Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

95 results about "Lanthanum phosphate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lanthanum is used to lower high blood phosphate levels in people who are on dialysis due to severe kidney disease. Dialysis removes some phosphate from your blood, but it is difficult to remove enough to keep your phosphate levels balanced. ... Lanthanum is a natural mineral that works by binding to phosphate in the foods you eat. The phosphate then passes out of your body in your stool.

Monazite-based thermal barrier coatings

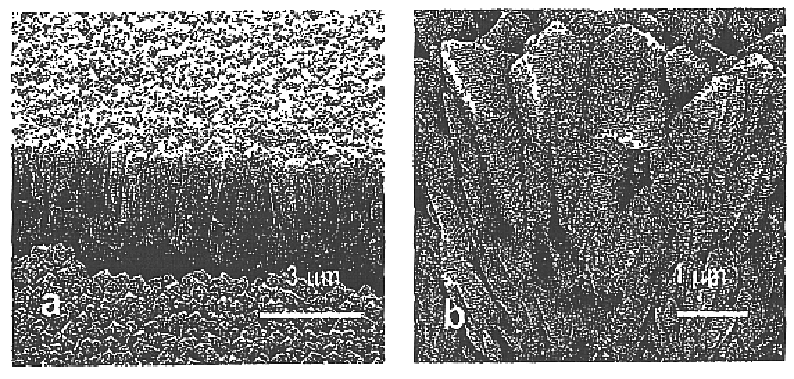

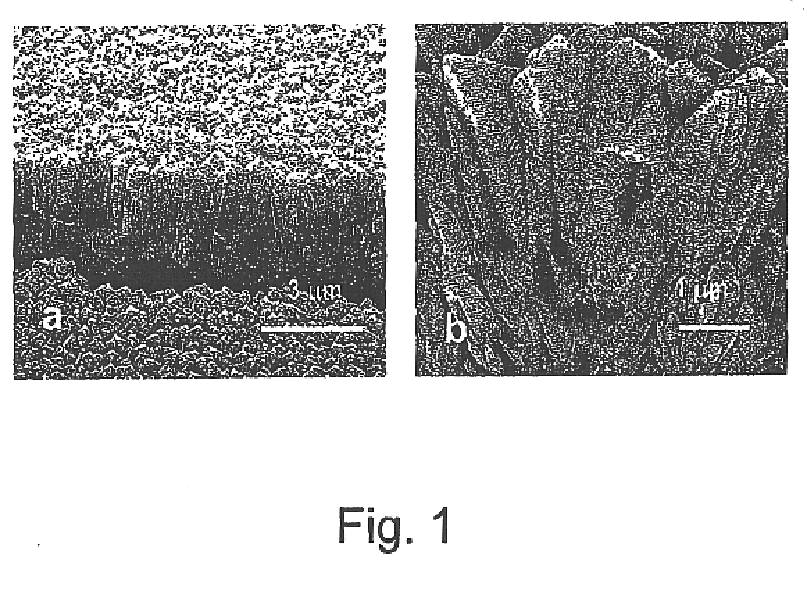

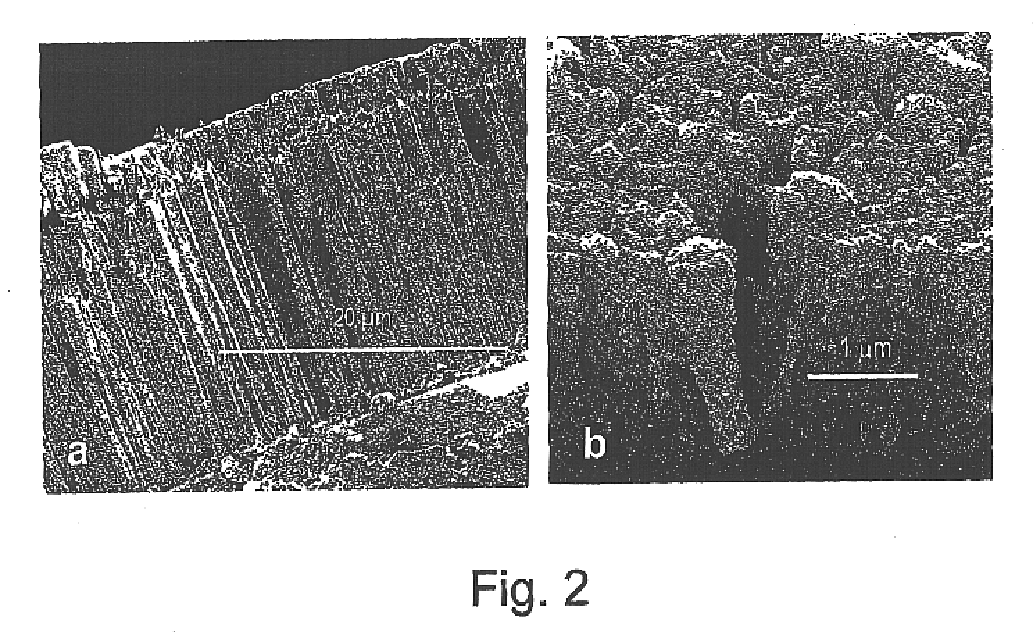

Monazites and xenotimes are rare-earth phosphates showing a combination of properties expected to be suitable for thermal barrier coatings. For example, lanthanum phosphate (La-monazite) can be used to form thermal barrier coatings to protect superalloy and ceramic parts exposed to high temperature and damage by sulfur, vanadium, phosphorus and other contaminants. The monazite or xenotime coatings can be applied using any of the common application methods including EB-PVD, laser ablation and plasma spraying. The stoichiometry of the coatings can be modulated according to the stoichiometry of specially prepared starting target (source) material. The most effective coatings appear to be largely crystalline and show a columnar structure with feather-like microstructure. For La-monazite, effective coatings between 10 and 500 micrometers in thickness can be deposited on substrates having temperatures between about 750° C. and about 950° C.

Owner:TELEDYNE SCI & IMAGING

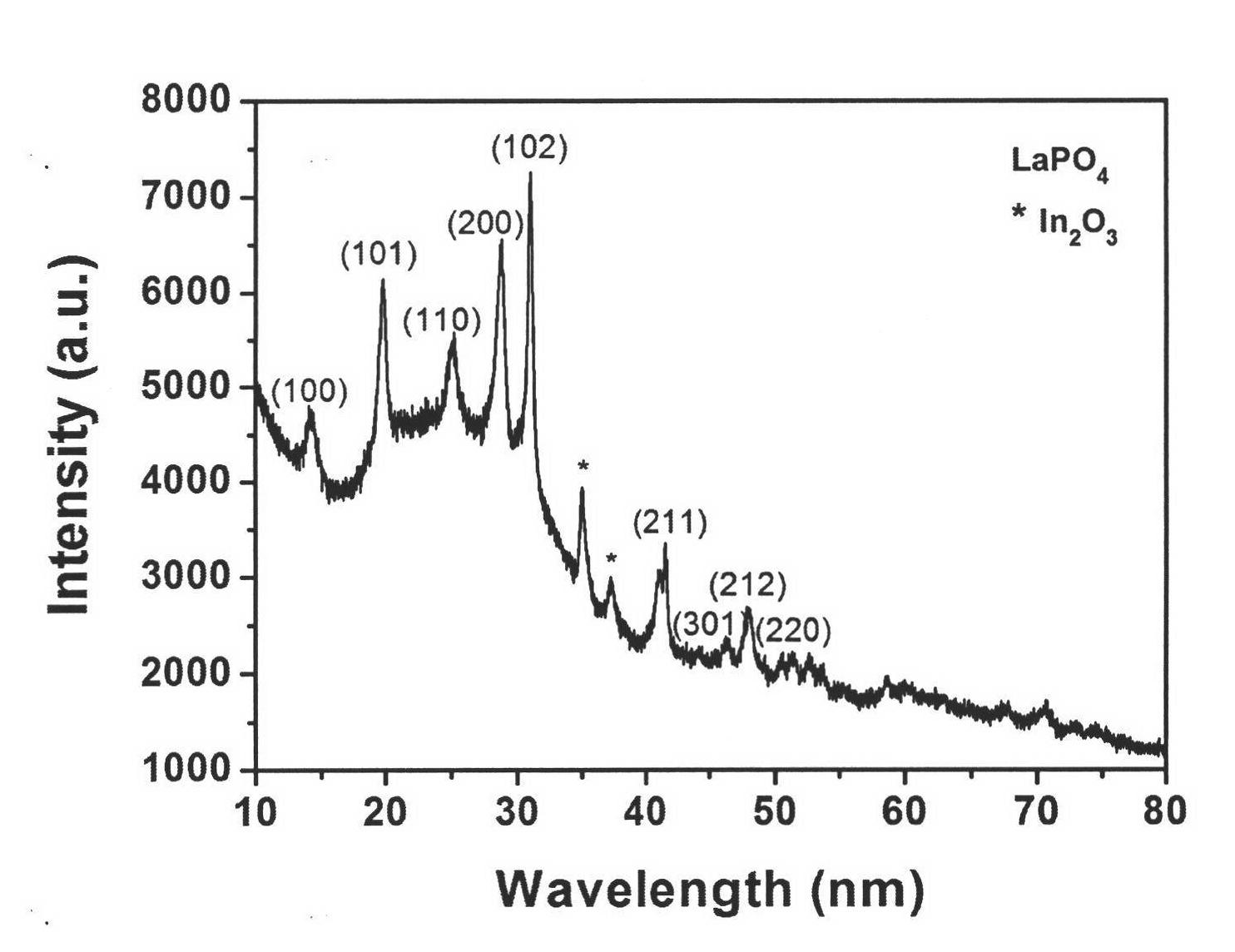

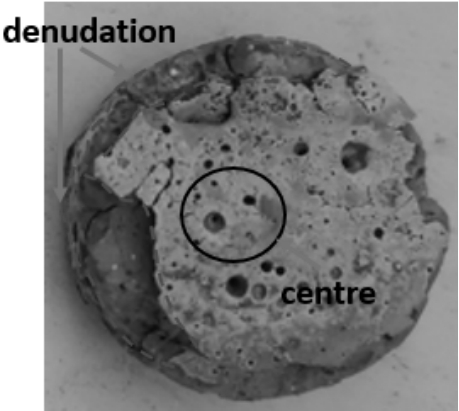

Electrochemical preparation method of lanthanum phosphate or rare earth doped lanthanum phosphate film

InactiveCN101962805ALow growth temperatureHigh crystallinityPolycrystalline material growthElectrolytic inorganic material coatingSodium phosphatesRare earth

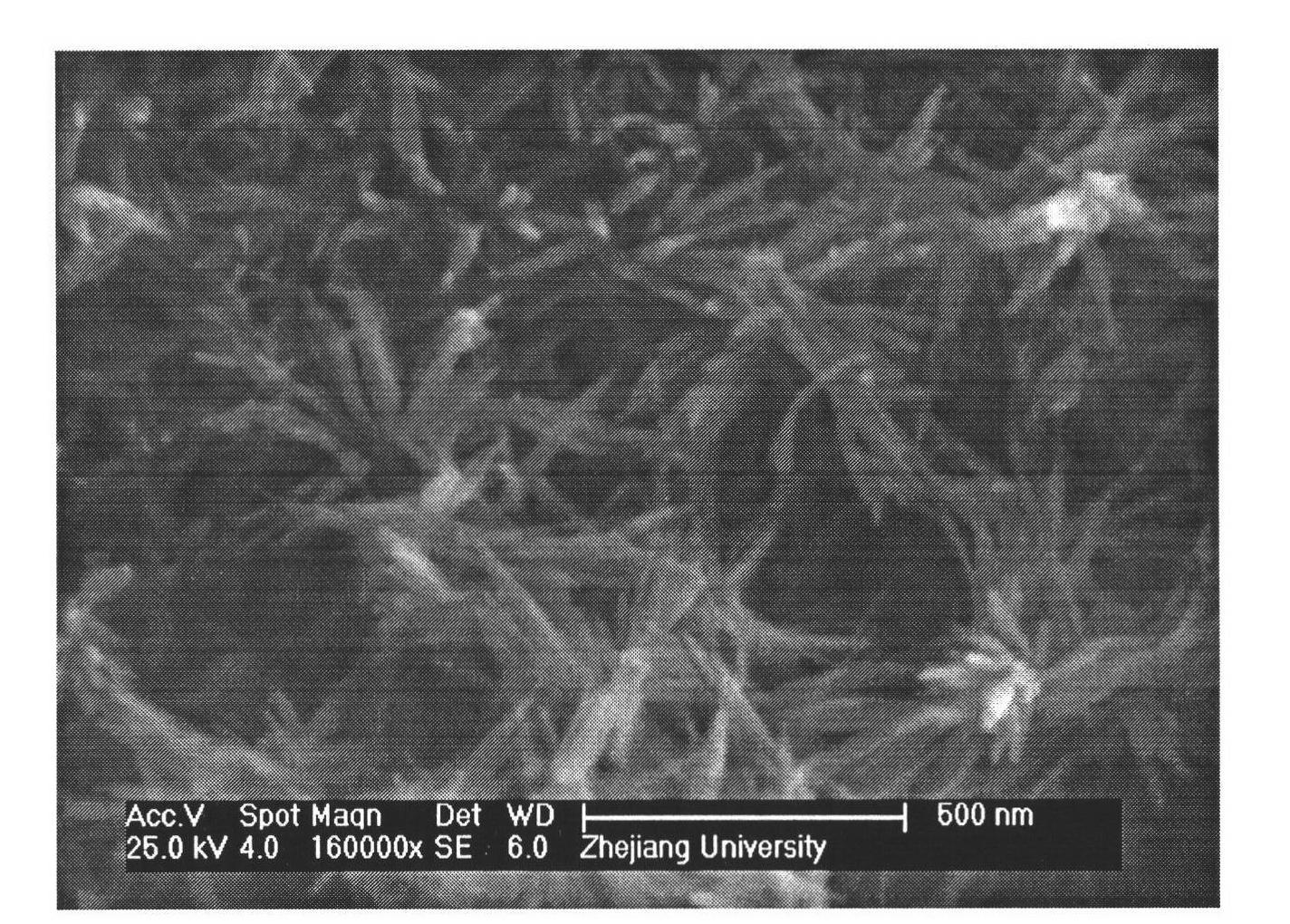

The invention discloses a method for preparing a lanthanum phosphate or rare earth doped lanthanum phosphate film through electrodeposition, which comprises the following steps of: (1) cleaning ITO (Indium Tin Oxide) conducting glass 2-3 times with acetone, cleaning the ITO conducting glass with deionized water for 10-30 min in an ultrasonic cleaner, activating the ITO conducting glass in a 10 vol% saltpeter solution for 10-30 s, and cleaning with deionized water for later use; (2) adding a sodium phosphate solution into a 0.005-0.5 mol / L complex solution of ethylene diamine tetraacetic acid and lanthanide ions, and regulating the pH value to 4-6 to obtain an electrolyte for later use; and (3) placing the ITO conducting glass used as a working electrode, a platinum electrode used as a counter electrode and a calomel electrode used as a reference electrode in the electrolyte for electrodeposition to obtain the lanthanum phosphate film, wherein the positive deposition potential relative to the calomel electrode is 1.2-1.8 V. The invention has the advantages of simple equipment, low cost, normal pressure and low temperature. The method not only is applicable to scientific research, but also is hopeful for realizing large-scale industrial production.

Owner:ZHEJIANG UNIV

Nitrogen-phosphorus expansion flame retardant containing flame retardant synergist and preparation method thereof

The invention discloses a nitrogen-phosphorus expansion flame retardant containing a flame retardant synergist and a preparation method thereof. The nitrogen-phosphorus expansion flame retardant containing the flame retardant synergist is characterized in that 90-99.95 percent of the nitrogen-phosphorus expansion flame retardant and 0.05-10 percent of the flame retardant synergist are evenly mixedaccording to the mass; the nitrogen-phosphorus expansion flame retardant comprises a nitrogen-phosphorus compound expansion flame retardant or / and a nitrogen-phosphorus simple substance expansion flame retardant; and the flame retardant synergist is selected from lanthanum phosphate, cerous phosphate, manganese pyrophosphate, ferric phosphate and / or ferric pyrophosphate. The nitrogen-phosphorus expansion flame retardant containing the flame retardant synergist can be suitable for anti-flaming of polyolefin, polyester or phenyl polymer, thereby overcoming the defects of low flame retardant efficiency, large addition quantity, and the like in the prior nitrogen-phosphorus expansion flame retardant, reducing the adverse effect of flame retardant property of a matrix due to the hygroscopicityof a flame retardant agent and reducing the adverse effect of mechanical property of the matrix due to the flame retardant agent with both convenience of production and use.

