Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Uniform degradation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bracket material for bone tissue engineer and preparation method thereof

InactiveCN101417145AImprove mechanical propertiesGood biocompatibilityProsthesisDrug biological activityProtein C

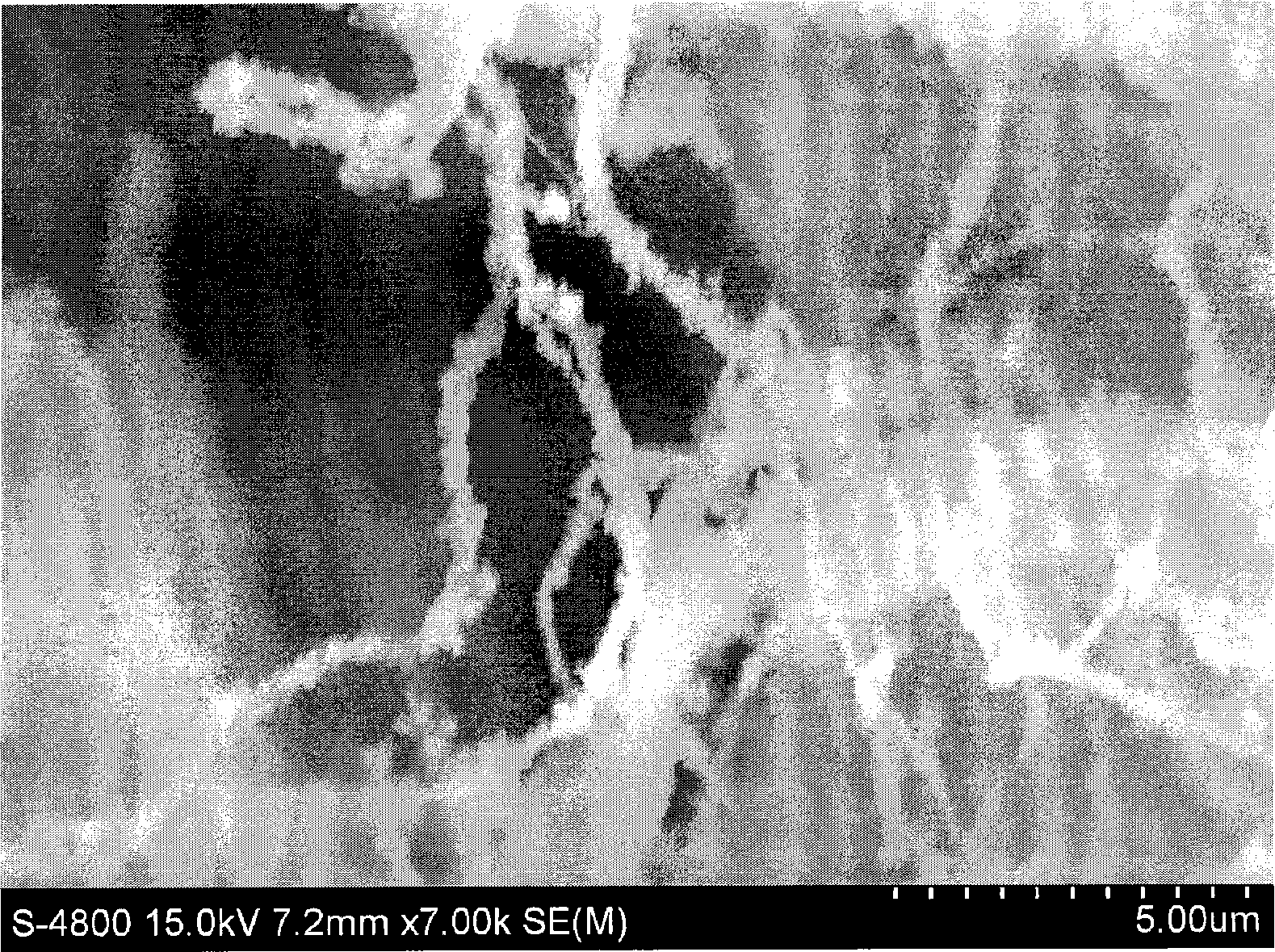

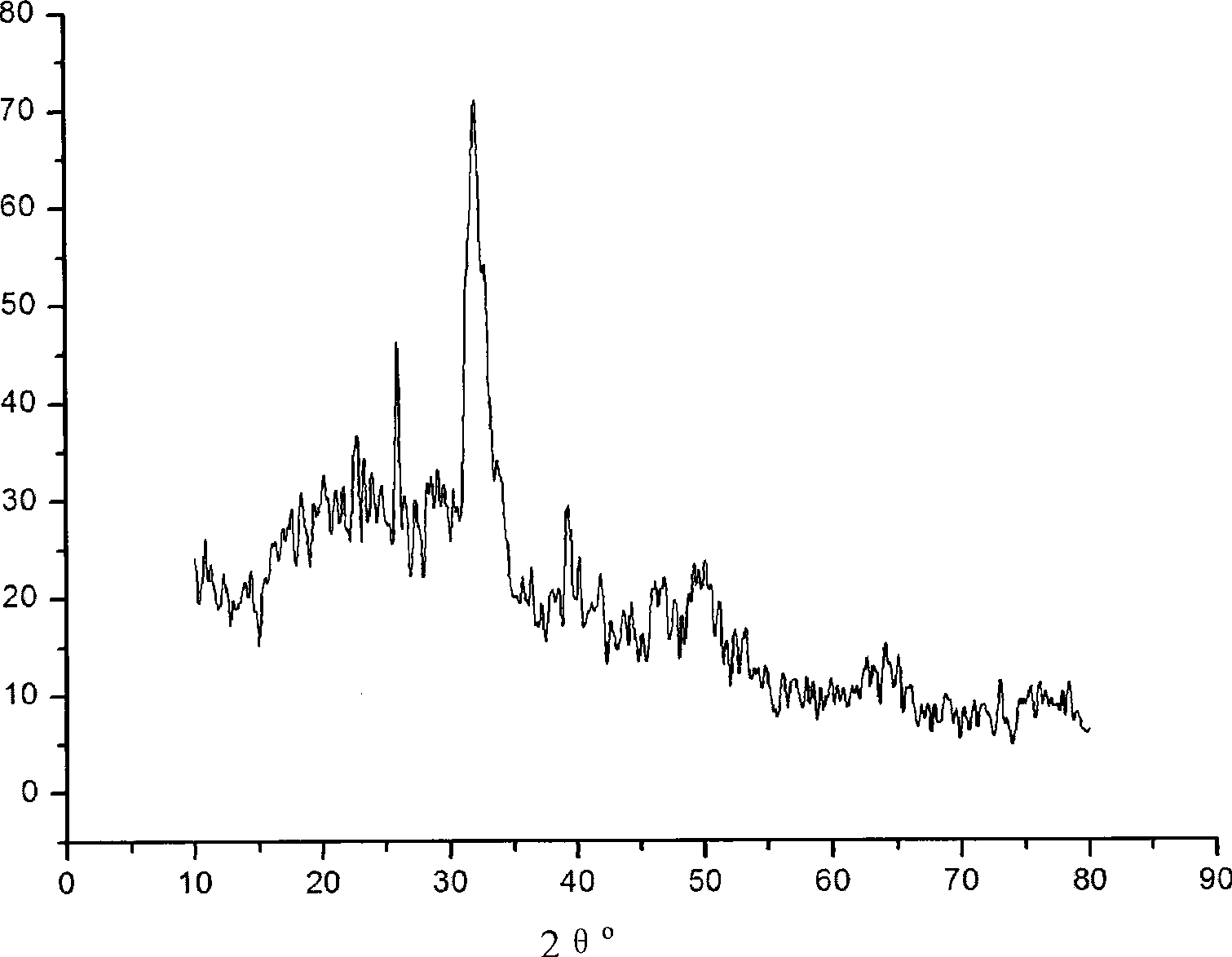

The invention relates to a bracket material used for an osseous tissue project, and a preparation method thereof. Firstly, the bracket of a type I collagen is extracted from a small fresh pigskin by a mature extracting technique. Then, the bracket is further expanded in a Tris cushion liquid, the pH of which is equal to 8.8 to obtain a natural porous collagen bracket by the treatments of freezing and drying. The bracket is respectively and repeatedly mineralized in a CaCl2 liquid and in (NH4)2HPO4 liquid or mineralized in simulated body fluid for a long period to lead the weakly crystallized HA to be uniformly settled into the collagen bracket; and then a pigskin collagen-hydroxyapatite ossein is obtained by the treatments of freezing and drying to replace the natural bracket material. The invention not only maintains the natural bracket structure of the collagen in an organism, but also has the advantages of low material cost, simple devices, short period and easy operation. The obtained compound bracket material used for the pigskin collagen-hydroxyapatite osseous tissue project has the characteristics of high intensity, large toughness, non-antigenicity, higher biological activity as well as degradation and releasing control.

Owner:SHANDONG UNIV

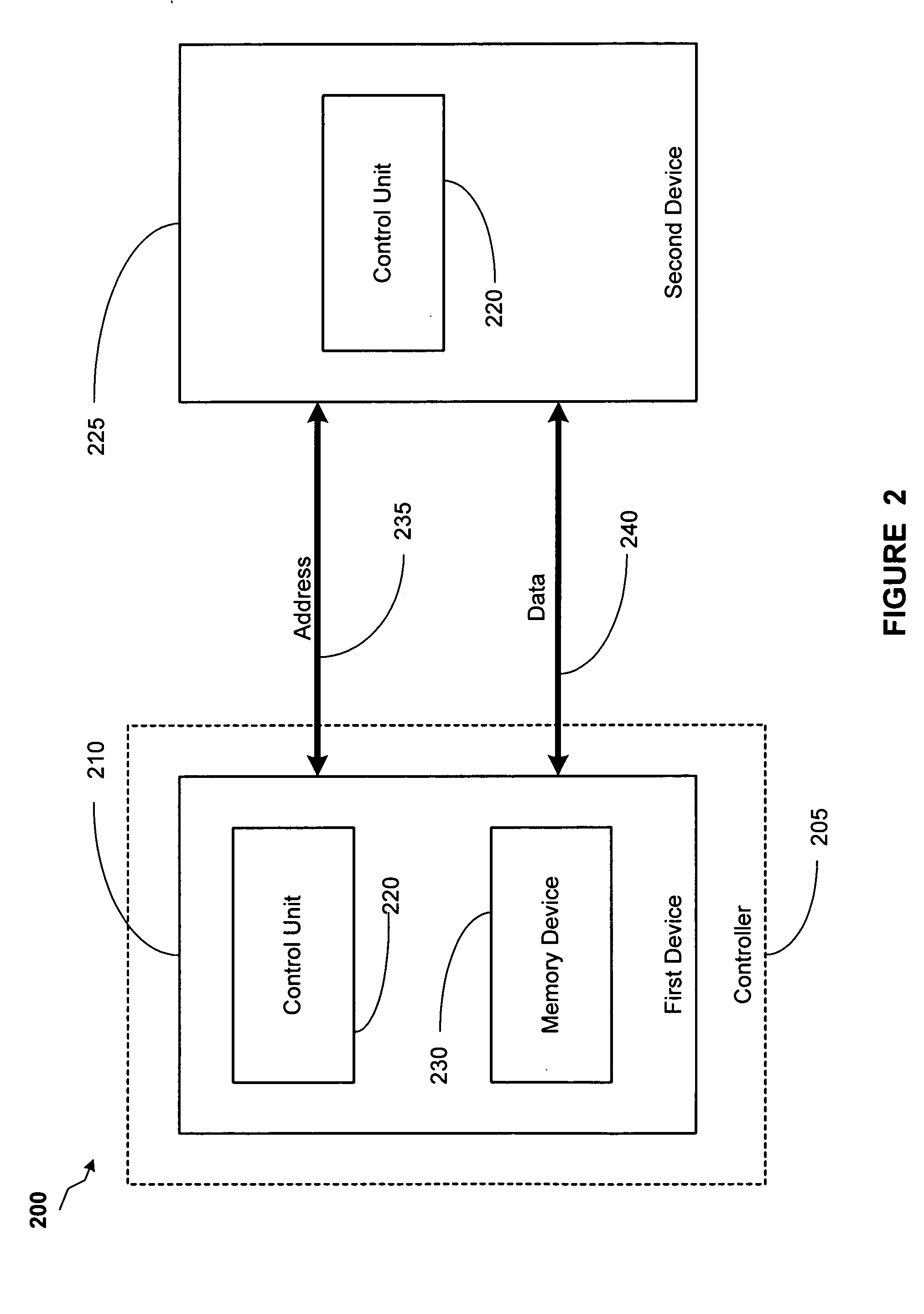

Delay line off-state control with power reduction

ActiveUS20060044029A1Reduce the required powerUniform degradationPulse automatic controlDigital storagePhase differenceDelay-locked loop

