Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34results about How to "Transparency impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

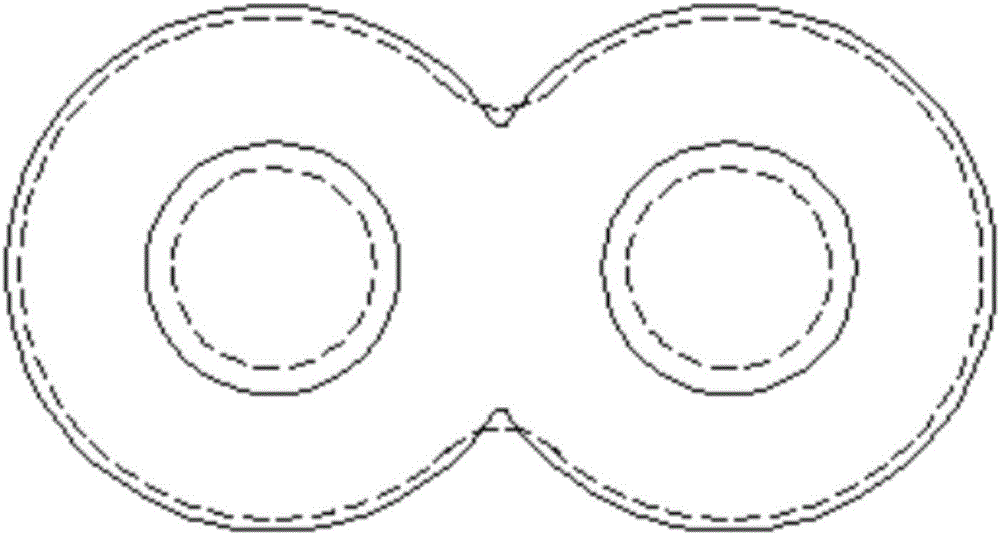

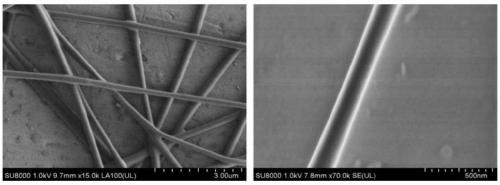

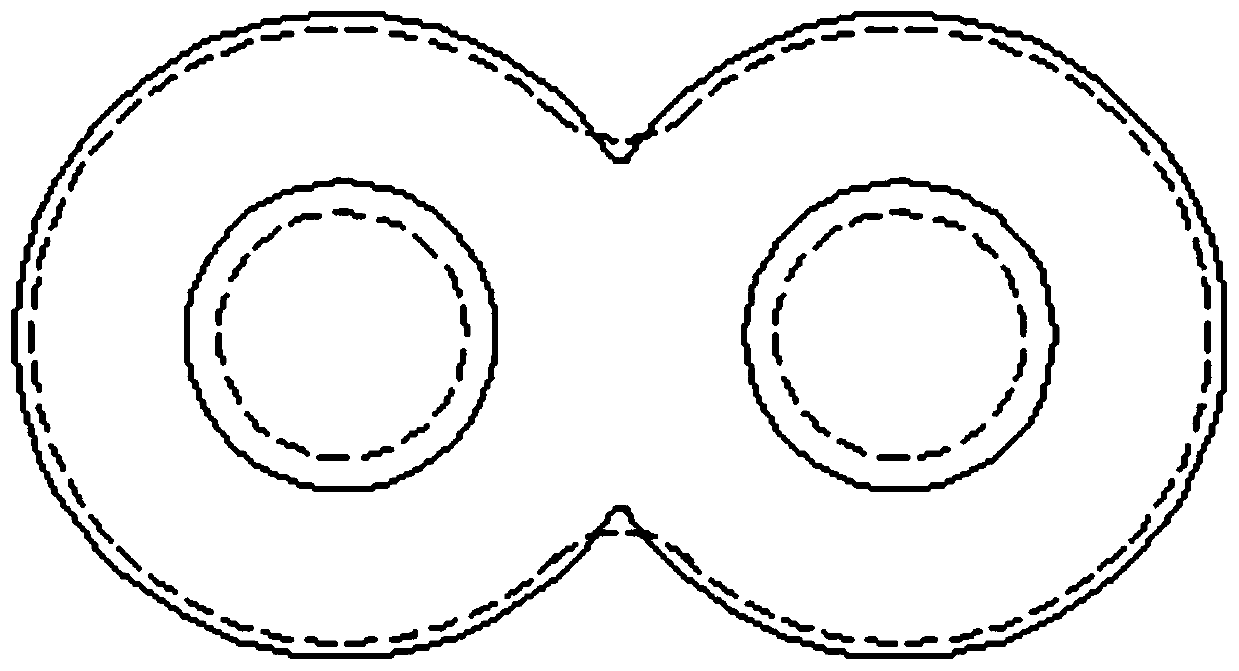

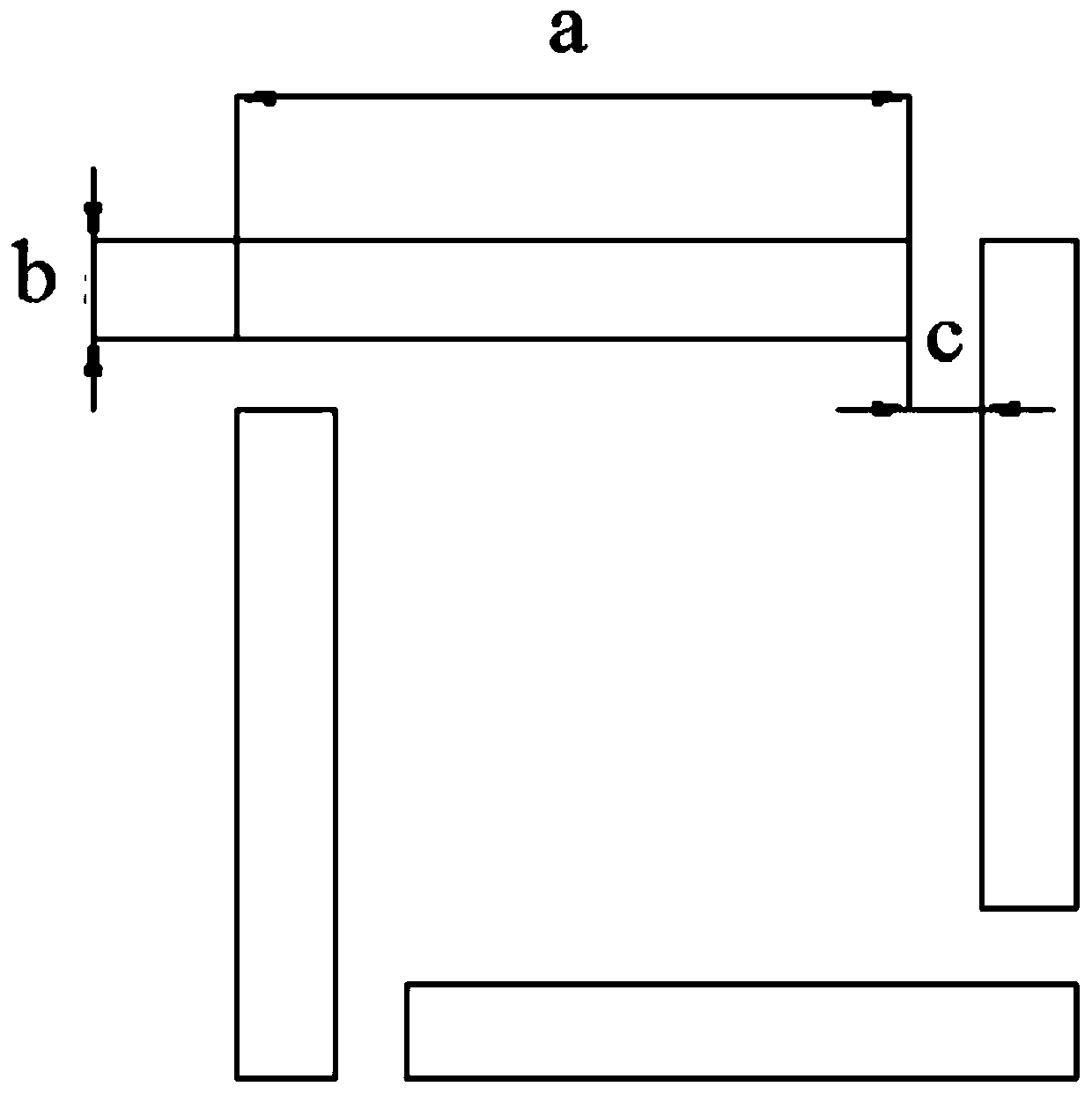

8-shaped hollow polyester fiber FDY (Fully Drawn Yarn) and preparation method thereof

ActiveCN106801265AReduce extrusion swelling effectImprove featuresMelt spinning methodsMonocomponent polyesters artificial filamentYarnFiber

The invention belongs to the polyester spinning field and relates to an 8-shaped hollow polyester fiber FDY (Fully Drawn Yarn) and a preparation method thereof. A spinning melt contains saturated fatty acid metal salt and modified polyester, wherein the mass ratio of saturated fatty acid metal salt to modified polyester is (0.0005-0.002) to 1; saturated fatty acid metal salt is fatty acid metal salt, the carbon atomic number is 12-22, the melting point is 100-180 DEG C, and the kinetic viscosity is less than or equal to 1Pa.s; a molecular chain of modified polyester comprises a terephthalic acid chain segment, a glycol chain segment and a rigid structure chain segment, and the molar ratio of the rigid structure chain segment to the terephthalic acid chain segment is (0.02-0.05) to 1; and the die swell ratio of the spinning melt is 1.23-1.33, and the after-filtration pressure during the spinning is 85-125kg / cm<2>. The prepared 8-shaped hollow polyester fiber FDY has relatively high degree of hollowness and relatively good shape-preserving effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

