Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

278 results about "Alpha-Cyclodextrin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Α-Cyclodextrin is a hexasaccharide derived from glucose. It is related to the β- (beta) and γ- (gamma)cyclodextrins, which contain seven and eight glucose units, respectively. All cyclodextrins are white, water-soluble solids with minimal toxicity. Cyclodextrins tend to bind other molecules in their quasi-cylindrical interiors. This inclusion (and release) behavior leads to applications in medicine. The compound is of wide interest because it exhibits host–guest properties, forming inclusion compounds.

Compositions comprising dietary fat complexer and methods for their use

InactiveUS6890549B2Decrease in levelTotal calories lowPowder deliveryOrganic active ingredientsHigh densityBioavailability

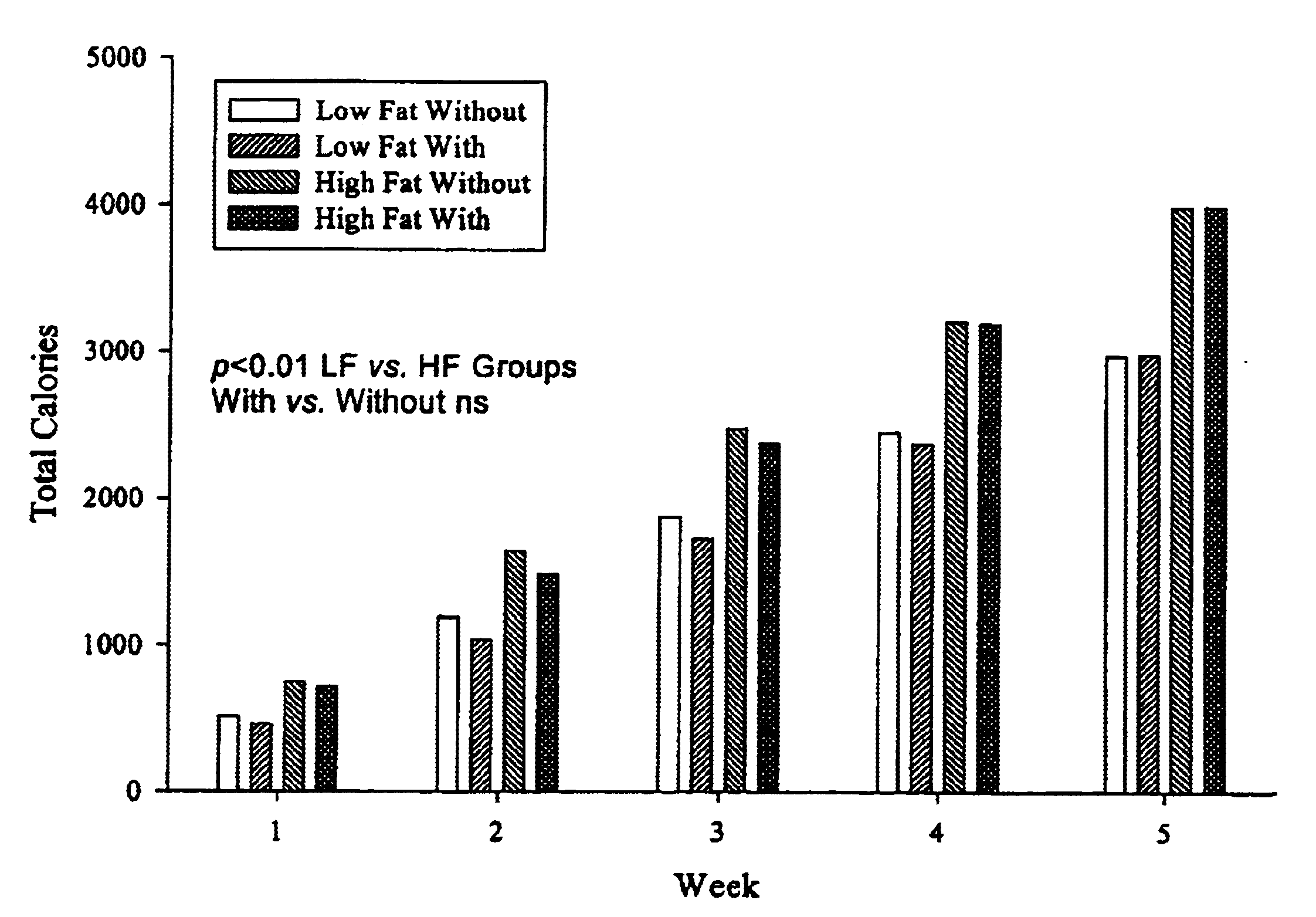

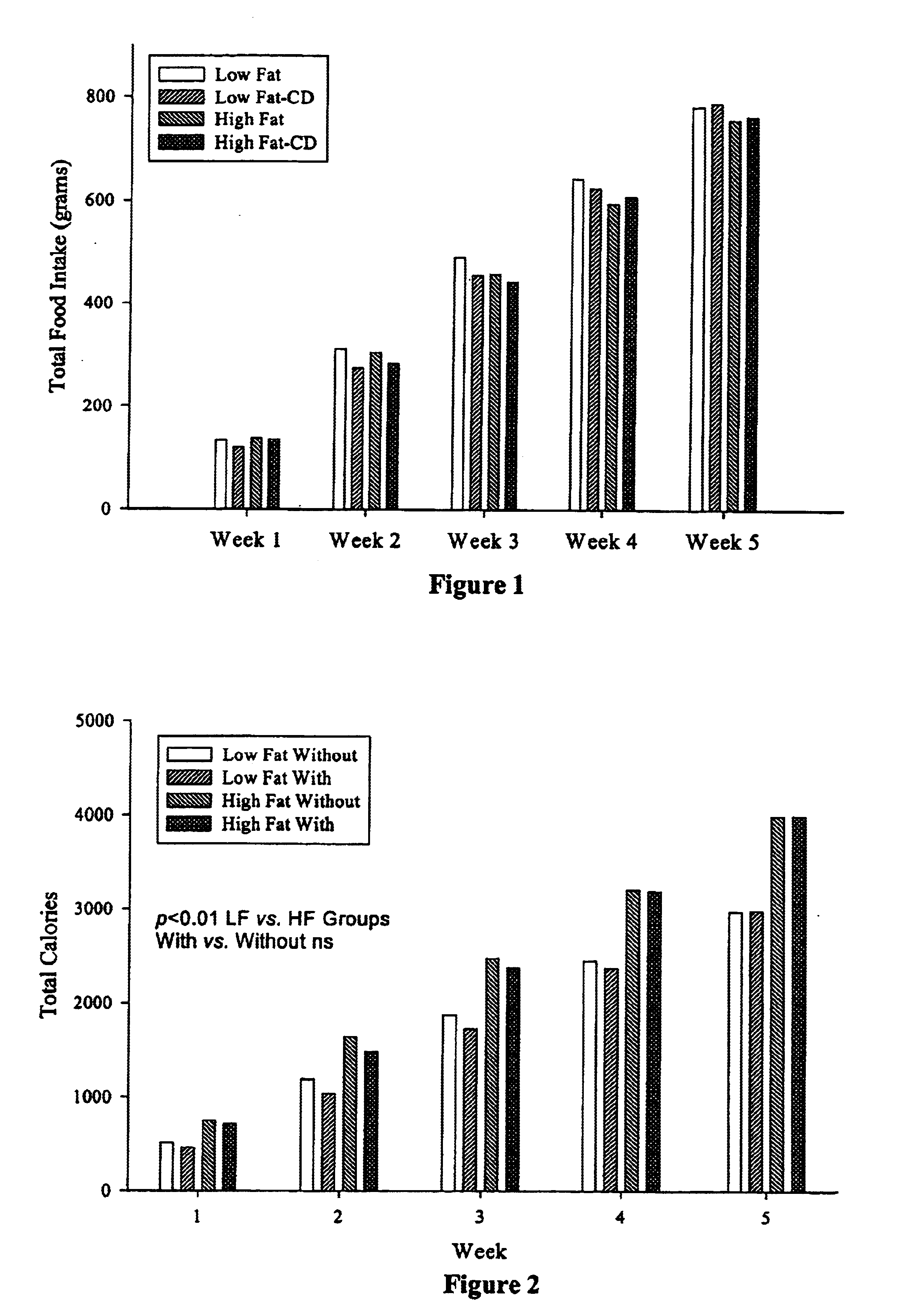

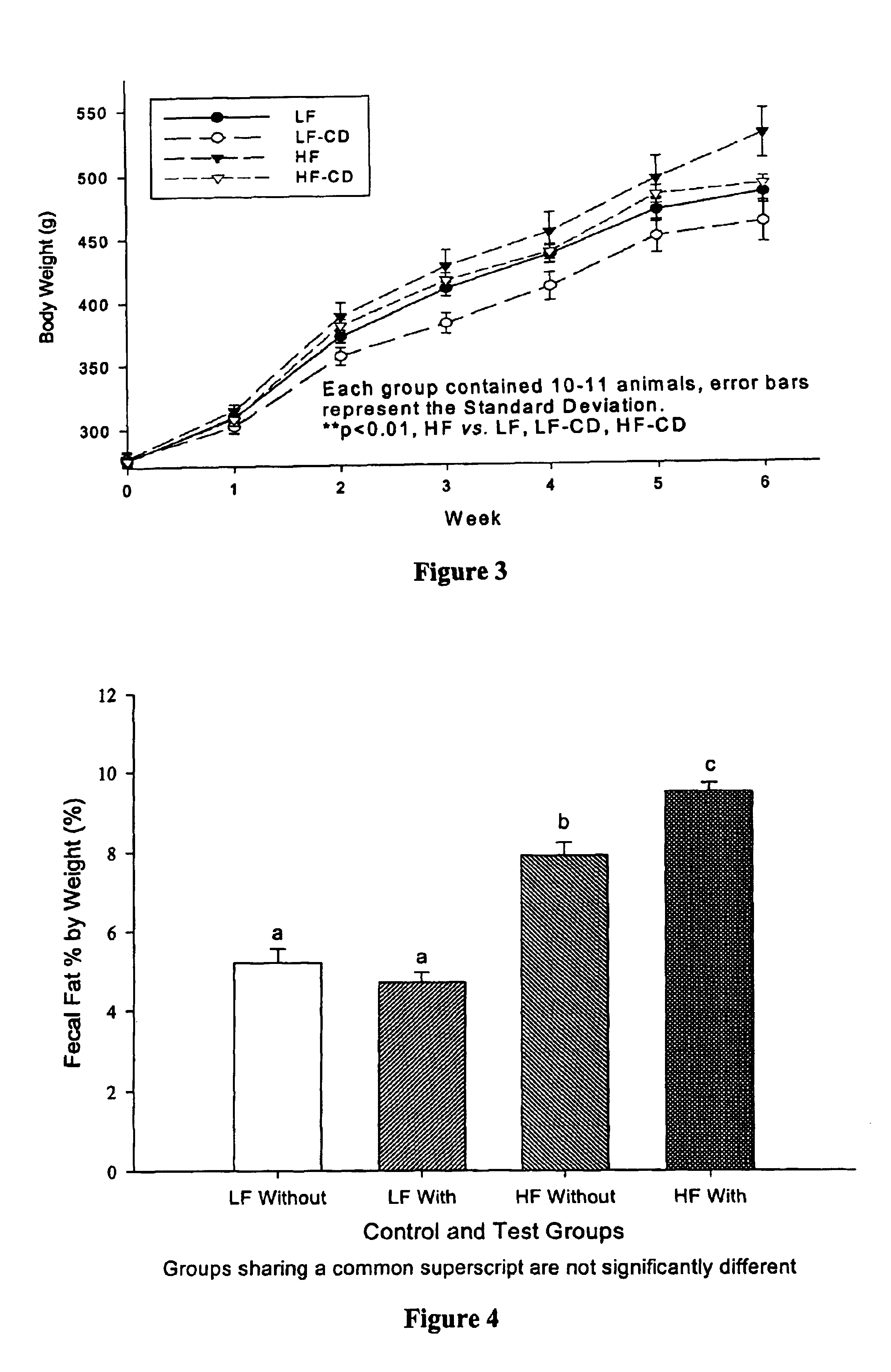

This invention relates to fat containing consumable food products comprising α-cyclodextrin. The food products have reduced levels of bioavailable fat but have substantially the same fat, cholesterol and caloric content as a like food without α-cyclodextrin. The invention also relates to methods for reducing the bioavailability of fats in fat containing food products without reducing caloric intake as determined by bomb calorimetry and to methods for increasing high density lipoproteins in a subject and reducing or controlling weight by administering the food products of this invention.

Owner:SOHO FLORDIS INT

Cyclodextrins in dental products

InactiveUS6942848B2Reduce developmentReduce the populationOrganic active ingredientsCosmetic preparationsTriclosanMethyl salicylate

Oral rinse and dentifrice compositions, comprising a phenolic selected from the group consisting of menthol, eucalyptol, methyl salicylate, thymol, triclosan, and mixtures thereof; and a cyclodextrin selected from the group consisting of hydroxypropyl β-cyclodextrin, hydroxyethyl β-cyclodextrin, hydroxypropyl γ-cyclodextrin, hydroxyethyl γ-cyclodextrin, α-cyclodextrin, methyl β-cyclodextrin, and mixtures thereof. These compositions are useful in retarding the development of plaque, treating gingivitis, and in treating the presence of micro-organisms in the oral cavity.