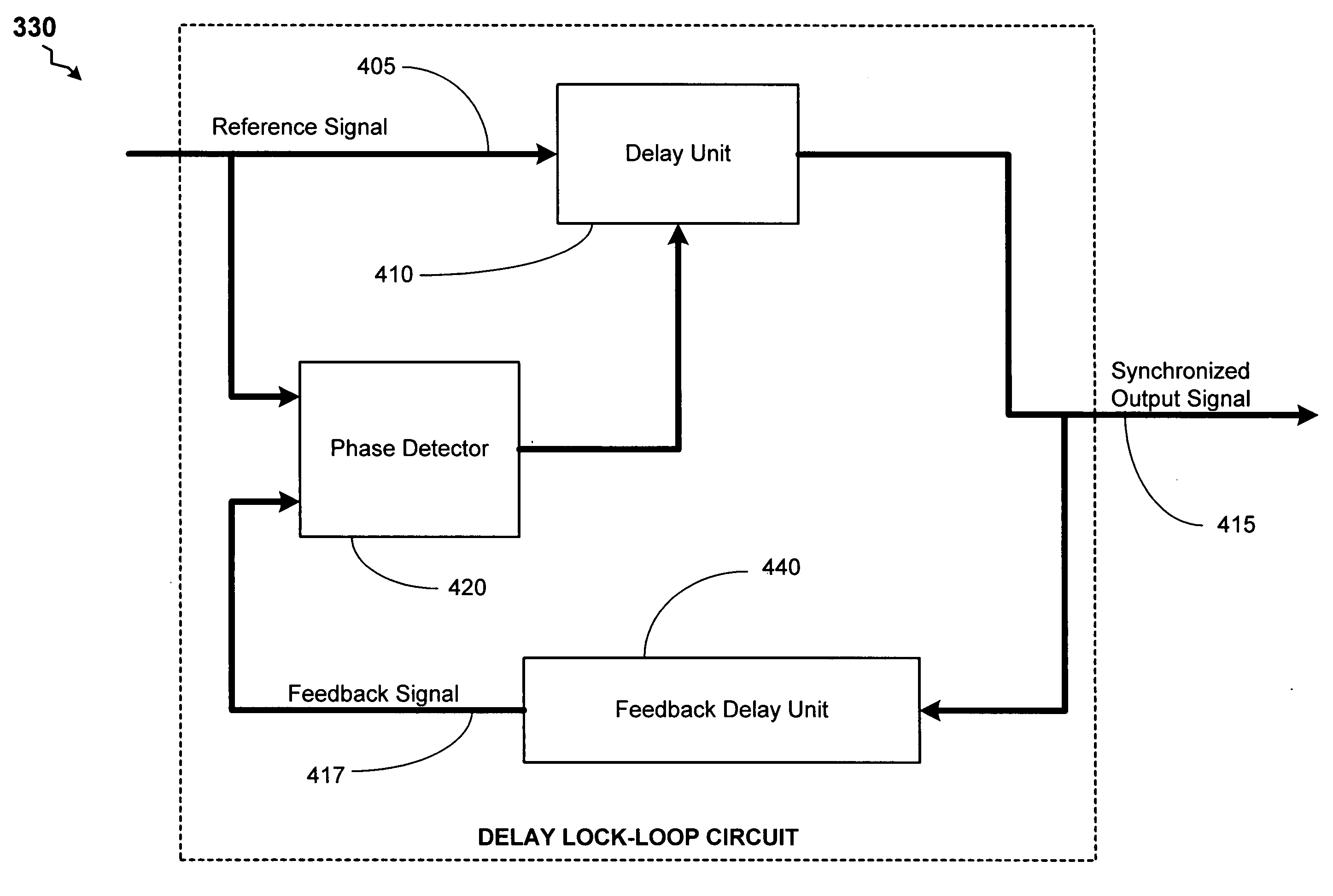

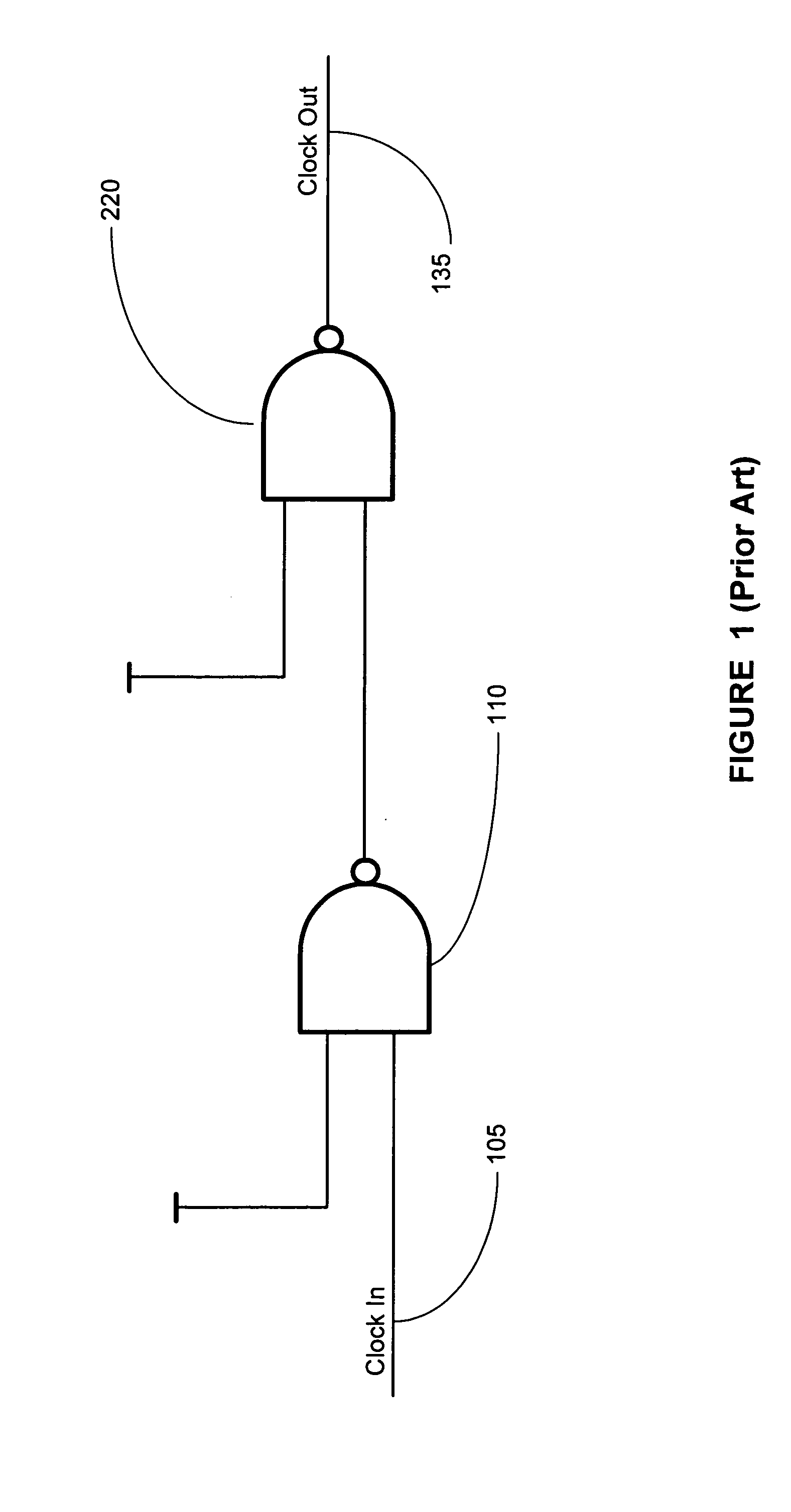

A method and apparatus is provided for controlling a delay line for achieving power reduction. The device comprises a delay lock loop to provide an output signal based upon a phase difference between a reference signal and a feedback signal, said delay lock loop comprising at least one delay circuit comprising a plurality of logic gates configured to provide for substantially uniform degradation of a plurality of NAND gates in a static state.

Owner:MICRON TECH INC

Uniformly degradable orthopedic implant magnesium alloy material

InactiveCN103014465AUniform degradation rateHigh elongationSurgeryOsteoblastUltimate tensile strength

The invention relates to a medical alloy material, in particular to a uniformly degradable orthopedic implant magnesium alloy material. The orthopedic implant magnesium alloy material comprises the following components in percentage by weight: 0-5% of Gd, 1-5% of Nd, more than 0-2% of Sr, 0-0.5% of Zn, more than 0-1% of Zr and the balance of Mg. Due to the addition of magnesium alloy elements Gd and Nd, the strength and the corrosion resistance of the magnesium alloy are improved. In addition, a small amount of Gd and Nd are better in bio-safety; Sr has the effect of inducing growth of osteoblasts; Zn is a human necessary micronutrient element, and the ductility and the corrosion resistance of the alloy can be improved due to the addition of the Zn; and Zr has the effects of refining crystal grains and improving the strength and the corrosion resistance of the alloy and can enable the magnesium degrading speed to be more uniform, and no cell toxicity exists after a small amount of Zr is added.

Owner:JIANGSU KONSUNG MEDICAL EQUIPMENT CO LTD +1

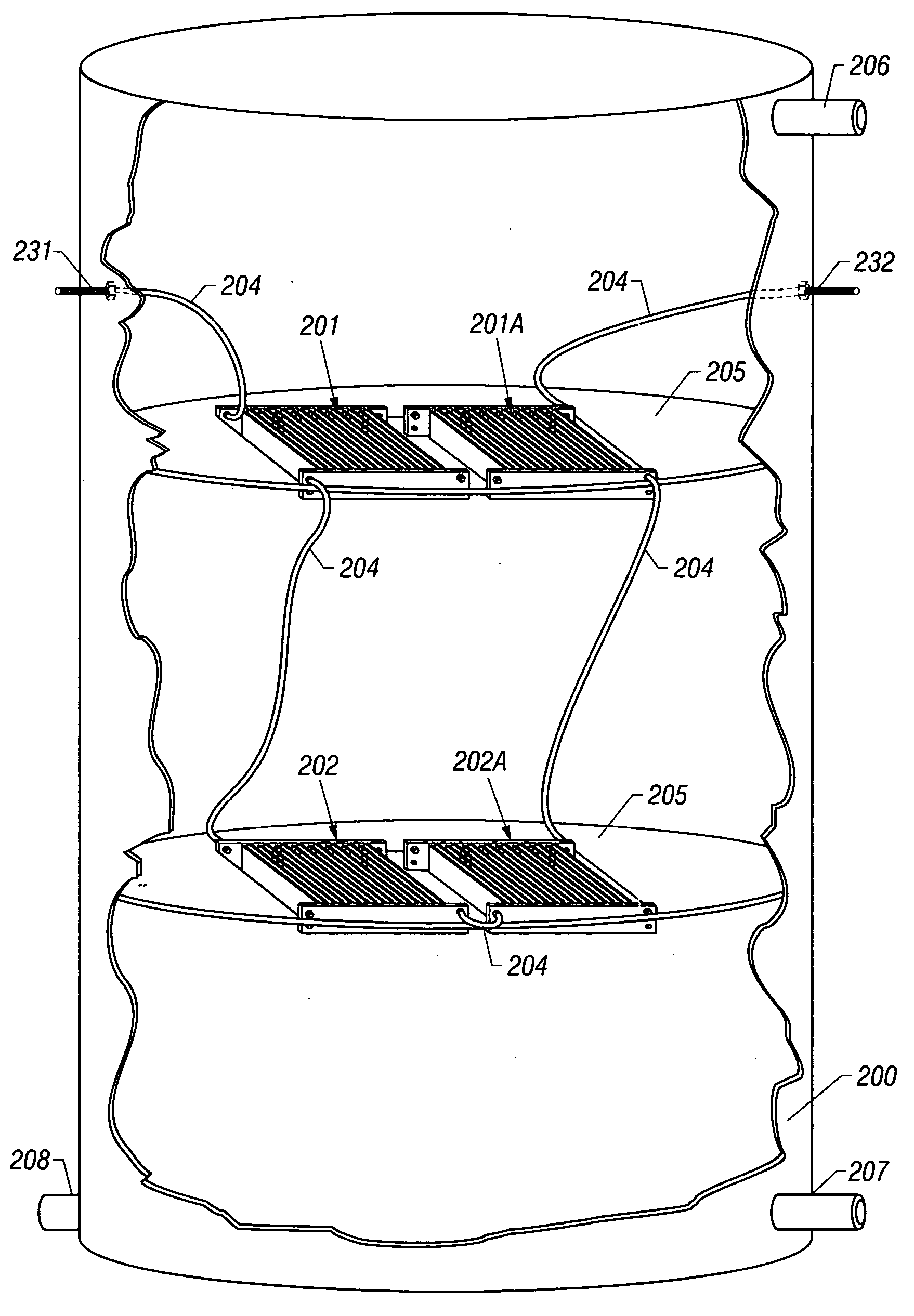

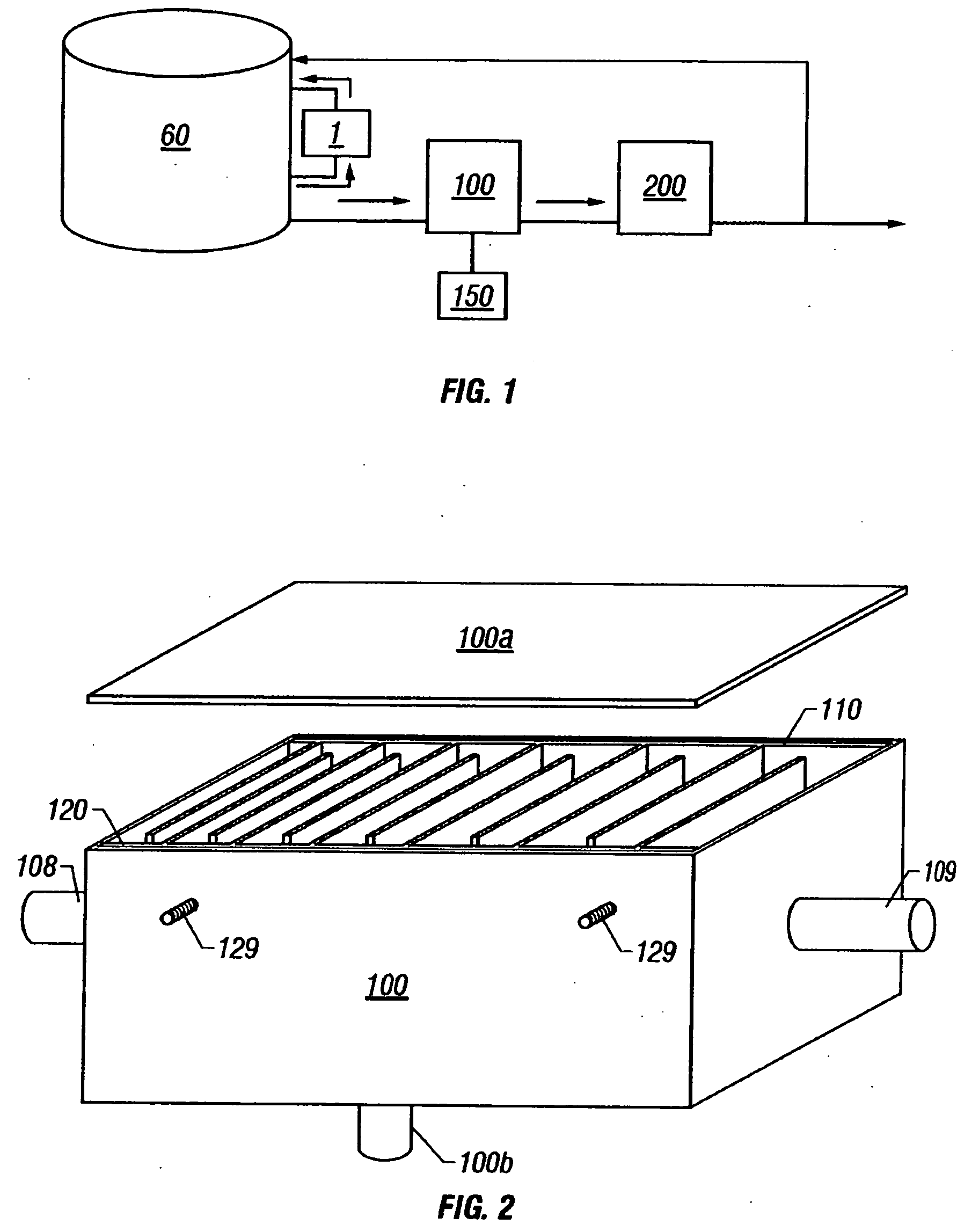

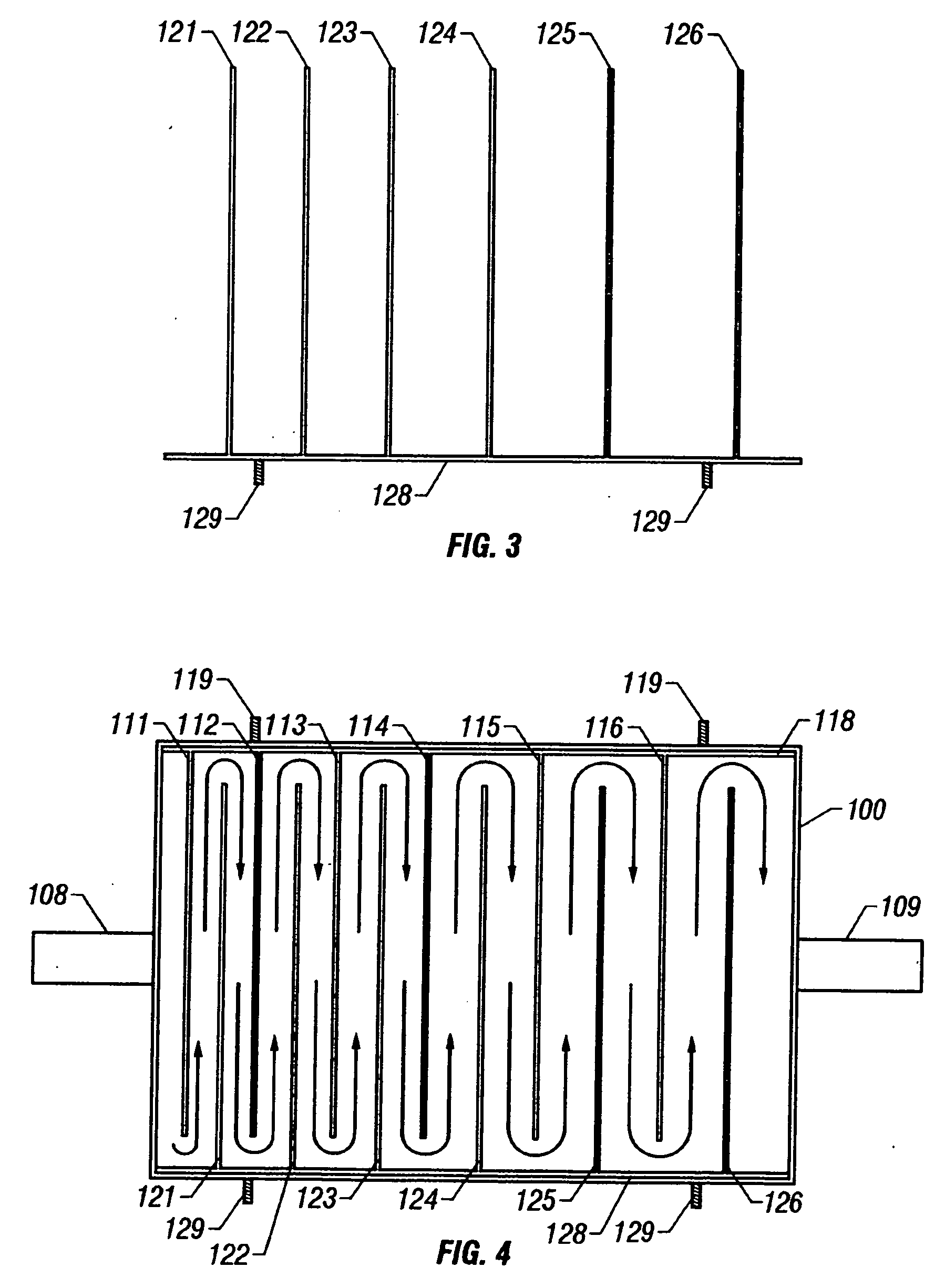

Method and apparatus for removing contaminants from conduits and fluid columns

InactiveUS20060175200A1Enhance contaminant separationUniform degradationElectrostatic separatorsLiquid separation by electricityPollutantElectric field

A method and apparatus for contaminant separation utilizes an interleaved array of oppositely charged electrode plates for fluid treatment. Spacing between the parallel electrode plates is graduated so that the volume of the cavities between the opposing electrodes provides varying levels of treatment of a broad range of contaminants from a variety of fluid columns. A fluid flow path extending substantially orthogonal to the direction of the electrical field established between opposing electrode plates provides a feed stream with exposure to the varying levels of electrical charges between the electrode plates. The method and apparatus provide an effective means of contaminant separation by a device having a small footprint and requiring low amounts of electrical energy.

