Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

156 results about "Diphosphenes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, a diphosphene is an organophosphorus compound that has a phosphorus-phosphorus double bond, denoted by R-P=P-R'. These compounds are not common but are of theoretical interest. Normally, compounds with the empirical formula RP exist as rings. However, when the organic substituent is very large, the diphosphene becomes stable. The parent compound, called diphosphene (diphosphaethylene), has the formula P₂H₂, but is not stable near room temperature.

Olefin Oligomerization catalysts and Methods of Making and Using Same

InactiveUS20120172645A1Reduce polymer formationReduce the amount requiredGroup 5/15 element organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsPolymer scienceOligomer

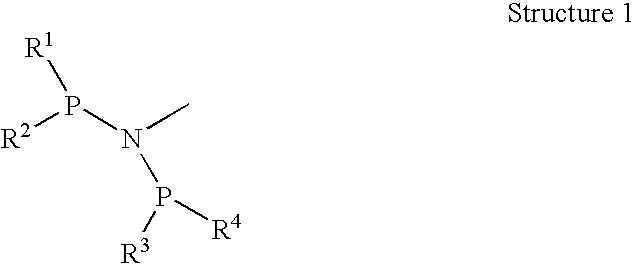

This disclosure provides for a process for preparing a catalyst system comprising a) contacting a metal compound, a diphosphino aminyl ligand metal complex, and a metal alkyl for a time period to form a mixture; and b) aging the mixture. The disclosure also provides for olefin oligomerization process comprising: a) contacting i) a metal compound, ii) a diphosphino aminyl ligand, and iii) a metal alkyl to form a mixture; b) aging the mixture; c) contacting the aged mixture with an olefin monomer; and d) forming an olefin oligomer product.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

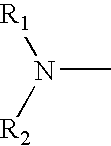

Olefin oligomerization catalysts and methods of using same

InactiveUS7378537B2Organic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionPtru catalystHeteroatom

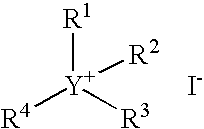

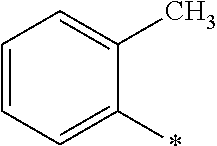

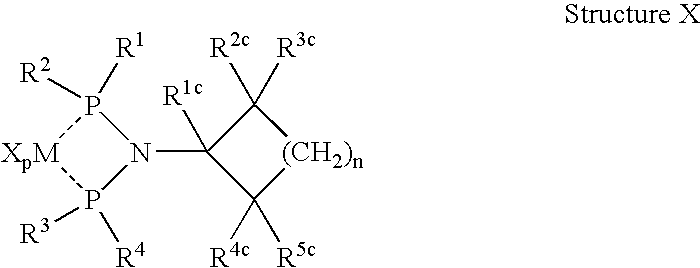

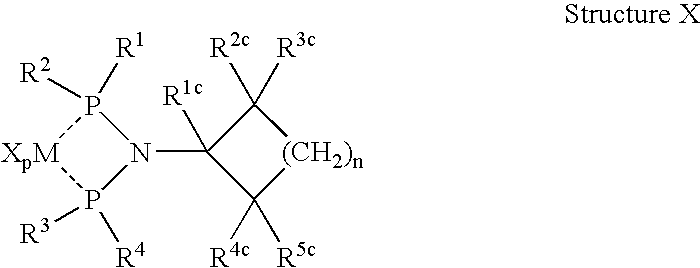

A metal complex comprising a metal compound complexed to a heteroatomic ligand, the metal complex having Structure X:wherein R1, R2, R3, and R4 are each independently an alkyl group, a cycloalkyl group, a substituted cycloalkyl group, an aromatic group, or a substituted aromatic group, R1c, R2c, R3c, R4c, and R5c are each independently hydrogen or an alkyl group, and MXp comprises a group IVB, VB, or VIB metal. A metal complex comprising a metal compound complexed to a diphosphino aminyl ligand comprising at least two diphosphino aminyl moieties and a linking group linking each aminyl nitrogen atom of the diphosphino aminyl moieties.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

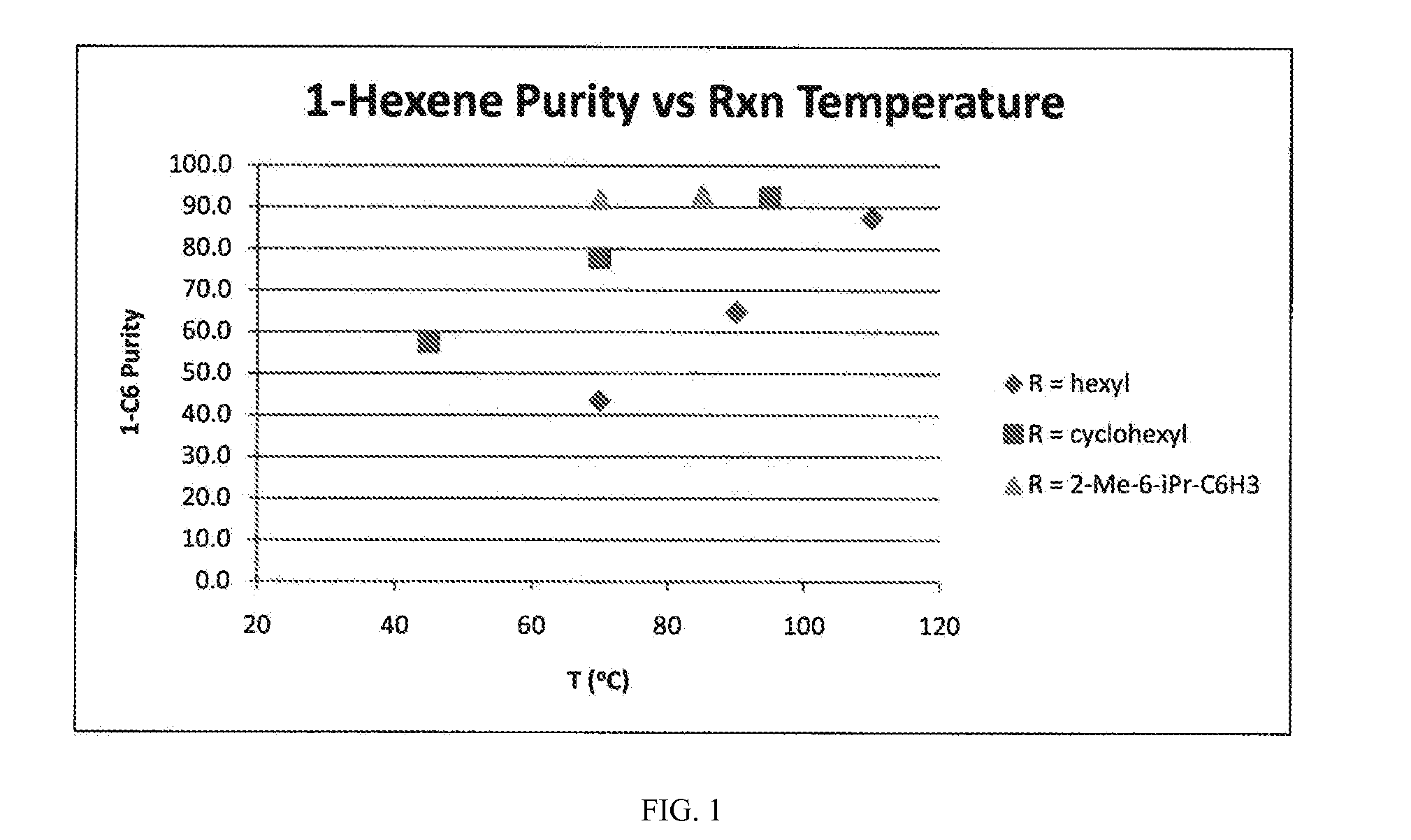

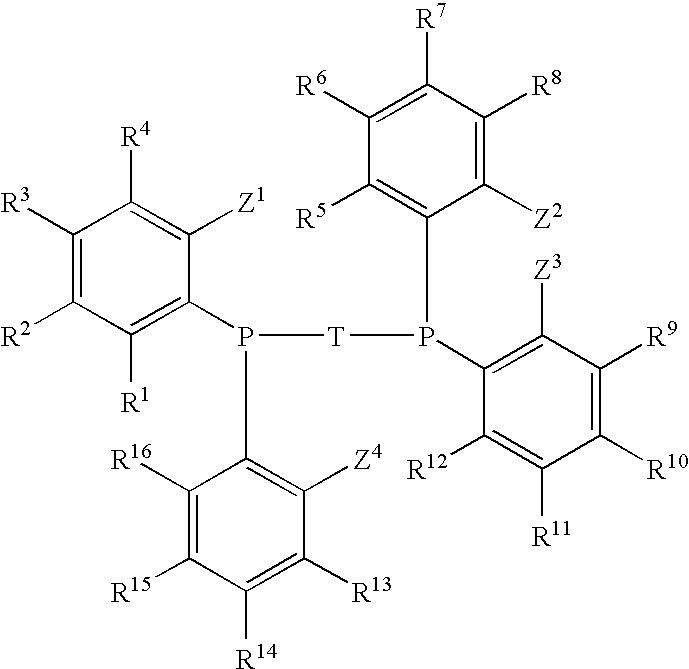

Phosphine Ligand-Metal Compositions, Complexes, and Catalysts For Ethylene Trimerizations

This invention relates to a method to selectively oligomerize olefins comprising contacting olefins with: 1) at least one diaryl-substituted diphosphine ligand; 2) a chromium metal precursor; and 3) optionally, one or more activators. In a particular embodiment, the method for selectively oligomerizing olefins includes trimerizing ethylene to selectively form 1-hexene.