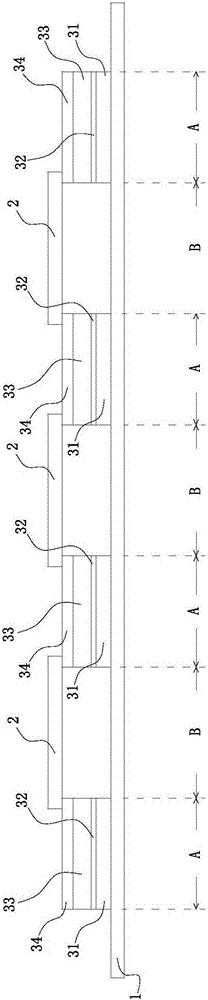

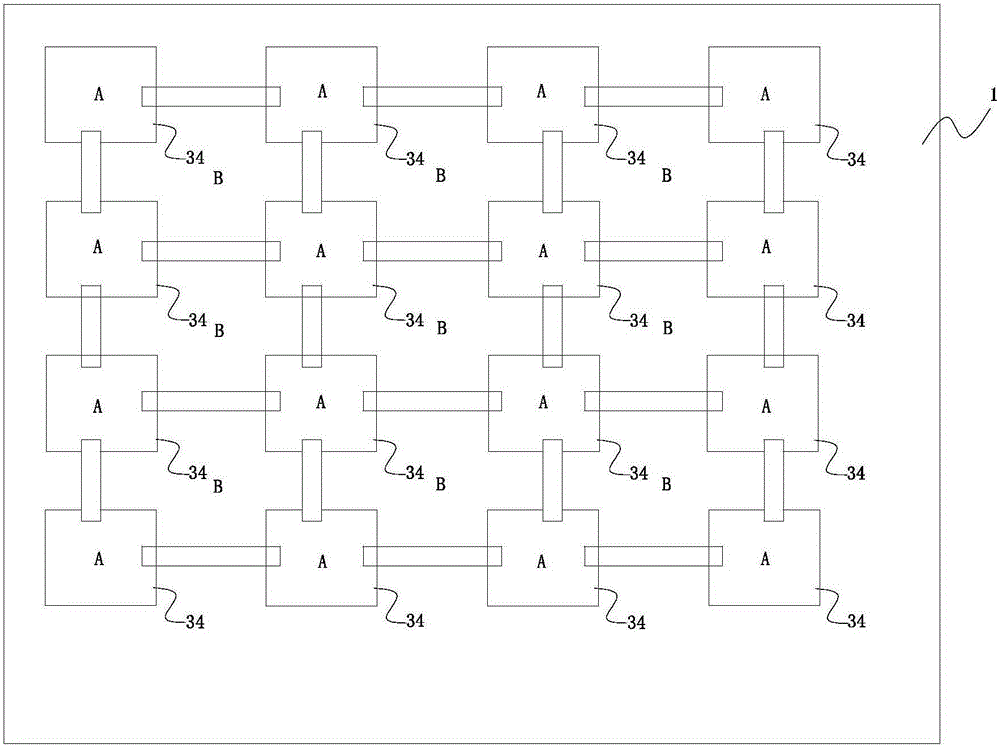

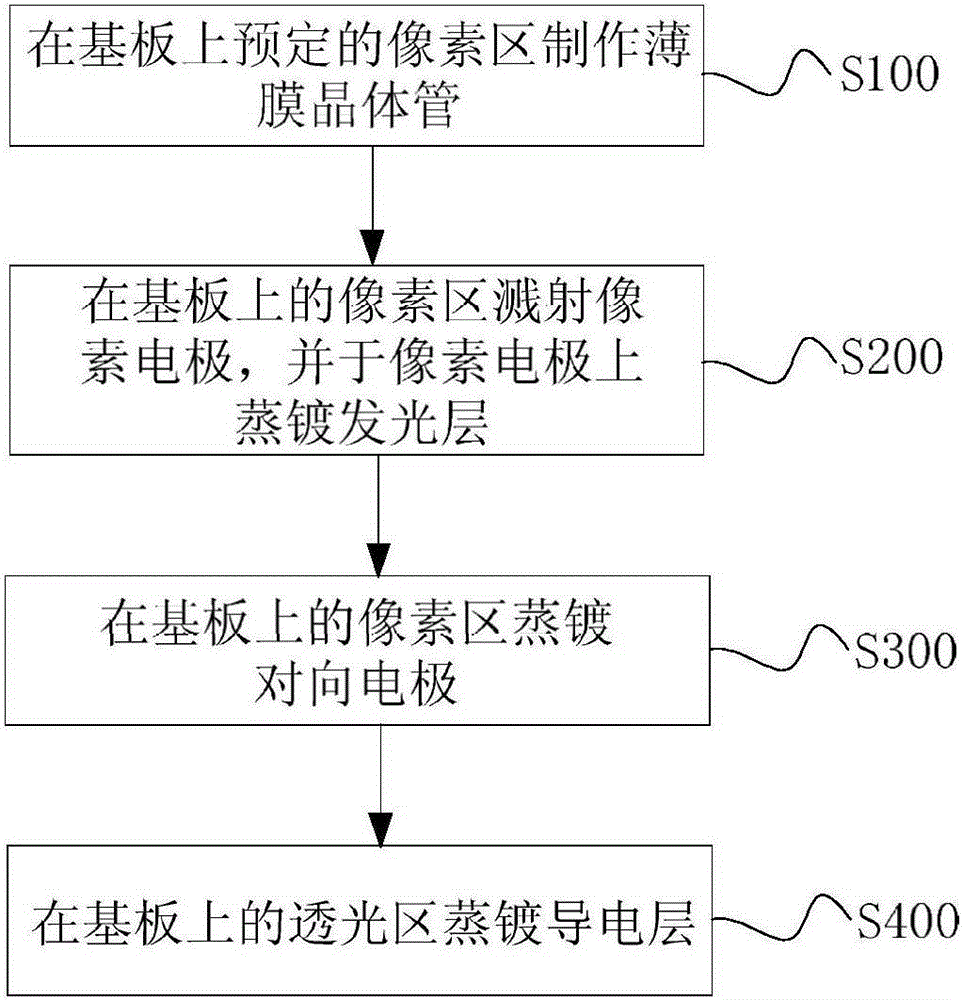

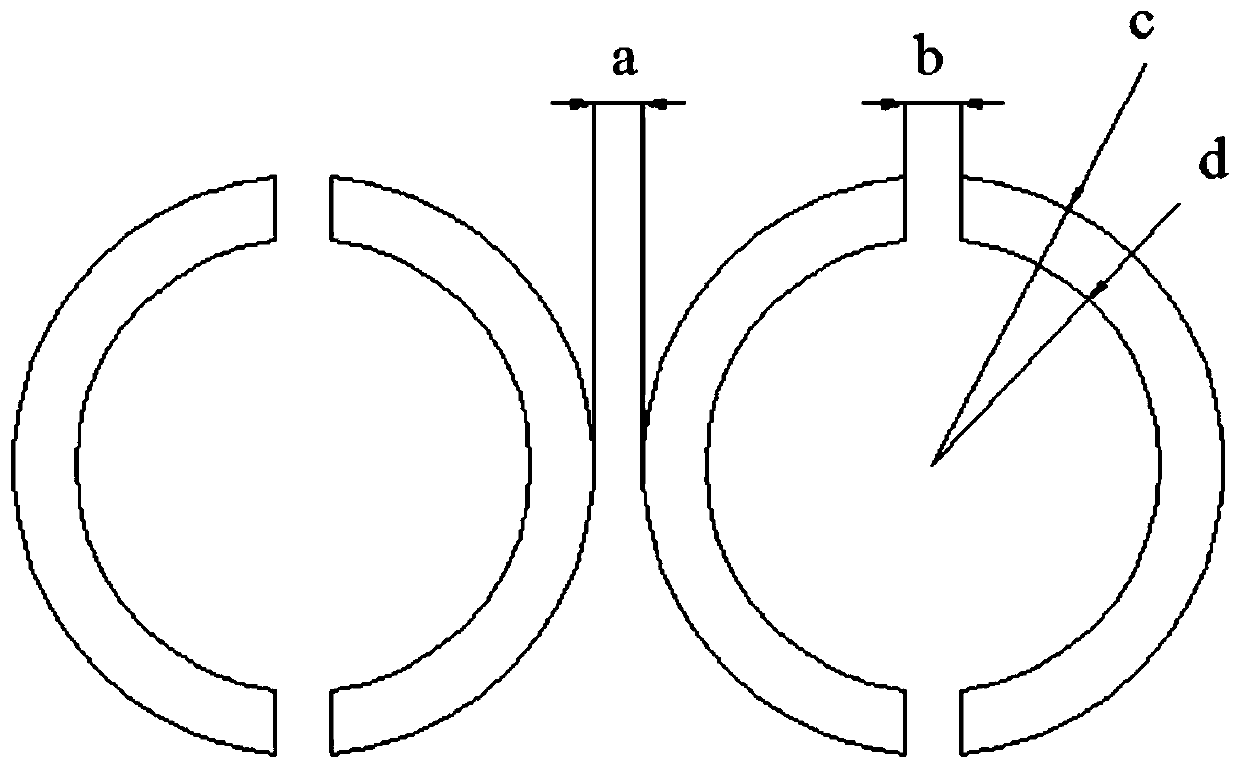

Transparent display panel and manufacturing method thereof

InactiveCN105206650AAchieve conductionLower evaporation temperatureSolid-state devicesSemiconductor/solid-state device manufacturingConductive materialsOrganic electroluminescence

The invention discloses a transparent display panel and a manufacturing method thereof. The transparent display panel comprises a substrate, organic electroluminescent devices, pixel electrodes, light-emitting layers, opposite-direction electrodes and a conductive layer, wherein the substrate comprises a plurality of pixel areas and a light transmitting area surrounding the pixel area; the organic electroluminescent devices are arranged on the substrate, correspond to the pixel areas of the substrate and comprise thin film transistors which are arranged on the pixel areas of the substrate; the pixel electrodes are arranged on the thin film transistors and electrically connected with the thin film transistors; the light-emitting layers are arranged on the pixel electrodes; the opposite-direction electrodes are arranged in the pixel areas of the substrate and located above the light-emitting layers; the conductive layer is arranged above the light transmitting area, located between the two opposite-direction electrodes and used for connecting the two adjacent opposite-direction electrodes; the conductive layer is made from conductive materials with the evaporation temperature lower than 600 DEG C.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

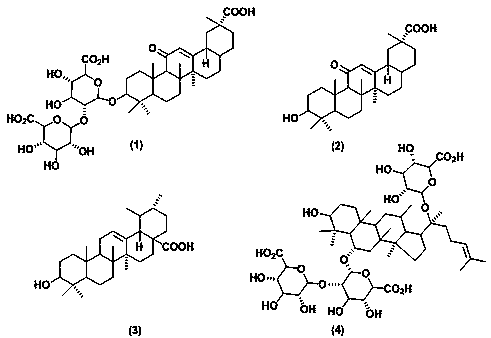

Method for improving performance of macromoledule substrate in obstructing water

InactiveCN1539896ATransparency impactImprove barrier propertiesLiquid surface applicatorsCoatingsPolymer scienceFlat panel display

A process for improving the water imperviousness of high-molecular substrate features that the fluoric acrylic acid or fluoric acrylate is attached on the surface by plasma polymerization, or optical or thermal polymerization to generate a (5-500)-nm high-molecular film. It is suitable for the substrate of microelectronic device.

Owner:FUDAN UNIV

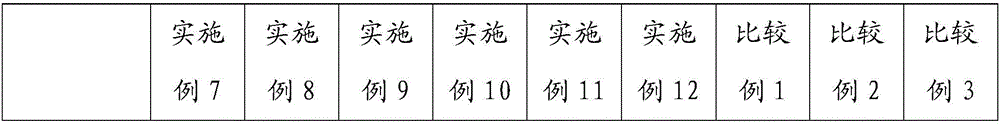

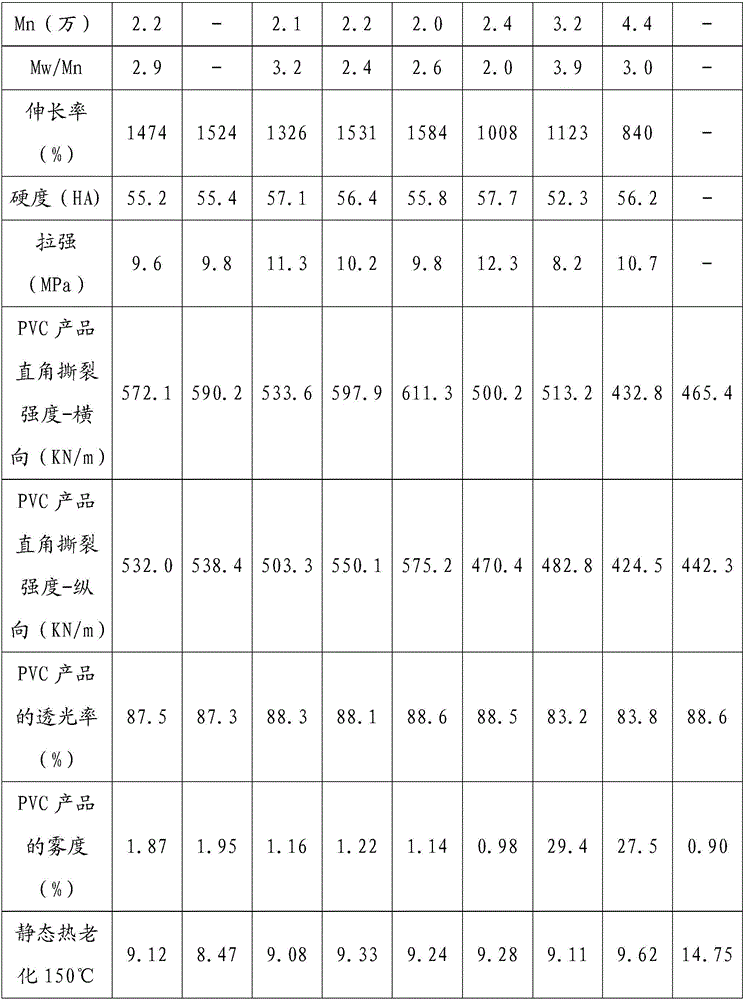

Toughening modifying agent for transparent polyvinyl chloride product and high-transparency polyvinyl chloride mixture

The invention discloses a toughening modifying agent for a transparent polyvinyl chloride (PVC) product and a high-transparency polyvinyl chloride mixture. The toughening modifying agent is selected from chlorinated polyethylene or a copolymer of the chlorinated polyethylene and (methyl) alkyl acrylate or a mixture of the chlorinated polyethylene and a (methyl) alkyl acrylate polymer; the grain diameter D50 of the chlorinated polyethylene is smaller than 20 microns, the number-average molecular weight Mn is smaller than 25000 and the molecular weight distribution is more than or equal to 2.0 and smaller than or equal to 3.5; the polyvinyl chloride mixture is prepared from: (a) 100 parts of polyvinyl chloride resin; (b) 3 to 15 parts of the toughening modifying agent; (c) 0.5 to 5 parts of a stabilizer; (d) 0 to 10 parts of a PVC product machining auxiliary agent; (e) 0 to 10 parts of an anti-impact modifying agent; (f) 0 to 5 parts of a lubricant; (g) 0 to 10 parts of a plasticizer. The toughening modifying agent provided by the invention is used for modifying the PVC product and the obtained product has high light transmittance, good weather resistance and good toughness.

Owner:SHANDONG RIKE CHEM

Anti-dripping transparent flame-retardant TPU material and preparation method thereof

The invention discloses an anti-dripping transparent flame-retardant TPU material and a preparation method thereof. The effects that halogen-free flame retardants DIDOPO have high flowability; when the DIDOPO is used for achieving flame-retardant effects on the TPU, the TPU / DIDOPO flame-retardant material has excellent flame-retardant performance; the transparency of the TPU / DIDOPO flame-retardant material is not influenced; meanwhile, after the addition of transparent synergists, the flame-retardant synergistic effect is achieved on the TPU / DIDOPO flame-retardant material; meanwhile, the anti-reflection effect is achieved on the TPU / DIDOPO flame-retardant material, but the TPU / DIDOPO flame-retardant material can easily drip and fall are discovered. Therefore, the applicant discovers that the anti-dripping agent PTFE achieves an anti-dripping effect through the heated shrinkage by using the fibrillation of polytetrafluoroethylene polymers in the plastic processing process through the study; the flame spreading is reduced. When the anti-dripping agent PTFE is added into the TPU / DIDOPO flame-retardant material, the melt strength and the collapse resistance performance of the polymers are improved, so that the flame-retardant and anti-dripping performance of the TPU / DIDOPO is improved.

Owner:JIANGLIN GUIZHOU HI TECH DEV CO LTD

Antibacterial solution for glass product and use method of antibacterial solution

The invention discloses an antibacterial solution for a glass product and a use method of the antibacterial solution. The antibacterial solution contains silver ions, including silver ions and copper ions, and the silver ions are provided by silver ion salt which can be any one or two of silver nitrate and silver lactate. The antibacterial solution further comprises an auxiliary material condensed sodium phosphate or / and butyl hementerin. When the antibacterial solution is used, through steps of coating, drying, thermal treatment, stripping, washing and the like, the glass product with the antibacterial property can be produced, the operation is simple, and the produced antibacterial glass product is relatively good in security and has long-lasting antibacterial property.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE

