnace typesHeat treatment furnacesElectrical steelNodulations

The invention discloses an electrical steel annealing and heating support method which comprises a furnace body (2), wherein the furnace body (2) comprises a heating zone (3), a soaking zone (4), a support roller (6) and a plasma nozzle (5); the heating zone (3) and the soaking zone (4) are used for annealing a steel strip; the support roller (6) is used for supporting the steel strip in the furnace body (2); the plasma nozzle (5) is used for ejecting a gas from the steel strip and supporting the steel strip; and the steel strip is separated from the support roller (6) in the annealing process and is kept suspended through the plasma nozzle (5), so that damages or nodulation to the support roller (6) in the heating process can be avoided or relieved; and high-silicon and high-grade electrical steel with high magnetic properties (low iron loss and relatively high grade) and excellent surface quality is obtained.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Efficient composite desulfurization agent, preparation method and applications thereof

The present invention provides an efficient composite desulfurization agent, a preparation method and applications thereof, wherein the efficient composite desulfurization agent comprises, by mass, 65-75% of quick lime, less than or equal to 10% of limestone, 5-10% of soda ash, less than or equal to 10% of fluorite, and less than or equal to 5% of graphite. According to the present invention, the premix, ie., the composite desulfurization agent, is transported by a tank car and is subjected to pressurization conveying to a desulfurization agent bin, and during the desulfurization treatment, the desulfurization agent is introduced into a spraying-blowing tank from the desulfurization agent bin, and is pressurized, and the pressurized desulfurization agent is sprayed into liquid iron in a spraying-blowing manner so as to perform desulfurization; and compared to the unimproved Baosteel steelmaking plant torpedo car desulfurization agent, the efficient composite desulfurization agent of the present invention has the following characteristics that the consumption is significantly reduced (the maximum unit consumption decrease of the desulfurization agent during the application is 2.95 Kg / t) under the same liquid iron condition and the same desulfurization requirement, and due to the significantly reduced desulfurization agent consumption, the temperature decrease of the desulfurization treatment is significantly decreased (the temperature decrease is decreased by 9.43 DEG C / torpedo car).

Owner:BAOSHAN IRON & STEEL CO LTD

Mullite-chromium light weight castable

The invention provides a mullite-chromium light weight castable. The mullite-chromium light weight castable is prepared from the following raw materials in parts by weight: 50 to 65 percent by weight of mullite microporous spheres, 20 to 45 percent by weight of low-iron three-grade high-aluminum clinker powder, 1 to 5 percent by weight of chrome oxide green, 3 to 8 percent by weight of silica micropowder, 4 to 7 percent by weight of pure calcium aluminate cement, and 0.01 to 0.5 percent by weight of a dispersing agent; the mullite microporous spheres are spherical mullite granules formed by secondary granulation sintering of raw ores; the content of Fe2O3 in the low-iron three-grade high-aluminum clinker powder is not greater than 1.5 percent by weight. The mullite-chromium light weight castable has the advantages of higher strength at normal temperature and high temperature, good volume stability and lower heat conduction coefficient; direct reduction of nodules on the surface of an iron furnace lining can be reduced, and the aims of reducing the usage of a furnace lining material, saving energy and prolonging the service life of the furnace lining are achieved.

Owner:JIAOZUO JINXIN HENGTUO REFRACTORIES

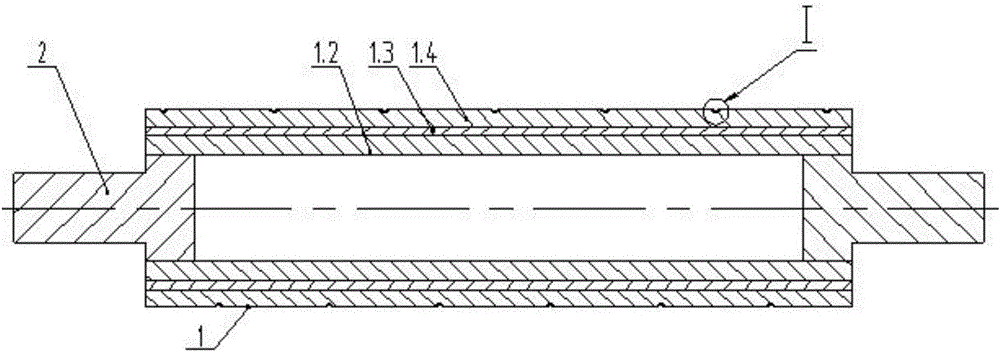

Electrical sheet plasma suspension device and manufacturing method thereof

ActiveCN104831054AAvoid or mitigate damageAvoid or reduce nodulesFurnace typesHeat treatment furnacesElectricityConductive materials