Owner:UNIV OF SCI & TECH OF CHINA

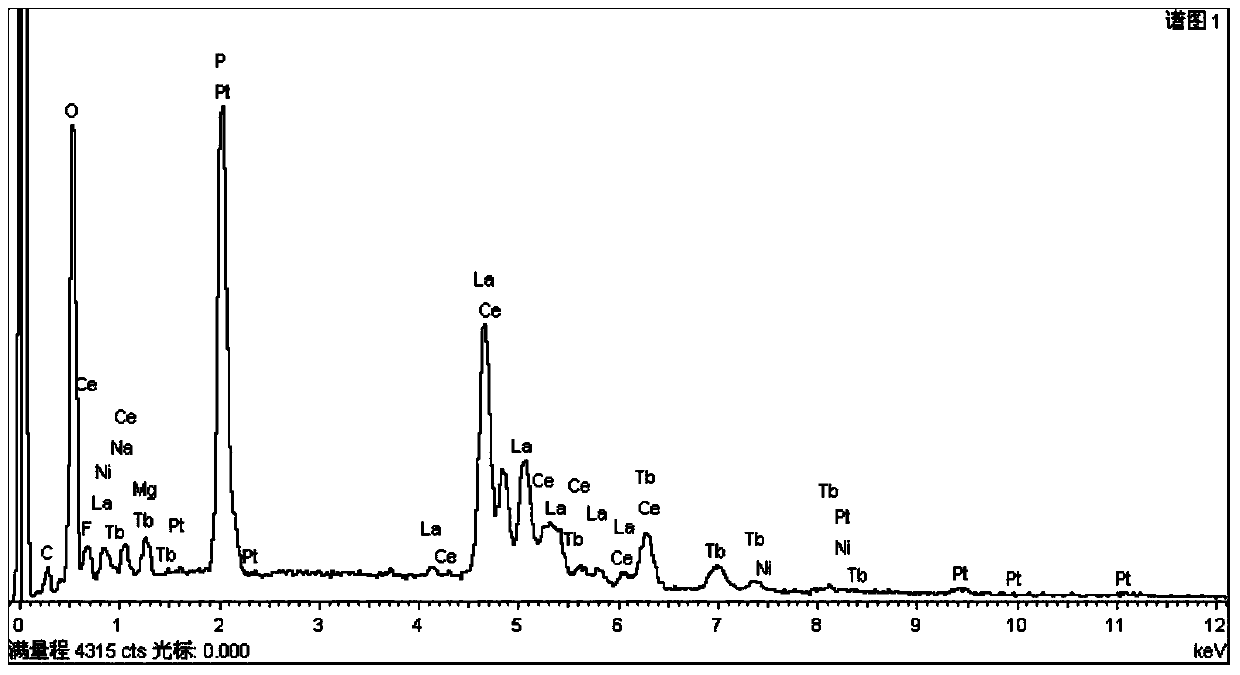

Core shell phosphor and method of making the same

InactiveUS20110311823A1Synthetic resin layered productsCellulosic plastic layered productsPhosphorCompound (substance)

A method of making a core-shell phosphor is provided. The method comprises mixing a lanthanum phosphate (LaPO4) core with a shell precursor mixture comprising at least one compound of La, at least one compound of Ce, and at least one compound of Tb to form a core+shell precursor mixture, heating the core+shell precursor mixture to a temperature in a range from about 900° C. to about 1200° C. with an inorganic flux material in presence of a reductant to provide a heated core+shell precursor mixture, cooling the heated core+shell precursor mixture to ambient temperature to provide a product core-shell phosphor dispersed in the inorganic flux material; and separating the product core-shell phosphor from the inorganic flux material.

Owner:GENERAL ELECTRIC CO

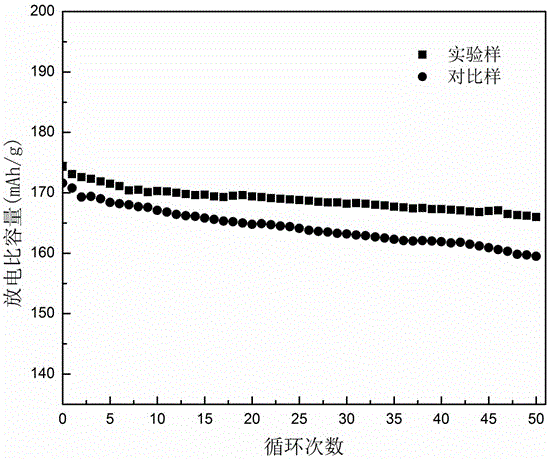

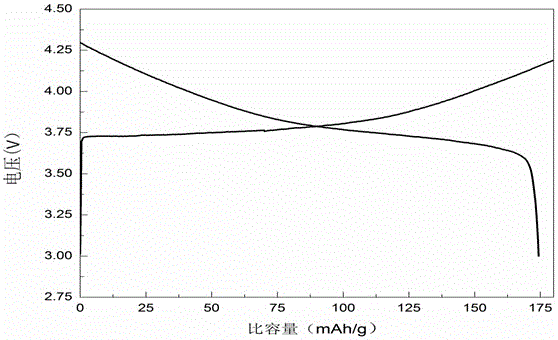

Method for lanthanum phosphate coated lithium ion battery cathode material nickel cobalt lithium manganate

InactiveCN105958054AGood chemical stabilityImprove cycle performanceCell electrodesSecondary cellsPhysical chemistryManganate

The invention relates to a method for lanthanum phosphate coated lithium ion battery cathode material nickel cobalt lithium manganate. The lanthanum phosphate cladding method comprises the following steps: (1) adding a ternary precursor, a lithium salt, a lanthanum salt and phosphate into a high-speed material mixing machine, and stirring for 1-4 h at the speed of 500-2000 rpm; and (2) heating materials treated in the first step in an oxygen-containing atmosphere of 750-1200 DEG C for 5 to 20 hours, preserving the temperature for 4-10 h, and cooling to obtain the lanthanum phosphate coated lithium ion battery cathode material nickel cobalt lithium manganate. According to the method, an LaPO4 compound in an amorphous state can be formed on the surface of a nickel cobalt lithium manganate ternary cathode material, and the LaPO4 in the amorphous state is coated on the surface of the nickel cobalt lithium manganate ternary cathode material, so that the content of impurity lithium can be effectively reduced, and the cycle performance and electrochemical performance of a lithium ion battery under high voltage can be effectively improved.

Owner:CENT SOUTH UNIV

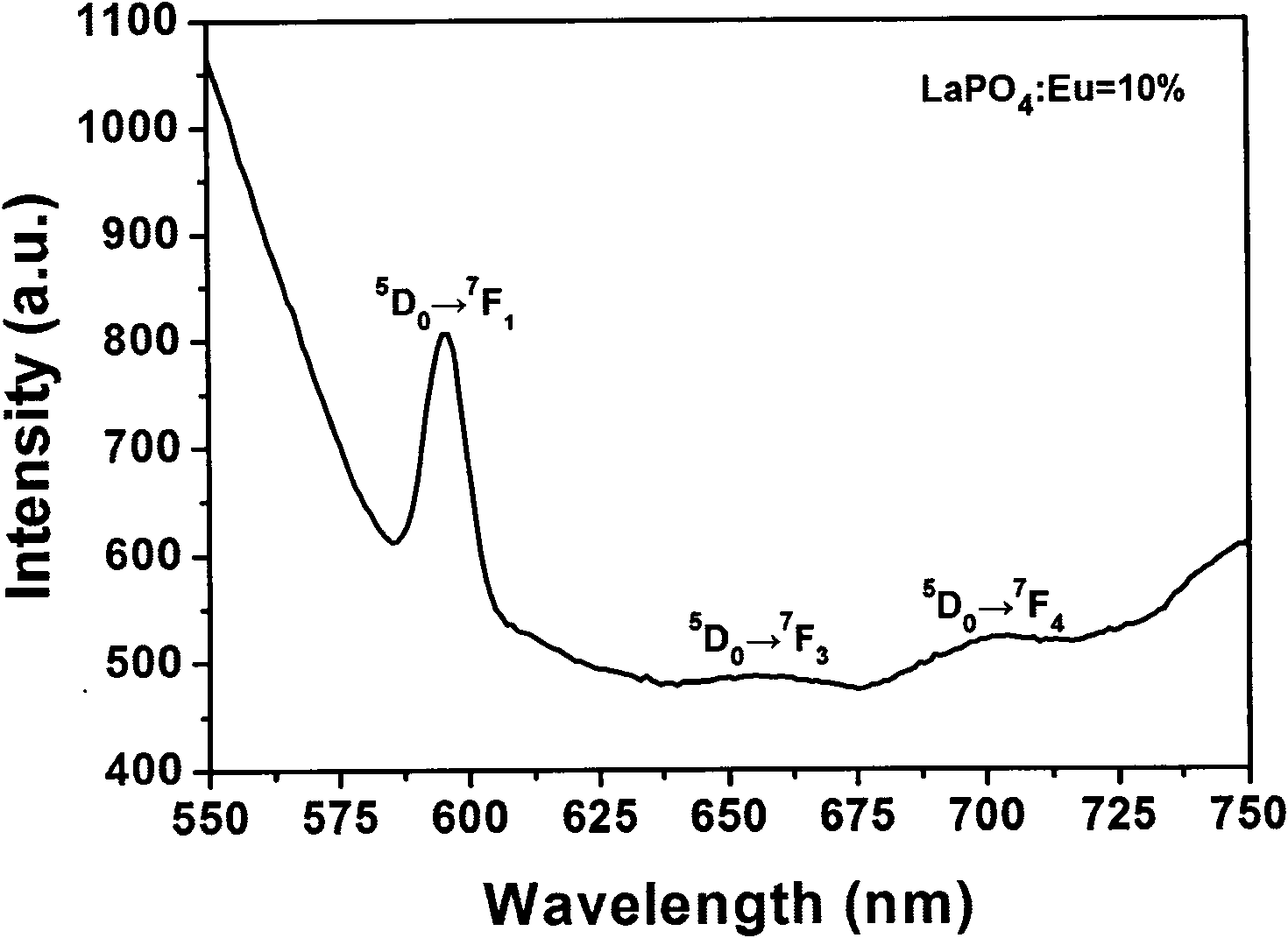

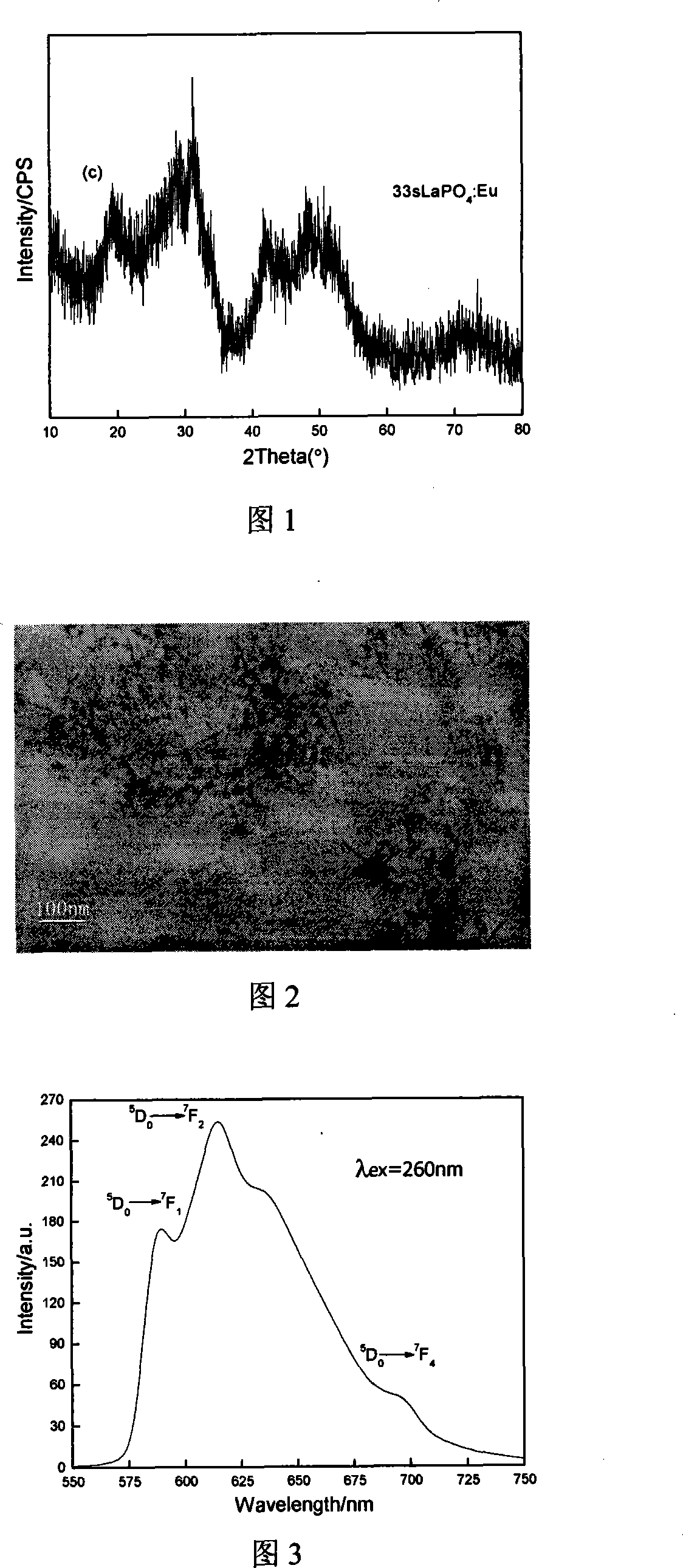

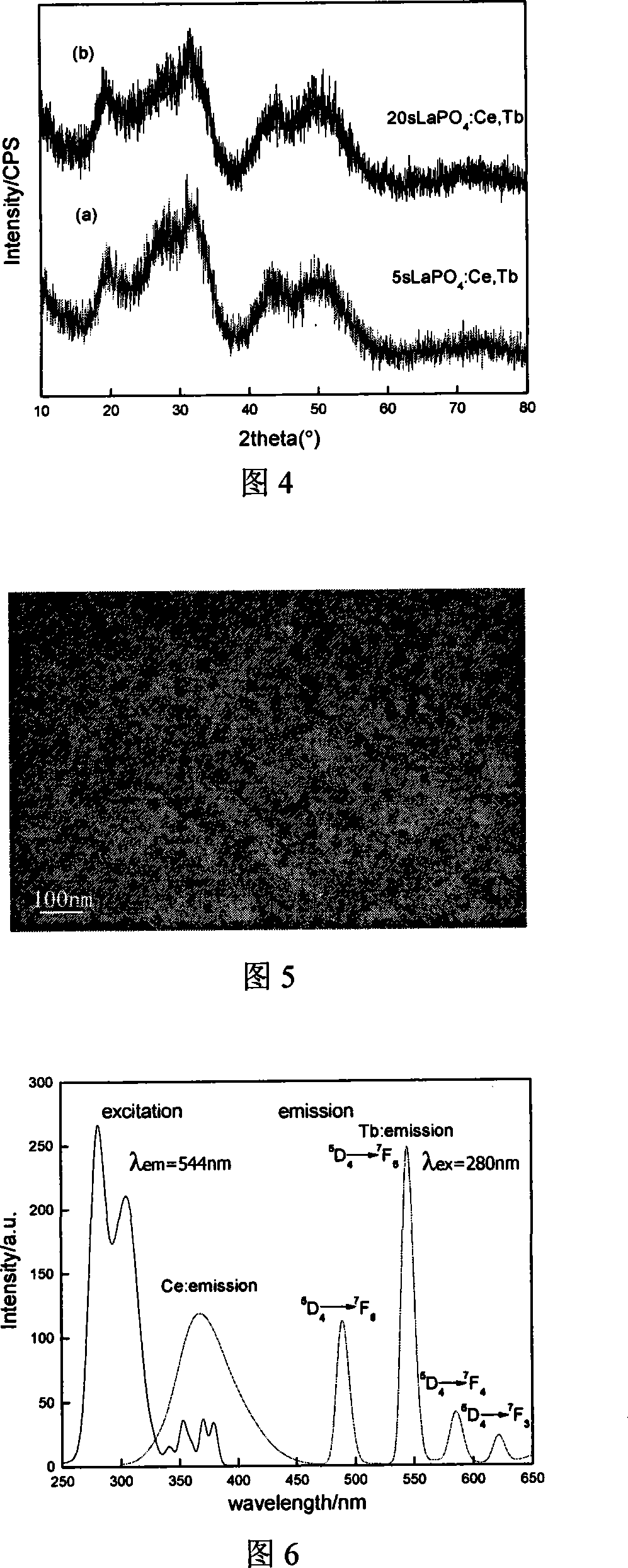

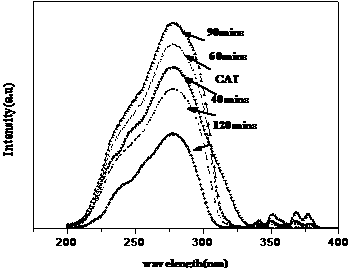

Method for preparing rare-earth doped lanthanum phosphate nano luminous particles

The invention relates to a method for preparing luminescent nano-particles of rare earth doped with lanthanum phosphate, comprising the following steps: preparing stock solutions including lanthanum nitrate polyol solution doped with rare earth element of Ln and polyol solution of NaH2PO4-2H2O; mixing the stock solutions in a micro mixer and heating the mixture in oil under constant temperature after the mixture enters the micro-channels, after which the mixture will react to produce polyol solution of luminescent nano-particles of rare earth doped with lanthanum phosphate; obtaining luminescence nano-particles of rare earth doped with lanthanum phosphate by extracting, washing and centrifugal separation. With simple technology and easy for batch production, the obtained nano-particles are provided with small particles, good dispersibility and fluorescence.