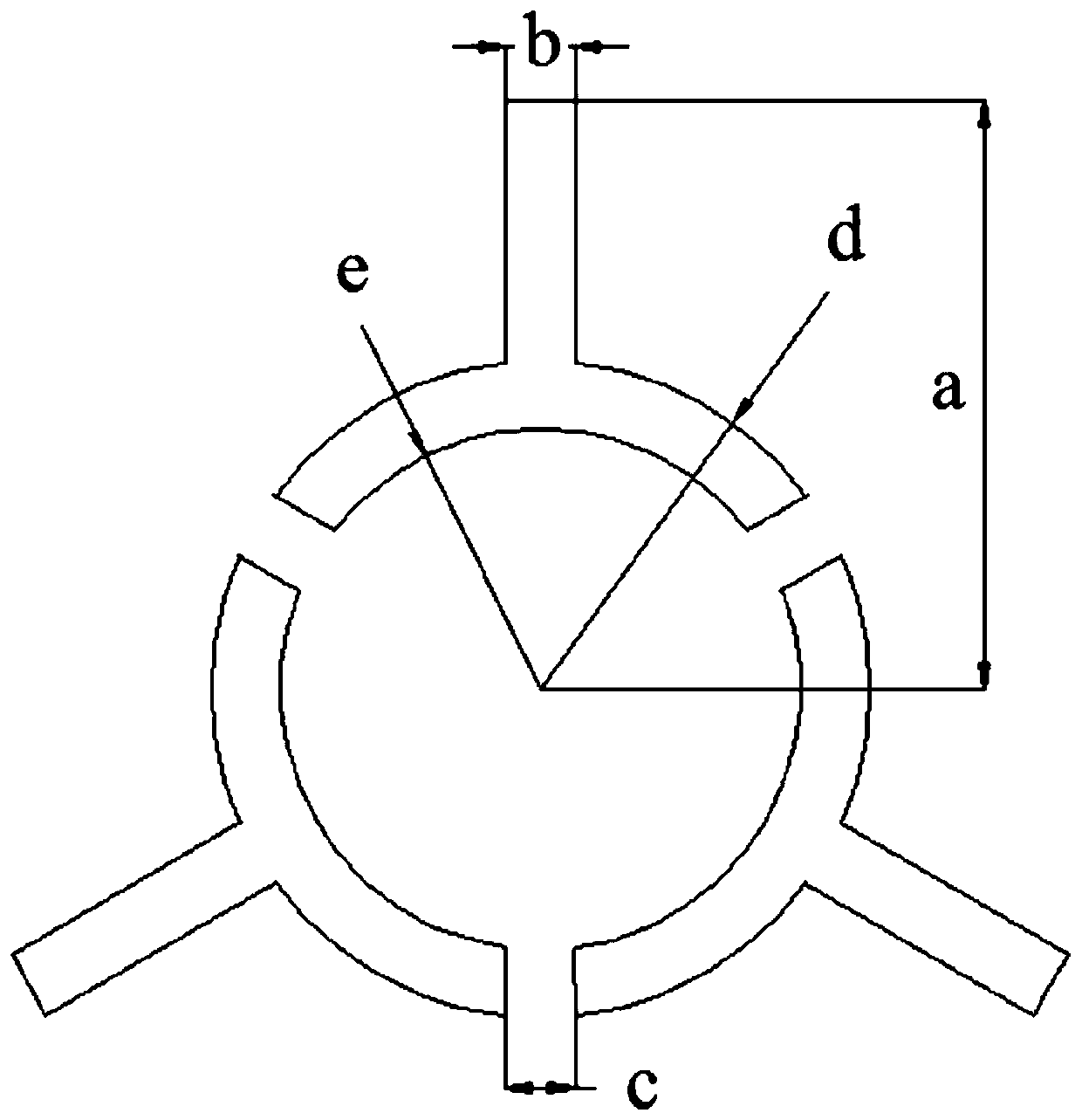

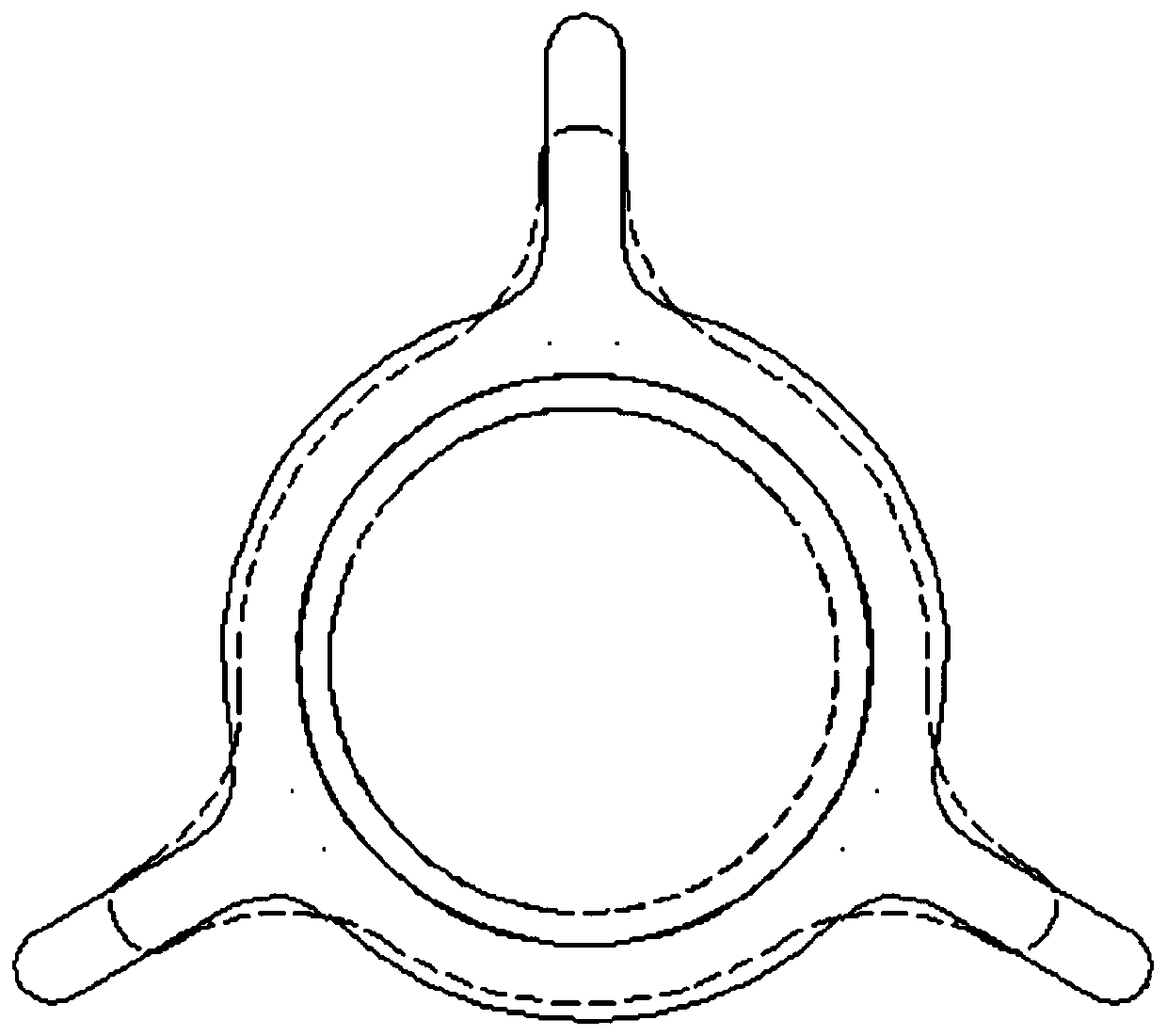

Multilobal hollow polyester fiber FDY (fully drawn yarn) and preparation method thereof

ActiveCN106835334AReduce extrusion swelling effectReduce surface tensionHollow filament manufactureMonocomponent polyesters artificial filamentFiberYarn

The invention belongs to the field of polyester spinning, and relates to a multilobal hollow polyester fiber FDY (fully drawn yarn) and a preparation method thereof. A spinning melt comprises a saturated fatty acid metal salt and modified polyester according to a mass ratio of (0.0005 to 0.002) to 1; the saturated fatty acid metal salt is a fatty acid metal salt with carbon atom number of 12 to 22, melting point of 100 to 180 DEG C, and dynamic viscosity less than or equal to 1Pa.s; a molecular chain of the modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment and a rigid structure chain segment, the molar ratio of the rigid structure chain segment to the terephthalic acid chain segment is (0.02 to 0.05) to 1, the extrusion swelling ratio of the spinning melt is 1.20 to 1.31, and the post-filtering pressure is 80 to 120kg / cm<2> during spinning. The prepared multilobal hollow polyester fiber FDY has higher hollow degree and a better shape preserving effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

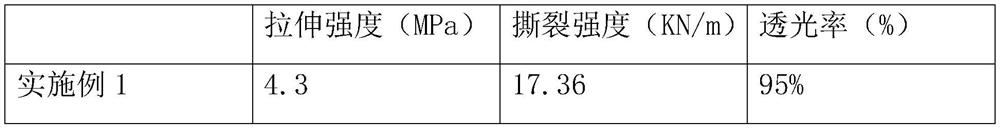

Transparent double-component flame-retardant liquid silicone rubber perfusion material and preparation method thereof

The invention relates to the technical field of addition type silicone rubber, and discloses a transparent double-component flame-retardant liquid silicone rubber perfusion material which is composed of the following components: a component A comprising the following components: 10-50 parts of high-viscosity vinyl silicone oil, 30-70 parts of low-viscosity vinyl silicone oil, 5-15 parts of vinyl silicone resin, 5-15 parts of fumed silica and 1-5 parts of a catalyst; and the component B comprising the following components: 10-50 parts of high-viscosity vinyl silicone oil, 30-70 parts of low-viscosity vinyl silicone oil, 5-15 parts of hydrogen-containing silicone oil, 5-15 parts of fumed silica, 0.02-0.2 part of an inhibitor and 1-3 parts of a flame retardant. The prepared silicone rubber pouring material has good leveling property, silicone rubber formed after mixing and curing of the silicone rubber perfusion material has the characteristics of high tensile strength, high tearing strength, excellent flexibility, good mechanical vibration resistance, high transparency and good flame retardant effect, and is suitable for pouring of electronic components; and the practicability of the transparent double-component flame-retardant liquid silicone rubber pouring material is enhanced.

Owner:浙江中特化工有限公司

Thermal laminating film for printing matters

InactiveCN109628011AStrong adhesionLow costMonocarboxylic acid ester polymer adhesivesFilm/foil adhesivesVinyl acetateCarvacryl acetate

The present invention relates to a laminating film, in particular to a thermal laminating film. The thermal laminating film is compounded to printing matters digitally printed with aqueous ink in a thermal laminating mode, and comprises a base layer and an adhesive layer; 70% or above of the adhesive layer is composed of, by weight, thermoplastic materials made of polyvinyl acetate, vinyl acetate-ethylene copolymer and a mixture of polyvinyl acetate and vinyl acetate-ethylene copolymer; the weight content of vinyl acetate in the vinyl acetate ethylene copolymer is 50% or above. The thermal laminating film has excellent adhesion to the printing matters digitally printed with the aqueous ink. A process of bonding the thermal laminating film to the printing matters can be automated by using existing thermal laminating equipment, through automation, the laminating speed can be increased, the labor is saved, and therefore the productivity is improved.