The invention discloses an electrical sheet plasma suspension device and a manufacturing method thereof. The electrical sheet plasma suspension device comprises a support seat and an electrode bar (2), wherein the support seat is fixedly connected with a furnace bottom plate (1) and is insulated from the furnace bottom plate (1); a cavity is arranged in the support seat; the electrode bar (2) extends into the cavity of the support seat; an outlet (8), through which gas in the cavity of the support seat is ejected, is formed in the upper end surface of the support seat; the upper end surface of the support seat is an electrical sheet supporting surface; an inlet (7), through which gas flows into the cavity from a furnace, is formed in the lower end of the support seat; a power supply (6) is connected with the electrode bar (2) and the support seat through a circuit; and the part, which is connected with the circuit, of the support seat is made of a conductive material; and the gas flowing into the cavity through the inlet (7) discharges electricity in an upper cavity (41) and a lower cavity (31) to form plasma, and then is ejected from the outlet (8) to a running steel strip to form a support for the steel strip so as to avoid or reduce the surface damage of the annealed steel strip.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Method for producing pellets by coal injection of grate-rotary kiln

The invention relates to a method for producing pellets by coal injection of a grate-rotary kiln, and belongs to the technical field of production methods of iron ore powder pellets, which solves thetechnical problem of easiness in nodulating in the rotary kiln in the production process. By adopting the technical scheme, the method comprises the following steps of (1) performing fine grinding oncoke powder or dry quenching coke powder; (2) fine grinding of mixed coal powder: uniformly mixing bitumite and anthracite according to a weight ratio of 2:3, and performing fine grinding; (3) proportioning and mixing: uniformly mixing the coke powder or the dry quenching coke powder after fine grinding and the mixed coal powder after fine grinding; (4) injection and roasting: injecting the mixture obtained in step (3) into the rotary kiln to roast, wherein the pellet in the rotary kiln is the hematite powder pellet. The method has the advantage that the coke powder or the dry quenching coke powder after fine grinding is injected into the grate-rotary kiln according to a certain ratio so as to produce the raw pellet, so that the nodulating phenomenon in the grate-rotary kiln is reduced, the production cycle is extended, the normal production in the rotary kiln is guaranteed, and the guarantee is provided for the production of high-quality pellets.

Owner:太原钢铁(集团)有限公司 +1

Nozzle coating for continuous casting of rare earth steel and preparation method of nozzle coating

ActiveCN114716850AReduce nodulationGuaranteed travelMelt-holding vesselsAnti-corrosive paintsContinuous castingAluminium

The invention discloses a nozzle coating for continuous casting of rare earth steel and a preparation method of the nozzle coating, belongs to the technical field of refractory materials, and solves the problem that a nozzle is nodulated and blocked in the current continuous casting process of the rare earth steel. The invention relates to a nozzle coating for continuous casting of rare earth steel, which comprises the following components: magnesium aluminum oxide and rare earth oxide, and the mass ratio of the magnesium aluminum oxide to the rare earth oxide is 83.3-94: 1.98-10; the magnesium-aluminum oxide is MgO.Al2O3 or takes MgO.Al2O3 as a main component, and contains a trace amount of MgO; the rare earth steel is steel containing rare earth cerium and / or lanthanum, and the type of the rare earth oxide is the same as that of rare earth in the rare earth steel. The nozzle coating can reduce nodulation of the submersed nozzle in the rare earth steel continuous casting process, so that the replacement frequency of the submersed nozzle is averagely reduced by more than 50%, and smooth operation of rare earth steel continuous casting is guaranteed.

Owner:CENT IRON & STEEL RES INST +1

Electroforming nickel component forming method and electroforming nickel component forming device

ActiveCN104674309AShorten the production cycleReduce distortionElectroforming processesTO-18Electrical conductor

The invention provides an electroforming nickel component forming method. The method comprises the following steps: a, producing a pictographic auxiliary cathode, namely producing a pictographic auxiliary cathode in a concentrated area of electric wires according to the distribution characteristic of current on a core mold, wherein the pictographic auxiliary cathode is a framework structure made of a metal conductor, the pictographic auxiliary cathode comprises a central skeleton, a left side wing frame and a right side wing frame, and the contour of the central skeleton and the wing frames is maintained consistent with that of the concentrated area of the electric wire; b, electroforming, namely, placing the core mold in a plating solution, fixing two ends of the central skeleton of the pictographic auxiliary cathode onto the core mold, integrally covering the core mold by virtue of the pictographic auxiliary cathode, wherein the distance between the pictographic auxiliary cathode and the core mold is 10mm to 20mm, the core mold and the pictographic auxiliary cathode are respectively connected with an electroforming cathode, an electroforming anode is connected with a nickel plate, the electroforming process parameter is as follows: the current density is 16 to 18 A / dm<2>, and the electroforming time is 13 to 16 hours; and c, taking out the component from the core mold.