Owner:DONGHUA UNIV

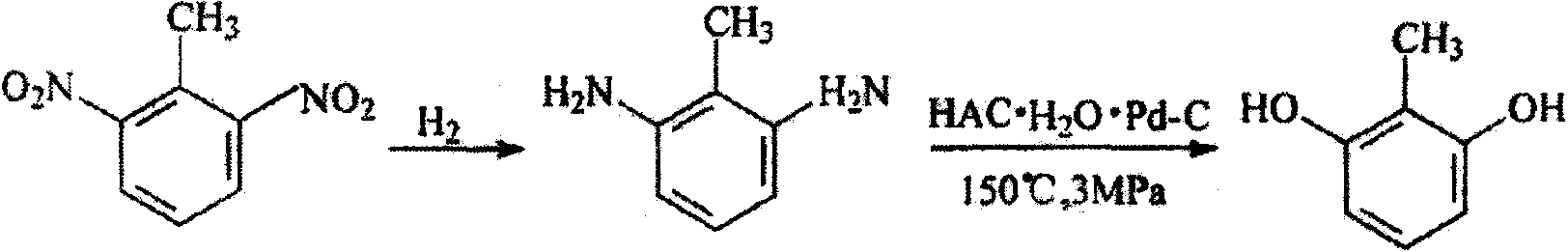

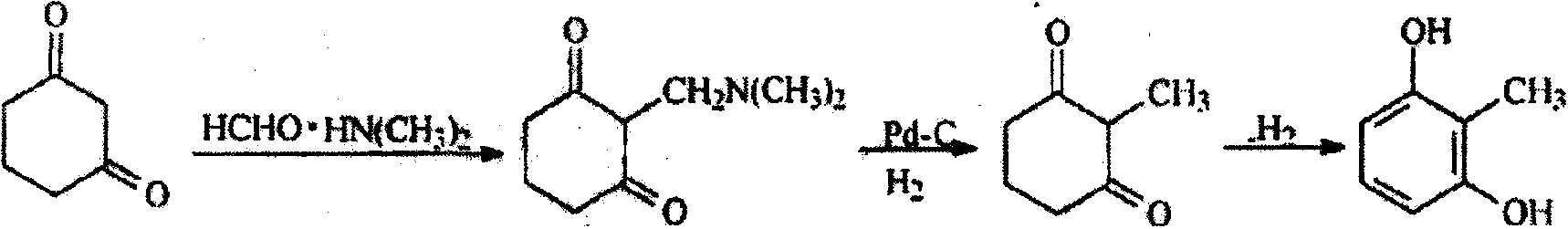

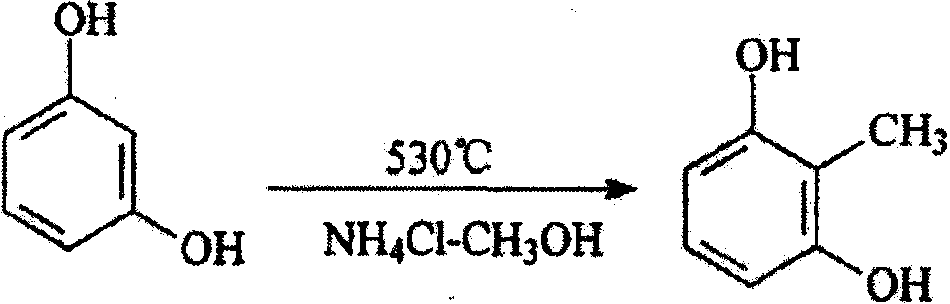

Synthesis method for 2, 6-dihydroxytoluene

ActiveCN104341275AWide variety of sourcesSimple processOrganic chemistryOrganic compound preparationSynthesis methodsRare earth

The invention discloses a synthesis method for 2, 6-dihydroxytoluene. According to the method, the 2, 6-dihydroxytoluene is obtained from 3-chloro-2-methylaniline is used as raw materials through diazotization reaction, lanthanum phosphate catalysis hydrolysis, alkali dissolution and acidification. The synthesis method has the advantages that (1) the raw material resources are wide; (2) the process is simple, and the operation is easy; (3) active rear earth is used as catalysts, and the color and luster of products can be optimized; (4) the reaction conditions are relatively mild, and the safety factor is high; (5) the total yield is as high as more than 65 percent, the purity reaches more than 99.0 percent, in addition, solvents can be recovered and reused, and the energy-saving and emission-reduction effects are obvious.

Owner:JIANGSU DINGYE PHARMA CO LTD

Mercury UV lamp with improved actinic spectrum

InactiveUS20120319011A1Discharge tube luminescnet screensWater/sewage treatment by irradiationNitrosoPhosphor

A low-pressure mercury or amalgam lamp with praseodymium (Pr) doped particles of lanthanum phosphate converts 185 nm radiation to UV-C (186 nm-280 nm). For water purification, a plurality of low-pressure mercury or amalgam lamps with phosphor that convert 185 nm radiation to UV-C (186 nm-280 nm) may be used. A method for photolysis of nitroso dimethyl amine (NDMA) may include passing electrical current through a low pressure mercury or amalgam lamp, radiating 254 nm radiation through the lamp envelope into water containing the NDMA, converting 185 nm radiation within the lamp into 230 nm-240 nm radiation within the lamp via a phosphor within the lamp, and radiating the 230-240 nm radiation through the lamp envelope and into the water containing the NDMA, with the radiation from the lamp photolysizing the NDMA.

Owner:BRABHAM DALE E +2

Organic phase back-extraction method for preparing cerium terbium lanthanum phosphate

The invention relates to an organic phase back-extraction method for preparing cerium terbium lanthanum phosphate, which comprises the following process steps: (1) using hydrochloric acid or nitric acid to dissolve lanthana, cerium oxide and terbia respectively to obtain first solution; (2) preparing organic extractant solution which consists of one or two extractants of 2-ethylhexyl phosphate 2-ethylhexyl ester, trioctyl tertiary amine, dioctylphosphoric acid ester, tributyl phosphate, Cyanex272 and naphthenic acid and sulfonated kerosene to obtain second solution; (3) adding the first solution and the second solution into a reactor to prepare third solution; (4) preparing solution containing phosphate groups to form rare-earth phosphate sediment; and (5) after the precipitation reaction is finished, washing products by water, performing centrifugal dehydration on the product, mixing the product and absolute ethanol into slurry, placing the slurry, carrying out drying treatment on the slurry and calcinating the dried slurry to obtain a cerium terbium lanthanum phosphate powder body. The cerium terbium lanthanum phosphate prepared by the method has low content of impurity, controllability of the granularity of particles, even distribution of the granularity of the particles and good crystal morphology.

Owner:江阴加华新材料资源有限公司

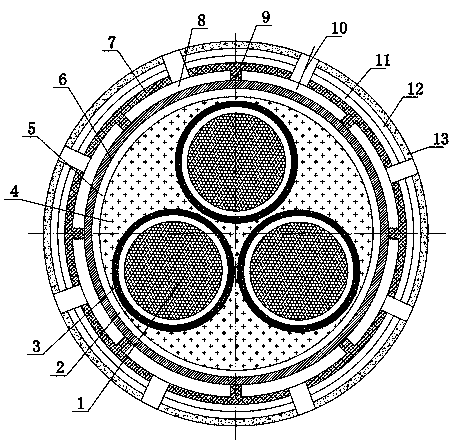

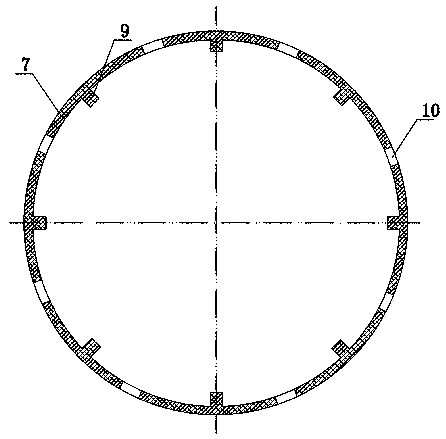

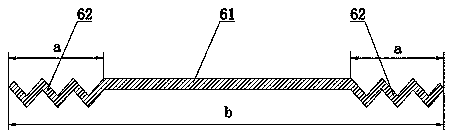

High-efficiency fire-resistant heat-dissipating cable

PendingCN108806856AAccurate lap positioningControl tensionConjugated diene hydrocarbon coatingsPower cables with screens/conductive layersEpoxyWave shape

The invention discloses a high-efficiency fire-resistant heat-dissipating cable. Shielding tapes are coated and connected mutually by wave-shaped overlapped segments at the two sides to form a shielding layer; and heat collecting chambers are arranged between the shielding layer and a heat collecting sheath and are communicated to the outer surface of the cable through cooling holes. Armored steeltapes are coated and connected mutually to form a metal armor layer by steel tape overlap-joint segments at the two sides; embedded holes are formed in the steel tape overlap-joint segment at one side of each armored steel tape; and embedded bosses are arranged at the steel tape overlap-joint segment at the other side of the armored steel tape. When overlapped joint is performed, the embedded bosses are embedded into the embedded holes. Besides, a rare-earth fire-resistant layer is made of a material comprising 8wt% to 12wt% of fluororubber, 5wt% to 8wt% of aluminum hydroxide, 2wt% to 4wt% ofrare earth oxide, 1wt% to 2wt% of glycerol, 2wt% to 4wt% of silicon carbide, 3wt% to 6wt% of lanthanum phosphate, 6wt% to 8wt% of zirconic acid gadolinium, and remainder being epoxy resin. The cablehas the good high-temperature-resistant and flame-retardant performances; heat can be dissipated efficiently; and the cable has the stable structural integrity and the good mechanical performance.

Owner:JIANGSU DONGQIANG

Catalyst for carbon monoxide normal-temperature catalytic and oxidation as well as preparation method and application

InactiveCN103736511AReduce dosageImprove catalytic oxidation efficiencyPhysical/chemical process catalystsDispersed particle separationCopper chlorideActive component

The invention relates to a catalyst for carbon monoxide normal-temperature catalytic and oxidation as well as a preparation method and application. Palladium chloride and copper chloride are taken as active components of the catalyst, and activated aluminum oxide modified from phosphate acts as a carrier, wherein phosphate is one or two of lanthanum phosphate and cerous phosphate. The activated aluminum oxide carrier modified from phosphate is prepared by a deposition method. Palladium chloride and copper chloride are loaded on the carrier by a dipping method, and the required catalyst is obtained after high-temperature roasting. The catalyst can be used for catalyzing and oxidizing carbon monoxide under the conditions of normal temperature, low concentration and high airspeed, can eliminate carbon monoxide in air effectively, and has high stability.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Preparation method for high-toughness nanometer black porcelain material

The invention provides a preparation method for a high-toughness nanometer black porcelain material. The preparation method comprises the following steps: 1) adding granular solids of zirconia, alumina and titanium dioxide whisker into absolute ethyl alcohol, carrying out wet ball milling, then carrying out mixing with a polyvinyl alcohol solution after drying, adding yttrium oxide and lanthanum phosphate, successively carrying out uniform mixing, drying and thermosetting molding at a high temperature under vacuum and grinding an obtained nanometer black porcelain material into powder; and 2) adding granular raw materials consisting of SiC and BN into absolute ethyl alcohol, carrying out wet ball milling, then carrying out uniform mixing with the nanometer black porcelain material powder after drying, putting an obtained mixture into a graphite die, placing the graphite die in a hot press furnace, carrying out secondary sintering at a high temperature under vacuum and carrying out temperature maintenance so at to prepare the high-toughness nanometer black porcelain material. The invention has the following advantages: the preparation method employs in situ synthesis, yttrium oxide is added as a stabilizing agent, so particle refinement and decrease of sintering temperature are realized; the preparation method is simple and easy to operate and has low cost; and the prepared nanometer black porcelain material has high toughness and good thermal shock resistance and can be used in a solar heat collection plate in replacement of metal.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

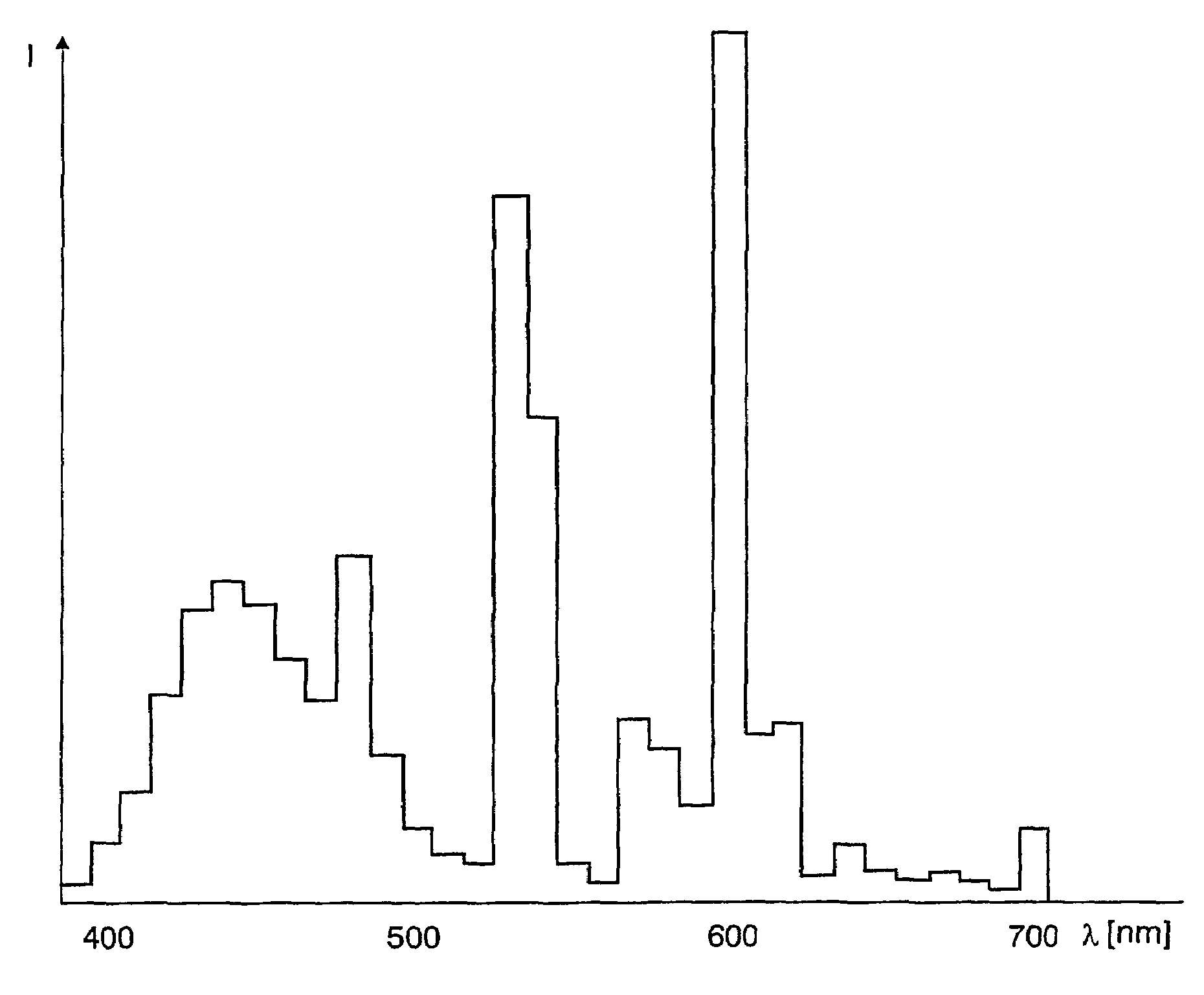

Phosphor composition for a low-pressure discharge lamp with high color temperature

InactiveUS7670507B2Physical improvementEnhances spiritual well-beingDischarge tube luminescnet screensLamp detailsPhosphoric acidManganese

A phosphor composition for a low-pressure discharge lamp with a high light yield and a high color temperature contains phosphors which emit in the red wavelength region, including yttrium oxide doped with europium or gadolinium-zinc-magnesium pentaborate doped with cerium and manganese, phosphors which emit in the green wavelength region including lanthanum phosphate doped with cerium and terbium and / or cerium-magnesium aluminate doped with terbium and / or cerium-magnesium pentaborate doped with terbium, and optionally a phosphor which emits in the blue wavelength region of the barium-magnesium aluminate doped with europium type. The phosphor composition additionally contains at least one phosphor which emits in the blue or blue-green wavelength region selected from the group consisting of manganese-strontium-barium-magnesium aluminate doped with manganese and europium or barium-magnesium aluminate doped with europium and manganese and strontium aluminate doped with europium and strontium-barium-calcium chloroapatite doped with europium and strontium borophosphate doped with europium.