Owner:惠州艺都文化用品有限公司

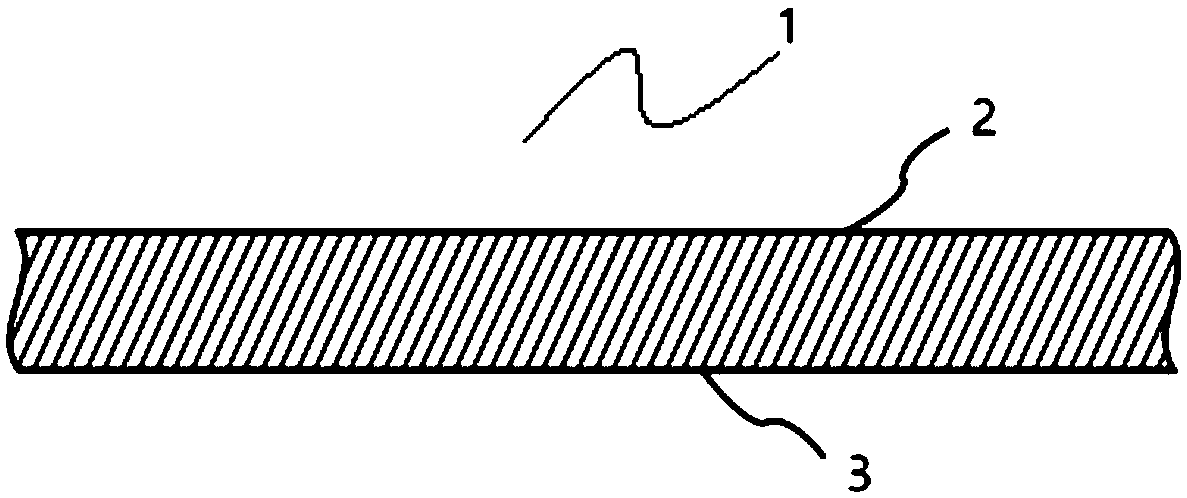

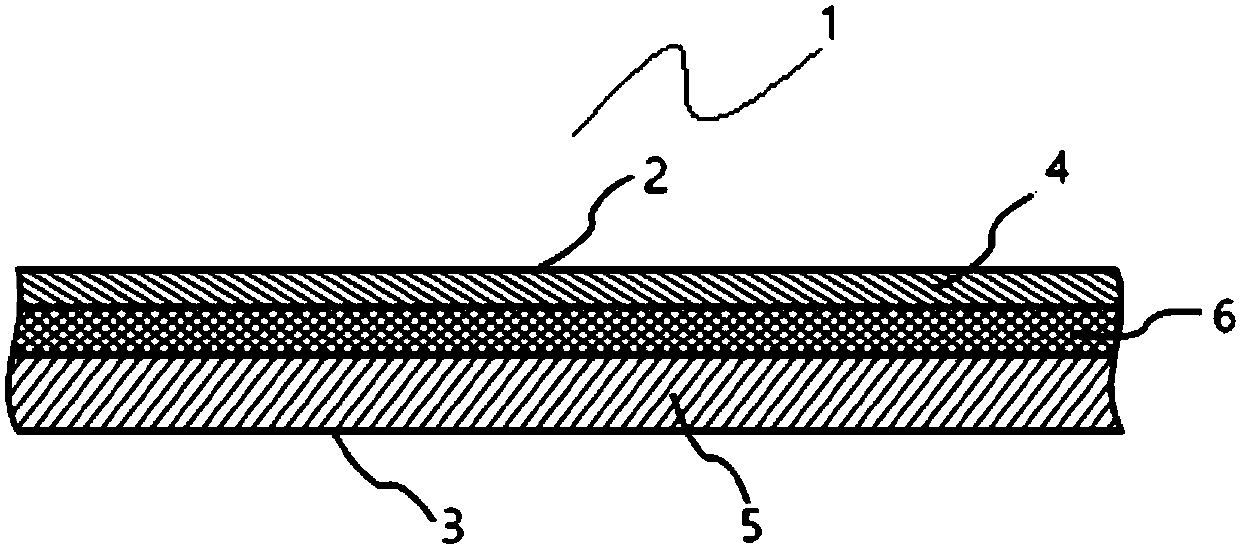

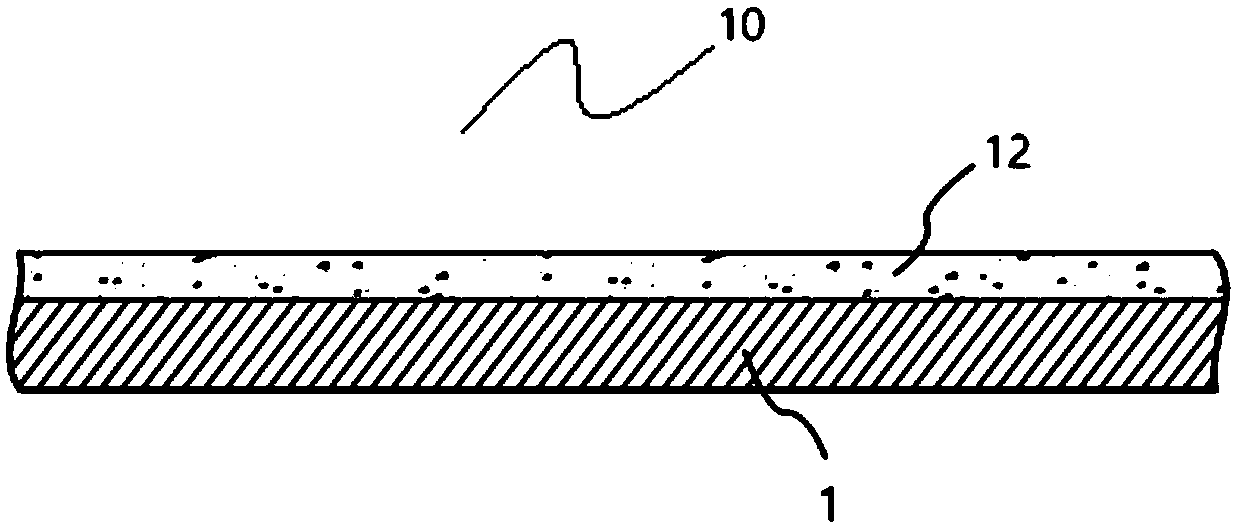

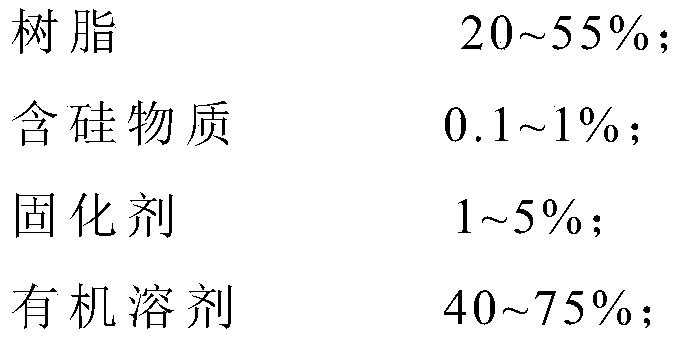

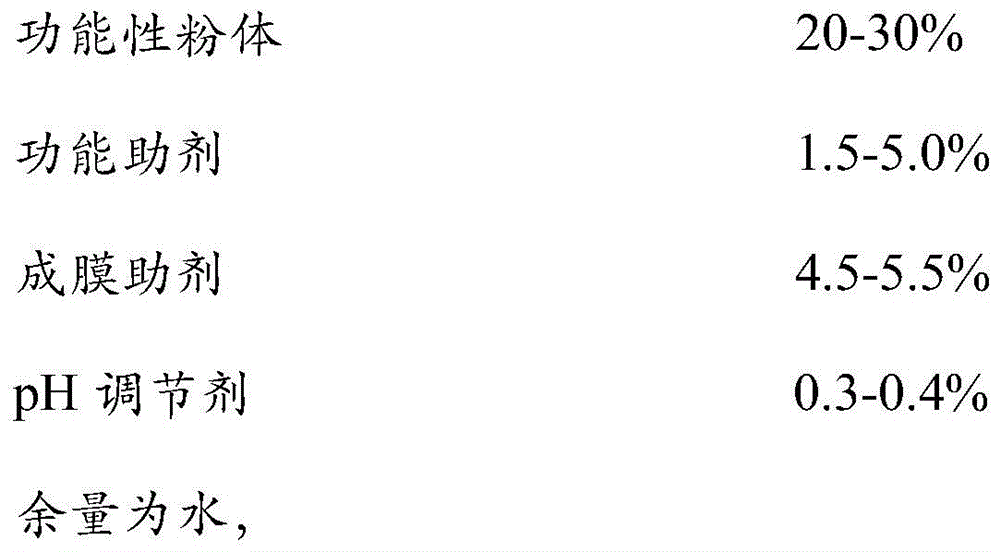

Coating material, coating layer, transparent back plate and preparation methods of coating material, coating layer and transparent back plate

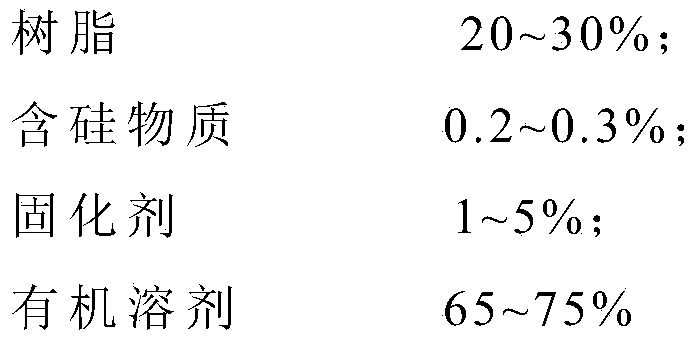

InactiveCN110157319AGood adhesionHigh densityPolyurea/polyurethane coatingsPhotovoltaic energy generationOrganic solventHydrolysis

The invention relates to a coating material, a coating layer, a transparent back plate and preparation methods of the coating material, the coating layer and the transparent back plate. The coating material comprises the following raw material components, in percentages by weight: 20-55% of resin, 0.1-1% of a silicon-containing substance, 1-5% of a curing agent and 40-75% of an organic solvent, wherein the silicon-containing substance is obtained by performing hydrolysis condensation on silicate and a silane coupling agent in the presence of a catalyst. The coating layer and transparent back plate prepared from the coating material provided by the invention have good transparency and abrasion resistance, excellent resistance to moist heat aging and good adhesion to different substrates, and the preparation methods of the coating material, the coating layer and the transparent back plate are simple and have low preparation costs, the mass production is easy to realize.

Owner:CYBRID TECHNOLOGIES INC

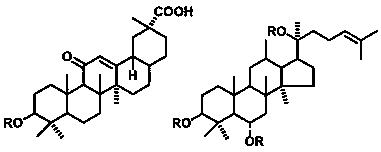

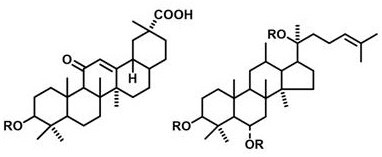

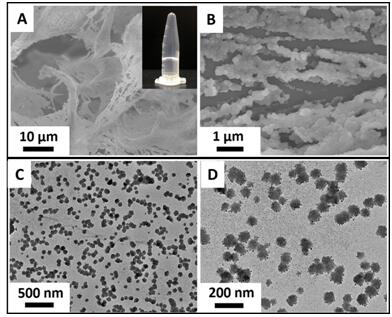

Injectable natural triterpene compound antibacterial hydrogel and preparation method thereof

ActiveCN110585122ALow toxicityAvoid biotoxicityAntibacterial agentsOrganic active ingredientsPhosphoric acidSolvent

The invention relates to the field of biological antibacterial hydrogel materials, in particular to injectable natural triterpene compound antibacterial hydrogel and a preparation method thereof. Thehydrogel disclosed by the invention is obtained by employing a mixture of glycyrrhizic acid and a pentacyclic triterpene compound or a tetracyclic triterpene compound as a gel molecule and phosphoricacid buffer salt solution (PBS) as a gel solvent, and utilizing non-covalent bond acting force formed between mixture through a micromolecule self-assembly mechanism. The prepared hydrogel can show antibacterial property without adding antibacterial drugs, and the mechanical property of the hydrogel is remarkably improved. The preparation method of the injectable antibacterial hydrogel is simple,a preparation process of the injectable antibacterial hydrogel can be simplified, and the application field of the triterpenoids is expanded. Therefore, a novel injectable antibacterial material withbiomedical application characteristics and mechanical strength can be prepared.

Owner:BEIJING UNIV OF CHEM TECH

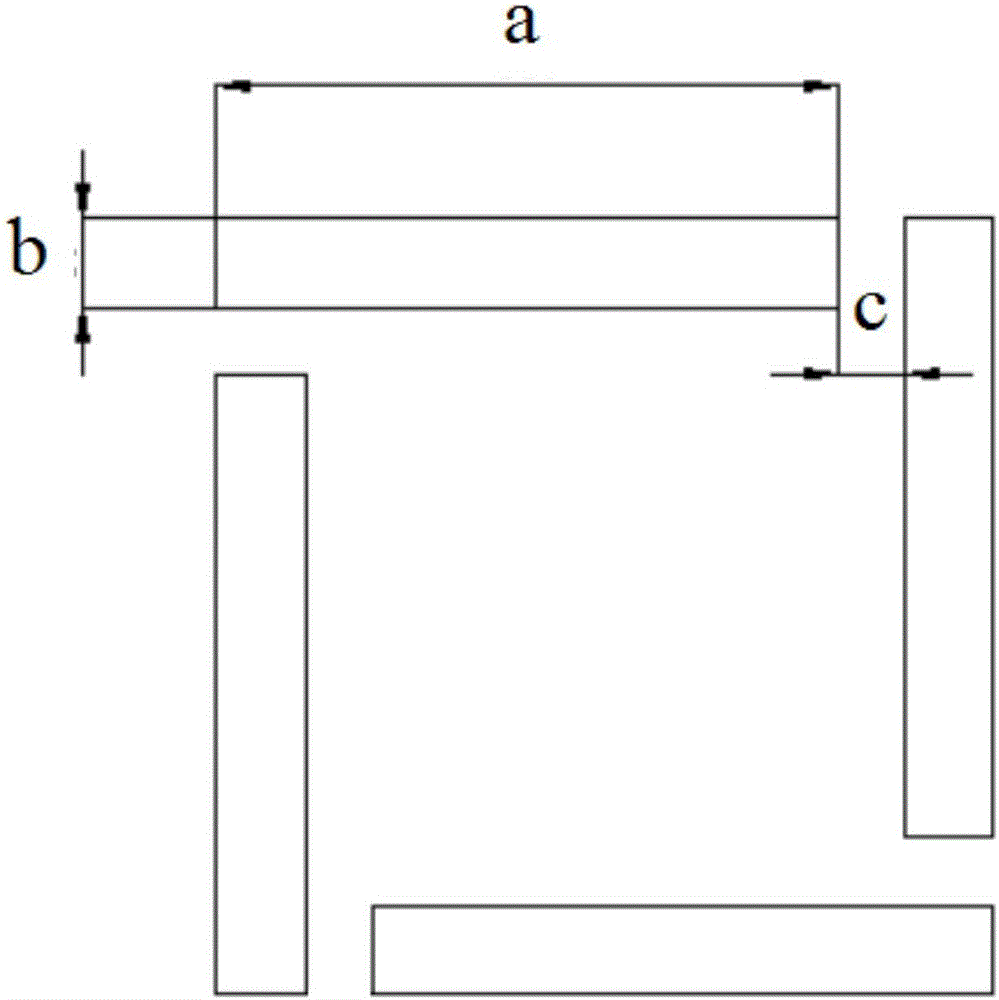

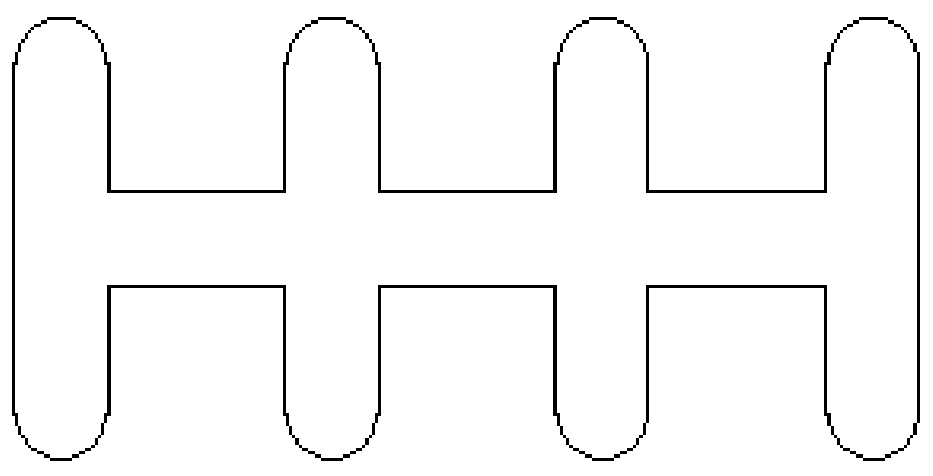

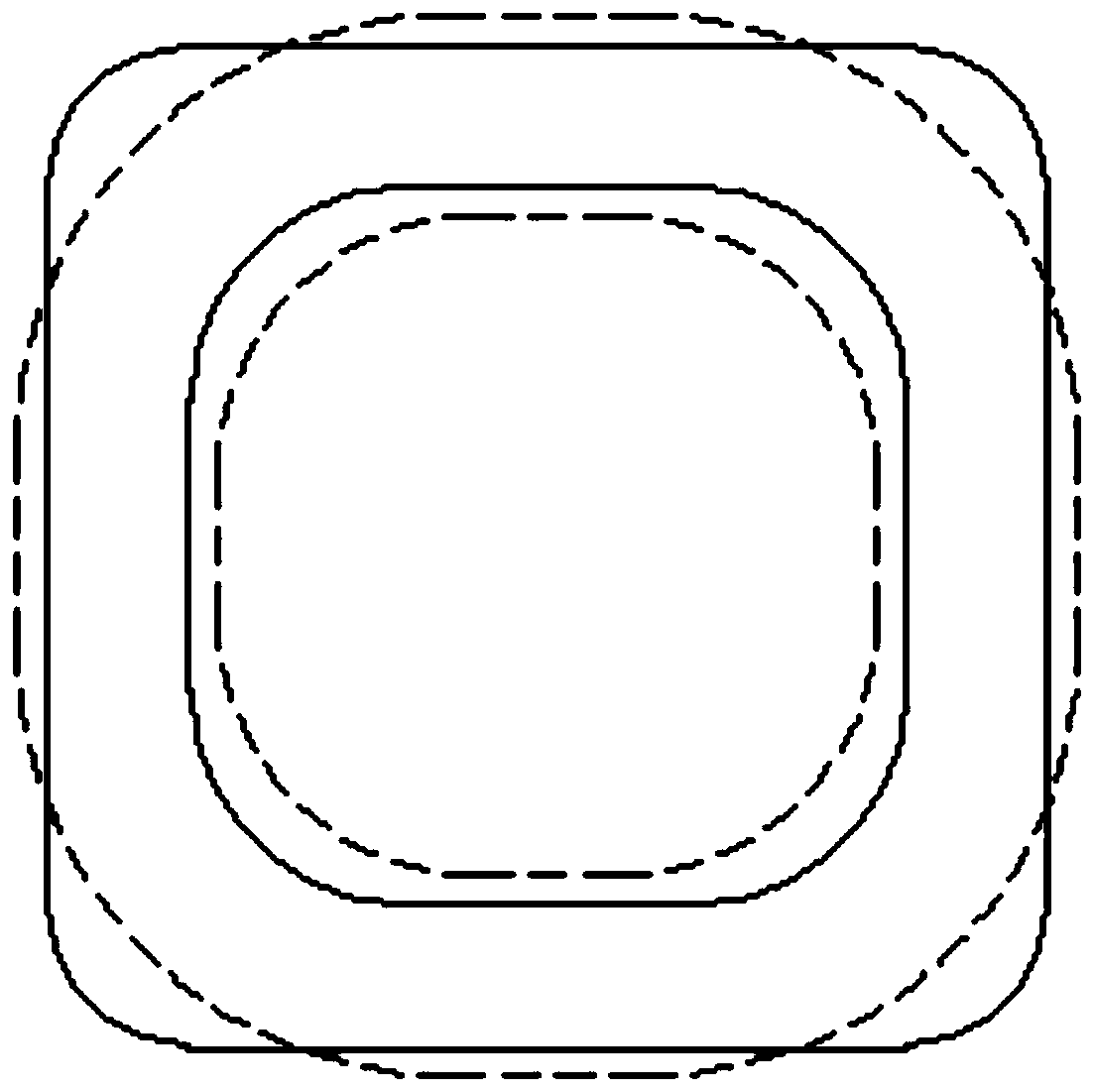

Square hollow polyester fiber FDY (Fully Drawn Yarn) and preparation method thereof