Owner:EXXONMOBIL CHEM PAT INC

Ethylene oligomerization

InactiveUS20120101321A1Organic-compounds/hydrides/coordination-complexes catalystsHydrocarbons from unsaturated hydrocarbon additionAluminoxaneAromatic solvent

The oligomerization of ethylene using a chromium catalyst having a bridged diphosphine ligand can produce a selective product distribution (to predominantly hexene or predominantly octene / hexene) when activated with an aluminoxane. The oligomerization reaction also produces polymer by product—particularly when the aluminoxane is provided in a non-aromatic solvent. The present invention mitigates this problem.

Owner:NOVA CHEM (INT) SA

Non-cyanide alkaline copper plating bath, preparation and use method thereof

The present invention is a new non-cyanide alkaline copper plating bath, preparation and use method thereof. In the copper plating bath, using copper sulfate or basic copper carbonate as main salt, using hydroxy-ethylidene diphosphonic acid as main complexant, using trisodium citrate, potassium citrate or potassium sodium tartrate as auxiliary complexant, using sodium nitrate or potassium nitrate as conductive salt, using sodium hydroxide or potassium hydrate as pH value regulator; the operation conditions are: cathode current density is 0.5-3.0 A / dm [2], pH of plating bath controlled between 12 and 13, plating bath temperature is 50-70 DEG. Comparing with the prior known technology, the invention has following advantages or positive effects: simple plating bath formula, easy control and operation, wide temperature range of plating bath using, high current efficiency, fine crystallization coating, good appearance color, stable plating bath, strong uniform plating and covering ability, low cost, easy wastewater treatment. The invention can be used for pre copper plating or direct electro-coppering instead of virulent cyaniding electro-coppering process.

Owner:KUNMING UNIV OF SCI & TECH

Developing solution for photoresist

InactiveUS20050130082A1Good storage stabilityPrevent precipitationPhotoprinting processesSemiconductor/solid-state device manufacturingHexamethyldiamineTricarboxylic acid

A novel developing solution for photoresists which is suitable for use as a developing solution for a photoresist formed on an aluminum-containing base formed on a wafer. It comprises an alkali builder, a calcium compound, and a chelating agent, the chelating agent being selected from the group consisting of 1-hydroxyethylidene-1,1-diphosphonic acid, aminotrimethylenephosphonic acid, 2-phosphonobutane-1,2,4-tricarboxylic acid, ethylenediaminetetramethylenphosphonic acid, diethylencetriaminepentamethylenephosphonic acid, hexamethylenediaminetetraethylenephosphonic acid, and diethylenetriaminepenta(methylenephosphonic acid).

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Use of curable mixtures comprising silane compounds and also phosphonic diesters or diphosphonic diesters as coupling agents

InactiveUS20090223631A1Improve adhesionCohesive fractureLaminationLamination apparatusPolyesterSilane compounds

The use of curable mixtures comprising(A) at least one phosphonic diester and / or at least one diphosphonic diester and(B) at least one compound containing at least two condensable silane groups,as coupling agents, particularly as coupling agents in laminates comprising at least one substrate, at least one coating, at least one adhesive layer, and at least one sheet, and also a new process for producing such laminates using the coupling agents, the laminates which are producible using the coupling agents, and thermally curable mixtures comprising the coupling agents and at least one thermally curable polyester (C).

Owner:BASF COATINGS GMBH

Catalytic hydrogenation processes

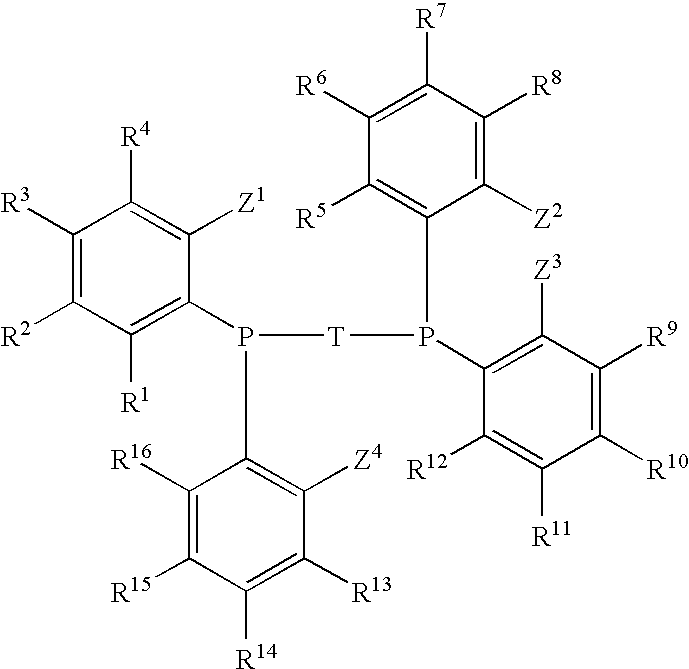

ActiveUS20040063966A1High hydrogenation yieldHigh yieldRuthenium organic compoundsOrganic compound preparationHalogenHydrogen

The catalysts of formula (II): [Ru(L)m(L')wXY], wherein X and Y represent simultaneously or independently a hydrogen or halogen atom, a hydroxy group, or an alkoxy, carboxyl or other anionic radical, m is 1 or 2, w is 1 when m is 1 and w is 0 when m is 2, L is a phosphino-amine or phosphino-imine bidentate ligand and L' a diphosphine, are useful for the hydrogenation of substrates having a carbon-hetero atom double bond.

Owner:FIRMENICH SA

Method for synthesizing high-stability thiourea dioxide

A manufacture method for synthesizing thiourea dioxide with high stability is the manufacturing method of a chemical product, which overcomes the disadvantages in other technologies and is confected by adopting the following raw materials: the molar ratio between thiourea and oxydol of 27.5 percent is 1:1.9 to 1:2.1; the mass ratio between polyethyleneglycol that is a stabilizing agent and hydroxyl ethidene diphosphonate tetrasodium is 1:1, and the quantity of polyethyleneglycol and hydroxyl ethidene diphosphonate tetrasodium can be 0.5 to 2.0 percent of the total quantity of thiourea; the mass ratio between postassium acetate that is an accelerant and ammonia bicarbonate is 2:3, and the quantity of postassium acetate and ammonia bicarbonate is 4.0 to 6.0 percent of the total auantity of thiourea. A method for preparing thiourea dioxide comprises the steps of confecting an accessory ingredient, catalysis synthesis, crystallization, dehydration, drying, and completing through packing. The main performance index of the product includes the aspects as follows: the main content of thiourea dioxide is more than or equals to 99.0 percent; residual thiourea is less than or equals to 0.1 percent, and sulphate is less than or equals to 0.17 percent; the iron content is less than or equals to 10ppm; the moisture content is less than or equals to 0.05 percent; the thermal stability is more than or equals to 55 minutes in water bath when the temperature is 95 DEG C. The manufacture method has the high yield of product and high thermal stability, effectively changes the product quality, and increases the safety performance of product transport and storage.

Owner:濮阳圣恺环保新材料科技股份有限公司

Water treatment medicine and adding method thereof

InactiveCN1483684AScale removal and water softeningWater/sewage treatment using germicide/oligodynamic-processSlurryWater soluble

The present invention discloses a water treatment agent and its matched application method. It is made into the form of paste or slurry, and can be slowly and uniformly dissolved in the water completely, in addition to the water (including crystal water) said water treatment agent also contains corrosion inhibitor, antiscale, dispersing agent, sterilizing algaecide, thickening agent and pH regulating agent. The essential component of said water treatment agent is water, includes crystal water, and its cotent is 37%-50%, also contains water soluble zinc salt and hydroxyethylidene diphosphonate and its water-soluble salt. Said invention also provides its application method and steps.

