Degradable film preparation process

A preparation process and technology of degradable film, applied in the field of degradable film preparation process, can solve the problems of uncultivable land, livestock eating by mistake, high production cost, etc., achieve the effects of reducing agglomeration and delamination, improving uniformity and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

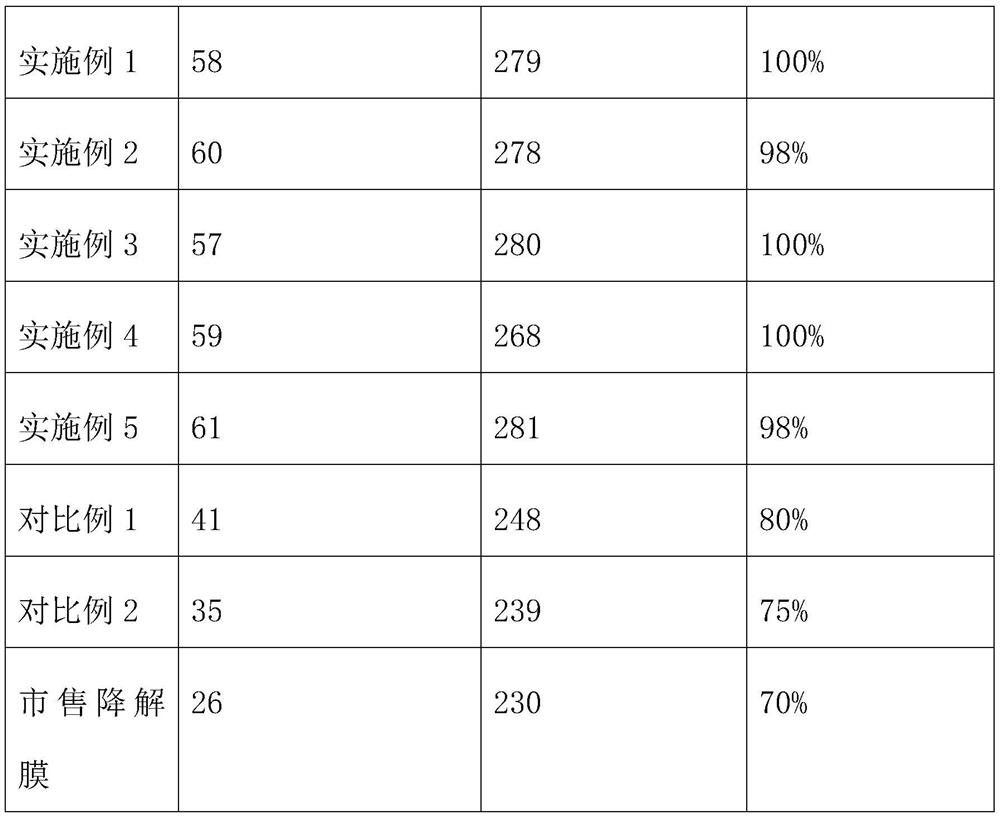

Examples

preparation example Construction

[0013] (1) Preparation of photodegradable masterbatch: dry the photosensitizer at 25-35°C for 0.5-1h, mix the dried photosensitizer with dispersant, polypropylene resin, antioxidant, hydrophobic agent and lubricant Granulation to obtain photodegradable masterbatch; among them, the drying temperature of the photosensitizer should not be too low, too low for insufficient drying, and not too high, too high will destroy the properties of the photosensitizer, and the photosensitizer and dispersant, polypropylene resin , Antioxidant, Hydrophobic Agent, Lubricant mixed, the dispersant makes the photosensitizer well into the macromolecular chain of polypropylene resin, and can prevent the dispersant, polypropylene resin, antioxidant, Hydrophobic agent, lubricant, etc. The agglomeration improves the uniformity of the substance and improves the uniformity of the degradation of the degraded film.

[0014] The photodegradable masterbatch includes by weight: 0.5-1 part of photosensitizer, ...

Embodiment 1

[0022] A kind of degradable membrane preparation process, comprises the following steps:

[0023] (1) Preparation of photodegradable masterbatch: dry 0.5 parts by weight of benzoin n-butyl ether at 25°C for 1 hour, mix the dried benzoin n-butyl ether with 0.1 parts by weight of polyethylene wax, 0.1 parts by weight of coke Sodium phosphate, 30 parts by weight of polypropylene resin, 0.1 parts by weight of antioxidant 1098, 0.2 parts by weight of acrylamide, and 0.1 parts by weight of stearic acid are mixed and granulated in a twin-screw granulator to obtain photodegradable masterbatches , the granulation conditions are as follows: the temperature is 120°C, the screw speed is 120rpm, and the screw length-to-diameter ratio L / D is 40;

[0024] (2) Preparation of starch-based degradable masterbatch: dry 25 parts by weight of starch at 30°C for 1 hour, mix and stir the dried starch and 0.2 parts by weight of aluminate at 40°C to obtain Starch mixture, then the starch mixture is mi...

Embodiment 2

[0027] A kind of degradable membrane preparation process, comprises the following steps:

[0028] (1) Preparation of photodegradable masterbatch: 1 part by weight of cerium stearate was dried at 35°C for 0.5h, and the dried cerium stearate was mixed with 0.3 parts by weight of polyethylene wax, 0.3 parts by weight of The polypropylene resin of sodium pyrophosphate, 40 parts by weight, the antioxidant 1076 of 0.5 parts by weight, the ammonium thiocyanate of 0.8 parts by weight, the butyl stearate of 0.5 parts by weight are mixed in twin-screw granulator and granulated. To obtain photodegradable masterbatch, the granulation conditions are as follows: temperature is 140°C, screw speed is 130rpm, and screw length-to-diameter ratio L / D is 40;

[0029] (2) Preparation of starch-based degradation masterbatch: 35 parts by weight of starch was dried at 35°C for 0.5h, and the dried starch and 0.6 part by weight of borate were mixed and stirred evenly at 45°C to prepare Obtain the starc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com