Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

361 results about "Chromate and dichromate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chromate salts contain the chromate anion, CrO²⁻₄. Dichromate salts contain the dichromate anion, Cr₂O²⁻₇. They are oxoanions of chromium in the 6+ oxidation state and are moderately strong oxidizing agents. In an aqueous solution, chromate and dichromate ions can be interconvertible.

Non-toxic polyaniline modified anti-corrosive coating and preparation method thereof

ActiveCN101643618AAchieve passivationImprove corrosion resistanceRubber derivative coatingsAnti-corrosive paintsAfter treatmentPhytic acid

The invention relates to coating technology, in particular to a non-toxic polyaniline modified anti-corrosive coating and a preparation method thereof to solve the problems that that prior antirust pigment has poor corrosion resistance, and the coating is matched with harmful lead-containing and chromate-containing pigment in the manufacturing process. The non-toxic polyaniline modified anti-corrosive coating comprises a film forming matter, polyaniline modified antirust pigment, and the like. A polyaniline coating layer is formed on the surface of the antirust pigment by an oxidative polymerization method; the antirust pigment after treatment has passivating effect on metal; and a phytic coating layer on the surface of the antirust pigment also has corrosion inhibiting effect on the metal. The non-toxic polyaniline modified anti-corrosive coating has strong corrosion resistance and permeability resistance, and can be applied to anti-corrosive projects such as petrochemical equipment,pipelines, offshore oil platforms, wharf facilities, shipping and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

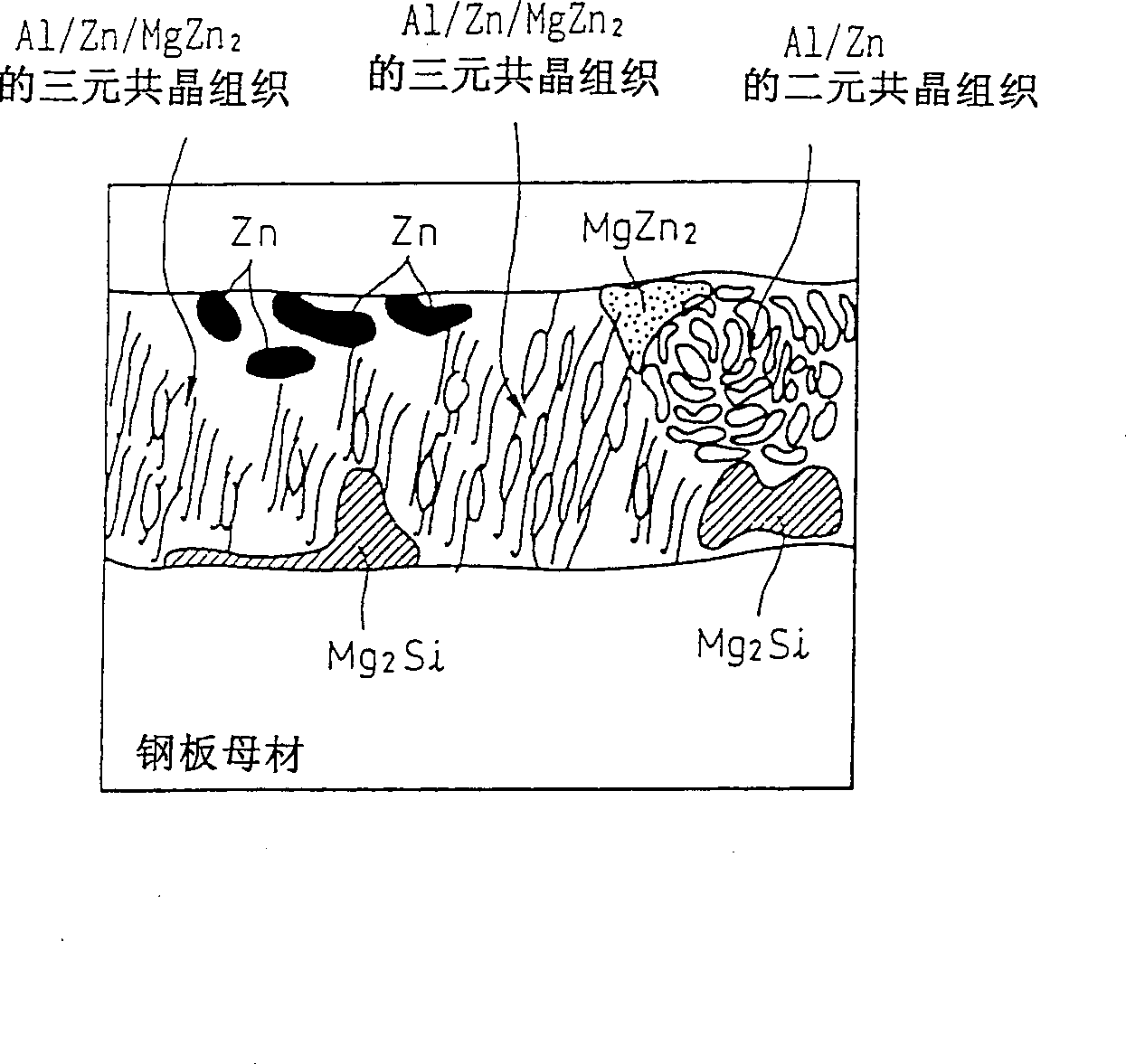

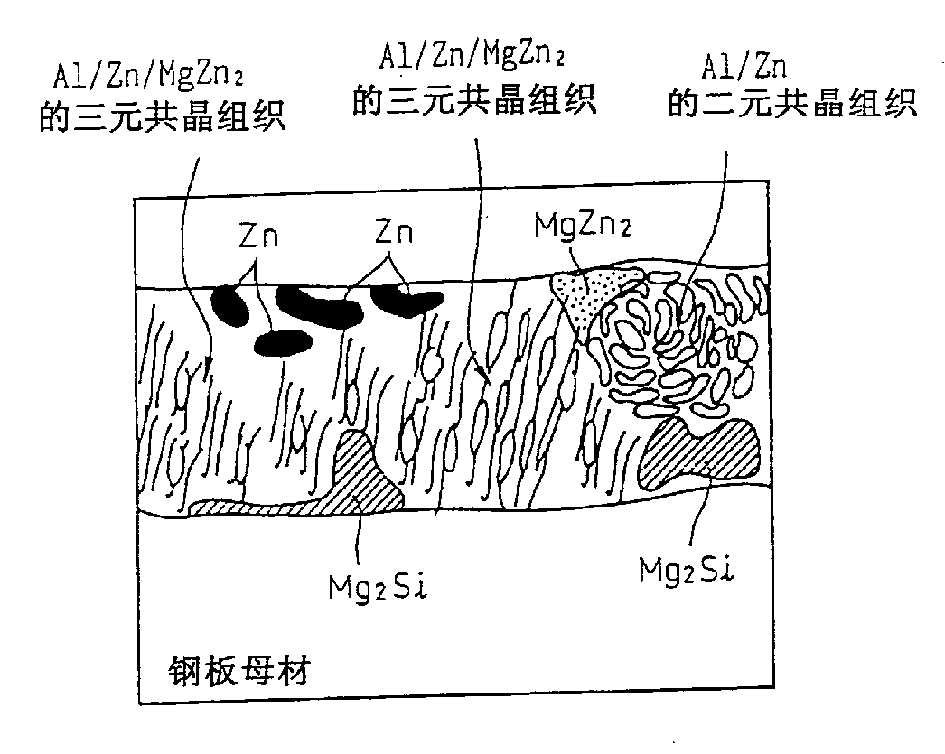

Plated steel product, plated steel sheet and precoated steel sheet having excellent resistance to corrosion

InactiveCN1342211AImprove adhesionImprove scratch resistanceHot-dipping/immersion processesLiquid surface applicatorsPhysical chemistryAlloy coating

Owner:NIPPON STEEL CORP

Pocess for providing metallic substrates with corrosion resistance

InactiveUS20160024310A1Superior chemical and mechanical propertyImprove corrosion resistanceSynthetic resin layered productsAnti-corrosive paintsCorrosion resistantChromate free

Owner:BYK USA

Treating fluid and method for preparing vanadium-zirconium composite conversion coatings with self-repairing performance on aluminum alloy surfaces through same

ActiveCN102766862AImprove corrosion resistanceGuaranteed stabilityMetallic material coating processesMetallic bondingSodium fluoride

The invention belongs to the technical field of chemical materials, and relates to a treating fluid and a method for preparing vanadium-zirconium composite conversion coatings with self-repairing performance on aluminum alloy surfaces through the same. The method includes the steps of firstly preparing the treating fluid containing fluorozirconate, metavanadate, sodium fluoride, nitrate, an accelerate and an additive; then putting an aluminum alloy after surface pretreatment into a working fluid made of the diluted treating fluid for 2min-10min; and finally subjecting the aluminum alloy to washing, drying and cooling to obtain the vanadium-zirconium composite conversion coatings. The preparation process is simple, heavy metals such as hexavalent chromium and nickel are not contained, the environment is friendly, the conversion coatings of the aluminum alloy after a conversion coating treatment are dense and high in binding force, metal ions in the conversion coatings can bond with base metal under a corrosion environment and provided with a certain self-repairing performance, and the treating technology of vanadium-zirconium conversion coatings can effectively replace chromate treatment on aluminum alloy surfaces.

Owner:湖南松井先进表面处理与功能涂层研究院有限公司

Method for extracting vanadium and chromium from materials containing vanadium or/and chromium

InactiveCN105420519AEasy to separateHigh recovery rateProcess efficiency improvementPregnant leach solutionVanadate

A method for extracting vanadium and chromium from materials containing the vanadium or / and the chromium is characterized by comprising the following steps: taking salt and alkali of alkali metal or the alkali of the alkali metal as an oxidation transformation medium of the materials containing the vanadium or / and the chromium; carrying out treating for 0.5-6 hours at the temperature of 160-600 DEG C under the effect of an oxidizing agent and enabling the vanadium and the chromium in the materials to be converted into soluble vanadate and soluble chromate; carrying out water leaching to obtain leaching liquor containing the vanadium or / and the chromium; adding a precipitant A in the leaching liquor containing the vanadium or / and the chromium to selectively precipitate the vanadium at first, and adding a precipitant B to precipitate the chromium to obtain vanadium-rich residues and chromium-rich residues; and then separating and recycling the vanadium and the chromium from the vanadium-rich residues and the chromium-rich residues respectively. The vanadium and the chromium are separated and recycled effectively, and moreover, the effect of removing impurities simultaneously is achieved; liquor obtained after chromium precipitation is subjected to oxidization regeneration, evaporated and concentrated to obtain media, and the media are returned to an oxidation transformation procedure for the materials containing the vanadium or / and the chromium and are recycled. The method has the advantages of the simple technology, easiness and convenience in operation, the good vanadium and chromium separating effect, a high metal recovery rate, low production cost, environmental friendliness and the like, and is suitable for industrial application of extracting the vanadium and the chromium from the materials containing the vanadium or / and the chromium.

Owner:CENT SOUTH UNIV

Method for treating metallic surfaces

InactiveUS6572983B2Improve corrosion resistanceEasy to processPretreated surfacesEfficient propulsion technologiesWater dispersiblePhosphate ion

A method of treating a metallic surface which comprises treating a metal-coated steel panel with a nonchromate metallic surface treating agent containing, in each liter thereof, (a-1) a silane coupling agent and / or a hydrolytic condensation product thereof, (a-2) water-dispersible silica in a proportion, and (a-3) a zirconium compound and / or a titanium compound, drying the treated steel panel and coating it with an anticorrosion coating agent containing, in each liter of an aqueous resin solution or dispersion, (b-1) a silane coupling agent and / or a hydrolytic condensation product thereof, (b-2) water-dispersible silica and (b-3) at least one phosphorus-containing ion selected from among phosphate ion, phosphite ion and hypophosphite ion.

