Toughening modifying agent for transparent polyvinyl chloride product and high-transparency polyvinyl chloride mixture

A technology of toughening modifier and polyvinyl chloride, which is applied in the field of polyvinyl chloride, can solve the problems of poor weather resistance, poor toughness, easy precipitation and transparency, etc., to improve tear resistance, improve toughness, and good transparency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

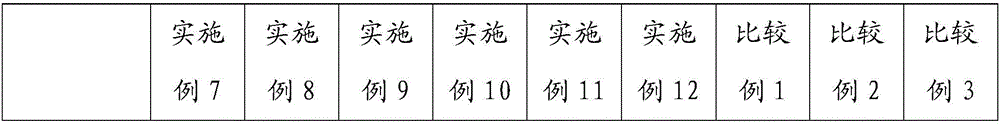

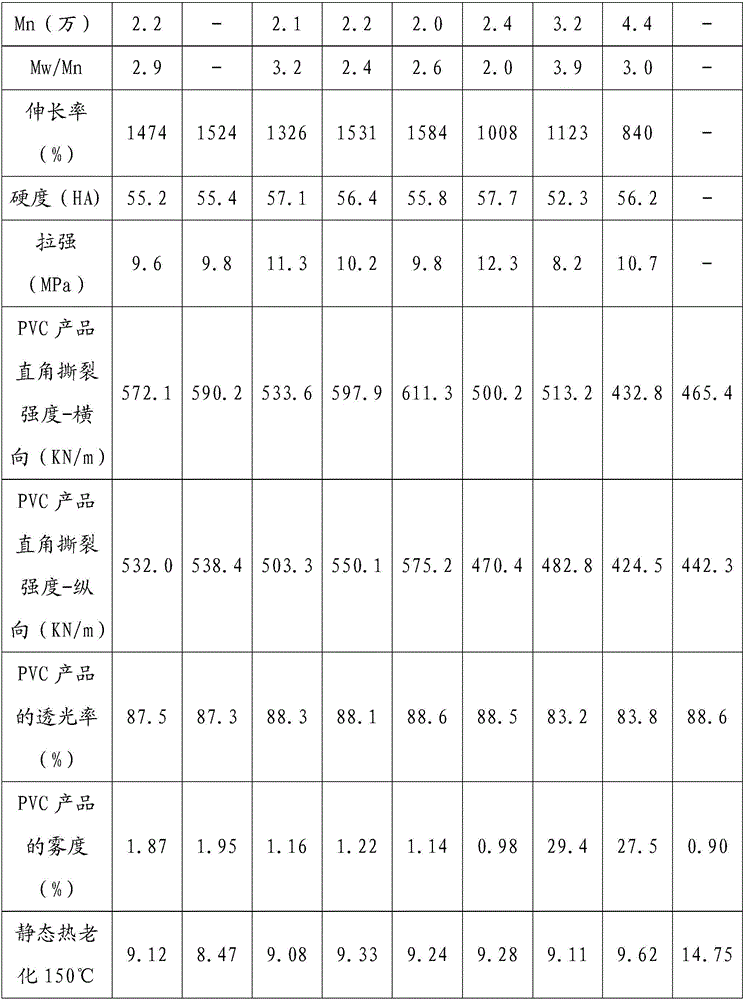

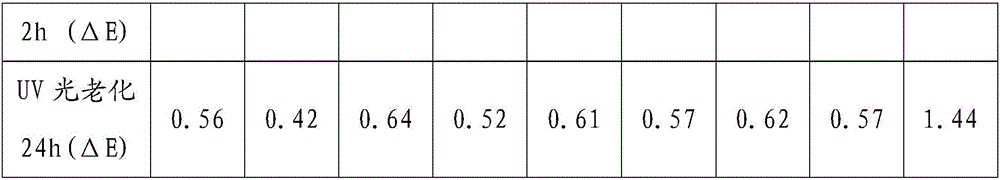

Embodiment 1

[0056] Add 0.6 parts of methyl methacrylate / acrylic acid copolymer dissolved in water as a dispersant, and 0.18 parts of polyoxyethylene lauryl ether as an emulsifier into a 24-cubic reactor equipped with a stirring paddle , then add water so that the total water consumption and all auxiliary raw materials are 300 parts, and then add 27.5 parts with a number average molecular weight (Mn) of 22,000, a molecular weight distribution (Mw / Mn) of 2.9, and a particle size of D 50 It is 170 micron high-density polyethylene. Under stirring conditions, after the temperature of the reaction material rises to 78°C, 10 parts of chlorine gas is introduced, and the speed of chlorine flow is maintained at 10 parts per hour, and then the temperature is raised to 123°C, the heating time is 1 hour, and the heating and chlorine gas flow are carried out at the same time. After the reaction temperature reaches 123°C, keep the temperature above 123°C, and feed the remaining 16 parts of chlorine gas a...

Embodiment 2

[0058] In a 24-cubic reactor equipped with a stirring paddle, add 0.1 part of methyl methacrylate / acrylic acid copolymer as a dispersant, 0.05 part of an initiator, and add water so that the total water consumption and all auxiliary raw materials are 250 parts , then add 30 parts of sample 1, after the temperature of the reaction material is raised to 80°C under stirring, then add 4 parts of butyl acrylate and 4 parts of methyl methacrylate, keep the temperature at 80-85°C, and react 3 Hours later, it was cooled to below 40° C., centrifuged and dried to obtain a rubber powder (sample 2) with an elongation of 1524%, a hardness of 55.4, and a tensile strength of 9.8 MPa. The conversion rate of the reaction was 99.4%, and the particle size of the powder was 260 microns.

Embodiment 3

[0060] Add 0.65 parts of water-soluble methyl methacrylate / acrylic acid copolymer to a 24-cubic reactor equipped with a stirring paddle as a dispersant, and add 0.20 parts of polyoxyethylene lauryl ether as an emulsifier , then add water so that the total water consumption and all auxiliary raw materials are 300 parts, and then add 30 parts with a number average molecular weight (Mn) of 21,000, a molecular weight distribution (Mw / Mn) of 2.5, and a particle size of D 50 It is 160-micron high-density polyethylene. Under stirring conditions, after the temperature of the reaction material rises to 82°C, 15 parts of chlorine gas is introduced, and the speed of chlorine flow is maintained at 15 parts per hour, and then the temperature is raised to 122°C, the heating time is 1 hour, and the heating and chlorine gas flow are carried out at the same time. After the reaction temperature reaches 122°C, keep the temperature above 122°C, and feed the remaining 18 parts of chlorine gas at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com