ActiveCN106835336AReduce extrusion swelling effectReduce surface tensionHollow filament manufactureFilament/thread formingChemistrySaturated fatty acid

The invention belongs to the field of polyester spinning, and relates to a square hollow polyester fiber FDY (Fully Drawn Yarn) and a preparation method thereof. A spinning melt contains a saturated fatty acid metal salt and modified polyester; the mass ratio of the saturated fatty acid metal salt to the modified polyester is (0.0005-0.002):1; the saturated fatty acid metal salt is a fatty acid metal salt of which the carbon atom number is 12-22, the melting point is 100-180 DEG C and the power viscosity is less than or equal to 1Pa*s; the molecular chain of the modified polyester comprises a terephthalic acid chain segment, a glycol chain segment and a rigid structure chain segment; the mole ratio of the rigid structure chain segment to the terephthalic acid chain segment is (0.02-0.05):1; the die swell ratio of the spinning melt is 1.21-1.32; the after-filtration pressure of the spinning melt in spinning is 82-123kg / cm<2>. The square hollow polyester fiber FDY provided by the invention is relatively high in hollowness degree and relatively good in conformal effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

Offset UV varnish printing ink with mirror surface effect and preparation method of offset UV varnish printing ink

ActiveCN104292969AImprove flatnessHigh transparencyInksDipropylene glycol diacrylatePolyethylene glycol

The invention relates to an offset UV varnish printing ink with mirror surface effect and a preparation method of the offset UV varnish printing ink. The offset UV varnish printing ink with mirror surface effect is characterized by comprising the following compositions in percentage by weight: 19%-23% of standard bisphenol A epoxy acrylate, 61%-65% of dipropylene glycol diacrylate, 3%-7% of p-benzoyl polyethylene glycol benzoate, and 9%-13% of reactive tertiary amine. According to the invention, the offset UV varnish printing ink with mirror surface effect has good levelness and transparency without addition of auxiliaries such as a leveling agent and a defoaming agent, the offset and polished product has a mirror-like effect, and the smooth, level and transparent effects of a mirror can be simulated on a paper package by means of printing. No reaction auxiliaries are added in the printing ink, so that the curing resistance can be reduced, and the influence on the transparency and compatibility of the printing ink can be reduced. The printing ink is less in side reaction in curing reaction, low in migration rate and volatility, thus having high environment-friendly property; and the Vocs smell can completely achieve the national standard requirement.