Owner:NIPPON PAINT CO LTD

Non-chromate conversion coating treatment for metals

InactiveUS7344607B2Enhance adhesionSolid state diffusion coatingNon-woven fabricsPolymer chemistryZinc

Chromate-free treatments and compositions, for applying a conversion or passivation coating to zinc coated metal surfaces. The compositions comprise a polyamidoamine / epihalohydrin polymer or cationic polyamine / epihalohydrin polymer component, fluoacid, H3PO4, and a film forming polymer latex component. The requisite metal surfaces are contacted by the compositions and dried. Rinsing is optional.

Owner:CHEMETALL CORP

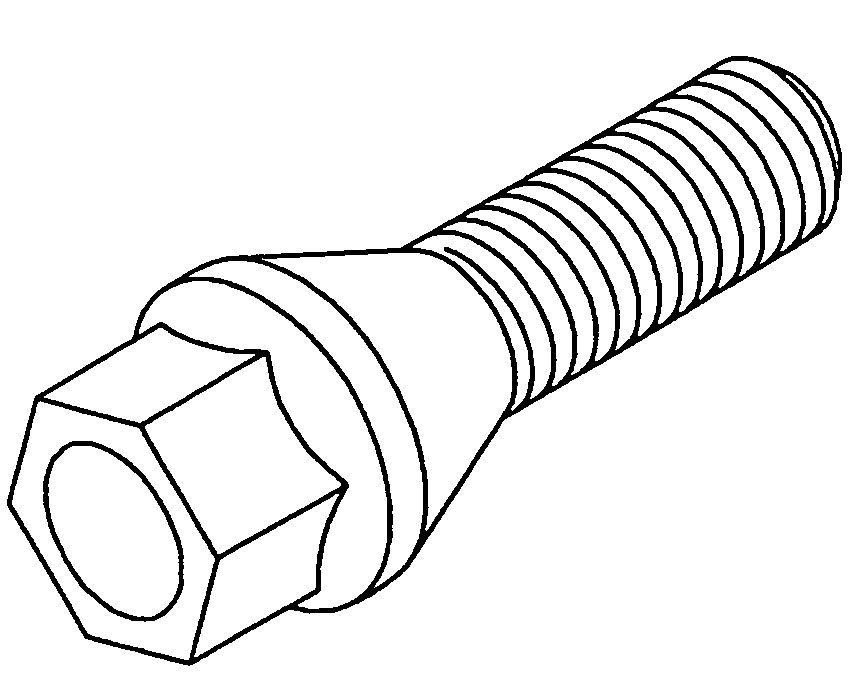

Corrosion resistant article and method of production thereof

InactiveUS7160630B2Highly resistant to chemical attackImprove friction performanceWashersRecord information storagePhosphateZinc

The disclosure relates to a corrosion resistant article comprising a metal body and a protective coating applied on at least one surface of said metal body, said protective coating comprising: (a) a zinc layer comprising metallic zinc; (b) a silicate layer comprising at least one silicate; and (c) a lubricant layer comprising at least one lubricant such as, for example, polyethylene wax. In particular, the disclosure relates to a corrosion resistant bolt and / or nut having a protective coating for use in motor vehicles. The protective coating is substantially free of chromates and phosphates and, hence, environmentally acceptable. The article has an excellent coefficient of friction, temperature resistance and anti-corrosion properties.