Owner:杨波 +1

Cloth cart

InactiveCN105331240AExcellent abrasion resistanceImprove corrosion resistanceAnti-corrosive paintsWorking fluidPhenol

The invention discloses a cloth cart. The cloth cart comprises a metal rotating shaft subjected to surface treatment. The surface treatment process includes the following steps that firstly, by mass, 1-2 parts of mercaptobenzothiazole, 0.9 part of nickel nitrate, 1.4 parts of 1-Hydroxyethylidene-1,1-diphosphonicacid, 2.3 parts of polyvinylpyrrolidone, 1.8 parts of dipyrazolone, 2.3 parts of 2,6-di-t-butyl-alpha-dimethylamino hydroquinone and 1.6 parts of tetramethyl ammonium bromide are added into 12 parts of deionized water and evenly stirred and mixed, and surface treatment working fluid is obtained; secondly, the surface treatment working fluid is heated to 53 DEG C; thirdly, the metal rotating shaft is put into the surface treatment working fluid to be steeped for 32 min, taken out and then dried. Due to the fact that the metal rotating shaft of the cloth cart is subjected to surface treatment, good rub resistance, corrosion resistance, rust resistance, heat resistance, cold resistance and weather resistance are achieved.

Owner:CHANGSHU NUO XIN DA MACHINERY EQUIP CO LTD

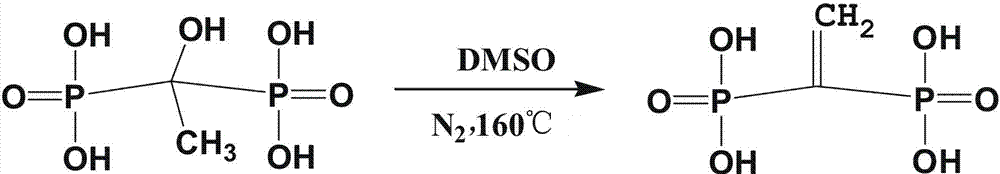

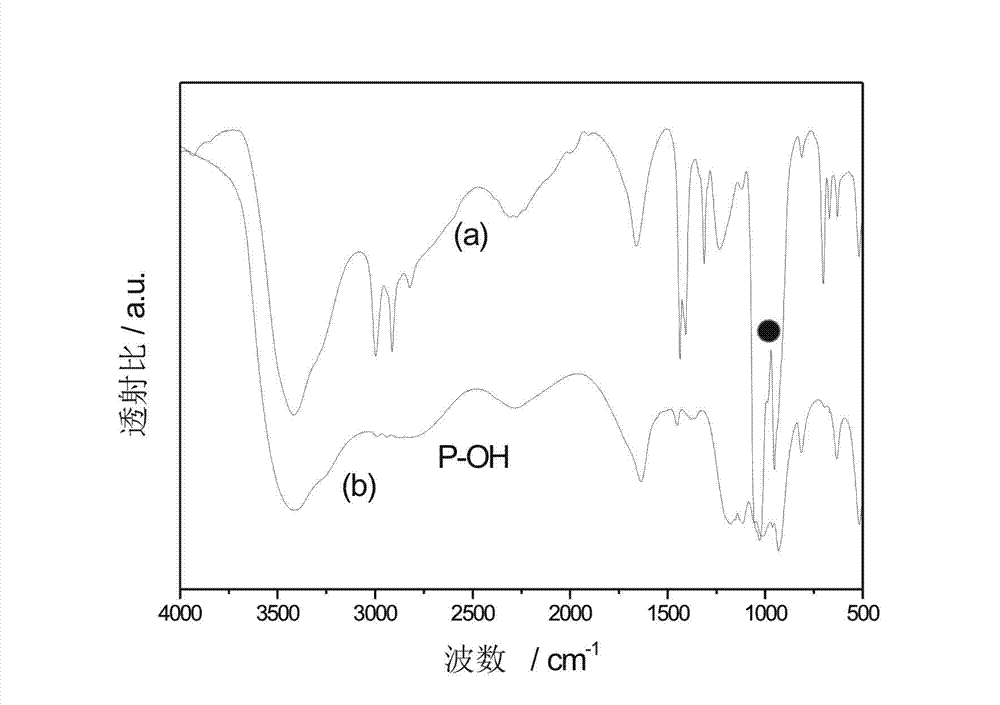

Chemically-bonded HEDP (1-hydroxy ethylidene-1, 1-diphosphonic acid) medium-temperature organic polysiloxane phosphate based proton exchange membrane and preparation method thereof

The invention relates to a chemically-bonded HEDP (1-hydroxy ethylidene-1, 1-diphosphonic acid) medium-temperature organic polysiloxane phosphate based proton exchange membrane. The membrane is prepared by the following steps: firstly, under protection of nitrogen, mixing dimethyl sulfoxide and HEDP, stirring to obtain clear and transparent mixture, and performing reflux reaction at 160 DEG C; removing the dimethyl sulfoxide after the solution is cooled to 110 DEG C to obtain 1,1-vinyl diphosphonic acid liquid; secondly, mixing 1, 1-vinyl diphosphonic acid, 3-(methacryloxy) propyl trimethoxyl silane, 2, 2'-azobisisobutyronitrile and ethanol, stirring at 60-80 DEG C to react, cooling to room temperature, adding diluted hydrochloric acid, and stirring to obtain clear and transparent sol; thirdly, performing gelation to the sol to obtain a gel membrane; and fourthly, drying the gel membrane to obtain the chemically-bonded HEDP medium-temperature organic polysiloxane phosphate based proton exchange membrane. The membrane has high proton conductivity under medium temperature and low humidity and has excellent flexibility and mechanical property.