Owner:ZHEJIANG MINONG CENTURY GRP +1

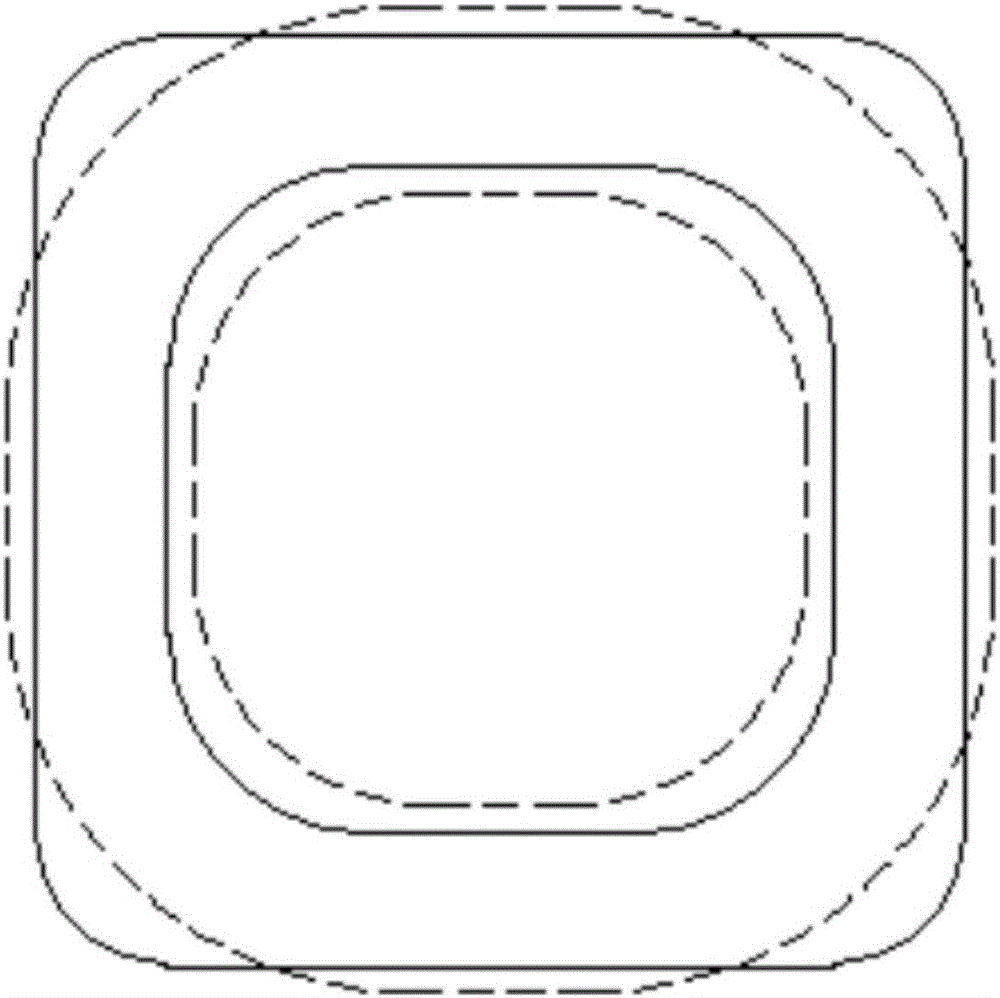

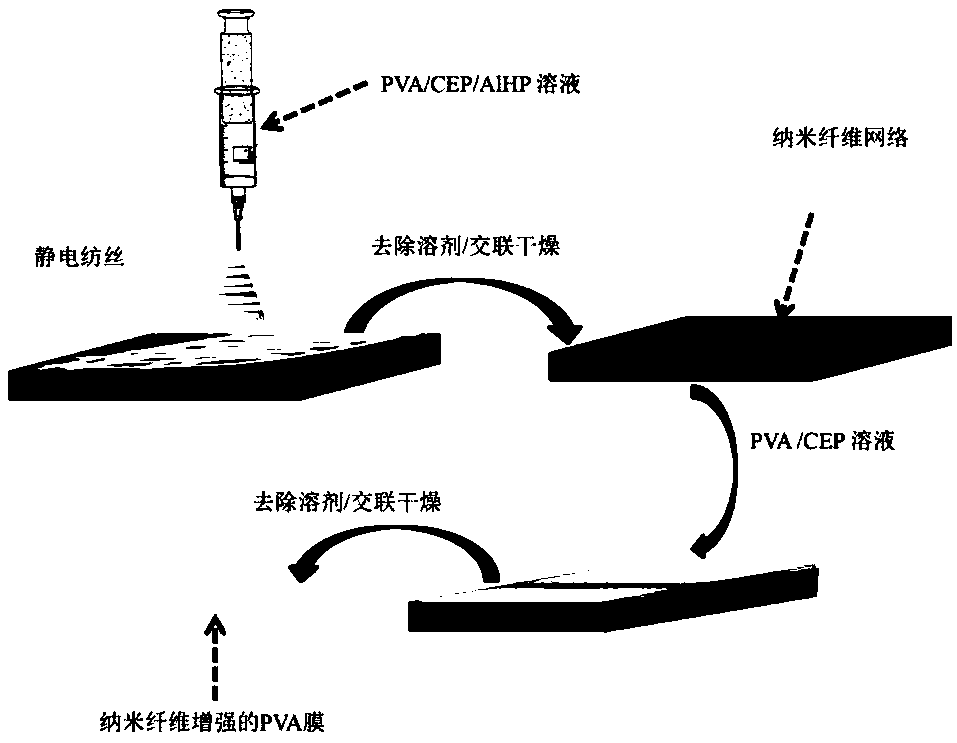

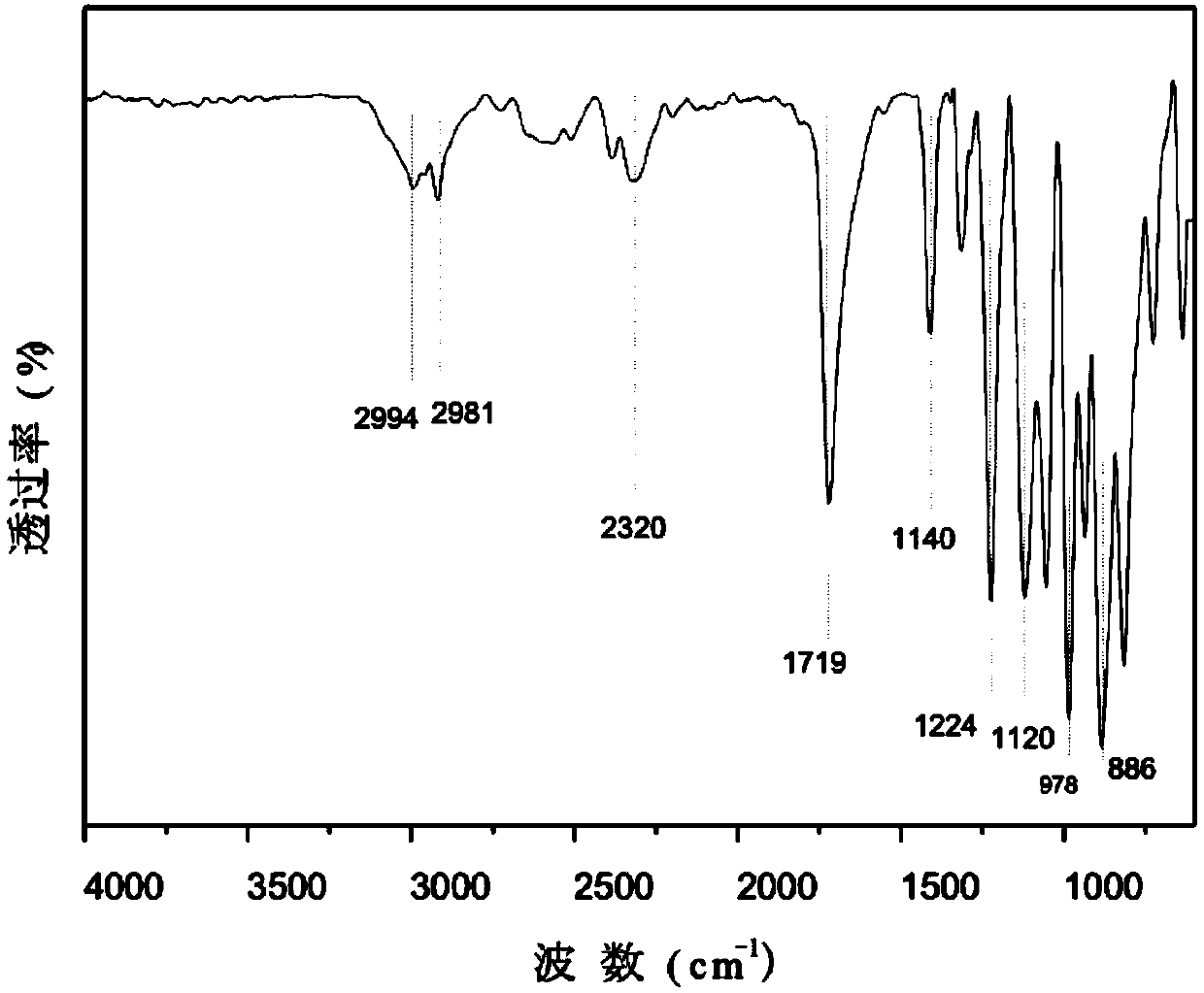

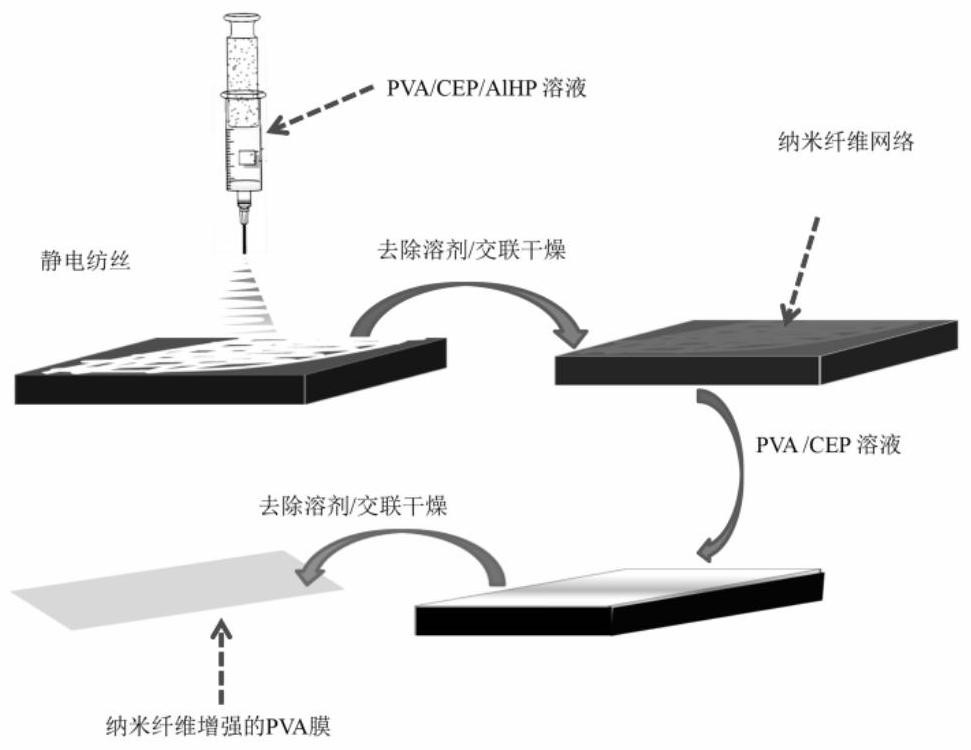

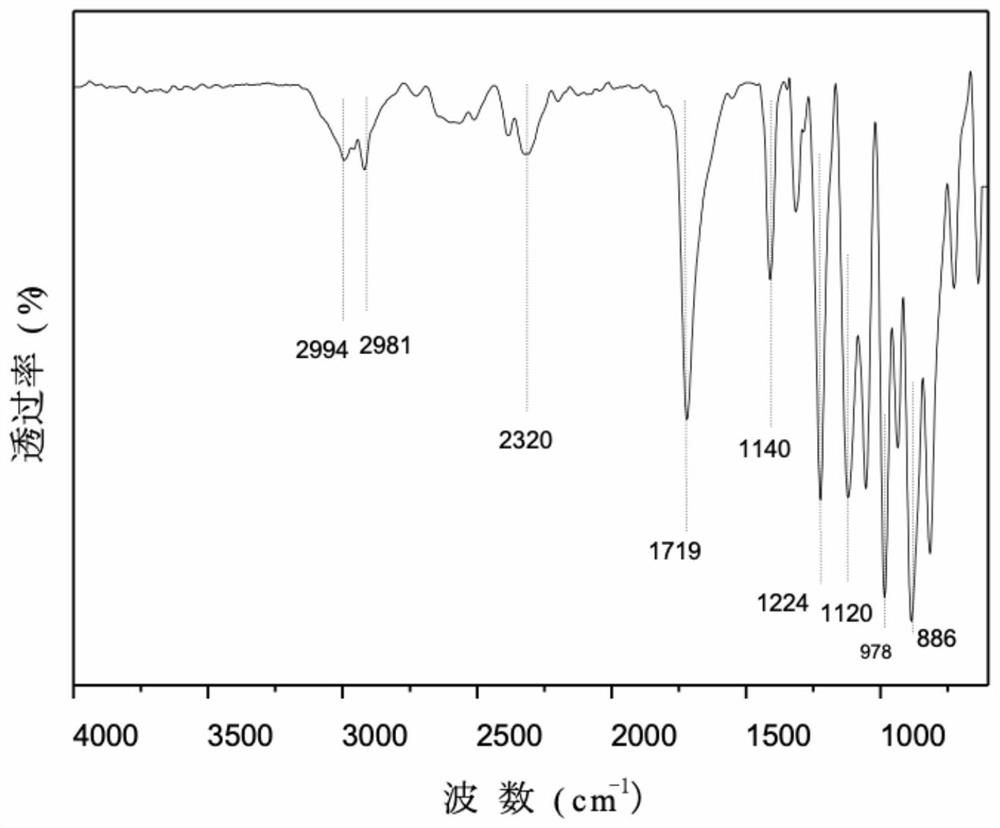

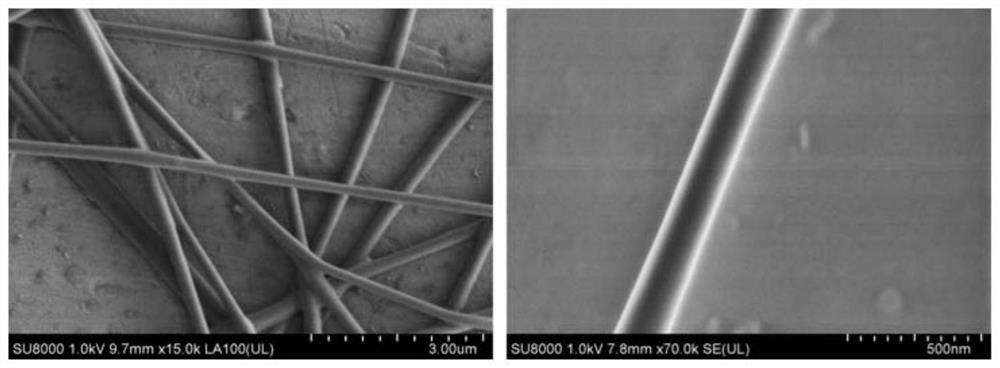

Transparent flame-retardant PVA film and preparation method thereof

ActiveCN109553902AImprove interfacial bond strengthImprove stabilityFlame-proof filament manufactureElectro-spinningFiberCross-link

The invention provides a transparent flame-retardant PVA film and a preparation method thereof, wherein the transparent flame-retardant PVA film has good transparency and good mechanical property under the premise of the ensuring of the flame retardancy of the PVA film. The preparation method comprises: (1) spinning at an electric-conduction substrate by using a mixed aqueous solution of PVA and methyl propionic acid phosphinic acid or a mixed aqueous solution of PVA, methyl propionic acid phosphinic acid and aluminum hypophosphite nanoparticles as a spinning liquid, arranging the spinning fibers into a network along an X-Y axis plane by using the surface of the electric-conduction substrate as the X-Y axis plane, and carrying out curing cross-linking within a range of 80-100 DEG C to obtain nano-fibers arranged on the surface of the electric-conduction substrate; and (2) casting the electric-conduction substrate prepared in the step (1) and covered with the nano-fibers by using a mixed aqueous solution of PVA and methyl propionic acid phosphinic acid as a casting liquid, and carrying out casting film forming to obtain the transparent flame-retardant PVA film.

Owner:JIANGHAN UNIVERSITY

A kind of injectable natural triterpenoid antibacterial hydrogel and preparation method thereof

ActiveCN110585122BLow toxicityAvoid biotoxicityAntibacterial agentsOrganic active ingredientsPolymer scienceAntimicrobial drug

Owner:BEIJING UNIV OF CHEM TECH

A kind of 8-shaped hollow polyester fiber fdy yarn and preparation method thereof

ActiveCN106801265BReduce extrusion swelling effectImprove featuresMelt spinning methodsMonocomponent polyesters artificial filamentYarnFiber

The invention belongs to the polyester spinning field and relates to an 8-shaped hollow polyester fiber FDY (Fully Drawn Yarn) and a preparation method thereof. A spinning melt contains saturated fatty acid metal salt and modified polyester, wherein the mass ratio of saturated fatty acid metal salt to modified polyester is (0.0005-0.002) to 1; saturated fatty acid metal salt is fatty acid metal salt, the carbon atomic number is 12-22, the melting point is 100-180 DEG C, and the kinetic viscosity is less than or equal to 1Pa.s; a molecular chain of modified polyester comprises a terephthalic acid chain segment, a glycol chain segment and a rigid structure chain segment, and the molar ratio of the rigid structure chain segment to the terephthalic acid chain segment is (0.02-0.05) to 1; and the die swell ratio of the spinning melt is 1.23-1.33, and the after-filtration pressure during the spinning is 85-125kg / cm<2>. The prepared 8-shaped hollow polyester fiber FDY has relatively high degree of hollowness and relatively good shape-preserving effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

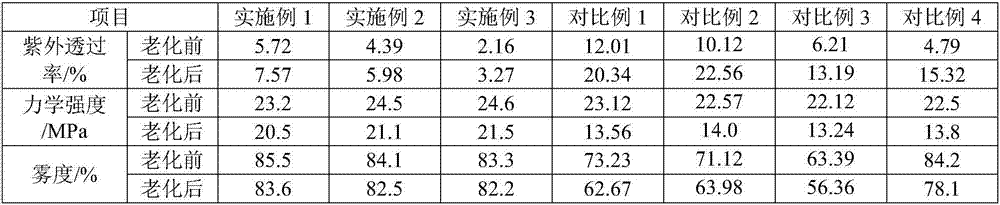

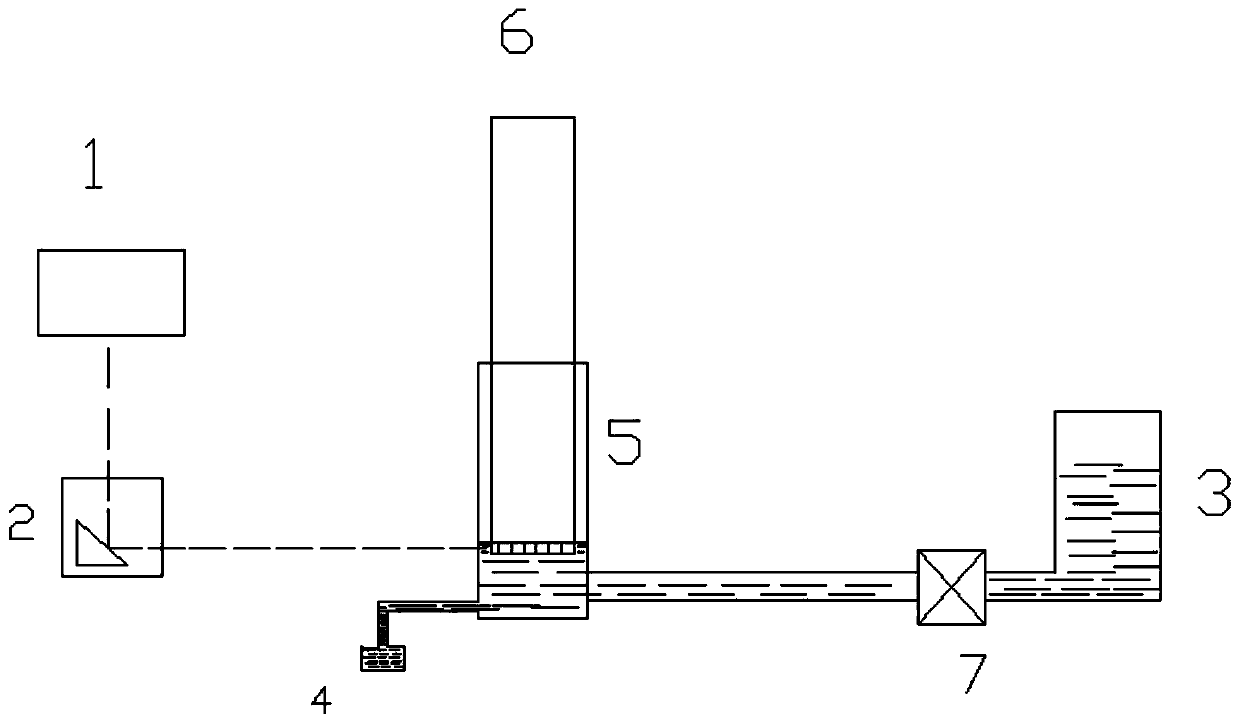

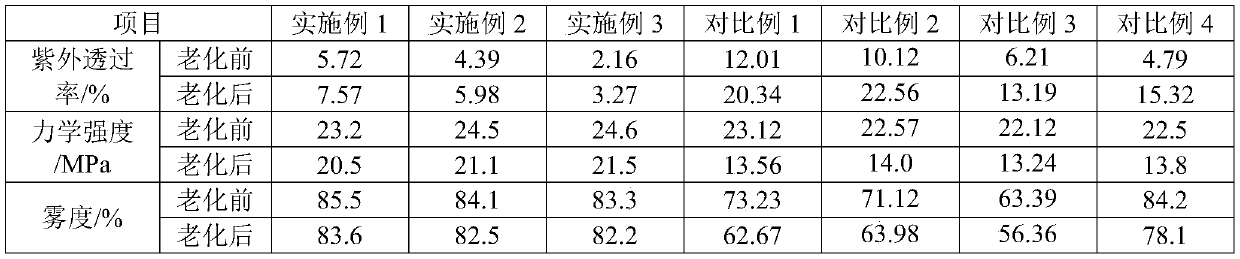

Anti-ultraviolet polypropylene composition and polypropylene and polypropylene film prepared from composition

The invention discloses surface modified nano-cerium oxide as well as a preparation method and use thereof. The invention further provides a polypropylene composition containing the modified nano-cerium oxide and polypropylene and a polypropylene film which are prepared from the composition. The surface modified nano-cerium oxide is prepared by the steps of reacting by virtue of large-particle cerium oxide and a surface modifier in a high-temperature and high-pressure microcell generated by laser bombardment so as to reduce the size of cerium oxide to a nano scale, and grafting the surface with the surface modifier. The surface modified nano-cerium oxide has the beneficial effects that on one hand, cerium oxide can be effectively subjected to surface treatment; on the other hand, nano-scale cerium oxide can be prepared from micron-scale cerium oxide, so that the material cost is saved; and furthermore, a columned cerium oxide solid target can continuously sink into a flow liquid phase, so that the preparation method has the advantage that the continuous operation is realized.

Owner:XIAMEN JUFU PLASTIC PRODS

A kind of anti-ultraviolet polypropylene composition and its prepared polypropylene and polypropylene film

The invention discloses surface modified nano-cerium oxide as well as a preparation method and use thereof. The invention further provides a polypropylene composition containing the modified nano-cerium oxide and polypropylene and a polypropylene film which are prepared from the composition. The surface modified nano-cerium oxide is prepared by the steps of reacting by virtue of large-particle cerium oxide and a surface modifier in a high-temperature and high-pressure microcell generated by laser bombardment so as to reduce the size of cerium oxide to a nano scale, and grafting the surface with the surface modifier. The surface modified nano-cerium oxide has the beneficial effects that on one hand, cerium oxide can be effectively subjected to surface treatment; on the other hand, nano-scale cerium oxide can be prepared from micron-scale cerium oxide, so that the material cost is saved; and furthermore, a columned cerium oxide solid target can continuously sink into a flow liquid phase, so that the preparation method has the advantage that the continuous operation is realized.

