Transparent flame-retardant polyvinyl alcohol film and preparation method thereof

A technology of polyvinyl alcohol film and polyvinyl alcohol, which is applied in the manufacture of fire-resistant and flame-retardant filaments, single-component synthetic polymer rayon, filament/thread molding, etc., which can solve the problem of transparency and/or mechanical property degradation, etc. problem, to achieve the effect of good interface bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

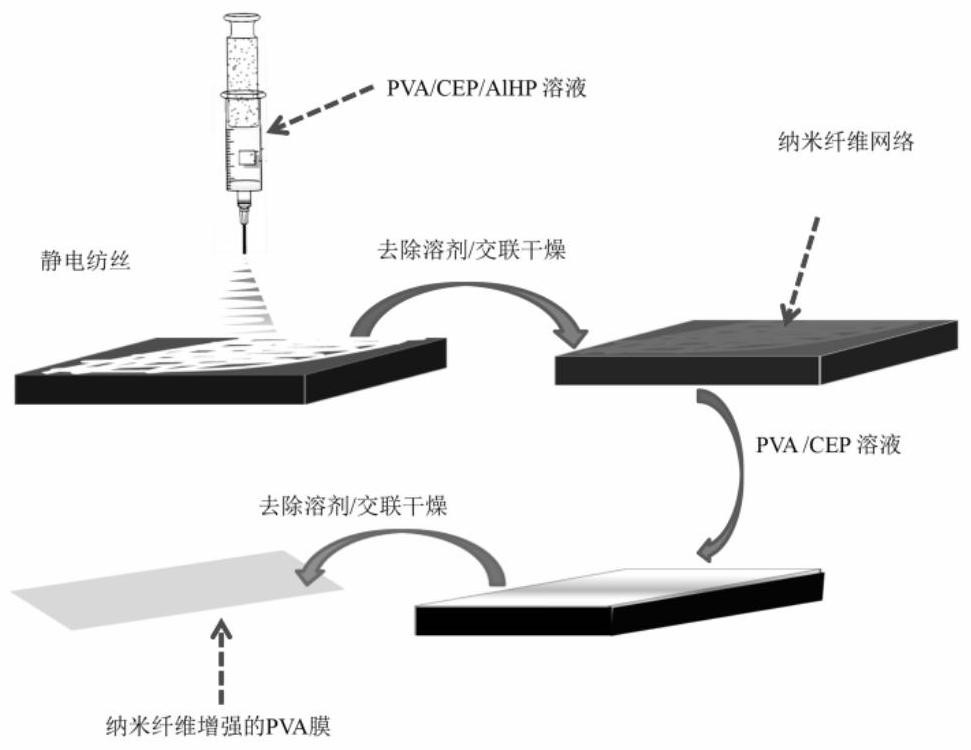

[0038] Such as figure 1 As shown, according to the first aspect of the present invention, the embodiment of the present invention provides a method for preparing a transparent flame-retardant PVA film, comprising the following steps:

[0039] (1) Use the mixed aqueous solution of PVA and CEP, or the mixed aqueous solution of PVA, CEP and AlHP nanoparticles as the spinning solution, spin on the conductive substrate, and use the surface of the conductive substrate as the X-Y axis plane to make the spinning fiber along the The X-Y axis plane is arranged into a network, and then solidified and cross-linked in the range of 80-100 ° C to obtain nanofibers arranged on the surface of the conductive substrate, wherein the solid content of the spinning solution is 10 wt%, CEP and The mass of AlHP nanoparticles is 1%-15% and 0-15% of PVA respectively;

[0040] (2) Use the mixed aqueous solution of PVA and CEP as pouring liquid, cast on the conductive substrate covered with nanofibers ob...

Embodiment 1

[0074] (1) 47.5g mass concentration 10% PVA transparent aqueous solution, after adding 0.05g CEP, 2g 10%AlHP dispersion, after mechanical stirring 30 minutes, 700W ultrasonic dispersion 60 minutes, obtain the spinning solution of AlHP / CEP / PVA.

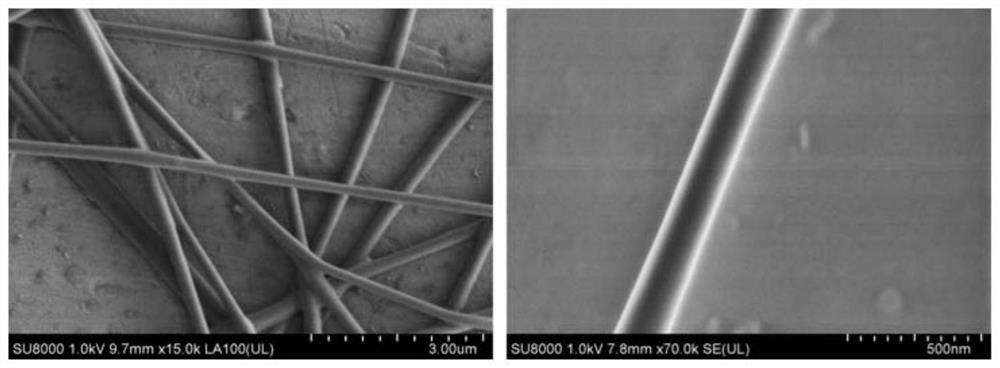

[0075] Electrospinning the above spinning solution, the conditions of electrospinning are: No. 6 needle (inner diameter 0.6mm) spinning voltage is 18KV, injection speed is 0.5ml / h The distance between the needle tip and the conductive glass of the receiving device is 13cm, so as to conduct electricity The glass surface is used as the X-Y axis plane, so that the spun fibers are arranged into a network along the X-Y axis plane, and then the conductive glass covered with the spinning solution is placed in a vacuum drying oven at 100°C for curing and cross-linking for 2 hours to obtain AlHP / CEP with a diameter of 200-300nm / PVA nanofibers.

[0076] (2) Add 4.75g CEP to 902.5g of 10% PVA transparent aqueous solution in mass concentration, a...

Embodiment 2

[0078] (1) 90g mass concentration 10% PVA transparent aqueous solution, after adding 0.5g CEP, 5g 10wt%AlHP dispersion, after mechanical stirring 30 minutes, 700W ultrasonic dispersion 60 minutes, obtain the spinning solution of AlHP / CEP / PVA.

[0079] Electrospinning the above spinning solution, the conditions of electrospinning are: No. 6 needle (inner diameter 0.6mm) spinning voltage is 18KV, injection speed is 0.5ml / h The distance between the needle tip and the conductive glass of the receiving device is 13cm, so as to conduct electricity The glass surface is used as the X-Y axis plane, so that the spun fibers are arranged into a network along the X-Y axis plane, and then the conductive glass covered with the spinning solution is placed in a vacuum drying oven at 100°C for curing and cross-linking for 2 hours to obtain AlHP / CEP with a diameter of 200-300nm / PVA nanofibers.

[0080] (2) Add 9 g of CEP to 810 g of a transparent aqueous solution of PVA with a mass concentratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com