Owner:WUHAN UNIV OF TECH

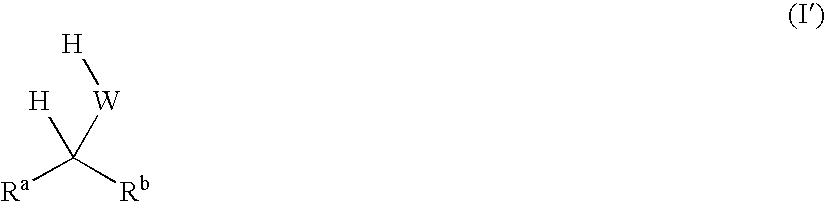

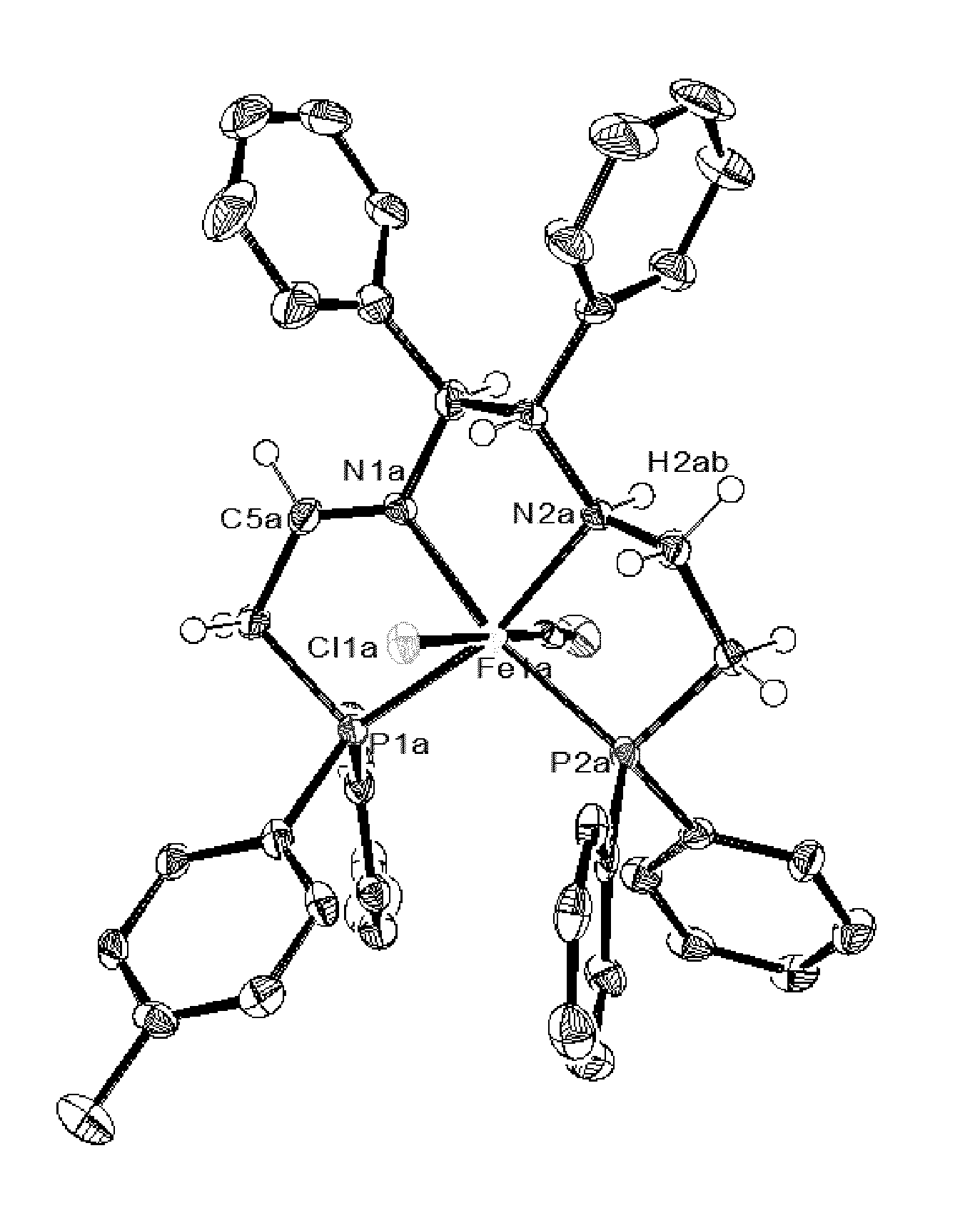

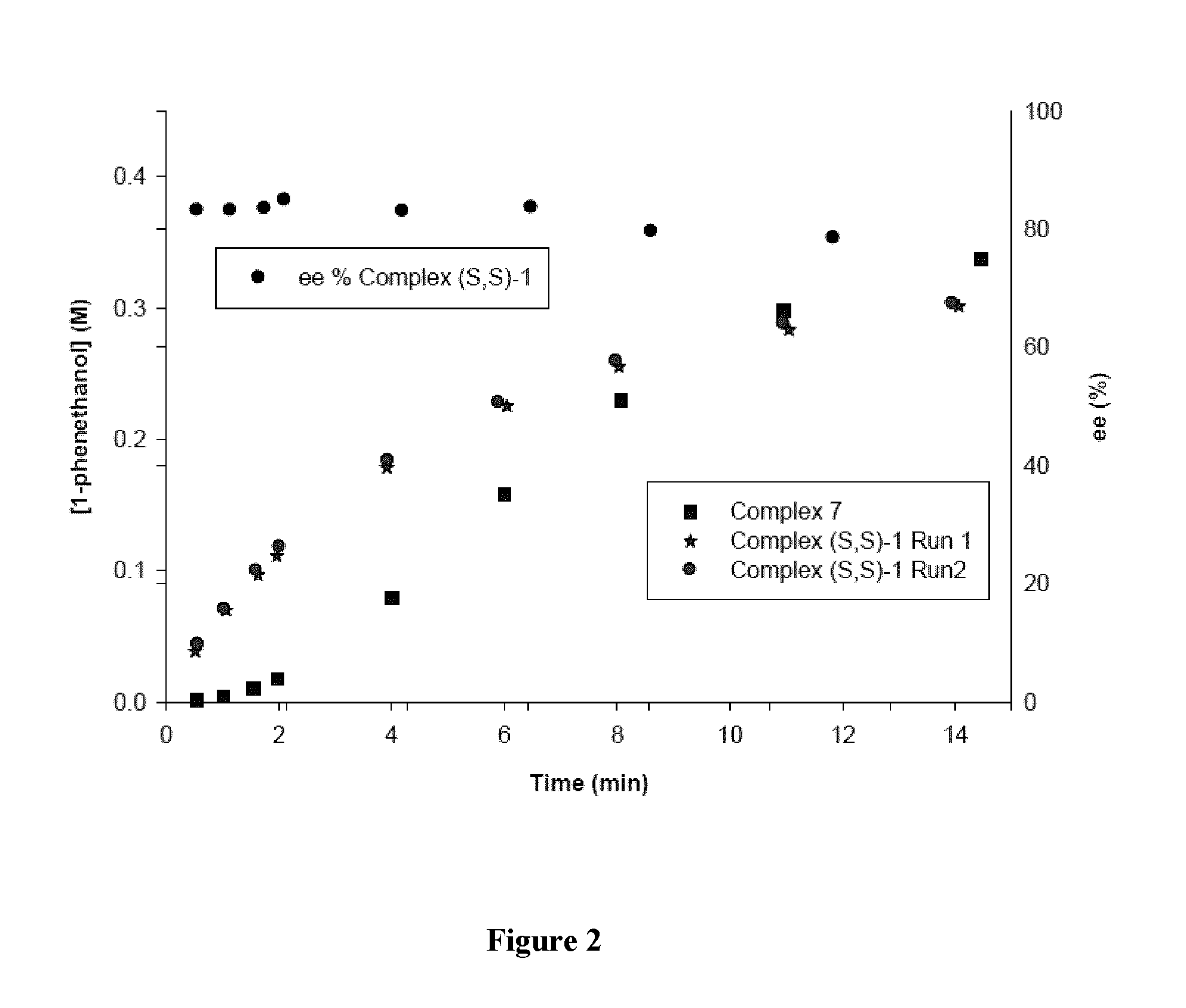

Iron catalysts with unsymmetrical pnn'p ligands

ActiveUS20150151289A1Easy to prepareHigh activityElectrolysis componentsOrganic compound preparationPolymer sciencePtru catalyst

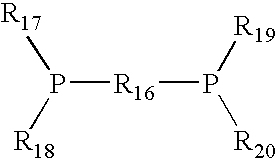

The present invention relates to catalytic materials for hydrogenation or asymmetric hydrogenation. In particular, the invention relates to iron (II) complexes containing unsymmetrical tetradentate diphosphine (PNN′P) ligands with two different nitro gen donor groups useful for catalytic transfer hydrogenation or asymmetric transfer hydrogenation of ketones, aldehydes and imines.

Owner:THE GOVERNINIG COUNCIL OF THE UNIV OF TORANTO

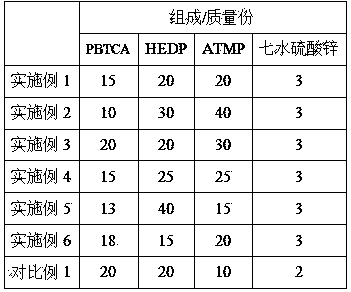

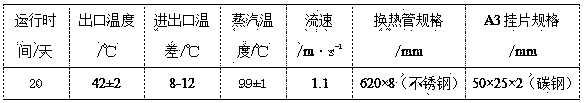

Composite slow-release scale inhibitor suitable for petrochemical wastewater reusing circulating water system

ActiveCN104230015AComply with corrosion rate less than 0.075 mm/a anti-corrosion requirementsAdd lessScale removal and water softeningAqueous corrosionPhosphate

The invention discloses a composite slow-release scale inhibitor suitable for a petrochemical wastewater reusing circulating water system. The composite slow-release scale inhibitor comprises 2-butane phosphate-1,2,4-tricarboxylic acid, hydroxy ethylidene diphosphonic acid, amino trimethylene phosphonic acid and zinc sulfate. After the composite slow-release scale inhibitor is adopted, by virtue of dynamic simulation experiment on oil refinery reuse water, the water quality inhibition rate is 86.18%; by virtue of the dynamic simulation experiment on ethylene plant reuse water, the water quality inhibition rate is 86.44%, and the scale inhibiting rate is 87.42%; the corrosion rate is reduced to 0.0168 mm / a and 0.0091 mm / a, which meets the anticorrosion requirement that the corrosion rate of China petrochemical circulating cooling water is less than 0.075 mm / a. Compared with the traditional polyphosphate carboxylate composite slow-release scale inhibitor, the composite slow-release scale inhibitor disclosed by the invention has the advantages of small addition amount and good corrosion inhibition effect and scale inhibition.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

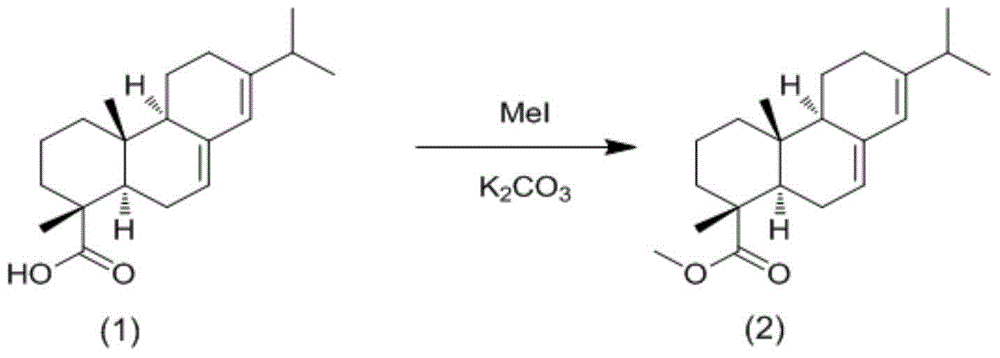

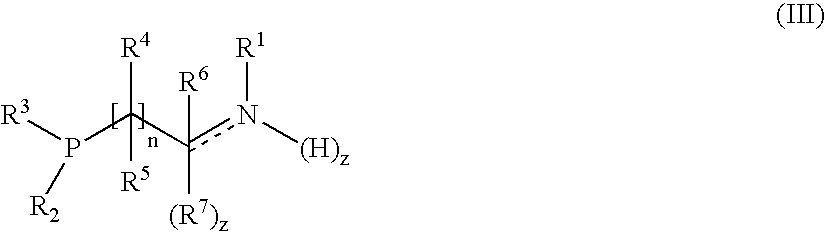

Process for the Preparation of Pyrido [2,1-a] Isoquinoline Derivatives by Catalytic Asymmetric Hydrogenation of an Enamine

The invention relates to a process for the preparation of pyrido[2,1-a] isoquinoline derivatives of the formulawherein R2, R3 and R4 are as defined in the specification, comprising the steps of a) catalytic asymmetric hydrogenation of an enamine of the formulawherein R1 is lower alkyl, in the presence of a transition metal catalyst containing a chiral diphosphane ligand, b) introduction of an amino protecting group Prot and c) amidation of the ester to form an amide of formulawherein R2, R3, R4 and Prot are as defined in the specification.

