Alloy material with antibacterial property and high toughness and preparation method and application thereof

A technology of alloy materials and magnesium alloys, which is applied in the field of antibacterial, strong and tough alloy materials and their preparation, and can solve the problems of low degradation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0126] Embodiment 1: the preparation of alloy material

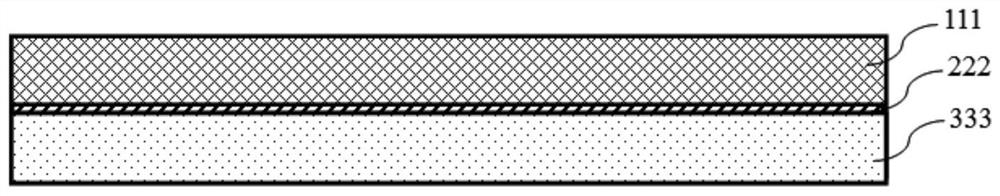

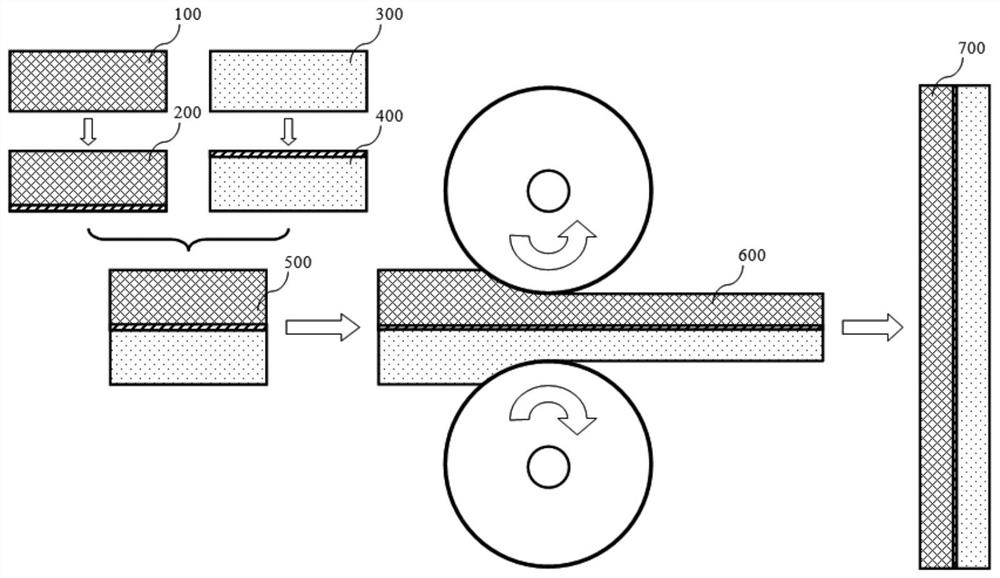

[0127] The present embodiment provides a flat plate-shaped alloy material with antibacterial properties and toughness, which comprises 59% of the magnesium alloy layer, 1% of the intermediate alloy layer and 40% of the zinc alloy layer according to the volume percentage; the intermediate alloy layer is composed of magnesium-zinc Composed of silver-copper alloy; the magnesium alloy layer does not contain Zn; the zinc alloy layer does not contain Mg.

[0128] The magnesium alloy layer is composed of magnesium alloy, and the magnesium alloy also includes the following components in terms of mass percentage:

[0129] Ag 4.0%

[0130] Cu 3.0%

[0131] Nd 3.0%.

[0132] The zinc alloy layer is composed of zinc alloy, and the zinc alloy also includes the following components in terms of mass percentage:

[0133] Ag 4.0%

[0134] Cu 3.0%

[0135] Nd 3.0%.

[0136] The preparation method of above-mentioned magnesium alloy ...

Embodiment 2

[0154] Embodiment 2: the preparation of alloy material

[0155] The present embodiment provides a flat plate-shaped alloy material with antibacterial properties and toughness, which comprises 67% of the magnesium alloy layer, 1.8% of the intermediate alloy layer and 31.2% of the zinc alloy layer according to volume percentage; the intermediate alloy layer is composed of magnesium zinc Composed of silver-copper alloy; the magnesium alloy layer does not contain Zn; the zinc alloy layer does not contain Mg.

[0156] The magnesium alloy layer is composed of magnesium alloy, and the magnesium alloy also includes the following components in terms of mass percentage:

[0157]

[0158] The zinc alloy layer is composed of zinc alloy, and the zinc alloy also includes the following components in terms of mass percentage:

[0159]

[0160] The preparation method of above-mentioned magnesium alloy comprises the following steps:

[0161] (1) Weigh Ag, Cu, Nd, Sn, Sr, Mg (remainder) ...

Embodiment 3

[0178] Embodiment 3: the preparation of alloy material

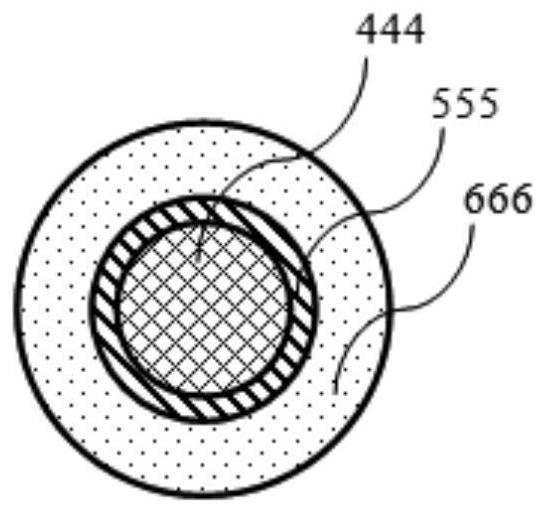

[0179] This embodiment provides a round rod-shaped alloy material with antibacterial properties and strong toughness. According to the volume percentage, from the inside to the outside, there are 70% of the magnesium alloy layer, 1% of the intermediate alloy layer and 29% of the zinc alloy layer. ; The intermediate alloy layer is composed of magnesium-zinc-silver-copper alloy; the magnesium alloy layer does not contain Zn; the zinc alloy layer does not contain Mg.

[0180] The magnesium alloy layer is composed of magnesium alloy, and the magnesium alloy also includes the following components in terms of mass percentage:

[0181] Ag 3.0%

[0182] Cu 2.5%

[0183] Nd 2.5%.

[0184] The zinc alloy layer is composed of zinc alloy, and the zinc alloy also includes the following components in terms of mass percentage:

[0185] Ag 3.0%

[0186] Cu 2.5%

[0187] Nd 2.5%.

[0188] The preparation method of the magnesium al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com