Owner:ELISHA HLDG LLC

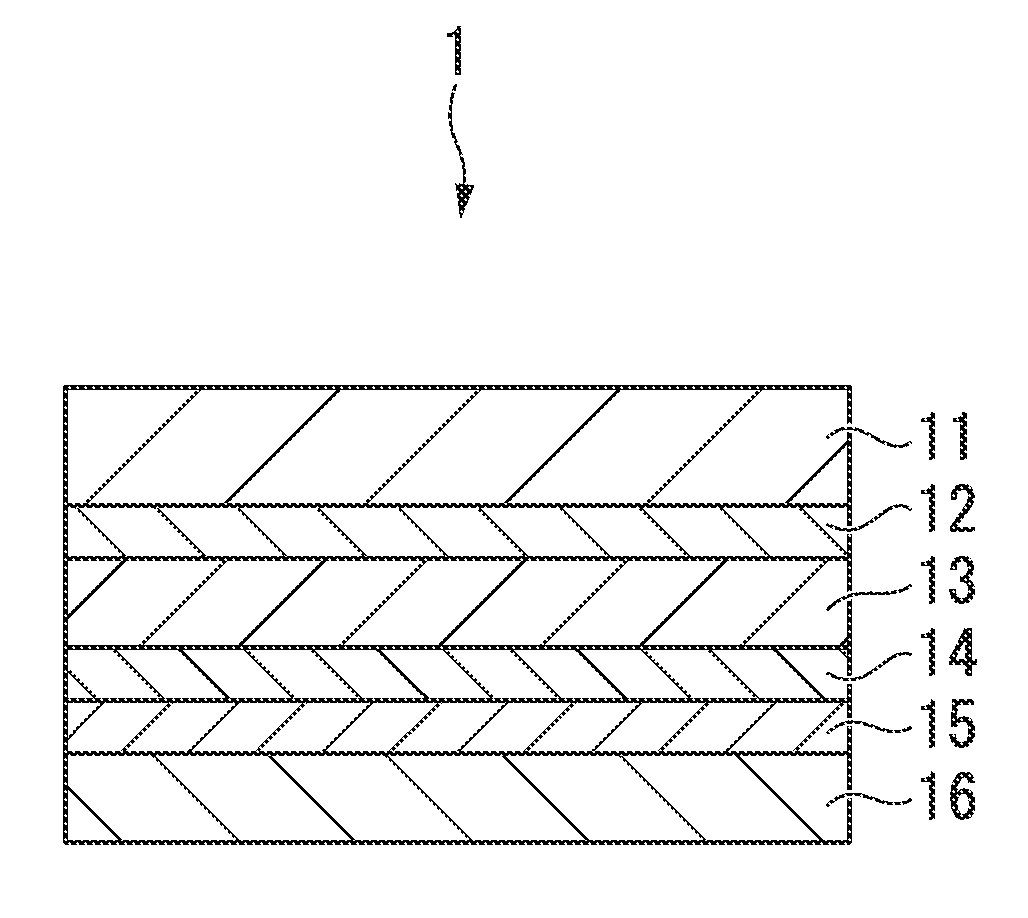

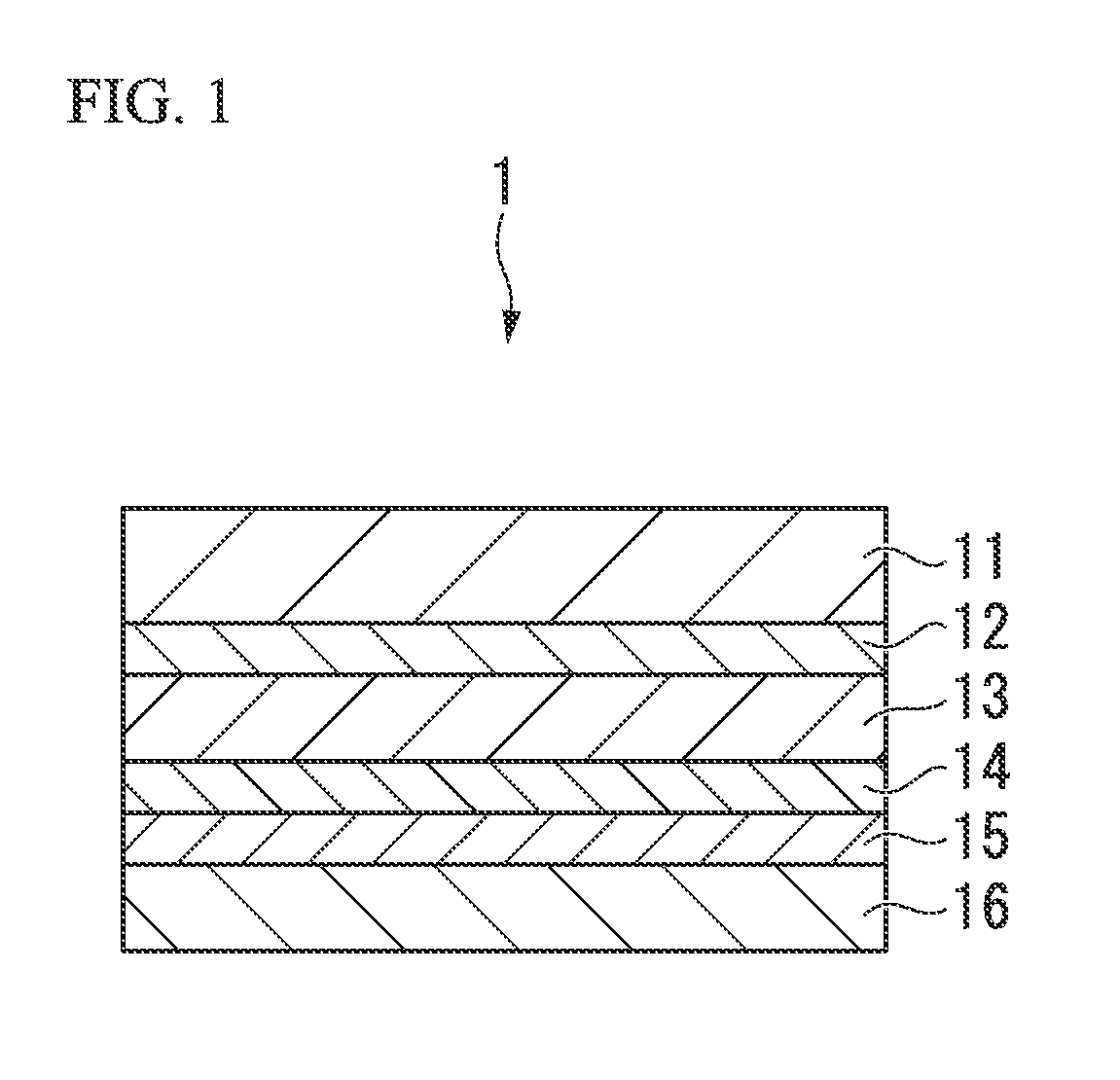

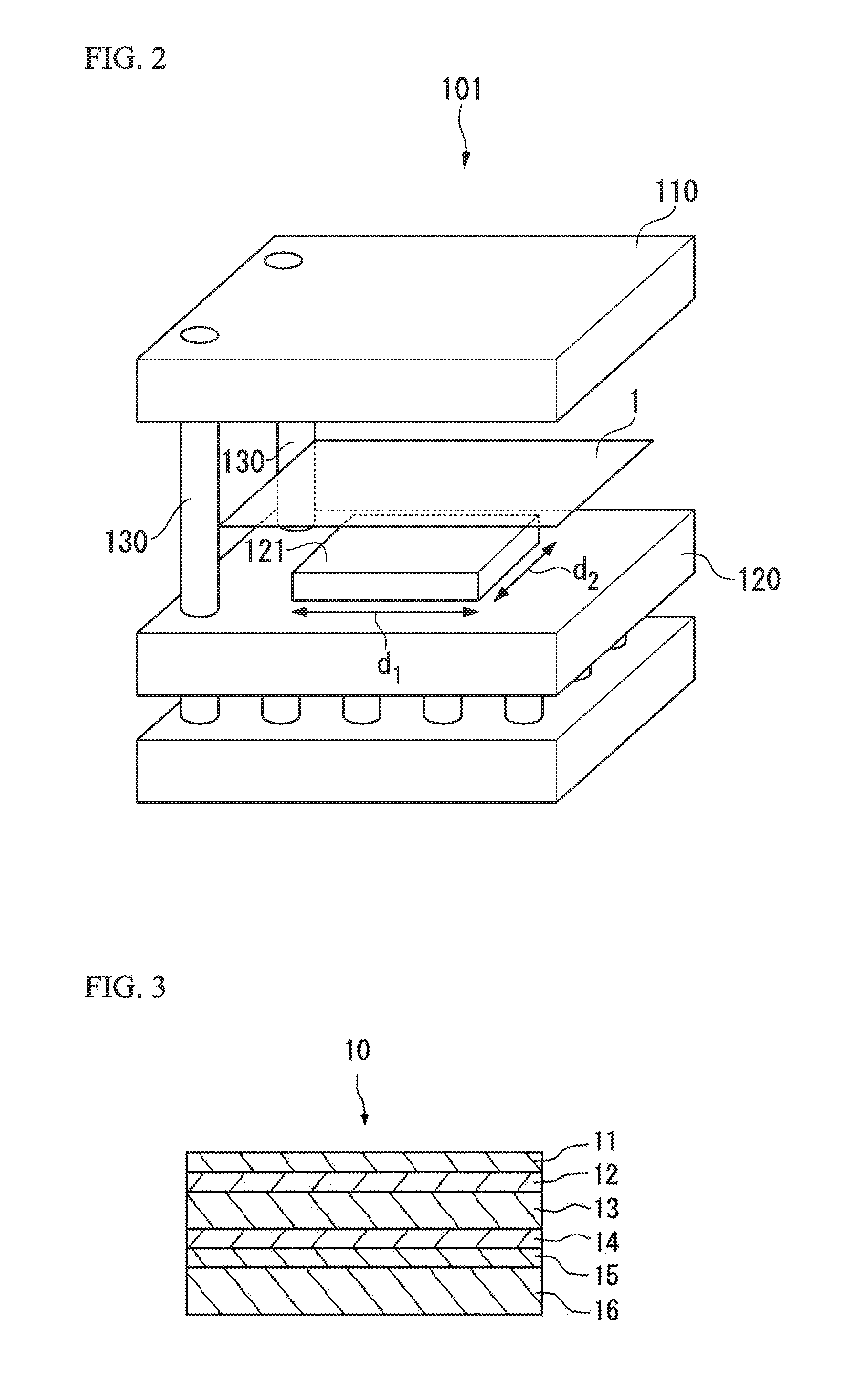

Lithium ion battery outer cover material

ActiveUS20130149597A1Solve the lack of resistanceGood deep drawing formabilitySmall-sized cells cases/jacketsLarge-sized cells cases/jacketsEngineeringSealant

According to the present invention, a lithium ion battery outer cover material that has superior resistance to electrolytes without chromate treatment, has superior deep drawing formability and high quality, and can be produced easily is provided. The lithium ion battery outer cover material (1) of a first embodiment of the present invention has a base material layer (11), first adhesive layer (12) containing an adhesive, aluminum foil layer (13), corrosion prevention treated layer (14), second adhesive layer (15) containing an adhesive or adhesive resin, and sealant layer (16) laminated in that order. The base material layer (11) is a film base material in which the difference (α2−α1) of the elasticity (α1) to the yield point and the elasticity (α2) to the rupture point as measured according to JIS-K7127 is 100% or greater in at least one of the MD direction and TD direction.

Owner:TOPPAN PRINTING CO LTD

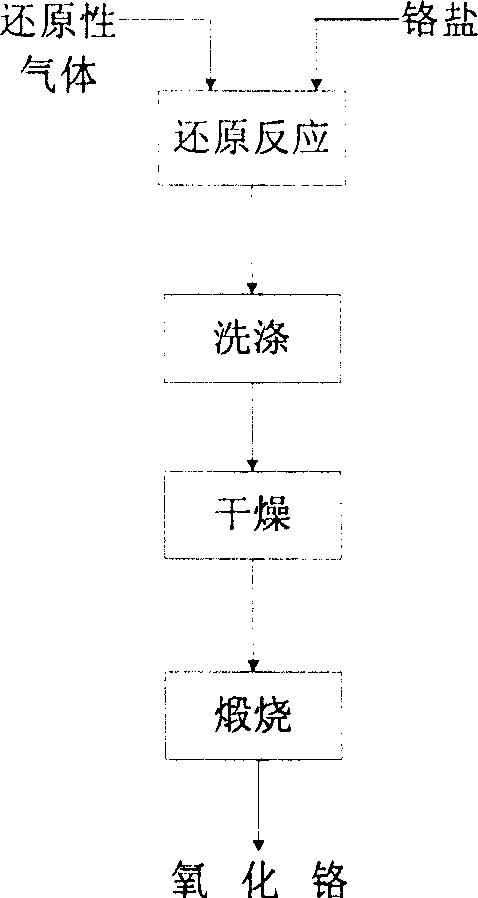

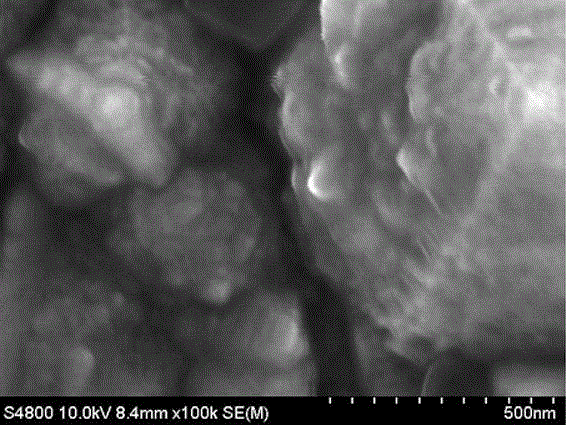

Method of preparing chromium oxide by reducing chromate with gaseous reducing agent at low temperature

InactiveCN1907865ASimple production processEasy to industrializeChromium oxides/hydratesHydrogenReaction temperature

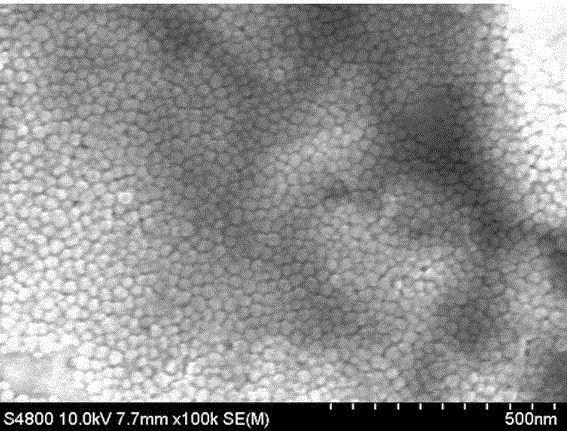

This invention involves a preparation method for chromium oxide with chromium salt as raw materials and reducing gas as a reductant. Said method comprises carrying out reaction of chromium salt with superfluous reducing gas at 300~850DEG C for 0.5-3 h and cooling to obtain a reaction mixture, washing the mixture and drying, and calcining at 400~1100DEG C for 1-3 h to obtain the ultrafine chromium oxide powders, wherein the chromium salt is chromate or dichromate, and the reducing gas is hydrogen, natural gas, gas or their mixtures. Compared with existing technologies, this invention has the advantages of simple production process and being easy for industrialization. The obtained chromium oxide has high purity, uniform particle size distribution and small particle size. The whole process does not produce containing chromium-containing waste, and is environmental friendly. The reaction by-product can be reused, which greatly reduces the cost of production. Low reaction temperature greatly reduces the reaction energy.

Owner:中蓝义马铬化学有限公司

Environment-friendly polyaniline modified aluminium powder anti-corrosive coating and preparation method thereof

ActiveCN101643619AAchieve passivationImprove corrosion resistanceRubber derivative coatingsAnti-corrosive paintsPetrochemicalCorrosion

The invention relates to coating technology, in particular to an environment-friendly polyaniline modified aluminium powder anti-corrosive coating and a preparation method thereof to solve the problemthat the prior aluminium powder coating has poor corrosion resistance, and is matched with harmful lead-containing and chromate-containing pigment in the manufacturing process. The environment-friendly polyaniline modified aluminium powder anti-corrosive coating comprises a film forming matter, polyaniline modified aluminium powder and the like. A polyaniline coating layer is formed on the surface of the aluminium powder by an oxidative polymerization method; the treated aluminium powder has passivating effect on metal; and a phytic coating layer on the surface of the aluminium powder also has corrosion inhibiting effect on the metal. The environment-friendly polyaniline modified aluminium powder anti-corrosive coating has strong corrosion resistance and permeability resistance, and can be applied to anti-corrosive projects such as petrochemical equipment, pipelines, offshore oil platforms, wharf facilities, shipping and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Environmental-friendly polyaniline modified micaceous iron oxide anticorrosive coating and preparation method thereof

ActiveCN101643620AAchieve passivationImprove corrosion resistanceRubber derivative coatingsAnti-corrosive paintsPhytic acidPetrochemical

The invention relates to coating technology, in particular to an environmental-friendly polyaniline modified micaceous iron oxide anticorrosive coating and preparation method thereof, which solves theproblem that the prior micaceous iron oxide coating has poor anticorrosion performance, and needs to be matched with pigments containing lead and chromate during manufacturing. The environmental-friendly polyaniline modified micaceous iron oxide anticorrosive coating comprises film-forming material, polyaniline modified micaceous iron oxide, and the like. As polyaniline coating layers are formedon the surfaces of the micaceous iron oxide by an oxidative polymerization method, the treated micaceous iron oxide has the effect of passivating metal, and phytic-acid coating layers on the surfacesof the micaceous iron oxide play a role in inhibiting corrosion of metal. The environmental-friendly polyaniline modified micaceous iron oxide anticorrosive coating has strong corrosion resistance andpermeation resistance, can be applied to heavy-duty engineering of petrochemical equipment, pipelines, offshore oil platforms, wharf facilities, ships and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

