Copper and lead separating cyanide-chrome-free beneficiation method for low-grade multi-metal sulfide ore

A copper-lead separation, cyanide-free and chromium-free technology, applied in solid separation, flotation, etc., can solve environmental pollution and other problems, achieve stable technical and economic indicators, easy process control, and improve the effect of return water utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

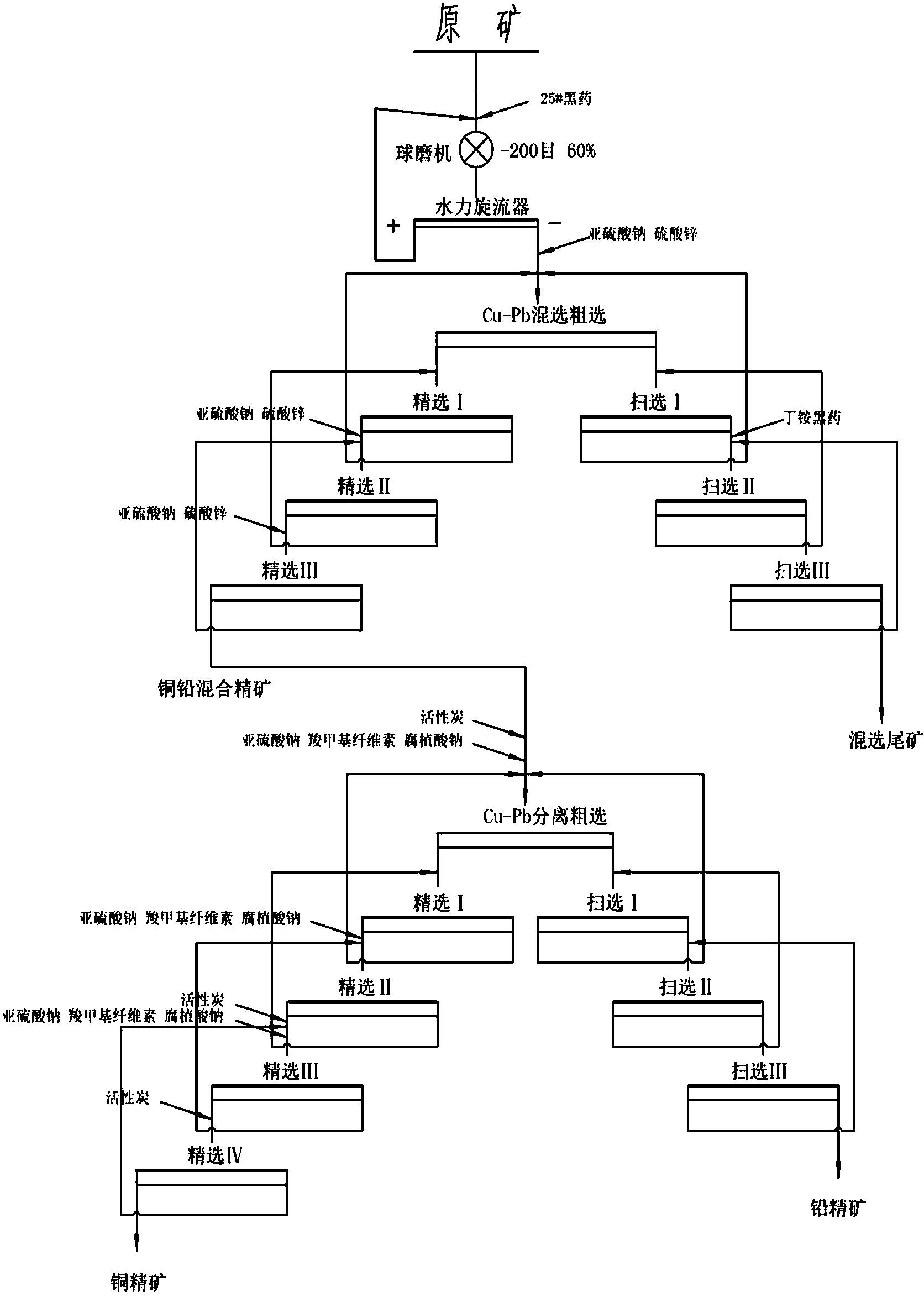

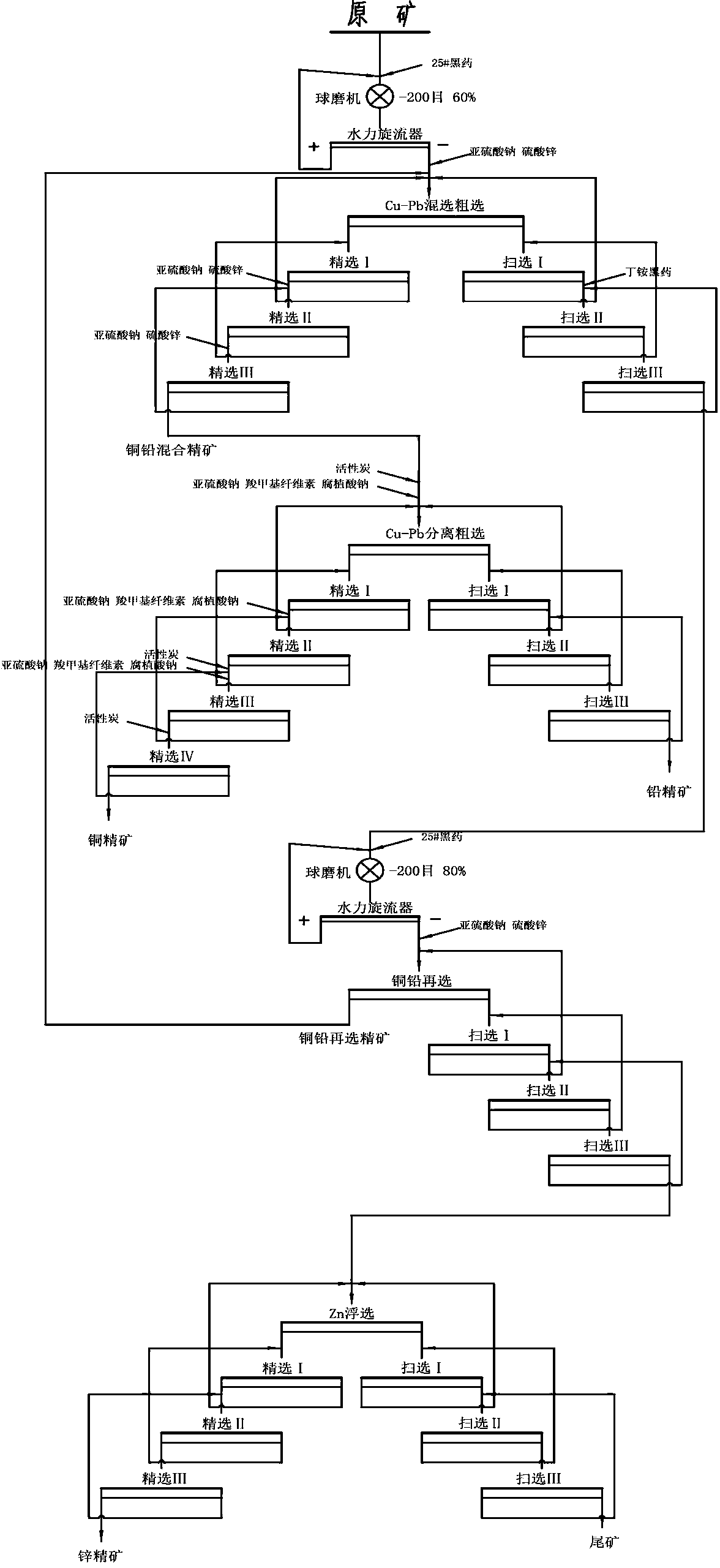

[0031] Copper-lead separation process of a low-grade copper-lead-zinc sulfide ore in Inner Mongolia. The raw ore contains 0.10-0.16% copper, 1.0-2.5% lead, and 2.0-2.5% zinc. The grades of copper, lead and zinc in the raw ore are low, and the useful minerals are embedded The situation is complicated. There are many kinds of copper minerals in the ore, the disseminated particle size of useful minerals is fine, and the symbiotic relationship is close, so it is difficult to separate copper and lead metals. The process adopts priority grinding and classification-copper and lead mixed flotation-regrinding and classification-copper and lead re-election-copper and lead separation-zinc flotation.

[0032] The raw ore is ground and graded into copper-lead mixed flotation to obtain copper-lead mixed concentrate and mixed flotation tailings, and the mixed flotation tailings are re-grinded and graded into the copper-lead re-election process to obtain copper-lead re-election concentrate and...