Owner:ABRECHT STEFAN +2

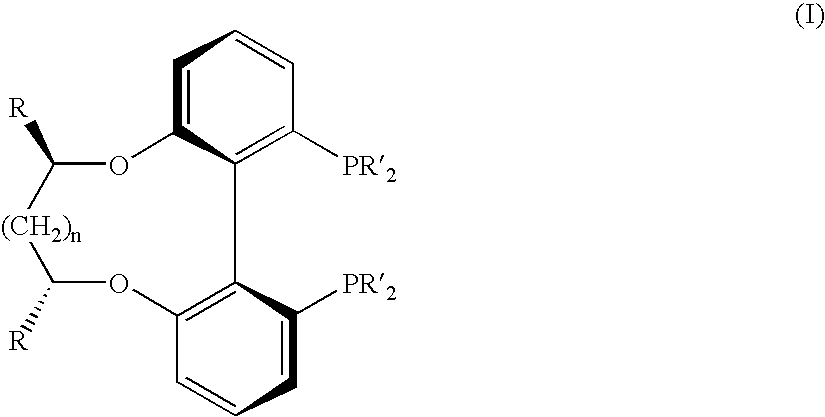

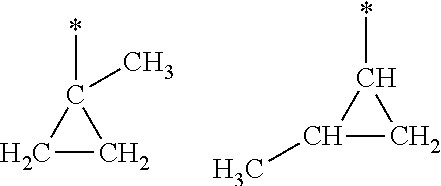

Biphenyldiphosphine compounds

InactiveUS20050014633A1High purityEasy accessRuthenium organic compoundsRhodium organic compoundsArylEnantiomer

The present invention provides compounds of the formula wherein R is optionally substituted lower alkyl, cycloalkyl or aryl; R′ is alkyl or aryl; n is zero or an integer of 1 or 2; or an enantiomer thereof; or an enantiomeric mixture thereof. The compounds of formula (I) are bridged C2-symmetric biphenyldiphosphine analogs and, thus, may be employed as ligands to generate chiral transition metal catalysts which may be applied in a variety of asymmetric reactions. The compounds of the present invention are easily accessible in high diastereomeric and optical purity according to the methods disclosed herein.

Owner:THE HONG KONG POLYTECHNIC UNIV

Process for the preparation of alkyl-and aryl-diphosphonic acids and salts thereof

The invention relates to a process for the preparation of diphosphonic acids by reaction of a carboxylic acid with a mixture of phosphorous acid and phosphorus oxychloride in defined molar ratios and in the absence of solvents. The invention futher relates to ibandronic acid monosodium salt in the amorphous form.

Owner:TRIFARMA

Carbonylation process

InactiveUS20090247783A1Increase carbonylation rateOrganic compound preparationPreparation by carbon monoxide or formate reactionHydrogen halideCarboxylic acid

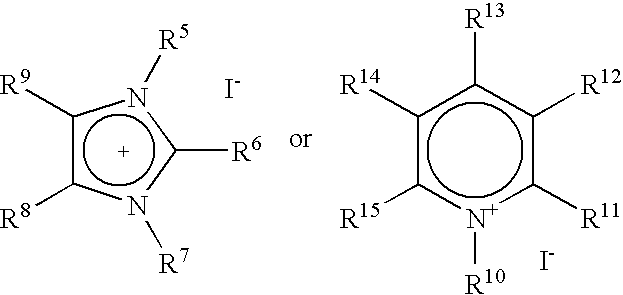

Disclosed is an improved carbonylation process for the production of carboxylic acids, carboxylic acid esters, and / or carboxylic acid anhydrides wherein a carbonylation feedstock compound selected from one or more organic oxygenates such as alcohols, ethers, and esters is contacted with carbon monoxide in the presence of a carbonylation catalyst and one or more onium compounds. The carbonylation process differs from known carbonylation processes in that a halide compound, other than the onium salt, such as a hydrogen halide (typically, hydrogen iodide) and / or an alkyl halide (typically, methyl iodide), extraneous or exogenous to the carbonylation process is not fed or supplied to the process. The process can be improved by using a bidentate ligand comprising two functional groups selected from tertiary amines and tertiary phosphines, such as 2,2′-bipyridine and diphosphine derivatives.

Owner:EASTMAN CHEM CO

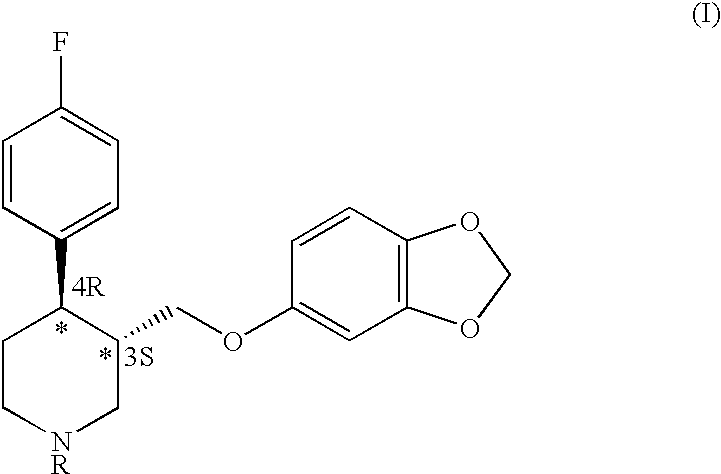

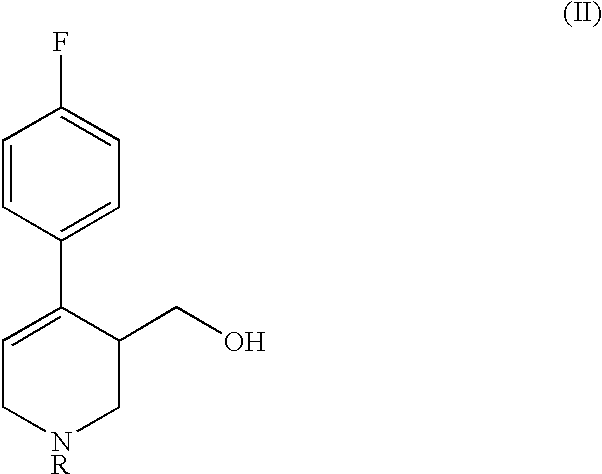

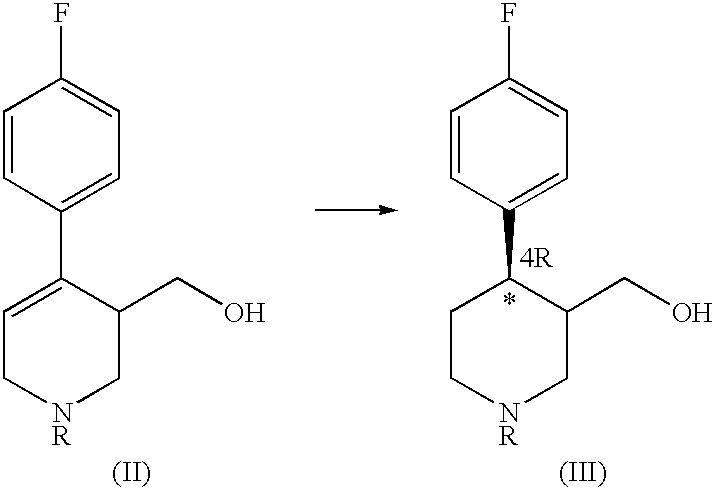

Process for the production of paroxetine

A process for the production of paroxetine is described, wherein N-substituted derivatives of 4-(p-fluorophenyl)-3-hydroxymethyl-1,2,3,6-tetrahydropyridine are treated according to the following sequence of reactions: (a) hydrogenation catalyzed by transition metal complexes with chiral diphosphinic ligands; (b) -OH derivatisation and nucleophilic substitution, the substituent being sesamol; (c) N-dealkylation. The process is highly stereospecific and brings about the formation of intermediates enriched with the desired isomeric components, which are converted into paroxetine in quantitative yields.