Owner:LEDVANCE GMBH

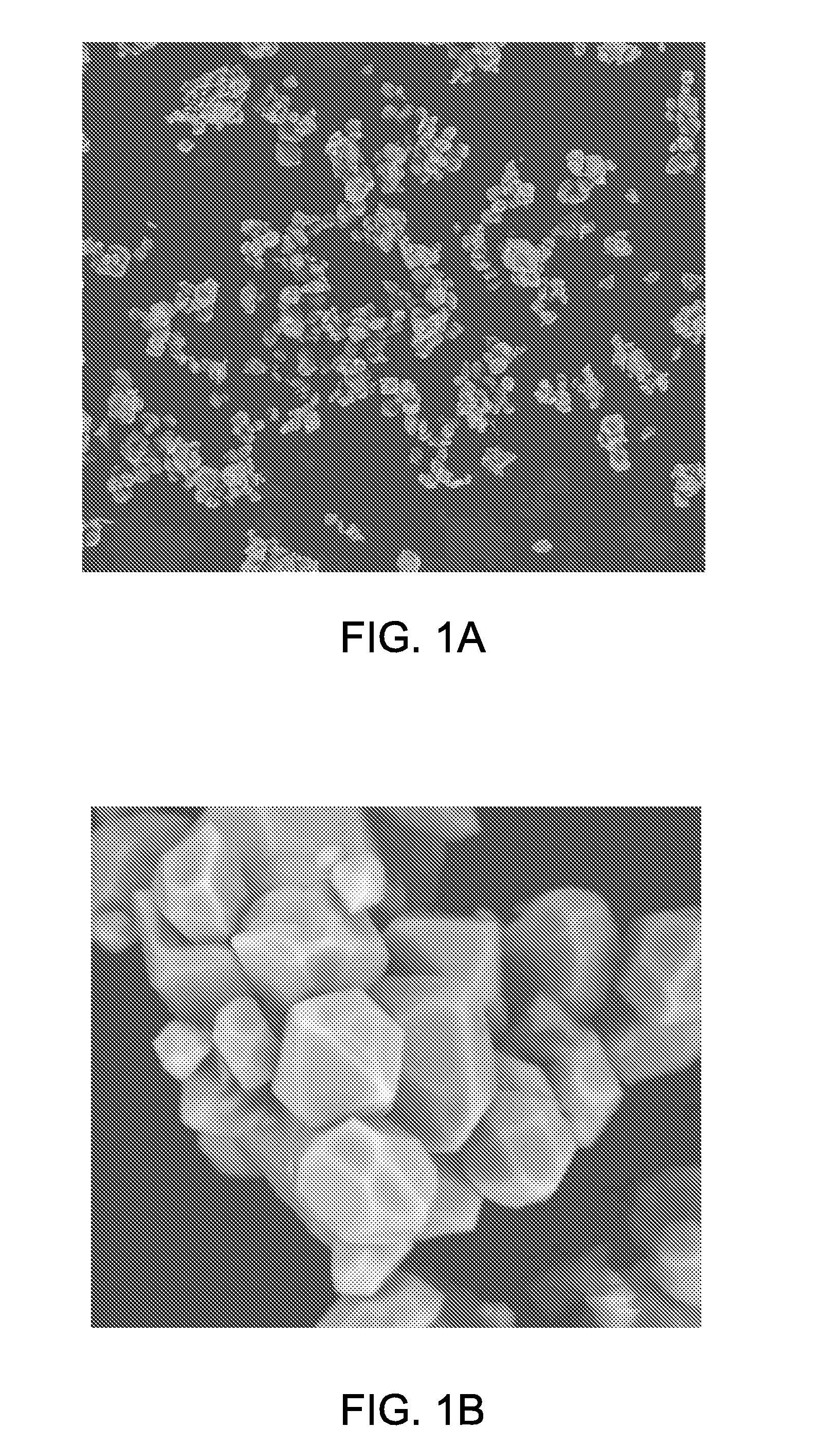

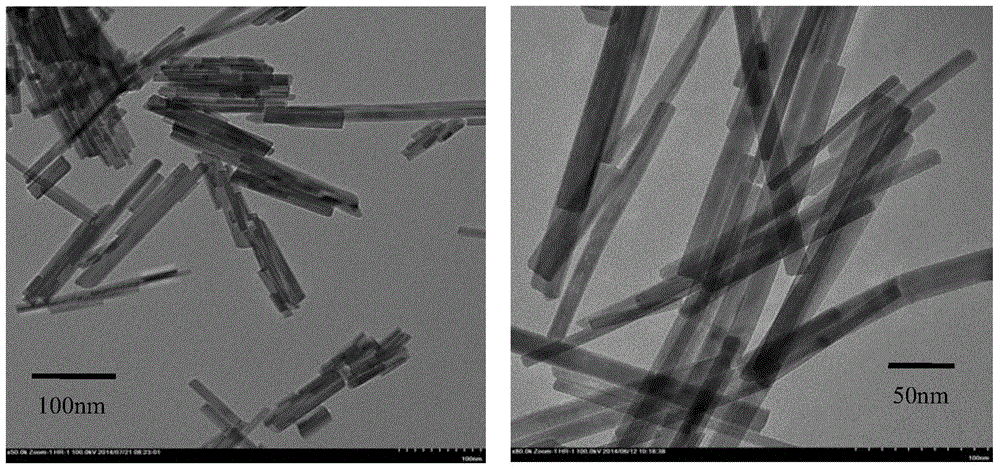

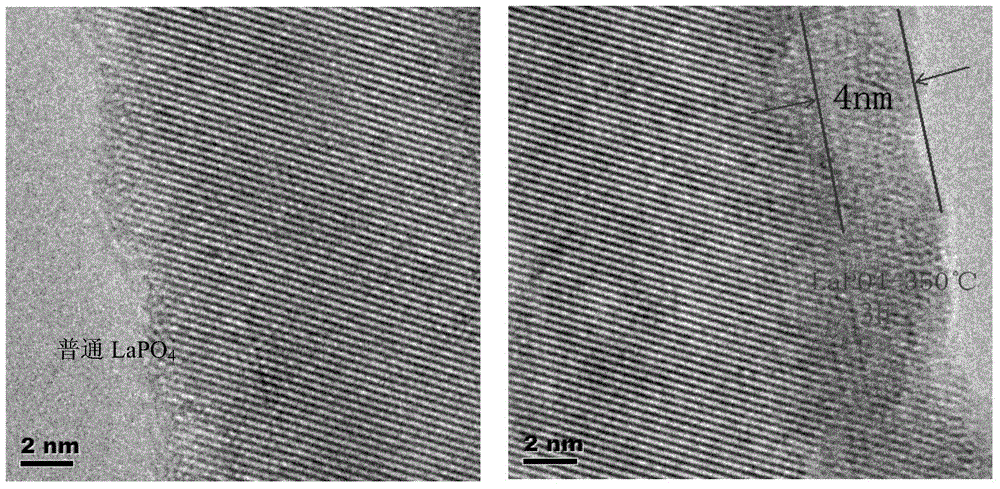

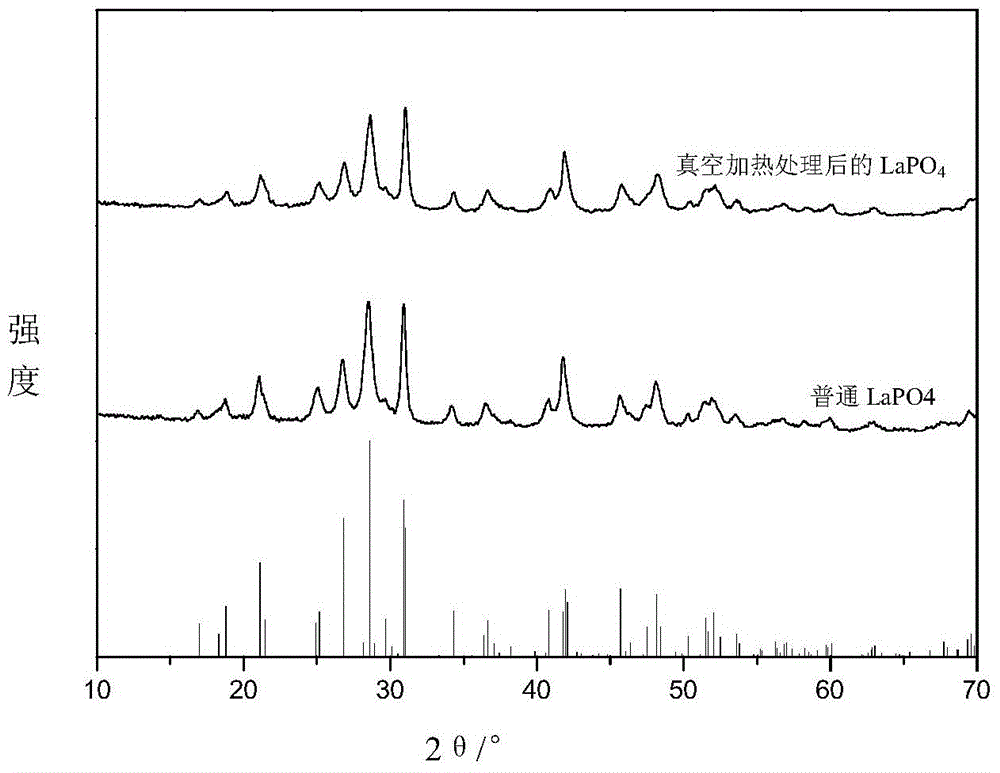

Preparation method for high-activity lanthanum phosphate nanorod and application of high-activity lanthanum phosphate nanorod as photocatalyst

InactiveCN104609383AUniform sizeEvenly distributedMaterial nanotechnologyPhysical/chemical process catalystsReaction temperatureHigh activity

The invention provides a high-activity lanthanum phosphate nanorod, a preparation method for the high-activity lanthanum phosphate nanorod and an application of the high-activity lanthanum phosphate nanorod as a photocatalyst in the field of photocatalysis. The preparation method comprises the following steps: producing a hydrothermal reaction of soluble lanthanum salt and soluble phosphate to obtain a lanthanum phosphate nanorod A; performing vacuum heating treatment on the lanthanum phosphate nanorod A at 340-360 DEG C for 1-5 hours to obtain the high-activity lanthanum phosphate nanorod. The high-activity lanthanum phosphate nanorod is prepared by utilizing the hydrothermal method and the vacuum heating treatment; compared with the lanthanum phosphate nanorod A not subjected to the vacuum heating treatment, the prepared lanthanum phosphate nanorod is uniform in size and size distribution, has the diameter of 10-20 nm and the length of 100-200 nm, has relatively high photocatalytic activity in water, and can be applied to catalytic degradation removal of pollutants in a water environment. The preparation method has the advantages of simple operation process, low-price raw materials, low reaction temperature, easiness for large-scale production and the like.

Owner:TSINGHUA UNIV

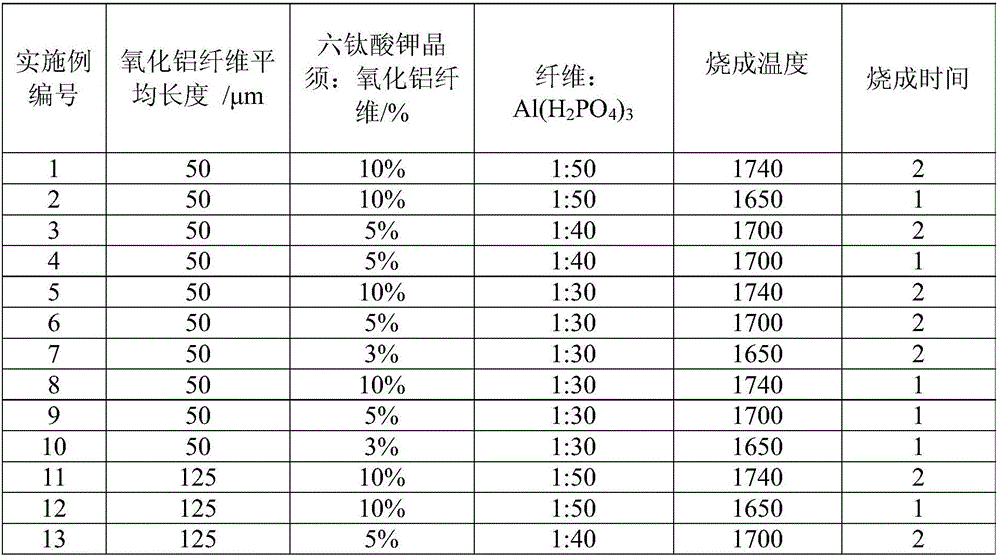

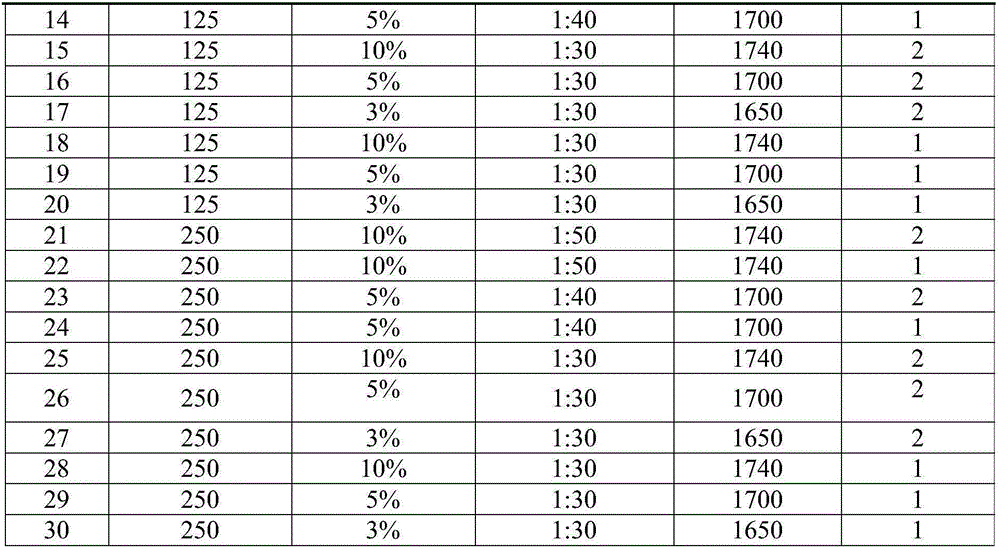

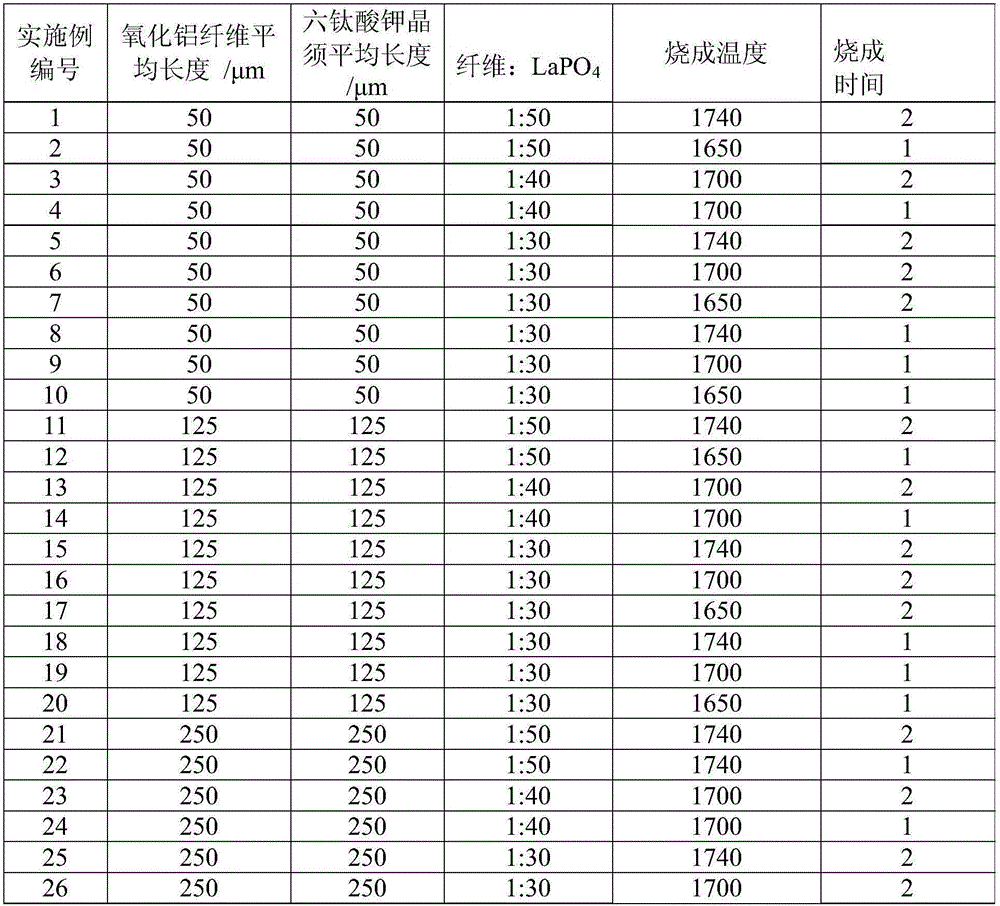

Preparation method of high-temperature-resistant, high-strength and rigid thermal insulation material

ActiveCN106587901AImprove mechanical propertiesImprove insulation performanceCeramicwareFiberPorosity

The invention relates to a preparation method of a high-temperature-resistant, high-strength and rigid thermal insulation material and belongs to the technical field of preparation of inorganic composite materials. The preparation method comprises steps as follows: (1) pretreatment: alumina fibers and potassium hexatitanate whiskers are chopped; (2) one of an aluminum dihydrogen phosphate binder or a lanthanum phosphate binder is selected as a binder; (3) suction filtration forming: the chopped alumina fibers and potassium hexatitanate whiskers prepared in step (1) are placed in the binder prepared in step (2) in the mass ratio and mixed, slurry obtained through mixing is stirred, subjected to suction filtration forming, demolding and transferred to a constant-temperature drying oven; (4) heat treatment: a material prepared in step (3) is placed in a kiln for heat treatment. The preparation method is simple to operate and easy to implement, and the obtained target product has high mechanical properties and thermal insulation performance on the premise that the high porosity is guaranteed and has good anti-scouring performance and thermal shock resistance.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