Owner:MCNEIL PPC INC

Gasified Food Products and Methods of Preparation Thereof

InactiveUS20080069924A1Good water solubilityImprove production efficiencyDough treatmentFrozen sweetsHot cerealFood products

The present invention provides a gasified food product comprising a solid-gas clathrate and methods for making the same. The solid-gas clathrates used in the present invention are selected from the group consisting of an α-cyclodextrin-gas clathrate and a derivative thereof. Furthermore, the present invention provides food products such as a powdered coffee mix, dough, sauce, soup, hot cereal and the like comprising the solid-gas clathrate.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

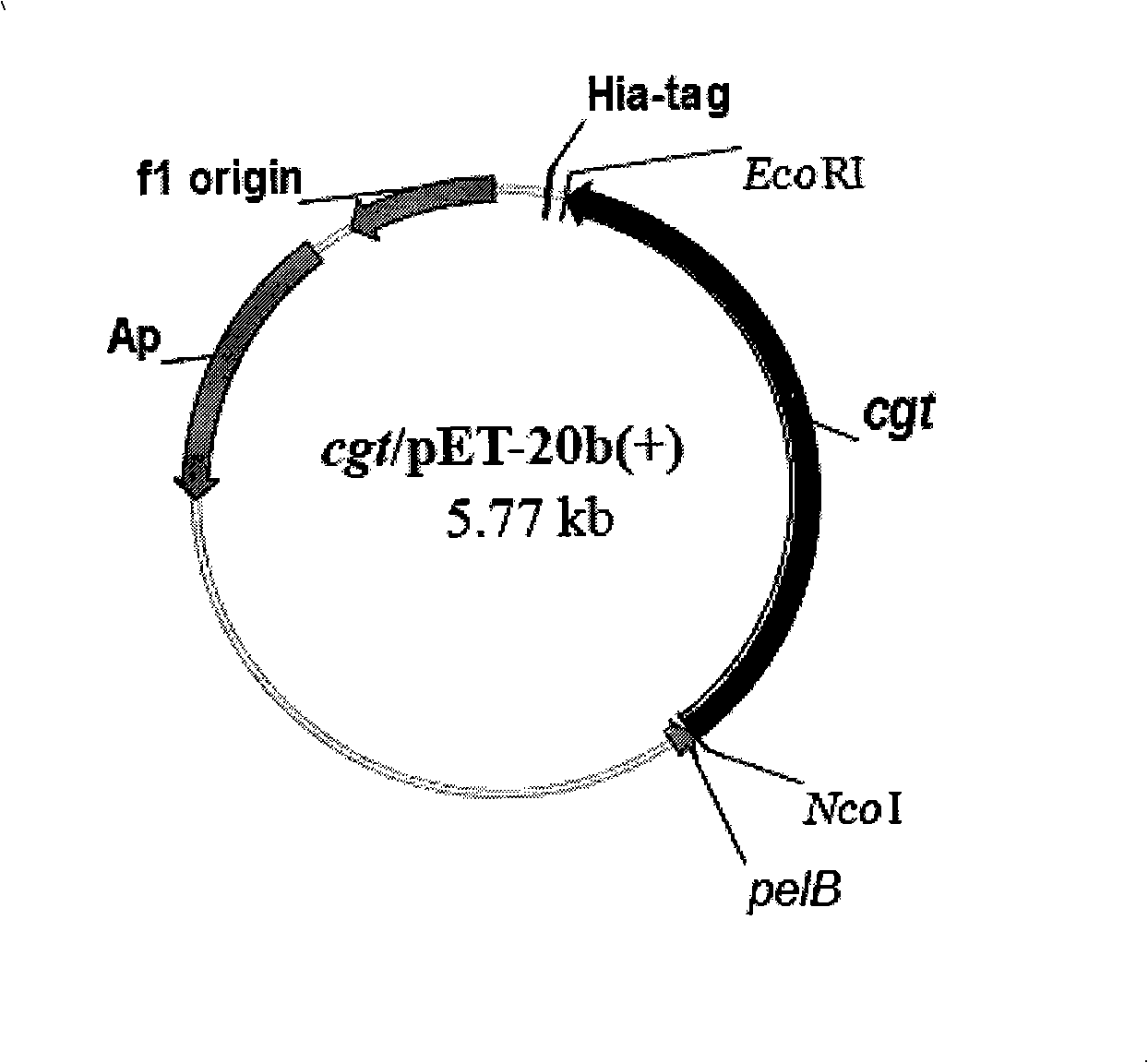

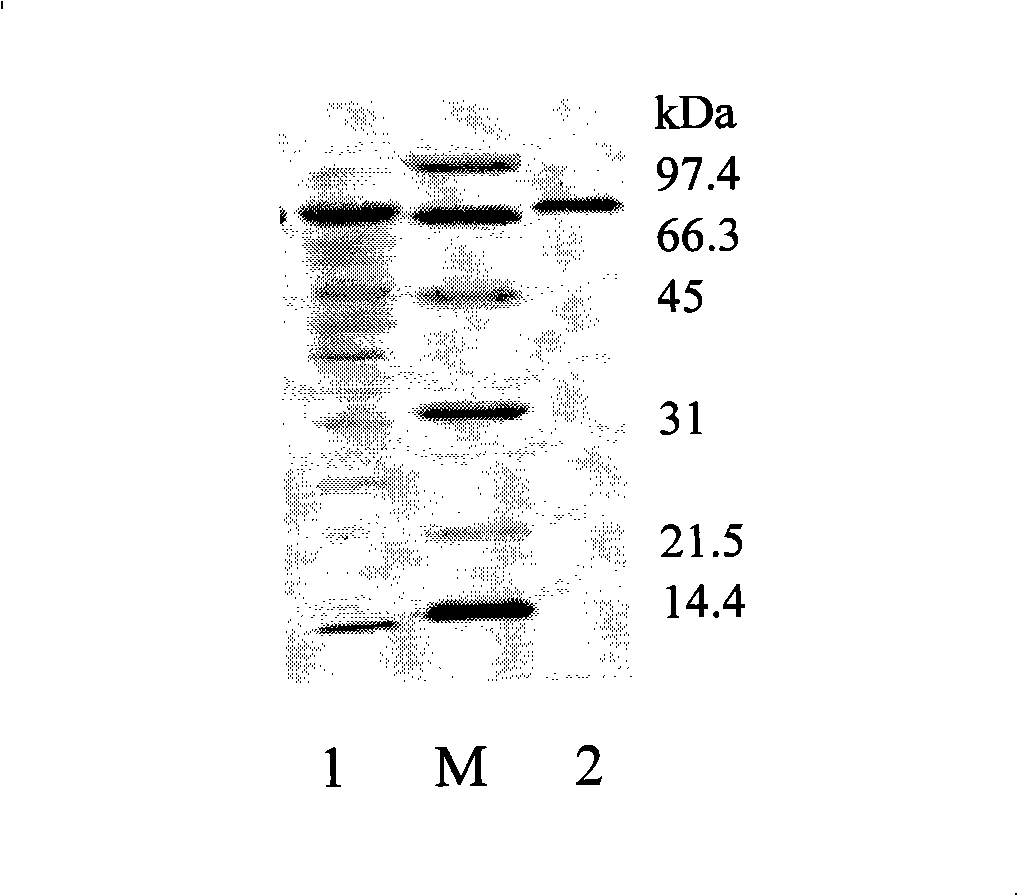

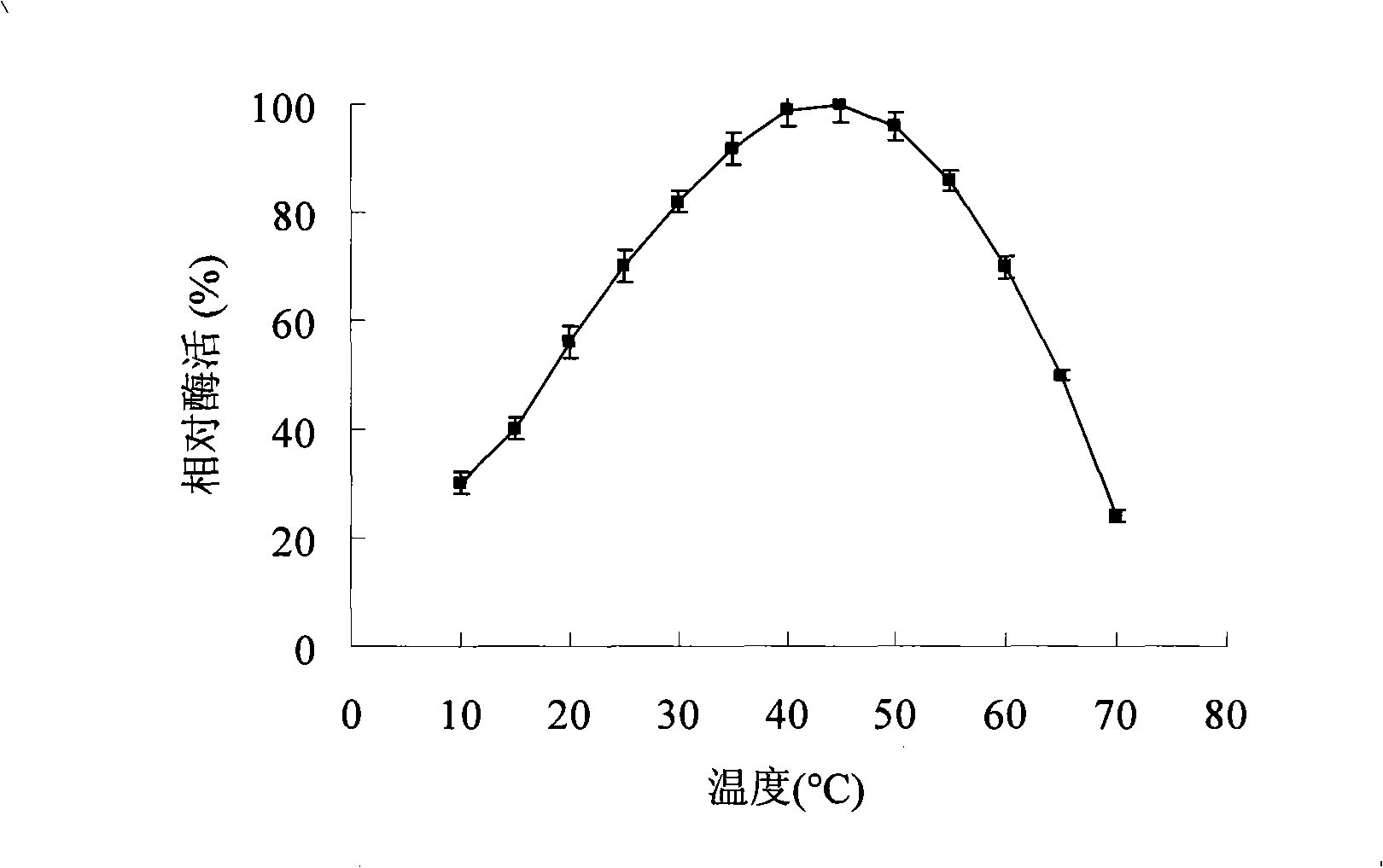

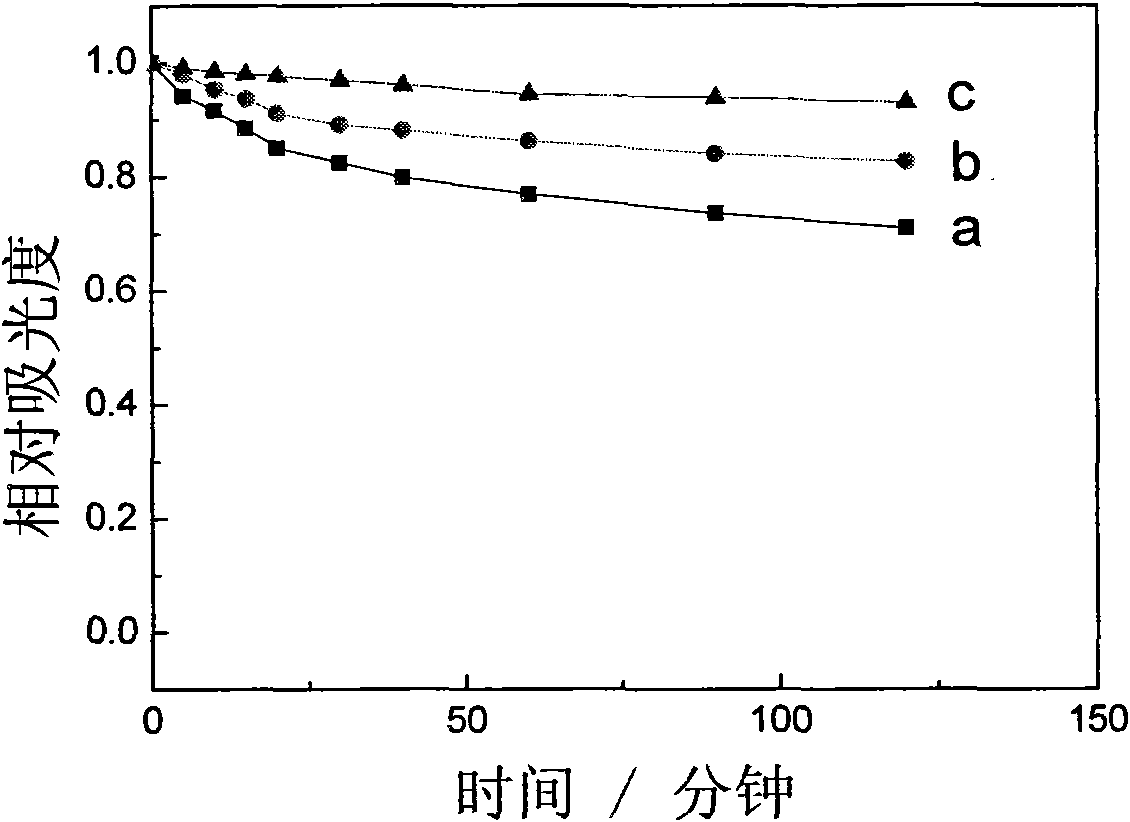

Alpha-cyclodextrin glucosyl transferase gene clone and expression

InactiveCN101294149ACyclization activityImprove thermal stabilityTransferasesFermentationEscherichia coliEnzyme Gene

The invention relates to the clone and the expression of alpha-cyclodextrin glycosyltransferase (alpha-CGTase), which belong to the field of enzyme gene engineering and enzyme engineering. The cgt gene expression method comprises the following steps: obtaining cgt gene SEQ ID NO:1 from total DNA of Peanibacillus macerans JFB05-01; selecting plasmid pET20b(+) as the expression vector of cgt gene; and selecting E.coli BL21(DE3) as the expression host to achieve high-efficiency extracellular expression of the cgt gene, wherein the cgt gene has 2,061 nucleotides and 687 coded amino acids; prokaryotic expression plasmid is constructed; and alpha-CGTase is expressed by transformed E.coli. Recombinase has cyclization activity and can transform starch and relevant matrix into cyclodextrin. The recombined alpha-CGTase has an optimal temperature of 40 to 45 DEG C and an optimal pH value of 5.5, and has higher thermal stability below 40 DEG C and poor thermal stability above 50 DEG C. The alpha-CGTase meets the requirement for industrial application such as food and medicines, and can be used for industrial production of alpha-cyclodextrin and beta-cyclodextrin.