Embodiment 2

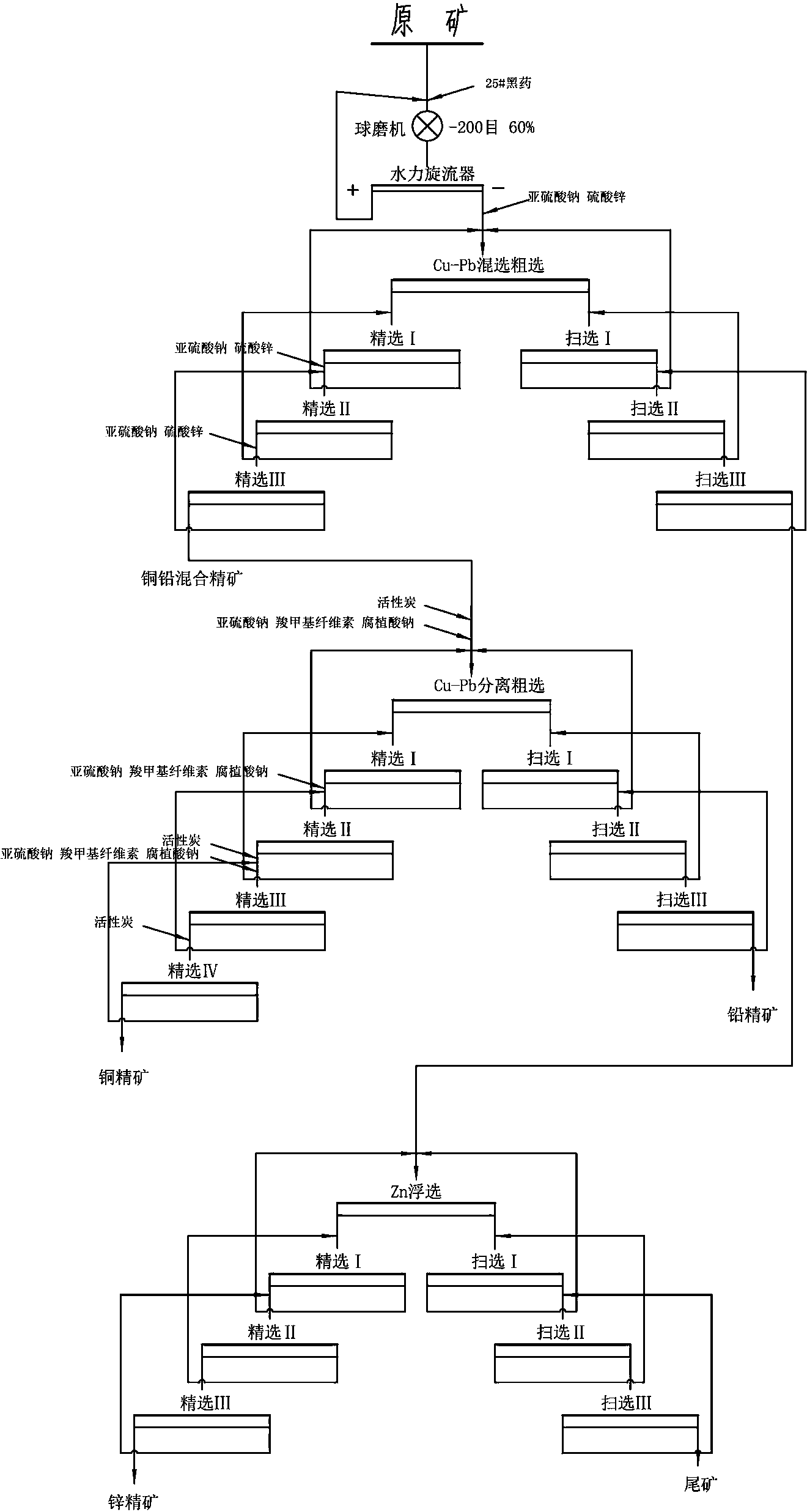

[0037] During the copper-lead separation process of a low-grade copper-lead-zinc sulfide ore in Inner Mongolia, the raw ore contains 0.10-0.16% copper, 2.5-3.5% lead, and 3.5-4.5% zinc. There are many types of minerals, fine particle size of useful minerals, close symbiotic relationship, and difficult separation of copper and lead metals. The process adopts grinding and classification-copper-lead mixed flotation-copper-lead separation-zinc flotation.

[0038] The raw ore is ground and classified into copper-lead mixed flotation to obtain copper-lead mixed concentrate and mixed tailings, and the mixed-selected tailings are subjected to zinc flotation to obtain zinc concentrate and final tailings, and copper-lead mixed concentrate is separated by copper and lead Qualified copper concentrate and lead concentrate are obtained by flotation. In the process of copper-lead mixed flotation, the ore dressing agent 25# black medicine is used as the collector of copper-lead minerals, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com