Owner:WILSA HLDG

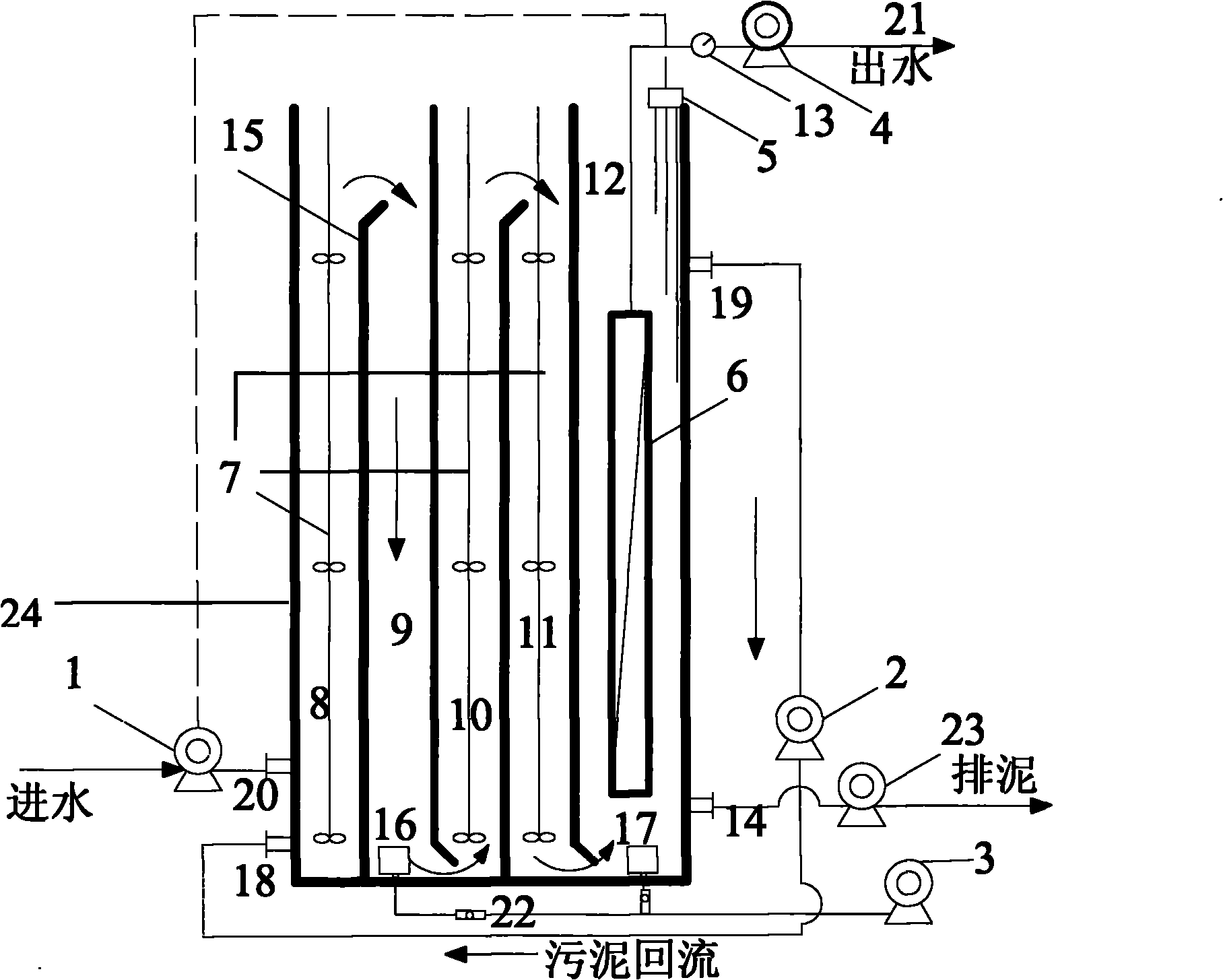

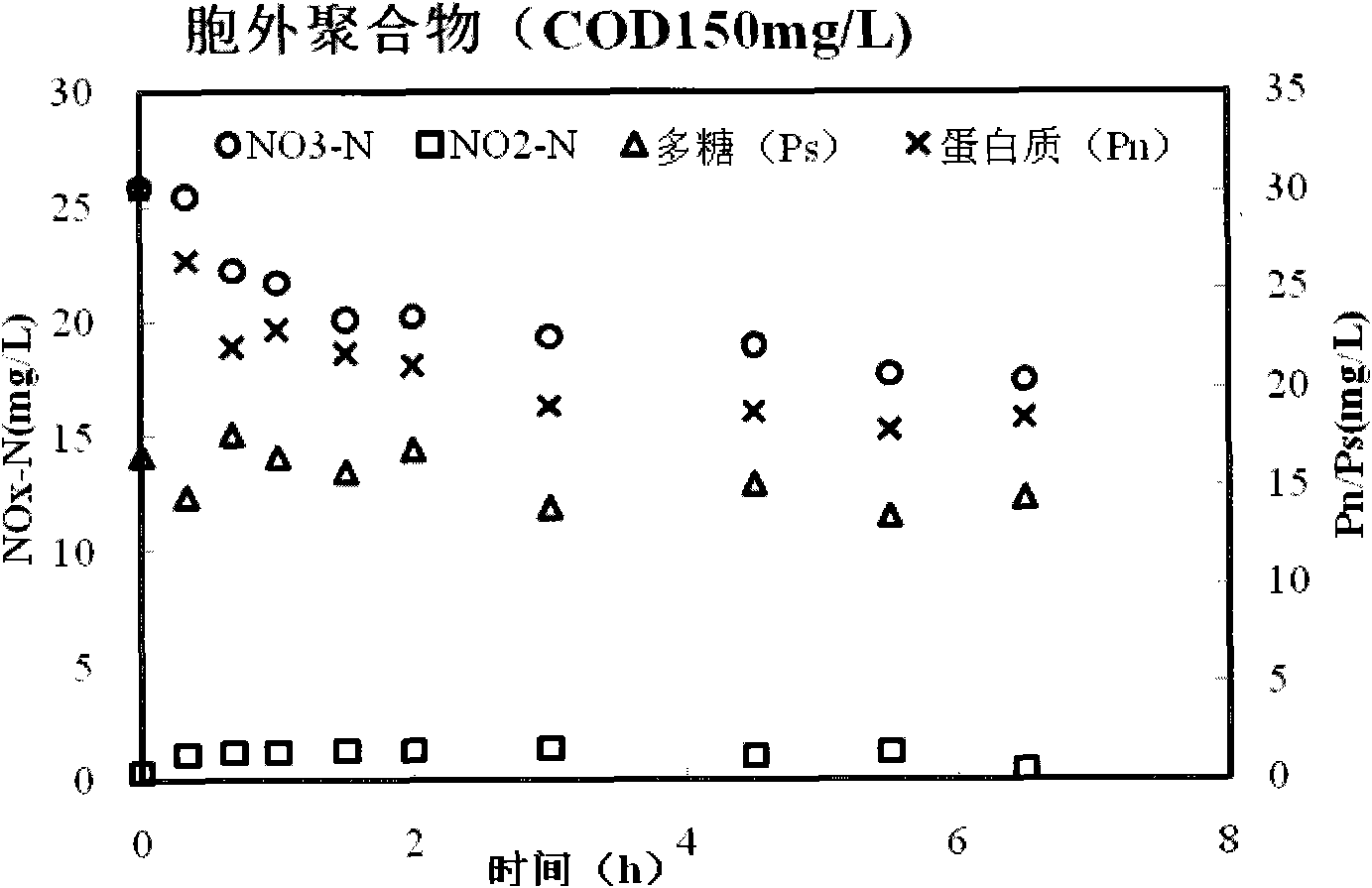

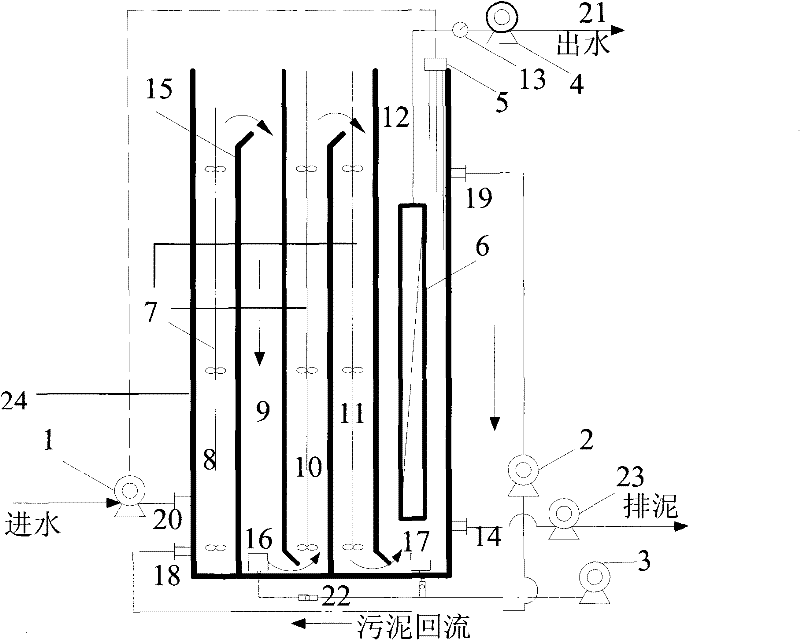

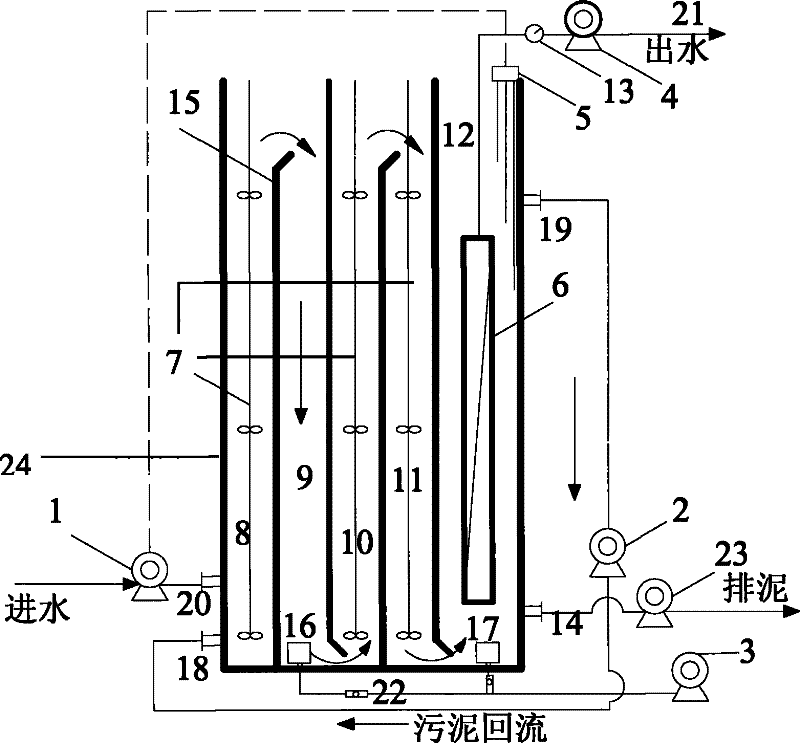

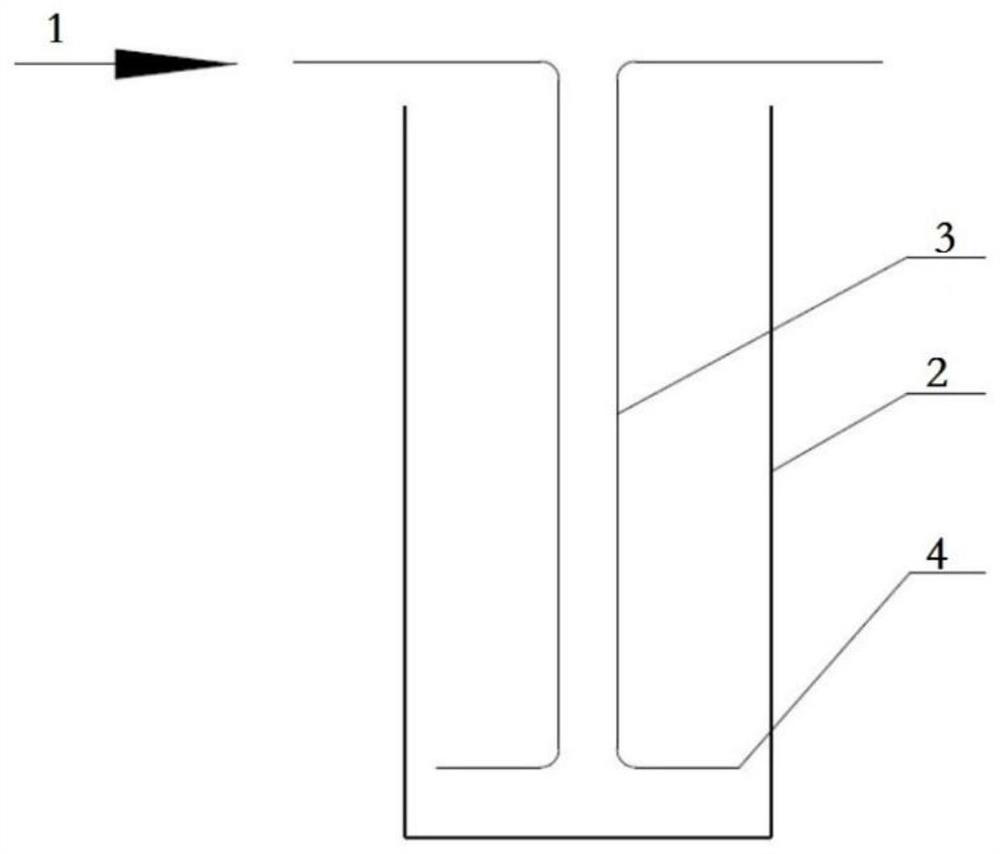

Membrane bioreactor for denitrification and waste water denitrification method

InactiveCN101863586AImprove water qualityRealize deep denitrification treatmentMultistage water/sewage treatmentFiltrationTrapping

The invention belongs to the field of environment protection and discloses a membrane bioreactor for denitrification and waste water denitrification method thereof. The membrane bioreactor is divided into a first anoxic pond, an aerobic pound, a second anoxic pound, an anaerobic pond and a membrane pound by a vertical deflecting baffle plate and an aeration device, wherein the ponds are five independent and communicated reactor chambers; after waste water enters the process, the biochemical treatment processes such as the degradation, nitrification and denitrification of organic matters are completed under the action of microorganisms; and effluent is obtained by membrane filtration and pumping. The bioreactor and the method have the advantages that: sludge mixed liquid flows in a piston flow mode in the whole system, but is in a fully mixed state in a single cell and a refluxing device is used, so the degree of mixing in the entire reactor is high and the mass transfer effect is good; under a condition of not adding extra carbon source, the process strengthens the denitrification by using high sludge concentration, so deep denitrification treatment is realized and the pollution to the membrane is relieved; and at the same time, due to the high efficiency trapping and separation characteristic of the membrane, the quality of effluent of filtration is high.

Owner:SUN YAT SEN UNIV

Method for producing alpha, omega-dihydroxy polydimethyl siloxane

The invention relates to a method for preparing Alpha and Omega-dihydroxy dimethylsiloxane and is characterized in that: copolymerization occurs between octamethylcy clotetrasiloxane or dimethyl cyclosiloxane and an alkaline catalyst; when the polymerization reaches to a certain degree, atomized water is sprayed on the surface of high viscosity high polymer to lead to degradation reaction, and after low-boiling-point compound separation process is carried out for 2 to 3 hours, the Alpha and Omega-dihydroxy dimethylsiloxane is obtained. The degradation method is characterized by being capable of leading molecular weight of the prepared Alpha and Omega-dihydroxy dimethylsiloxane to be distributed uniformly and high yield, etc.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

Magnesium alloy rapidly and uniformly degraded in tap water and manufacturing method of component made of same

The invention belongs to the technical field of metal materials and discloses a magnesium alloy rapidly and uniformly degraded in tap water and a manufacturing method of a component made of the same.The magnesium alloy comprises, by weight percentage, 4.0-8.0% of Gd, 0-2.0% of Y, 0.4-1.0% of Cu, 0-0.4% of Zn and 5.0-8.0% of the (MRAE) total of mixed reaction promoting elements such as Ni, Fe, Caand In or only Ni, the balance Mg and less than 0.01% of the total of impurity elements, namely Be, Zr and Ca, wherein the Ni accounts for 90% or above of the MRAE total. Compared with the prior art,the component made of the magnesium alloy can be degraded in the tap water rapidly and uniformly; at the normal temperature, the corrosion rate in the tap water can reach 30 mg / cm<2>.h or above; underthe condition that electrolyte is heated, the corrosion rate can reach 550 mg / cm<2>.h at the maximum; and the magnesium alloy is suitable for being applied to the mining industry field which has therapid and uniform degradation requirement for structural materials.

Owner:冉兴 +7

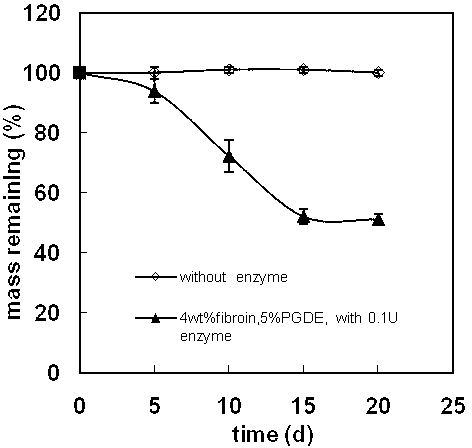

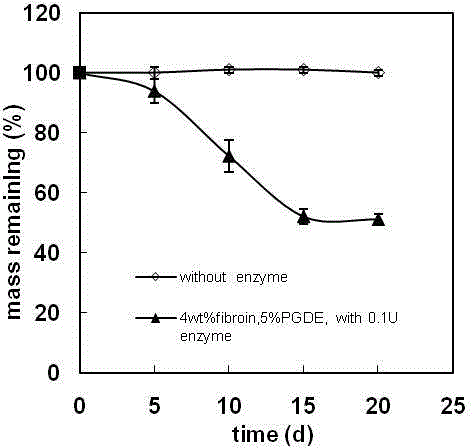

Preparation method of fibroin microsphere

InactiveCN103341175AUniform internal and external curing structureHigh embedding efficiencyAnimal feeding stuffAbsorbent padsMicrosphereRoom temperature

The invention relates to a preparation method of a fibroin microsphere, and the fibroin microsphere can be taken as a carrier of medicaments for slow release. At present, there is not a preparation method of a demand-satisfying fibroin microsphere; and wherein the demands are that the fibroin microsphere has high embedding efficiency, and the medicament can be released slowly and uniformly along with the degradation of the prepared fibroin microsphere. The preparation method comprises the following steps: adding the medicament needing to embed and release into a regenerated fibroin solution with a concentration of 3-10 wt%, then dropwise adding a coagulating agent with a concentration of 2-10 wt%, and slowly stirring at a rotary speed of 80-120 r / min to obtain a mixed solution; spraying the mixed solution into a space with a temperature of -20 DEG C to -80 DEG C and coagulating, collecting icy particles, continually preserving the icy particles in a space with a temperature of -20 DEG C to -80 DEG C for more than 2 hours, then unfreezing the icy particles at 0 DEGC to room temperature, washing and removing the coagulating agent at 0 DEG C to room temperature, collecting the fibroin microsphere by centrifuging or filtering. The fibroin microsphere prepared by the method is high in embedding efficiency and excellent in biological compatibility, and the medicament is released slowly and uniformly along with the degradation of the fibroin microsphere.