Owner:JIANGNAN UNIV

Antibacterial supermolecule aquogel and preparation method and application thereof

InactiveCN101564400AEasy to prepareEasy to operateAntibacterial agentsInorganic active ingredientsBiocompatibility TestingSILVER NITRATE CRYSTALS

The invention discloses a method for in-situ preparing antibacterial supermolecule aquogel. The method comprises the following operation steps: silver nitrate crystal and polyethyleneglycol-polypropylene glycol-polyethyleneglycol triblock copolymer solution are mixed and stirred to obtain mixed solution; the steps of stirring the mixed solution for 15 minutes and ultrasonically dispersing the mixed solution for 5 minutes are alternatively carried out for 2-4 hours to obtain nano silver sol; and the nano silver sol and Alpha-cyclodextrin solution are mixed, stirred and stands at the room temperature to obtain hydrogel. The hydrogel can be used for preparing injectable drug carriers. The invention has the advantages of simple operation, adjustable gel strength and the gelation time, room temperature forming, no involvement of chemical cross linking reaction and the usage of organic solvent, favorable biocompatibility and antibacterial property of obtained gel, and the like and is prospective to be widely applied in the field of biomedical engineering materials.

Owner:SUN YAT SEN UNIV

Photosensitive hydrogel containing cyclodextrin and azobenzene and preparation method of photosensitive hydrogel

The invention discloses a preparation method of a photosensitive hydrogel containing a cyclodextrin and an azobenzene. The method comprises the following steps: mixing polyethylene glycol PEG10K with an Alpha-cyclodextrin so as to prepare a polyrotaxane hydrogel; then, adding water-soluble dendrimers Me-G2-Azo into the polyrotaxane hydrogel so as to convert the hydrogel into sol; and reassembling and decomposing the sol under the alternate irradiation of ultraviolet light and visible light so as to prepare the photosensitive hydrogel containing the cyclodextrin and the azobenzene. The photosensitive hydrogel disclosed by the invention is a ternary system hydrogel which contains the Alpha-cyclodextrin, the polyethylene glycol (PEG10K) and the second generation of dendrimers (Me-G2-Azo) modified by the azobenzene. The photosensitive hydrogel disclosed by the invention is good in biocompatibility and easy to prepared, and can be applied to the fields of preparation of photoswitches, optically-controlled motors, release of optically-controlled medicines and the like.

Owner:EAST CHINA NORMAL UNIV

Prepn. of 1-methyl cyclopropene stable inclusion compound for fresh keeping of fruits and vegetables

ActiveCN1833494AHigh content of active ingredientsImprove freshnessDead plant preservationProduct gasReaction system

A stable inclusion compound for the antistaling purpose of fruit, vegetable, flower, plant, etc. is prepared from 1-methyl cyclopropene, starch and alpha-cyclodextrin or its derivative by using of a reaction system, which is composed of 1-methyl cyclopropene generator, three-pass gas washing unit, inclusion reactor and tail gas absorbing unit.

Owner:XI AN JIAOTONG UNIV +1

Composition Comprising Dietary Fat Complexer and Methods of Using Same

InactiveUS20090023682A1Unpleasant gastrointestinal side effects of lipase inhibitors are greatly reduced or eliminated.BiocideOrganic active ingredientsSide effectLipase inhibitors

A composition includes α-cyclodextrin and at least one lipase inhibitor. A method for promoting weight loss, inhibiting weight gain, or maintaining weight in a subject in need thereof includes administering α-cyclodextrin and at least one lipase inhibitor to the subject, thereby reducing the bioavailability of ingested fat and reducing the unpleasant gastrointestinal side effects.

Owner:ARTISS JOSEPH +1

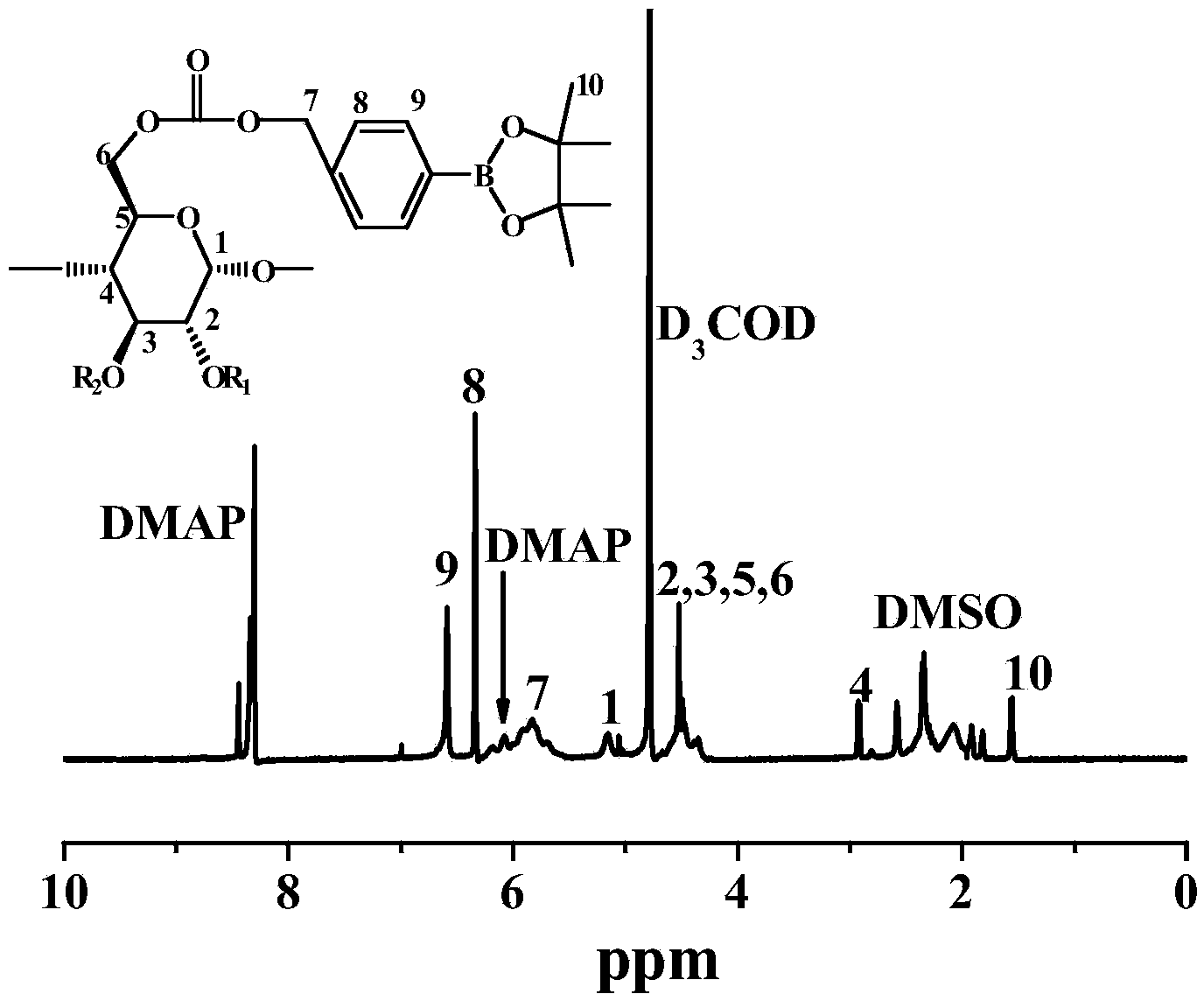

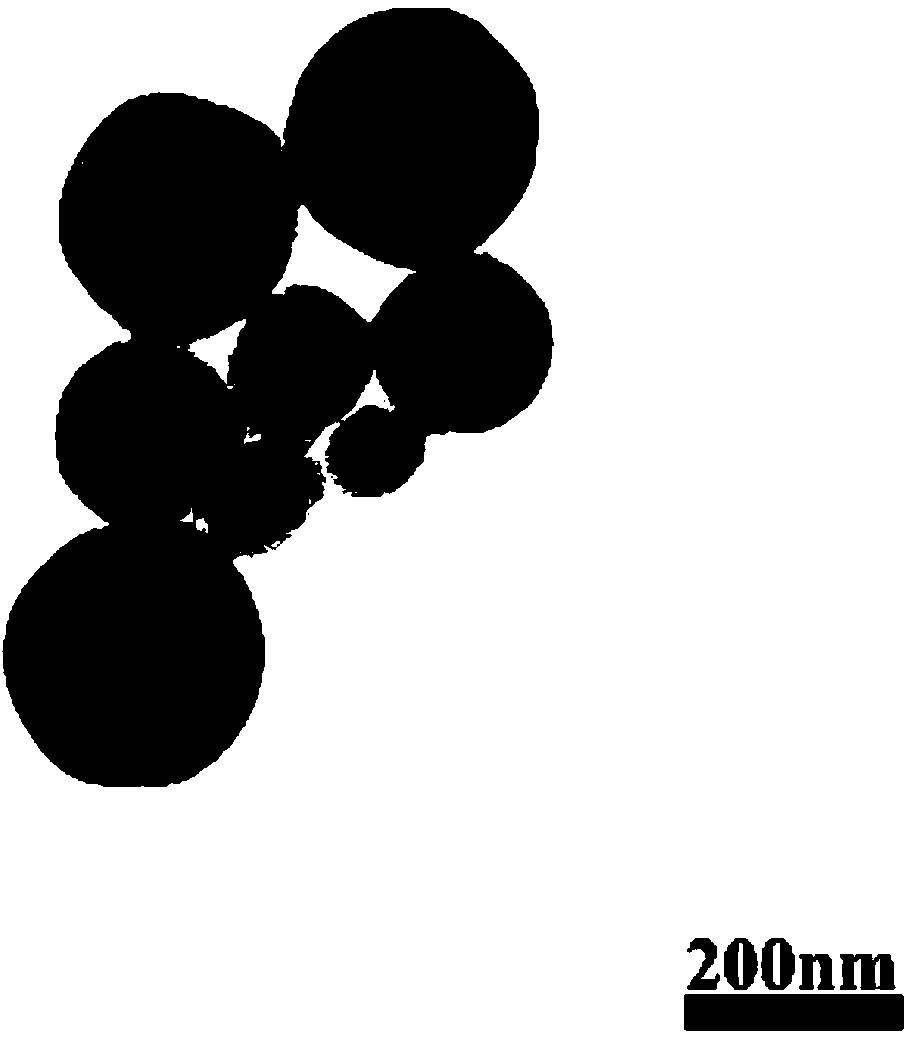

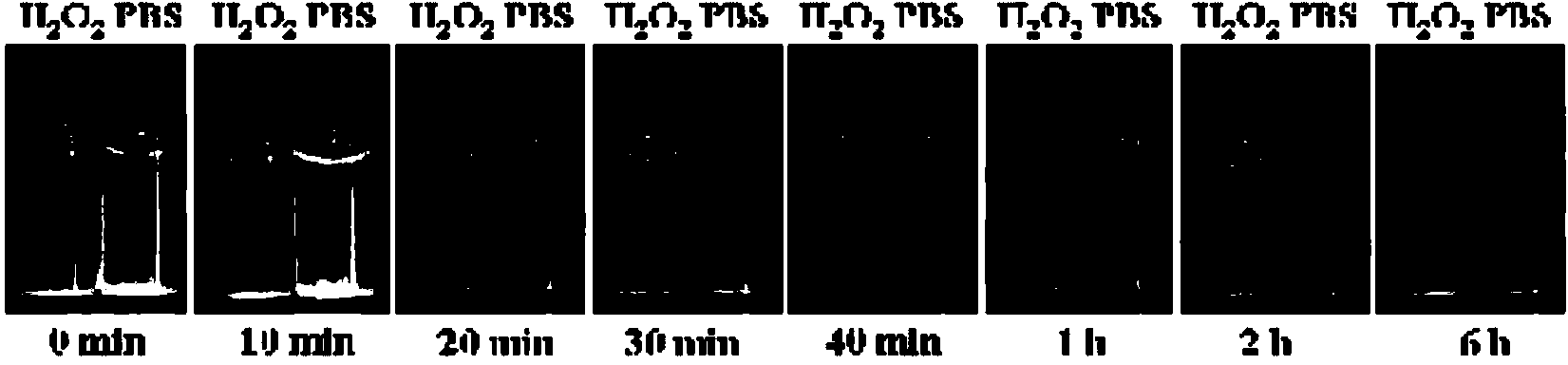

Active oxygen free radical sensitive cyclodextrin material as drug delivery carrier and preparation method thereof

ActiveCN103755839AGood in vivo biocompatibilityEasy to prepareMacromolecular non-active ingredientsChemical structureReactive oxygen radicals

The invention aims to provide an active oxygen free radical sensitive cyclodextrin material as a drug delivery carrier. The chemical structure of the cyclodextrin material is disclosed in the specification, wherein n is equal to 6, 7 or 8 which are respectively corresponding to active oxygen free radical sensitive alpha-cyclodextrin, beta-cyclodextrin or gamma-cyclodextrin material; R is -H or disclosed in the specification; and the glucose unit of each cyclodextrin molecule at least has one R group disclosed in the specification. The invention also provides a preparation method of the cyclodextrin material.

