Phosphosilicate type rare earth ore flotation collector and preparation method and application thereof

A technology of phosphosilicate and rare earth ore, applied in the field of rare earth, can solve the problems such as the difficulty of meeting environmental protection, unsatisfactory comprehensive effect, difficult degradation of chemicals, etc. The effect of high ore recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The phospho-silicate type rare earth ore flotation collector of this embodiment is composed of the following mass ratio materials: 10 parts of octyl ether propyl-a-amino-1,1-diphosphonic acid, 80 parts of coconut oleic acid , 8 parts of sodium cetyl sulfonate, 2 parts of Tween-60.

[0022] The preparation method of the phospho-silicate type rare earth ore flotation collector of the present embodiment:

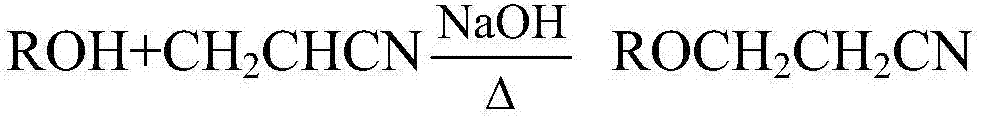

[0023] Put octanol and sodium hydroxide with a concentration of 30-40% into the enamel reaction kettle at a mass ratio of 100:2, stir evenly and heat up to 60°C, then slowly add acrylonitrile with 0.9 times the amount of octanol, and keep the temperature at 70 ℃, after adding acrylonitrile, stop heating after 2 hours of reaction, cool down to room temperature, and centrifuge statically to remove the precipitated sodium hydroxide and soap impurities.

[0024] Put octyl ether nitrile, pyrophosphoric acid and ethanol into the enamel reaction kettle at a mass ratio of 1:1.2...

Embodiment 2

[0029] The phospho-silicate type rare earth ore flotation collector of this embodiment is composed of the following mass ratio materials: 15 parts of octyl ether propyl-a-amino-1,1-diphosphonic acid, 75 parts of coconut oleic acid , 7 parts of sodium cetyl sulfonate, 3 parts of Tween-60.

[0030] The preparation method of the phospho-silicate type rare earth ore flotation collector of the present embodiment:

[0031] Put octanol and sodium hydroxide with a concentration of 30-40% into the enamel reaction kettle at a mass ratio of 100:3, stir evenly and heat up to 70°C, then slowly add acrylonitrile with 0.9 times the amount of octanol, and keep the temperature at 70°C ℃, after adding acrylonitrile, stop heating after 1 hour of reaction, cool down to room temperature, and centrifuge statically to remove the precipitated sodium hydroxide and soap impurities.

[0032] Put octyl ether nitrile, pyrophosphoric acid and ethanol into the enamel reaction kettle at a mass ratio of 1:1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com