Owner:APOTECNIA

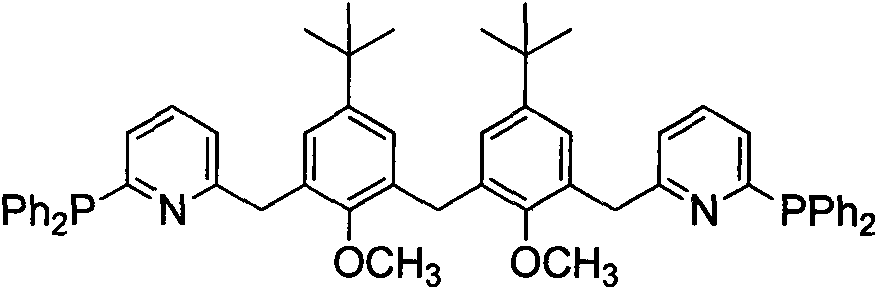

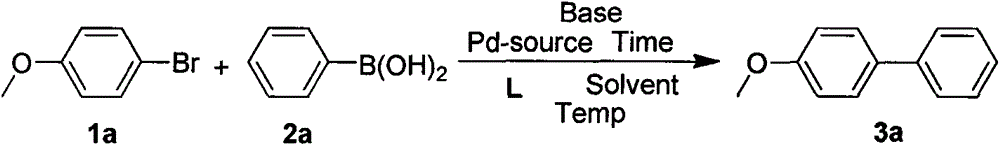

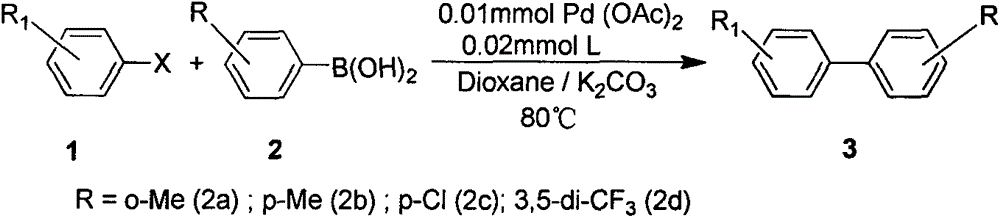

Synthetic method and application of novel multi-aryl bridged long-chain diphosphine ligand

InactiveCN103554183AHigh reactivityReduce dosageOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsOrganic synthesisCarbon–carbon bond

A novel multi-aryl bridged long-chain diphosphine ligand is disclosed. A semi-calix[4]arene is taken as a structural skeleton and subjected to double-side decoration, so that a novel phosphine-nitrogen ligand is designed and synthesized, and also the novel ligand and a palladium salt are used for in-situ catalysis of a Suzuki coupling reaction. The preparation method of the ligand comprises: synthesizing a semi-calix intermediate bis(5-tert-butyl-3-hydroxymethyl-2-methoxyphenyl)methane, brominating the intermediate and bridging with an intermediate 2-bromo-6-diphenylphosphanylpyridine to obtain the multi-aryl bridged long-chain diphosphine ligand. The advantages comprise that the novel diphosphine ligand employs the calixarene fragment as the main body, pyridine structure is used to stabilize the molecule and to adjust the molecular cavity, and the ligand is used to catalyze the Suzuki coupling reaction in the presence of trace palladium for carbon-carbon bond construction in organic synthesis. The ligand is stable in structure; the synthesis reaction is short in time, mild in condition, high in yield, easy for mass production and commercialization; and the catalyst use amount is small when the ligand is used for Suzuki coupling reactions, and it is expected that functional groups with specific function can be introduced for promoting synthesis of multiple medicaments.

Owner:NANKAI UNIV

Computer electronic display screen cleaning agent and preparation method thereof

InactiveCN105238579AThe preparation process is simpleEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBenzoic acidPhosphoric Acid Esters

The present invention relates to a computer electronic display screen cleaning agent, which comprises, by mass, 52-56 parts of biochemical fulvic acid, 54-58 parts of benzotriazole, 50-54 parts of 1-hydroxyethylidene-1,1-diphosphonicacid, 54-58 parts of alkanol phosphate ester, 50-54 parts of hydroxyethylenediamine, 54-58 parts of sodium ligninsulfonate, 50-54 parts of caprylic / capric triglyceride, 56-60 parts of benzoic acid, 50-54 parts of potassium dihydrogen phosphate, 54-58 parts of polyacrylamide, 50-54 parts of polyethylene glycol stearate, 54-58 parts of sodium humate, 50-54 parts of polyepoxysuccinic acid, 54-58 parts of mercaptobenzothiazole, 50-54 parts of isothiazolinone, 54-58 parts of cyclic silicone oil, 50-54 parts of lecithin, 54-58 parts of permethrin, 50-54 parts of butyl acetate, 54-58 parts of dodecyl dimethyl benzyl ammonium chloride, 50-54 parts of benzimidazole allyl thioether, 54-58 parts of aliette, 50-54 parts of a silver ion antibacterial agent, and 1000-2000 parts of water. The cleaning agent of the present invention has good cleaning ability.

Owner:龚灿锋

Heteroaromatic diphosphines as chiral ligands

InactiveUS6077958ASimple processEasy to getRuthenium organic compoundsRhodium organic compoundsPtru catalystCombinatorial chemistry

Chiral diphosphines are constituted by an aromatic pentatomic biheterocyclic system, suitable to act as chiral ligands and complexes between the diphosphines and transition metals. They may be utilized as chiral catalysts in stereocontrolled reactions, such as diastereo- and enantioselective reduction reactions. Process is for the preparation of these chiral diphosphines; and process is for the preparation of these complexes and for their utilization as chiral catalysts in stereocontrolled reactions.

Owner:ITALFARMACO SUD

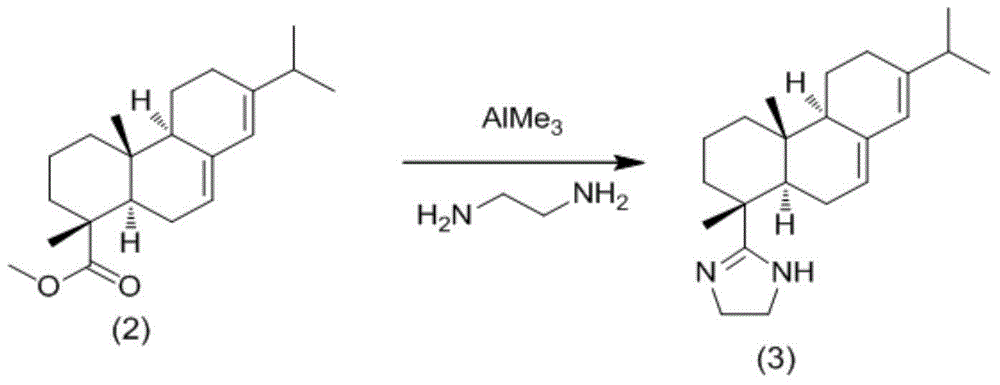

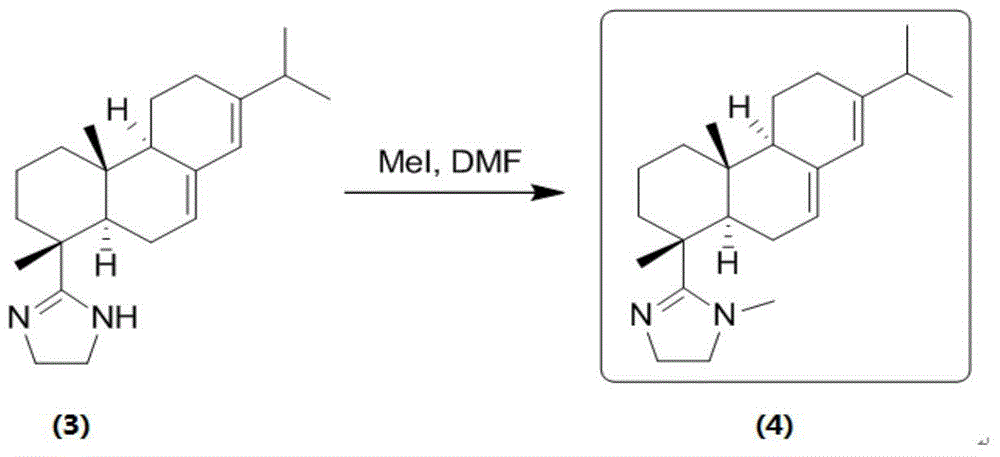

Novel rosin imidazoline corrosion inhibitor

ActiveCN105272916AImprove thermal stabilityLow toxicityOrganic chemistryBorehole/well accessoriesMetallic materialsRosin