Owner:ARMY MEDICAL UNIV

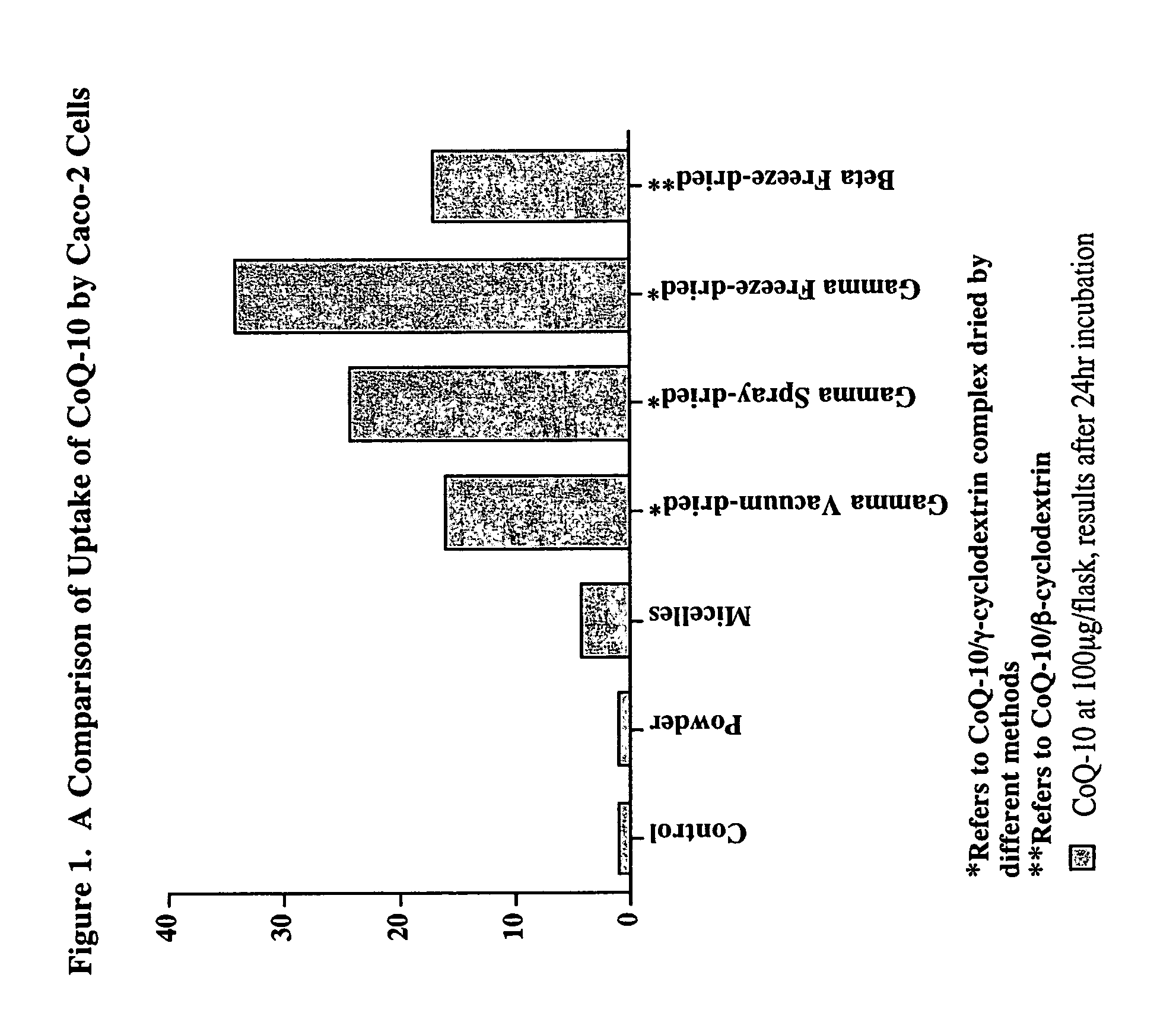

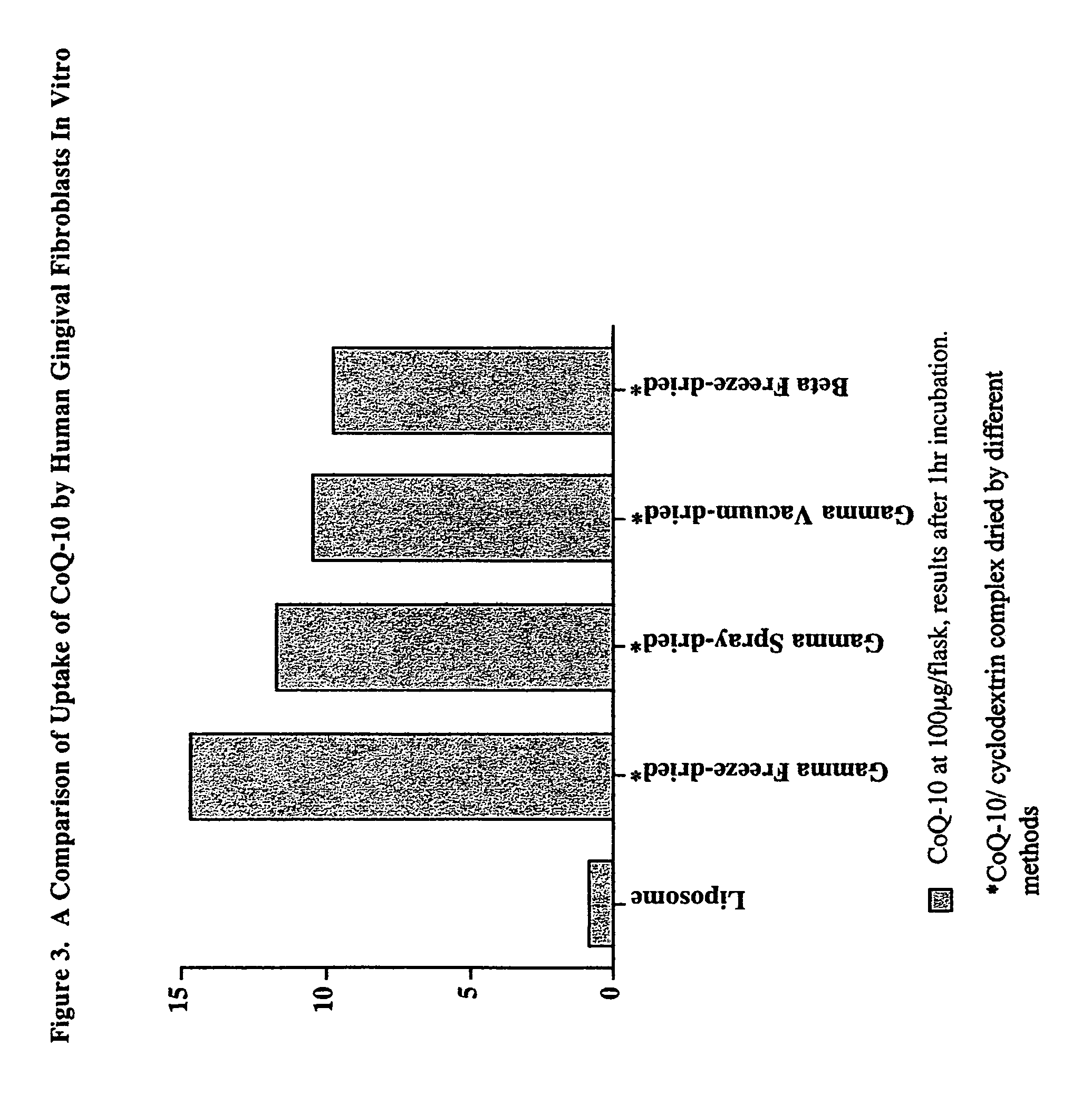

Highly bioavailable coenzyme Q-10 cyclodextrin complex

ActiveUS7030102B1Improve bioavailabilityImprove concentrationBiocideOrganic active ingredientsWater dispersibleFreeze-drying

The present invention is based on the unexpected discovery that CoQ-10 can be made commercially in a highly bioavailable form suitable for topical, sublingual formulations, or for oral ingestion. One such bioavailable form is a water dispersible freeze-dried CoQ-10 / γ-cyclodextrin complex. Complexation in general with γ- or α-cyclodextrin improved the cellular uptake of CoQ-10 as compared to water dispersible liposomal or micellar forms of CoQ-10. Thus, the present invention includes a highly bioavailable CoQ-10 / cyclodextrin complex for use in the nutritional supplement, oral care, and pharmaceutical industry.

Owner:BIOACTIVES

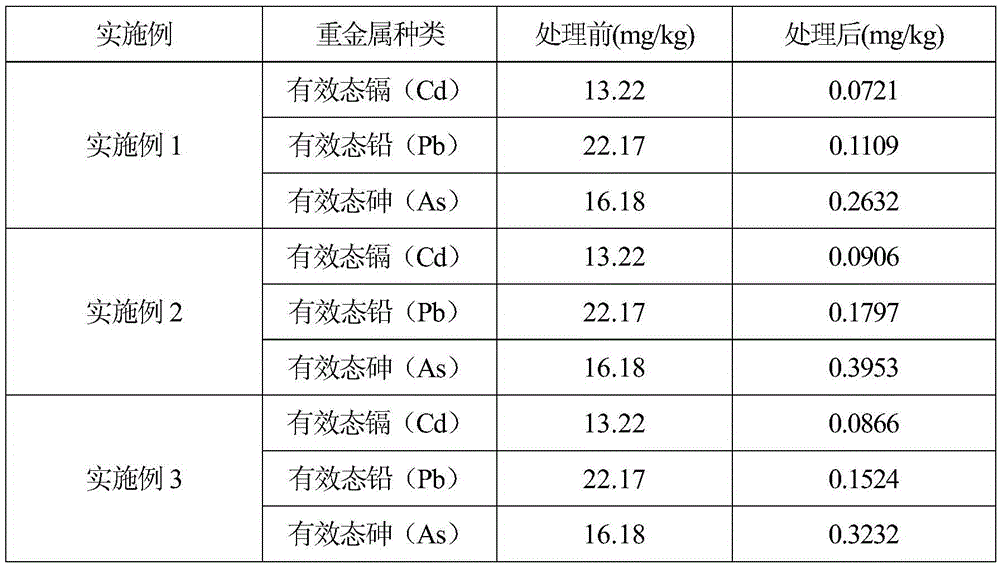

Remediation agent and application for combined contaminated soil

ActiveCN105583223AEasy to prepareGood governanceAgriculture tools and machinesOther chemical processesCalcium biphosphateSoil remediation

The invention provides a remediation agent and application for combined contaminated soil. The remediation agent is composed of, by weight, 30%-50% of biomass charcoal, 10%-20% of hydroxy calcium phosphate, 10%-20% of potassium humate, 10%-20% of alpha-cyclodextrin, 5%-10% of kieselguhr and 5%-10% of plant ash. The components give full play to the synergistic effect, through the effects of chelating, depositing, adsorbing, improving, PH value adjusting and the like, the content of available heavy metal in the soil is made to be decreased greatly, and the prepared soil remediation agent has a good effect during cadmium-lead-arsenic combined contaminated soil remedying. The remediation agent for the combined contaminated soil has the advantages that the preparation method is simple and practicable, and the remediation effect is good.