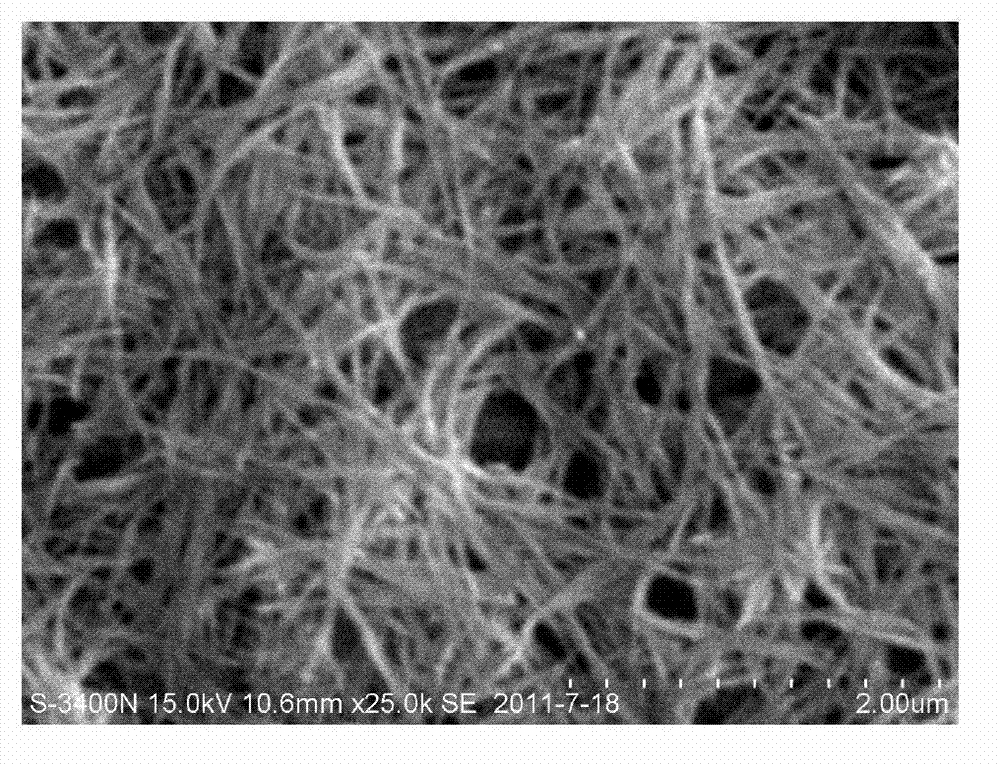

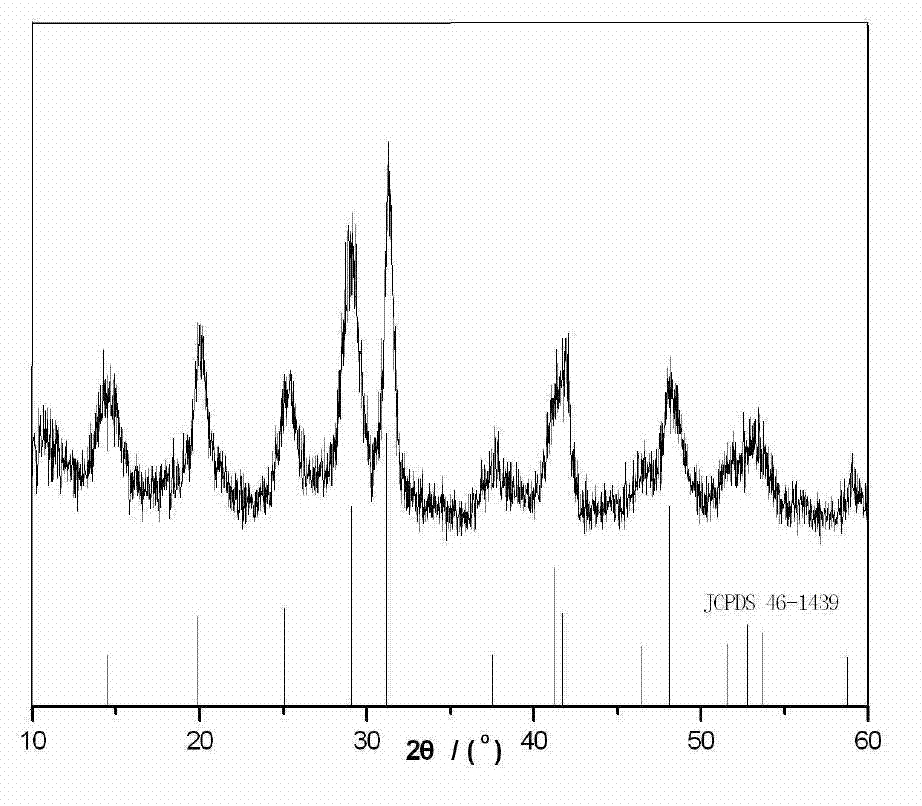

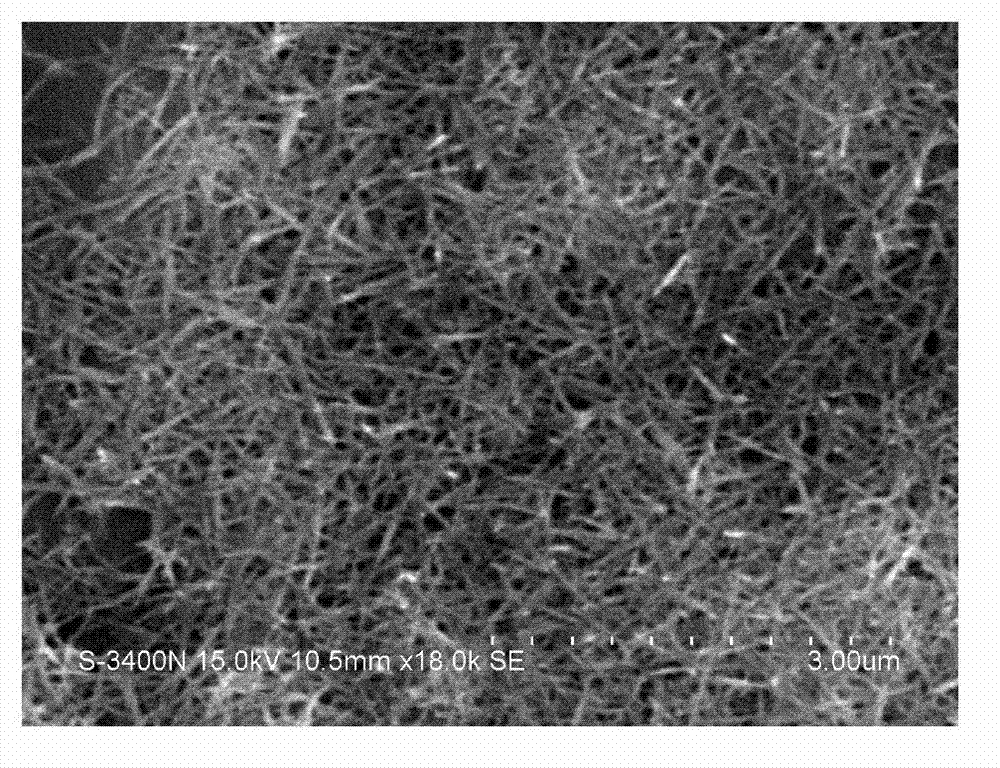

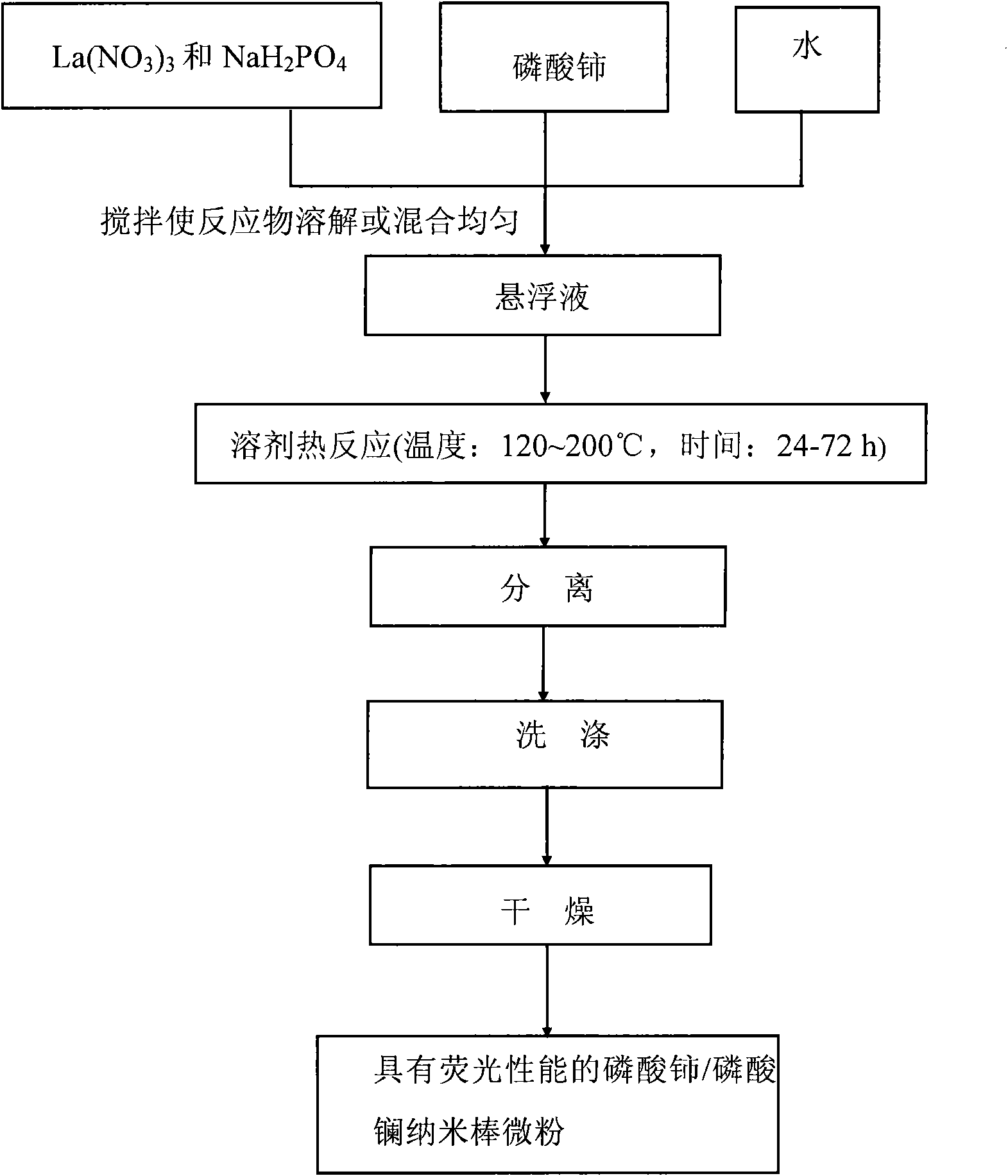

Solvent-thermal synthesis of lanthanum phosphate nanorod

The invention discloses a method for using a solvent to carry out thermosynthesis so as to obtain nanorods of lanthanum phosphate; the method comprises the following steps of: mixing a lanthanum chloride solution with the concentration of 1.0-2.0mol / L and a sodium phosphate solution with the concentration of 1.0-2.0mol / L, wherein, the sodium phosphate and the lanthanum chloride have equal molar ratio; adding an n-butanol solvent and leading the volume ratio of water and the n-butanol to be 0.5 to 2 : 1 with the molar concentration of the lanthanum chloride in the mixed solution being 0.2 to 0.5mol / L; stirring the mixture till the mixture is even; adjusting the PH value of the solution to be 3 to 6 by phosphoric acid and hot reaction is carried out for 6.0 to 48 hours under the condition that the temperature is 140 to 220 DEG C. The synthetic method of the invention is simple, environment-friendly, green and economical, low-temperature, without needing calcination, and can obtain products directly in the solution; the obtained lanthanum phosphate has high purity, belongs to the monoclinic crystal system and is the nano rod with monazite structure; the nano rod has the diameter of less than 10nm, even fineness, single appearance and good dispersity.

Owner:SUN YAT SEN UNIV

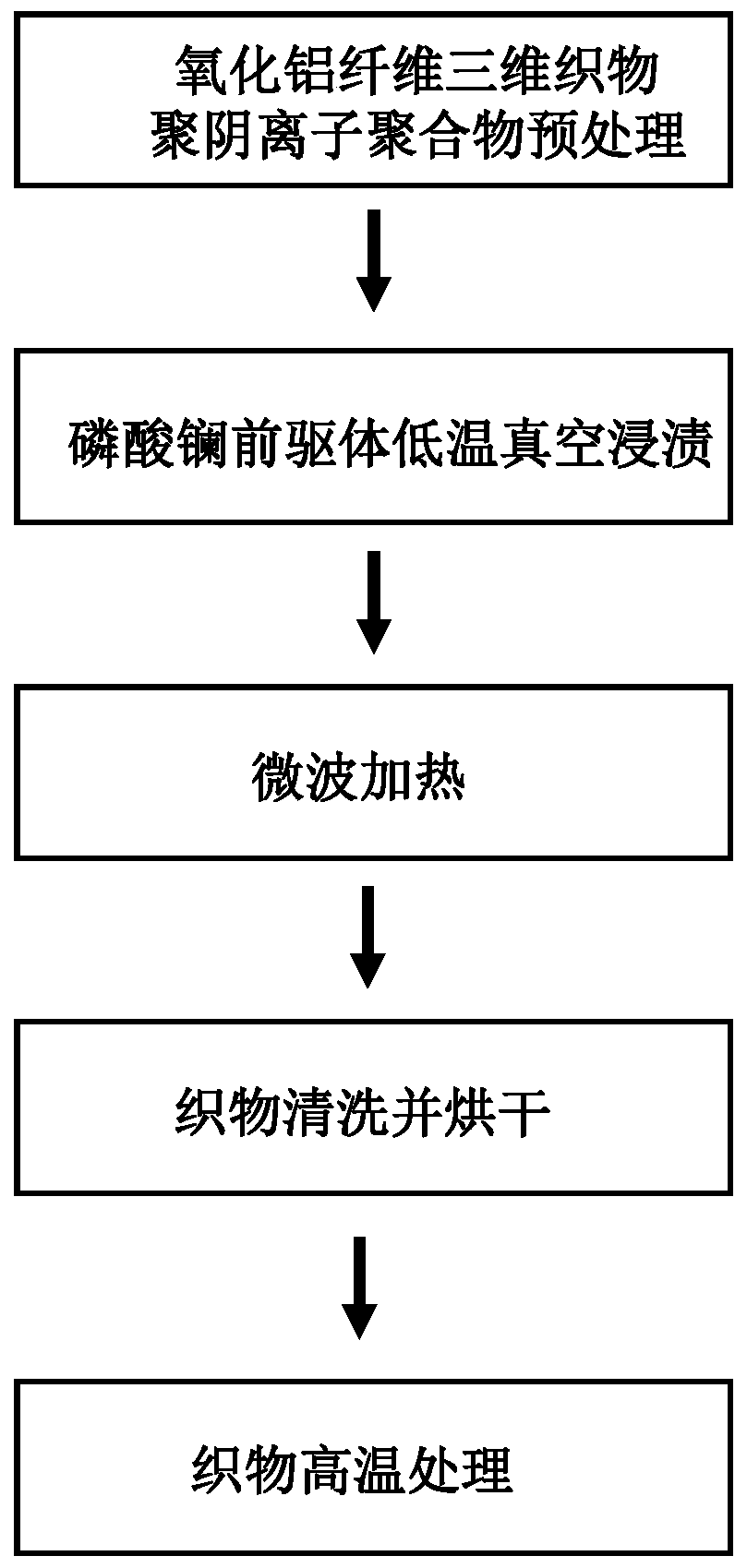

Method for carrying out interface modification on alumina fiber three-dimensional fabric and modified alumina fiber three-dimensional fabric prepared by same

ActiveCN111005226AMild reaction conditionsIncrease profitPhysical treatmentLiquid/gas/vapor removalFiberAlumina composite

The invention relates to a method for carrying out interface modification on an alumina fiber three-dimensional fabric and a modified alumina fiber three-dimensional fabric prepared by the same. The method comprises the steps of: carrying out preprocessing on the alumina fiber three-dimensional fabric by adopting polyanion polymer solution to obtain a preprocessed alumina fiber three-dimensional fabric; preparing lanthanum phosphate precursor solution of which a temperature is not higher than 5 DEG C; under the conditions of vacuum and a temperature which is not higher than 10 DEG C, carryingout vacuum impregnation on the preprocessed alumina fiber three-dimensional fabric by adopting the lanthanum phosphate precursor solution; and carrying out microwave heating processing on the aluminafiber three-dimensional fabric subjected to vacuum impregnation, and then sequentially carrying out steps of cleaning, drying and high-temperature processing so as to complete interface modification on the alumina fiber three-dimensional fabric. The method is simple in process, does not require complex equipment and regents, and is high in utilization rate of a raw material and low in cost; and analumina fiber reinforced aluminum oxide composite material prepared by adopting the fiber three-dimensional fabric modified by the process disclosed by the invention still has high strength after long-time high-temperature processing.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

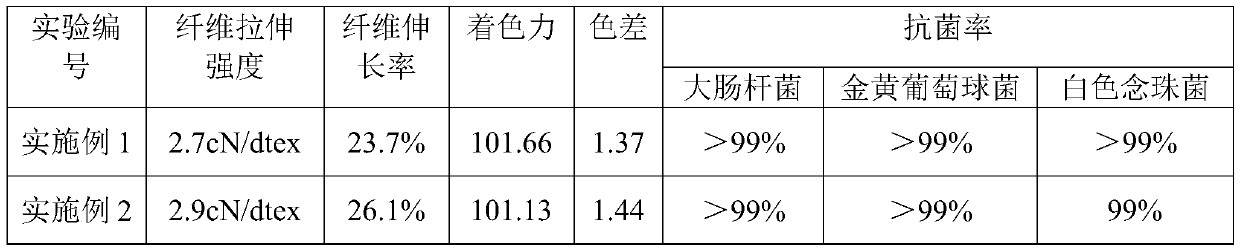

Antibacterial color master batch and preparation method of stock solution colored PET antibacterial functional fiber

ActiveCN111548607AGood antibacterial effectExcellent fungal effectMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterFiber

The invention provides an antibacterial color master batch and a preparation method of stock solution colored PET antibacterial functional fiber. The invention is prepared from the following raw materials: antibacterial powder, a coloring agent, an antioxidant, a dispersing agent and polyester powder, wherein the antibacterial powder is prepared from the following raw materials: a diamino modifiedsilver-loaded lanthanum phosphate antibacterial agent and an antibacterial metal oxide; the antibacterial metal oxide is TiO2 nano-powder, ZnO nano-powder or a mixture of the TiO2 nano-powder and theZnO nano-powder. The antibacterial powder in the antibacterial color master batch is novel inorganic antibacterial nano-powder; silver ions are reduced into nano-silver elementary substances and loaded on rare earth (lanthanum phosphate nano-powder), and the novel inorganic antibacterial agent is prepared. According to the antibacterial agent, the antibacterial activity of a rare earth compound and the synergistic antibacterial effect of rare earth and elemental silver are utilized, and the excellent antibacterial and antifungal effects are achieved.