Owner:ZHEJIANG UNIV

Rapid degradation type soybean protein simulation plastic film and preparation method thereof

ActiveCN105419193ANo pollution in the processPromote degradationEnvironmental resistancePolymer science

The invention discloses a rapid degradation type soybean protein simulation plastic film and a preparation method thereof and belongs to the processing field of biological materials and food packaging technologies. The preparation method of the soybean protein simulation plastic film which can be rapidly degraded and has a certain mechanical strength, elasticity, gas barrier property and water tightness is provided. The soybean protein simulation plastic film is prepared from 2-4% of soybean separation protein, 1.5-2.5% of polyvinyl alcohol, 2-3% of nano-crystalline cellulose and 2% of plasticizer. The nano-crystalline cellulose effectively increases the degradation speed of film materials and improves the mechanical performance of the film materials; the plasticizer is added so that the soybean protein, polyvinyl alcohol and the nano-crystalline cellulose can form a more compact and uniform three-dimensional net structure, and various properties of plastics can be highly simulated. The degradation time of the film ranges from 2 months to 7 months. The simulation plastic film is simple in preparation technology, is convenient to operate, free of pollution to the environment and good in biological compatibility and biodegradability, the requirement for environment friendliness is met, and the plastic film can be widely applied to the food packaging field.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

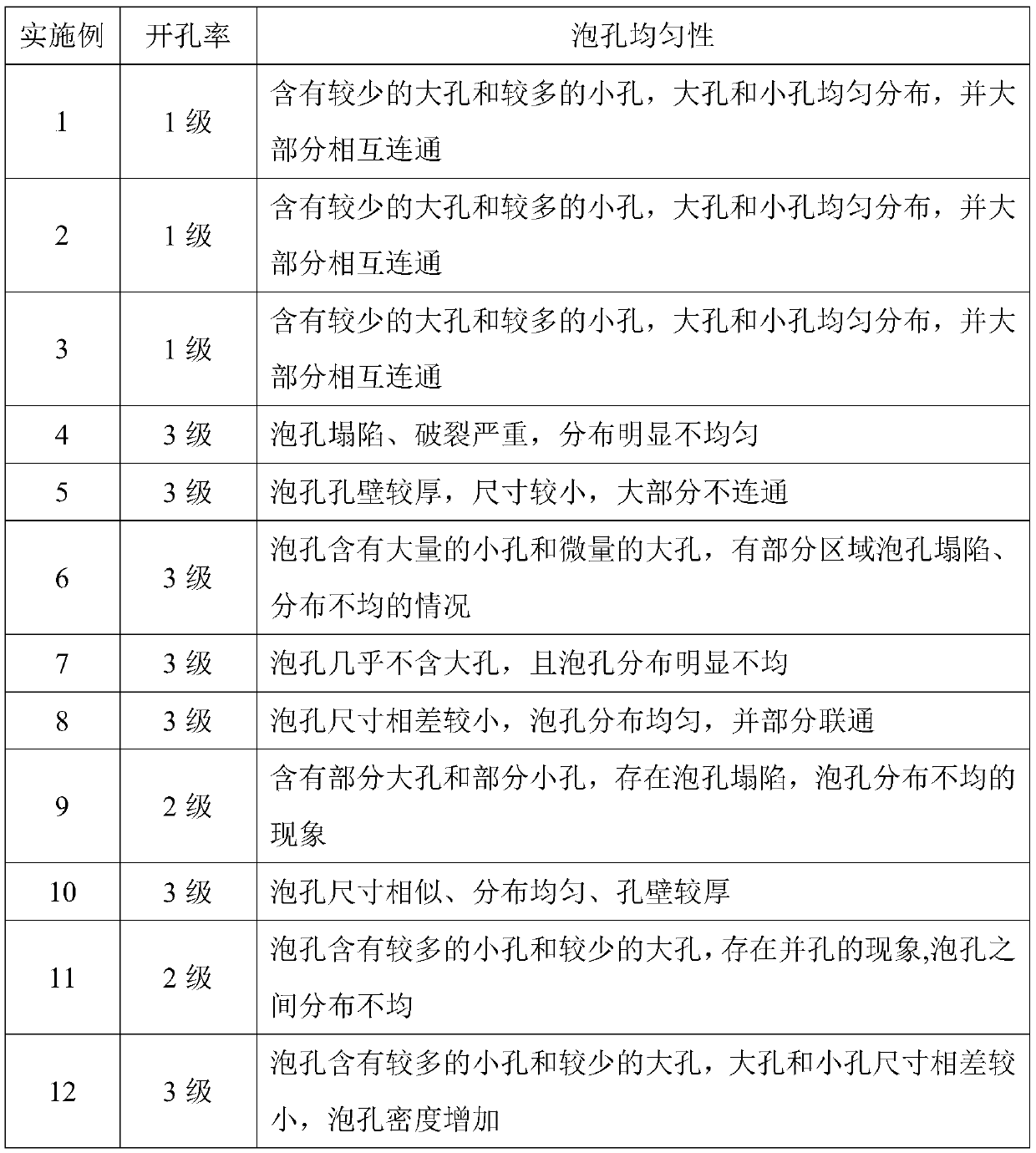

Polypropylene nucleating and cooling bifunctional master batch and preparation method and application thereof

The invention relates to the technical field of melt-blowing, in particular to a polypropylene nucleating and cooling bifunctional master batch and a preparation method and application thereof. According to the polypropylene nucleating and cooling bifunctional master batch, the prepared difunctional master batch with the stable cell and the aperture ratio can effectively absorb peroxide, the peroxide is uniformly dispersed in the bifunctional master batch, the dispersion of peroxide and the nucleating agent can be promoted when a melt-blown material is prepared to achieve uniform degradation,excessive degradation and other phenomena are avoided, the melt-blown material with the high melt flow rate is obtained, refining of melt-blown material grains by nucleating agents and the like can bepromoted, the melt-blown material with high transparency is obtained, non-woven fabric and the like can be prepared, and therefore the melt-blown material can be used for the fields of filtering, absorbing, keeping warm, absorbing oil and the like, such as mask preparation.

Owner:星贝达新材料有限公司

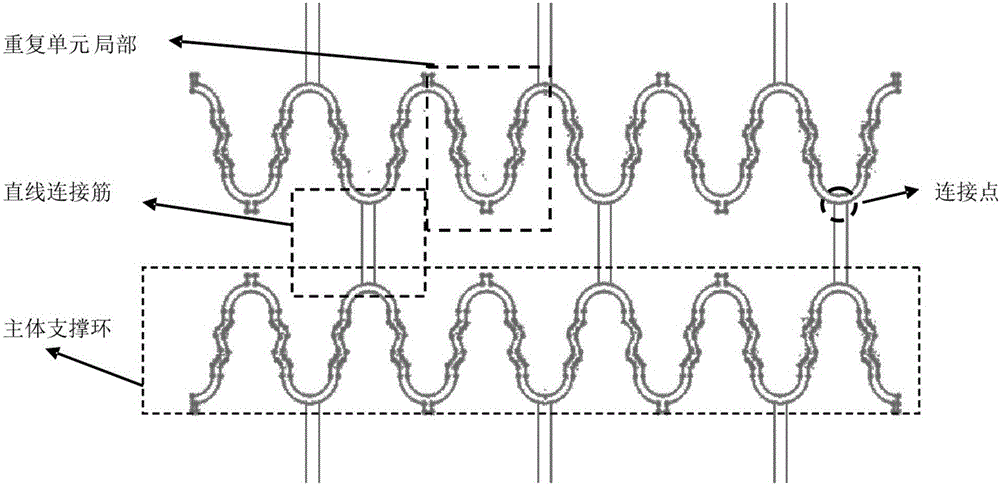

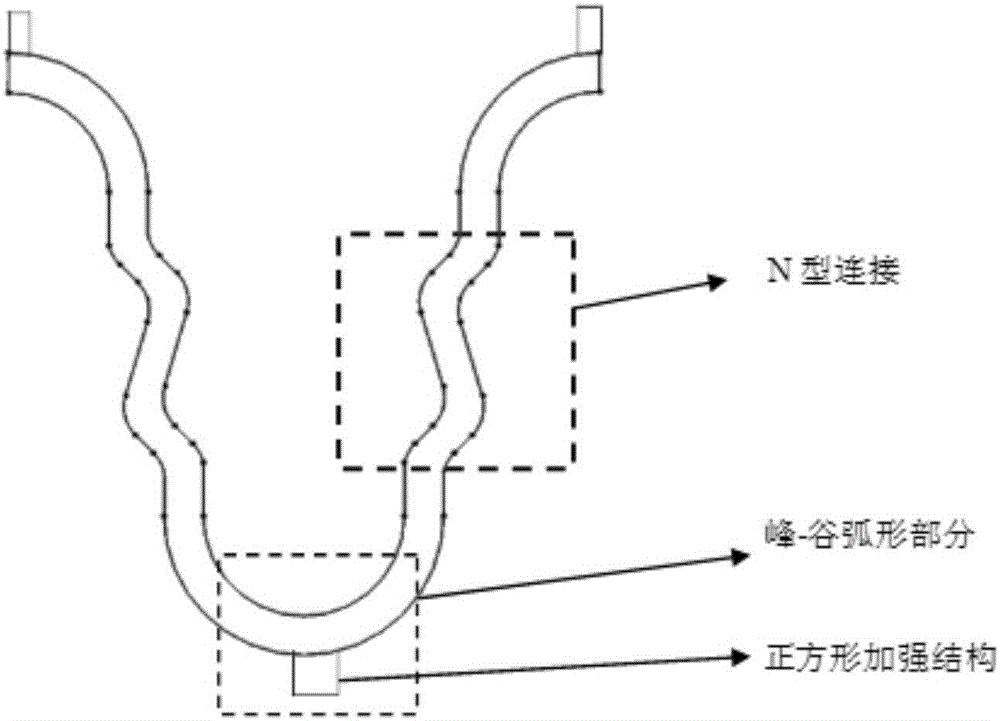

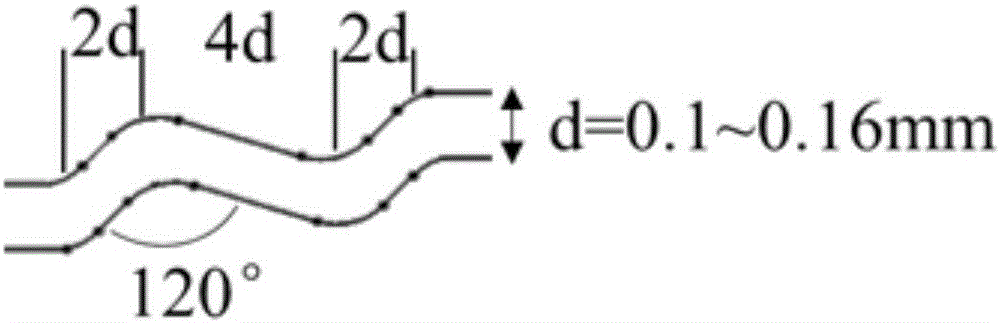

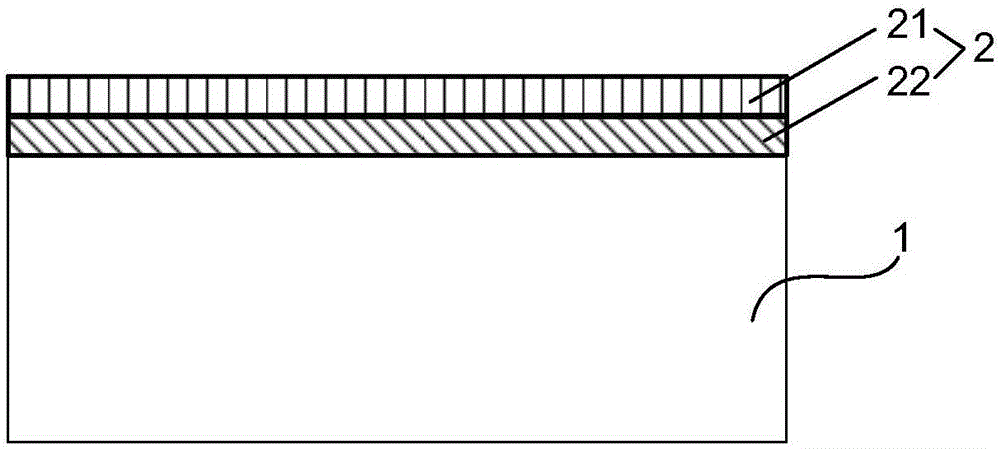

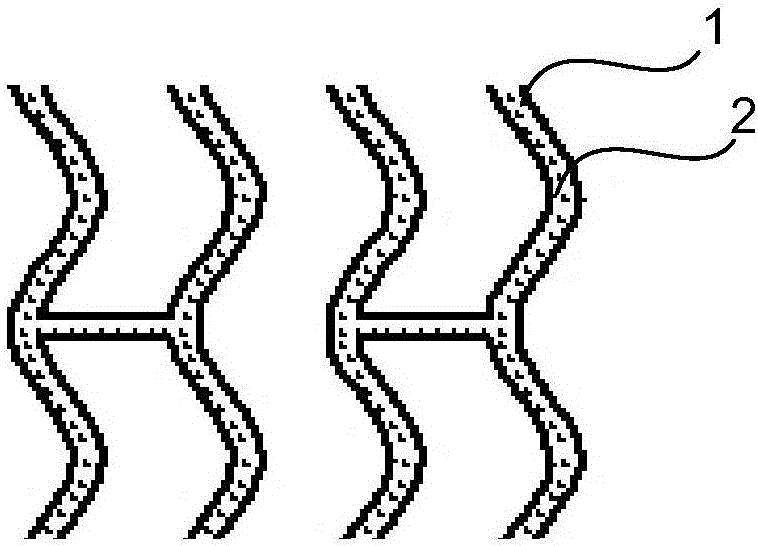

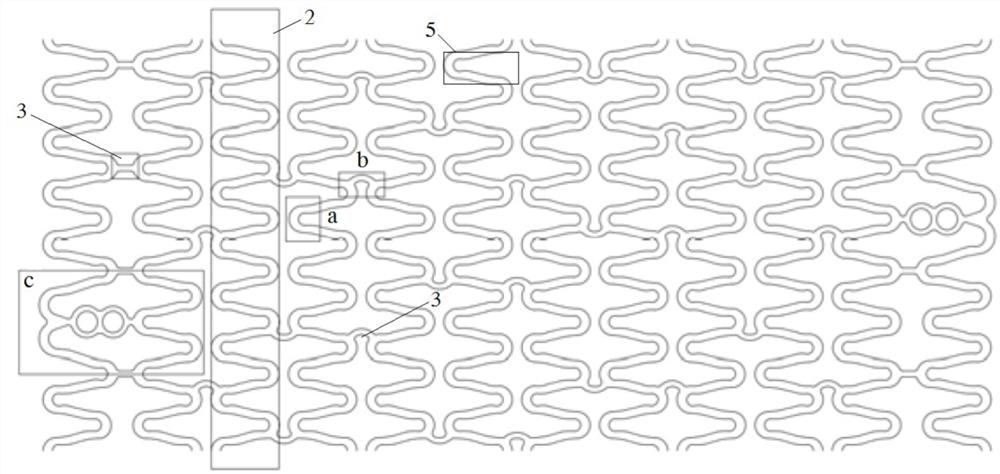

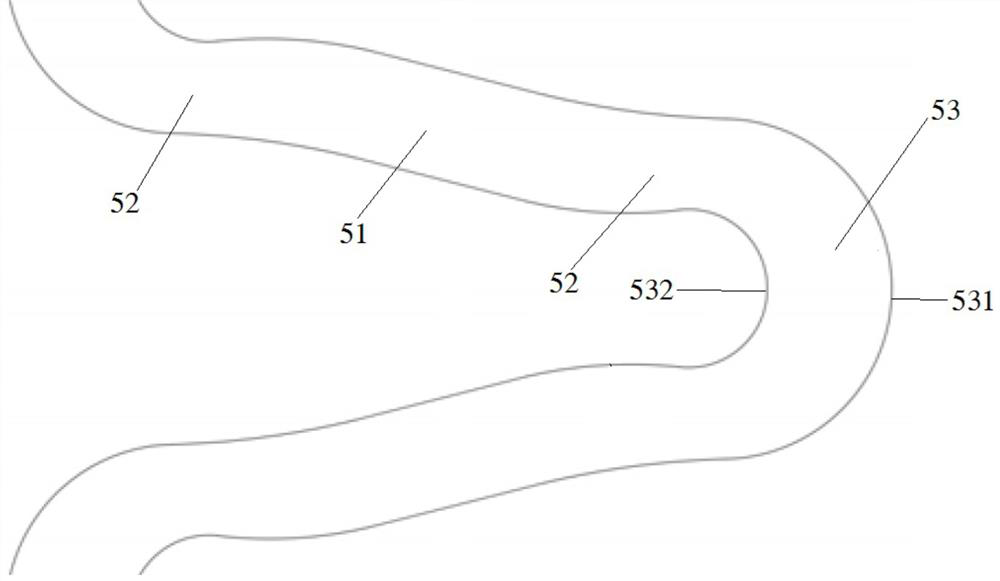

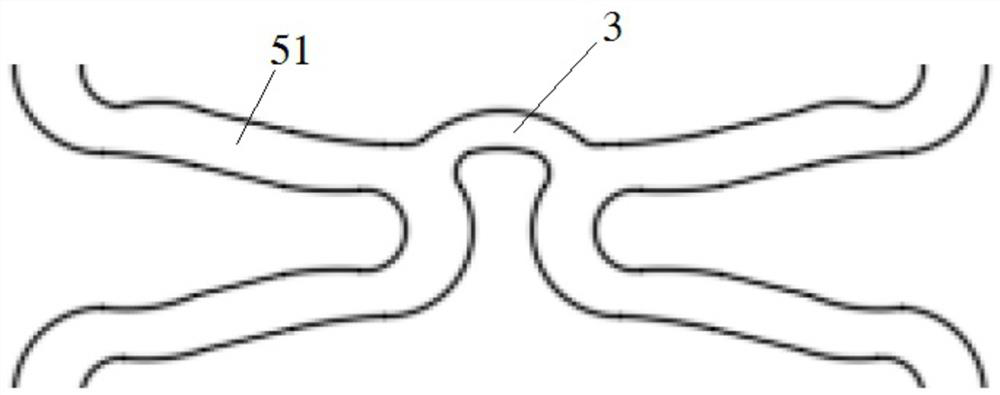

Uniformly-degradable polylactic acid based intravascular stent

InactiveCN106726037AReduce bracket stress extremesBracket stress distribution evenlyStentsSurgeryWave troughSize parameter

The invention relates to the field of interventional therapy equipment for cardiovascular diseases and discloses a uniformly-degradable polylactic acid based intravascular stent. The intravascular stent comprises body supporting rings and linear connection ribs, each body supporting ring comprises six wave peaks and six wave troughs, the wave peaks and the wave troughs of every two adjacent body supporting rings are in staggered arrangement, the wave peaks of each body supporting ring correspond to the wave troughs of the next body supporting ring, every two adjacent body supporting rings are connected through three of the linear connection ribs at equal intervals, and connection points are closer peak-trough points. Reinforcement structures are additionally provided for other peak-trough arc portions without connection points, and every two adjacent arc structures are connected through an 'N'-shaped line. The uniformly-degradable polylactic acid based intravascular stent has advantages that stent size parameters are optimized reasonably, stent stress extreme values are decreased while stent supporting strength is guaranteed, high stress distribution uniformity of the stent is realized, degradation uniformity is achieved, and integral supporting time of the stent is prolonged.