Owner:深圳润康生态环境股份有限公司

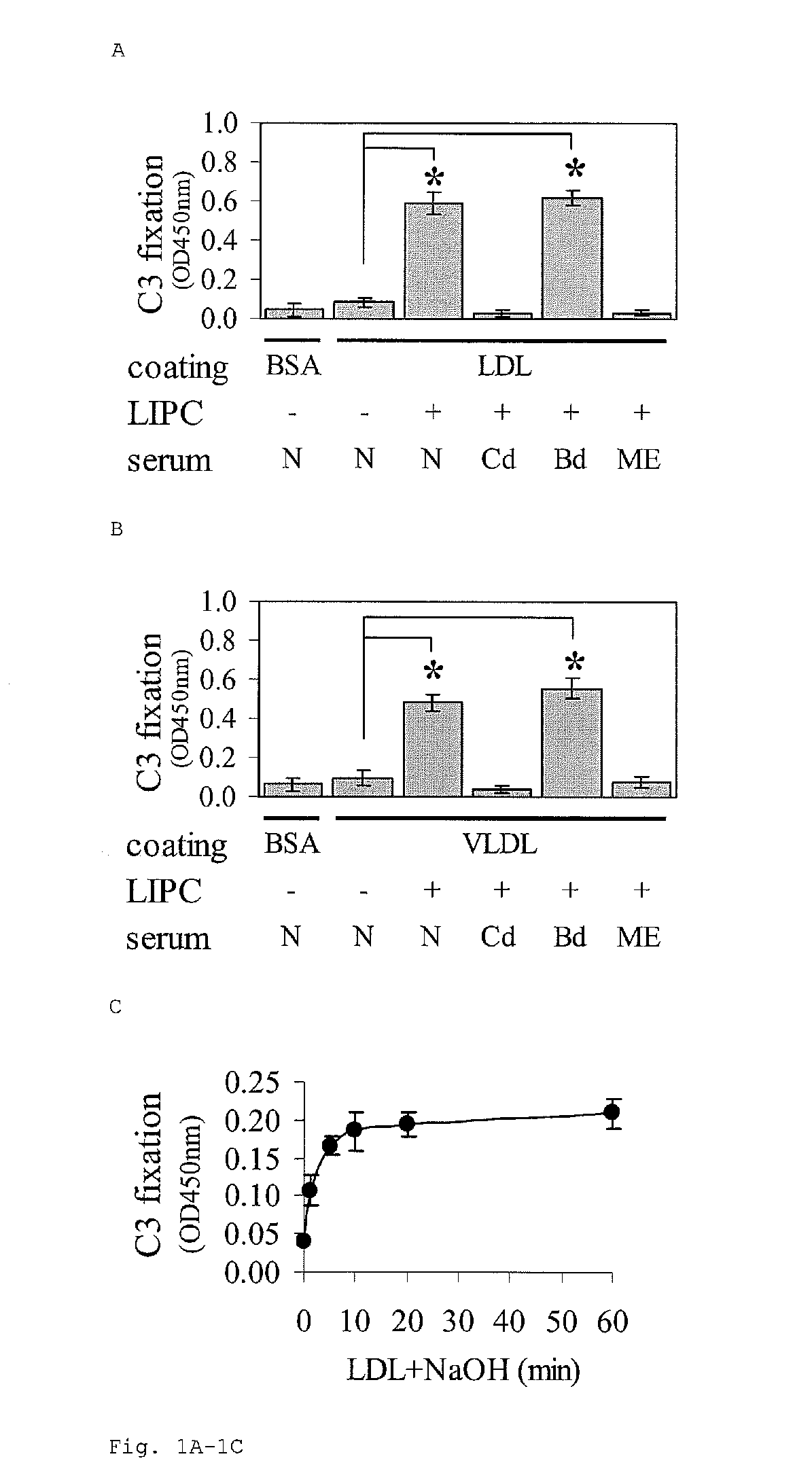

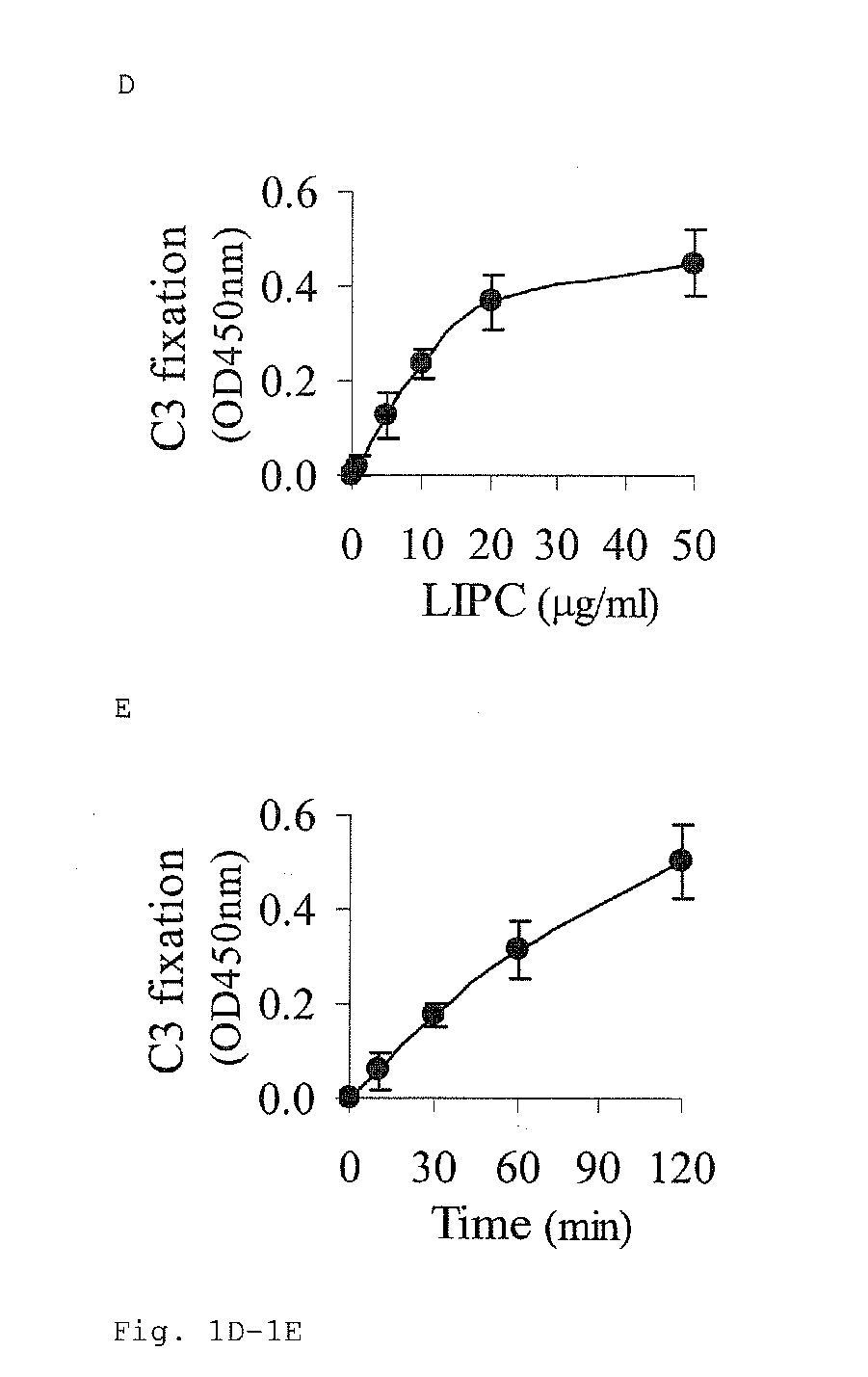

Clearance of bioactive lipids from membrane structures by cyclodextrins

The present invention provides a method of treating a subject suffering from wet acute macular degeneration which comprises administering to the subject an amount of a modified alpha cyclodextrin effective to treat the subject, wherein the modified alpha cyclodextrin binds to bioactive lipids which accumulate in the subject's eye and are characterized by the presence of a single chain of fatty acids.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK

Technology for producing alpha-cyclodextrins by biological method

ActiveCN101712972AImprove conversion rateLow costTransferasesMicroorganism based processesGlycosyltransferaseAlpha-cyclodextrin glycosyltransferase

Owner:JIANGNAN UNIV

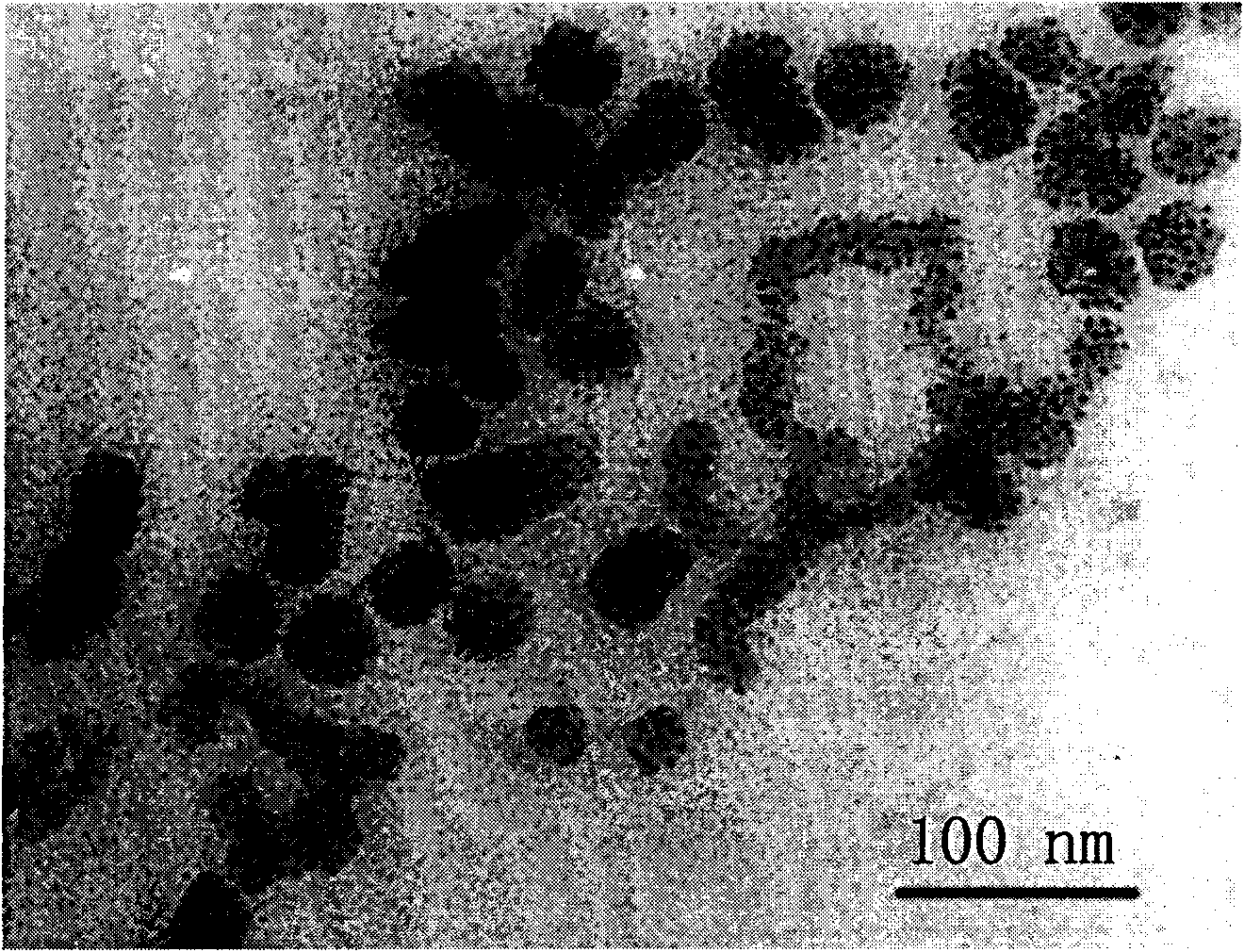

Functionalized Fe3O4 nano-particle and preparation method and application thereof

InactiveCN103041782ASimplified processing stepsImprove processing efficiencyOther chemical processesPreparing sample for investigationPhosphateAqueous sodium hydroxide

The invention discloses a functionalized Fe3O4 nano-particle and a preparation method and application of the functionalized Fe3O4 nano-particle. The preparation method comprises the following steps of: (1) under inert atmosphere, adding FeCl2 and FeCl3 into the mixed solution of sodium hydroxide aqueous solution and hydrochloric acid solution for reaction to obtain Fe3O4 nano-particles; and (2) reacting carboxymethyl-alpha-cyclodextrin with Fe3O4 nano-particles in PBS (Phosphate Buffer Solution), thereby obtaining the functionalized Fe3O4 nano-particles. The Fe3O4 nano-particle modified by alpha-cyclodextrin provided by the invention can simultaneously have good enrichment and purification abilities to trace phenylarsonic acid in complex samples; and meanwhile, the Fe3O4 nano-particle is superparamagnetic, so that centrifugation is not needed in sample processing, the pretreatment procedures of the sample are greatly simplified, the pretreatment time is shortened, and the pretreatment efficiency of the sample is improved.