Owner:XIAMEN JUFU PLASTIC PRODS

A kind of flat polyester fiber fdy yarn and preparation method thereof

ActiveCN106835338BReduce bloatPromote crystallizationFilament forming substance formingArtificial thread manufacturing machinesPolyesterYarn

The invention relates to a flat polyester fiber FDY (Fully Drawn Yarn) and a preparation method thereof. The spinning melt comprises a saturated fatty acid metal salt and polyester, wherein a mass ratio of the saturated fatty acid metal salt to polyester is (0.0005-0.002):1; the filtered pressure during spinning is 84-126kg / cm<2>; a die-swell ratio of the spinning melt is 1.22-1.34; and the saturated fatty acid metal salt refers to a fatty acid metal salt with the carbon atom number of 12-22, the melting point of 100-180 DEG C and the dynamic viscosity of less than or equal to 1Pa.s. The saturated fatty acid metal salt is added into the spinning melt, and the filtered pressure and extrudate swelling during spinning can be effectively reduced, so that the product has an excellent shape preserving effect; meanwhile, the saturated fatty acid metal salt can serve as a nucleating agent, so that the fiber curing speed is increased, and the fiber shape preserving effect is improved. In addition, the fiber structure regularity is not greatly damaged by the saturated fatty acid metal salt, and excellent performances of the polyester fibers are maintained.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

A Polyester Spinning Method for Reducing Extrusion Swelling Ratio

ActiveCN106835335BReduce bloatPromote crystallizationFilament forming substance formingArtificial thread manufacturing machinesPolyesterFiber

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

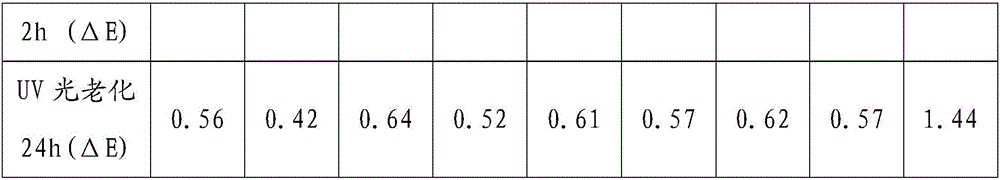

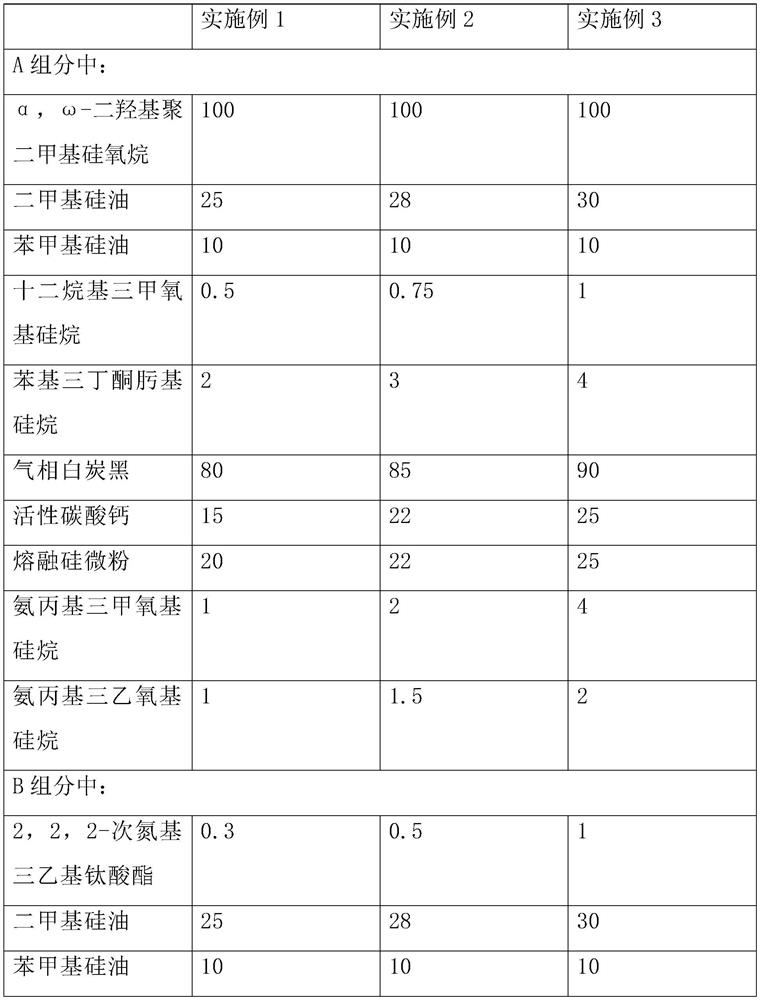

Curing-speed-adjustable two-component adhesive

ActiveCN112724918AAdjust dosageIncrease or decrease cure speedNon-macromolecular adhesive additivesPolymer scienceVulcanization

The invention relates to the field of silicone rubber, and particularly discloses a curing-speed-adjustable two-component adhesive which comprises a component A and a component B. The component A and the component B are mixed in any proportion, and the component A comprises the following components in parts by mass: 100 parts of alpha,omega-dihydroxy polydimethylsiloxane, 30-40 parts of a plasticizer, 2.5-5 parts of a cross-linking agent, 100-120 parts of a filler, and 2-6 parts of a coupling agent, wherein the viscosity range of the alpha,omega-dihydroxy polydimethylsiloxane at the temperature of 25 DEG C is 10,000 mPa*s to 50,000 mPa*s; the component B comprises the following components in parts by mass: 10-15 parts of a plasticizer, and 0.1-1 part of a catalyst. The preparation method disclosed by the invention has the advantage of reducing the influence of a user on the mechanical property of silicone rubber when the vulcanization speed of the silicone rubber is adjusted.

Owner:GUANGZHOU GLORYSTAR CHEM

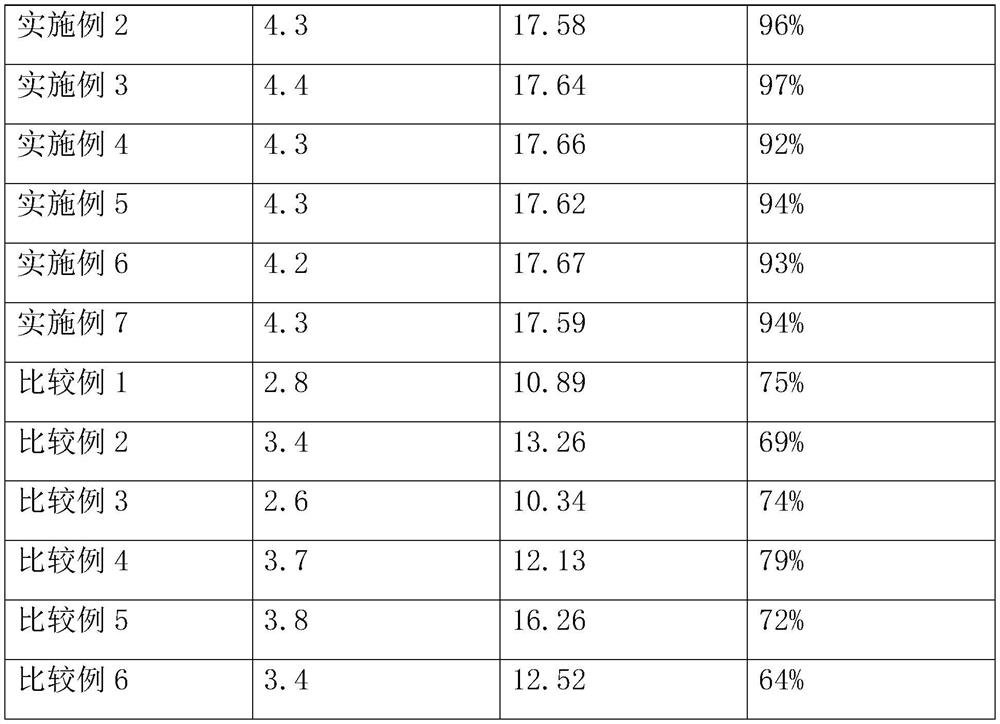

Composite flame retardant for paint

The invention provides a composite flame retardant for paint. The composite flame retardant for the paint is characterized by comprising the components in parts by weight: 5-15 parts of resorcinol bi(diphenyl phosphate) (RDP), 10-25 parts of triethyl phosphate (TEP), 15-30 parts of phosphate tri(beta-chloroethyl) ester (TCEP) and 30-50 parts of phosphate tri(2-chloropropyl) ester (TCPP). The composite flame retardant is added into various common paint according to the ratio of 10-15%, so that the composite flame retardant has inflame-retarding and fireproofing functions under the premise that original color, transparency, adhesive force and resistant fastness are not affected; and the preparation process is simple, and the production cost is low.

Owner:SUZHOU CUIZHI NEW TECH DEV

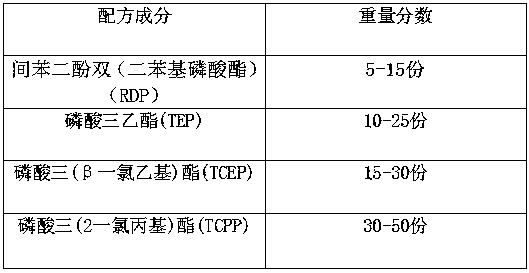

Wear-resistant nanometer thermal insulation film manufacturing process

InactiveCN110254016AHelp to escapeTransparency impactSynthetic resin layered productsPolyurea/polyurethane coatingsPrepolymerSilicon nitride

The invention discloses a wear-resistant nanometer thermal insulation film manufacturing process, which comprises: mixing and stirring nanometer antimony-doped tin dioxide, nanometer dysprosium-doped tin dioxide, nanometer silicon nitride, ethyl 3-hydroxyoctanoate and ethyl acetate to form a mixed solution; stirring and mixing a polyurethane prepolymer and dihydroxy polyoxypropylene ether according to a certain mass part ratio under vacuum, and stirring while heating to a temperature of 40-50 DEG C; adding dimethyl adipate, p-hydroxybenzenesulfonic acid, 2-(2H-benzotriazole-2-yl)-6-dodecyl-4-cresol, a tertiary amine catalyst and the mixed solution, heating to a temperature of 50-80 DEG C, and continuously stirring for at least 30 min; and stirring while cooling to a room temperature to obtain the nanometer thermal insulation solution. According to the present invention, the nanometer ceramic efficient thermal insulation film can easily dissipate heat so as to reduce the indoor temperature, wherein the temperature can be reduced by 5-8 DEG C, and the infrared blocking rate can reach more than 95%.