Owner:JIANGXI CHANGHE AVIATION IND

A nozzle swirl generating device and a nozzle swirl continuous casting method

A nozzle cyclone generating device and a nozzle cyclone continuous casting method. The device is divided into a cylindrical cyclone generator and a cylindrical cyclone tundish. The cylindrical cyclone generator is installed inside the traditional continuous casting tundish. The traditional continuous casting The inner cavity of the tundish is connected to the immersed nozzle through the cylindrical cyclone generator; the cylindrical cyclone tundish has two installation forms. The first one: the cylindrical cyclone tundish is used in conjunction with the traditional continuous casting tundish. The cyclone tundish is installed outside the traditional continuous casting tundish, and the traditional continuous casting tundish is connected to the immersed nozzle through the cylindrical cyclone tundish; the second type: the cylindrical cyclone tundish is used alone, and the nozzle of the ladle is It is directly connected to the immersed water inlet through the cylindrical cyclone tundish. The method is: before continuous casting, select the nozzle swirl generating device according to the continuous casting process, and then assemble it with the traditional continuous casting tundish. During continuous casting, the molten steel will rotate under the action of the gravity of the molten steel and the tangential inlet, and the immersed The molten steel in the nozzle produces a rotating flow.

Owner:NORTHEASTERN UNIV LIAONING

A method and device for forming electroformed nickel parts

ActiveCN104674309BShorten the production cycleReduce distortionElectroforming processesElectrical conductorEngineering

The invention provides an electroforming nickel component forming method. The method comprises the following steps: a, producing a pictographic auxiliary cathode, namely producing a pictographic auxiliary cathode in a concentrated area of electric wires according to the distribution characteristic of current on a core mold, wherein the pictographic auxiliary cathode is a framework structure made of a metal conductor, the pictographic auxiliary cathode comprises a central skeleton, a left side wing frame and a right side wing frame, and the contour of the central skeleton and the wing frames is maintained consistent with that of the concentrated area of the electric wire; b, electroforming, namely, placing the core mold in a plating solution, fixing two ends of the central skeleton of the pictographic auxiliary cathode onto the core mold, integrally covering the core mold by virtue of the pictographic auxiliary cathode, wherein the distance between the pictographic auxiliary cathode and the core mold is 10mm to 20mm, the core mold and the pictographic auxiliary cathode are respectively connected with an electroforming cathode, an electroforming anode is connected with a nickel plate, the electroforming process parameter is as follows: the current density is 16 to 18 A / dm<2>, and the electroforming time is 13 to 16 hours; and c, taking out the component from the core mold.

Owner:JIANGXI CHANGHE AVIATION IND

Detoxification formula with high chromium slag amount and process for cooperating with light aggregate production

ActiveCN114349477AFast consumption processingEasy to handleSolid waste managementSolid waste disposalSlagKaolinite

The invention relates to a high-chromium-slag detoxification formula and a synergistic light aggregate production process. The formula comprises the following raw materials in percentage by mass: 60-80% of chromium slag, 15-40% of aluminum-silicon concentrate and 1-5% of a compound additive. The aluminum-silicon concentrate comprises one or more of clay, potassium feldspar, quartz, aluminum oxide, flint clay, mullite and kaolinite. And the compound additive plays a role in reduction and fluxing. The raw materials are dried, metered, crushed, ball-milled, granulated, fired and screened to obtain a fired lightweight aggregate product. Compared with the prior art, the specific gravity of the chromium slag in the formula is increased to 80%, the firing temperature is reduced to 900-1000 DEG C on the basis that hexavalent chromium in the fired lightweight aggregate product is thoroughly reduced and cured by adding the compound additive, and trivalent chromium cannot be oxidized due to temperature reduction under the condition of no cooling process. On one hand, thorough harmlessness of the chromium slag is achieved, and on the other hand, complete recycling of the chromium slag is achieved.

Owner:湖南国发控股有限公司

Roasting shaft furnace

The invention discloses a roasting shaft furnace which comprises a furnace body, more than two combustion chambers and a drying bed located at the top of the furnace body. An inner cavity of the furnace body is sequentially divided into a drying section, a roasting section, a soaking section and a cooling section from top to bottom. The combustion chambers are located at the position, corresponding to the roasting section, of the lateral side of the furnace body and communicated with the inner cavity of the furnace body. A hot air return assembly is arranged on the furnace body. An air inlet end of the hot air return assembly is communicated with the position, located at the bottoms of the combustion chambers, of the inner cavity of the furnace body. An air outlet end of the hot air return assembly is communicated with the position, located between the tops of the combustion chambers and the drying bed, of the inner cavity of the furnace body. The roasting shaft furnace has the advantages of being simple and compact in structure, low in cost, long in service life, stable and reliable in working, strong in operational adjustment, capable of optimizing furnace inside atmosphere and reducing energy consumption for material roasting, even in heating and the like.

Owner:ZHONGYE-CHANGTIAN INT ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com