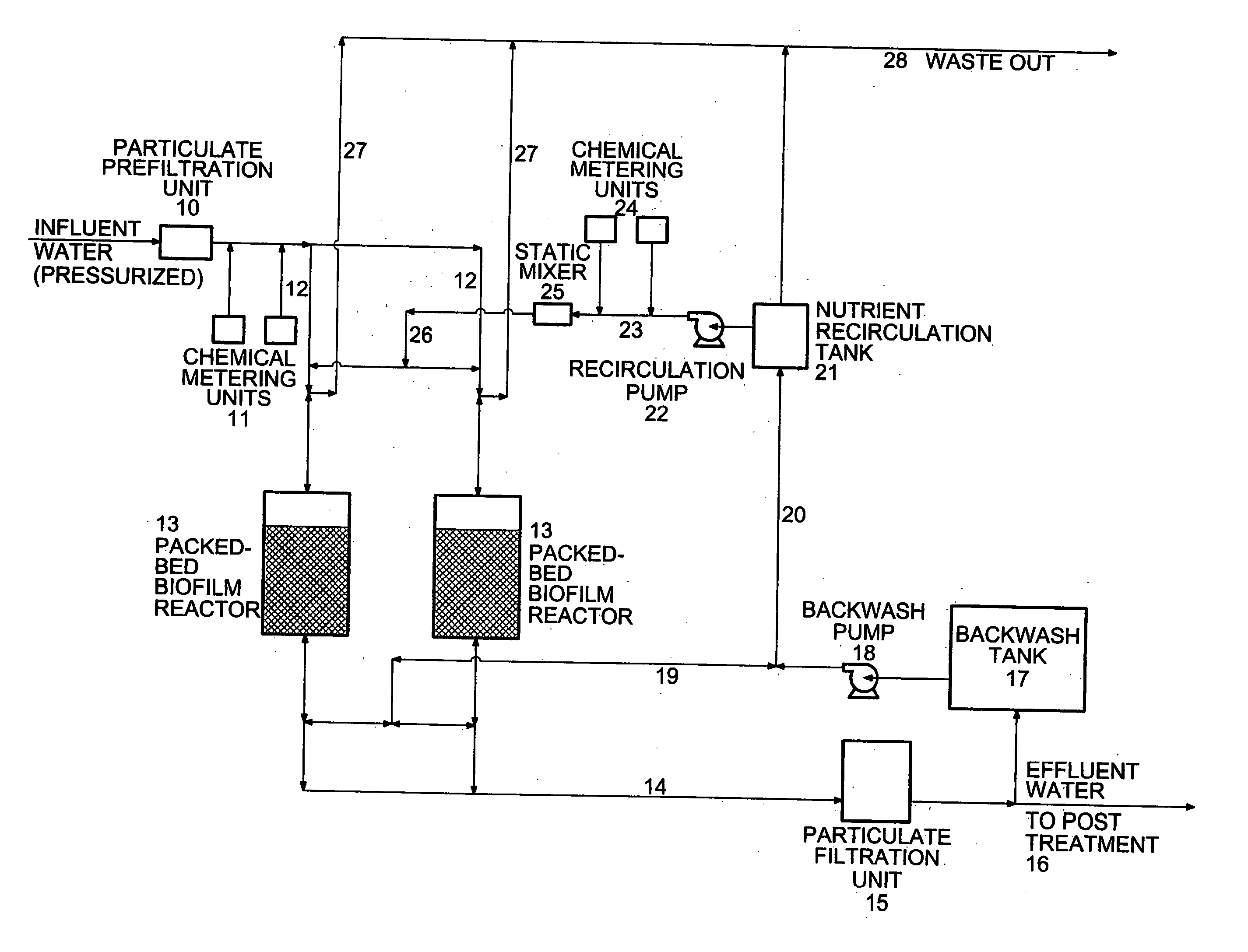

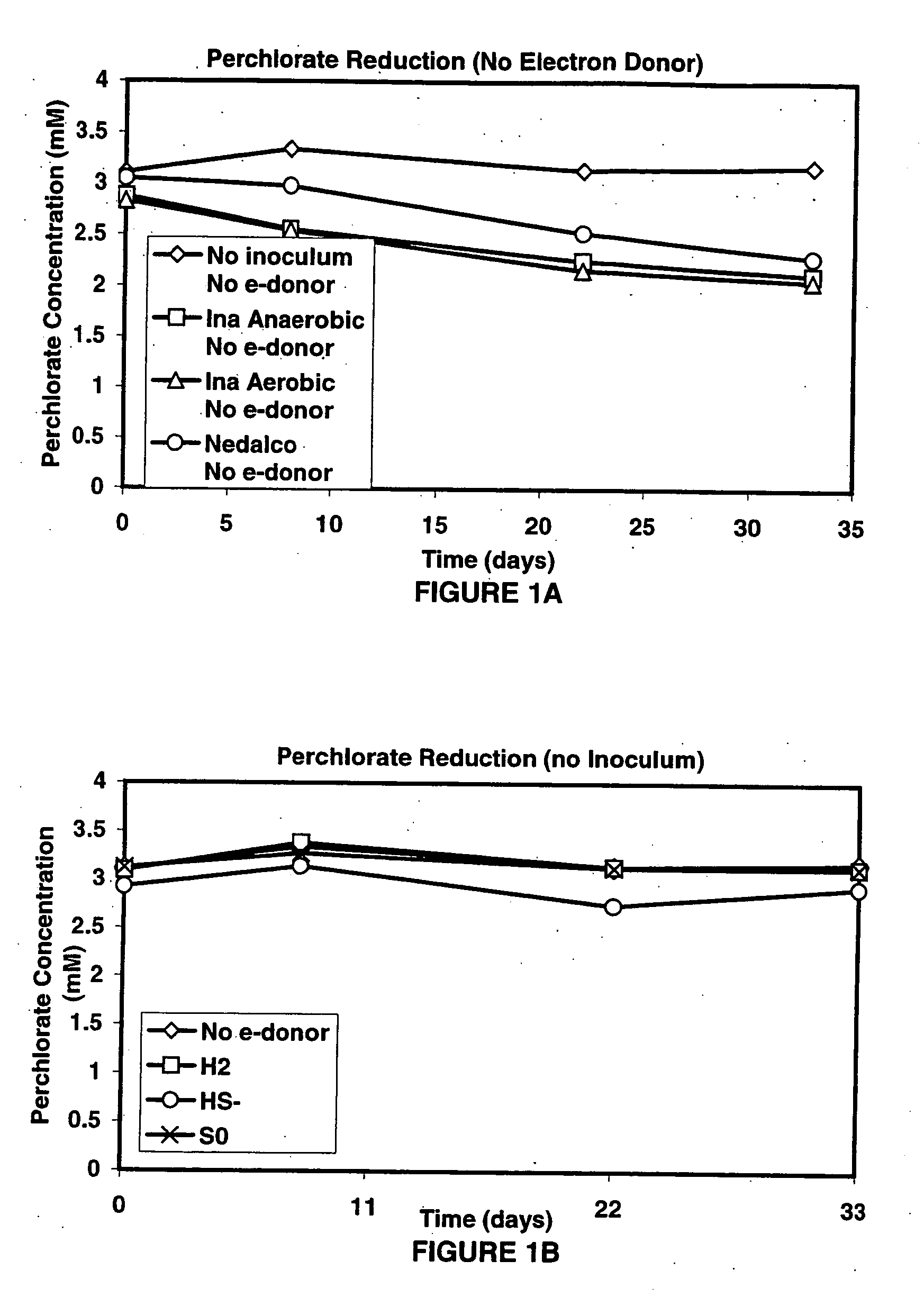

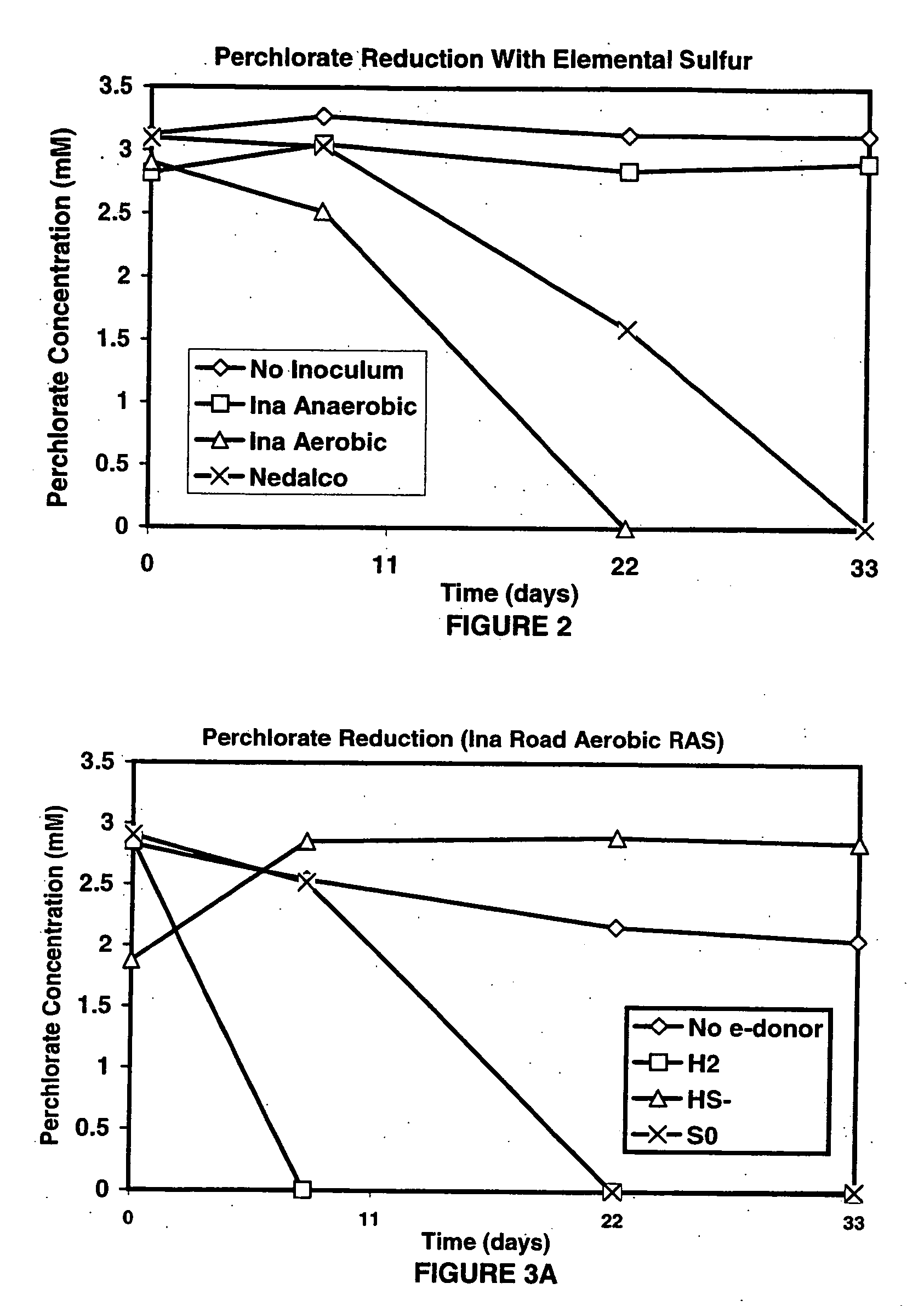

Method and system for treating oxidized contaminant-containing matrix

InactiveUS20060292684A1Reduce maintenanceHigh degreeWater treatment compoundsWater contaminantsSulfurElectron donor

A new and useful way of treating oxidized-contaminant-containing water, soil, rock, other geological or non-geological matrix formation (such as a landfill) is provided. A bioreactor is provided that includes elemental sulfur and a microbial population capable of oxidizing sulfur and reducing pertechnate (TcO4−), arsenate (H2AsO4−), chromate (CrO42−), bromate (BrO3−), chlorite (ClO2−), chlorate (ClO3−), perchlorate (ClO4−), and uranium(VI) oxide, with biological reduction of these oxidized contaminants in the matrix containing the oxidized contaminant performed by the bioreactor, with the elemental sulfur as the electron donor.

