A kind of highly transparent modified polyolefin material and its preparation method

A polyolefin and transparent technology, applied in the field of modified plastics, can solve the problems of high temperature stability, poor aging resistance, and affecting visual effects, etc., to improve toughness and rigidity, ensure dimensional stability, and avoid impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

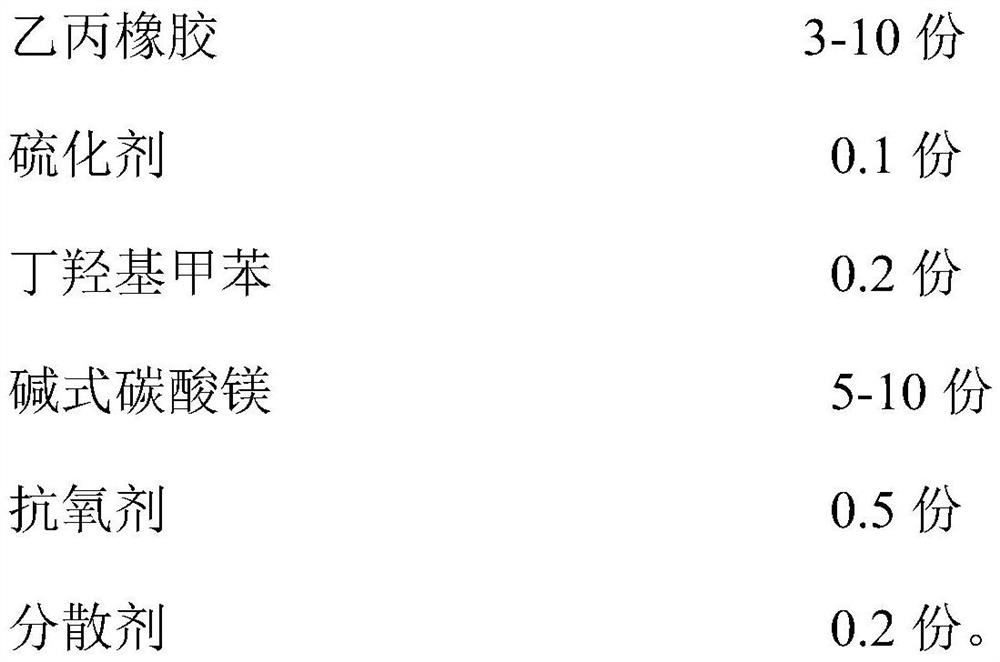

Method used

Image

Examples

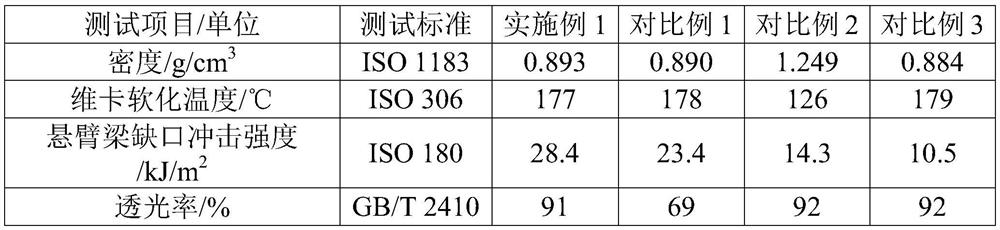

Embodiment 1

[0026] Add 65 parts of poly-4-methyl-1-pentene, 10 parts of basic magnesium carbonate, 0.5 parts of antioxidant, and 0.2 parts of dispersant into the vacuum internal mixer, mix well for 5 minutes, and then add 15 parts of polyisobutylene 10 parts of ethylene-propylene rubber, 0.1 part of vulcanizing agent, and 0.2 part of butylated hydroxytoluene. After 3 minutes of continuous mixing, the tablets can be opened, or granulated by drawing rods through the die; the processing temperature of the internal mixer is 260 ° C, and the upper The pressure of the ram is 0.55MPa, and the screw speed of the internal mixer is 50r / min. The product performance is shown in Table 1.

Embodiment 2

[0028] Add 75 parts of poly-4-methyl-1-pentene, 7 parts of basic magnesium carbonate, 0.5 parts of antioxidant, and 0.2 parts of dispersant into the vacuum internal mixer, mix well for 4 minutes, and then add 10 parts of polyisobutylene 8 parts of ethylene-propylene rubber, 0.1 part of vulcanizing agent, 0.2 part of butylated hydroxytoluene, continue to knead for 2 minutes to open the tablet, or granulate through the die drawstring; the processing temperature of the internal mixer is 250 ℃, and the upper The pressure of the ram is 0.55MPa, and the screw speed of the internal mixer is 40r / min. The product performance is shown in Table 1.

Embodiment 3

[0030] Add 85 parts of poly-4-methyl-1-pentene, 5 parts of basic magnesium carbonate, 0.5 parts of antioxidant, and 0.2 parts of dispersant into the vacuum internal mixer, mix well for 3 minutes, and then add polyisobutylene 7 1 part, 3 parts of ethylene-propylene rubber, 0.1 part of vulcanizing agent, 0.2 part of butylated hydroxytoluene, continue to knead for 1 minute, then you can open the tablet, or granulate through the die-stretch; the processing temperature of the internal mixer is 240 ℃, and the upper The pressure of the ram is 0.55MPa, and the screw speed of the internal mixer is 30r / min. The product performance is shown in Table 1.

[0031] Table 1

[0032] Test item / unit standard test Example 1 Example 2 Example 3 Density / g / cm 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com