Owner:INST OF QUALITY STANDARD & TESTING TECH FOR AGRO PROD OF CAAS

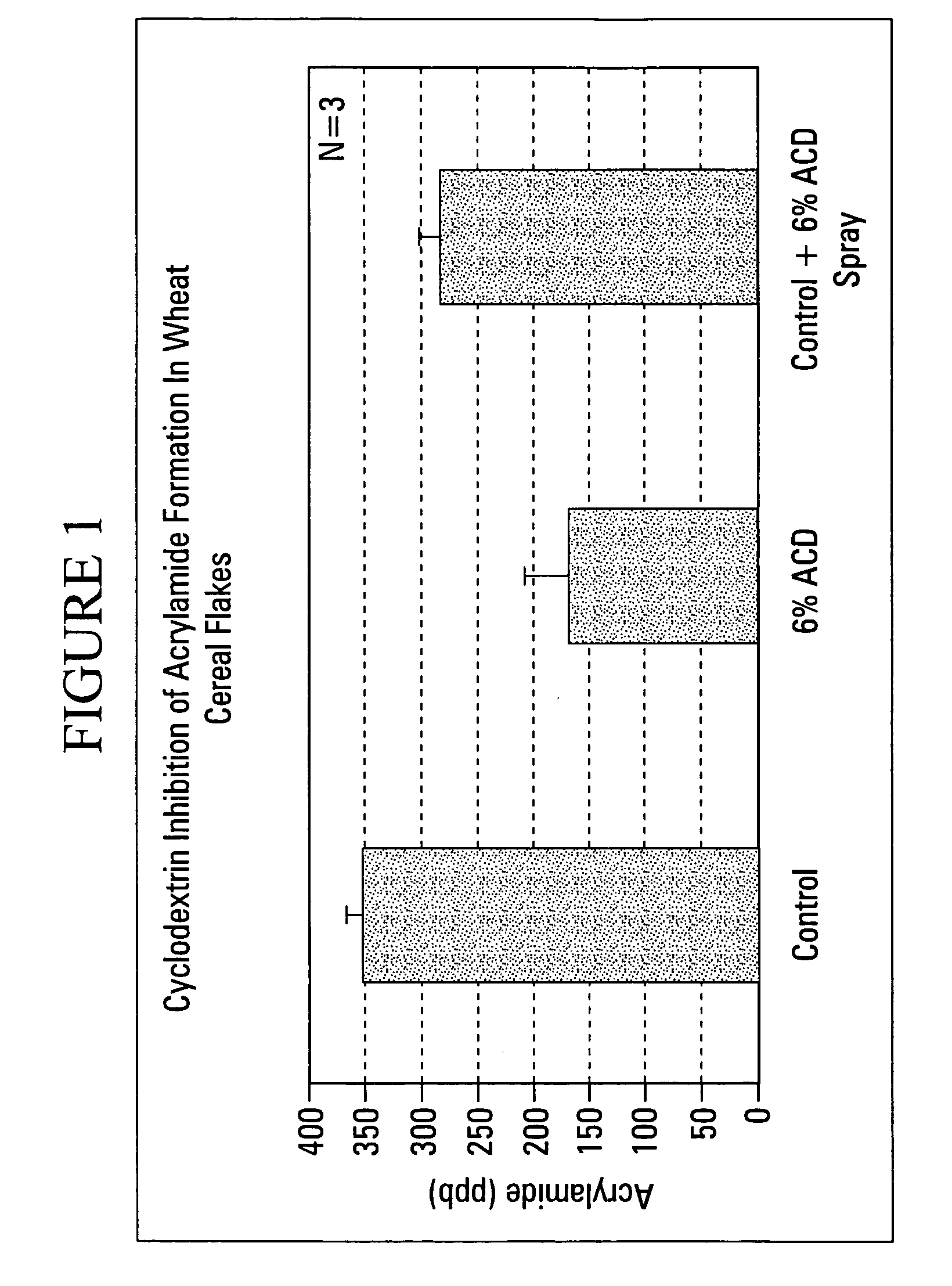

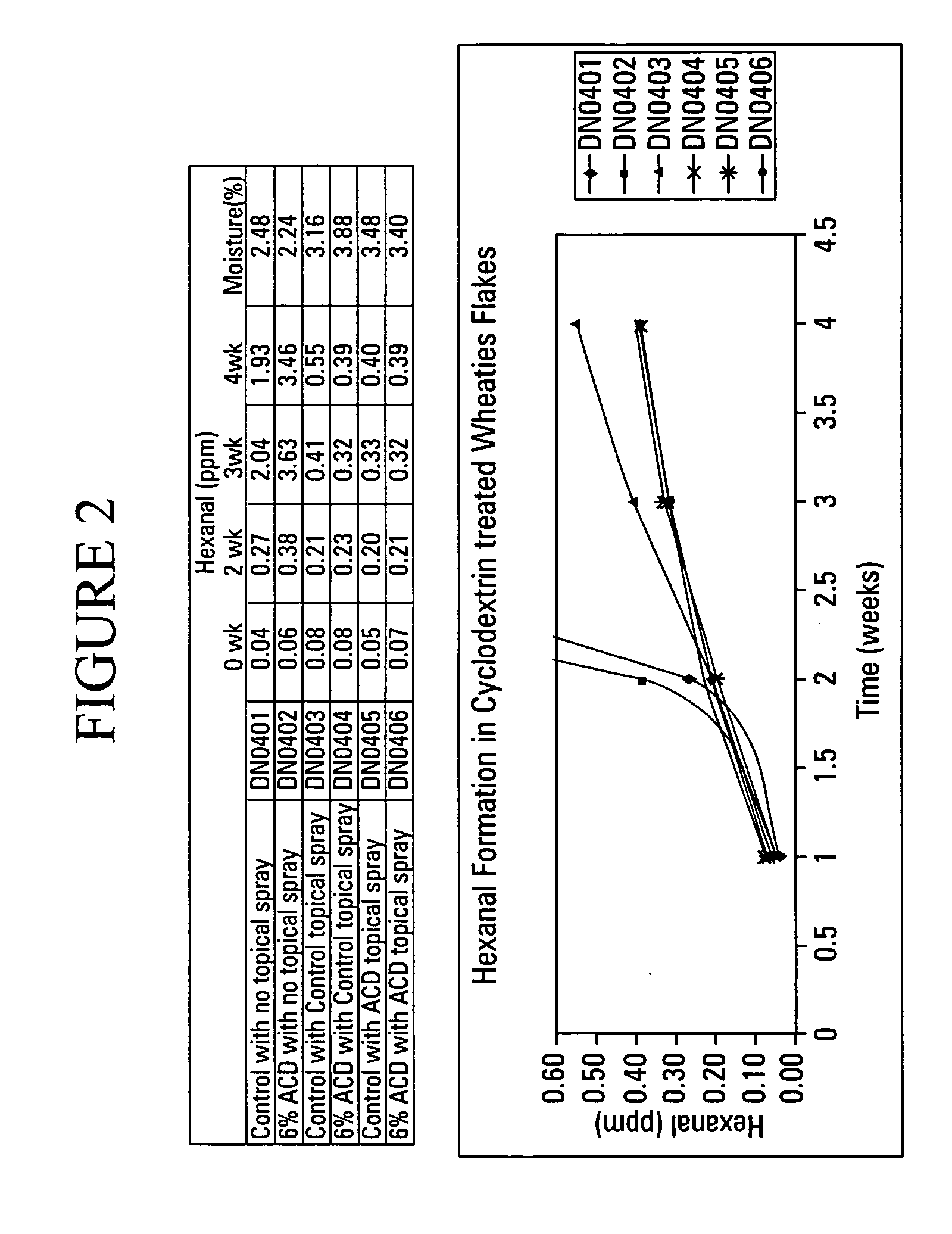

Treatment composition for reducing acrylamide in food products and food intermediates

InactiveUS20050025875A1Reduce acrylamide contentAvoid reactionMilk preservationFruit and vegetables preservationBeta-CyclodextrinsFood products

The present invention relates to a novel treatment composition for use in treating food products and food intermediates. The treatment composition may be used in single, home use settings as well as commercial applications for larger scale treatment of food products in the course of manufacture. The treatment composition of the present invention uses at least one of alpha-cyclodextrin, beta-cyclodextrin, gamma-cyclodextrin or combinations and modified derivatives thereof along with a suitable carrier such as in an aerosol, liquefied mister and the like.

Owner:GENERAL MILLS INC

Curcumin and mixed-cyclodextrin inclusion compound and preparation method thereof

InactiveCN103272245AHigh inclusion rateImprove solubilityMetabolism disorderDigestive systemAqueous solutionBeta-Cyclodextrins

The invention belongs to the technical field of medicines, and in particular relates to a curcumin and mixed-cyclodextrin inclusion compound and a preparation method thereof. The technical scheme provided by the invention is as follows: an alpha-cyclodextrin, beta-cyclodextrin and gamma-cyclodextrin mixture and curcumin are adducted in a low-concentration ethanol-water solution, the inclusion rate is improved, and the dissolvability and the stability are enhanced.

Owner:江苏丰园生物技术有限公司

Process for extracellularly producing recombinant alpha-cyclodextrin glucosyltransferase

ActiveCN101831414AReduce pollutionImprove purification efficiencyTransferasesMicroorganism based processesHybrid proteinOxygen

The invention discloses a process for producing recombinant alpha-cyclodextrin glucosyltransferase in a fermenting way by culturing escherichia coli in high density through a temperature two-stage control strategy and a constant oxygen-dissolved and feed-supplemented batch technology, belonging to the technical field of fermentation engineering. The method comprises the following steps of: inoculating recombinant escherichia coli BL21(DE3) as a production strain at the inoculation quantity of 5-10 percent and fermenting in batch; starting adding a supplementing liquid in a flowing mode when dissolved oxygen rises to about 80-100 percent, ensuring that a strain body exponentially grows, controlling the temperature of the growth phrase of the strain body to be 33-37DEG C and maintaining the dissolved oxygen to 20-30 percent; adding 0.75-1.5 percent (mass volume percent) of glycine when the strain body OD600 reaches about 15-30; reducing the temperature to be 23-27DEG C and continuously supplementing 0.2-0.4g.l<-1>.h<-1> when the strain body OD600 reaches 45-60 and supplementing the supplementing liquid by adopting a gradient diminishing mode at the same time; and enabling the enzymeactivity of the extracellular alpha-cyclodextrin glucosyltransferase to reach 200-280U / ml by fermenting culture for 30-35 hours. By adopting the strategy to ferment, the invention realizes the high-efficiency extracellular expression of the alpha-cyclodextrin glucosyltransferase and greatly improves the production intensity. The invention has the advantages of wide source of raw materials, simple and feasible process and suitability for large-scale production; with effective extracellular expression, the pollution on host bacteria hybrid proteins can be greatly reduced and the purification efficiency of the protein can be improved. The invention lays a foundation for large-scale production of the alpha-cyclodextrin glucosyltransferase.

Owner:JIANGNAN UNIV

An additive cigarette production technology

InactiveCN1543884AImprove stabilityNo effect on tasteTobacco treatmentCigar manufactureNitrosoNitroso Compounds

The invention relates to an addition agent for lowering the content of N-nitroso compound in cigarette and the cigarette production process, wherein the addition agent is a plant polyphenol microcapsule with plant polyphenol as the core, and alpha-cyclodextrin or beta-cyclodextrin or hydroxypropyl beta-cyclodextrin is used as molecular embedding agent for charging plant polyphenol microcapsule into the molecular embedding agent, forming stabilized colloid, by dissolving the colloidal solution and adding into the shredded tobacco, the content of N-nitroso compound in cigarette can be substantially reduced.

Owner:李波

Heavy metal pollution soil restoration agent and application thereof

InactiveCN105542792AHigh porosityHigh adsorption valueAgriculture tools and machinesOther chemical processesThioureaTherapeutic effect

The invention provides a heavy metal pollution soil restoration agent which is composed of the following components in percentage by weight: 30-45% of biomass charcoal, 10-25% of alpha-cyclodextrin, 10-15% of glucose, 10-15% of iron powder, 10-15% of ferrous sulfate, 5-10% of polyacrylamide, 1-5% of sodium sulfide and 1-5% of thiocarbamide. The soil restoration agent has favorable effects on restoring cadmium / lead / zinc / mercury combined pollution soil. The restoration agent has the advantages of simple and feasible preparation and favorable treatment effect.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

Ginkgolide B nanometric liposomes medicine and the preparing method thereof

InactiveCN101036642AImprove solubilityPhysiological activity unchangedPowder deliveryOrganic active ingredientsCholesterolPolyethylene glycol

The invention relates to a ginkgolide B nanoliposomes drug and a method for preparing the same. The invention provides the ginkgolide B nanoliposomes drug including the following materials and the following radios: 8-12 mol compositions of cephalin and distearoyl choline with mole ratio of 1:3-6; 6-8 mol compositions of sojasterol and cholesterin with mole ratio of 1:2-4; 4-6 mol compositions of gamma-cyclodextrin / 2-hychoxypropyl-beta-cyclodextrin and alpha-cyclodextrin with mole ratio of 3:1; 0.2-0.4 mol methoxy polyethylene glycol 2000-hydrogenated soybean phosphatidylethanolamine; 2 mol ginkgolide B; and 0.1-0.5 mol vitamine E. A method for preparing the ginkgolide B nanoliposomes drug is also provided in the invention to produce the ginkgolide B nanoliposomes for target treating blocking of vessel or endothelial cell thereof, with a better healing effect than ordinary preparations of ginkgolide B.