Owner:HYDRO GEO CHEM

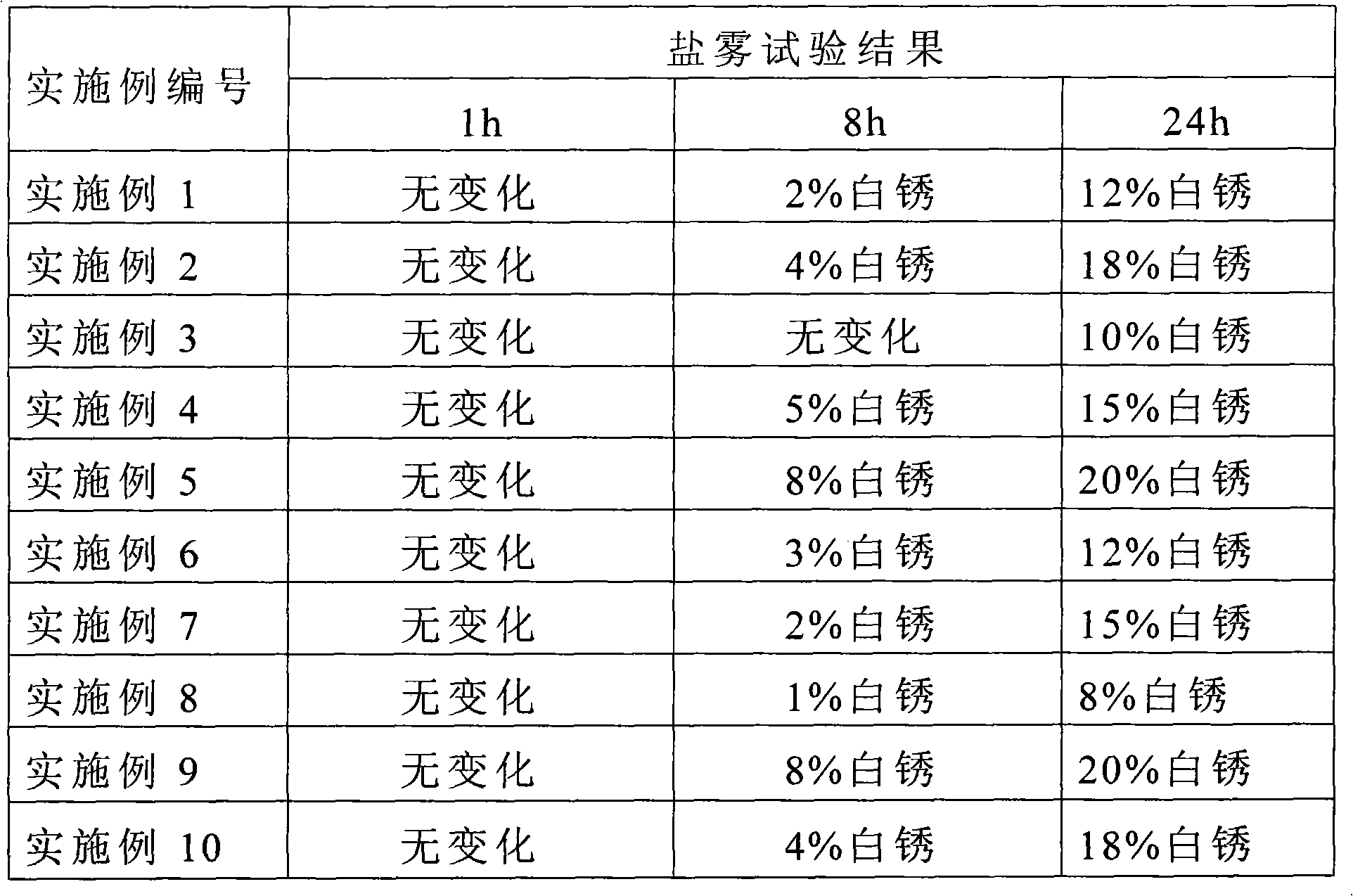

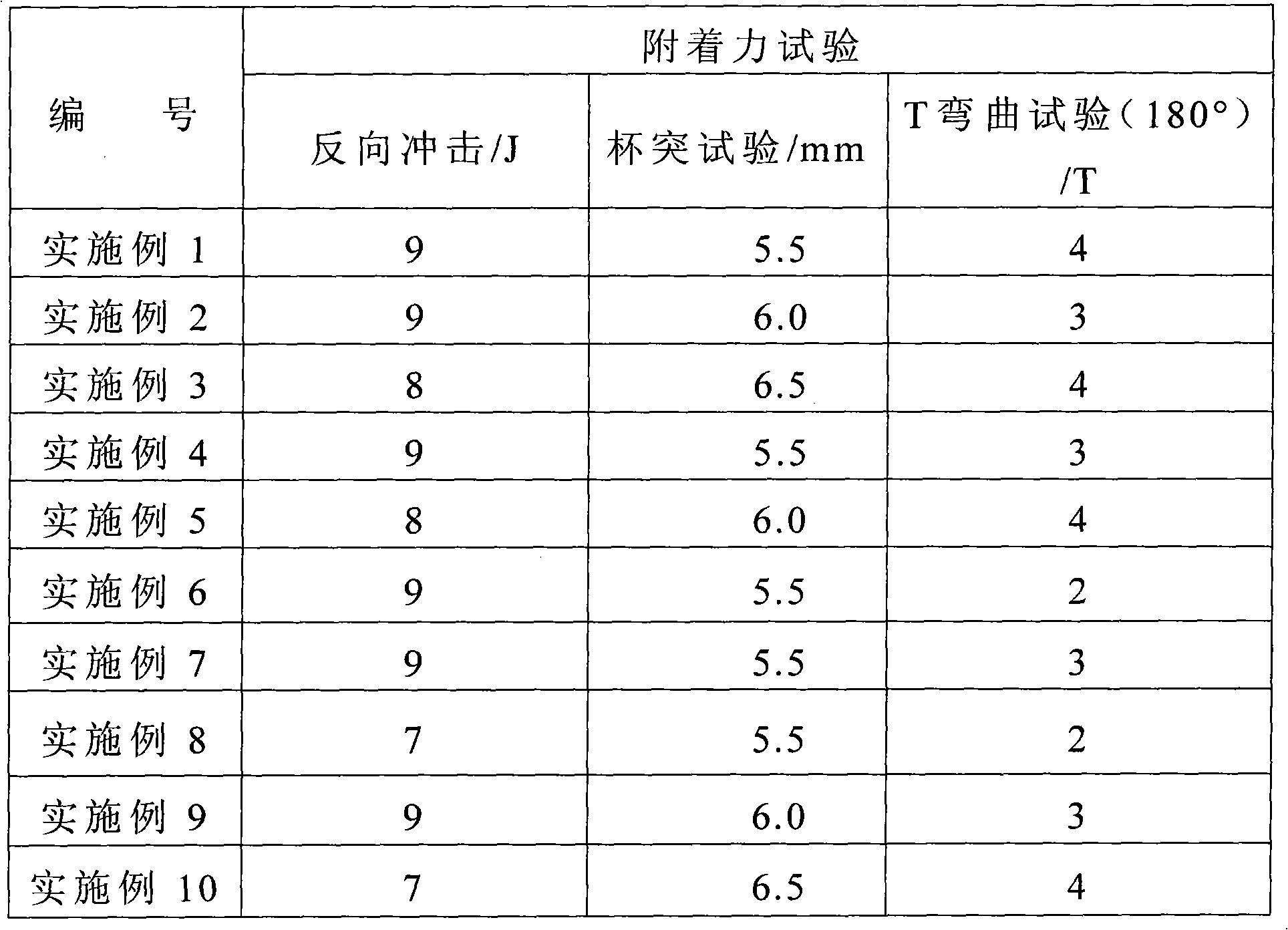

Non-chromium pretreating agent for color coated steel plate

InactiveCN101603174AImprove corrosion resistanceImprove precisionMetallic material coating processesCarboxylic acidBinding force

The invention discloses a non-chromium pretreating agent for a color coated steel plate, which is a solution prepared by mixing solute formed by multiple substances with deionized water according to the weight percentage of 1:4 to 7, wherein the solute includes the following substances by weight percentage: 0 to 10 percent of organic carboxylic acid containing 4 to 18 carbon atoms or water soluble salt thereof, 5 to 30 percent of organic polymer with molecular weight ranging from 3000 to 200000, 10 to 15 percent of salt with oxidation capacity, 15 to 60 percent of inorganic fluorochemical with the function of complexation, 5 to 10 percent of high valence state titanium salt, 5 to 15 percent of inorganic zinc salt and 5 to 30 percent of inorganic phosphate. The pretreating agent of the invention does not include substances harmful to the environment and human bodies, such as high valence chromate, and the like; meets the RoHs requirement, and belongs to environment-friendly green products. Proved by experiments, the product of the invention can greatly improve the binding force between a coating and a galvanized plate, and can enhance the decay resistance of the coating.

