Functional polyolefin solid degradation agent

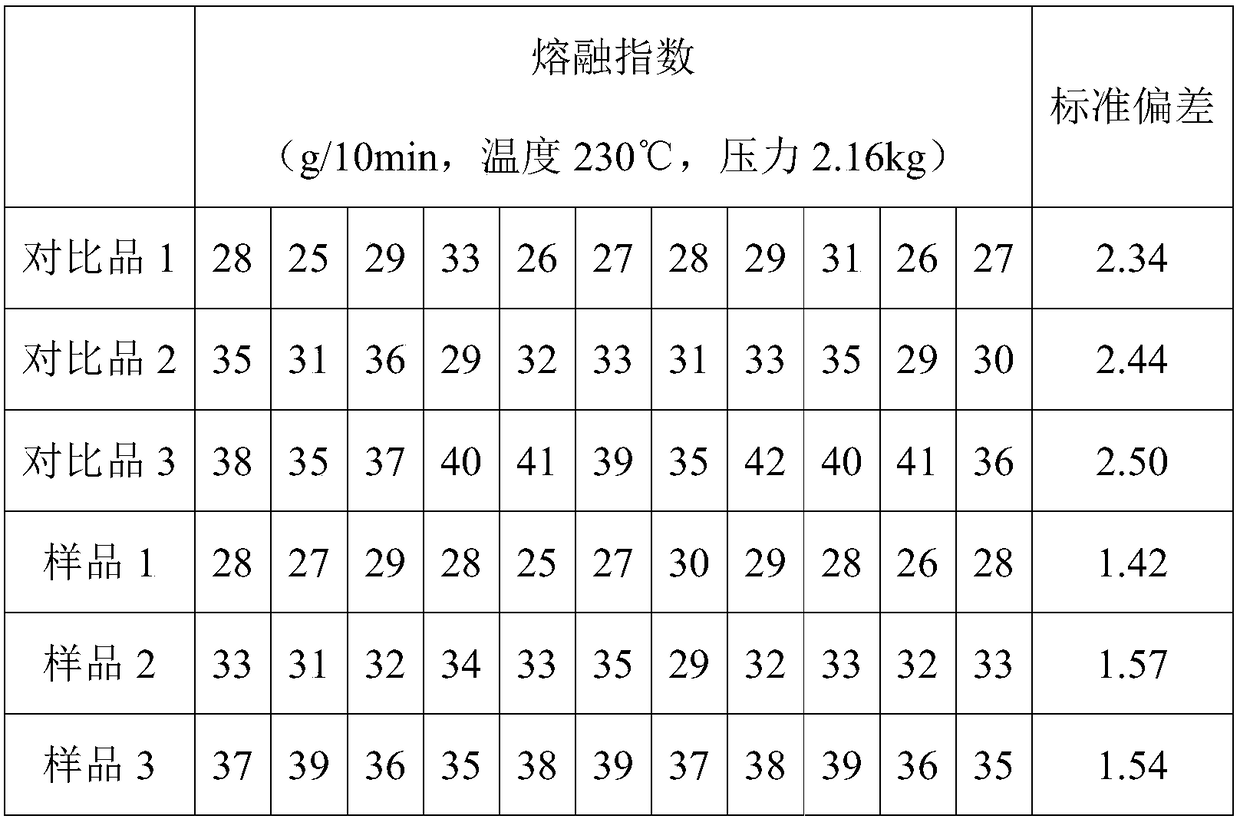

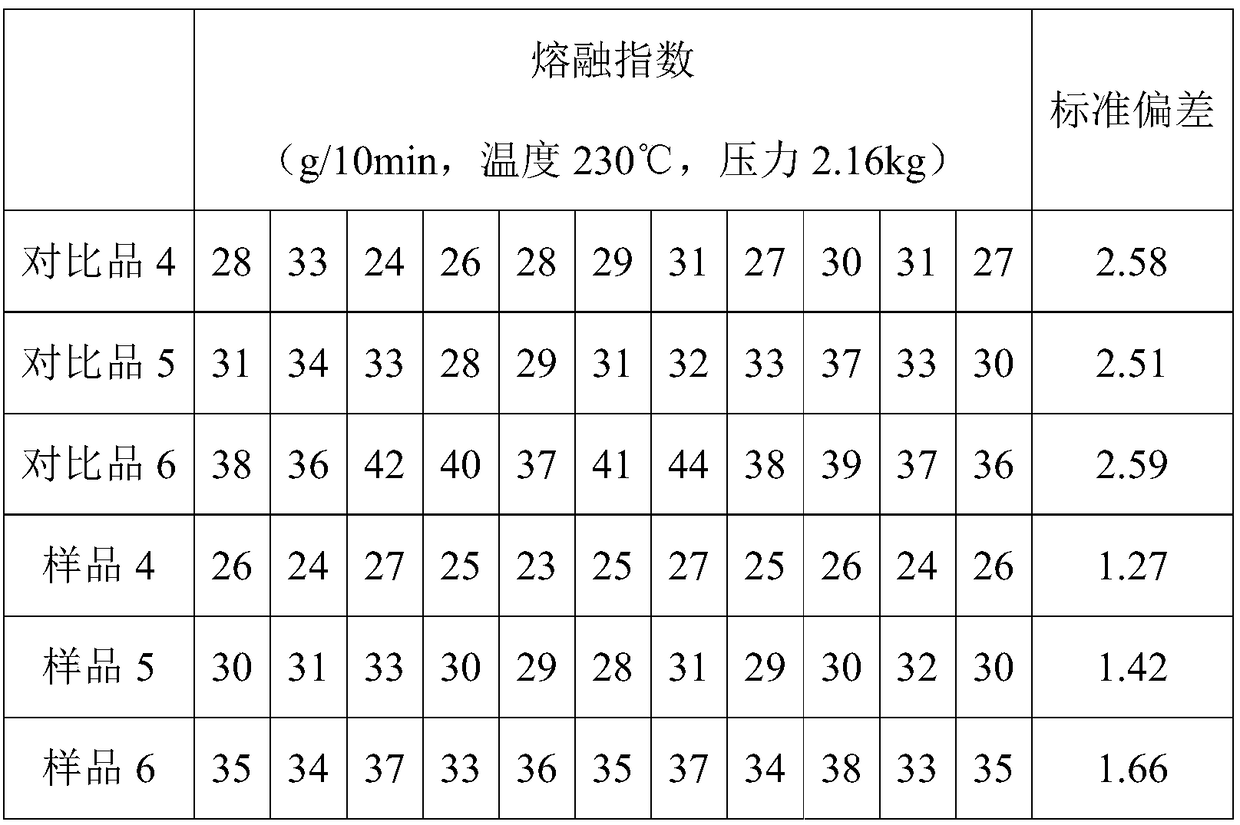

A functional polyolefin and degrading agent technology, applied in the field of degrading agents, can solve the problems of unstable melt index, poor uniformity, high risk, etc., and achieve the effects of excellent antioxidant performance, uniform degradation process and narrow molecular weight distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

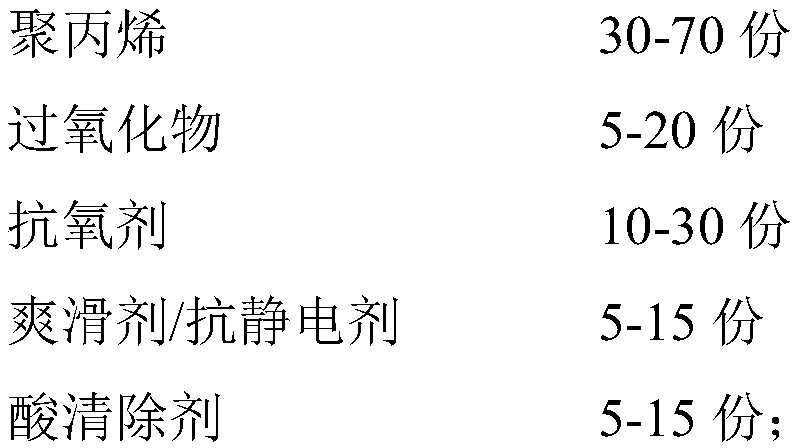

[0037] A preparation method of a functional polyolefin solid degradation agent, the preparation method is: by weight, 70 parts of polypropylene, 10 parts of peroxide, 20 parts of antioxidant, 5 parts of slippery agent / antistatic agent and 5 parts of acid scavenger are extruded and granulated in an extruder to obtain cylindrical functional polyolefin solid degradation agent particles, the diameter of the bottom surface of the cylinder is 2-4mm, and the height of the cylinder is 2-4mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com