Owner:BEIJING UNIV OF CHEM TECH

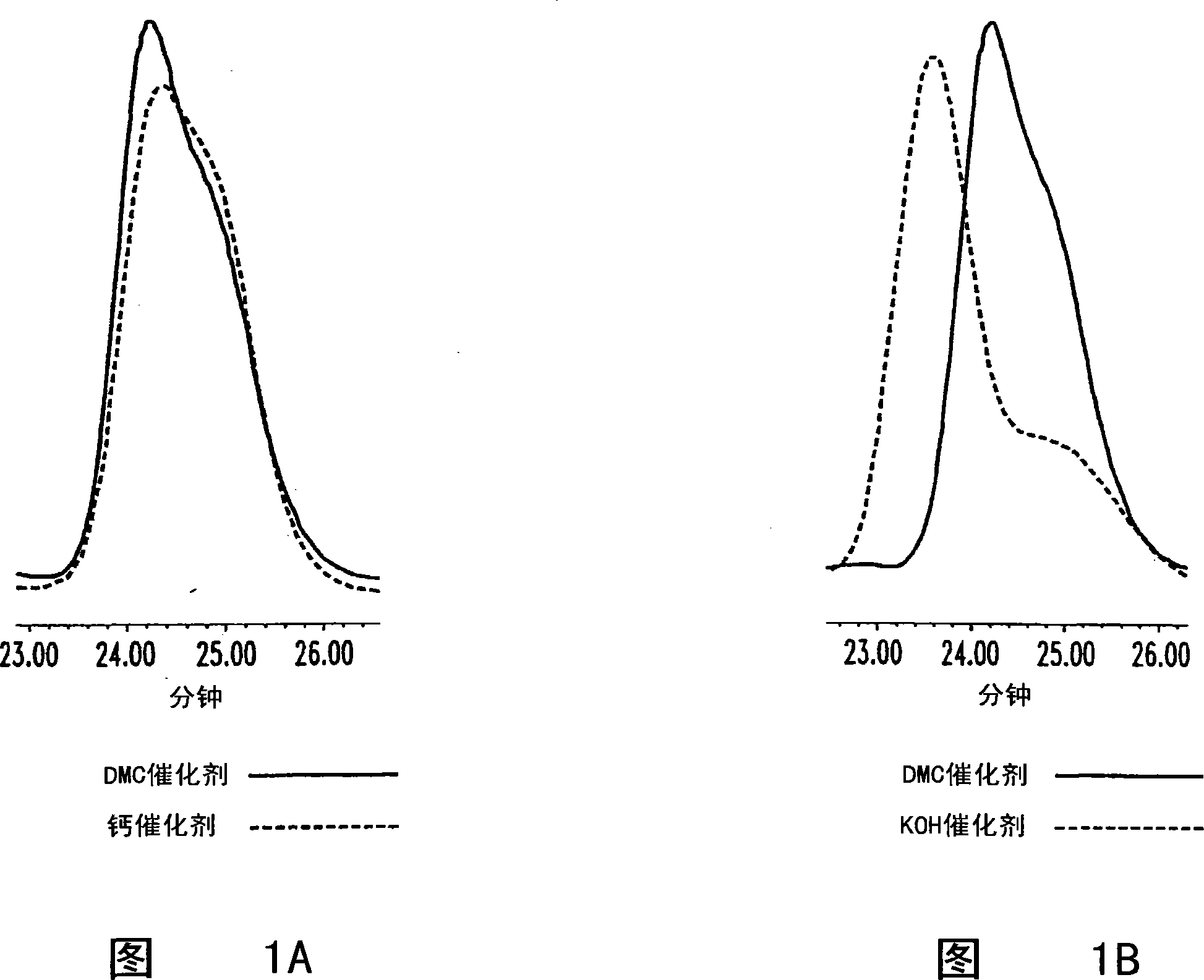

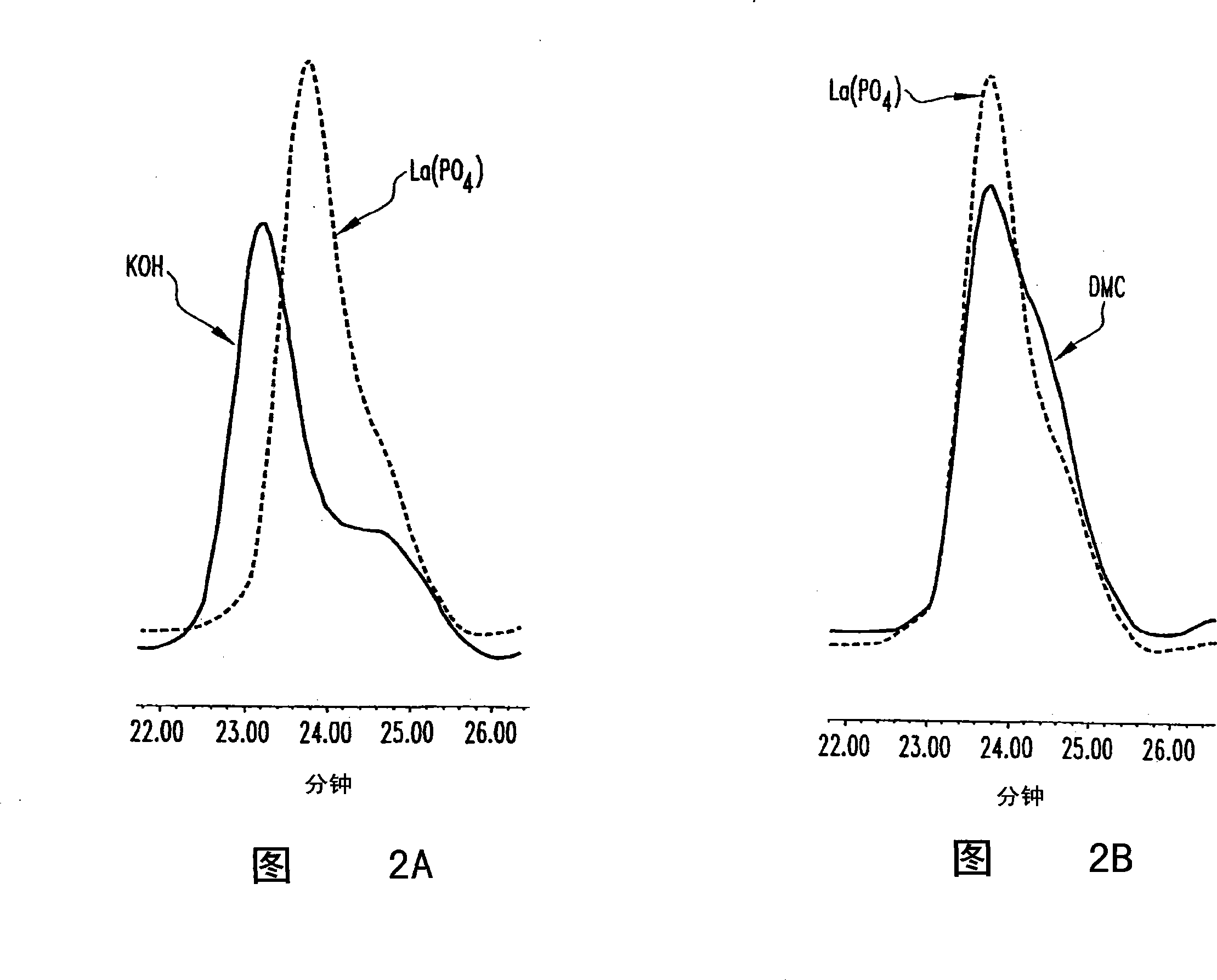

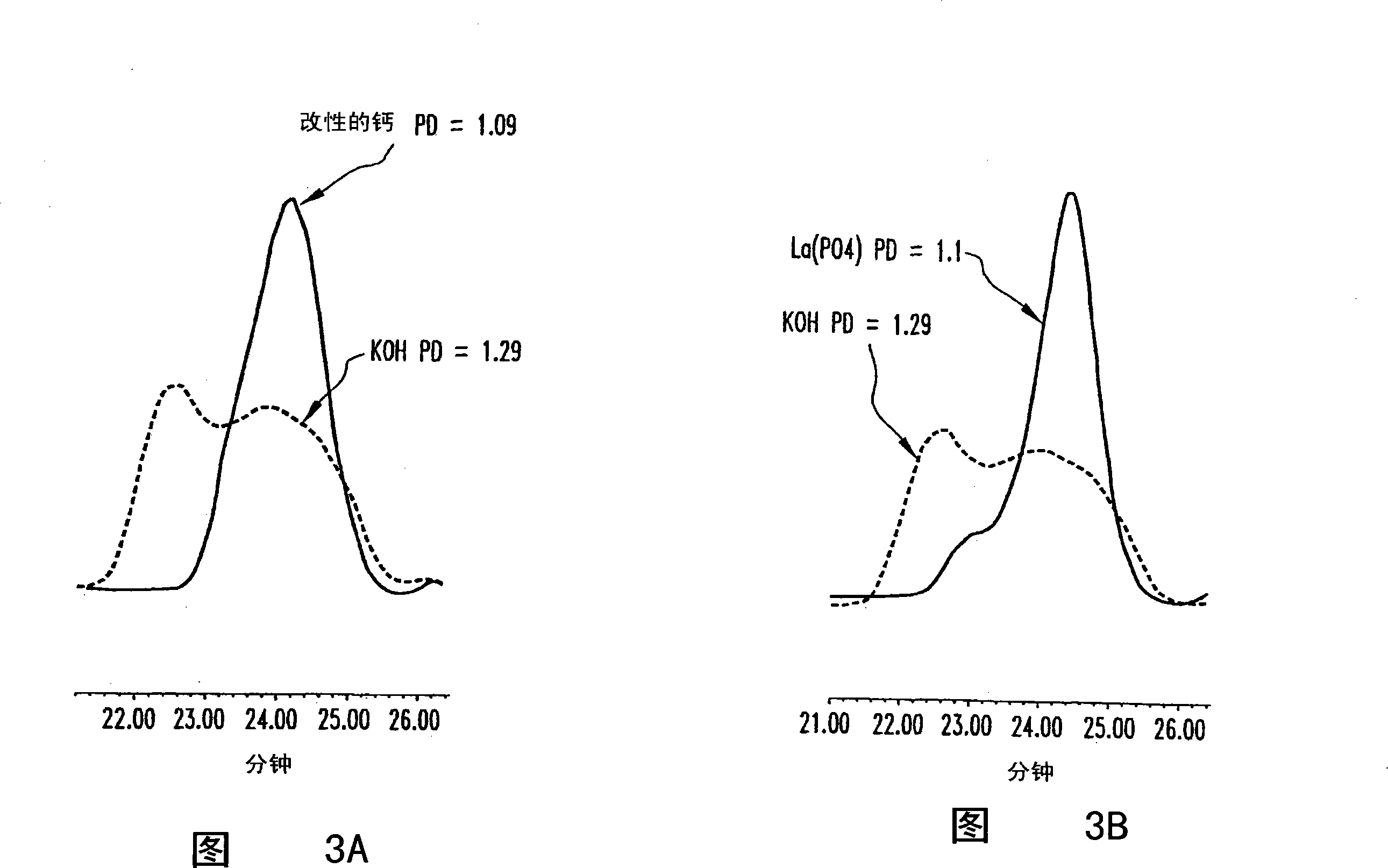

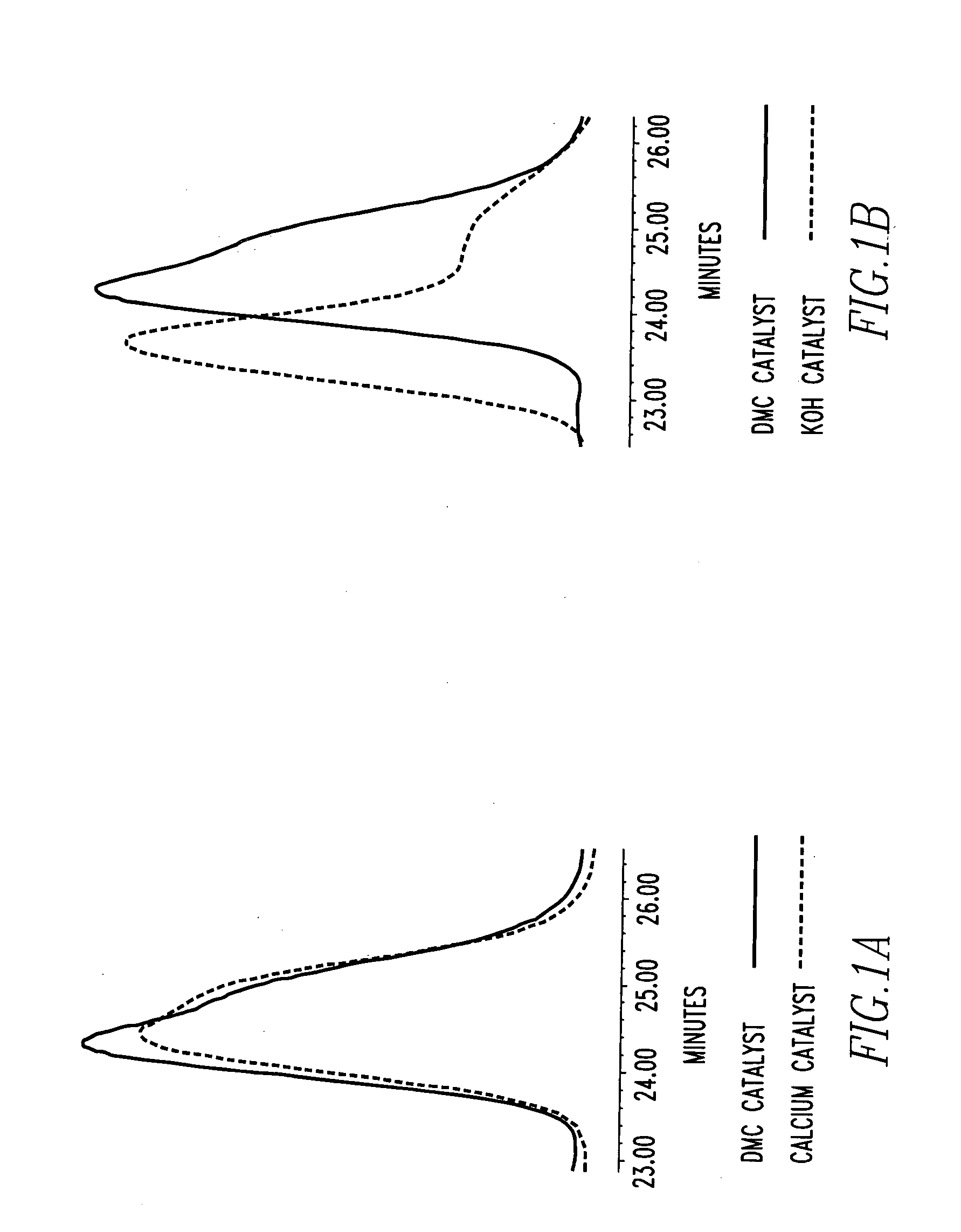

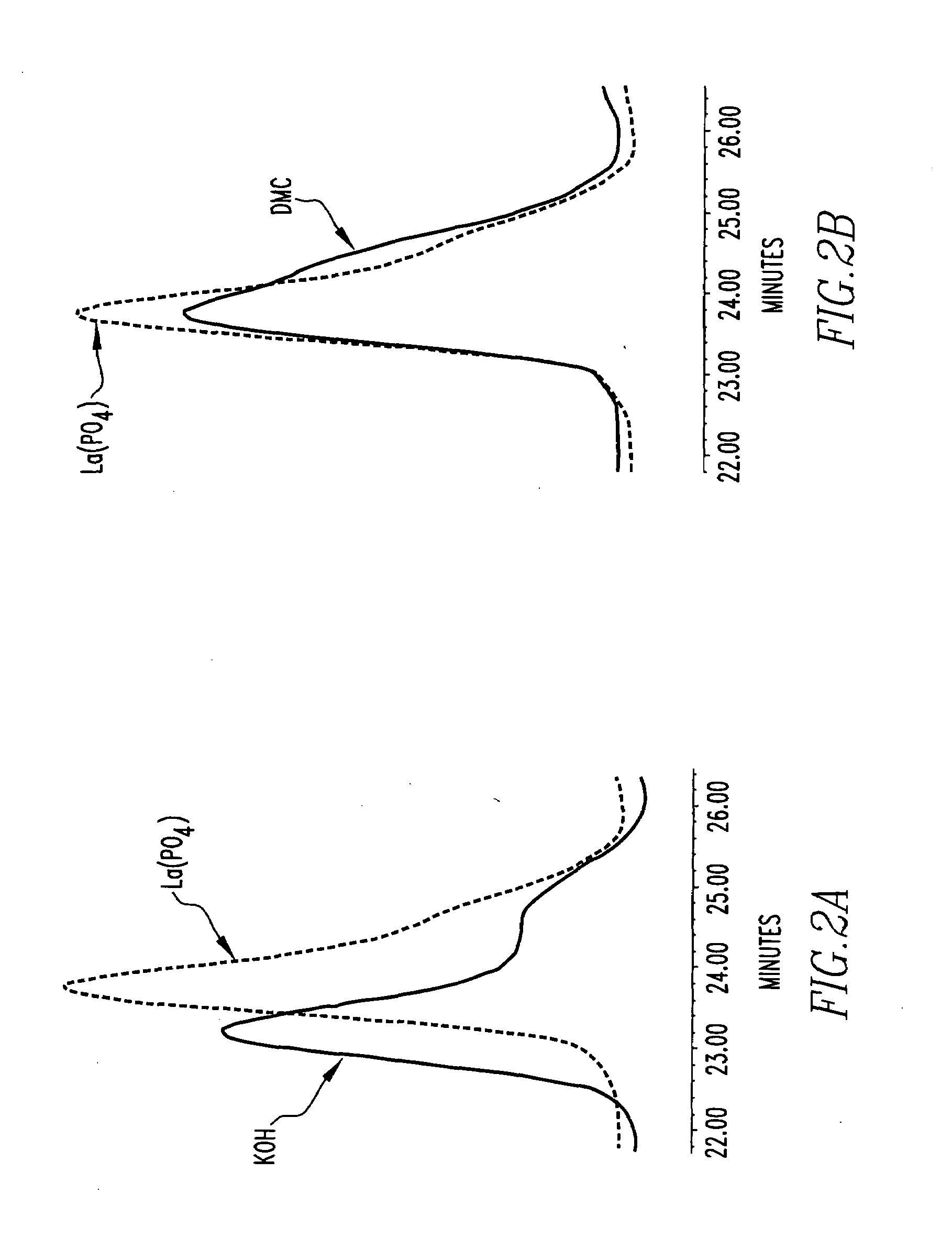

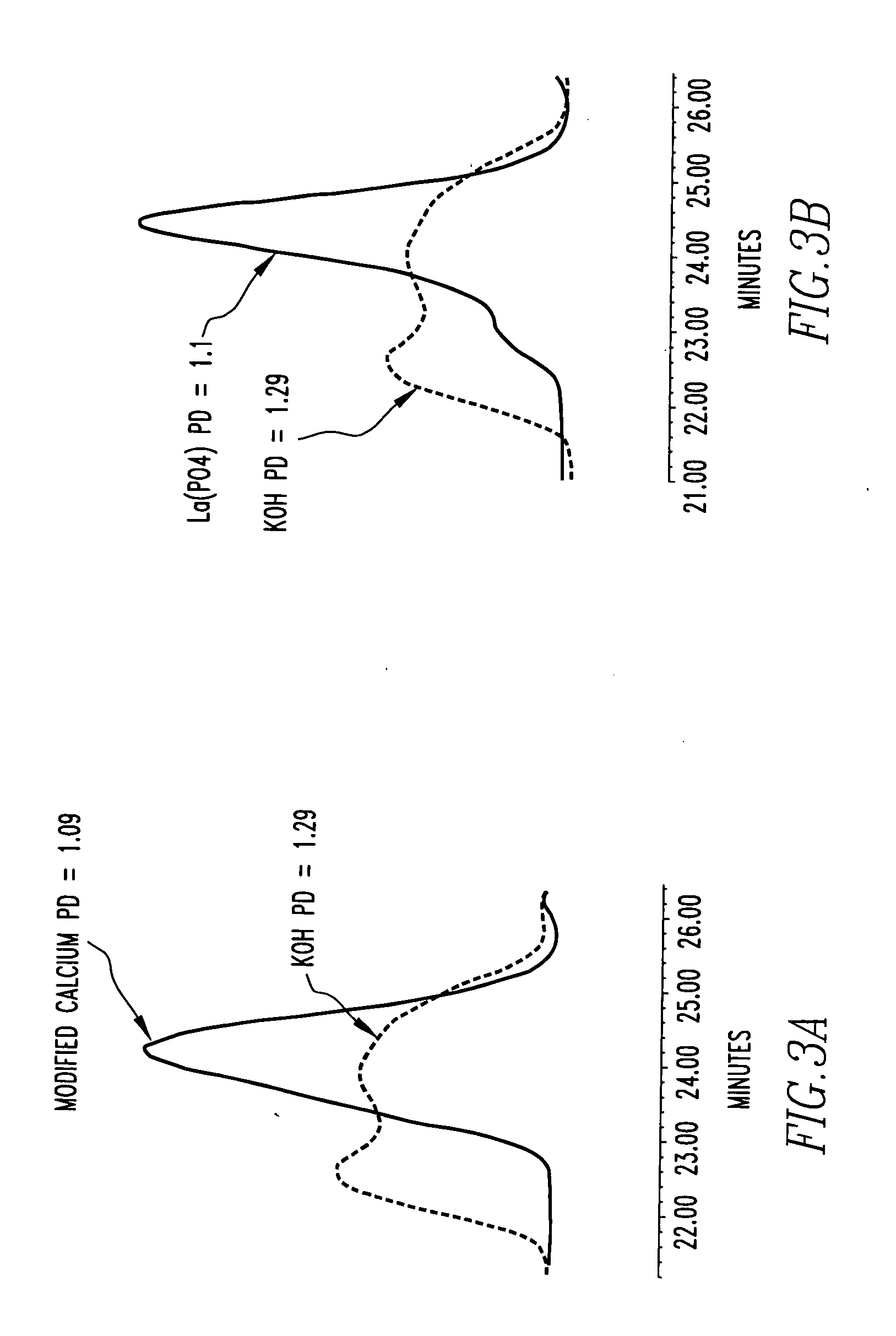

High productivity alkoxylation processes

The present invention provides a continuous process for the preparation of a polyoxyalkylene polyether product of number average molecular weight N employing continuous addition of starter, involving a) establishing in a continuous reactor a first portion of a catalyst / initial starter mixture, b) continuously introducing into the continuous reactor one or more alkylene oxides, c) continuously introducing into the continuous reactor one or more continuously added starters, d) continuously introducing into the reactor fresh catalyst and / or further catalyst / further starter mixture, e) polyoxyalkylating combined starters by continuously practicing at least steps b) through d) herein until a polyoxyalkylene polyether product of number average molecular weight N is obtained and f) continuously removing the polyoxyalkylene polyether product from the continuous reactor. Modified-calcium hydroxide or modified calcium oxide and lanthanum phosphate catalysts exhibit catch-up kinetics and are thus useful for the production of polyalkylene oxides using the continuous and CAOS processes.

Owner:BAYER MATERIALSCIENCE AG

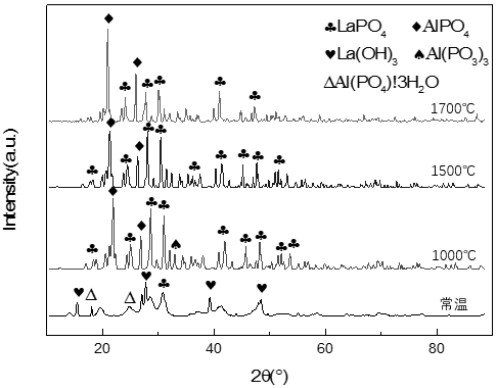

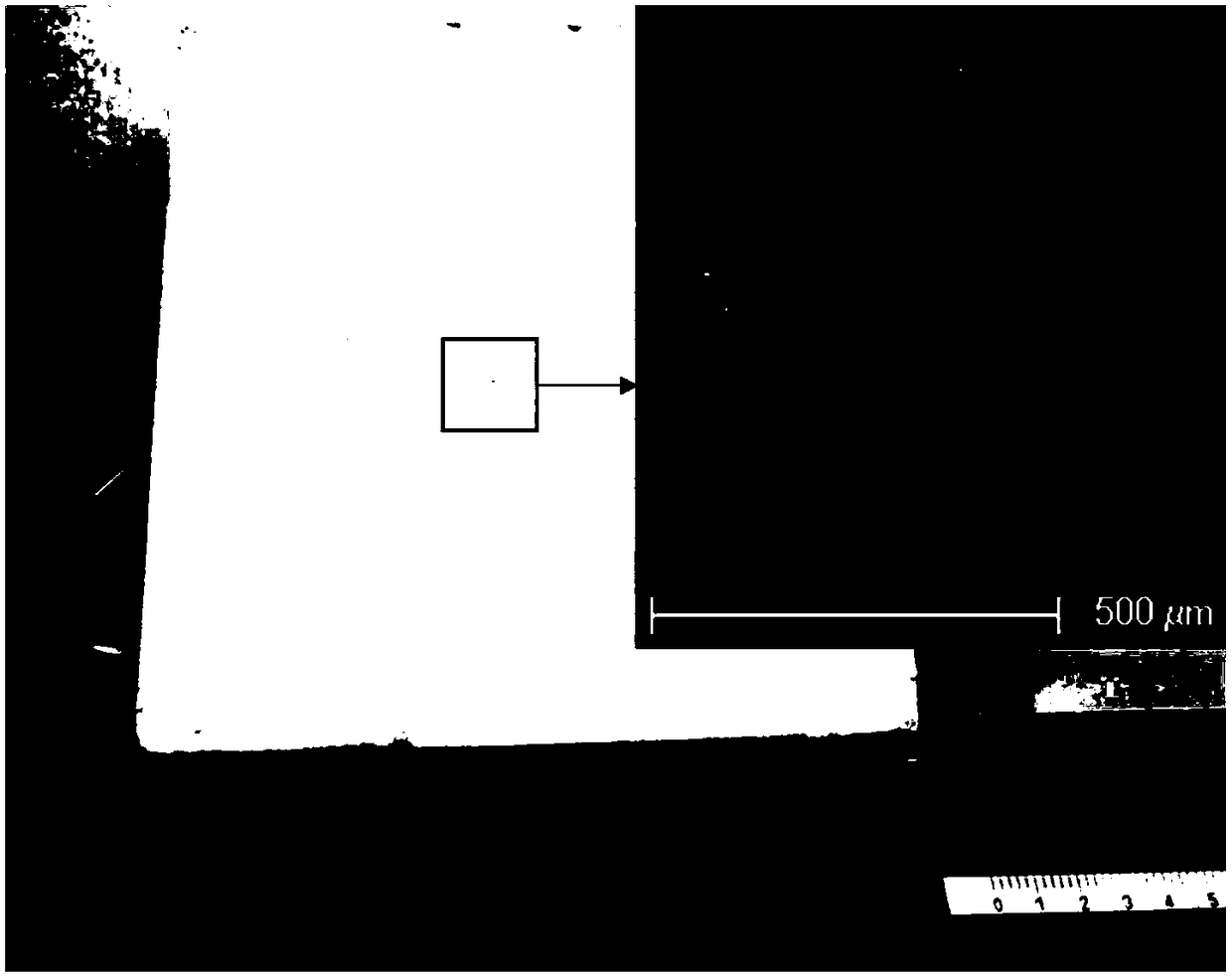

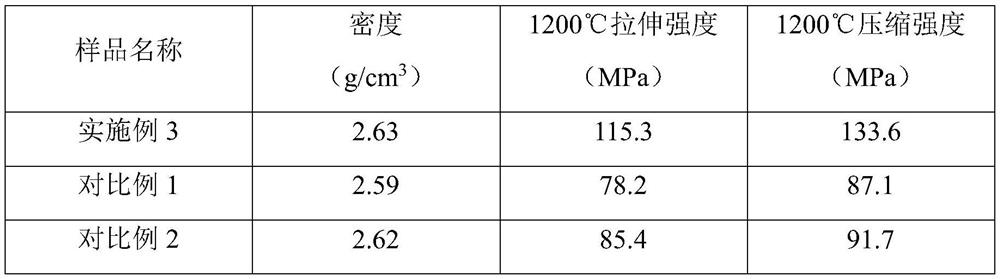

Lanthanum-aluminum phosphate composite material cured at normal pressure and low temperature as well as preparation method and application thereof

The invention provides a lanthanum-aluminum phosphate composite material. The lanthanum-aluminum phosphate composite material comprises lanthanum phosphate and aluminum phosphate compounded with lanthanum phosphate. The composite material has specific phase composition and micro-structure, and lanthanum phosphate and aluminum phosphate are mutually doped and compounded and bonded