Owner:BEIHANG UNIV

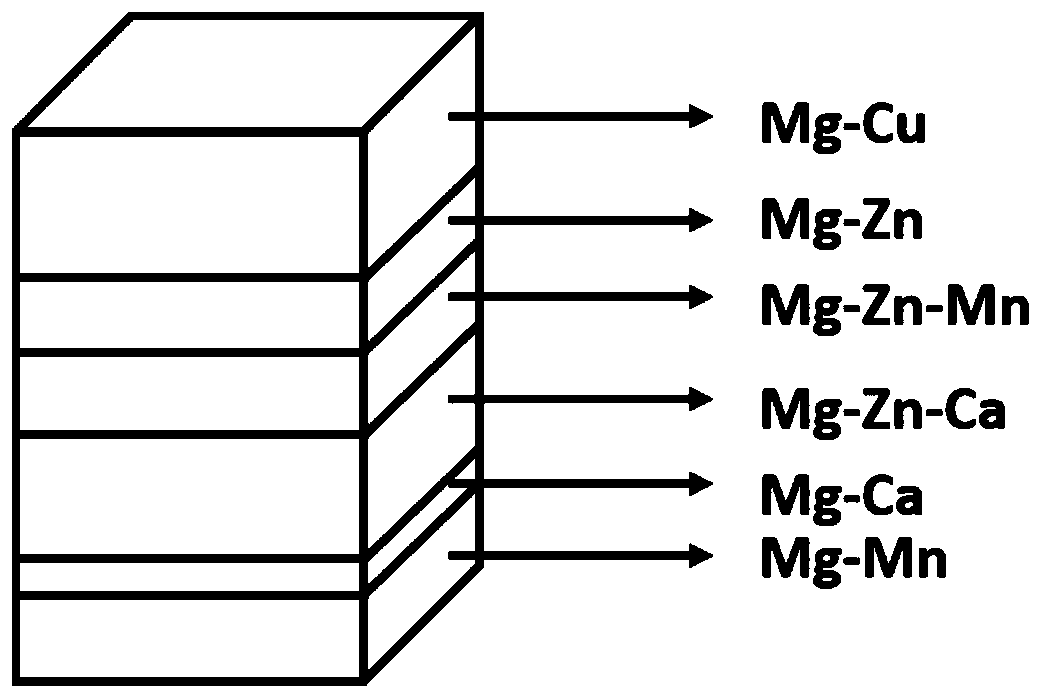

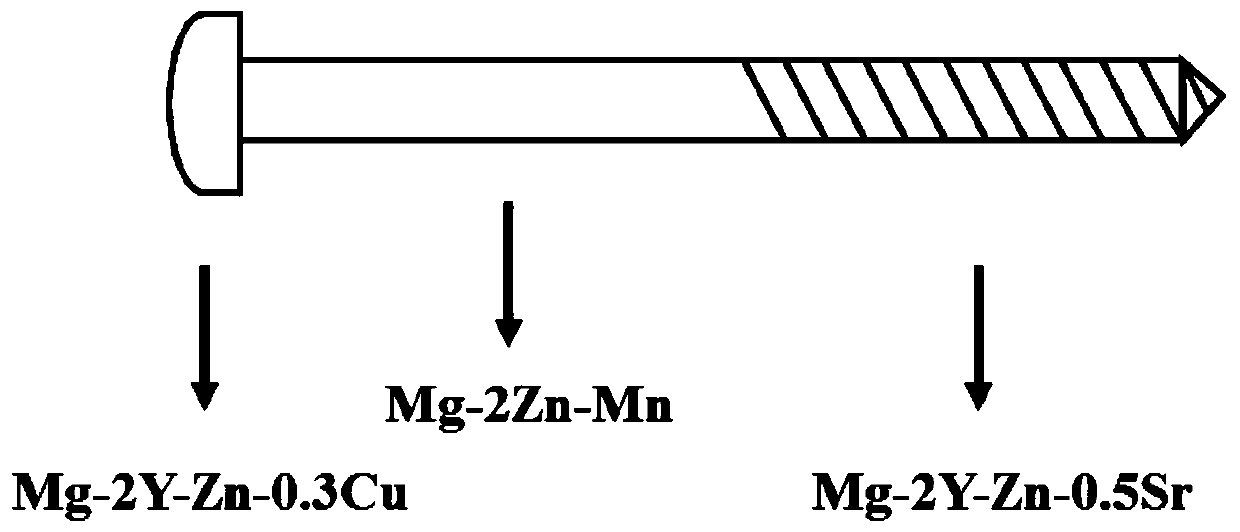

Degradable magnesium alloy material composed of multiple components as well as preparation method and application thereof

ActiveCN110976860ASolve the degradation rateSolve the mechanical propertiesAdditive manufacturing apparatusSurgeryComputer printingMetal powder

The invention discloses a degradable magnesium alloy material composed of multiple components as well as a preparation method and application thereof. The magnesium alloy material is formed by stacking a plurality of magnesium alloy layers with different component differences, wherein the component difference is that the adding elements in the magnesium alloy are different or the adding elements are the same, but the adding concentration is different. The preparation method comprises the following steps of (1) determining the type of required components, and placing the pure metal powder in different powder bins of a laser melting printer; (2) controlling the powder feeding amount of the pure metal powder of each element, and fully and mechanically mixing and then feeding the powder into apowder supply groove; and (3) carrying out melting and layered printing on the powder supplying laser in the powder supply groove to obtain the degradable magnesium alloy material with the corresponding shape and size and multiple components. The material is used as a medical implantable material to prepare bone repair or support materials. According to the degradable magnesium alloy material, mutual matching among the mechanical property, the degradation rate and the functionalization of the material is realized, and the requirements of the service environment of the biological material on the mechanical property, the degradation rate and the functionalization of the magnesium alloy are met.

Owner:SOUTHEAST UNIV

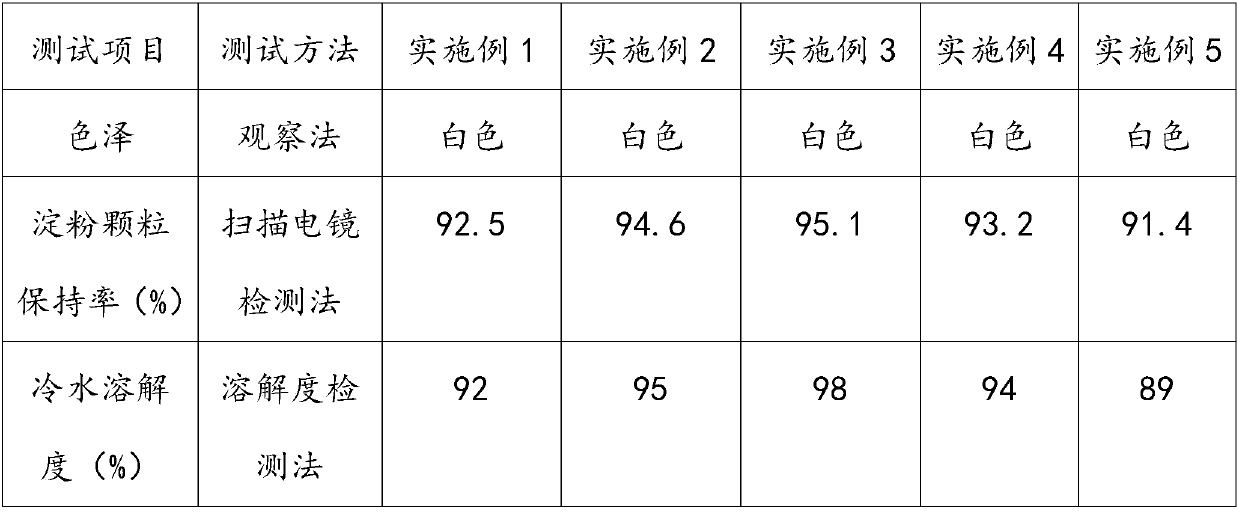

Production method of granular cold-water-soluble starch

The invention belongs to the technical field of production of starch and discloses a production method of granular cold-water-soluble starch. The method mainly includes: 1) feeding starch into a mixerand atomizing and spraying hydrochloric acid into the starch with uniform mixing to make acidified starch; 2) placing the acidified starch into a container or starch bag to perform fermentation; 3) washing the fermented starch in a washing pool for settlement, and adding an alkali solution for neutralization, thus obtaining modified starch; 4) centrifugally separating the modified starch in a centrifuge, flash-drying the modified starch in a drying machine, and sieving the modified starch to prepare the granular cold-water-soluble starch. The production method is simple in process and low incost, is safe and environment-friendly, is easy to carry out and apply in large scale, only needs normal temperature and pressure and is low in energy consumption. The granular cold-water-soluble starch has excellent performance and high granule completeness. Dissolution rate of the product in cold water can reach 98% at most.

Owner:HENAN ZHENGHONG PHARMA ADJUVANT CO LTD

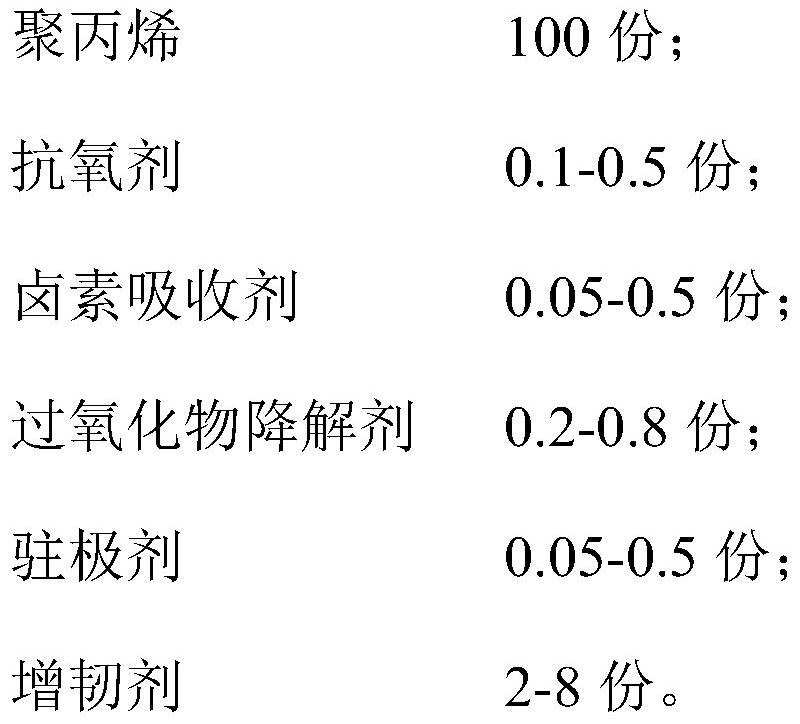

Low-odor, high-toughness and high-electret polypropylene melt-blown material and preparation method thereof

PendingCN112194850ANarrow molecular weight distributionSmall smellFilament-forming treatmentPolymer scienceAnoxomer

The invention discloses a low-odor, high-toughness and high-electret polypropylene melt-blown material and a preparation method thereof. The low-odor, high-toughness and high-electret polypropylene melt-blown material comprises 100 parts of polypropylene, 0.1-0.5 part of an antioxidant, 0.05-0.5 part of a halogen absorbent, 0.2-0.8 part of a peroxide degradation agent, 0.05-0.5 part of an electretagent and 2-8 parts of a flexibilizer. The invention also provides a preparation method of the low-odor, high-toughness and high-electret polypropylene melt-blown material. The polypropylene melt-blown material provided by the invention has the characteristic of low odor, and the melt-blown cloth prepared from the melt-blown material has good toughness and electret effect.

Owner:ZHEJIANG JAVA SPECIALTY CHEM CO LTD

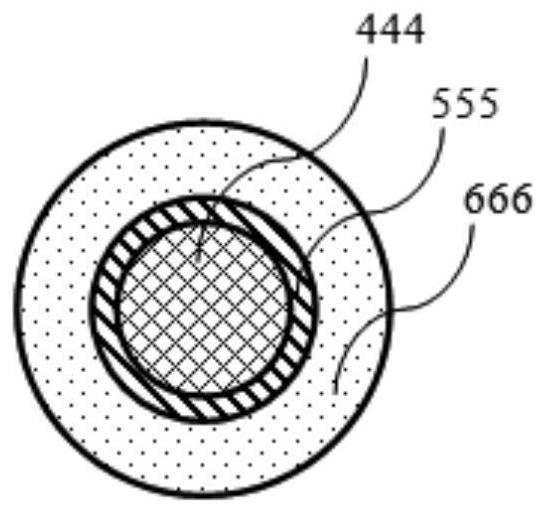

Surface coating composition of implantable medical apparatus, medical apparatus and manufacturing method of medical apparatus

InactiveCN106390211AInhibit sheddingExcellent drug release performanceSurgeryCoatingsControlled releaseInsertion stent

The invention provides a surface coating composition of an implantable medical apparatus, the medical apparatus and a manufacturing method of the medical apparatus, wherein the surface coating composition is at least prepared by mixing a degradable carrier and therapeutic drugs; the degradable carrier is selected from either polylactic acid or a copolymer thereof; and the weight of the therapeutic drugs accounts for 0.1-80% in terms of the weight of the surface coating. The coating provided by the invention has such outstanding performances that the coating is excellent in drug controlled-release property, good in binding property with a main body stent, uniform in degradation and the like, and a degradation product is harmless to human body. Meanwhile, a provided coating preparation technique has significant advantages of being simple and convenient to operate, high in yield, being controllable and the like.

Owner:NANJING YONGMING MEDICAL APP & INSTR CO LTD

Alloy matrix particles for preparing degradable mulching films

ActiveCN101812187AAddress water resistanceSolve balance problemsPlant protective coveringsMicrocrystalline waxAlloy

The invention relates to preparation of matrix particles capable of producing degradable mulching films, in particular to alloy matrix particles for preparing the degradable mulching films. The alloy matrix particles for preparing the degradable mulching films comprises the following components in percentage by weight: 0.01 to 0.03 percent of tert-butyl peroxy isopropyl benzene, 1.50 to 2.25 percent of fumaric acid, 4.50 to 5.60 percent of microcrystalline wax, 3.60 to 5.40 percent of polyethylene wax, 3.00 to 4.20 percent of MG70, 9.00 to 13.0 percent of N210 and 68 to 80 percent of corn starch. The alloy matrix particles for preparing the degradable mulching films have the advantages that: the alloy matrix particles can be restructured with PE structures to form a network bridge, so the prepared mulching films can be degraded quite uniformly; the problem of balancing the water tolerance and the hydrophilicity is solved, so the prepared mulching films can be attached to the ground surface, are difficult to blow away by wind, and have better function when used as the mulching films; and the mulching films can be blown to the thickness of 0.005mm and have small specific gravity, so the same amount of raw materials can produce more mulching films.

