Composite flame retardant for paint

A compound flame retardant and phosphoric acid three technology, applied in the direction of coating, can solve the problems of color, transparency, adhesion, fastness, complicated process, uneconomical production cost, etc. The effect of simple process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

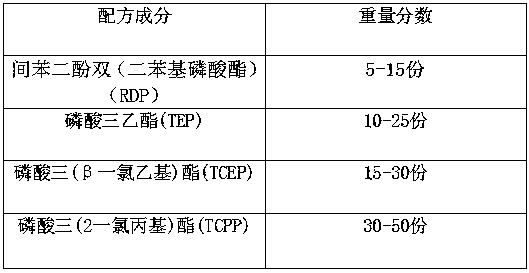

Image

Examples

Embodiment 1

[0012] In a 300ml flask, sequentially add 15 parts of resorcinol bis(diphenyl phosphate) (RDP), 25 parts of triethyl phosphate (TEP), and 15 parts of tris(β-chloroethyl) phosphate (TCEP) 1. 30 parts of tris(2-chloropropyl) phosphate (TCPP), fully stirred at room temperature for 20 minutes to obtain a composite flame retardant for paint.

Embodiment 2

[0014] In a 300ml flask, sequentially add 5 parts of resorcinol bis(diphenyl phosphate) (RDP), 10 parts of triethyl phosphate (TEP), and 30 parts of tris(β-chloroethyl) phosphate (TCEP) 1. 50 parts of tris(2-chloropropyl) phosphate (TCPP), fully stirred at room temperature for 20 minutes to obtain a composite flame retardant for paint.

Embodiment 3

[0016] In a 300ml flask, sequentially add 10 parts of resorcinol bis(diphenyl phosphate) (RDP), 15 parts of triethyl phosphate (TEP), and 25 parts of tris(β-chloroethyl) phosphate (TCEP) 1. 40 parts of tris(2-chloropropyl) phosphate (TCPP), fully stirred at room temperature for 20 minutes to obtain a composite flame retardant for paint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com