through ionic bonds, so that the lanthanum-aluminum phosphate composite material which can be quickly cured and molded at low temperature and has excellent performance at high temperature is obtained. The phosphate composite material provided by the invention can be cured and formed at normal pressure and low temperature, so that the product can be formed without special high-temperature sintering by special equipment, complex high-temperature sintering is omitted in the forming process, and energy is saved. The composite material is excellent in high temperature resistance and good in ablation resistance, the surface of an ablated sample is complete at the ablation temperature of 2000 DEG C, melting does not happen, the preparation process is simple, and the preparation period is short.

Owner:CENT SOUTH UNIV

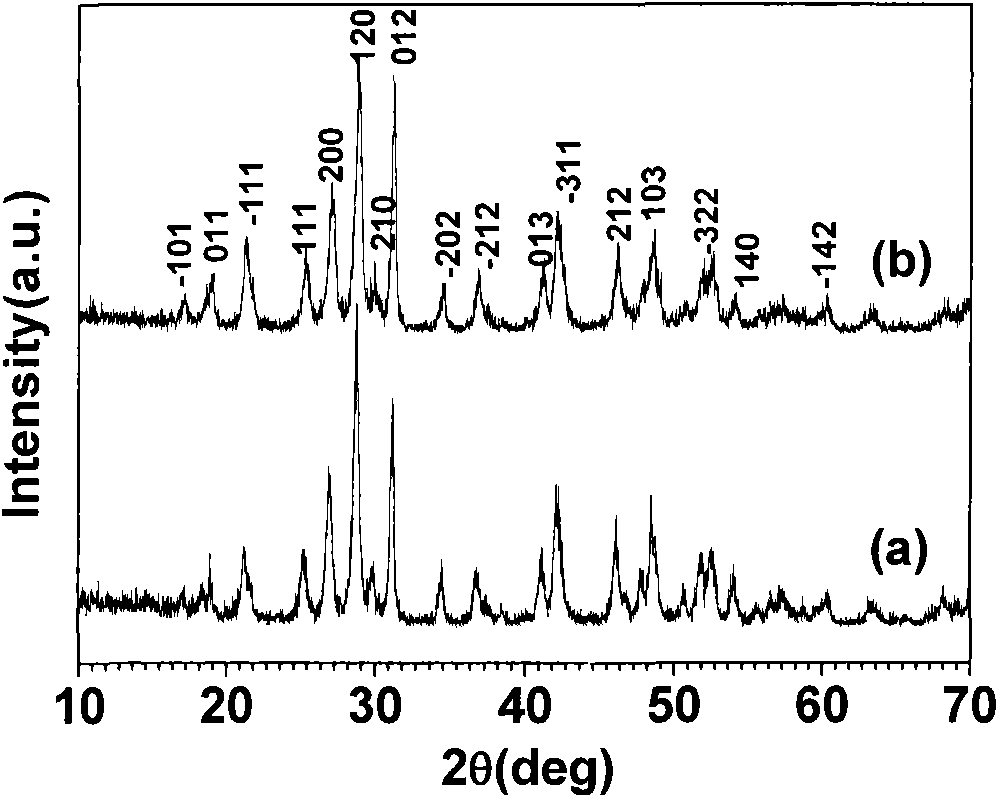

Preparation method of lanthanum phosphate nano-wires

InactiveCN102849707AMild preparation conditionsEnvironmentally friendlyMaterial nanotechnologyPhosphorus compoundsEnvironment effectSalt solution

The invention provides a preparation method of lanthanum phosphate nano-wires. The preparation method comprises the following steps: respectively preparing an La<3+> salt solution and a PO4<3-> salt solution; adding the PO4<3-> salt solution to the La<3+> salt solution under continuous stirring to obtain a mixed solution I; stirring the mixed solution I, and adjusting the pH value of the mixed solution I to 0.8-9.0 to obtain a mixed solution II; and ageing the mixed solution II at 4-95DEG C under an environmental pressure for above 1h to obtain the lanthanum phosphate nano-wires (comprising hexagonal crystal phase lanthanum phosphate nano-wires and monoclinic crystal phase lanthanum phosphate nano-wires). The preparation method can be implemented through adopting simple and cheap equipment under the environmental pressure, so it is convenient for realizing the industrialized production; and there is no need to add a template in the preparation process, so the environmental influence possibly brought by a waste liquid is avoided.