Owner:常州百利基生物材料科技有限公司

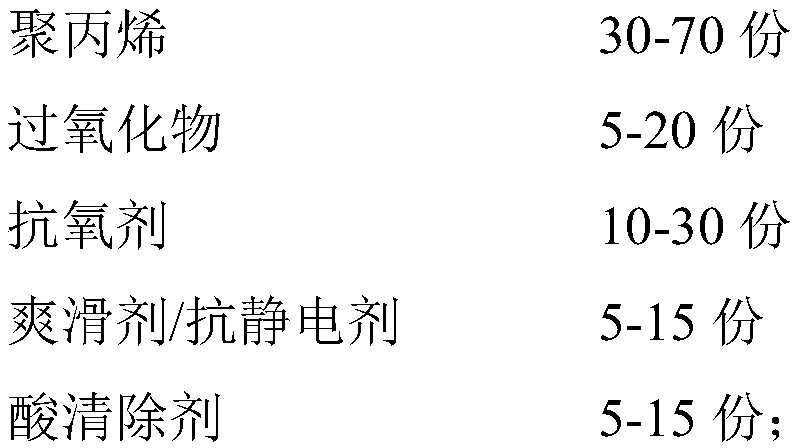

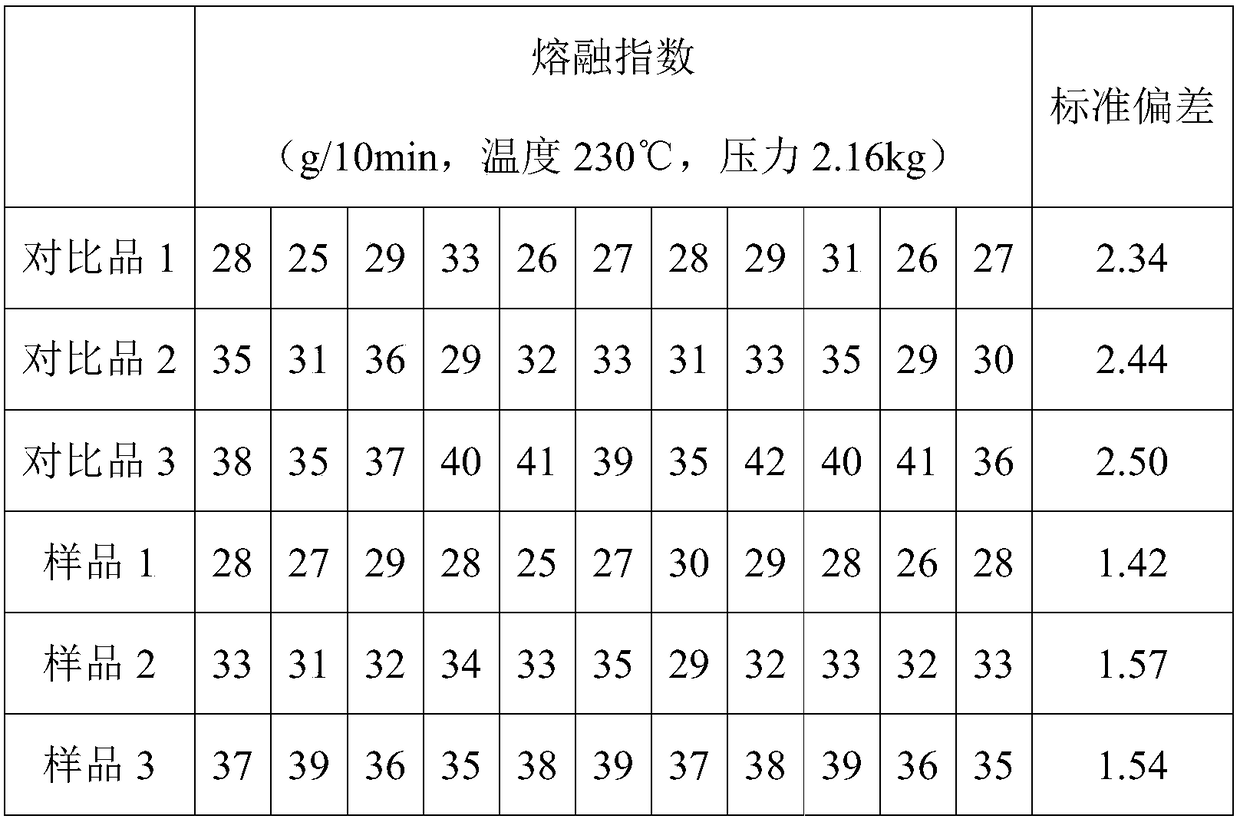

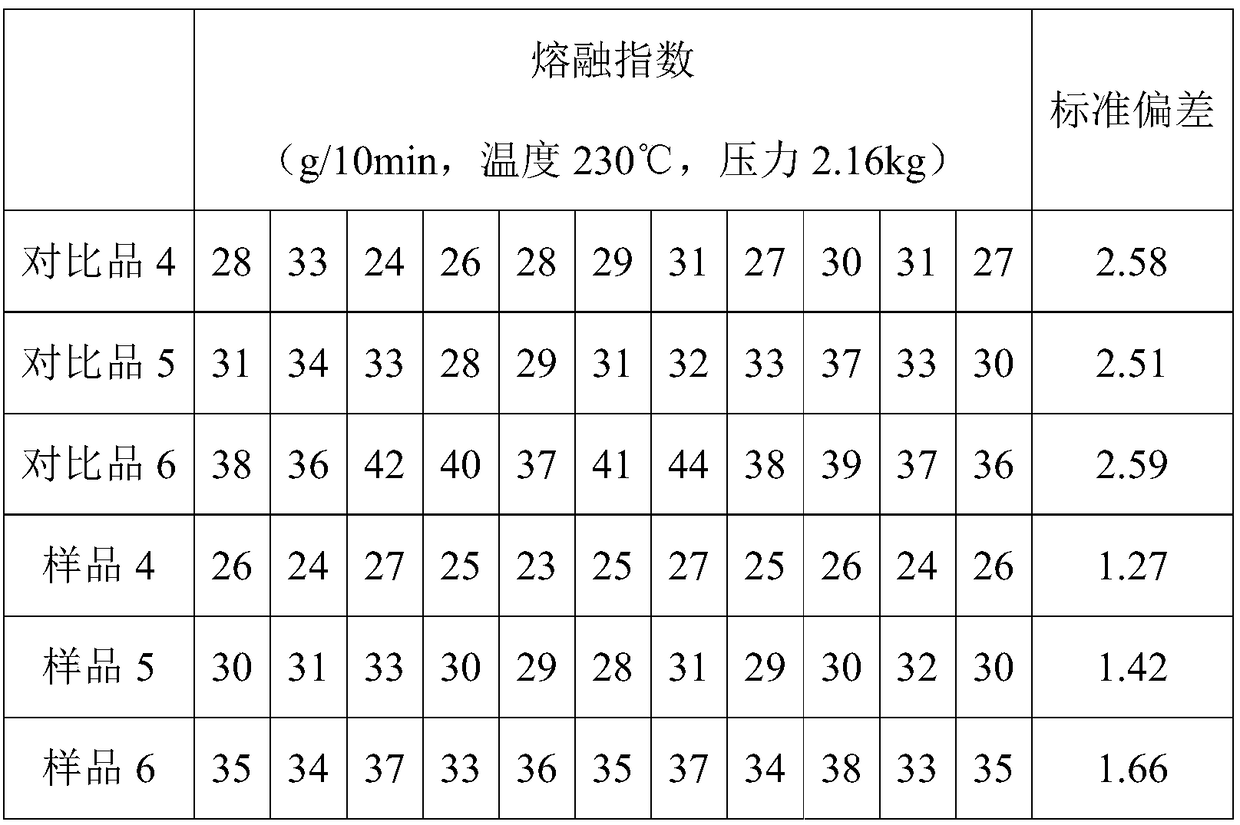

Functional polyolefin solid degradation agent

The invention relates to a functional polyolefin solid degradation agent and belongs to the technical field of degradation agents. The functional polyolefin solid degradation agent is prepared from the following components in parts by weight: 30 to 70 parts of polypropylene, 5 to 20 parts of peroxide, 10 to 30 parts of an antioxidant, 5 to 15 parts of a smoothening agent / antistatic agent and 5 to15 parts of an acid cleaning agent, wherein peroxide is at least one of di-tert-pentyl peroxide, 2,5-dimethyl-2,5bis(tert-butylperoxyl)hexane and dicumyl peroxide. A high-melting-index polypropylene product produced by the functional polyolefin solid degradation agent has narrow molecular weight distribution and also has excellent anti-oxidization performance; the oxidative induction time of a product is greater than 8min when the temperature is 200 DEG C.

Owner:DALIAN XINGHUI CHEM

Degradable biomedical magnesium alloy drug eluting intravascular stent and preparation method thereof

The invention provides a degradable biomedical magnesium alloy drug eluting intravascular stent and a preparation method thereof. Wherein the magnesium alloy is prepared from the following components in percentage by weight: 3.0 to 6.0 percent of Gd, 2.5 to 5.5 percent of Y, 1.0 to 3.0 percent of Li, 0.3 to 1.0 percent of Zn, 0.2 to 1.0 percent of Zr and the balance of Mg on the basis that the total weight of the magnesium alloy is 100 percent. The stent has good radial supporting strength and strain dispersion capacity through finite element design. After the protective coating designed by the invention is used, the corrosion resistance of the magnesium alloy stent is greatly improved. The arsenic trioxide or rapamycin and tacrolimus composite drug sustained-release system is used, and is fully adapted to the damage repair process of blood vessels. The implantation result of a large animal shows that the intravascular stent system has a good anti-restenosis treatment effect.

Owner:BEIJING AMSINO MEDICAL

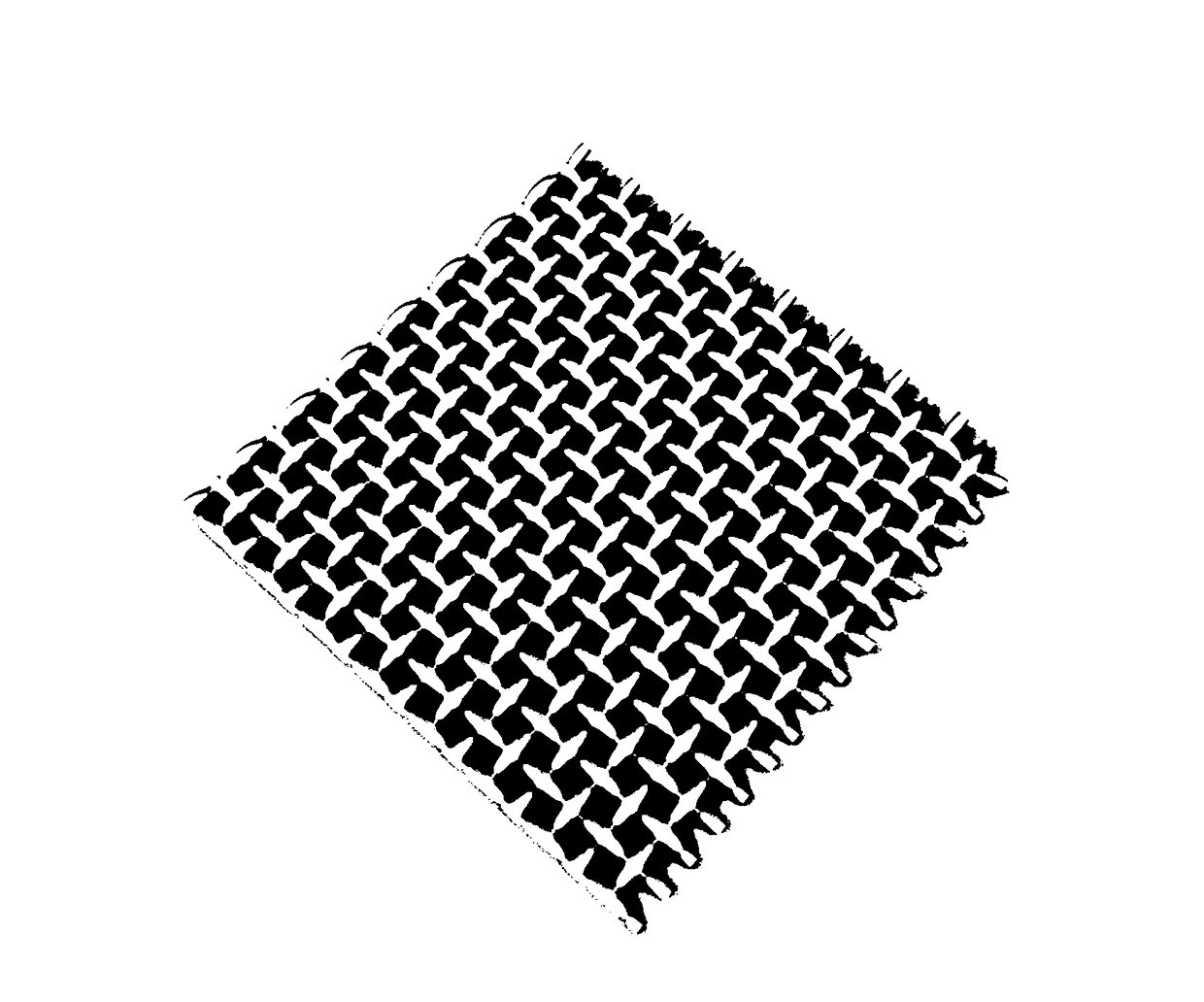

Biodegradable medical zinc alloy repairing patch as well as preparation method and application thereof

ActiveCN108853603AAvoid long-term complicationsStable supportSurgeryTissue regenerationDiseaseBiocompatibility Testing

The invention provides a biodegradable medical zinc alloy repairing patch as well as a preparation method and application thereof, and belongs to the technical field of medical consumables. The biodegradable medical zinc alloy repairing patch is characterized in that zinc alloy wire materials with the cross sections in a round shape, an oval shape or a rectangular (flat strip) shape are used for weaving a porous reticular structure; an absorbable coating is arranged on the reticular structure. The repairing patch can be prepared into different film coated repairing patches through being pressed with an absorbable film layer on the surface, and can be applied to different clinic diseases. The prepared repairing patch has the advantages of low cost, simple processing, low thickness, high toughness, good biocompatibility and the like. After the repairing patch is implanted into the human body, high mechanical property can be maintained in a certain period; meanwhile, after the wound of the patient heals, the patch can be degraded and absorbed by the human body without residue in the body; uncomfortable feeling and untoward effect of the patient in the later period of the healing can be reduced.

Owner:SHANGHAI JIAO TONG UNIV

Membrane bioreactor for denitrification and waste water denitrification method

InactiveCN101863586BImprove water qualityRealize deep denitrification treatmentMultistage water/sewage treatmentFiltrationTrapping

The invention belongs to the field of environment protection and discloses a membrane bioreactor for denitrification and waste water denitrification method thereof. The membrane bioreactor is divided into a first anoxic pond, an aerobic pound, a second anoxic pound, an anaerobic pond and a membrane pound by a vertical deflecting baffle plate and an aeration device, wherein the ponds are five independent and communicated reactor chambers; after waste water enters the process, the biochemical treatment processes such as the degradation, nitrification and denitrification of organic matters are completed under the action of microorganisms; and effluent is obtained by membrane filtration and pumping. The bioreactor and the method have the advantages that: sludge mixed liquid flows in a piston flow mode in the whole system, but is in a fully mixed state in a single cell and a refluxing device is used, so the degree of mixing in the entire reactor is high and the mass transfer effect is good; under a condition of not adding extra carbon source, the process strengthens the denitrification by using high sludge concentration, so deep denitrification treatment is realized and the pollution to the membrane is relieved; and at the same time, due to the high efficiency trapping and separation characteristic of the membrane, the quality of effluent of filtration is high.