The invention relates to the synthesis and application technology field of compounds used for metal anticorrosion, and concretely discloses a novel rosin imidazoline corrosion inhibitor, a synthetic method and applications. The initial raw material of the provided compound is rosin acid, the raw material is single and the synthetic route operation is simple. The method for preparing a corrosion inhibitor from the synthesized compound is simple, the compound is dissolved in dimethyl formamide, then the obtained solution is dissolved in water, then 1-hydroxyethylidene-1,1-diphosphonic acid is added, and uniform stirring is carried out. The corrosion inhibitor is safe and environmentally friendly, and has excellent corrosion inhibition effects. The corrosion inhibitor can be used for oil and gas field ground gathering and storage and transportation pipes, prevents damage of corrosive gases to metal materials of steel and the like and reduces corrosion loss.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

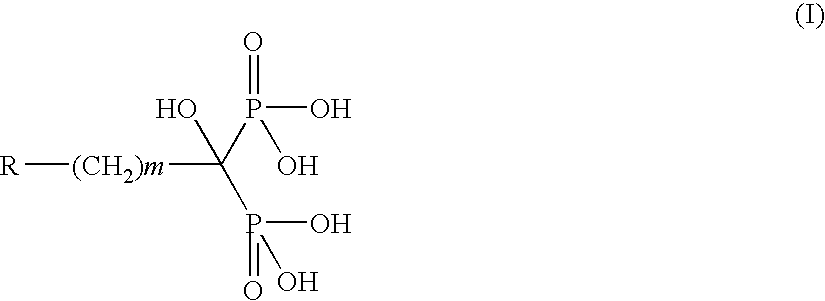

Novel compositions magnetic particles covered with gem-bisphosphonate derivatives

InactiveCN1744920AEasy to coverImprove stabilityAntipyreticGroup 5/15 element organic compoundsChemical compoundOrganic group

The invention relates to a composition comprising acid magnetic particles (p) based on an iron compound, the acid magnetic particles (p) being complexed by one or more gem-bisphosphonate compounds, of formula I X-L-CH(PO3H2)2 (I) in which L represents an organic group connecting the X group to the gem-bisphosphonate group -CH(PO3H2)2; X represents a chemical group capable of reacting with a biovector; all or some of the X groups of the particles optionally being coupled to a biovector. The invention relates also to a process for the preparation of the compositions and their use, in particular as contrast products for Magnetic Resonance Imaging (MRI).

Owner:GUERBET SA

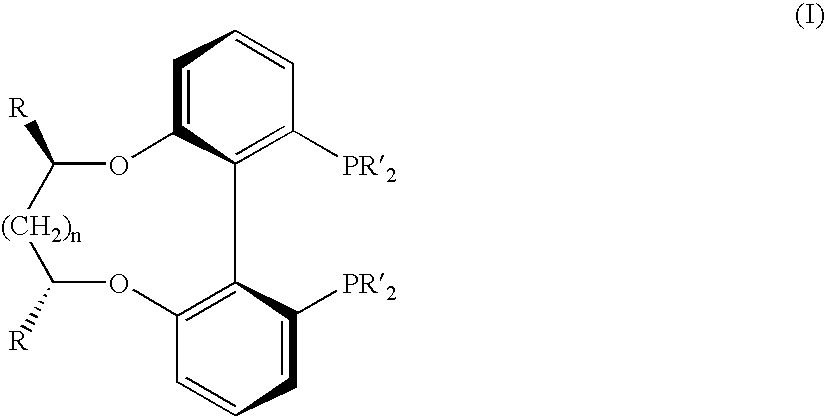

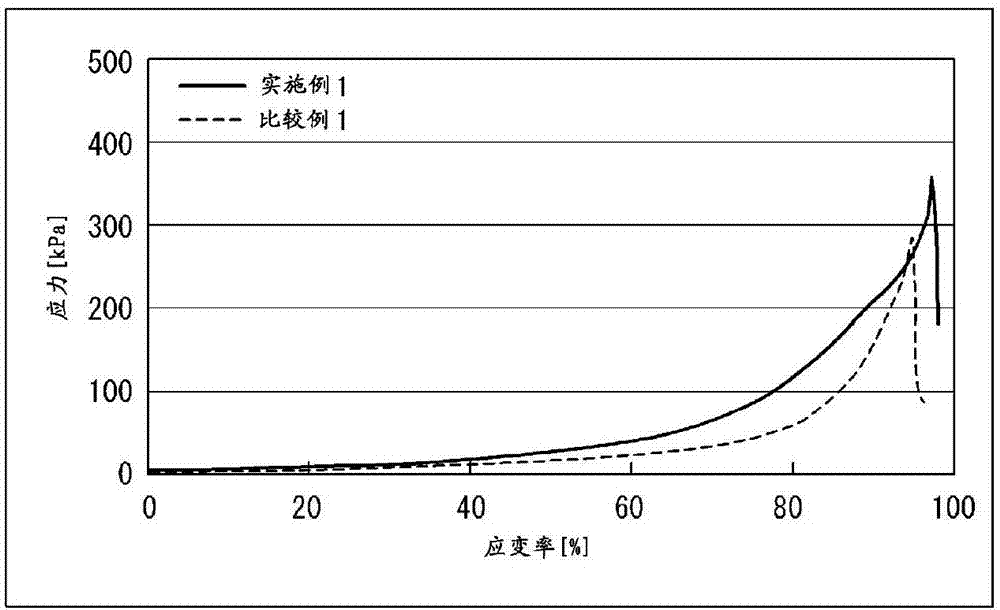

Hydrogel-forming composition and high strength hydrogel formed from same

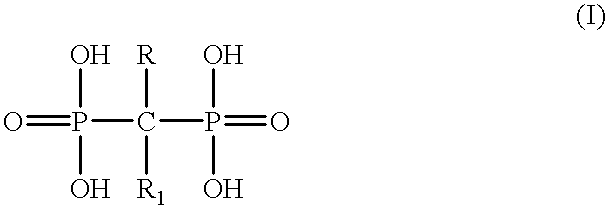

ActiveCN107429074AHigh modulus of elasticityIncreased fracture stressAcid polymer adhesivesOrganic acidPolymer science

[Problem] To provide: a self-supporting hydrogel which is highly strengthened and is able to be produced merely by mixing at room temperature; and a method for producing this hydrogel. [Solution] A hydrogel-forming composition which is capable of forming a self-supporting hydrogel, and which is characterized by containing (A) a water-soluble organic polymer having an organic acid structure, an organic acid salt structure or an organic acid anion structure, (B) a silicate salt, (C) a compound having a diphosphonic acid structure represented by formula (1) (wherein each of R1 and R2 independently represents a specific substituent; each of X1 and X2 independently represents a single bond or a linking group; and n represents an integer of 1-5) or a salt thereof, and (D) a compound which has or generates a divalent or higher-valent positive charge; a hydrogel which is formed from the composition; and a method for producing this hydrogel.