Owner:武钢集团有限公司

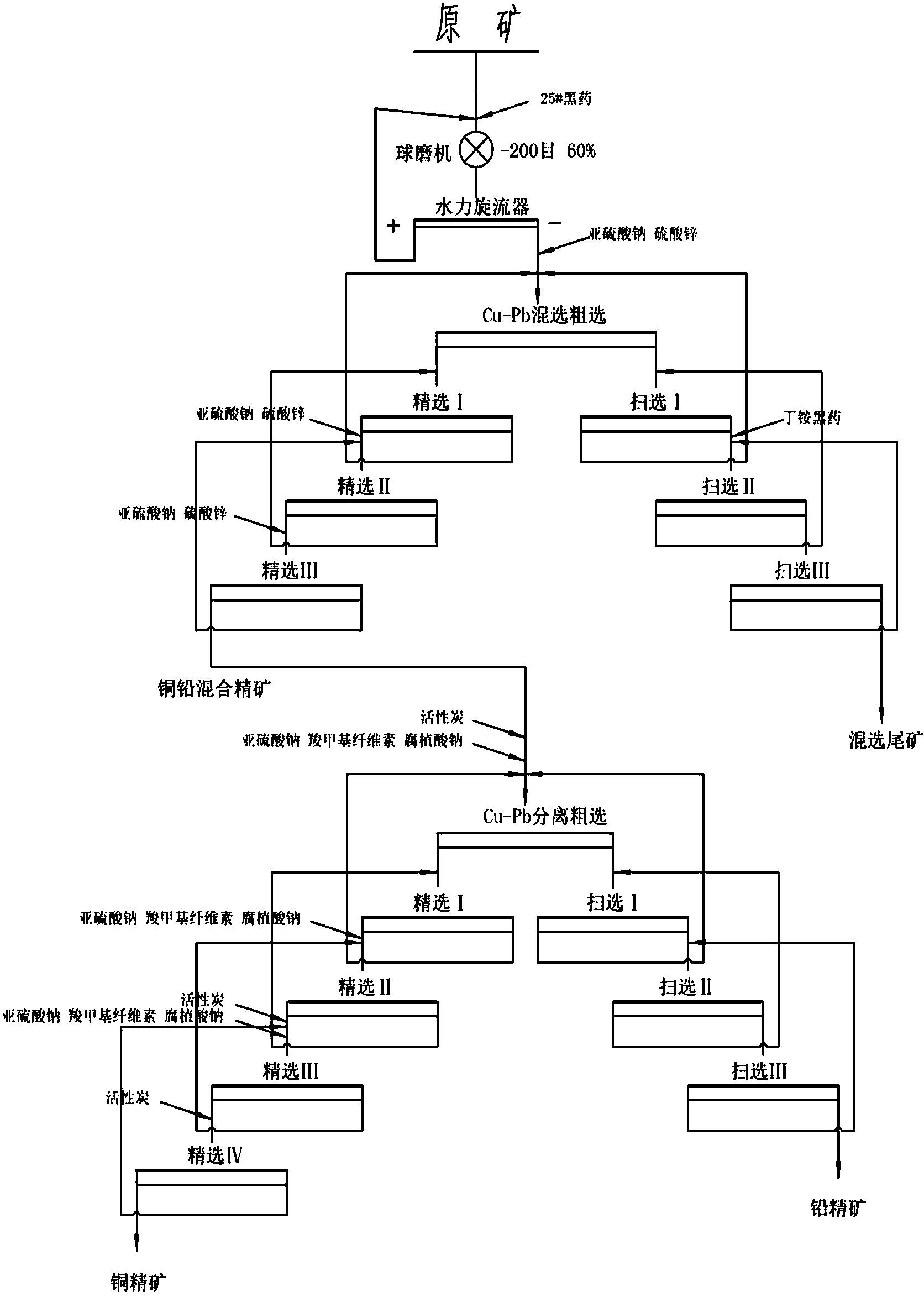

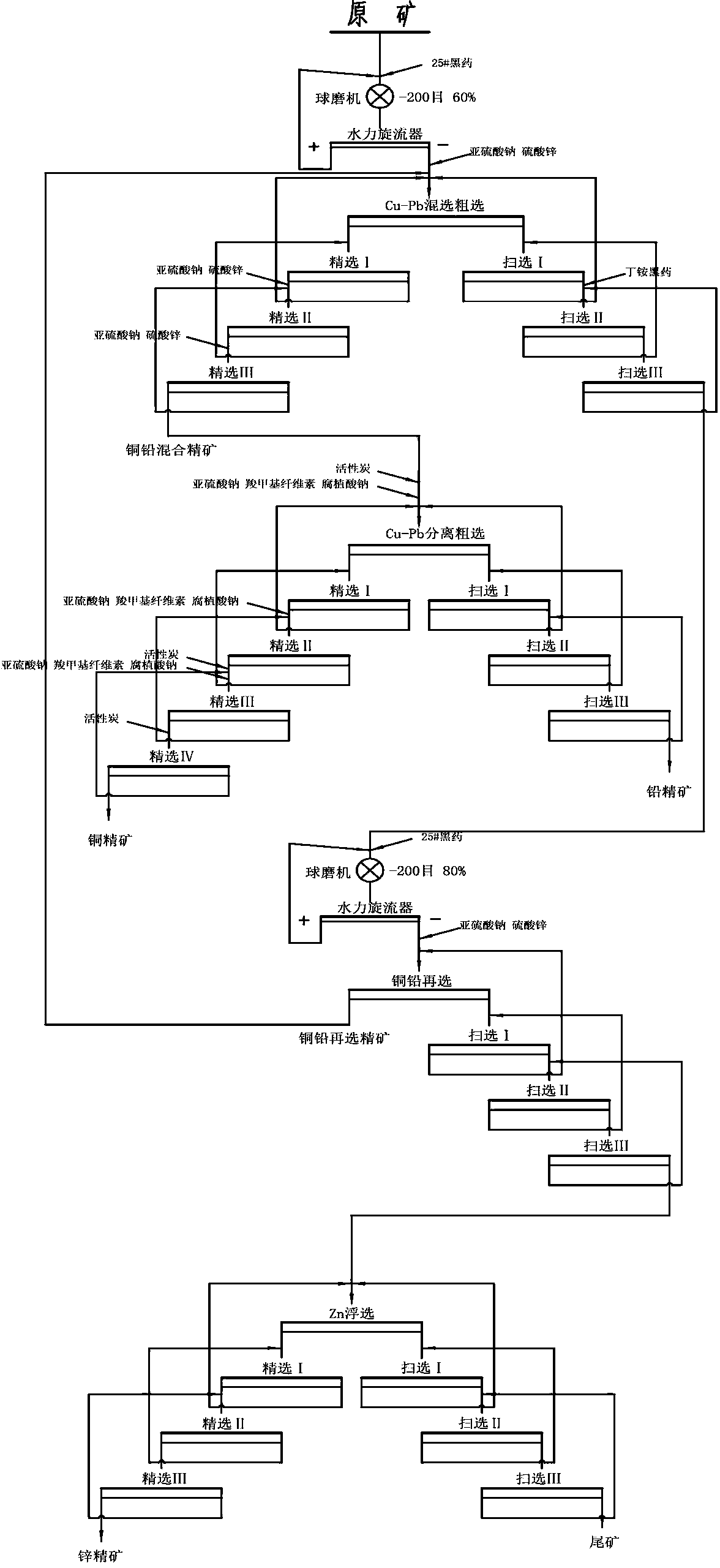

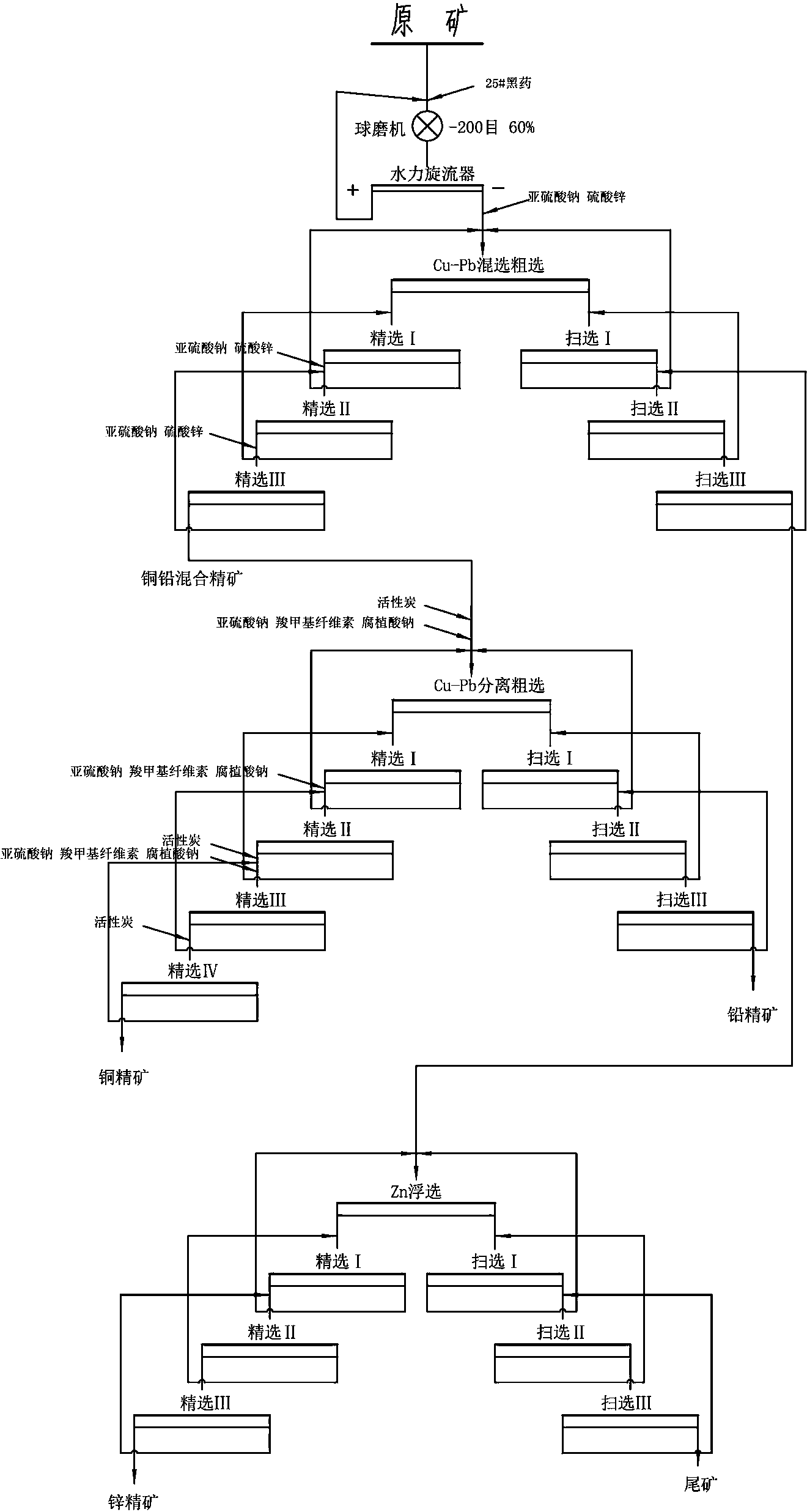

Copper and lead separating cyanide-chrome-free beneficiation method for low-grade multi-metal sulfide ore

The invention discloses a copper and lead separating cyanide-chrome-free beneficiation method for low-grade multi-metal sulfide ore. The beneficiation method is performed according to the following steps that (1) raw ore after ore grinding and grading enters the step of copper and lead bulk flotation to obtain copper and lead bulk concentrate and bulk flotation tailings, beneficiation reagents including 25# black powder and tetrabutyl ammonium black powder are adopted as collecting agents for copper and lead ore, and sodium sulfite and zinc sulfate are adopted as inhibitors of zinc ore; (2) copper and lead separating flotation is performed on the copper and lead bulk concentrate to obtain qualified copper concentrate and lead concentrate, in the copper and lead separating flotation process, activated carbon is adopted for reagent removal, and an inhibitor combined by sodium sulfite, sodium carboxymethyl cellulose and sodium humate serves as the inhibitor of lead sulfide ore. The beneficiation method has the following advantages of being low in price and production and application cost, it is unnecessary to perform special treatment on ore pulp, the process is easy to control, and technological and economic indexes are stable. The great defect that a dichromate titration method, a cyanide method and a less-cyanide-chrome technology can cause pollution to the environment is overcome, and the usage amount of beneficiation new water is greatly reduced.

Owner:XINBARHU YOU BANNER RONG DA MINING LLC

Method for recycling heavy metal resources of stainless steel pickling waste water neutralization sludge

InactiveCN102660687ASimple processLess investmentSludge treatmentSolid waste disposalSludgeManganese

The invention discloses a method for recycling heavy metal resources of stainless steel pickling waste water neutralization sludge and belongs to the technical field of recycling of sludge after sewage treatment. The method comprises the following steps of: 1) performing acid pickling, namely extracting the stainless steel pickling waste water neutralization sludge by using sulfuric acid as extractant, and adding an additive to inhibit the leaching of ferrum; 2) oxidizing, namely adding oxidant into a leaching solution to oxidize Mn(II) into manganese dioxide; 3) performing ion exchange, allowing a solution obtained after oxidation to pass through an anion exchange column, enriching and recycling hexavalent chromium, adsorbing and saturating, regenerating by using regenerant, and recycling chromate from a regeneration solution; and 4) performing neutralization precipitation, namely recycling nickelous hydroxide from ion exchange effluent by a neutralization precipitation method. By the method, ferrum is inhibited at an acid pickling section, the acid pickling is performed while ferrum is removed, the multi-stage multi-step recycling of manganese, chromium, and nickel metal resources can be realized, the innocent treatment of sludge and recycling of heavy metal are realized, and the method has comprehensive benefit of economic benefit, environmental benefit and social benefit.

Owner:NANJING UNIV

Method for extracting vanadium and chromium from vanadium chromate mixed solution

InactiveCN106893877AReduce processing costsEasy to separateProcess efficiency improvementBarium saltSlag

The invention relates to a method for extracting vanadium and chromium from a vanadium chromate mixed solution. The method has the characteristics that the vanadium in the vanadium chromate mixed solution is separated and recycled through the crystallization precipitation method or the hydrolysis precipitation method or the calcium salt precipitation method at first, then the chromium in the enrichment solution is separated through the copper salt precipitation method or the barium salt precipitation method, an obtained chromium precipitation enrichment product is then transformed into chromium enrichment liquid, the chromium enrichment liquid is further processed into products of chromic acid and chromate, and production of vanadium-chromium reducing slag and ammonia-nitrogen wastewater in the separation and recycling process of the vanadium and the chromium in the solution is effectively avoided. The method for extracting the vanadium and the chromium from the vanadium chromate mixed solution has the advantages of being good in vanadium and chromium separation effect, short in technological process, high in metal recycling rate, easy and convenient to operate, low in production cost, environmentally friendly and the like and is suitable for industrial production and application.

Owner:CENT SOUTH UNIV

Surface active agent modification zeolites, method of preparing thereof and usage

InactiveCN101549873AEfficient removalImprove activity stabilityAluminium silicatesWater/sewage treatment by ion-exchangeWater qualityWater processing

The present invention relates to a zeolites and a method for preparing thereof, in particularly a method for preparing a modification zeolite which can treat raw water and groundwater pollutated by chromates, and using as water processing material. The method belongs to the environmental-protecting technical field. The method includes steps as follows: firstly, processing activating to the natural zeolite by using a mixing solution of alcaine and citric acid for obtaining the activating zeolite; then processing modification to the zeolite by using surfactants cetyl bromination pyridine (HDPB) for obtaining the surfactants modification zeolite. The surfactants modification zeolite can be used for treating various raw water and ground water with substandard water quality which can remove chromates tainting substance with high efficient.