Owner:江苏仲德医药科技有限公司

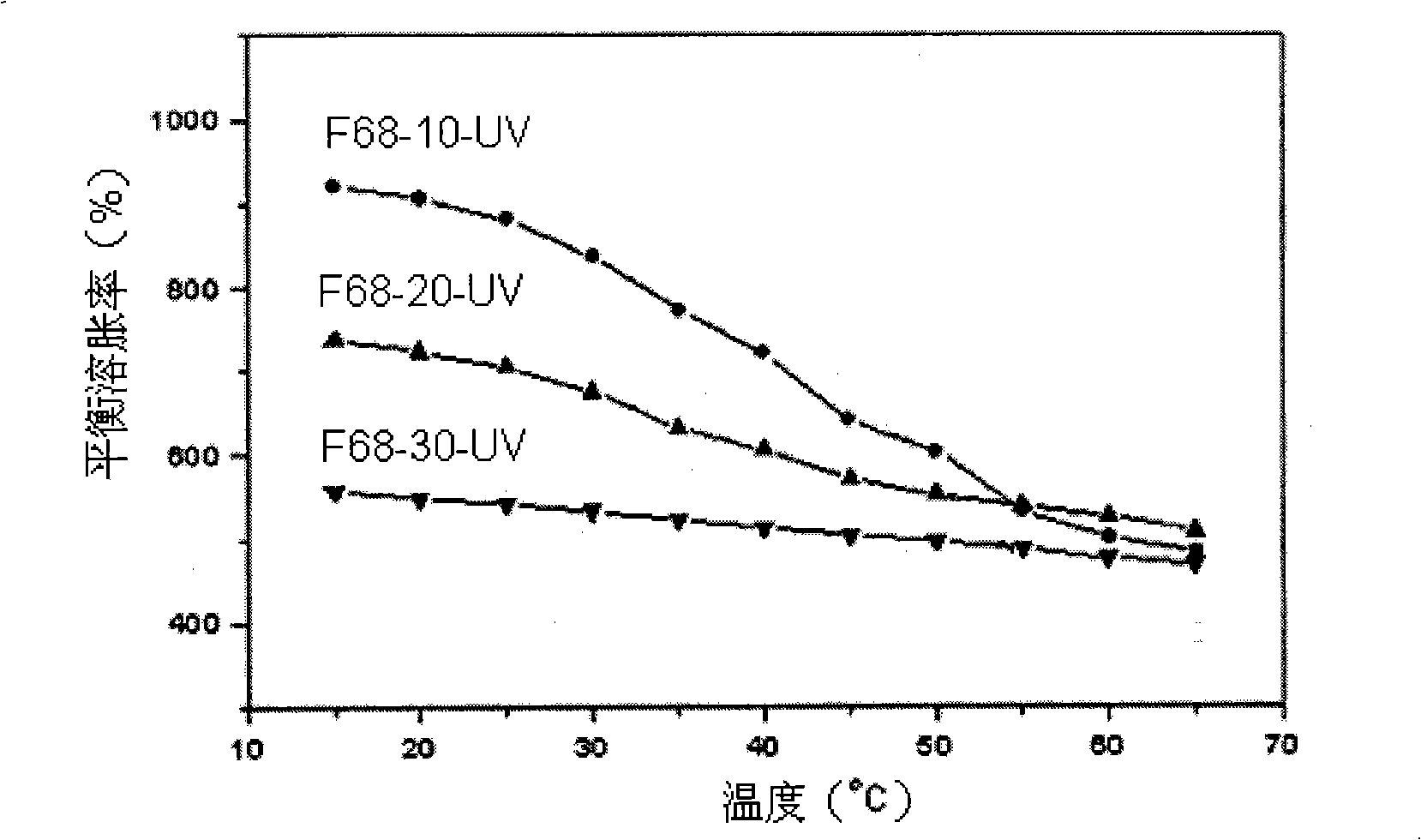

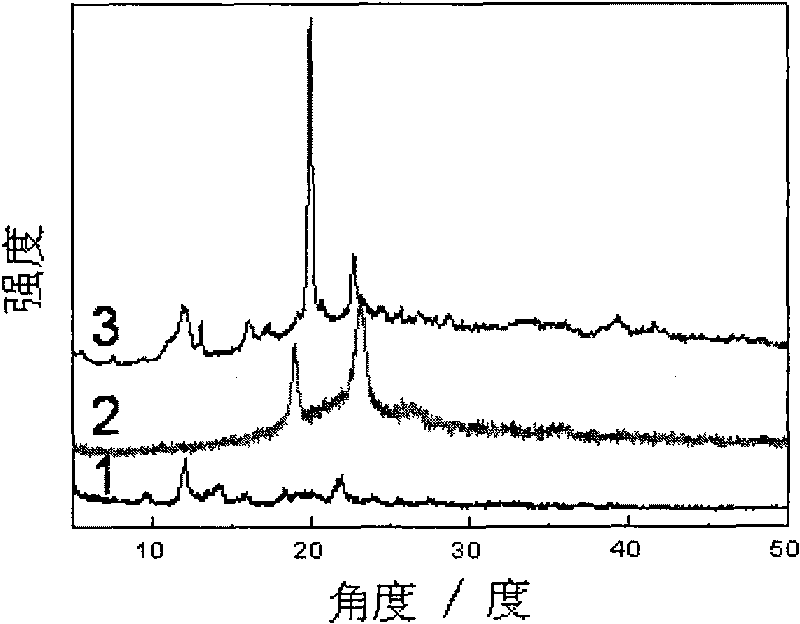

Preparation method of high intensity biodegradable supramolecule hydrogel

InactiveCN101288782APhotopolymerizableSensitive to temperatureSurgeryPharmaceutical non-active ingredientsMethacrylateCross-link

The invention belongs to the field of a biological medical polymeric material and relates to a preparation method of biodegradable supermolecular hydrogel with high strength. The preparation method is that firstly, Pluronic block copolymer and stannous octoate are used as coinitiator to initiate Epsilon-caprolactone monomer ring-opening polymerization and acrylate or methacrylate is terminated to obtain a photopolymerisable macromonomer. Then, macromonomer solution which is mixed with micro-photo initiator is mixed with Alpha-cyclodextrin solution of certain concentration to rapidly form the precursor of supermolecular physical gel. The precursor of physical gel can rapidly form the supermolecular hydrogel with high strength in situ after the irradiation of ultraviolet. The preparation method of the invention relates no organic solvent, cross linking agent and related reaction. The preparation method is simple and can be applied rapidly. And the strength and the temperature responsive property of the supermolecular hydrogel can be regulated and controlled. The obtained biodegradable supermolecular hydrogel with high strength can be widely applied to the field of the biological medical engineering material.

Owner:WUHAN TEXTILE UNIV

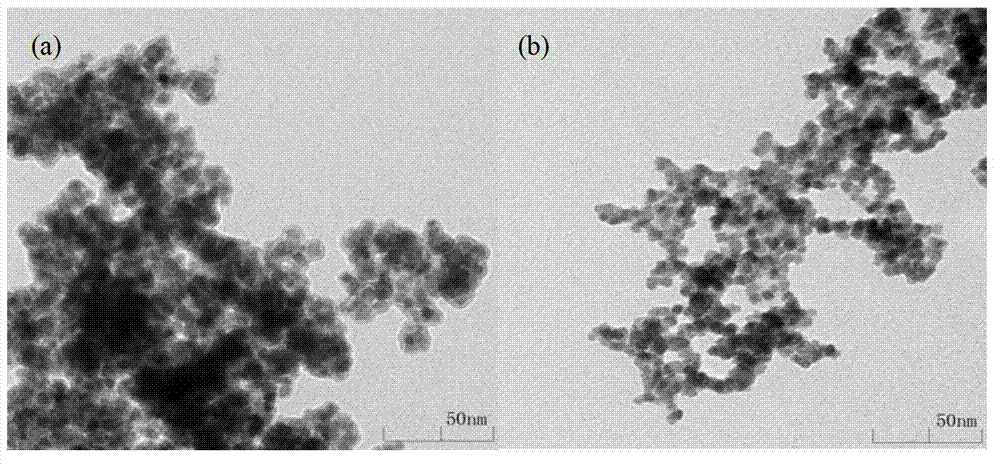

Silver nanoparticles with function of identifying chiral isomer, preparation method thereof and application thereof

InactiveCN101935525AQuick identificationEfficient identificationMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsWater solubleAmino acid

The invention discloses silver nanoparticles with a function of sensitively identifying chiral isomer, a preparation method thereof and application thereof. The silver nanoparticles modified by 6-sulfydryl-alpha-cyclodextrin consist of the silver nanoparticles and the 6-sulfydryl-alpha-cyclodextrin which are connected by chemical bonds. In the invention, the silver nanoparticles modified by water soluble alpha-cyclodextrin are prepared by preparing stable silver nanoparticles by using silver nitrate as a source and then modifying the stable silver nanoparticles with the alpha-cyclodextrin serving as a chiral selector and by a simple method, so that the colorimetric differentiation and identification of many D-type amino acids and many L-type amino acids are realized successfully. The chiral isomer detection method provided by the invention has a simple process and high operability and can be efficiently applied to the detection of chiral amino acids and chiral medicaments.

Owner:UNIV OF SCI & TECH OF CHINA

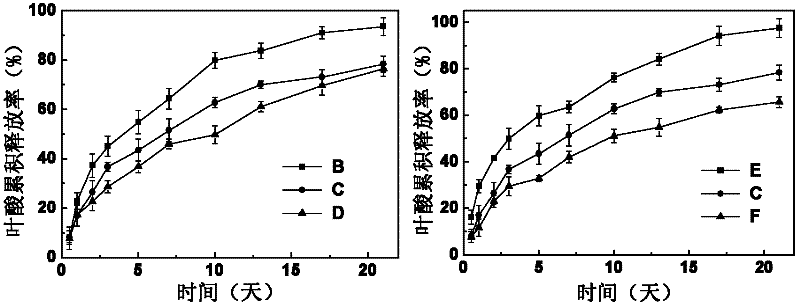

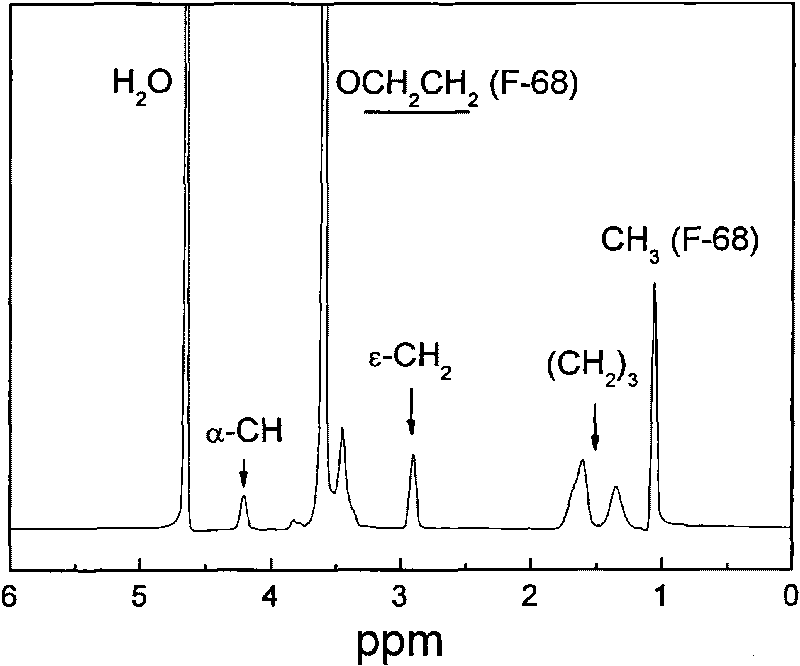

Super-molecular hydrogel double-medicament carrier and preparation method as well as application thereof

InactiveCN102247602AWide range of usesEasy to preparePharmaceutical non-active ingredientsPharmaceutical active ingredientsPolyethylene glycol monomethyl etherProdrug

The invention discloses a super-molecular hydrogel double-medicament carrier for simultaneously loading hydrophilic and hydrophobic medicaments and a preparation method as well as application thereof. The method comprises the following operating steps of: performing chemical modification on the hydrophobic medicament by using methoxypolyethylene glycol to synthesize a water-soluble macromolecularprodrug; physically mixing prodrug molecules with the hydrophilic medicament; further mixing the mixed solution with an alpha-cyclodextrin solution and stirring; and standing at room temperature to obtain the super-molecular hydrogel double-medicament carrier for simultaneously loading the hydrophilic and the hydrophobic medicaments. The carrier has the advantages of easiness in operation, adjustable gel strength and gelation time, forming at room temperature, no chemical crosslinking reaction or organic solvent, high bioavailability, sustainable and controllable release of the medicament andthe like, and is expected to be widely applied to the field of biomedical engineering materials.

Owner:SUN YAT SEN UNIV

Supramolecular hydrogel gene vector material, and preparation method and application thereof

InactiveCN101716346AEasy to prepareMild conditionsGenetic material ingredientsImmunological disordersEnd-groupGene vector

The invention discloses a supramolecular structural hydrogel gene vector material and a preparation method and application thereof. The method comprises the following operation steps: synthesizing a multi-block copolymer with cation chain segments through modification of a terminal group of triblock copolymer of a polyethylene glycol-polypropylene glycol-polyethylene glycol which is modified by polylysine; then, mixing the copolymer with DNA solution to obtain DNA compound micelle; further, mixing and then stirring the micelle solution and solution of alpha-cyclodextrin; and keeping mixed solution at the room temperature to obtain hydrogel. The hydrogel can be used for preparing an injectable gene vector. The method has the advantages that the method has simple operation, can adjust the strength of the hydrogel and the gelatination time, can mold at the room temperature and does not relate to chemical crosslinking reaction and the use of organic solvent; and the obtained hydrogel has the advantages of temperature sensitivity, good bio-compatibility, obvious transfection effect and the like; and the method is hopeful to be widely applied in the field of a biomedical engineering material.

Owner:SUN YAT SEN UNIV

Supermolecular hydrogel and preparation method and application thereof

InactiveCN102634043ALow cytotoxicityGood gene deliveryMacromolecular non-active ingredientsVector-based foreign material introductionBiocompatibility TestingPolyethylene glycol

The invention discloses supermolecular hydrogel and preparation method and application thereof. The preparation method of the supermolecular hydrogel comprises the following steps of: synthesizing a polyethylene glycol modified cation copolymer; mixing with a nucleic acid solution and standing to obtain a copolymer / nucleic acid composite solution; and finally, mixing with alpha-cyclodextrin solution, and standing to obtain the supermolecular hydrogel capable of acting on a gene vector material. In the forming process of the hydrogel disclosed by the invention, a chemical crosslinking reactiondoes not happen, and thus the influence of a byproduct of the chemical crosslinking reaction on the activity of nucleic acid is effectively avoided, an efficient gene transfer effect is realized, andthe transfection efficiency is obviously improved over the conventional gel material; and moreover, the preparation method is convenient and quick, realizes formation at room temperature, imposes relatively low requirements on concentration and temperature, and is favorable for maintaining the biological activity of embedded gene and the biocompatibility of the material.