Owner:NISSAN CHEM CORP

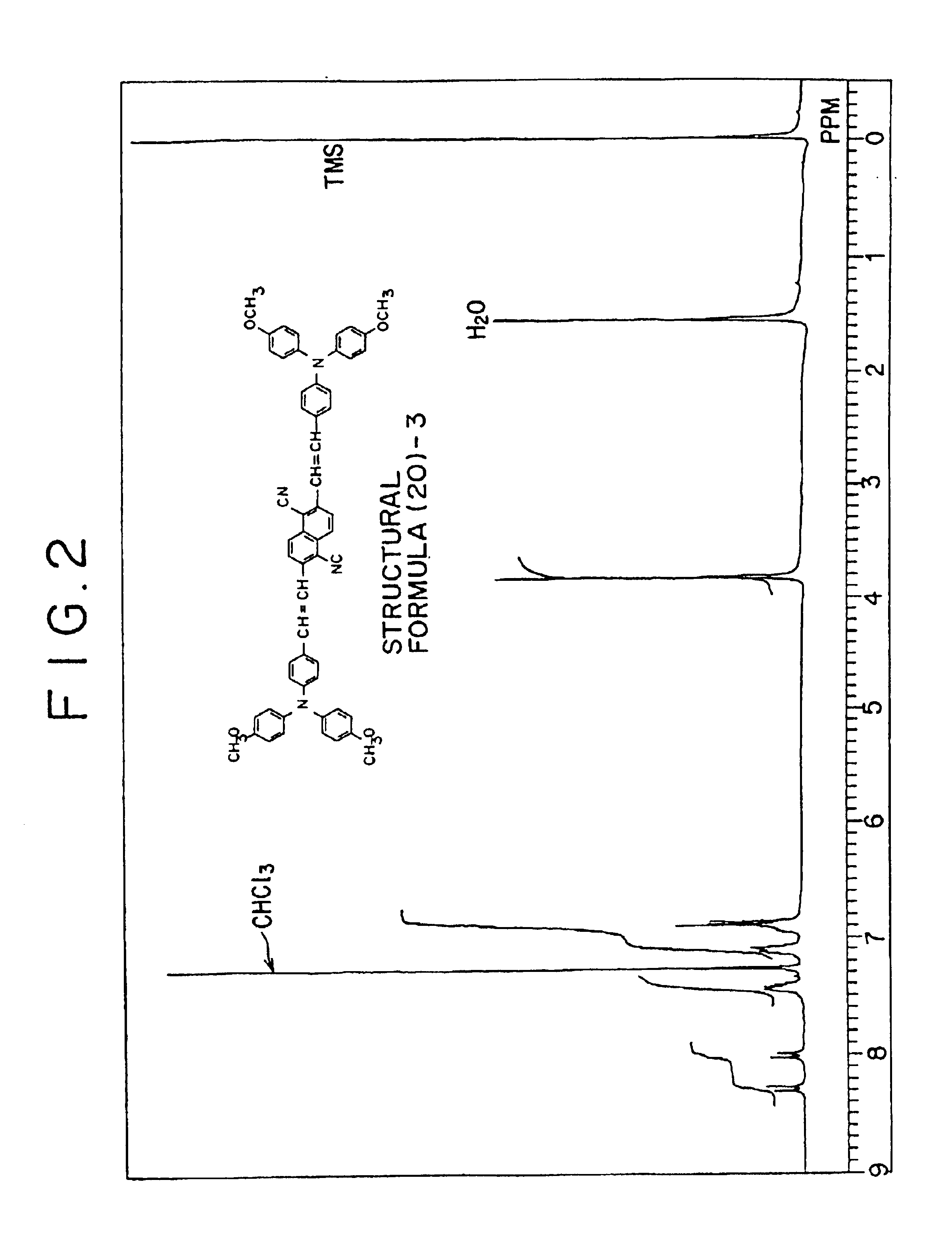

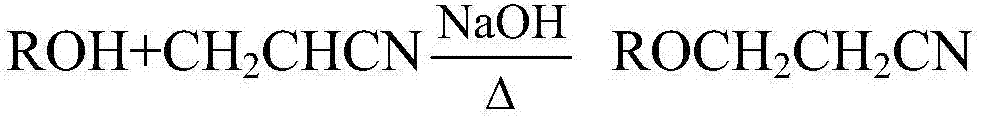

Bis(aminostyryl)naphthalene compound, synthesis intermediate thereof, and process for production thereof

A bis(aminostyryl)naphthalene compound represented by the general formula [I] or the like below. (where R2 and R3 each denotes an unsubstituted aryl group; R1 and R4 each denotes an aryl group having a specific substituent such as methoxy group; and R5 and R6 each denotes a cyano group or the like.)A process for producing a bis(aminostyryl)naphthalene compound represented by the general formula [I] by condensation of, for example, 4-(N,N-diarylamino)benzaldehyde with diphosphonic ester or diphosphonium.The bis(aminostyryl)naphthalene compound emits intense yellow or red light. The process permits efficient production of the bis(aminostyryl)naphthalene compound.

Owner:JOLED INC

Phosphosilicate type rare earth ore flotation collector and preparation method and application thereof

The invention discloses a phosphosilicate type rare earth ore flotation collector and a preparation method and an application thereof. The phosphosilicate type rare earth ore flotation collector is prepared from the following materials according to the mass ratio: 5 to 15 parts of octyl ether propyl-a-amino-1,1-diphosphonic acid, 60 to 80 parts of dist coconut fatty acid, 5 to 10 parts of hexadecyl sulfonate and 1 to 3 parts of Tween-60. The phosphosilicate type rare earth ore flotation collector has the advantages of high collecting capability, high concentrate recovery rate, low production cost, less consumption and good separation effect when the phosphosilicate type rare earth ore flotation collector is applied to the floatation of phosphosilicate type rare earth ore or xenotime.

Owner:INST OF MULTIPURPOSE UTILIZATION OF MINERAL RESOURCES CHINESE ACAD OF GEOLOGICAL SCI

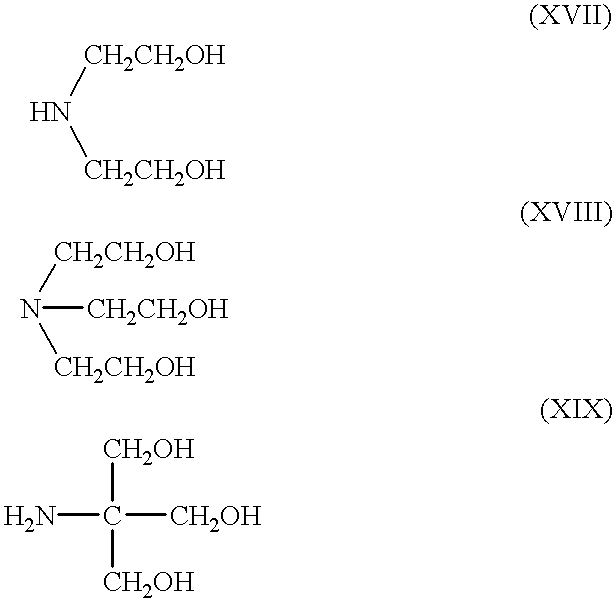

Diphosphonic acid salts for the treatment of osteoporosis

InactiveUS6410782B1Improve bioavailabilityEffective treatmentOrganic active ingredientsGroup 5/15 element organic compoundsAlcoholDiphosphonates

Diphosphonates or their salts between acids and linear, branch substituted and non-substituted, cyclic, heterocyclic and aromatic amino alcohols are used to treat osteoporosis. Pharmaceutical compositions and therapeutic methods of treating osteoporosis are described.

Owner:GEANGE +2

Workshop floor cleaner

InactiveCN104845748AEasy to cleanShort cleaning timeNon-ionic surface-active compoundsDetergent compounding agentsVegetable oilCleansing Agents

Disclosed is a workshop floor cleaner. Raw materials of the cleaner include, by weight: 2.4 to 3.2 parts of benzene sulfonate, 2.5 to 6.5 parts of polyacrylamide, 1.3 to 4.2 parts of amido-sulfonic acid, 2 to 5 parts of sodium silicate, 2.5 to 3.2 parts of potassium chloride, 4.5 to 7.5 parts of aspartic acid, 2 to 3.5 parts of cleaning aids, 2.6 to 4.5 parts of fatty acid diethanolamide, 0.5 to 1.2 part of dehydroascorbate, 0.8 to 1.4 part of tertiary butylhydroquinone, 2.5 to 4.5 parts of naphthenic acid, 4.5 to 6 parts of triethylene glycol alkyl ether, 2 to 5 parts of benzotriazole, 0.2 to 1.5 part of molybdate and 8 to 14 parts of hydroxyethylidene diphosphonic acid. The workshop floor cleaner has the advantages that the cleaning effect of mineral oil, vegetable oil and mixed oil is fine, cleaning time is short, and labor force and working time are saved.

Owner:QINGDAO DONGCHANGRUI TEXTILE

Scale inhibitor for mechanical equipment

InactiveCN104163510AReduce formationAvoid elevationScale removal and water softeningMetallurgyChloramine

A scale inhibitor for mechanical equipment is prepared from the following raw materials, by weight, 8-15 parts of organic phosphonate, 4-7 parts of sodium dodecyl benzene sulfonat, 8-15 parts of 1-hydroxyethylidene-1,1-diphosphonicacid, 2-6 parts of magnesium nitrate, 3-7 parts of linseed oil, 2.5-6 parts of potassium pyrophosphate, 3.5-8 parts of chloramine, 1.2-4 parts of triethanolamine, 2.5-7 parts of n-propanol and 3.4-8 parts of a thickening agent. The invention has the following beneficial effects: the scale inhibitor can be used to delay formation of dirt and scale and form a protective layer to prevent expansion of dirt and is widely applied to metal equipment such as pipelines, heat exchangers, boilers and the like.

Owner:QINGDAO QIYUAN ZHENDONG ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Process for the Preparation of Pyrido [2,1-a] Isoquinoline Derivatives by Catalytic Asymmetric Hydrogenation of an Enamine Process for the Preparation of Pyrido [2,1-a] Isoquinoline Derivatives by Catalytic Asymmetric Hydrogenation of an Enamine](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/8bfeef15-c639-4104-b88c-350beb927c10/US20120010413A1-20120112-C00001.png)

![Process for the Preparation of Pyrido [2,1-a] Isoquinoline Derivatives by Catalytic Asymmetric Hydrogenation of an Enamine Process for the Preparation of Pyrido [2,1-a] Isoquinoline Derivatives by Catalytic Asymmetric Hydrogenation of an Enamine](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/8bfeef15-c639-4104-b88c-350beb927c10/US20120010413A1-20120112-C00002.png)

![Process for the Preparation of Pyrido [2,1-a] Isoquinoline Derivatives by Catalytic Asymmetric Hydrogenation of an Enamine Process for the Preparation of Pyrido [2,1-a] Isoquinoline Derivatives by Catalytic Asymmetric Hydrogenation of an Enamine](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/8bfeef15-c639-4104-b88c-350beb927c10/US20120010413A1-20120112-C00003.png)