Owner:曾玉彬 +1

Chronium-free deactivator solution for preventing white rust in galvanized layer and its coating method

InactiveCN1974842AImprove bindingHas the ability to "self-heal"Pretreated surfacesMetallic material coating processesChromium freeSilanes

The present invention discloses one kind of chromium-free deactivator solution for preventing white rust in galvanized layer and its coating method. Into silane solution containing cilane coupler in 1-50 vol% concentration, molybdenate corrosion inhibitor in 1-30 g / L is added to compound pH 3-7 clear transparent deactivator solution. The deactivator solution is soaked, brushed or sprayed to the surface of galvanized layer to form one adhesive transparent spontaneously curing protecting layer with corrosion resistance similar to that of conventional chromate. The method can prevent white rust formed in the surface of galvanized product and is environment friendly.

Owner:SOUTH CHINA UNIV OF TECH

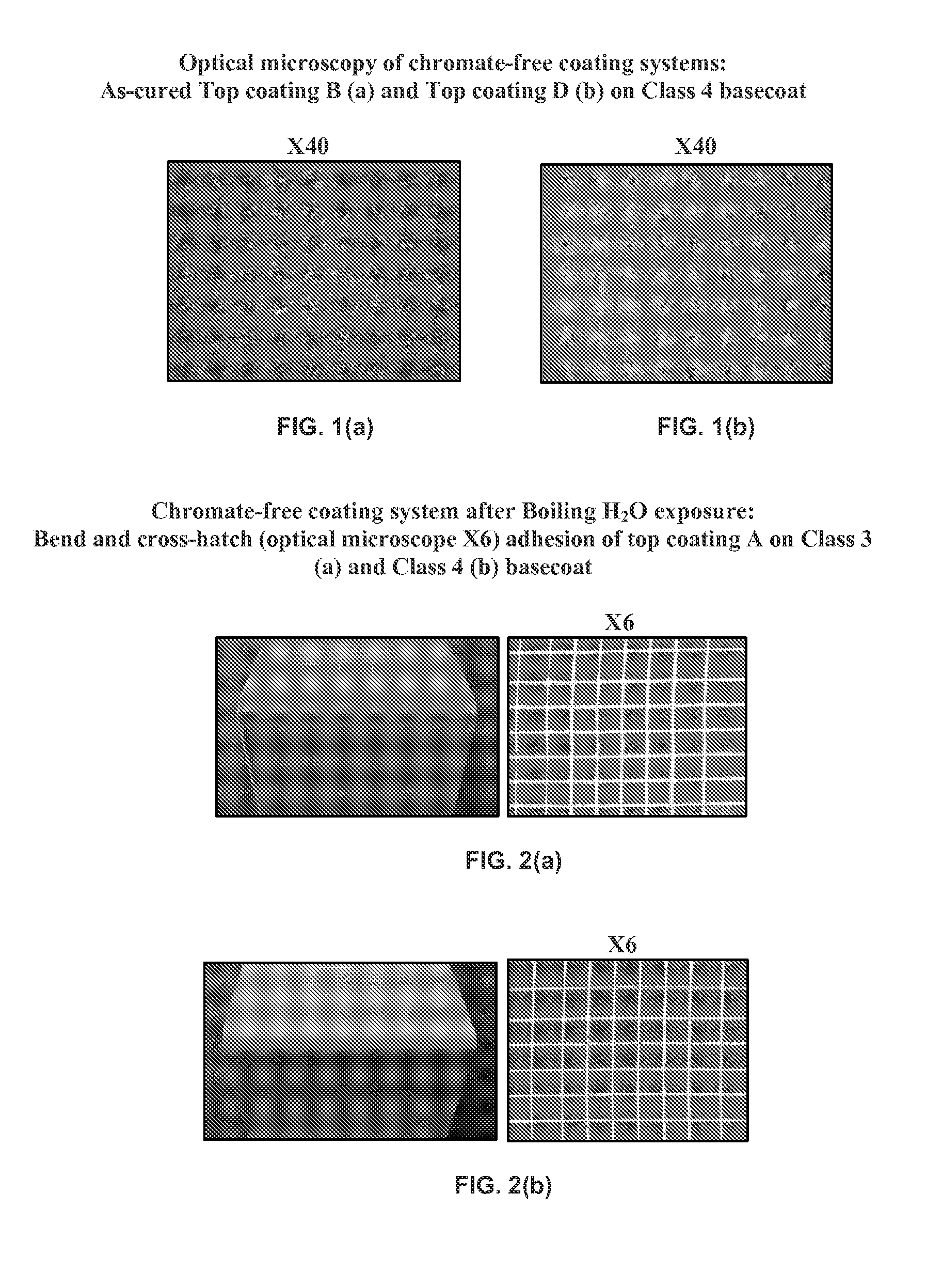

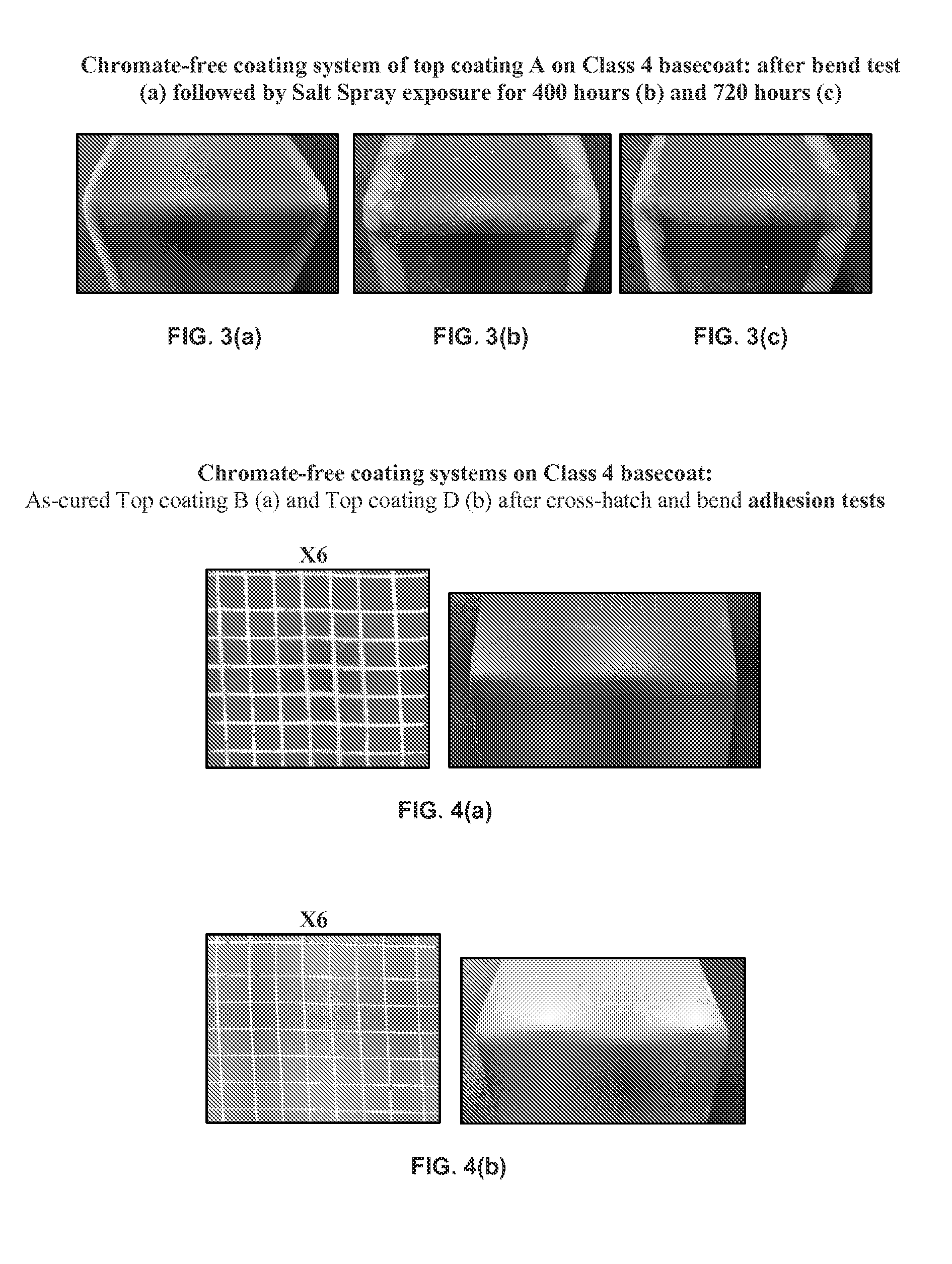

Chromate-free ceramic coating compositions

ActiveUS20150183998A1Improve corrosion resistanceImprove heat resistanceAlkali metal silicate coatingsAnti-corrosive paintsLithiumCoating system

A novel chromate-free multi-layer coating system composed of a lithium-doped potassium silicate binder based basecoat composition that is sealed with an aluminum phosphate-based top coat composition is described. The multi-layer coating system exhibits superior corrosion and heat oxidation resistance which can replace traditional chromate-containing coating systems.

Owner:PRAXAIR ST TECH INC

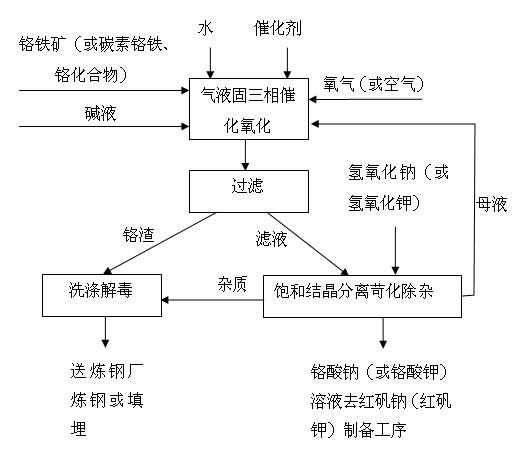

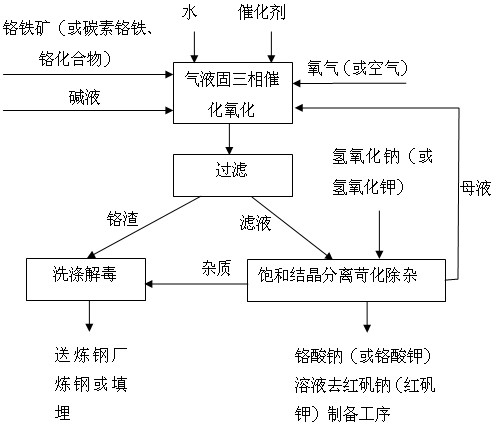

Three-phase catalytic oxidation preparation technology of soluble chromate

ActiveCN102320661AAvoid generatingReduce the difficulty of separation and recoveryChromates/bichromatesCatalytic oxidationOxygen

The invention relates to a preparation technology of chromate, specifically to a three-phase catalytic oxidation preparation technology of soluble chromate. The technology comprises the following steps of: heating alkali liquor with concentration of 20-60% to 50-300 DEG C, then, mixing chromite or carbon ferrochrome with the alkali liquor according to mass ratio of Cr2O3 : alkali liquor = 1 : 1.5-10 to form suspending liquid, and introducing the suspending liquid into a reactor; continuously inputting the air or the oxygen heated to 50-300 DEG C to the bottom of the reactor through a pipeline; setting a catalyst in the reactor according to the mass ratio of catalyst : Cr2O3 = 0.1-1.5 : 100, maintaining the temperature of the suspending liquid in the reactor at 50-300 DEG C, executing gas-liquid-solid three-phase bubbling reaction for 0.5-6 hours to generate soluble chromate raw products and chromium residues; removing impurities through filtering and crystallization to obtain the chromate. With the three-phase catalytic oxidation preparation technology of the soluble chromate, Cr2O3 conversion rate is high, reaction speed is fast, energy consumption is low, residue quantity is low, environment pollution is less, equipment investment is low and corrosion is low.