Owner:SUN YAT SEN UNIV

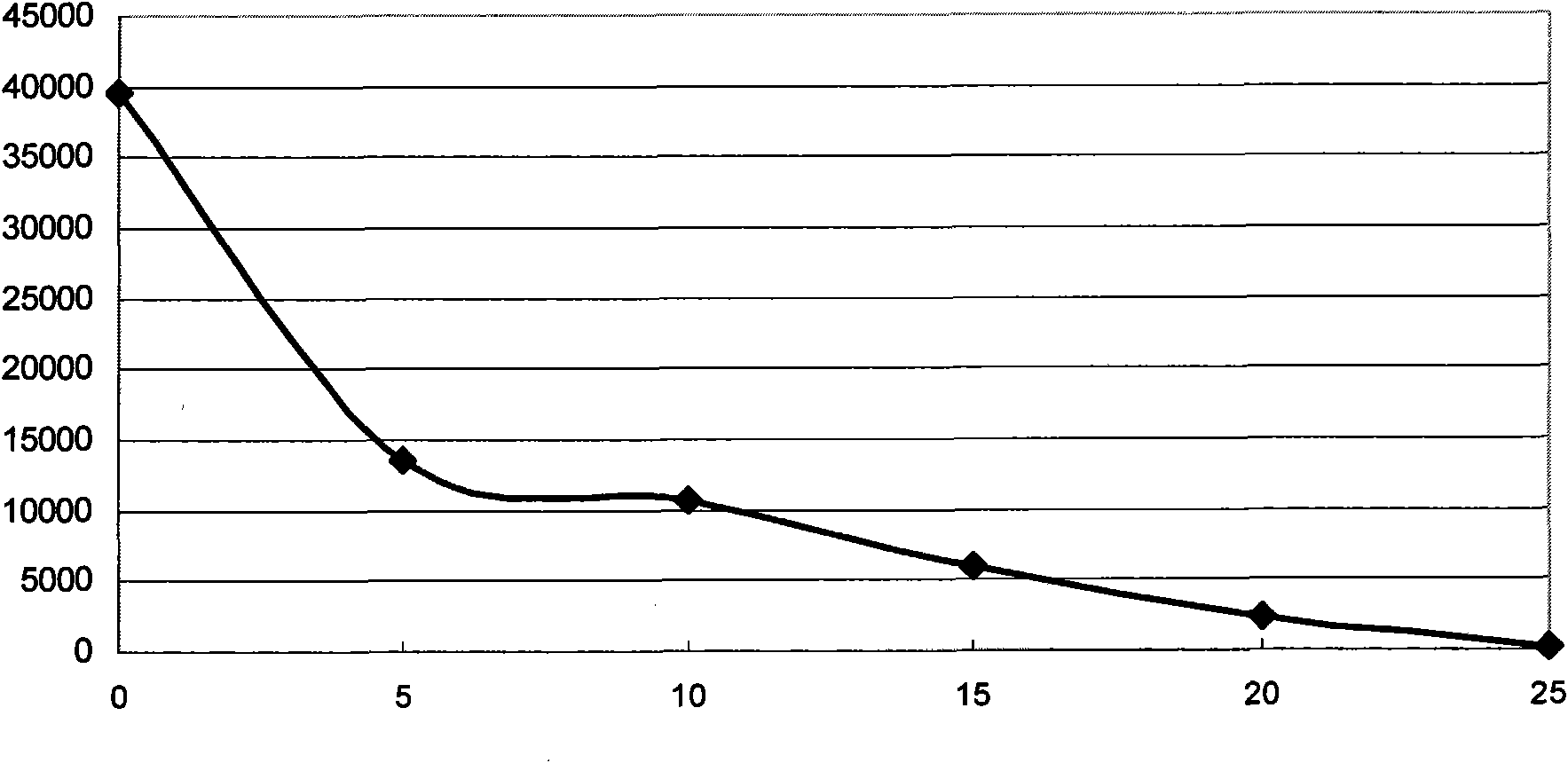

Prepn of high flowability polypropylene

The present invention relates to the preparation process of high flowability polypropylene and solves the technological problem of providing high energy ray preparation process of high melt flowability polypropylene. The present invention features that polypropylene grains are set inside high energy ray irradiation chamber and irradiated in the irradiation dosage over 100 Mrad at normal temperature for over 10 hr to obtain high flowability polypropylene with melt rate of flow MRF as high as 50-100 g / 10 min. The present invention adopts high energy gamma ray with powerful penetration capacity and homogeneous degradation from inside grain to outside and can regulate the flowability of the polypropylene product easily via regulating irradiation dosage. The process of the present invention needs no mechanical stirring, low power consumption and low cost.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

A kind of preparation method of silk fibroin microsphere

InactiveCN103341175BUniform internal and external curing structureHigh embedding efficiencyAnimal feeding stuffAbsorbent padsMicrosphereRoom temperature

Owner:ZHEJIANG UNIV

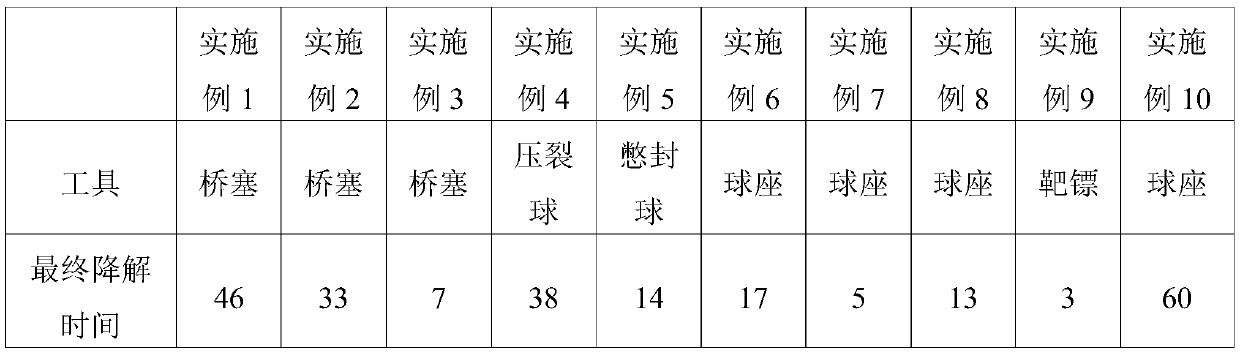

A kind of magnesium alloy material for oil and gas development and its preparation method and application

The invention discloses a magnesium alloy material for oil and gas development, a preparation method and application thereof, which belong to the technical field of nonferrous metals. The composition content of the magnesium alloy material is: cerium-rich mixed rare earth: 0.5-25wt.%, Sn: 0-10wt.%; Fe: 0-10wt.%, Ti: 0-10wt.%; Ni: 0-10wt.% .%; Cu: 0~10wt.%; the balance is Mg. The tools made of the magnesium alloy material of the present invention can be used in oil wells, shale gas, and oil and gas wells for oil and gas production downhole operations, and the tools include soluble bridge plugs, soluble ball seats, fracturing balls, plugging balls, darts, etc. . The material can precisely control and predict the evolution of its mechanical properties and dissolution rate in the oil and gas well environment, establish an accurate prediction model, and directly select the most suitable composition and preparation and deformation methods for different shale oil and gas well environments, greatly shortening the delivery time cycle, ensure the safety and efficiency of oil and gas extraction, and reduce the risk and cost of production accidents.

Owner:GRIMAT ENG INST CO LTD

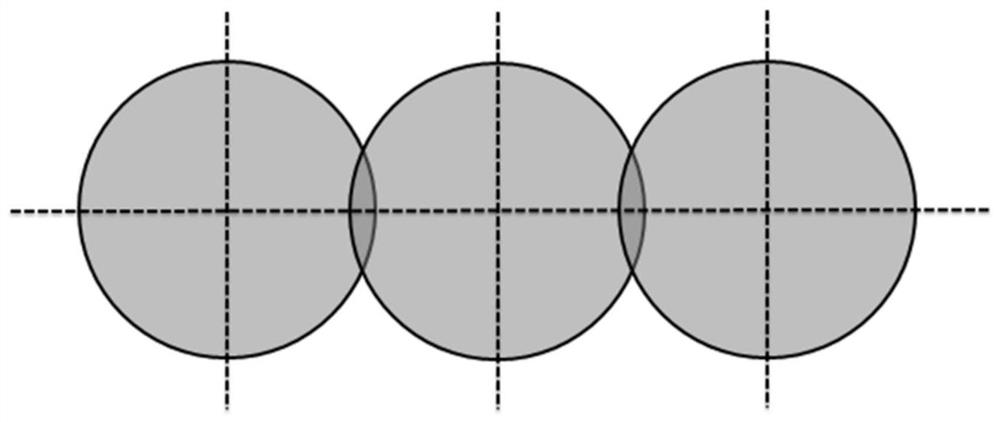

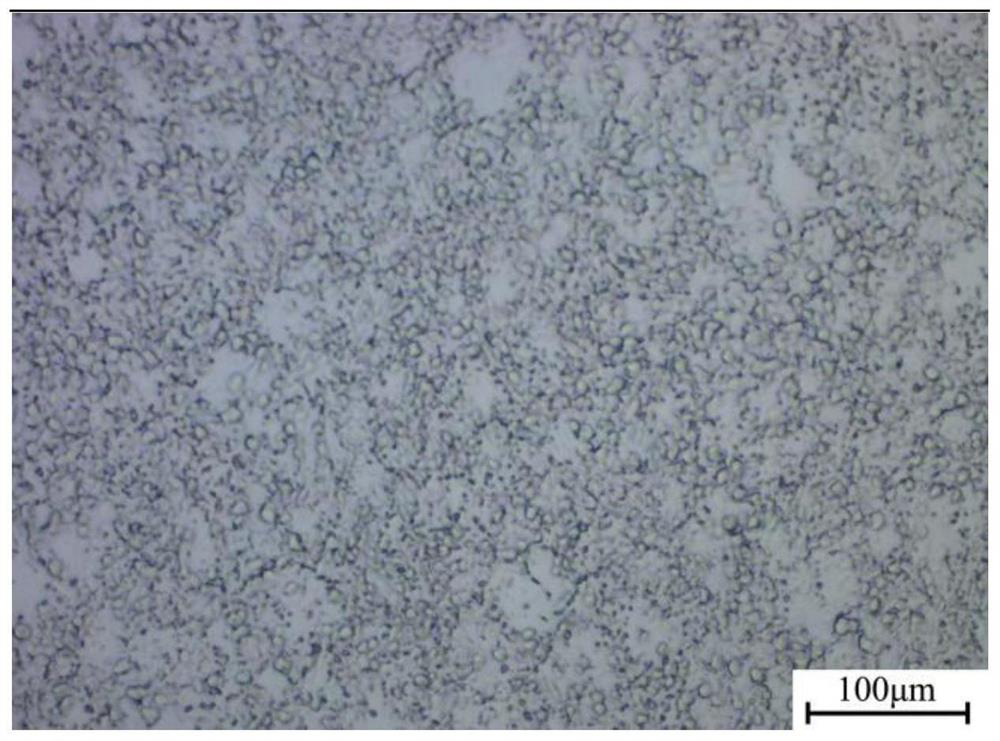

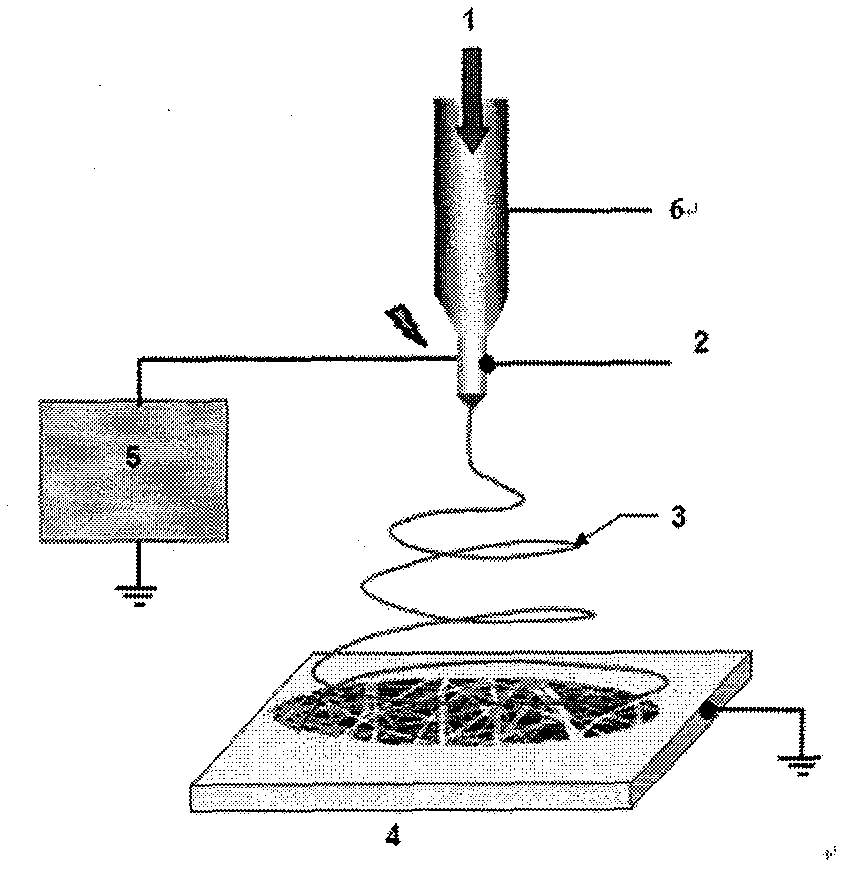

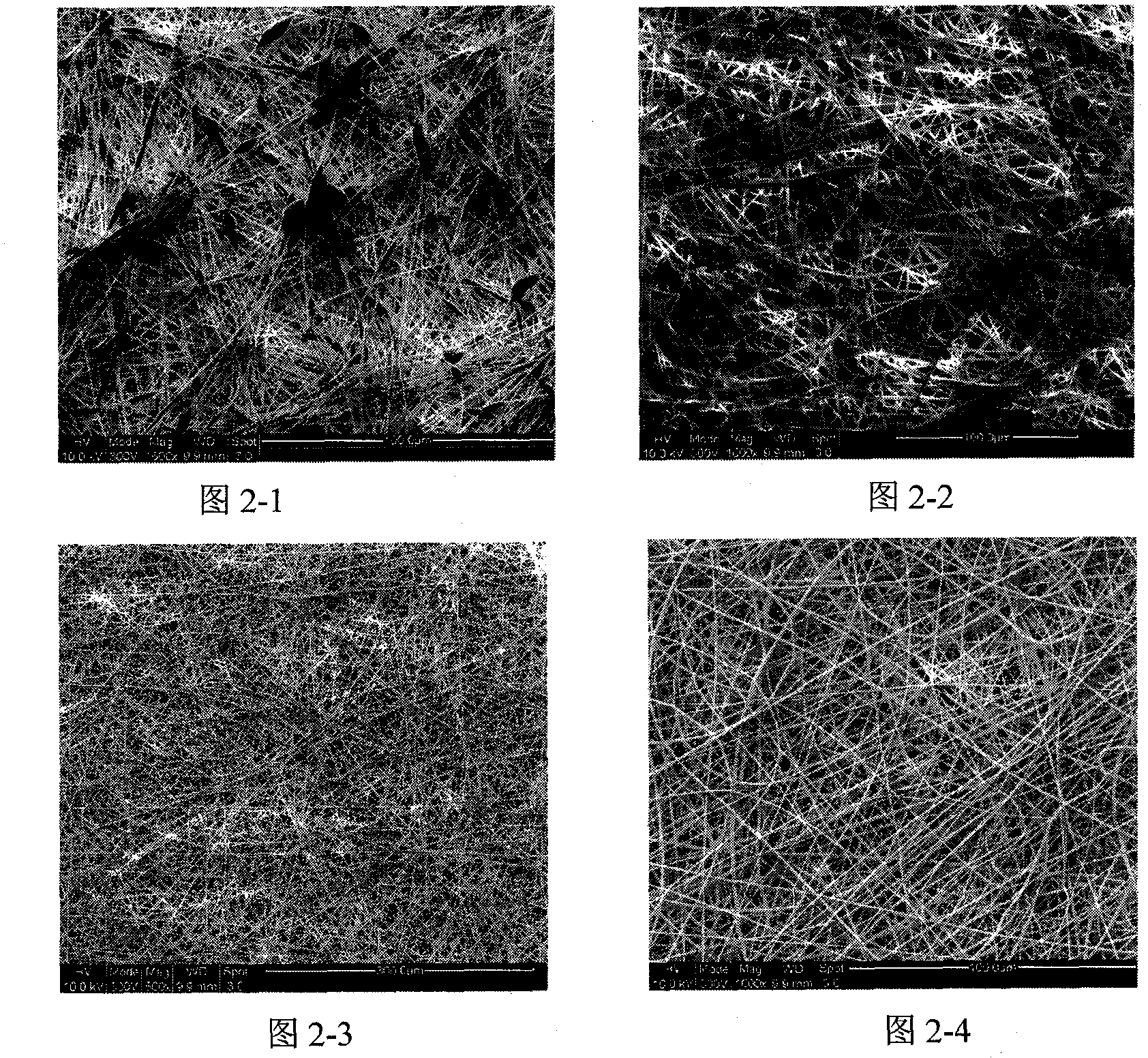

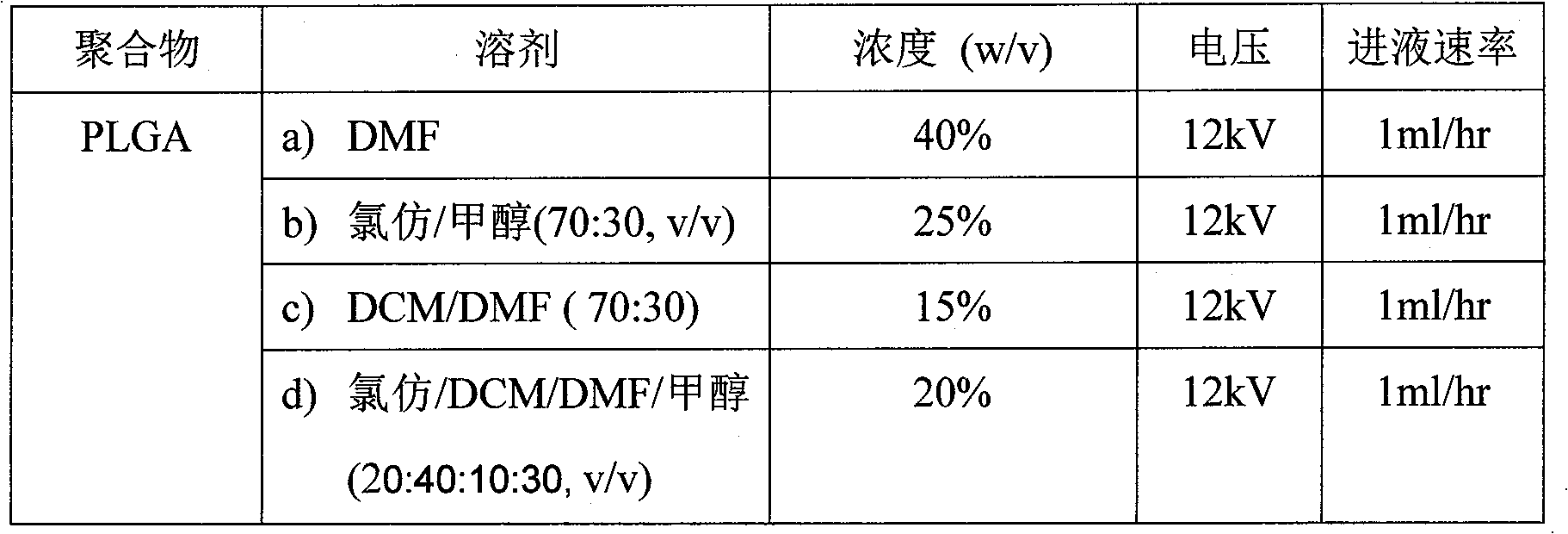

Degradable submicron fiber membrane for postoperative adhesion prevention and preparation thereof

InactiveCN102758260APromote exchangePrevent penetrationFilament/thread formingNon-woven fabricsFiberSpinning

The invention relates to a degradable non-woven submicron fiber membrane and a preparation method thereof, as well as a purpose thereof for postoperative adhesion prevention of tissues and organs. A textile is prepared by adopting an electrostatic spinning method. The fiber membrane prepared by the method has good flexibility, air permeability and an effective tissue cell isolation function. A submicron structure with high specific surface area is also conductive to fast and uniform degradation of fiber. The fiber membrane after sterilization treatment can be used as a postoperative anti-adhesion membrane.