Owner:SHENZHEN UNIV

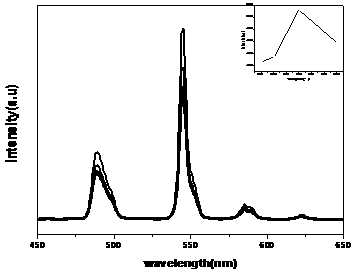

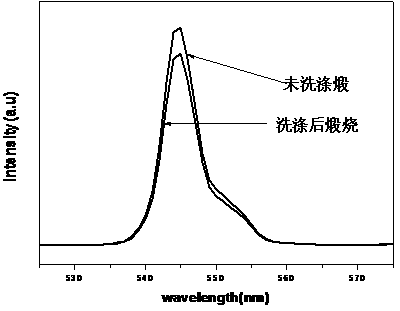

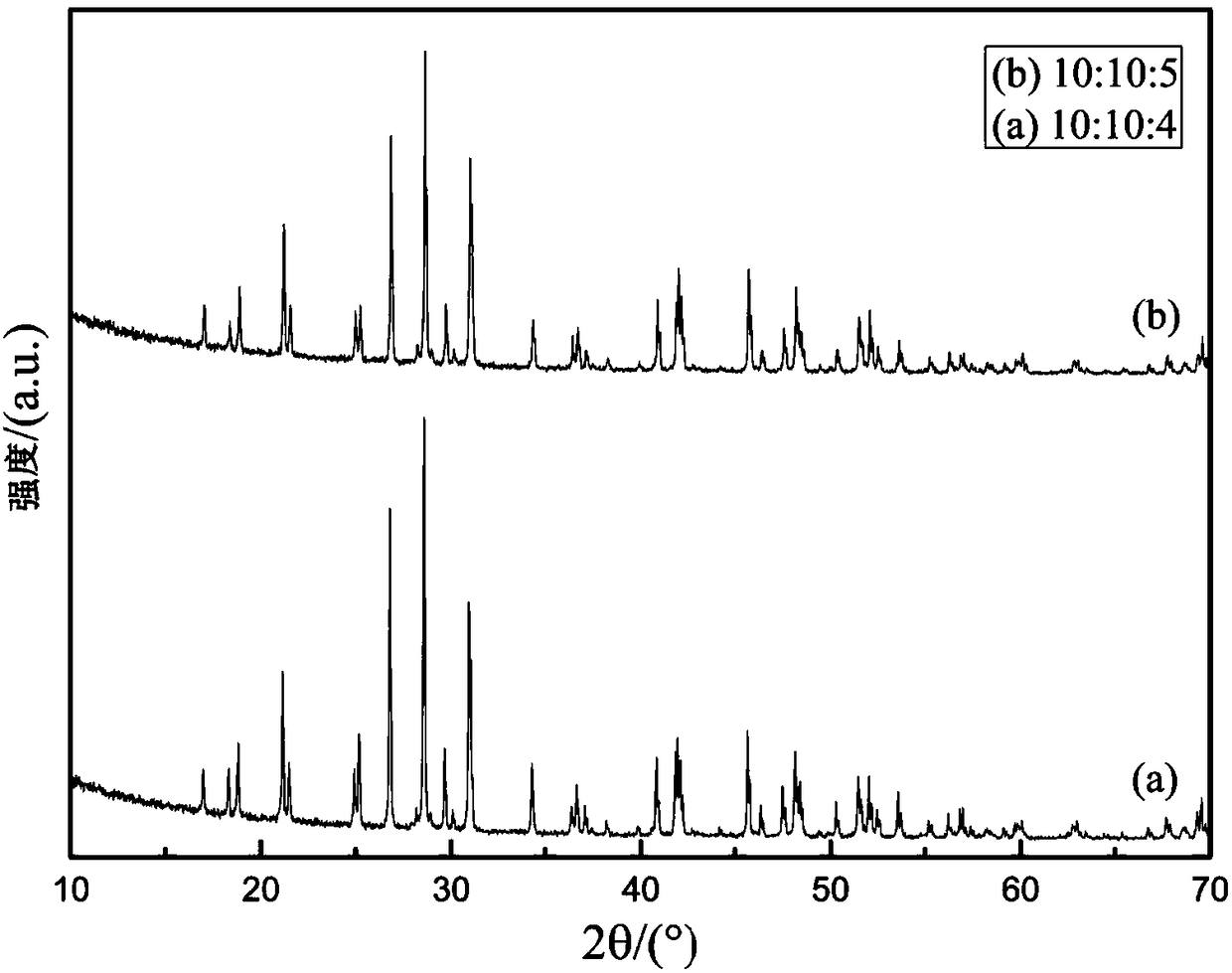

Preparation method of small size and high brightness lanthanum phosphate activated by cerium and terbium, green phosphor

InactiveCN103351864AGreat excitementBig launchChemical industryLuminescent compositionsPhosphoric acidCerium

A preparation method of small size and high brightness lanthanum phosphate activated by cerium and terbium, green phosphor comprises following steps: rare earth soluble salt containing crystal water, and chloride or nitrate, are mixed with alkali metal or phosphatic of ammonium and then the mixture is grinded or ball milled at the room temperature, the precursor of lanthanum phosphate activated by cerium and terbium is obtained after a drying process, then the precursor is sintered for 1 to 24 hours in the presence of auxiliary agent Li2(CO3)3 in a reduction atmosphere at the temperature of 950 to 1250 DEG C, and finally the phosphor product is produced after a washing post-treatment. The substrate of the phosphor is LaPO4, Ce3+ is the sensitization particle, and Tb3+ is the activating center. The chemical formula of the phosphor is La<x>Ce<y>Tb<1-x-y>PO4. The phosphor can give off strong green light with a wavelength around 545 nm under the activation of ultraviolet. The phosphor has the advantages that the particles of the synthesis phosphor are small, the diameters of the median particles are smaller than 1 micrometer, and the light intensity of the phosphor is higher than that of aluminate green phosphor in the present market.

Owner:NANCHANG UNIV

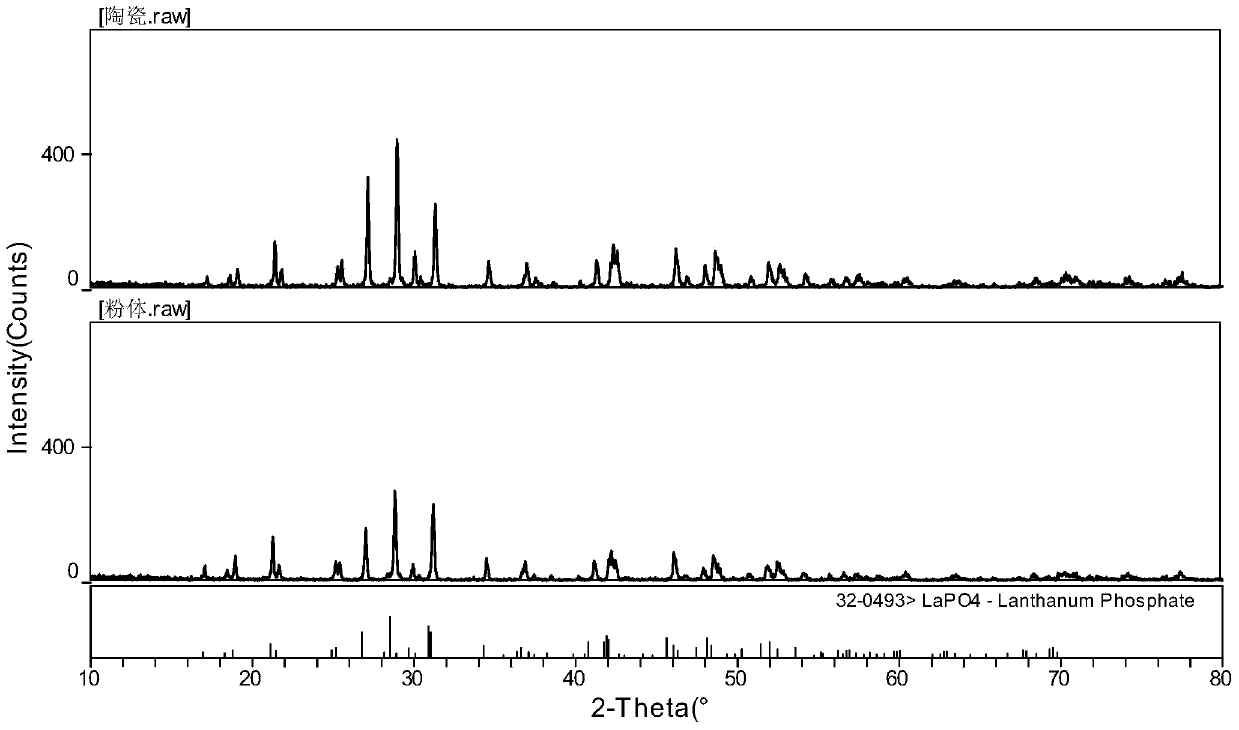

Preparation method of lanthanum phosphate ceramic fluorescent material

The invention relates to a preparation method of a lanthanum phosphate ceramic fluorescent material. Cerium-terbium-codoped lanthanum phosphate luminescent ceramic is quickly prepared at a low temperature by adopting a method combining microwave treatment with coprecipitation, so that the sintering temperature is reduced, the heat preservation time is reduced, and output and transmission of bright green fluorescence are achieved by rare-earth doping and addition of fluxing agent.

Owner:CHANGCHUN UNIV OF SCI & TECH

Preparation method of lanthanum phosphate, lanthanum phosphate porous ceramic as well as preparation method and application thereof

ActiveCN108395240AEasy to operateCalcination temperature is lowCeramicwarePhosphoric acidGel casting

The invention discloses a preparation method of lanthanum phosphate powder. The preparation method of the lanthanum phosphate powder comprises the steps of uniformly mixing lanthanum carbonate and strong phosphoric acid in water, stirring until reacting completely, drying, wet milling, and grinding after drying; preserving heat for a ground product at 900 DEG C to 1200 DEG C for 0.5 to 5h, and obtaining lanthanum phosphate powder. The invention also discloses a method for preparing a lanthanum phosphate porous ceramic through gel casting a foaming slurry suspensoid containing the lanthanum phosphate powder, drying, degreasing and sintering, and application of the prepared lanthanum phosphate porous ceramic used as a wave-transmitting material. The lanthanum phosphate powder prepared by themethod provided by the invention is high in purity, good in dispersibility and uniform in particle size distribution; the prepared lanthanum phosphate porous ceramic has the porosity being larger than or equal to 70 percent, the average pore size being 50 to 120mu m, the dielectric constant of 10GHz being 2 to 4, and the loss tangent being 1.5 to 3.5*10<-3>, and has favorable wave transmission performance and heat insulating property.

Owner:SOUTHEAST UNIV

High productivity alkoxylation processes

InactiveUS20080167501A1Maintain catalytic activitySuitable for useEther preparationLanthanideRare earth

The present invention provides a continuous process for the preparation of a polyoxyalkylene polyether product of number average molecular weight N employing continuous addition of starter, involving a) establishing in a continuous reactor a first portion of a catalyst / initial starter mixture effective initiate polyoxyalkylation of the initial starter after introduction of alkylene oxide into the continuous reactor, b) continuously introducing into the continuous reactor one or more alkylene oxides, c) continuously introducing into the continuous reactor one or more continuously added starters which may be the same or different than said initial starter, d) continuously introducing into the reactor fresh catalyst and / or further catalyst / further starter mixture such that the catalytic activity is maintained, wherein the catalyst is selected from the group consisting of modified oxides and hydroxides of calcium, strontium and barium, lanthanum phosphates or lanthanide series (rare earth) phosphates and hydrotalcites and synthetic hydrotalcites, e) polyoxyalkylating combined starters by continuously practicing at least steps b) through d) herein until a polyoxyalkylene polyether product of number average molecular weight N is obtained and f) continuously removing the polyoxyalkylene polyether product from the continuous reactor. Modified-calcium hydroxide or modified calcium oxide and lanthanum phosphate catalysts exhibit catch-up kinetics and are thus useful for the production of polyalkylene oxides using the continuous and CAOS processes.

Owner:BAYER MATERIALSCIENCE AG

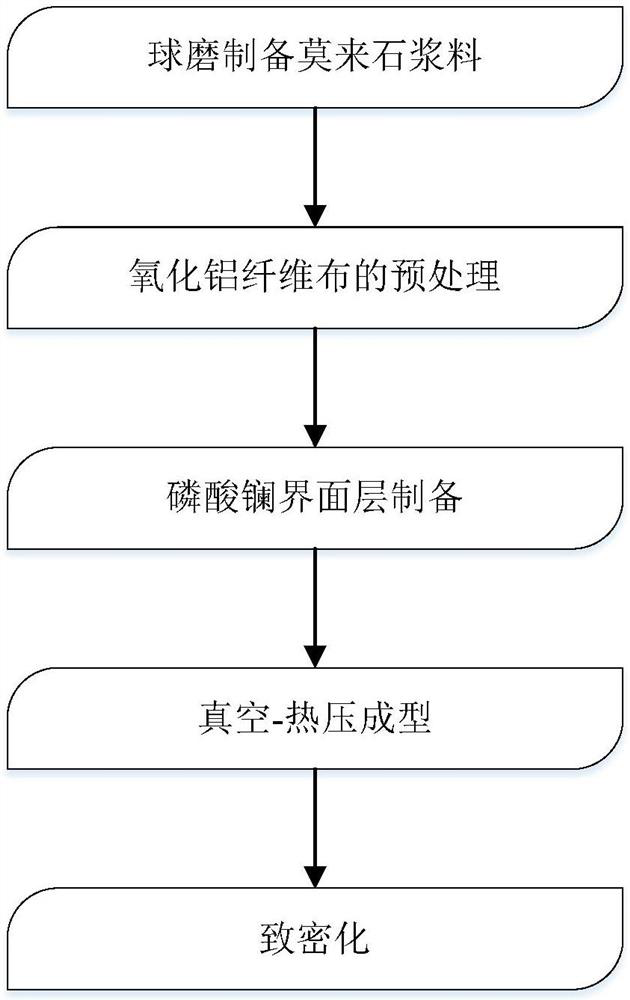

Alumina fiber reinforced mullite ceramic-based composite material and preparation method thereof

ActiveCN114409420AExcellent high temperature mechanical propertiesSimple manufacturing methodFiberCeramic composite

The invention discloses an alumina fiber-reinforced mullite ceramic-based composite material and a preparation method thereof, and relates to the technical field of fiber-reinforced ceramic composites.The method comprises the preparation steps of preparation of mullite slurry through ball milling, pretreatment of alumina fiber cloth, preparation of a lanthanum phosphate interface layer, vacuum-hot press molding and densification. And finally obtaining a finished product of the alumina fiber reinforced mullite ceramic-based composite material. The alumina fiber is used as a reinforcing phase to enhance the strength of the alumina matrix, the preparation process is simple, and the prepared finished product has excellent high-temperature mechanical properties.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

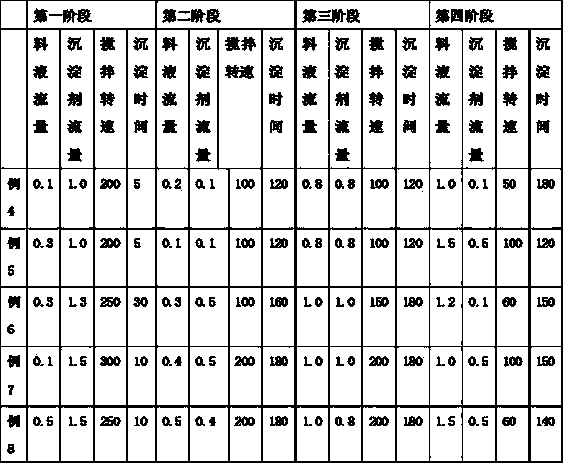

Method for preparing small-granularity cerium terbium lanthanum phosphate rare earth product with high luminous efficiency

ActiveCN104178164AImproved particle size distributionFine granularityLuminescent compositionsFiltrationRare earth

The invention relates to a method for preparing a small-granularity cerium terbium lanthanum phosphate rare earth product with high luminous efficiency. The method comprises the following steps of preparing a 0.2-0.5 mol / l rare earth chloride or nitrate solution and a 0.5-1.0 mol / l precipitant containing phosphate radical; adding the raw materials into a reactor containing a base solution of which the temperature is 30-50 DEG C and the acidity is 0.1-0.5N and reacting; after the precipitation is carried out, aging, washing with water, carrying out vacuum dehydration and microwave drying, sieving and firing to obtain the cerium terbium lanthanum phosphate product. According to the invention, the raw materials are subjected to precipitation, feeding and mixing by virtue of a precision control system, the control process is divided into four stages, the precipitation process is effectively controlled in the four stages, the morphology and performance of a precipitate particle are improved, the product obtained by vacuum filtration, microwave drying and other methods has excellent quality in the aspects of impurities, granularity, the crystal morphology and the like, the method meets the industrial needs and is suitable for being popularized and the preparation is simple.

Owner:YIXING XINWEI LEESHING RARE EARTH

Method for synthesizing small-granularity narrow-distribution green fluorescent precursor

The invention discloses a method for synthesizing small-granularity narrow-distribution green fluorescent precursor. The method comprises the following steps: mixing the following raw materials in parts by mass: 1 part of lanthanum cerium terbium mixed rare earth oxide, 1.05-1.2 parts of diammonium hydrogen phosphate, 0-0.15 parts of boric acid, 0.01-0.1 parts of lithium tetraborate and 0.01-0.2 parts of aluminum oxide and then feeding the mixture into a firing furnace; introducing hydrogen and nitrogen; controlling the hydrogen content to be 2-10 percent, the oxygen content to be less than 30 PPM, the maximum temperature to be 1,050-1,250 DEG C and the time to be 30-120 minutes; sintering to obtain the small-granularity narrow-distribution LAP (Lanthanum Phosphate) green fluorescent powder precursor. According to the method, the rare earth oxide is used as the raw material, so that the production cost is reduced; by adjusting the proportion of lanthanum oxide, cerium oxide and terbium oxide in the raw material, LAP green fluorescent powders of different compositions are synthesized; by controlling the granularity and distribution of the rare earth raw material, the granularity and distribution of the green fluorescent powder are controlled; by adding a fluxing agent, the quality of the LAP green fluorescent powder is improved.

Owner:GUANGZHOU ZHUJIANG PHOTOELECTRIC NEW MATERIALS

Process for manufacturing zirconium oxide/lanthanum phosphoric acid full porcelain oral cavity body material which can be cut

InactiveCN101219894ASolve the strength problemSolve processabilityImpression capsPhosphatesMaterials preparationComposite ceramic

The invention relates to a preparation method of an all-ceramic oral cavity repairing composite material with machinable zirconia / lanthanum phosphate, belonging to an inorganic composite material preparation field. The method of the invention is essentially characterized by adjusting the strength and toughness of compound ceramic of zirconia and lanthanum phosphate through controlling the content of zirconia and lanthanum phosphate; the preparation technology of the invention comprises the following processes: lanthanum phosphate powders are prepared; mixture powders of yttrium oxide, lanthanum phosphate and zirconia are prepared by a certain mass ratio; isostatic pressing and sintering is carried out for the mixture under 150 to 250MPa and 1,500 to 1,650 DEG C respectively; and finally the dental composite ceramic material with machinable zirconia and lanthanum phosphate of the invention is obtained. The composite of the invention is suitable for all-ceramic dental repair of oral cavity clinic.

Owner:SHANGHAI UNIV

Nanometer fluorescence material with nuclear shell structure and preparation method thereof

InactiveCN101781563AExcellent fluorescence performancePromote crystallizationLuminescent compositionsFluorescenceCerium

The invention discloses a preparation method of a nanometer fluorescence material with a nuclear shell structure, which comprises the following steps carried out in order: a) carrying out a reaction of cerate and phosphate to prepare cerous phosphate with a monocline structure; and b) carrying out a reaction of lanthanite and phosphate in a colloidal solution of cerous phosphate to prepare the cerous phosphate / lanthanum phosphate nano rods. The preparation method of the invention has the characteristics of cheap raw material, simple process, convenient operation, controllable product appearance, high fluorescence efficiency of the prepared fluorescence nanometer materials and the like.

Owner:BEIJING FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com