Owner:广州新犇富科技有限公司

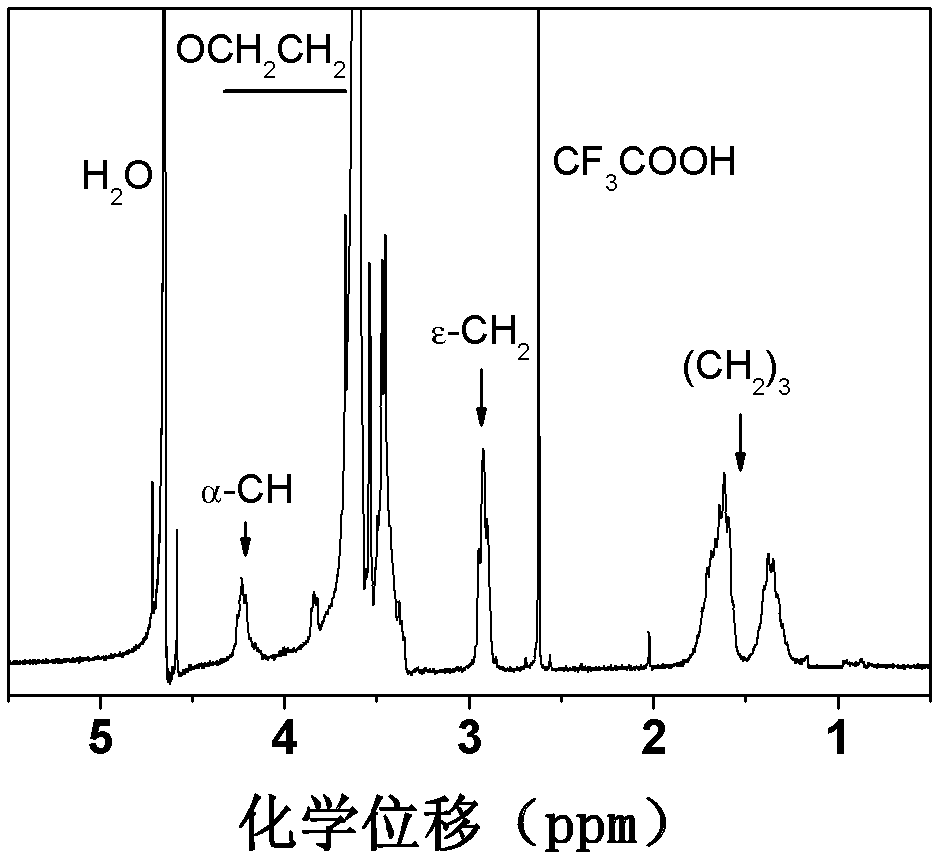

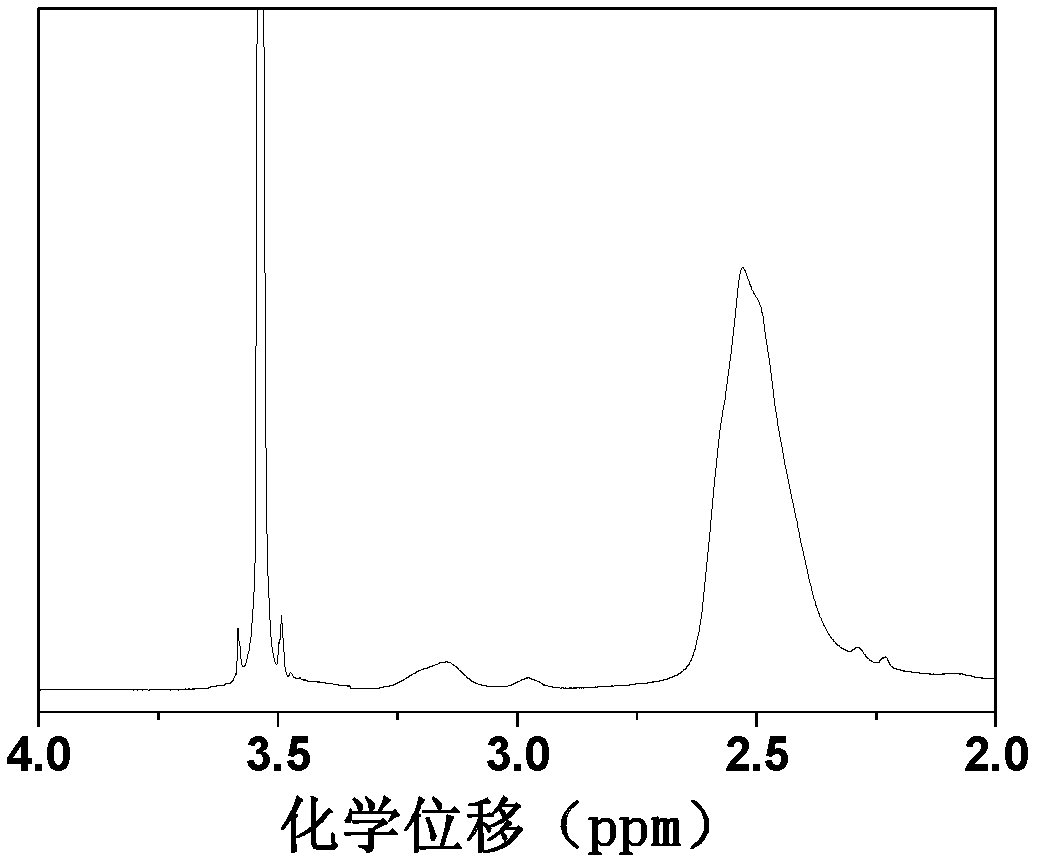

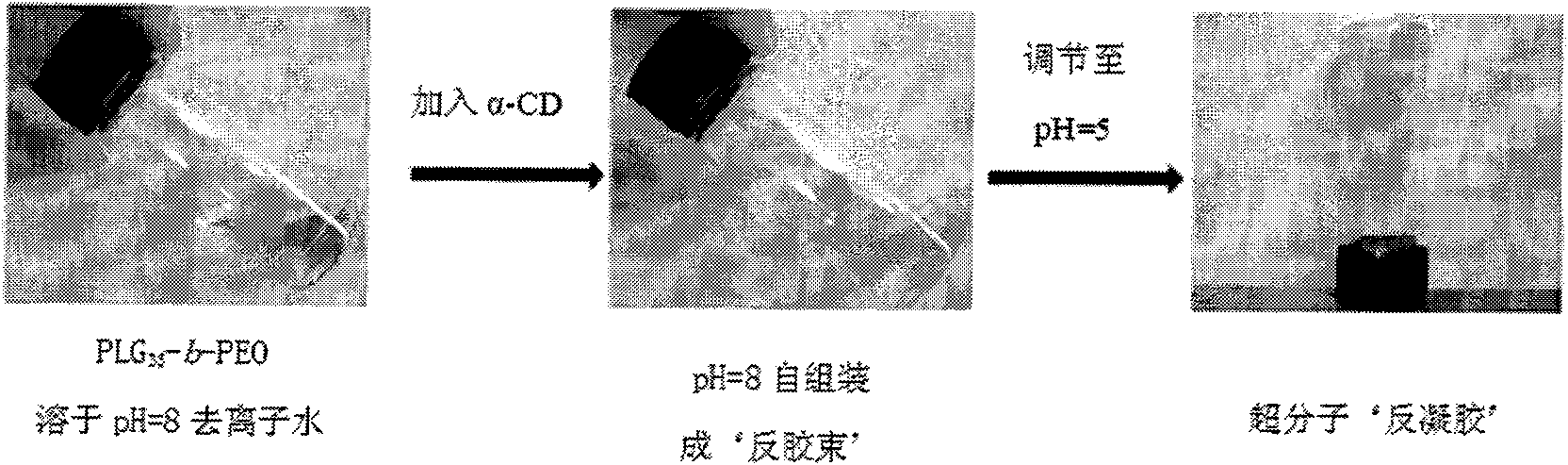

Double stimuli responsive type poly amino acid-based supermolecular reverse gel and method for preparing same

The invention provides a double stimuli responsive type poly amino acid based supermolecular reverse gel used in the technical field of water gel and a method for preparing the same, wherein the method comprises the following steps of: synthesizing a linear poly(L-benzyl-glutaric acid ester)-polyethylene glycol diblock copolymer; preparing a poly(L-glutamic acid)-polyethylene glycol di-block copolymer used for forming the reverse gel; forming the supermolecular reverse micelle in which the alpha-cyclodextrin-polyethylene glycol complex serves an inner core and the poly(L-glutamic acid) servesa shell; and protonating the poly(L-glutamic acid) chain segments in an acid environment, forming crosslinking by using the mutual action of the hydrogen bonds between the poly(L-glutamic acid) chainsegments, and allowing the supermolecular reverse micelles to mutually gather to form the double stimuli responsive type poly amino acid-based supermolecular reverse gel at room temperature. Comparedwith the prior art, the elastic modulus of the gel is further improved, the gel system prepared by the method is damaged when the pH value of the gel system is higher than 8, the reverse gel can be formed again when the pH value of the gel system is adjusted to be 5, so that the pH value reversibility is good.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method of sulfur mesoporous silica composite material for nano-valve packaging

The invention relates to a preparation method of a sulfur mesoporous silica composite material for nano-valve packaging. The method is as below: 1, preparing a mesoporous silica carrier by using a ''template method''; 2, carrying out surface modification on mesoporous silica by using an organic silane chain molecule; 3, injecting elemental sulfur into the pore tunnel or cavity of the mesoporous silica by a vacuum heat treatment method; and 4, then sealing pores of mesoporous silica by using alpha-cyclodextrin as a nano-valve. The invention applies the composite material to lithium-sulfur battery, uses the high specific surface area of mesoporous silica to solve the problem of lower sulfur content in lithium-sulfur battery cathode material of the prior art, and inhibits volume expansion of sulfur in the process of charging and discharging; and meanwhile the introduced nano-valve can inhibit the dissolution of polysulfide and improve the cycle stability of lithium-sulfur battery.

Owner:CHINA UNIV OF MINING & TECH

Modification method for improving saline tolerance of acrylic acid macromolecule water uptake resin with alpha-cyclodextrin

The invention relates to a modification method for improving the salt tolerance of a crylic acid macromolecule absorbent resin. The modification method which utilizes Alpha-cyclodextrin to improve the salt tolerance of the crylic acid macromolecule absorbent resin is characterized by comprising the following steps: 1) according to the parts of all component raw materials by weight as follows: 15 portions to 40 portions of crylic acid, 5 portions to 18 portions of sodium hydroxide, 0.02 portion to 1 portion of N, N'- methylene bisacrylamide, 0.05 portion to 2 portions of Alpha-cyclodextrin, 0.04 portion to 2 portions of ammonium peroxydisulfate and 15 portions to 54 portions of water, the raw materials are selected; 2) all raw materials are added into a reaction kettle with a water bath, the temperature is risen to 65 DEG C to 80 DEG C and the reaction lasts for 1 hour to 3 hours; 3) stirring in the reaction kettle is stopped and the kettle is allowed to stand for 0.5 hour to 2 hours and reaction mass in the reaction kettle is discharged; and 4) after being dried, the reaction mass is crushed, thus obtaining the modified crylic acid macromolecule absorbent resin. The method can evidently improve the salt tolerance of the crylic acid macromolecule absorbent resin prepared by the method can be evidently improved.

Owner:WUHAN UNIV OF TECH

Stainless steel oxidizing layer cleaning agent and preparation method and application thereof

The invention discloses a stainless steel oxidizing layer cleaning agent and a preparation method and application thereof. The stainless steel oxidizing layer cleaning agent comprises the following raw materials: 30% to 50% of cyclodextrin, 10% to 20% of organic acid, 10% to 20% of a composite surface active agent, and the balance of water, wherein the cyclodextrin is a mixture of one or more than two of alpha-cyclodextrin, beta-cyclodextrin, gamma-cyclodextrin, hydroxypropyl beta-cyclodextrin and methylase beta-cyclodextrin; the organic acid is a mixture of one or more than two of methane acid, ethane acid, propionic acid, lemon acid, oxalic acid, maleic acid and lauric acid; the composite surface active agent is a mixture of one or more than two of sodium oleate, alkyl glycoside, lauryl sodium sulfate, coconut fatty acid diethanol amide, fatty alcohol-polyoxyethylene ether and polyethylene glycol. The stainless steel oxidizing layer cleaning agent has the advantages that the preparation method is simple, the use and operation are convenient, the service life is long, the generation amount of wastewater is small, the components can be easily and biologically degraded, the green and environment-friendly effects are realized, and the cost is low. The stainless steel oxidizing layer cleaning agent has the potentiality of replacing the existing stainless steel oxidizing layer cleaning agent using inorganic acid as the main component.

Owner:ZHEJIANG UNIV OF TECH

Reduced glutathione percutaneous absorption preparation and preparation method thereof

ActiveCN102100904AImprove bioavailabilityGuaranteed reducibilitySenses disorderMetabolism disorderHalf-lifeMedicine

The invention relates to a reduced glutathione percutaneous absorption preparation and a preparation method thereof, and belongs to the field of medicinal preparations. In the technical problem, the invention provides a reduced glutathione percutaneous absorption preparation which has the sustained-release effect. The reduced glutathione percutaneous absorption preparation is prepared from an auxiliary material bag and reduced glutathione, wherein an auxiliary material is at least one of gamma-cyclodextrin, a derivative of the gamma-cyclodextrin, alpha-cyclodextrin and a derivative of the alpha-cyclodextrin. The reduced glutathione percutaneous absorption preparation has the advantages of quick response, long half-life period and high bioavailability, is convenient to use and does not have pain. The reduced glutathione provides a new preparation, and has a wide application prospect.

Owner:CHENGDU JOY YOUNG BIOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com