Owner:苏州艾达仕电子科技有限公司

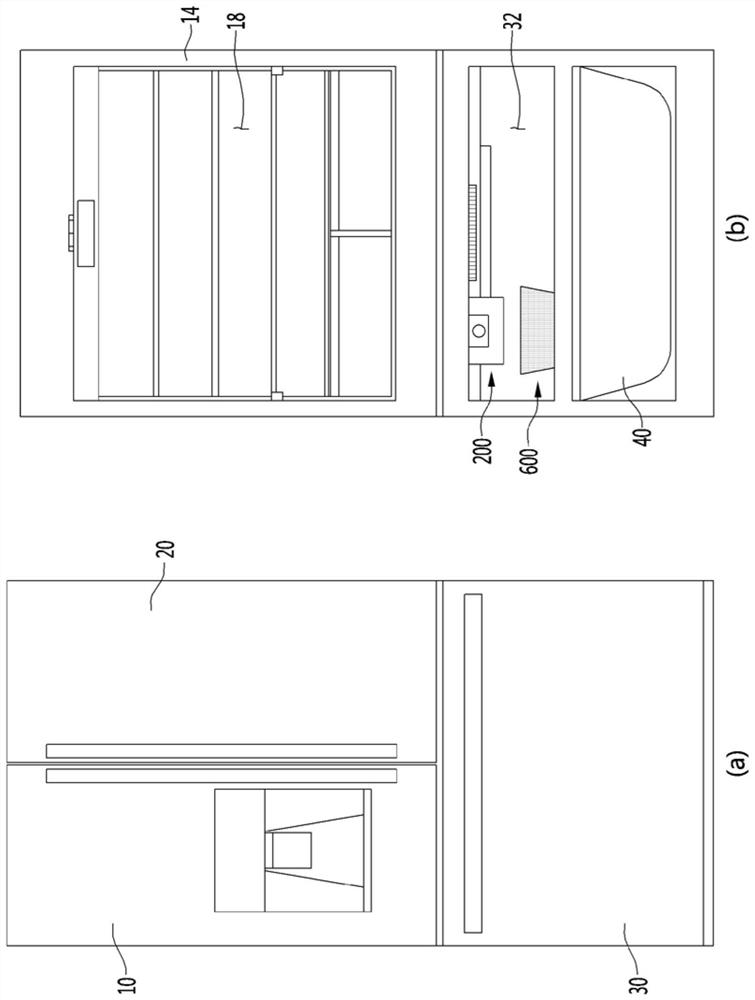

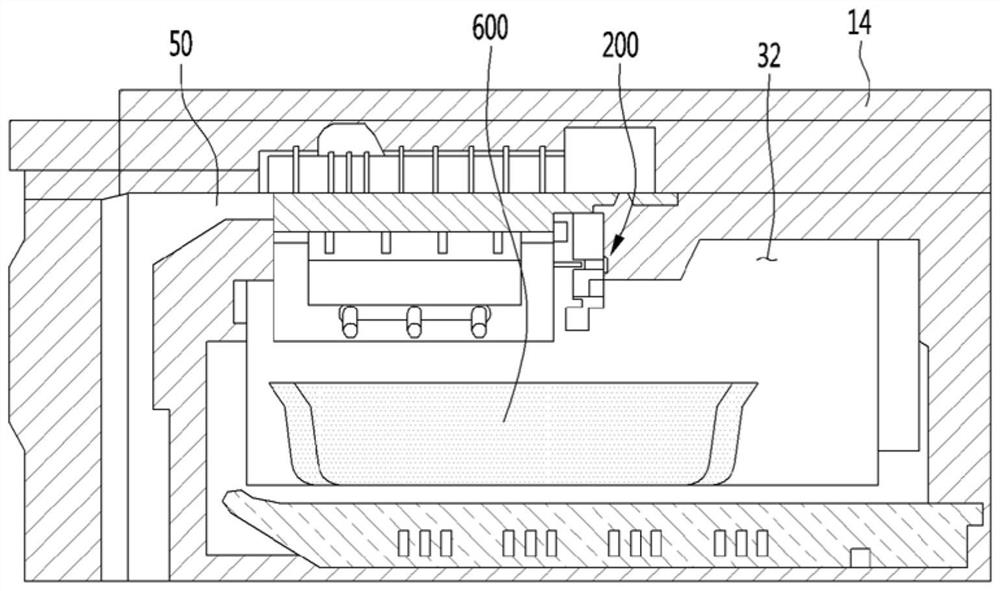

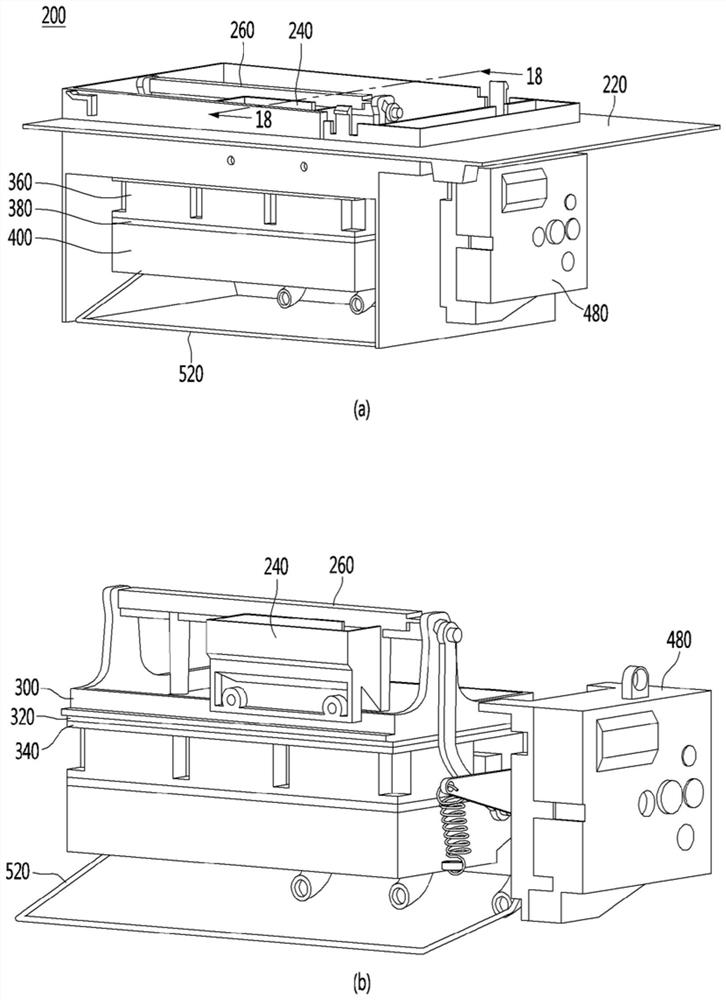

Refrigerator and controlling method therefor

ActiveCN112789470ATransparency impactOvercooling releaseLighting and heating apparatusIce productionThermodynamicsElectric discharge

A refrigerator of the present invention comprises: a first tray for forming a part of an ice-making cell; a second tray for forming another part of the ice-making cell; a tray temperature sensor for detecting a temperature of the ice-making cell; an electric discharge spark generator located around any one of the first tray and the second tray and provided with an electrode; and a controller for controlling the electric discharge spark generator to generate a spark in the electrode when water in the ice-making cell is determined to be in an overcooling state on the basis of the temperature measured by the tray temperature sensor.

Owner:LG ELECTRONICS INC

A kind of ultra-fine denier polyester fiber fdy yarn and preparation method thereof

ActiveCN107245768BReduce bloatPromote crystallizationMelt spinning methodsMonocomponent polyesters artificial filamentPolyesterFiber

The present invention relates to an ultrafine denier polyester fiber FDY filament and a preparation method thereof, wherein a spinning melt comprises a saturated fatty acid metal salt and a polyester according to a mass ratio of the saturated fatty acid metal salt to the polyester of 0.0005-0.002:1, the post-filtration pressure during spinning is 125-155 kg / cm<2>, the extrusion expansion ratio of the spinning melt is 1.25-1.35, and the saturated fatty acid metal salt has the carbon atom number of 12-22, the melting point of 100-180 DEG C, and the dynamic viscosity of less than or equal to 1 Pa.s. According to the present invention, the saturated fatty acid metal salt is added to the spinning melt so as to provide the effect of the addition of the lubricant, such that the post-filtration pressure during the spinning is effectively reduced so as to effectively reduce the outlet expansion, and the product has the good shape retention effect; and the saturated fatty acid metal salt can be used as the nucleating agent to increase the fiber curing speed so as to further improve the fiber shape retention effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

Transparent flame-retardant polyvinyl alcohol film and preparation method thereof

ActiveCN109553902BImprove interfacial bond strengthImprove stabilityFlame-proof filament manufactureElectro-spinningFiberSpinning

The invention provides a transparent flame-retardant PVA film and a preparation method thereof, wherein the transparent flame-retardant PVA film has good transparency and good mechanical property under the premise of the ensuring of the flame retardancy of the PVA film. The preparation method comprises: (1) spinning at an electric-conduction substrate by using a mixed aqueous solution of PVA and methyl propionic acid phosphinic acid or a mixed aqueous solution of PVA, methyl propionic acid phosphinic acid and aluminum hypophosphite nanoparticles as a spinning liquid, arranging the spinning fibers into a network along an X-Y axis plane by using the surface of the electric-conduction substrate as the X-Y axis plane, and carrying out curing cross-linking within a range of 80-100 DEG C to obtain nano-fibers arranged on the surface of the electric-conduction substrate; and (2) casting the electric-conduction substrate prepared in the step (1) and covered with the nano-fibers by using a mixed aqueous solution of PVA and methyl propionic acid phosphinic acid as a casting liquid, and carrying out casting film forming to obtain the transparent flame-retardant PVA film.

Owner:JIANGHAN UNIVERSITY

A kind of multi-leaf hollow polyester fiber fdy yarn and preparation method thereof

ActiveCN106835334BReduce extrusion swelling effectReduce surface tensionHollow filament manufactureMonocomponent polyesters artificial filamentFiberYarn

The invention belongs to the field of polyester spinning, and relates to a multilobal hollow polyester fiber FDY (fully drawn yarn) and a preparation method thereof. A spinning melt comprises a saturated fatty acid metal salt and modified polyester according to a mass ratio of (0.0005 to 0.002) to 1; the saturated fatty acid metal salt is a fatty acid metal salt with carbon atom number of 12 to 22, melting point of 100 to 180 DEG C, and dynamic viscosity less than or equal to 1Pa.s; a molecular chain of the modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment and a rigid structure chain segment, the molar ratio of the rigid structure chain segment to the terephthalic acid chain segment is (0.02 to 0.05) to 1, the extrusion swelling ratio of the spinning melt is 1.20 to 1.31, and the post-filtering pressure is 80 to 120kg / cm<2> during spinning. The prepared multilobal hollow polyester fiber FDY has higher hollow degree and a better shape preserving effect.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

A kind of square hollow polyester fiber fdy yarn and preparation method thereof

ActiveCN106835336BReduce extrusion swelling effectReduce surface tensionHollow filament manufactureFilament/thread formingFiberYarn

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

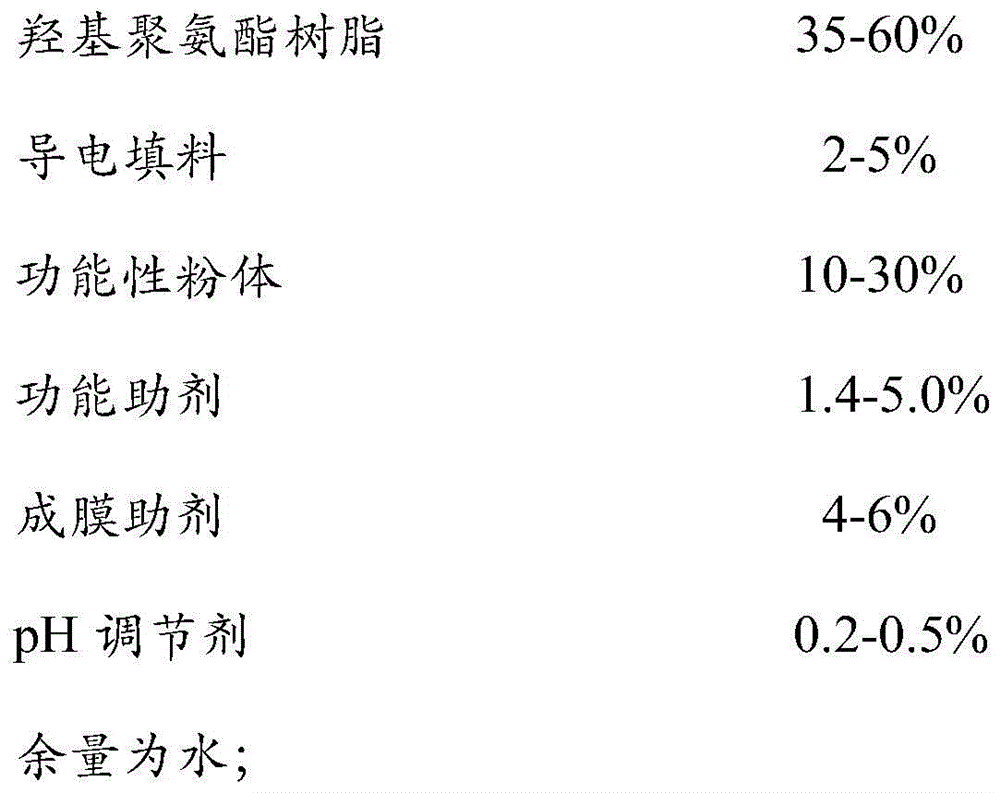

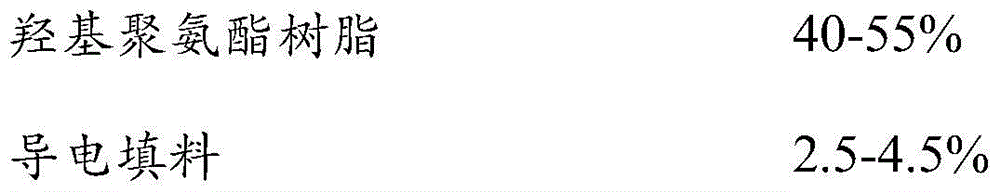

Water-based high-solid antistatic coating and preparation method thereof

InactiveCN104403543BHigh solid contentImprove water resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedElectromagnetic shielding

Owner:广州益景春环保材料科技有限公司

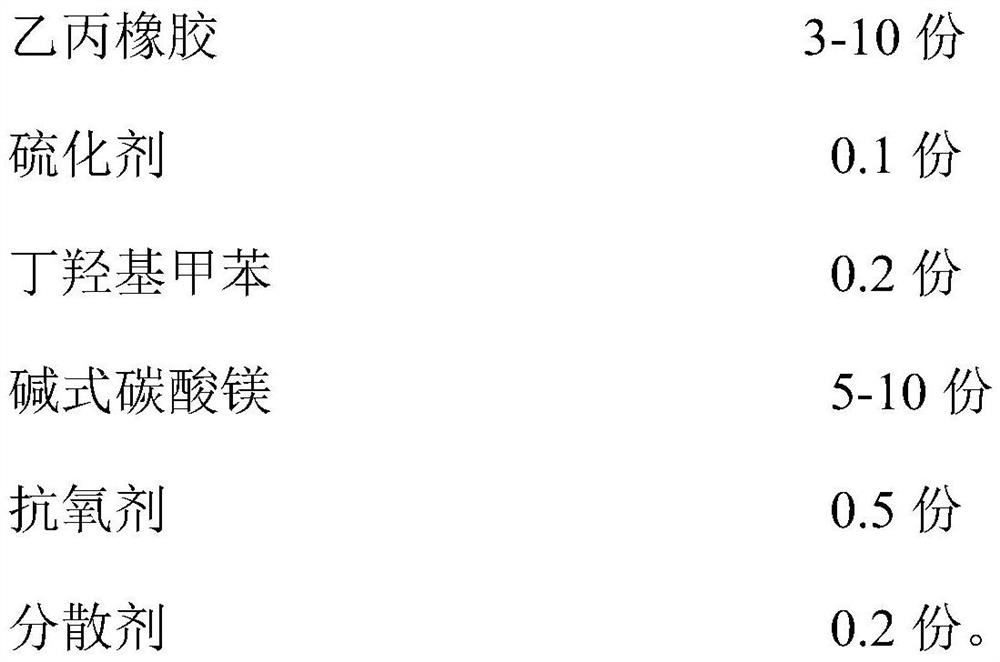

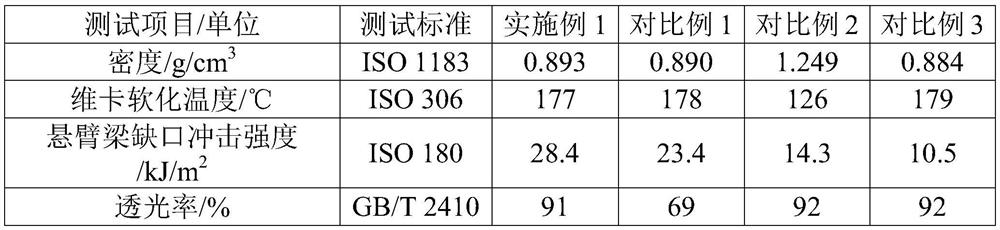

A kind of highly transparent modified polyolefin material and its preparation method

The invention discloses a highly transparent modified polyolefin material and a preparation method thereof, which comprises 65-85 parts of poly-4-methyl-1-pentene, 7-15 parts of polyisobutylene, 3-10 parts of ethylene-propylene rubber, Prepared by 0.1 part of vulcanizing agent, 0.2 part of butylated hydroxytoluene, 5-10 parts of basic magnesium carbonate, 0.5 part of antioxidant and 0.2 part of dispersant. The highly transparent modified polyolefin material provided by the present invention selects poly-4-methyl-1-pentene, a crystalline material with excellent light transmission effect, as the base material, which ensures the dimensional stability of the material at relatively high temperatures; Molecular weight polyisobutylene and slightly cross-linked low molecular weight EPDM rubber are used as tougheners, and basic magnesium carbonate with special optical refractive index is used as filler material, which not only improves the toughness and rigidity of the material, but also avoids Effect on the overall transparency of the material.

Owner:HEFEI GENIUS NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com