Hydrogel-forming composition and high strength hydrogel formed from same

一种水凝胶、组合物的技术,应用在具有自支撑性的水凝胶领域,能够解决粘度变高、水凝胶制作困难等问题,达到安全性高的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0124] [Manufacture example 1: Manufacture of 2% sodium polyacrylate aqueous solution with addition of 1% magnesium chloride]

[0125] Dissolve 1 part of magnesium chloride hexahydrate (manufactured by Junsei Chemical Co., Ltd.) in 97 parts of water, then add 2 parts of sodium polyacrylate (manufactured by Wako Pure Chemical Industries, Ltd.: polymerization degree 22,000 to 70,000), and stir at 25°C until Form a homogeneous solution and obtain the target substance.

manufacture example 2

[0126] [Manufacturing Example 2: Manufacture of 10% Raponite XLG Water Dispersion Added with Sodium Hydroxyethylidene Diphosphonate]

[0127] 0.5 part of disodium hydroxyethylidene diphosphonate (manufactured by Tokyo Chemical Industry Co., Ltd.) was dissolved in 89.5 parts of water, and 10 parts of Raponite XLG (manufactured by Rockwood Adidas Co., Ltd.) was added thereto, and stirred at 25° C. for 24 hours, Get the target.

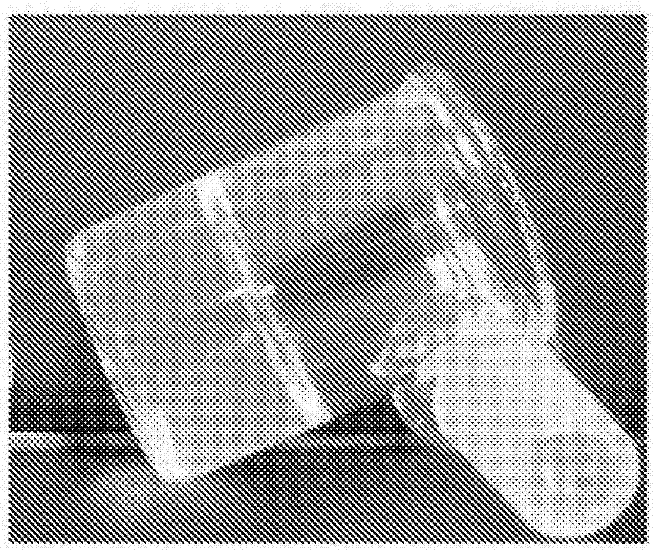

Embodiment 1

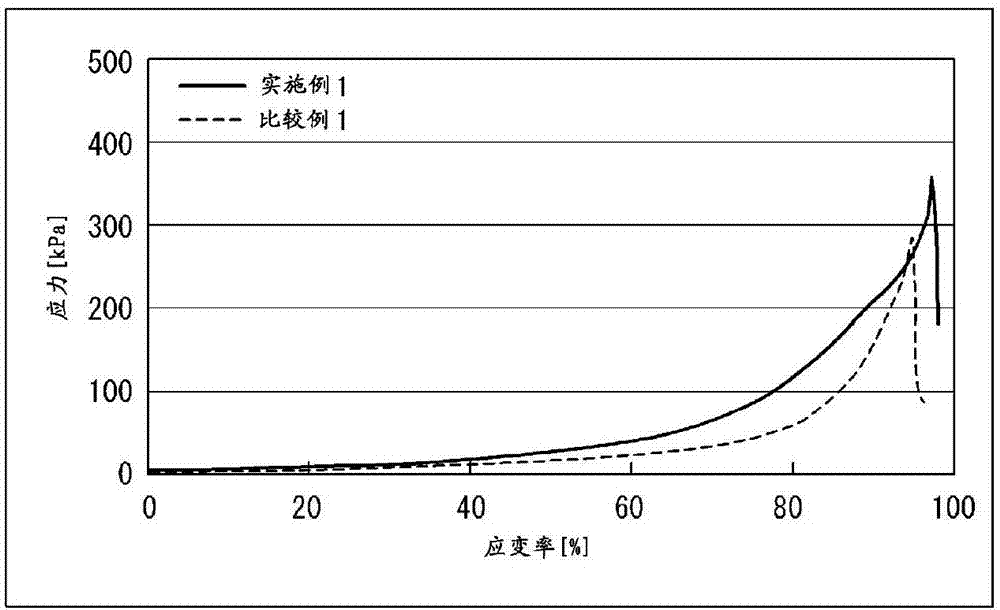

[0128] [Example 1: Production of 5% raponite XLG hydrogel to which sodium hydroxyethylidene diphosphonate was added]

[0129] Mix 50 parts of the 2% sodium polyacrylate aqueous solution with 1% magnesium chloride added in Production Example 1, and 50 parts of the 10% Raponite XLG aqueous dispersion with sodium hydroxyethylidene diphosphonate added in Production Example 2, and use a magnetic stirrer to Stir for 1 minute. After standing at room temperature for 48 hours, a hydrogel was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Weight-average Molecular Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com