Zn-RE-Cu-series zinc alloy material for oil and gas exploitation and preparation method and application thereof

A technology of zn-re-cu and zinc alloy, which is applied in the direction of mining fluid, earthwork drilling, wellbore/well parts, etc., can solve the problems of unapplicable oil and gas wells, unclear interaction mechanism of alloy components, short total dissolution time, etc. problems, to achieve the effect of saving drilling and grinding recovery process, controllable degradation time, and improving single well production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

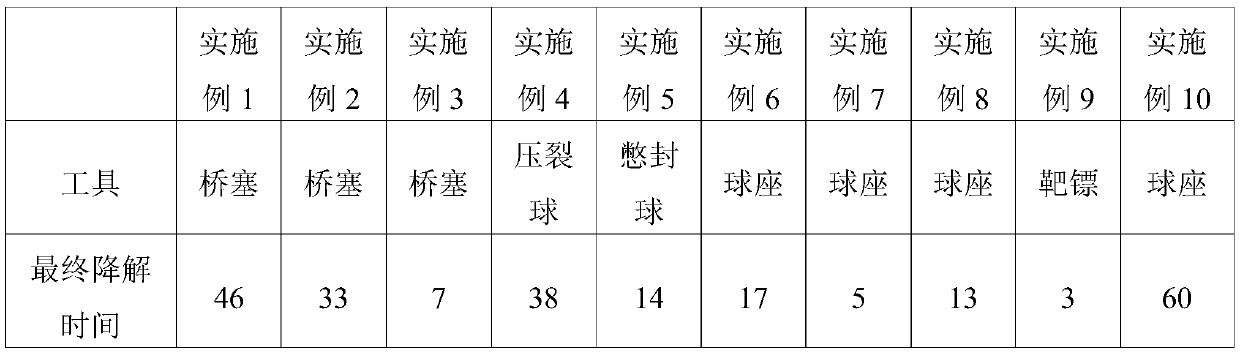

Examples

Embodiment 1

[0030] A Zn-RE-Cu series zinc alloy for oil and gas development of the present invention, its element composition and mass percentage are: Gd 10%, Cu 4.5%, Mg 0.1%, Ni 0.1%, and the balance is Zn and unavoidable impurities.

Embodiment 2

[0032] A Zn-RE-Cu series zinc alloy for oil and gas development of the present invention, its element composition and mass percentage are: Y8%, Cu 3.5%, Mg 0.1%, Ni 0.1%, and the balance is Zn and unavoidable impurities.

Embodiment 3

[0034] A Zn-RE-Cu series zinc alloy for oil and gas exploitation according to the present invention, its element composition and mass percentage are: Nd 3%, Cu 1%, Mg 0.1%, Ni 0.1%, and the balance is Zn and unavoidable impurities.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com