Owner:SHENZHEN FEIXIANG SHIJI BIOLOGICAL

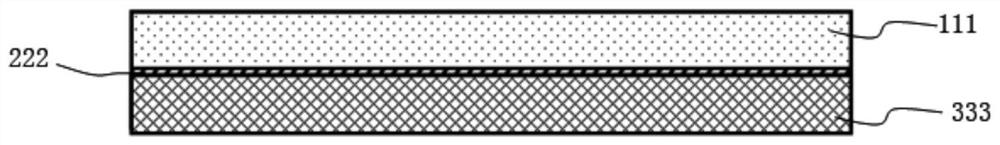

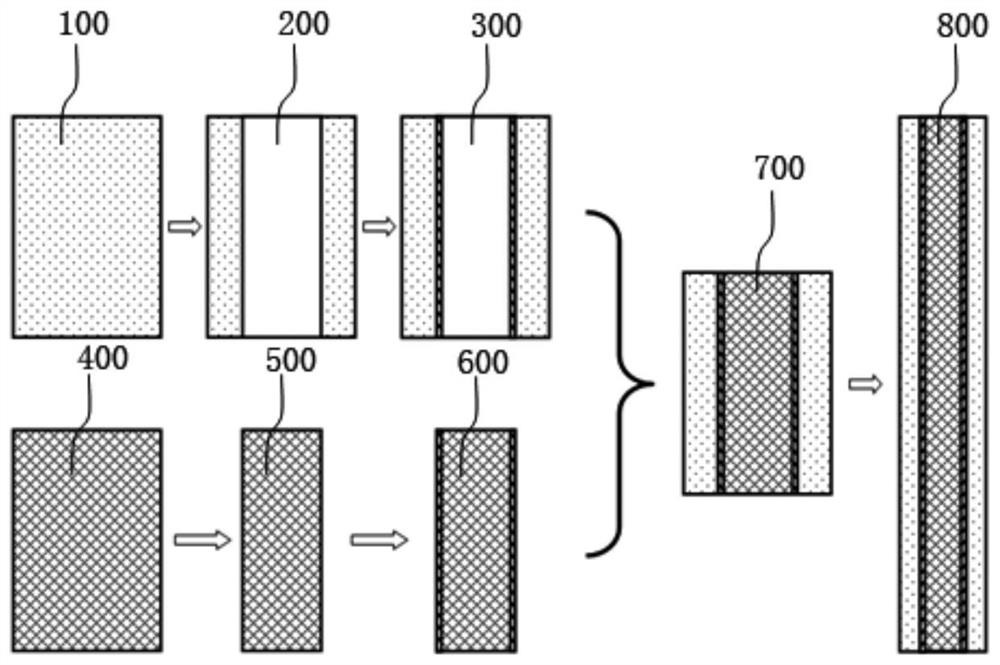

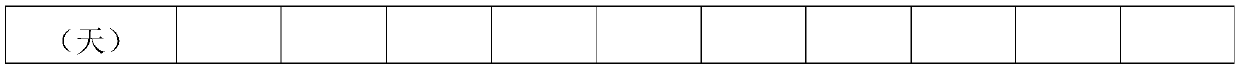

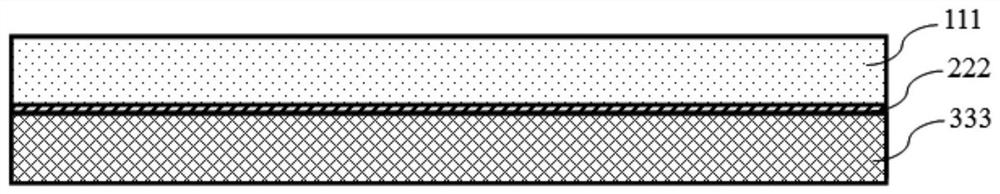

Degradable and high-toughness composite material and preparation method thereof

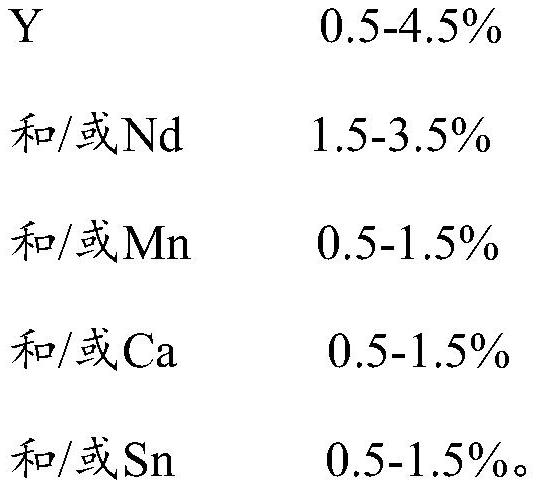

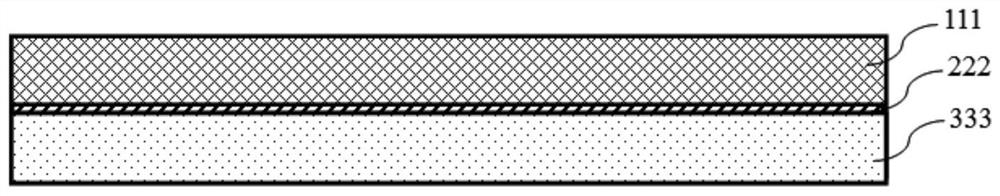

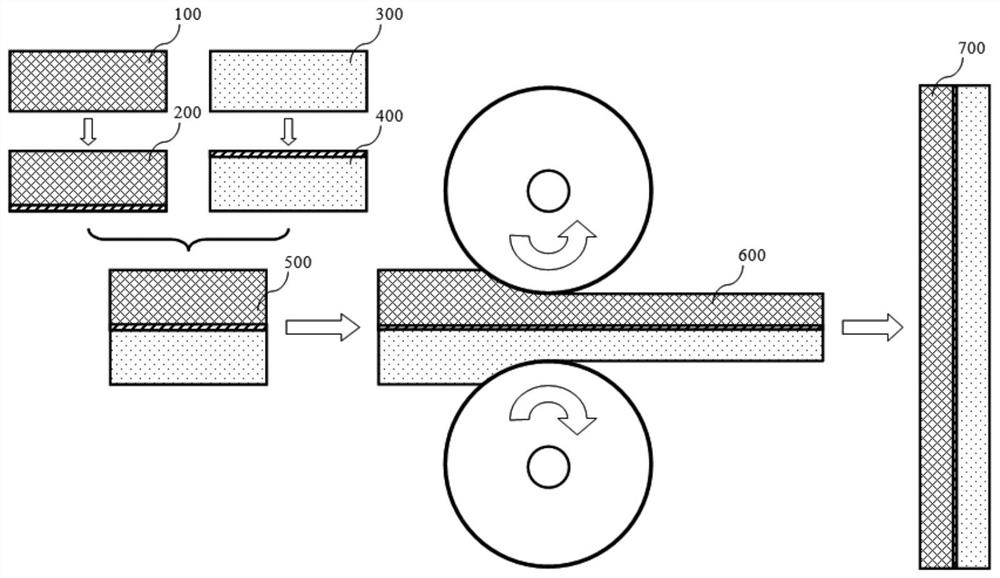

The invention belongs to the technical field of alloy materials, and discloses a degradable and high-toughness composite material and a preparation method thereof. The composite material comprises a zinc alloy layer, an intermediate alloy layer and a magnesium alloy layer, wherein the intermediate alloy layer is composed of a magnesium-zinc alloy, the zinc alloy layer does not contain Mg, the magnesium alloy layer does not contain Zn, the zinc alloy layer is composed of a zinc alloy, the zinc alloy further comprises Y and / or Nd, the magnesium alloy layer is composed of a magnesium alloy, the magnesium alloy further comprises Y and / or Nd, and the magnesium-zinc alloy comprises the following components in percentage by mass: 50-80% of Mg and 20-50% of Zn. Due to the existence of the intermediate alloy layer in the composite material, the connection between the zinc alloy layer and the magnesium alloy layer is enhanced, the mechanical property of the composite material is improved, and particularly, an elastic modulus of the composite material is obviously reduced relative to an elastic modulus of the zinc alloy, so that the healing of bone tissues is not influenced, and a degradationrate of the composite material in a human body is reduced.

Owner:珠海中科先进技术研究院有限公司

Deplasticization film-forming oil and preparation method thereof

PendingCN112358763AEasy to degradeMeet the requirements of green environmental protectionInksIsooctyl acrylatePolymer science

The invention provides deplasticization film-forming oil and a preparation method thereof. The deplasticization film forming- oil is prepared from laminating adhesive, waterborne acrylic solid resin,a first auxiliary and a second auxiliary, the first auxiliary is a leveling agent and a wetting agent, and the laminating adhesive is prepared from a reaction monomer, a modified monomer, a third additive, a fourth additive and water; the reaction monomer at least comprises acrylic acid, butyl acrylate, styrene, hydroxyethyl acrylate and 2-ethylhexyl acrylate, the modified monomer is an N- (hydroxymethyl) acrylamide aqueous solution, the third additive is a coalescing agent, an emulsifier and an initiator, and the coalescing agent is Texanol. The deplasticization film-forming oil disclosed bythe invention is high in film-forming speed, strong in adhesive force, high in glossiness and good in mechanical property, does not contain plastic components such as PP, PVC, PET and PE in a traditional protection film, and is a protection film material with excellent comprehensive performance.

Owner:东莞市神乐高分子科技有限公司

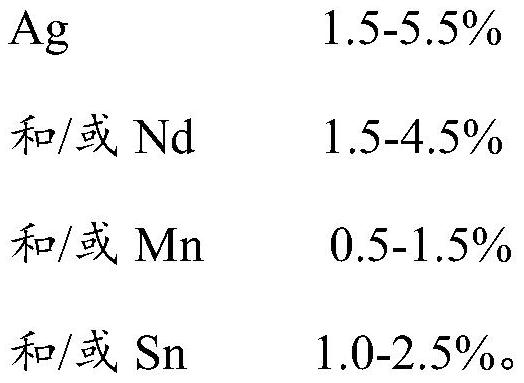

Alloy material with antibacterial property and high toughness and preparation method and application thereof

ActiveCN112371983AImprove performanceImprove antibacterial propertiesSurgeryAgainst vector-borne diseasesStaphyloccocus aureusZinc alloys

The invention belongs to the technical field of alloy materials, and discloses an alloy material with antibacterial property and high toughness and a preparation method and application thereof. The alloy material comprises a magnesium alloy layer, an intermediate alloy layer and a zinc alloy layer, wherein, the magnesium alloy layer and the zinc alloy layer comprise Ag and Cu; and the intermediatealloy layer is made of magnesium-zinc-silver-copper alloy. The magnesium alloy layer is made of magnesium alloy, and the magnesium alloy further comprises at least one of Nd, Sn or Sr; and the zinc alloy layer is made of zinc alloy, and the zinc alloy further comprises at least one of Nd, Sn or Sr. The alloy material can simultaneously satisfy the characteristics of long-acting antibacterial function, lower degradation rate and favorable mechanical properties, has obvious killing effects on staphylococcus aureus, Escherichia coli, Candida albicans, pneumobacillus, proteus and salmonella typhimurium, and has important application value in the field of medical implant materials.

Owner:珠海中科先进技术研究院有限公司

Zn-RE-Cu-series zinc alloy material for oil and gas exploitation and preparation method and application thereof

InactiveCN111349818AUniform degradationDegradation time controllableFluid removalWell/borehole valve arrangementsPhysical chemistryProcess engineering

The invention discloses a Zn-RE-Cu-series zinc alloy material for oil and gas exploitation and a preparation method and application thereof. The Zn-RE-Cu-series zinc alloy material comprises, by mass,0.005%-25% of RE, 0.001%-15% of Cu, 0.001%-0.5% of Mg, 0.001%-0.5% of Ni and the balance Zn and inevitable impurities. A zinc alloy fracturing tool produced by the components is used for an oil and gas well which does not need to be exploited within a long time (3-60 days) after fracturing construction is finished, the zinc alloy tool has the effect of temporarily sealing the well, when the sealing storage period is finished, the tool is completely and evenly degraded in the underground environment, and therefore the drilling, grinding and recycling procedures are omitted. The tool degradation time is controllable, the engineering difficulty is lowered, and the construction efficiency and the single well yield can be improved.

Owner:GRIMAT ENG INST CO LTD

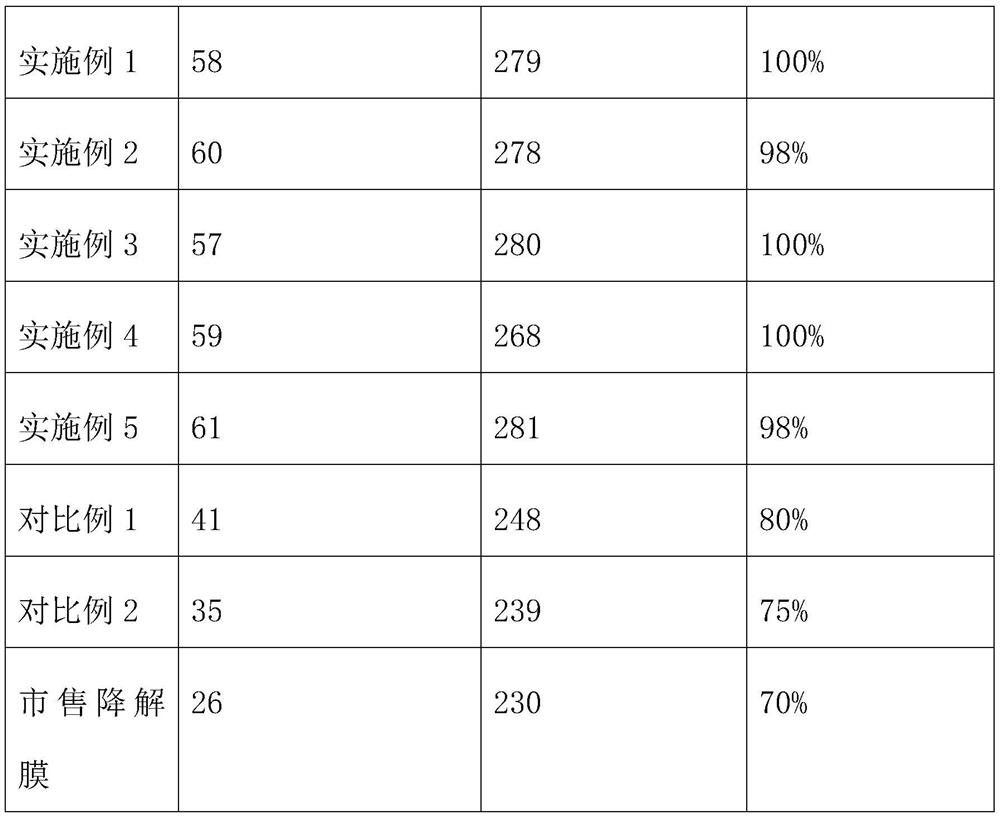

Degradable high-toughness composite material with antibacterial function and preparation method thereof

ActiveCN112192919AImprove performanceImprove antibacterial functionMedical patchesFurnace typesAg alloyMagnesium alloy

The invention belongs to the technical field of alloy materials, and discloses a degradable high-toughness composite material with an antibacterial function and a preparation method thereof. The composite material comprises a magnesium alloy layer, an intermediate alloy layer and a zinc alloy layer, wherein the magnesium alloy layer and the zinc alloy layer comprise Ag; the intermediate alloy layer is made of magnesium-zinc-silver alloy; the magnesium alloy layer is made of magnesium alloy, and the magnesium alloy further comprises at least one of Nd, Mn or Sn; and the zinc alloy layer is madeof zinc alloy, and the zinc alloy further comprises at least one of Nd, Mn or Sn. The composite material can simultaneously meet the characteristics of long-acting antibacterial function, low degradation rate and good mechanical property, and is beneficial to the application of the composite material in the medical field.

Owner:珠海中科先进技术研究院有限公司

Degradable film preparation process

The invention provides a degradable film preparation process, comprising the following steps: (1) Preparation of photodegradable masterbatch: drying the photosensitizer for 0.5-1h, drying the dried photosensitizer, dispersant, polypropylene resin, antioxidant, Mix and granulate hydrophobic agent and lubricant to prepare photodegradable masterbatch; (2) Preparation of starch-based degradable masterbatch: dry starch for 0.5-1h, mix and stir dried starch and coupling agent evenly to prepare starch mixture, Then mix and granulate the starch mixture with polypropylene resin and plasticizer to obtain starch masterbatch; (3) preparation of degradable film: mix photodegradable masterbatch and starch masterbatch and dry for 0.5-1h, then dry the dried The photodegradable masterbatch and starch masterbatch are kneaded at high speed in a high-speed kneader to obtain a blow molding masterbatch, and the blow molding masterbatch is blow molded to obtain a degradable film. The process is simple and the cost is low, and the prepared degradable film has good mechanical properties, high degradation rate and uniform degradation.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com