Method for preparing rare-earth doped lanthanum phosphate nano luminous particles

A rare earth doped and luminescent particle technology is applied in the field of preparation of rare earth doped lanthanum phosphate, which can solve problems such as unreported research, and achieve the effects of simple synthesis process, small size and good luminous performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

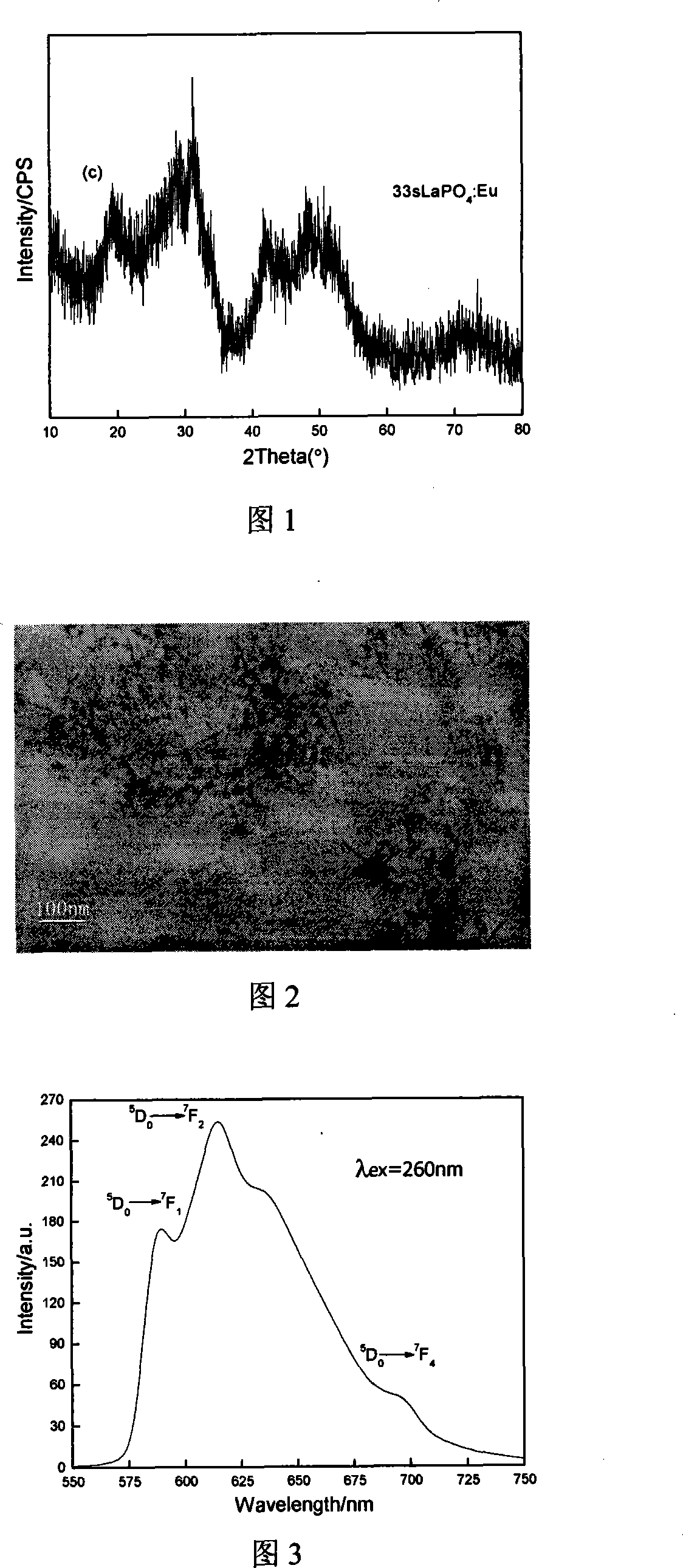

Embodiment 1

[0042] Weigh 1.949g La(NO 3 ) 3 ·6H 2 O, added to 100mL ethylene glycol solution, magnetically stirred until dissolved; weighed 0.176gEu 2 o 3 , 0.278g concentrated HNO 3 Added to the above solution, magnetically stirred until dissolved, to obtain 3+ (Ln=Eu, La) 0.05mol / L ethylene glycol reaction stock solution, wherein Eu 3+ : La 3+ =1:9 (molar ratio); Weigh 0.780gNaH 2 PO 4 2H 2 O was added to 100mL ethylene glycol solution, and magnetically stirred until dissolved to obtain 0.05mol / L NaH 2 PO 4 Ethylene glycol reaction stock solution. The two reaction solutions were added to two equal-diameter syringes, and sealed with silicon ester to prevent leakage. Push the reaction solution into the micro-mixer with a micro-propellant pump, and the solution enters the micro-tube after mixing, and reacts in a constant temperature oil bath at 80°C. After the reaction is completed, the product is received with a sample bottle to obtain LaPO 4 :Eu 3+ Ethylene glycol solution of...