Owner:CHONGQING MINFENG CHEM

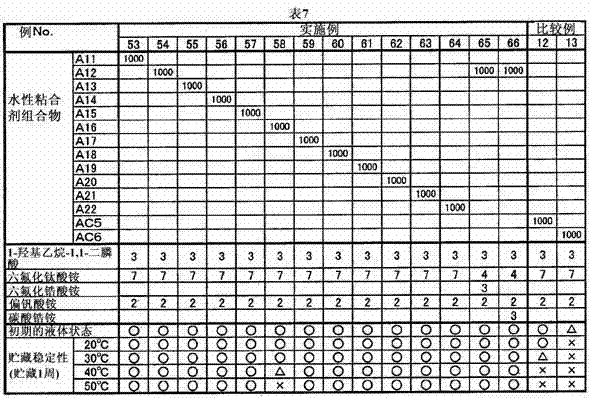

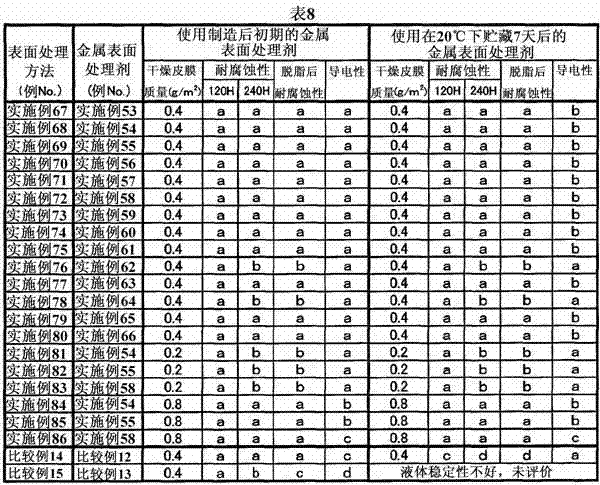

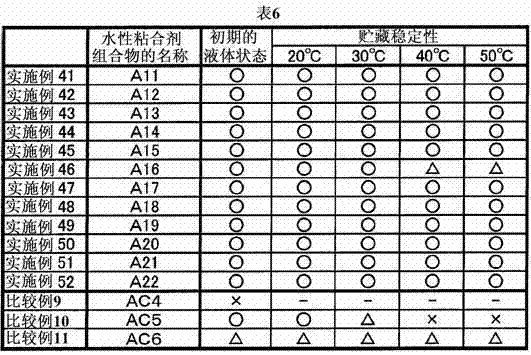

Nonchromate metallic surface treating agent for PCM use, method for PCM surface treatment, and treated PCM steel panel

InactiveUS20010037748A1Easy to processIncrease resistancePretreated surfacesSolid state diffusion coatingSilanesZirconium compounds

The present invention has for its object to provide a metallic surface treating agent for PCM use, which is capable of imparting high processability and corrosion resistance to PCM steel panels with the additional advantage of improved storage stability, a method for surface treatment of a PCM steel panel, a method of producing a PCM steel panel, and a PCM steel panel as produced by said method. This invention provides a nonchromate metallic surface treating agent for PCM use which comprises, in each liter thereof, (a) a silane coupling agent and / or a hydrolytic condensation product thereof in an amount of 0.01 to 100 g / l, (b) water-dispersible silica in a proportion of 0.05 to 100 g / l (solids), and (c) a zirconium compound in an amount of 0.01 to 50 g / l in terms of zirconium ion and / or a titanium compound in an amount of 0.01 to 50 g / l in terms of titanium ion.

Owner:NIPPON PAINT CO LTD

Surface-treated steel sheet for fuel tanks and method of fabricating same

InactiveUS6387538B1Improve cosmetic corrosion resistance and fuel corrosion resistanceImprove featuresLiquid surface applicatorsWax coatingsEpoxyColloidal silica

Owner:POHANG IRON & STEEL CO LTD

Novel non-chrome metal treatment composition

InactiveUS20060090818A1Anti-corrosive paintsLiquid/solution decomposition chemical coatingSilanesPhosphoric acid

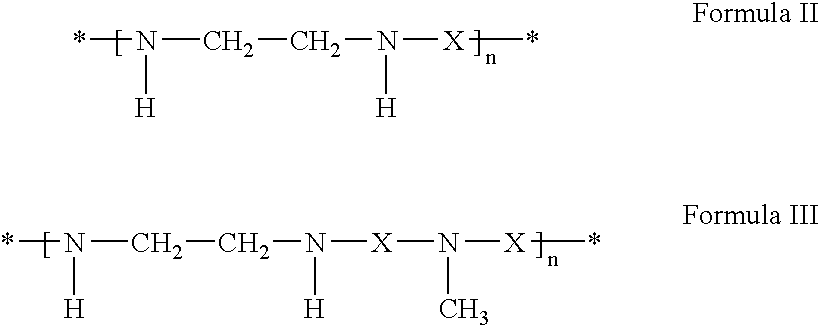

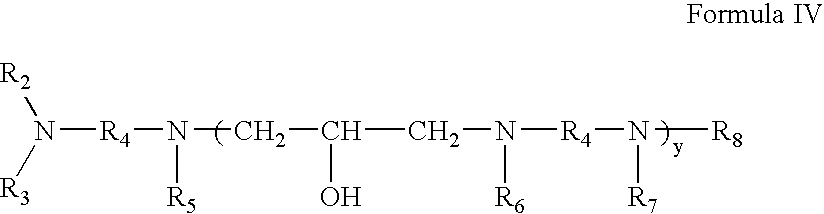

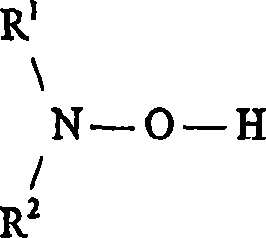

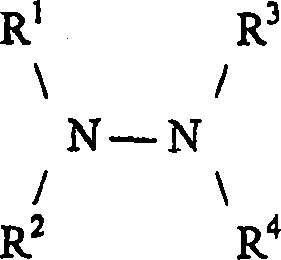

Chromate-free treatments and compositions for applying a conversion or passivation coating for metals, more particularly zinc coated metal surfaces. The methods of the invention comprise contacting the requisite metal surface with a phosphonomethylated polyamine. Other aspects of the invention involve methods and compositions in which the following optional components can be included: fluoacid, silane, inorganic phosphorus, acid, latex film forming component and pH adjustment agent.

Owner:CHEMETALL CORP

Metal surface processing composition

InactiveCN1396226AImprove corrosion resistanceExcellent adhesionLiquid surface applicatorsPolyurea/polyurethane coatingsResin acidSurface finishing

The present invention provides a metal surface treating composition. The metal surface treating composition contains (B) 1 to 100 pts.wt. silica particles, (C) 1 to 100 pts.wt. aziridinyl group- or oxazoline group- containing compound, (D) 0.5 to 30 pts.wt. vanadic acid compound and (E) 0.5 to 30 pts.wt. zirconium compound per (A) 100 pts.wt. carboxyl group- containing urethane resin of a resin acid value 5 to 50. The surface treating composition of a pollution-free type has the rust preventive power equivalent to that of chromate treatment and phosphate treatment. The present invention provides the armor plate which by the metal surface treating composition treating also.

Owner:KANSAI PAINT CO LTD

Sulfate dispersion chromate reducer

A chromium VI reducing composition comprising particles of solid material selected from the group consisting of iron (II) sulfate and tin sulfate, the particles being substantially uniformly dispersed within a liquid carrier. Methods for modifying hydratable cementitious materials using the chromium reducing composition are also disclosed and provide advantages over dry powder or dissolved forms of sulfate compositions when used in cement manufacturing.

Owner:WR GRACE & CO CONN

Chromate-Free Surface Treated Metal Material with Excellent Corrosion Resistance, Heat Resistance, Fingermark Resistance, Conductivity, Coatability, and Blackening Resistance at the Time of Working

InactiveUS20090110921A1Satisfy corrosion resistanceLayered productsMetallic material coating processesAdditive ingredientPhosphoric acid

The present invention provides a metal material given a chrome-free surface treatment satisfying all of the requirements of corrosion resistance, heat resistance, fingermark resistance, conductivity, coatability, and blackening resistance at the time of working, which was difficult to achieve with conventional chromate-free technology. The chromate-free surface treated metal material of the present invention is comprised of a metal material on the surface of which is coated and dried an aqueous metal surface treatment agent comprising an organic silicon compound (W), obtained by blending a silane coupling agent (A) containing one amino group in its molecule and a silane coupling agent (B) containing one glycidyl group in its molecule in a solid weight ratio [(A) / (B)] of 0.5 to 1.7, at least one type of fluorocompound (X) selected from fluorotitanic acid or fluorozirconic acid, phosphoric acid (Y), and a vanadium compound (Z) so as to form a composite coating containing the different ingredients.

Owner:NIPPON STEEL CORP

Water-based composite passivation solution for galvanized steel plate and preparation method of water-based composite passivation solution

InactiveCN104451641AImprove corrosion resistanceQuality improvementMetallic material coating processesWater basedChromium free

The invention relates to a water-based composite chromium-free passivation solution for a galvanized steel plate. The passivation solution contains 10-30g / L of sodium molybdate, 0-10g / L of sodium phosphate, 5-10g / L of organic phosphoric acid, 1-10g / L of fluotitanic acid, 5-15g / L of a silane coupling agent, 5-20g / L of sodium metasilicate, 0.1-1% of a wetting dispersant and the balance of deionized water. The passivation solution provided by the invention consists of an organic phosphoric acid-molybdate system in match with the modified hydrolysis type silane coupling agent and a nano-inorganic filler, does not contain a chromate and is in line with ROHS requirements; the passivation and drying curing time is short, the degree of stability is high, the quality of a film layer is good, the white rust area in a 72h salt fog test does not exceed 5%, the cost is relatively low, a passivation process device does not need to be changed, and continuous passivation can be realized by using a hexavalent chromium passivation device in early period.

Owner:北京蓝星清洗有限公司

Aqueous binder composition for metal surface treatment agents

InactiveCN103946421AAvoid condensationImprove stabilityAnti-corrosive paintsMetallic material coating processesSiliconMetal

The present invention provides an aqueous binder composition for chromate-free metal surface treatment agents that have excellent coatability and liquid stability and are capable of forming a surface treatment film having excellent corrosion resistance, adhesiveness and electrical conductivity. This aqueous binder composition for metal surface treatment agents contains: a reaction product of a silane coupling agent containing an amino group and a silane coupling agent containing an epoxy group, or a reaction product of the above-described silane coupling agents and an alkoxysilane compound such as trialkoxysilane wherein a hydrocarbon group such as an alkyl group is directly bonded to a silicon atom; a specific acid compound; and water.

Owner:KANSAI PAINT CO LTD

Corrosion inhibitor and using method thereof

The invention discloses a corrosion inhibitor and a using method thereof. The corrosion inhibitor is prepared from the following components including silica, oxygen-containing metal salt, a surfactant, organic siloxane and a solvent. The corrosion inhibitor does not contain toxic and harmful substances including chromate, nitrite and organic phosphine, and the metal surface subjected to coating treatment is good in corrosion resistance and finger resistant effect. The corrosion inhibitor is cheap, easily available, environmentally friendly and efficient as well as is simple and convenient in using method, good in stability and strong in practicability.

Owner:XIAMEN RUNNER IND CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com