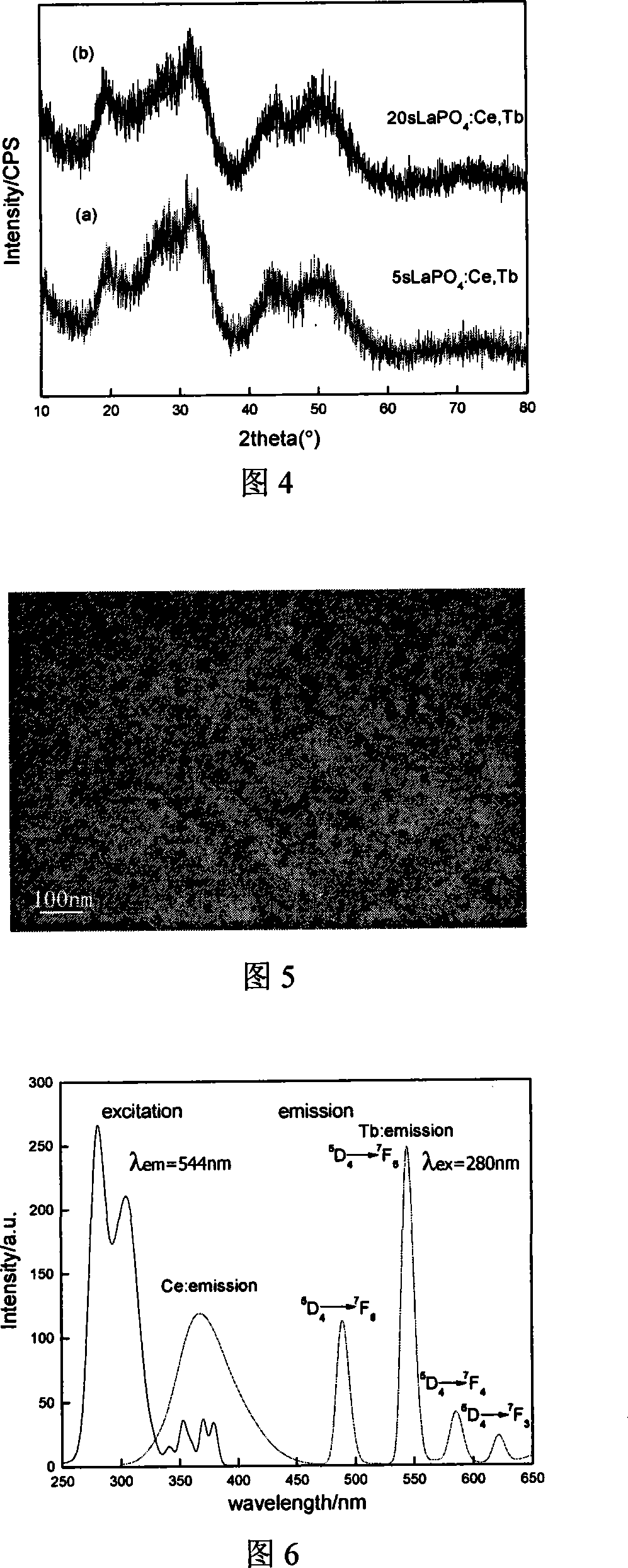

Embodiment 2

[0044] Weigh 0.866g La(NO 3 ) 3 ·6H 2 O, added to 100mL ethylene glycol solution, stirred magnetically until dissolved; weighed 0.977gCe(NO 3 ) 3 ·6H 2 O, 0.340gTb(NO 3 ) 3 ·6H 2 O, add the above solution, stir magnetically until dissolved, and get the solution containing Ln 3+ (Ln=La, Ce, Tb) 0.05mol / L ethylene glycol reaction stock solution, wherein La 3+ : Ce 3+ :Tb 3+ =8:9:3 (molar ratio). Weigh 0.780gNaH 2 PO 4 2H 2 O was added to 100mL ethylene glycol solution, and magnetically stirred until dissolved to obtain 0.05mol / L NaH 2 PO 4 Ethylene glycol reaction stock solution. Then add the two reaction liquids into two equal-diameter syringes, seal with silicon ester to prevent liquid leakage, push the reaction liquid into the micro-mixer with a micro-push pump and mix it into a micro-tube, and carry out in a constant temperature oil bath at 80°C. Reaction, receive the product with a sample bottle after the end of the reaction, and obtain Ce 3+ , Tb 3+ dope...

Embodiment 3

[0046] Weigh 1.019g La(NO 3 ) 3 ·6H 2 O, added to 100mL ethylene glycol solution, stirred magnetically until dissolved; weighed 1.149gCe(NO 3 ) 3 ·6H 2 O, added to the above solution, magnetically stirred until dissolved, to obtain 3+ (Ln=La, Ce) 0.05mol / L ethylene glycol reaction stock solution, wherein La 3+ : Ce 3+ =8:9 (molar ratio). Weigh 0.780gNaH 2 PO 4 2H 2 O was added to 100mL ethylene glycol solution, stirred magnetically until dissolved to obtain 0.05mol / L NaH 2 PO 4 Ethylene glycol reaction stock solution. Then add the two reaction liquids into two equal-diameter syringes, seal them with silicon ester to prevent leakage, push the reaction liquids into the micro-mixer with a micro-push pump and mix them into micro-tubes, and carry out in a constant temperature oil bath at 100°C. Reaction, receive the product with a sample bottle after the end of the reaction, and obtain Ce 3+ doped LaPO 4 Ethylene glycol solution of luminescent nanoparticles. Acetone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com